Page 1

L-9

Large Surface Area for Marking—

All XB Series terminal blocks have

generously sized surface areas for labeling.

This allows for clearly labeled wiring which

results in reduced start-up time and

simplifies activities such as testing and

maintenance. There are provisions for

marking individual terminal blocks and end

stops, strips of terminal blocks, and large

groups of terminal blocks.

Standardized Testing System—

All test plugs make contact in one of the

easily accessible bridge shafts. A 2.3 mm

diameter test plug is available for individual

measuring wires. Modular test plugs are also

available for more advanced testing.

TERMINAL BLOCKS

OVERVIEW

All models shown smaller

than actual size.

Product Family Overview

The XB Series offers a complete terminal

block system with a universal range of

accessories. Marking, bridging and testing

accessories are standardized across the

different clamping technologies—reducing

inventory and logistics costs. The modular

terminal block design allows for use of the

different terminal block types together or

individually, providing the highest degree

of flexibility.

Application Description

The metal portion of the XB Series terminal

blocks are made from highgrade,

strain-crack and corrosion-proof copper

alloys. They won’t experience any

electrolytic corrosion or rusting, even

when moisture is present. The metal

surfaces are protected with a lead-free,

galvanic nickel or tin plating.

The good electrical conductivity permits

only a low temperature rise. The Polyamide

6.6 housings allow for operating

temperatures up to 125°C and are certified

for inflammability Class V0 in accordance

with UL 94.

Features

Global Acceptance— The XB Series

terminal blocks are designed to meet

worldwide standards and the latest

international requirements.

Flexible Plug-In Bridge System—

All 3 technologies (screw, spring and IDC)

use the same bridge system, allowing for

individual potential distribution and quickly

bridged connections among the same

terminal block type or across different

types. The XB Series terminal blocks have

2 bridge shafts arranged in 1 line, making

flexible chain bridging and skip bridging

between non-adjacent terminal blocks

possible. Plug-in bridges are available

from 2 to 50 positions. Reducing bridges

are also available to connect a larger

terminal block to a smaller one.

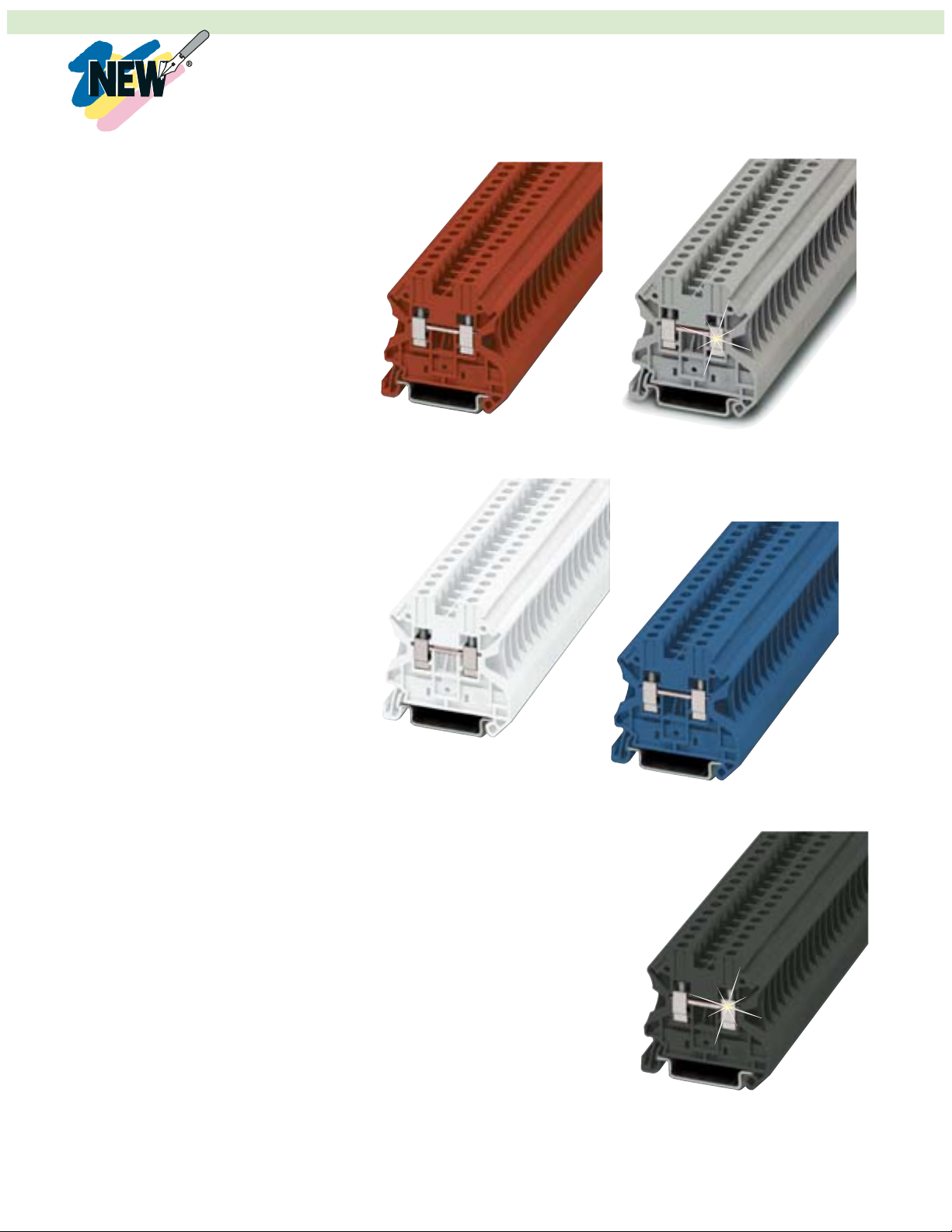

XBUT4BL-50PK

$40.50 for pkg

of 50

XBUT4BLK-50PK

$40.50 for pkg

of 50

XBUT4WH-50PK

$40.50 for pkg

of 50

XBUT4RD-50PK

$40.50 for pkg

of 50

XBUT4-50PK

$40.50 for pkg

of 50

Page 2

L-10

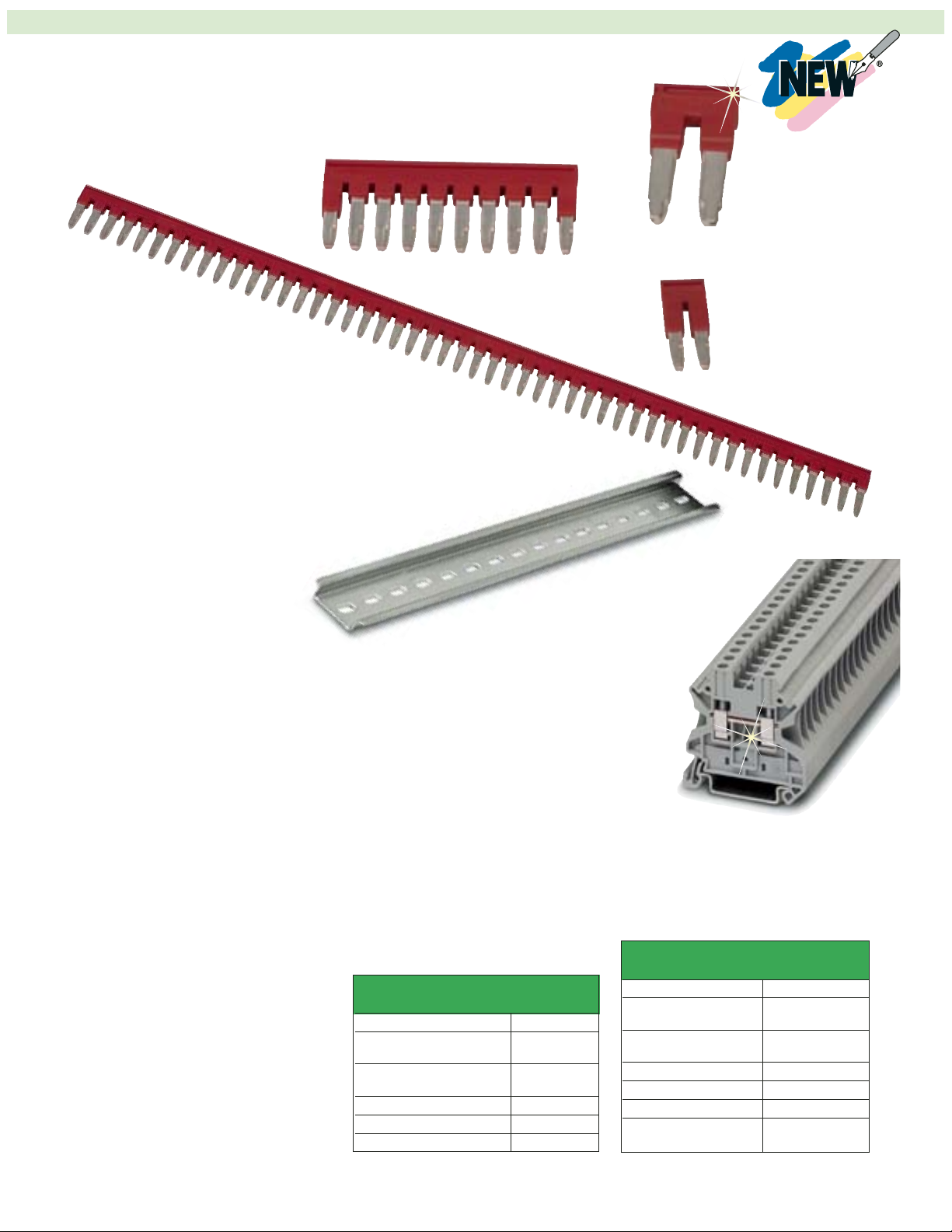

XBANS3575P, $9.00

XBUT25-50PK, $38.50

Modular Terminal Blocks for

Potentially Explosive Environments

The standard modular terminal blocks

are approved for potentially explosive

environments. In addition to the usual

approvals, they also have been approved by

a testing center authorized by the EU.

No extra approval is required in intrinsic

safety type applications. Modular terminal

blocks on the internet address listed below

fulfill the requirements for “increased safety”

protection type when installation instructions

are followed, and have a type examination

certificate in accordance with the Ex

directive Ex-RL 94/9/EU. These test

certificates are recognized in all the EU

member states and beyond.

The modular terminal blocks are approved

for fitting in Zone 1, the Ex environment, as

well as Zone 2. Zone 1 fitting is conditional

upon terminal blocks being used in

connection boxes approved for EEx e type

protection and having the equivalent of at

least IP54 protection.

The EEx approved modular terminal blocks

can be divided into the following groups:

Screw connection terminal blocks

Spring-cage connection terminal blocks

Insulation displacement connection

terminal blocks

Mini terminal blocks

Terminal blocks for specialized

applications

Identification

Explosion protected electrical equipment

must be marked so that the safety

characteristics are identifiable. The

identification of electrical equipment is

described in the harmonized standard EN

50014, as shown in the following example:

SPECIFICATIONS

Insulation Material: Polyamide 6.6

Dielectric Strength: 600 kV/cm

Creep Resistance: 600 CTI

Internal Insulation Resistance: 10

12

Surface Resistance: 10

10

Flammability Rating: UL 94 V0

Continuous Operating Temperature:

-40 to 125°C (-40 to 257°F)

STANDARDS AND CERTIFICATIONS

UL and cUL Recognized: File no.

E67464; CE approved

LVD*: EN 60947-7-1, EN 60947-7-2,

EN 60998-2-3, EN 60352-4/A1

ATEX Approval: Eex e applications

* Not all standards apply to all

terminal blocks.

Identification in Accordance

with ATEX-RL

Electrical equipment that is certified in

accordance with the ATEX 100a guideline

also receives identification describing the

site for use.

XBAFBS25-10 PK, $3.40

XBAFBS210-10 PK, $11.20

XBAFBS105-10 PK, $27.30

XBAFBS506, $17

All models shown

smaller than actual size.

TABLE 55-1. EN 50014

STANDARD EXAMPLE

Type Designation XBUT25

Abbreviation of

Explosion Protection EEx e ll

Protection Type Increased

Safety “e” e

Equipment Group II

Mark of the Testing Body KEMA

Approval Number 05ATEX2158 U

TABLE 55-2. ATEX GUIDELINE

EXAMPLE

Manufacturing Data 02.01.2004

Address of the

Manufacturer Duncan, SC

Number of the

Appointed Dept 344

Common Marking Ex symbol

Equipment Group II

Category 2

Use in Gas and/or

Dust Atmospheres G D

Page 3

L-11

FEED-THROUGH

TERMINAL BLOCK

Maintenance-Free Connections

Global Acceptance

Multi-Conductor Connections

Flexible Plug-In Bridge System

Large Surface Area for Marking

Standardized Testing System

Metal Parts Made of Tin-Plated

Copper Alloy

XBUT Series

Starts at

$

38

50

Pack of 50

MODEL NO. PRICE DESCRIPTION

XBUT25-50PK $38.50 Gray single level connection, package of 50

XBUT25BU-50PK 38.50 Blue single level connection, package of 50

ACCESSORIES

XBACUT10-10PK $3.50 Gray end cover package of 10

XBATUT10-10PK 4.60 Gray partition plate package of 10

XBAFBS25-10PK 3.40 Red 2 position plug-in bridge package of 10

XBAFBS35-10PK 6.70 Red 3 position plug-in bridge package of 10

XBAFBS55-10PK 13.00 Red 5 position plug-in bridge package of 10

XBAFBS105-10PK 27.30 Red 10 position plug-in bridge package of 10

XBAFBS505 13.80 Red 50 position plug-in bridge

XBATSPAI4-10PK 80.00 Test adaptor package of 10

XBMZB5-10PK 4.60 5.2 mm white blank marker strip package of 10

XBANS3575P 9.00 DIN rail 35 x 7.5 mm x 2 m slotted

XBANS3575U 9.30 DIN rail 35 x 7.5 mm x 2 m solid

XBANS3515P 17.00 DIN rail 35 x 15 mm x 2 m slotted

XBANS3515U 17.00 DIN rail 35 x 15 mm x 2 m slotted

XBAES35C-50PK 42.00 1-screw mounted end stop package of 50

XBAES35T-50PK 31.50 3-screw mounted end stop package of 50

XBAES35N-50PK 26.50 Snap-on end stop package of 50

To Order

(Specify Model Number)

MOST POPULAR MODELS HIGHLIGHTED!

SPECIFICATIONS FOR XBUT25

Terminal Width: 5.2 mm

Maximum Wire Size: 12 AWG/2.5 mm

2

IEC 60 947-7-1 in V/A/AWG:

800/32/26-12

EN 50 0191in V/A/AWG:

750/22 or 28/26-12

UL-cUL Ratings in V/A/AWG:

600/20/26-12

TECHNICAL DATA DIMENSIONS

Width/Length/Cover Width in mm (in):

5.2 (0.20)/46.9 (1.85)/2.2 (0.09)

Height for 35 x 7.5/35 x 15 in mm (in):

47.5 (1.87)/55.0 (2.17)

TECHNICAL DATA IN

ACCORDANCE WITH IEC

Maximum Load Current in A/Cross

Section in mm2: 32 / 4

Rated Surge Voltage in

kV/Contamination Class: 8 / 3

Surge Voltage Category/Insulating

Material Group: III / II

CONNECTION CAPACITY

Stranded with Ferrule/with Ferrule

and Plastic Sleeve in mm2:

0.25 to 2.5/0.25 to 2.5

MULTI-CONDUCTOR CONNECTION

(SAME CROSS-SECTION)

Solid/Stranded in mm

2

:

0.14 to 1.5/0.14 to 1.5

Stranded with Ferrules without Plastic

Sleeve in mm2: 0.25 to 1.5

Stranded with Twin Ferrule with

Plastic Sleeve in mm2: 0.5 to 1.5

Stripping Length in mm (in): 9 (0.35)

Thread: M3

Torque in in-lb (Nm): 5.3 to 7.1

(0.6 to 0.8)

The XBUT Series utilizes a screw connection

system that is accepted worldwide and is

suitable in most applications.

The maintenance-free connection

provides the reliability you expect.

Designed for applications with high

demands, the XBUT Series screw terminal

block has a maintenance-free wire

connection. Tightening of the terminal

screws is not necessary to ensure proper

operation. The screw locking technique

prevents the screws from backing out.

Copper wires can be clamped without

pre-treatment or ferrules can be used for

splicing protection. Multiple conductors

can be connected in the same clamping

mechanism, saving space.

The XBUT terminal blocks feature a

compact design and maintenance-free

screw connection. There is a double bridge

shaft providing maximum flexibility. The

double bridge shaft can accommodate

individual chain bridging and step down

bridging from other terminal blocks. There

are numerous options for accessories,

including those for testing and marking.

Terminal blocks are available for wire

cross-sections ranging from 12 AWG

(2.5 mm

2

) to 0 AWG (150 mm2).

XBANS3575P, $9.00, shown

smaller than actual size.

XBUT25-50PK, $38.50,

shown smaller than actual size.

Comes with instruction sheet.

Ordering Example: XBUT25-50

PK,

gray terminal blocks, XBACUT10-10PK,gray end covers,

$38.50 + 3.50 = $42.

Note 1: EU type-examination certificate number KEMA 05ATEX2158U.

RoHS

Page 4

XBUT4BU-50PK

$40.50 for pkg of 50

Ordering Example: XBUT4-50PK blue terminal blocks, XBUT4RD-50PK red terminal blocks, XBANS3575P, DIN rail

$40.50 + 40.50 + 9 = $90.

Note 1: EU type-examination certificate number KEMA 05ATEX2158U.

SPECIFICATIONS FOR XBUT4

Terminal Width: 6.2 mm

Maximum Wire Size: 10 AWG/4 mm

2

IEC 60 947-7-1 in V/A/AWG: 800/41/26-10

EN 50 0191in V/A/AWG: 750/30 or 38/26-10

UL-cUL Ratings in V/A/AWG: 600/30/26-10

TECHNICAL DATA DIMENSIONS

Width/Length/Cover Width in mm (in):

6.2 (0.24)/46.9 (1.85)/2.2 (0.09)

Height for 35 x 7.5/35 x 15 in mm (in): 47.5 (1.87)/55.0 (2.17)

TECHNICAL DATA IN ACCORDANCE WITH IEC

Maximum Load Current in A/Cross-Section in mm2: 41/6

Rated Surge Voltage in kV/Contamination Class: 8/3

Surge Voltage Category/Insulating Material Group: III/I

CONNECTION CAPACITY

Stranded with Ferrule/with Ferrule and Plastic Sleeve in mm2:

0.25 to 4/0.25 to 4

MULTI-CONDUCTOR CONNECTION (SAME CROSS-SECTION)

Solid/Stranded in mm2: 0.14 to 1.5/0.14 to 1.5

Stranded with Ferrules without Plastic Sleeve in mm2: 0.25 to 1.5

Stranded with Twin Ferrule with Plastic Sleeve in mm2: 0.5 to 2.5

Stripping Length in mm (in): 9 (0.35)

Thread: M3

Torque in in-lb (Nm): 0.6 to 0.8 (5.3 to 7.1)

MODEL NO. PRICE DESCRIPTION

XBUT4-50PK $40.50 Gray single level connection, package of 50

XBUT4BU-50PK 40.50 Blue single level connection

XBUT4OR-50PK 40.50 Orange single level connection

XBUT4YE-50PK 40.50 Yellow single level connection

XBUT4RD-50PK 40.50 Red single level connection

XBUT4WH-50PK 40.50 White single level connection

XBUT4BK-50PK 40.50 Black single level connection

XBUT4GN-50PK 40.50 Green single level connection

ACCESSORIES

XBACUT10-10PK $3.50 Gray end cover package of 10

XBATUT10-10PK 4.60 Gray partition plate package of 10

XBAFBS26-10PK 3.40 Red 2 position plug-in bridge package of 10

XBAFBS36-10PK 6.70 Red 3 position plug-in bridge package of 10

XBAFBS56-10PK 13.00 Red 5 position plug-in bridge package of 10

XBAFBS106-10PK 27.30 Red 10 position plug-in bridge package of 10

XBAFBS506 17.00 Red 50 position plug-in bridge package of 10

XBATSPAI4-10PK 80.00 Test adaptor package of 10

XBMZB6-10PK 4.60 5.2 mm white blank marker strip package of 10

XBANS3575P 9.00 DIN rail 35 x 7.5 mm x 2 m (1.4 x 0.30" x 6.6') slotted

XBANS3575U 9.30 DIN rail 35 x 7.5 mm x 2 m (1.4 x 0.30" x 6.6') solid

XBANS3515P 17.00 DIN rail 35 x 15 mm x 2 m (1.4 x 0.60" x 6.6') slotted

XBANS3515U 17.00 DIN rail 35 x 15 mm x 2 m (1.4 x 0.60" x 6.6') solid

XBAES35C-50PK 42.00 1-screw mounted end stop package of 50

XBAES35T-50PK 31.50 3-screw mounted end stop package of 50

XBAES35N-50PK 26.50 Snap-on end stop package of 50

To Order

(Specify Model Number)

MOST POPULAR MODELS HIGHLIGHTED!

XBUT4WH-50PK

$40.50 for pkg of 50

XBUT4RD-50PK

$40.50 for pkg of 50

All models

shown smaller

than actual size.

L-12

Page 5

L-13

SPECIFICATIONS FOR XBUT6

Terminal Width: 8.2 mm

Maximum Wire Size: 8 AWG/6 mm

2

IEC 60 947-7-1 in V/A/AWG:

800/57/24-8

EN 50 0191in V/A/AWG:

750/40 or 50/24-8

UL-cUL Ratings in V/A/AWG:

600/50/24-8

TECHNICAL DATA DIMENSIONS

Width/Length/Cover Width in mm (in):

8.2 (0.32)/46.9 (1.85)/ 2.2 (0.09)

Height for 35 x 7.5/35 x 15 in mm (in):

47.5 (1.87)/55.0 (2.17)

TECHNICAL DATA IN ACCORDANCE

WITH IEC

Maximum Load Current in A/

Cross-Section in mm2: 57/10

Rated Surge Voltage in kV/

Contamination Class: 8/3

Surge Voltage Category/Insulating

Material Group: III/I

CONNECTION CAPACITY

Stranded with Ferrule/with Ferrule

and Plastic Sleeve in mm2:

0.25 to 6/0 .25 to 6

MULTI-CONDUCTOR CONNECTION

(SAME CROSS-SECTION)

Solid/Stranded in mm2:

0.2 to 2.5/0.2 to 2.5

Stranded with Ferrules without Plastic

Sleeve in mm2: 0.25 to 1.5

Stranded with Twin Ferrule with

Plastic Sleeve in mm2: 0.5 to 4

Stripping Length in mm (in): 10 (0.39)

Thread: M4

Torque in in-lb (Nm): 13.3 to 15.9

(1.5 to 1.8)

Ordering Example: XBUT6-50PK, gray terminal blocks, XBANS3575P, DIN rail, $56 + 9 = $65.

Note 1: EU type-examination certificate number KEMA 05ATEX2158U.

MODEL NO. PRICE DESCRIPTION

XBUT6-50PK $56.00 Gray single level connection, package of 50

XBUT6BU-50PK 56.00 Blue single level connection, package of 50

ACCESSORIES

XBACUT10-10PK $3.50 Gray end cover package of 10

XBATUT10-10PK 4.60 Gray partition plate package of 10

XBAFBS28-10PK 4.20 Red 2 position plug-in bridge package of 10

XBATSPAI4-10PK 80.00 Test adaptor package of 10

XBMZB8-10PK 4.60 8.22 mm white blank marker strip package of 10

XBANS3575P 9.00 DIN rail 35 x 7.5 mm x 2 m (1.4 x 0.30" x 6.6') slotted

XBANS3575U 9.30 DIN rail 35 x 7.5 mm x 2 m (1.4 x 0.30" x 6.6') solid

XBANS3515P 17.00 DIN rail 35 x 15 mm x 2 m (1.4 x 0.60" x 6.6') slotted

XBANS3515U 17.00 DIN rail 35 x 15 mm x 2 m (1.4 x 0.60" x 6.6') solid

XBAES35C-50PK 42.00 1-screw mounted end stop package of 50

XBAES35T-50PK 31.50 3-screw mounted end stop package of 50

XBAES35N-50PK 26.50 Snap-on end stop package of 50

To Order

(Specify Model Number)

MOST POPULAR MODELS HIGHLIGHTED!

XBUT6-50PK, $56, shown

larger than actual size

Page 6

XBAES35C-10PK

$42 for pkg of 10

Ordering Example: XBUT10YE-50PK, yellow terminal blocks, $82.50

Note 1: EU type-examination certificate number KEMA 05ATEX2158U.

SPECIFICATIONS FOR XBUT10

Terminal Width: 10.2 mm

Maximum Wire Size: 6 AWG/10 mm

2

IEC 60 947-7-1 in V/ A/AWG: 1000/76/20-6

EN 50 0191in V/A/AWG: 750/54 or 69/20-6

UL-cUL Ratings in V/A/AWG: 600/65/20-6

TECHNICAL DATA DIMENSIONS

Width/Length/Cover Width in mm (in):

10.2 (0.40)/46.9 (1.85)/2.2 (0.09)

Height for 35 x 7.5 / 35 x 15 in mm (in):

47.5 (1.87)/55.0 (2.17)

TECHNICAL DATA IN ACCORDANCE WITH IEC

Maximum Load Current in A/

Cross-Section in mm2: 76/16

Rated Surge Voltage in kV/

Contamination Class: 8/3

Surge Voltage Category/Insulating

Material Group: III/I

CONNECTION CAPACITY

Stranded with Ferrule/with Ferrule and

Plastic Sleeve in mm2: 0.5 to 10/0.5 to 10

MULTI-CONDUCTOR CONNECTION

(SAME CROSS-SECTION)

Solid/Stranded in mm

2

: 0.5 to 4/0.5 to 4

Stranded with Ferrules without Plastic

Sleeve in mm2: 0.5 to 2.5

Stranded with Twin Ferrule with Plastic

Sleeve in mm2: 0.5 to 6

Stripping Length in mm (in): 10 (0.39)

Thread: M4

Torque in in-lb (Nm): 13.3 to 15.9 (1.5 to 1.8)

XBUT10-50PK

$73.50 for pkg of 50

XBANS3575SP, $9

XBACUT10-10PK

$3.50 for pkg of 10

XBATUT10-10PK

$4.60 for pkg of 10

L-14

MODEL NO. PRICE DESCRIPTION

XBUT10-50PK $73.50 Gray single level connection, package of 50

XBUT10BU-50PK 73.50 Blue single level connection, package of 50

XBUT10OR-50PK 82.50 Orange single level connection, package of 50

XBUT10RD-50PK 82.50 Red single level connection, package of 50

XBUT10YE-50PK 82.50 Yellow single level connection, package of 50

ACCESSORIES

XBACUT10-10PK $3.50 Gray end cover package of 10

XBATUT10-10PK 4.60 Gray partition plate package of 10

XBAFBS210-10PK 11.20 Red 2 position plug-in bridge package of 10

XBARBUT10-10PK 24.50 Red reducing bridge package of 10

XBMZB10-10PK 4.60 10.2 mm white blank marker strip package of 10

XBANS3575P 9.00 DIN rail 35 x 7.5 mm x 2 m (1.4 x 0.30" x 6.6') slotted

XBANS3575U 9.30 DIN rail 35 x 7.5 mm x 2 m (1.4 x 0.30" x 6.6') solid

XBANS3515P 17.00 DIN rail 35 x 15 mm x 2 m (1.4 x 0.60" x 6.6') slotted

XBANS3515U 17.00 DIN rail 35 x 15 mm x 2 m (1.4 x 0.60" x 6.6') solid

XBAES35C-50PK 42.00 1-screw mounted end stop package of 50

XBAES35T-50PK 31.50 3-screw mounted end stop package of 50

XBAES35N-50PK 26.50 Snap-on end stop package of 50

To Order

(Specify Model Number)

MOST POPULAR MODELS HIGHLIGHTED!

Page 7

L-15

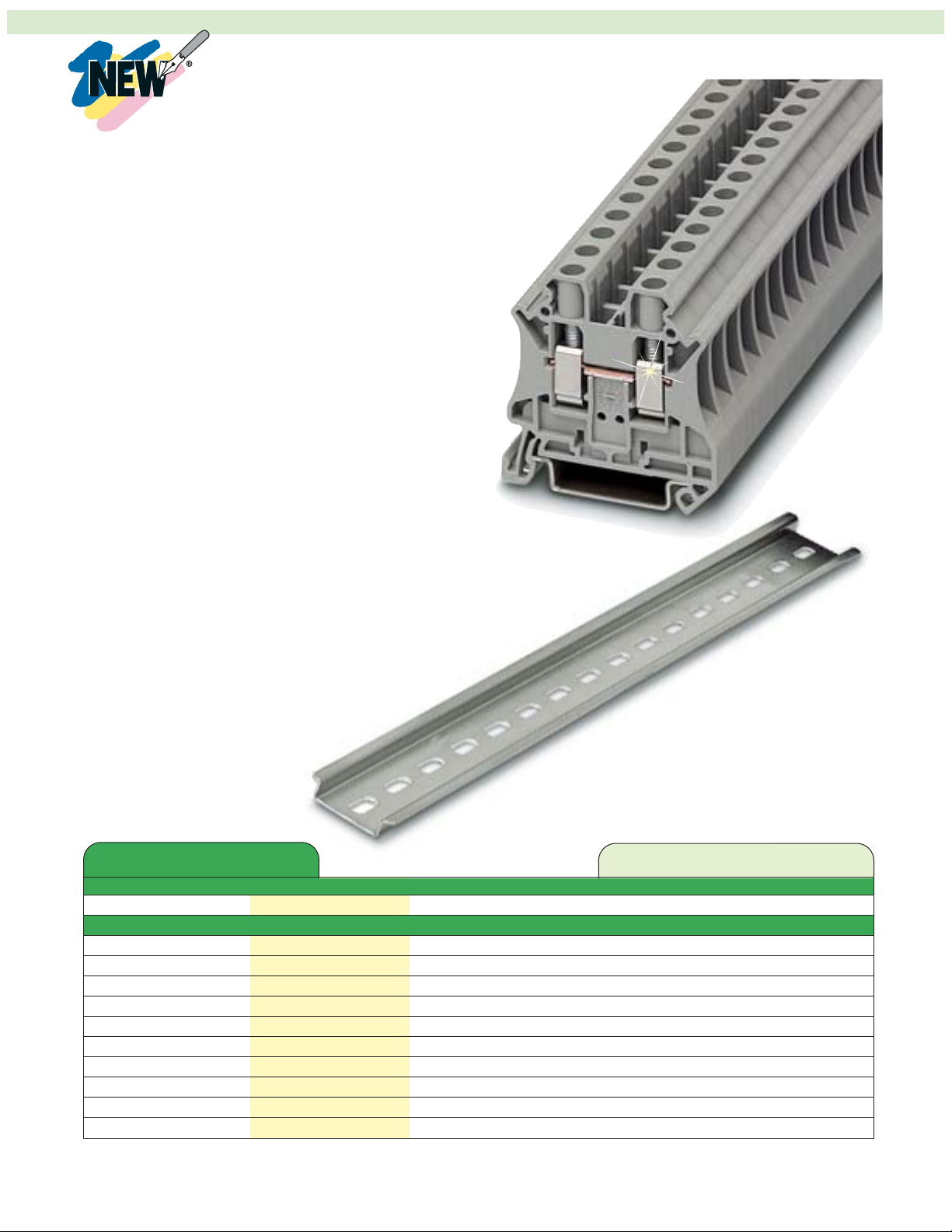

SPECIFICATIONS FOR XBUT16

Terminal Width: 12 mm

Maximum Wire Size: 4 AWG/16 mm

2

IEC 60 947-7-1 in V/A/AWG:

1000/101/17-4

UL-cUL Ratings in V/A/AWG:

600/85/16-4

TECHNICAL DATA DIMENSIONS

Width/Length/Cover Width in mm (in):

12 (0.47)/52.8 (2.08)/2.2 (0.09)

Height for 35 x 7.5/35 x 15 in mm (in):

54.8 (2.16)/62.3 (2.45)

TECHNICAL DATA IN ACCORDANCE

WITH IEC

Maximum Load Current in A/

Cross-Section in mm

2

: 101/25

Rated Surge Voltage in kV/

Contamination Class: 8/3

Surge Voltage Category/Insulating

Material Group: III/I

CONNECTION CAPACITY

Stranded with Ferrule/with Ferrule

and Plastic Sleeve in mm2:

1.0 to 16/1.0 to 16

MULTI-CONDUCTOR CONNECTION

(SAME CROSS-SECTION)

Solid/Stranded in mm2:

1.0 to 6/1.0 to 4

Stranded with Ferrules without Plastic

Sleeve in mm2: 1.0 to 4

Stranded with Twin Ferrule with

Plastic Sleeve in mm2: 0.75 to 10

Stripping Length in mm (in): 10 (0.39)

Thread: M5

Torque in in-lb (Nm): 22.1 to 26.6

(2.5 to 3.0)

Ordering Example: XBUT16-10PK, gray terminal blocks, XBANS3575P, DIN rail, $33 + 9 = $42.

MODEL NO. PRICE DESCRIPTION

XBUT16-10PK $33.00 Gray single level connection, package of 10

ACCESSORIES

XBACUT16-10PK $4.90 Gray end cover package of 10

XBAFBS212-10PK 13.30 Plug-in bridge package of 10

XBMZB10-10PK 4.60 8.22 mm white blank marker strip package of 10

XBANS3575P 9.00 DIN rail 35 x 7.5 mm x 2 m (1.4 x 0.30" x 6.6') slotted

XBANS3575U 9.30 DIN rail 35 x 7.5 mm x 2 m (1.4 x 0.30" x 6.6') solid

XBANS3515P 17.00 DIN rail 35 x 15 mm x 2 m (1.4 x 0.60" x 6.6') slotted

XBANS3515U 17.00 DIN rail 35 x 15 mm x 2 m (1.4 x 0.60" x 6.6') solid

XBAES35C-50PK 42.00 1-screw mounted end stop package of 50

XBAES35T-50PK 31.50 3-screw mounted end stop package of 50

XBAES35N-50PK 26.50 Snap-on end stop package of 50

To Order

(Specify Model Number)

AVAILABLE FOR FAST DELIVERY!

XBUT16-10PK, $33

shown larger

than actual size.

XBANS3575P, $9, shown

smaller than actual size.

Page 8

SPECIFICATIONS FOR XBUT35

Terminal Width: 16 mm

Maximum Wire Size: 0 AWG/35 mm

2

IEC 60 947-7-1 in V/A/AWG:

1000/150/15-0

UL-cUL Ratings in V/A/AWG:

600/150/14-1/0

TECHNICAL DATA DIMENSIONS

Width/Length/Cover Width in mm (in):

16.0 (0.63)/60.2 (2.37)/-

Height for 35 x 7.5/35 x 15 in mm (in):

65.7 (2.59)/73.2 (2.88)

TECHNICAL DATA IN ACCORDANCE

WITH IEC

Maximum Load Current in A/

Cross-Section in mm2: 150/50

Rated Surge Voltage in kV/

Contamination Class: 8/3

Surge Voltage Category/Insulating

Material Group: III/I

CONNECTION CAPACITY

Stranded with Ferrule/with Ferrule

and Plastic Sleeve in mm

2

:

1.5 to 35/1.5 to 35

MULTI-CONDUCTOR CONNECTION

(SAME CROSS-SECTION)

Solid/Stranded in mm2:

1.5 to 16/1.5 to 10

Stranded with Ferrules without Plastic

Sleeve in mm2: 1.5 to 10

Stranded with Twin Ferrule with

Plastic Sleeve in mm2: 1.5 to 10

Stripping Length in mm (in): 16 (0.63)

Thread: M6

Torque in in-lb (Nm): 28.3 to 32.7

(3.2 to 3.7)

Ordering Example: XBUT35-10PK, gray terminal blocks, XBANS3575P, DIN rail, $46 + 9 = $55.

MODEL NO. PRICE DESCRIPTION

XBUT35-10PK $46.00 Gray single level connection, package of 10

ACCESSORIES

XBAFBS216-10PK $15.10 Red 2 position plug-in bridge package of 10

XBMZB15-10PK 4.55 8.22 mm white blank marker strip package of 10

XBANS3575P 9.00 DIN rail 35 x 7.5 mm x 2 m (1.4 x 0.30" x 6.6') slotted

XBANS3575U 9.30 DIN rail 35 x 7.5 mm x 2 m (1.4 x 0.30" x 6.6') solid

XBANS3515P 17.00 DIN rail 35 x 15 mm x 2 m (1.4 x 0.60" x 6.6') slotted

XBANS3515U 17.00 DIN rail 35 x 15 mm x 2 m (1.4 x 0.60" x 6.6') solid

XBAES35C-50PK 42.00 1-screw mounted end stop package of 50

XBAES35T-50PK 31.50 3-screw mounted end stop package of 50

XBAES35N-50PK 26.50 Snap-on end stop package of 50

To Order

(Specify Model Number)

AVAILABLE FOR FAST DELIVERY!

XBUT35-10PK, $46, shown

larger than actual size

L-16

Page 9

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...