Omega Products VR206 Installation Manual

User’s Guide

http://www.omega.com

e-mail: info@omega.com

VR200 RE C O R D E R

I n s t ruction Manual

OMEGAne t®On-Line Service Internet e-mail

h t t p : / / w w w.omega.com i n f o @ o m e g a . c o m

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (001) 800-826-6342 FAX: (001) 203-359-7807

En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

SM

SM

SM

Servicing Europe:

Benelux: Postbus 8034, 1180 LAAmstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311 8 9 9 FAX: 420 (69) 631111 4

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Cert i f i e d Northbank, Irlam, Manchester

M44 5EX, United Kingdom

Tel: +44 (0) 161 777-6611 FAX: +44 (0) 161 777-6622

Toll Free in United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

a p p l y. OMEGA is constantly pursuing certification of its products to the European New Appro a c h

D i rectives. OMEGA will add the CE mark to every appropriate device upon cert i f i c a t i o n .

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

PREFACE

Thank you for purchasing the Omega VR200 Wide-view Recorder.

To take full advantage of all the functions of the VR200 Wide-view Recorder, and to

use this instrument correctly and efficiently, please read this instruction manual

carefully before use.

Notes

• In this manual, equipment of style number 2 is explained.

The following functions are added with style number 2.

· Bar graph display, digital value display, information display and list display.

· Writing message (section 3.5)

· On/off setting of waveform (section 4.7.3)

· Number of trip level (section 4.7.5)

· Message setting (section 4.8)

· Setting the number of divisions of scale for the bar graph display (section 4.9)

· On/off setting of the waveform span rate display and the message menu display

(section 4.10)

· Setting the remote cntrol function (section 6.9)

• This manual may be changed at any time without notice.

• If you find any ambiguities or errors in this manual, please inform Omega.

• All rights reserved. No part of this document may be reproduced in any form

without Omega’s written permission.

Trademarks

• “IBM” is a trademark of International Business Machines Corp.

• “MS-DOS” and “Windows” are trademarks of Microsoft Corporation.

• “PC-9801” is a trademark of NEC Corp., Japan.

1

SAFETY PRECAUTIONS

This recorder conforms to IEC 348 under the following two conditions:

• The VR200 is a Safety Class I instrument (provided with a terminal for protective

earthing) and CAT II (IEC1010).

• The VR200 is an EN55011 (EMI standard), Group 1, Class A instrument.

The following general safety precautions must be observed at all times of operation,

service, and repair of this instrument. Failure to comply with these precautions or with

specific WARNINGS given elsewhere in this manual violates the safety standards of

design, manufacture, and intended use of the instrument.

OMEGA assumes NO liability for the customer’s failure to comply with these

requirements.

General Definitions of Safety Symbols Used on Equipment

CAUTION: To avoid injury, death of personnel or damage to the

instrument, the operator must refer to the explanation in the instruction

manual.

Function grounding terminal: The terminal marked with this symbol

must not be used as a protective grounding terminal.

Protective grounding terminal: Used to protect against electrical

shock in case of a fault. This symbol indicates that the terminal must

be connected to ground before using the equipment.

High temperature: To avoid injury caused by hot surfaces, do not

touch the heatsink.

2

WARNING

Power Supply

Ensure the source voltage matches the voltage of the power supply before

turning on the power.

Power Cable and Plug (for Desk-top Model)

For the power cable, use those provided by Omega to prevent fire and electric

shock.

Connect the power cable of the VR recorder to a 3-pole power socket with a

protectibe grounding pole.

Do not use an extension cable without a protective grounding wire, since this

invalidates the protection.

Protective Grounding

Make sure to connect the protective grounding to prevent electric shock before

turning on the power.

Necessity of Protective Grounding

Never cut off the internal or external protective grounding wire or disconnect the

wiring of the protective grounding terminal, since doing so creates the risk of

shock.

Defective Protective Grounding and Fuse

Do not operate the instrument if the protective grounding or fuse might be

defective. Before operating this product, check that there is no defect in the

protective grounding and fuses.

Fuse

To prevent a fire, use the fuse of the specified standard (current, voltage, type).

Before replacing the fuse, turn off the power and disconnect the power source.

Do not use a different fuse nor short-circuit the fuse holder.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable liquids or vapors.

Operation of any electrical instrument in such an environment constitutes a

safety hazard.

Never T ouch the Interior of the Instrument

Inside this instrument there are areas of high voltage; never touch the interior if

the power supply is connected. This instrument contains parts which can be

adjusted inside; however, internal inspection and adjustments should be done

by qualified personnel only.

External Connection

To ground securely, connect the protective grounding before connecting to a

measurement or control unit.

3

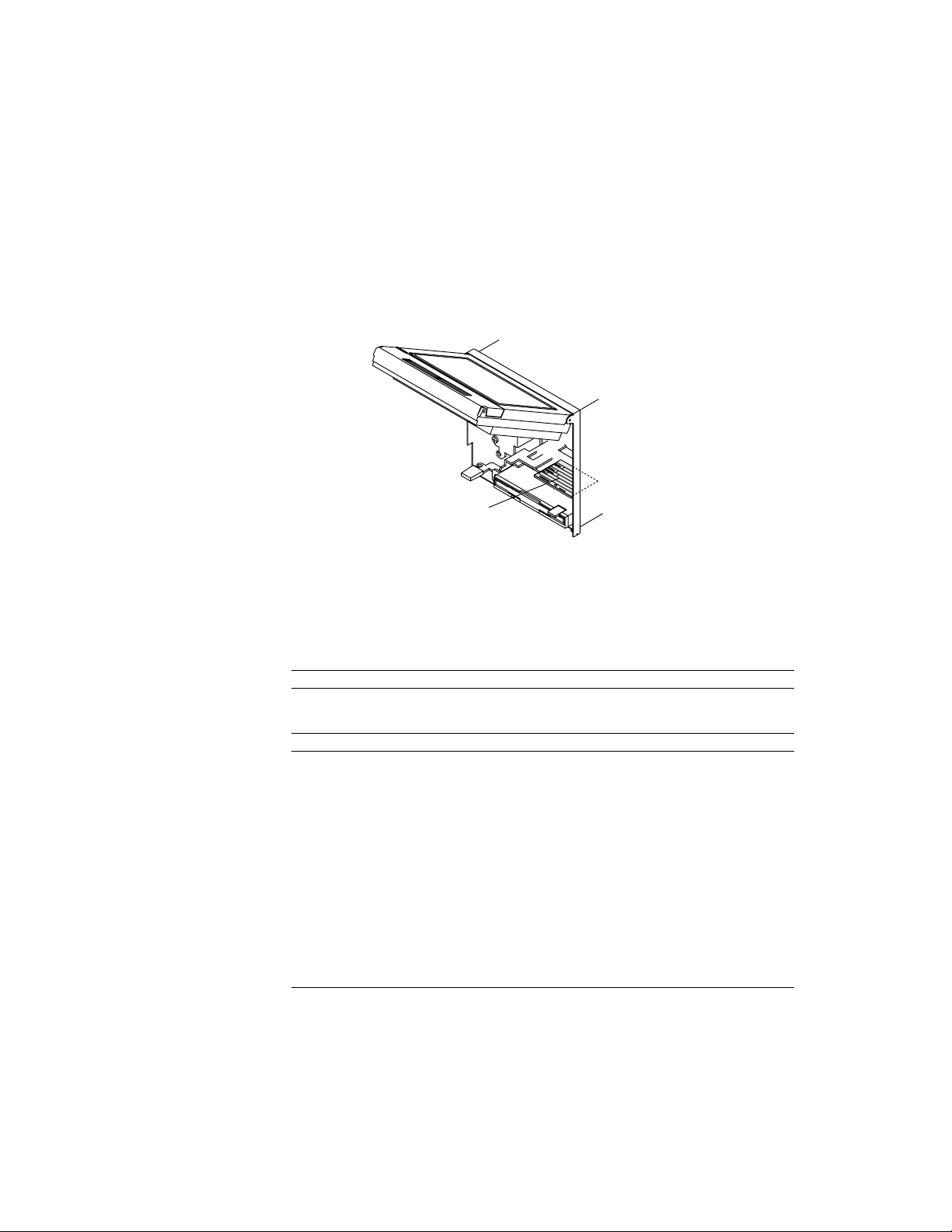

CHECKING THE PACKAGE CONTENTS

After opening the package, please check the following before use. If there are any

differences in the specifications or quantity, or any defect in appearance, please contact

the supplier.

VR200

Check the descriptions for MODEL and SUFFIX on the nameplate on the low inside

the recorder casing to make sure that the product is the same as you ordered. To see the

internal hardware, first remove the screw located right side of the power switch, then

swing open the front panel.

Nameplate

MODEL (Model Number)

VR202 VR200 panel-mounting, two-channel wide-view recorder

VR204 VR200 panel-mounting, four-channel wide-view recorder

VR206 VR200 panel-mounting, six-channel wide-view recorder

SUFFIX (Suffix Code)

Model Suffix Code Description

Software -0 Without application software

Power cable -W Screw terminals for power supply (power cable not provided)

Options /A1 Two alarm output contacts

-2 Provided with English version software for IBM PC/AT compatible

personal computers

/A2 Four alarm output contacts

/A3 Six alarm output contacts

/C3 RS-422-A communication interface

/D2 Fahrenheit degree display

/E4 Large memory

/F1 Fail/Memory End output relay

/H5D Disk top type. Power cord UL st’d

/H5F Disk top type. Power cord VDE st’d

/H5R Disk top type. Power cord SAA st’d

/H5J Disk top type. Power cord BS st’d

/M1 Mathematical functoin

/M2 Mathematical functoin with VA200-02

/N1 Cu10, Cu25 resistance temperature detector input

/R1 Remote Control contact input

/P1 24 V DC power supply

/H2 Clamped input terminals

NO. (Serial Number)

When contacting the supplier for repair, etc., please quote this serial number.

4

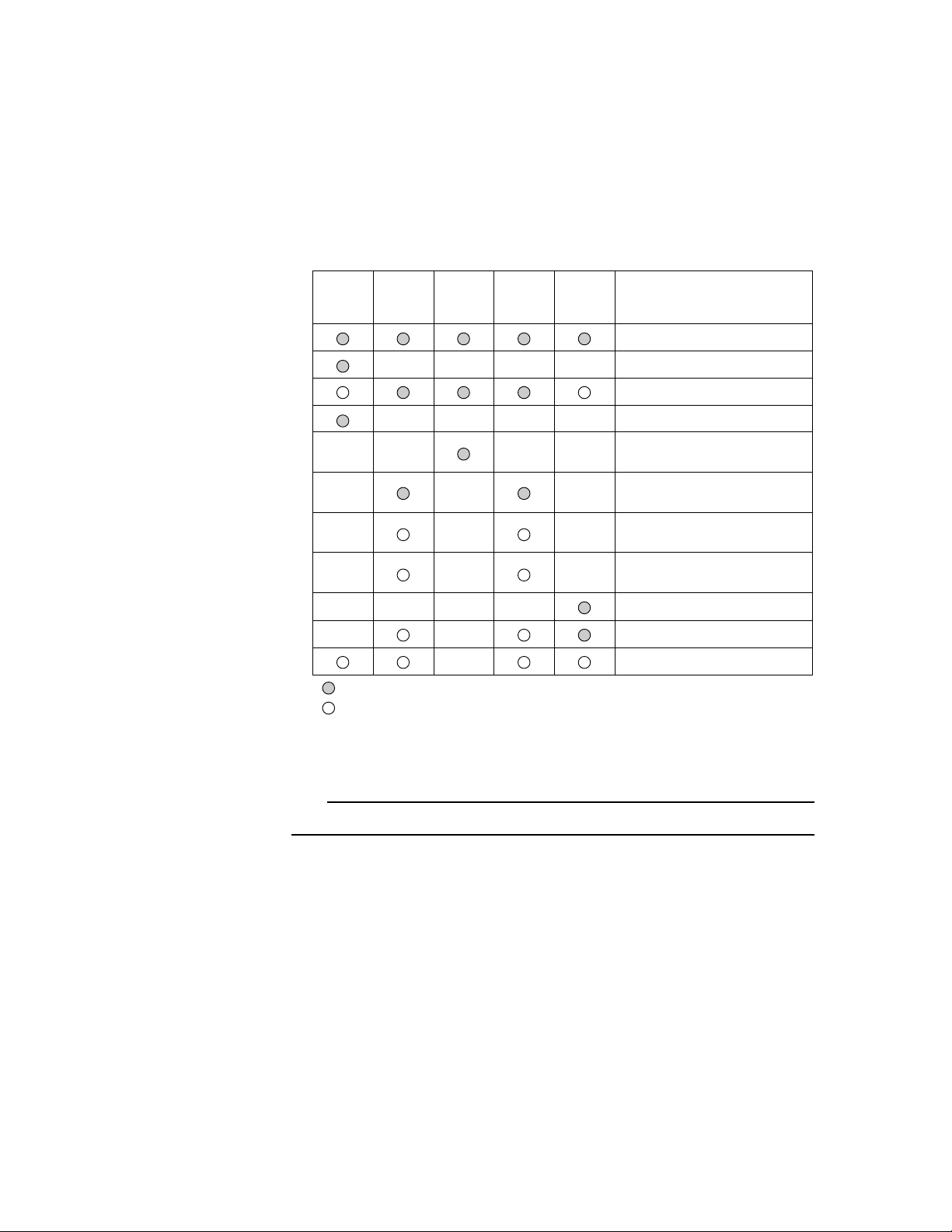

Accessories

1 2 3 4 5

The VR200 should come with the following accessories. Check that all are present in

the correct quantities and are not damaged.

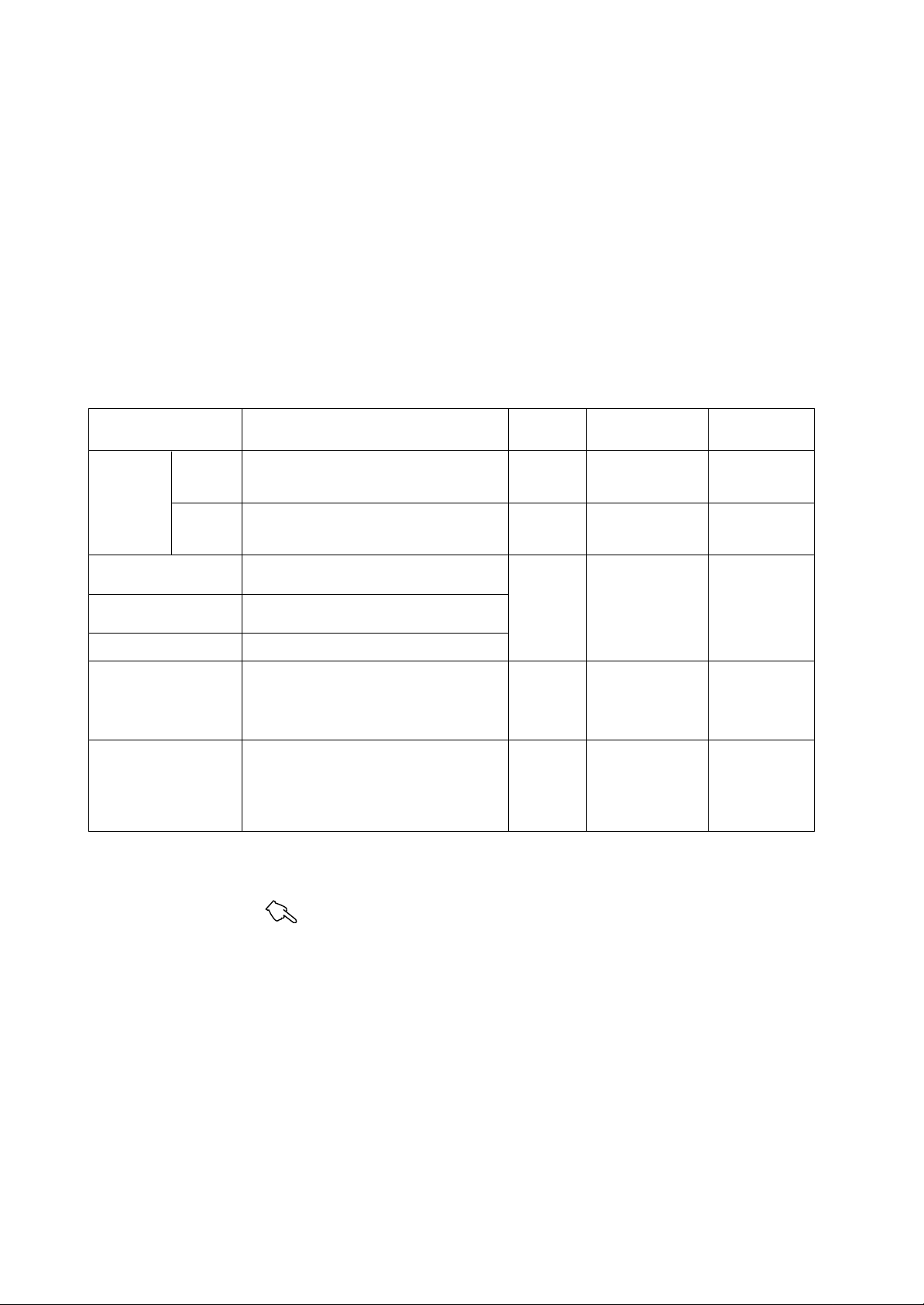

No. Name/Description Part Number Quantity Remarks

1 Fuse A1360EF 1 250 V, 500 mA time lag

(except for /P1 model)

A1102EF 1 250 V, 5 A time lag

(for /P1 model)

Recorders with a blue power switch

(delivered before July 6th 1998)

A1512EF 1 250 V, 800 mA time lag

(except for /P1 model)

A1513EF 1 250 V, 5 A time lag

(for /P1 model)

Recorders with a gray power switch

(delivered after July 7th 1998)

2 Terminal screws 5 M4

3 Mounting brackets B9900CW 2 For panel mounting.

4 Instruction manual IM 4N2A1-01E 1 This document

IM 4N2A1-11E 1 Provided only when “/C3” is specified

for the suffix code.

IM 4N1A1-61E 1 Provided only when “-2” is specified

for the suffix code.

IM 4N2A1-51E 1 Provided only when “/M1” and “/M2”

are specified for the suffix code.

IM 4N1A1-63E 1 Provided only when “/M2” are specified

for the suffix code.

5 Application software VP100-02 1 Provided only when “-2” is specified

for the suffix code. For MS-DOS(/

V), Windows 3.1

6 Power cord A1006WD 1 Provided only when “/H5D” is

(only for /H5■) specified for the suffix code.

A1009WD 1 Provided only when “/H5F” is

specified for the suffix code.

A1024WD 1 Provided only when”/H5R” is

specified for the suffix code.

A1023WD 1 Provided only when “/H5J” is

specified for the suffix code.

5

Optional Accessories

The items listed below are optional accessories that can be provided at extra cost. If

you have ordered these, please check that all are present in the correct quantities and are

not damaged.

For questions and orders for these optional accessories, please contact the supplier of

the VR200 recorder.

No. Name/Description Model (Part) Number Quantity Specification

1 3.5-inch floppy disks 7059 00 10 2HD, blank

2 Shunt resistors 4159 20 1 250 Ω ±0.1%

3 Shunt resistors 4389 20 1 250 Ω ±0.1%

4 Fuse A1360EF 4 250 V, 500 mA time lag

5 Mounting brackets B9900CW 2 —

(for screw terminals) 4159 21 1 100 Ω ±0.1%

4159 22 1 10 Ω ±0.1%

(for clamped terminals) 4389 21 1 100 Ω ±0.1%

4389 22 1 10 Ω ±0.1%

(except for /P1 model)

A1102EF 4 250 V, 5 A time lag

(for /P1 model)

Recorders with a blue power switch

(delivered before July 6th 1998)

A1512EF 4 250 V, 800 mA time lag

(except for /P1 model)

A1513EF 4 250 V, 5 A time lag

(for /P1 model)

Recorders with a gray power switch

(delivered after July 7th 1998)

Optional Software

The items listed below are optional software packages that can be provided at extra cost.

Name Model Number Required O/S

VR application software package VP100–02 MS-DOS or Windows 3.1

VR Enhanced Data Viewer VA100–02 Windows 3.1 or Windows 95

VR Data Viewer for Windows 95 VA200–02 Windows 95

6

HOW TO USE THIS MANUAL

SAFETY PRECAUTIONS (2 pages)

Checking the Package Contents (4 pages)

1 OVERVIEW OF VR200

2 BEFORE OPERATION

3 DAILY OPERATIONS (OPERATIONS IN

OPERATION MODE)

4 BASIC SETTINGS (OPERATIONS IN

SET MODE)

5 FLOPPY DISK AND FILES

(OPERATIONS IN SET MODE)

6 OPERATIONAL PREFERENCES SETUP

(OPERATIONS IN SETUP MODE)

7 MAINTENANCE

8 TROUBLESHOOTING

9 GENERAL SPECIFICATIONS

Chapter

Purchase

and

Installation

First Time

Setup

Daily

Operation

Changing

Settings

Maintenance

&

Troubleshooting

: Requisite

: Read as appropriate

Objectives of Each Chapter

This manual is composed of nine chapters, an appendix, and index. To help use this

manual, please refer to the following table. The table shows which chapter to refer to

depending on what you want to do.

For details on how to use options that are not described in this manual, please refer to the

separate option manuals.

Note

Although the versatility of the VR200 recorder allows the user to select whether to display the waveforms (trend graphs) vertically

or horizontally, most of the descriptions in this manual are based on a horizontal waveform display.

7

Signs and Abbreviations Used Throughout This Manual

Signs

K 1024. For example, 768K (file capacity)

M 1024K. For example, 1.2M (floppy disk capacity)

Notation Conventions

The following symbol conventions are used in this manual.

This marking on the product indicates that the operator must refer

to an explanation in the instruction manual in order to avoid injury

or death, or damage to the product. The manual describes that the

operator must take special care to avoid electric shock or other

dangers that may result in injury or loss of life.

This sign denotes a hazard, and calls attention to a procedure,

practice, condition or the like, which, if not correctly performed or

adhered to, could result in injury or loss of life.

This sign denotes a hazard, and calls attention to a procedure,

practice, condition or the like, which, if not correctly performed or

adhered to, could result in damage to or destruction of part of the

product.

Note This sign denotes important information which must be noted

when handling this product.

Conventions in Descriptions of Operation Procedures

In the descriptions of operation procedures, the following conventions are used

throughout this manual.

Bold or [ ] Denotes the keys on the front panel, e.g., MENU key, DISP key, [↵], etc.

‘ ’ Denotes a comment displayed on the screen, e.g., ‘SET=RANGE.’

Denotes an arbitrary item, e.g., ‘SET= .’

8

CONTENTS

PREFACE ................................................................................................................................................ 1

SAFETY PRECAUTIONS ...................................................................................................................... 2

CHECKING THE PACKAGE CONTENTS ........................................................................................... 4

HOW TO USE THIS MANUAL ............................................................................................................. 7

Chapter 1 OVERVIEW OF VR200

1.1 Functional Overview ...................................................................................................................... 1-1

1.1.1 Functional Configuration .................................................................................................... 1-1

1.1.2 Input Unit ............................................................................................................................ 1-1

1.1.3 Display Unit ........................................................................................................................ 1-2

1.1.4 Data Storage Functions ....................................................................................................... 1-4

1.1.5 Alarm Function ................................................................................................................... 1-6

1.1.6 Calculation Functions ......................................................................................................... 1-6

1.1.7 Other Functions................................................................................................................... 1-6

1.2 Component Names and Functions ................................................................................................. 1-7

1.2.1 Front Panel .......................................................................................................................... 1-7

1.2.2 Rear Panel ...........................................................................................................................1-8

1.3 Run Mode.......................................................................................................................................1-9

1.3.1 Modes.................................................................................................................................. 1-9

1.3.2 Mode Transition .................................................................................................................. 1-9

1.4 Display Format............................................................................................................................. 1-10

1.4.1 Screen in Operation Mode ................................................................................................ 1-10

1.4.2 Screen in SET Mode ......................................................................................................... 1-14

1.4.3 Screen in the SETUP Mode .............................................................................................. 1-14

1.5 How to Use the Panel Keys ......................................................................................................... 1-15

1.5.1 Keys Used in Operation Mode.......................................................................................... 1-15

1.5.2 Keys Used in SET and SETUP Modes ............................................................................. 1-15

1.6 Flow of Operation and Setting .....................................................................................................1-17

1.6.1 Operation Mode ................................................................................................................ 1-17

1.6.2 Flow Chart of SET Mode .................................................................................................. 1-18

1.6.3 Flow Chart of SETUP Mode............................................................................................. 1-20

Chapter 1 Chapter 2 Chapter 3 Chapter 4 Chapter 5 Chapter 6 Chapter 7 Chapter 8 Chapter 9 APPENDIX INDEX

Chapter 2 BEFORE OPERATION

2.1 Precautions .....................................................................................................................................2-1

2.1.1 Handling Precautions .......................................................................................................... 2-1

2.1.2 Cautions When Handling the Floppy Disk ......................................................................... 2-1

2.2 Installation......................................................................................................................................2-2

2.2.1 Installation Location ........................................................................................................... 2-2

2.2.2 Mounting ............................................................................................................................. 2-2

2.3 Input Signal Wiring ..................................................................................................................2-4

2.3.1 Input Signal Wiring ....................................................................................................... 2-4

2.3.2 Alarm Output Wiring .................................................................................................... 2-7

2.3.3 FAIL/Memory End Wiring ........................................................................................... 2-9

2.3.4 Remote Control Wiring..................................................................................................... 2-10

2.4 Power Supply Wiring ............................................................................................................. 2-12

Chapter 3 DAILY OPERATIONS (OPERATIONS IN OPERATION MODE)

3.1 Turning On/Of f the Power Switch ................................................................................................. 3-1

3.2 Saving the Measured Data on Floppy Disk ................................................................................... 3-2

3.3 Resetting an Alarm Output............................................................................................................. 3-4

3.4 Referencing the Past Measured Data (Historical Trend) ............................................................... 3-6

3.5 Writing the Message ......................................................................................................................3-8

3.6 Zooming/Reducing the Time Axis ................................................................................................. 3-9

3.7 To Start Storing the Measured Data by Manual Trigger .............................................................. 3-10

3.8 Swiching the Display Screen ....................................................................................................... 3-11

3.9 Detecting the FAIL and Memory End (Option) ........................................................................... 3-12

Chapter 4 BASIC SETTINGS (OPERATIONS IN SET MODE)

4.1 Setting the Input Range and Display Span .................................................................................... 4-1

9

CONTENTS

4.1.1 Voltage Input (VOLT) Setting .............................................................................................4-2

4.1.2 TC/RTD Input Setting.......................................................................................................... 4-3

4.1.3 Digital Input (DI) Setting ....................................................................................................4-4

4.1.4 Difference Computation (DELT) Setting ............................................................................ 4-5

4.1.5 Scale (SCL) Setting............................................................................................................. 4-7

4.1.6 Square Root Computation (SQRT) Setting......................................................................... 4-9

4.1.7 SKIP Setting...................................................................................................................... 4-11

4.2 Alarm Setting ............................................................................................................................... 4-12

4.3 Unit Assignment........................................................................................................................... 4-14

4.4 Setting of Waveform Span Rate (TIME/DIV) ............................................................................. 4-15

4.5 Clock Setting................................................................................................................................ 4-16

4.6 Copying the Channel Settings...................................................................................................... 4-17

4.7 Settings of Discrete Display (ZONE), Partial Expanded Display (PART), Scale Indication

On/Off (DISP_SCALE), Tags (TAG) and Trip Level (TRIP)...................................................... 4-18

4.7.1 Setting of Discrete Display (ZONE) .................................................................................4-18

4.7.2 Setting of Partial Expanded Display (PART) .................................................................... 4-20

4.7.3 On/Off Setting for Waveform and Scale Indication ..........................................................4-22

4.7.4 Tag Setting ........................................................................................................................ 4-23

4.7.5 Trip Level (TRIP) Setting ................................................................................................. 4-24

4.8 Message Setting ........................................................................................................................... 4-25

4.9 Setting the Number of Divisions of Scale for Bar graph Display................................................ 4-26

4.10 Turning ON/OFF the Waveform Span Rate Display and the Message Menu Display .............. 4-27

4.11 Settings of LCD Brightness and LCD Saver (LCD).................................................................. 4-28

Chapter 5 FLOPPY DISK AND FILES (OPERATIONS IN SET MODE)

5.1 Setting the Floppy Disk Format (AUX–FD) (Only for VR202/VR204) .......................................5-1

5.2 Setting the Data File Name (AUX–FILE) ..................................................................................... 5-2

5.3 Initializing the Data Memory (AUX–INIT_MEMORY)............................................................... 5-6

5.4 Formatting a Floppy Disk (FD_SET–INIT) .................................................................................. 5-7

5.5 Operations on SET Configuration File .......................................................................................... 5-8

5.5.1 Saving the SET Configuration File (FD_SET–SAVE) ....................................................... 5-8

5.5.2 Reading the SET Configuration File (FD_SET–LOAD) .................................................. 5-10

5.5.3 Deleting the SET Configuration File (FD_SET–DEL)..................................................... 5-11

5.6 Setting the Summer/Winter Time (AUX–DST) – Option ............................................................5-12

Chapter 6 OPERATIONAL PREFERENCES SETUP (OPERATIONS IN SETUP MODE)

6.1 Changing the Initial Settings for the Alarm Function (ALARM).................................................. 6-1

6.1.1 Setting the Reflash Function On/Off....................................................................................6-2

6.1.2 Setting the Logic of Representative Alarm Output Relay, AND or OR..............................6-4

6.1.3 Setting the Output Relay to Be Energized/De-energized When an Alarm Occurs ............. 6-5

6.1.4 Setting the Alarm Output Behavior, Hold or Non-hold ...................................................... 6-6

6.1.5 Setting the ALM Indication Behavior, Hold or Non-hold ..................................................6-8

6.1.6 Setting the Sampling Interval for Rate-of-change Alarms................................................ 6-10

6.1.7 Setting the Alarm Hysteresis On/Off ................................................................................ 6-12

6.2 Changing the Initial Settings for Input Processing ...................................................................... 6-13

6.2.1 A/D Integration Frequency (INTG) Setting ...................................................................... 6-13

6.2.2 TC Burnout Upscale/Downscale (B.OUT) Setting ...........................................................6-15

6.2.3 Setting of Reference Junction Compensation (RJC)......................................................... 6-16

6.2.4 Input Filter (FILTR) Setting (Only for VR202/VR204) ...................................................6-17

6.2.5 Moving Average (M_AVE) Setting (Only for VR206) ..................................................... 6-18

6.3 Settings of Direction of Waveform Display, Line W idths of Waveforms and Trip Levels, and

Number of Divisions of Scale (DISP).......................................................................................... 6-19

6.4 Display Color (COLOR) Setting ................................................................................................. 6-21

6.5 Setting the Temperature Unit (TEMP) ......................................................................................... 6-23

6.6 Setting of Data Storage Method (MEMORY) ............................................................................. 6-24

6.6.1 Precautions Before Setting................................................................................................ 6-24

6.6.2 Setting of Data Storage Method as Trigger-free ...............................................................6-29

6.6.3 Setting of Data Storage Method as Trigger-on or Trigger-rotation................................... 6-30

6.7 Auxiliary Function (AUX) Setting............................................................................................... 6-32

6.8 Operations on SETUP Configuration File ................................................................................... 6-34

6.8.1 Saving the SETUP Configuration File (FD_SET–SAVE) ................................................ 6-34

10

6.8.2 Reading the SETUP Configuration File (FD_SET–LOAD)............................................. 6-36

6.8.3 Deleting the SETUP Configuration File (FD_SET–DEL)................................................ 6-37

6.9 Setting the Remote Control Function .......................................................................................... 6-38

6.10 Initialization of Setup (INIT) ..................................................................................................... 6-39

6.11 Selecting the Display Language (LANG) – Option................................................................... 6-40

Chapter 7 MAINTENANCE

7.1 Periodic Maintenance.....................................................................................................................7-1

7.2 Replacing the Fuse .................................................................................................................. 7-2

7.3 Replacing the Battery..................................................................................................................... 7-3

7.4 Checking the Accuracy .................................................................................................................. 7-4

7.5 Recommended Replacement Periods for Consumable Parts ......................................................... 7-6

Chapter 8 TROUBLESHOOTING

8.1 Error Messages............................................................................................................................... 8-1

8.1.1 Error Messages at Boot-up (Power-on)...............................................................................8-1

8.1.2 Error Messages When Using Floppy Disk.......................................................................... 8-2

8.1.3 Error Messages During Parameter Setting Operations ....................................................... 8-3

8.2 Troubleshooting Flow Chart .......................................................................................................... 8-4

Chapter 9 GENERAL SPECIFICATIONS

9.1 Input Specifications........................................................................................................................9-1

9.2 Calculation Function Specifications .............................................................................................. 9-2

9.3 Display Specifications....................................................................................................................9-4

9.4 Data Saving Specifications ............................................................................................................ 9-5

9.5 Alarm Function Specifications.......................................................................................................9-6

9.6 General Specifications ................................................................................................................... 9-7

9.7 Dimensional Drawings................................................................................................................. 9-10

Chapter 1 Chapter 2 Chapter 3 Chapter 4 Chapter 5 Chapter 6 Chapter 7 Chapter 8 Chapter 9 APPENDIX INDEX

APPENDIX

Appendix 1 Parameters and Initial Settings ................................................................................... App.-1

Appendix 2 Data Formats of Parameter List File and Information File ........................................ App.-6

Appendix 3 Glossary...................................................................................................................... App.-9

11

Chapter 1 OVERVIEW OF VR200

1.1 Functional Overview

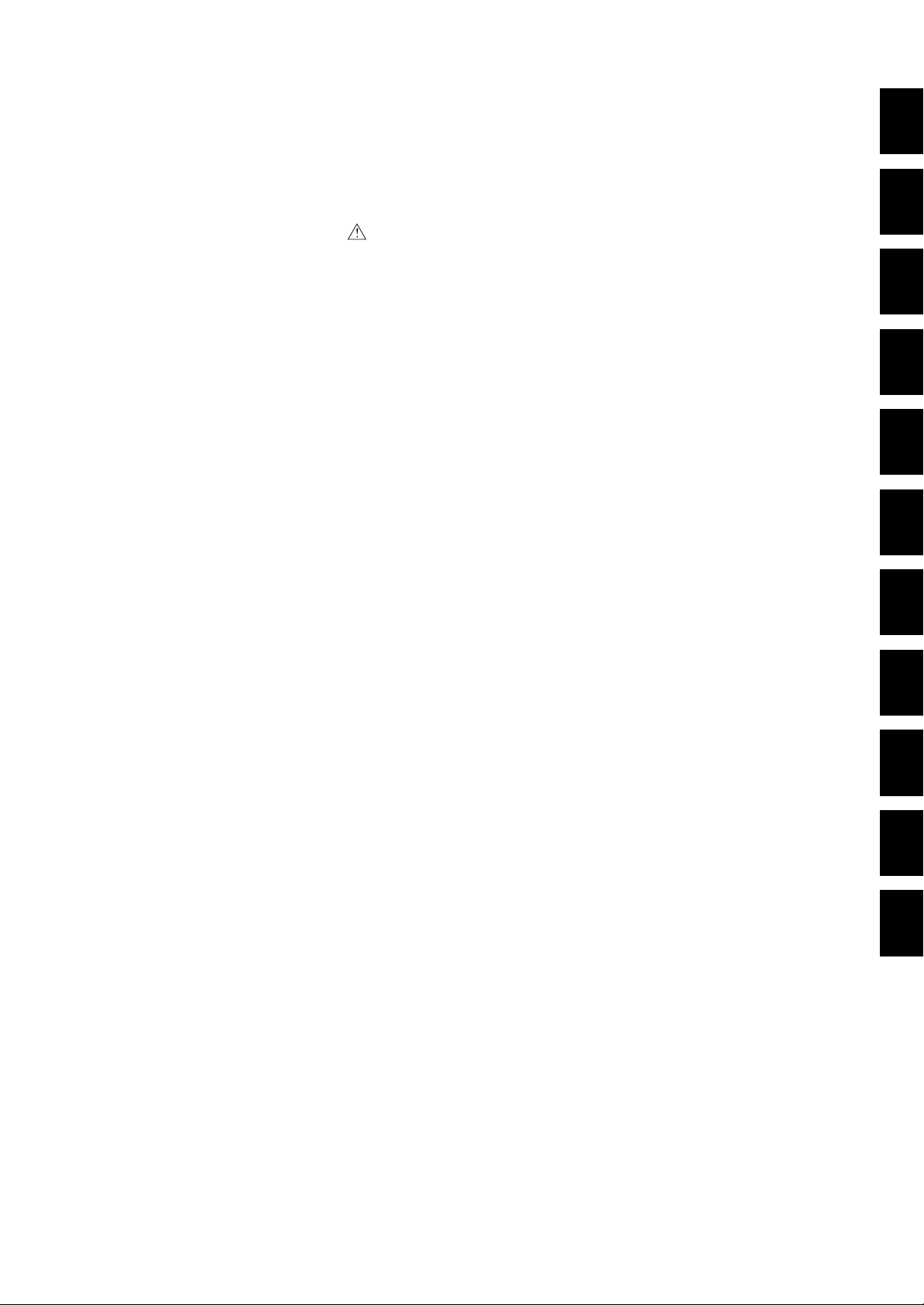

1.1.1 Functional Configuration

The functions of the VR200 recorder are illustrated below .

Data storage functionsVR200

1.1 Functional Overview

1. OVERVIEW OF VR200

1.1.2 Input Unit

FDD

Input unit LCD

Internal memory

Calculation function

Alarm function

Communication function

Remote control

Display unit

(optional)

(optional)

The following table outlines the possible input types for this recorder, measuring period,

and measuring ranges. For details, see Section 9.1, “Input Specifications.”

Item Description

Number of inputs VR202: Up to two channels (can be set from one to two *1)

Input types DCV: DC voltage

Measuring period VR202/VR204: 125 ms , VR206: 1 s or 2 s

Measuring range DCV: ±20 mV to ±20 V

VR204: Up to four channels (can be set from one to four *1)

VR206: Up to six channels (can be set from one to six, except five*1)

TC: Thermocouple

RTD: Resistance temperature detector

DI: On/off (contact) input

DCA: DC current *

TC, RTD: Corresponding to the range specified for each element type

DI: For voltage input; detecting off when less than 2.4 V, and on

when 2.4 V or greater

For contact input; on/off of contact

2

*1:To be defined in the SETUP mode.

*2:A DC current input requires an external shunt resistor.

In the measurement of each input channel, the following processing can be performed

depending on your setup.

Function Description

Burnout upscale/downscale Forcibly clamps the measured value reading to zero or full scale when the

Filter Suppresses the fluctuations of the input signals.

thermocouple burns out.

1 - 1

1.1.3 Display Unit

Waveform

(trend graph)

displayed

5.5-inch Color LCD

This recorder has a 5.5-inch TFT color LCD on which it displays the measured results

(240 (vertical) × 320 (horizontal) pixels).

*

82.79 181.11 143.70 1.310

MEM=26hour

100.00

2

1

3

4

200.00

200.00

6.000

97/02/05

13:30:40

Digital indications

(from the left,

channels 1, 2, 3, and 4)

1

Scale axis

0.00

-100.00

0.00

Engineering unit

*1: If 6 channels are defined to be used, the display information can be changed as follows.

*2: If the direction of the waveform (trend graph) display is set as vertical, the horizontal axis is the scale axis and

the vertical axis is the time axis.

*1

°C

Digital indications

for channels 1 to 3

MENU key

Engineering units

for channels 1 to 3

13:2513:23 13:27 13:29

Pa kl/h V

Time axis

*2

Digital indications

for channels 4 to 6

Engineering units

for channels 4 to 6

MENU key MENU key

-6.000

1 div. (30 pixels)

*2

Digital indications

for channels 1 to 3

Digital indications

for channels 4 to 6

Waveform Span Rate

The waveform(s) moves along with the time axis at a speed determined by the

waveform span rate. The waveform span rate, which is equivalent to the chart speed in

a conventional pen recorder and which determines the time span in each division (grid

interval) of the time scale, can be selected from six rates as shown in the following

table. To trace the waveform on the screen, the maximum and minimum values of the

measured values, which are sampled at the measurement period* within the interval

equivalent to one pixel of the time scale, are handled as the data to be traced on that

time-axis pixel. *The measurement period is 125 ms for the VR202/VR204, and 1 s or

2 s for the VR206. The following table shows the relation between the waveform span

rate and trend speed.

1 - 2

Waveform span rate 1 min 5 min 10 min 20 min 30 min 60 min

(time span per division of time axis) (2 S) (10 S) (20 S) (40 S) (60 S) (120 S)

Trend speed (mm/h) 615.0 123.0 61.5 30.7 20.5 10.2

(approximate)

The updating period of the digital indications at the top of the screen is fixed to one

second, regardless of the above. However, for the VR206, it is fixed to two seconds if

the measurement period is set as two seconds.

Operation Functions on Screen

The following operation functions are provided on the screen.

Function Description

Referencing past trend data Past trends stored in the internal memory are displayed on the left half of the

screen. All data stored in the internal memory can be viewed by scrolling

the screen.

Magnifying/reducing the time axis In addition to the normal trend screen determined by the waveform span

rate, the display span (= 8 divisions) can be switched to 8, 24, or 40 minutes

to magnify/reduce the time axis of the trend graphs.

Writing time-axis marks Time-axis marks can be displayed on arbitrary points on the time axis. The

information at the points of time thus marked is stored in the internal

memory as time-axis mark information.

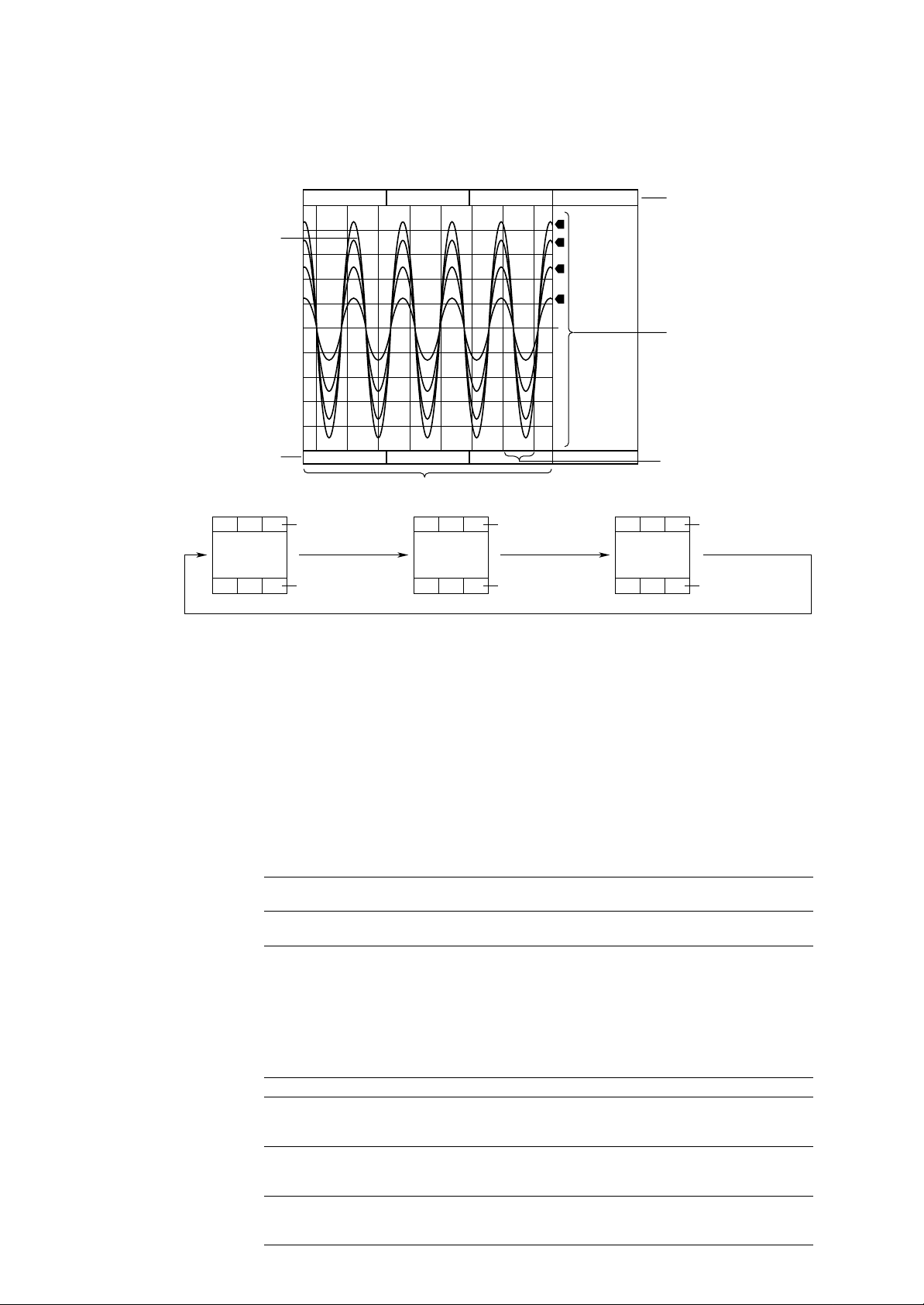

Trip level

Tag number

Discrete display Partial expansion Trip level and tag indications

14:03

MEM=26hour MEM=26hour

13:5913:57 14:01 14:5514:5114:49 14:53

VALVE1

°C

TANK1

Pa

VALVE2

klh

LINE1

V

100.00

200.00

200.00

6.000

0.00

-100.00

0.00

-6.000

144.41 1.332

14:2314:21 14:25 14:27

183.2083.30

97/02/05

14:29:01

2

1

3

4

1.1 Functional Overview

Referencing past trend data Magnifying/reducing the time axis Writing time-axis marks

02/06 13:44 MEM=26hour MEM=26hour

1. OVERVIEW OF VR200

13:4313:41

13:4513:4313:4113:39

Time-axis mark

Various Screen Settings

In addition to the standard screen where the trends of all channels are displayed on a

common scale axis, the following display settings are available.

Function Description

Discrete display Splits the display area into zones for individual channels for viewing the

Partial expansion Zooms in on a portion you want to view in detail.

Trip level indications Certain key levels can be drawn as horizontal lines (or vertical lines when

Tag indications Displays the tag numbers corresponding to channels.

Waveform display on/off Switches on/off the display of the waveform for each channel.

Scale indication on/off Switches on/off the indication of the scale for each channel.

trends discretely.

the waveform(s) moves vertically) on the graph.

LCD Display Preferences

The following display preferences can be set.

Preference Option

Display color The color of each waveform (trend) trace can be set to red, green, blue,

Background color The background color can be selected from among bright white, white, and

Direction of waveform display The direction of the waveform (trend graph) display can be switched

Line width The width of trace lines for waveforms and trip levels can be selected from

Number of divisions of scale The number of divisions of the scale can be selected from 4 to 12 divisions.

LCD brightness The brightness can be selected from fifteen levels.

LCD saver The backlight of the LCD automatically dims if no key is pressed for a

brown, red-purple, orange, light-blue and gray.

black.

between horizontal and vertical.

among 1, 2, or 3 pixels.

certain preset time (can be set from 1 to 60 minutes). This increases the life

of the backlight.

1 - 3

1.1.4 Data Storage Functions

Data Storage Action

For storing data, this recorder has 1 MB (for VR202/VR204) or 1.44 MB (for VR206)

of internal memory and is equipped with a 3.5-inch floppy disk drive (1.44 MB 2HD for

DOS). (Floppy disks formatted as 1.2 MB 2HD can be used only for the VR202/VR204

for users of an NEC 9800 series PC with Japanese-version OS (DOS/V).) The

measured data are always stored in the internal memory. Once the floppy disk is

inserted, the recorder starts copying the measured data from the internal memory to the

floppy disk automatically, together with the following data.

• Major setup parameters

• Information on time-axis marks, power failures, and alarms

Data Types

The table below shows the data types and contents which are saved on FDC.

Data Type

Measured data

Time-axis mark information

Power failure information

Alarm information

Setup parameter list

Parameter settings

Note: • The same file format as used in other recorders.

• The power failure information is not stored when sixteen event files and one data file are created. For details of the event and data files, see Section 6.6,

“Setting of Data storage Method (MEMORY).”

Display data

Event data

Storage Contents and Action File Format File (Extension) File Naming Method

• These are the data used to display the traces on the LCD.

• The data are stored up to the predefined memory length

and overwritten when the memory becomes full.

• Collected and stored at the specified sampling period.

• The data writing action differs depending on the trigger

setting. (For details, see Section 6.6.1.)

• Information at the points of time where the time-axis

marks are drawn (for the latest 32 marks) is saved.

• Information at the times of (the latest ten) power failures

is saved.

• Information on (the latest fifty) alarms is saved.

• These data are used to view the list of major parameters

to set up in the SET and SETUP modes.

• The file is automatically created when measured data

starts to be saved, and is saved together with the

measured data.

• These data are used to view the parameter settings made

in the SET and SETUP modes. (The user can set up the

recorder using these data.)

• The contents can be saved, read, or modified in the SET

or SETUP mode.

Standard

Note

format

Standard

Note

format

ASCII format

ASCII format

ASCII format

Display data file (.DAT)

Event file (.DAT)

Information file (.INF)

Parameter list file (.LST)

SET/SETUP

configuration files

(• Settings in the SET

mode: .PNL)

(• Settings in the SETUP

mode: .PNS)

Automatic setting

or user specified

Automatic setting

or user specified

The file name of

the measured data

is set automatically.

The file name of

the measured data

is set automatically.

User specified

1 - 4

For details of the SET and SETUP modes, see Section 1.3, “Run Mode.”

Collection of Event Data

The processing which occurs when collecting the event data is determined by

• File definitions (types and number of files defined);

• Sampling period; and

• Trigger action type (in the sample mode).

1.1 Functional Overview

The following table shows the selections available for these specifications.

Definition Description

File definitions The typ es and num ber of files to be created can be selected from the

following three combinations.

(a) Event file + display data file

One event file and display data file for each are created.

(b) Event file x 16 + display data file

This combination can be selected only when the sample mode is set to

trigger-on or trigger-rotation (see the second next row). Sixteen event

files, in which the measured data are to be stored after the trigger is

raised, are created together with one display data file.

(c) Event file only

Only one event file is created.

Sampling period The sample period at which to store the data can be selected from:

VR202/VR204: 125 ms, 250 ms, 500 ms, or 1 s

VR206: Fast, 2 s, 10 s , 30 s, 60 s, or 120 s

Sample mode The trigger action can be selected from the following three types. When

“trigger-on” or “trigger-rotation” is selected, various other trigger settings

can be made.

Trigger-free: Data collection starts after power-on. When the file in

the internal memory becomes full, the data are

overwritten.

Trigger-on: Data collection starts when a trigger is raised. When the

file in the internal memory becomes full, the data

collection stops.

Trigger-rotation: Data collection starts when a trigger is raised. After the

file in the internal memory becomes full, the data are

overwritten.

1. OVERVIEW OF VR200

Relation Between Measuring Period and Sampling Period

This recorder captures the input data into its A/D converter at the measuring period

shown below. The sampling period denotes the interval used to sample and store the

measured data in memory. If the sampling period is set to the same value as the

measuring period, all measured data values are stored in the memory.

Measuring period:

VR202/VR204:125 ms

VR206: 1 s (when the A/D integration frequency is set as 50 Hz, 60 Hz, or

“AUTO”)

2 s (when the A/D integration frequency is set as 100 ms)

Trigger

This recorder is usually used such that, upon power-on, it runs the self-diagnostics and

then automatically starts data collection into the memory. However, this recording

action can be set to be suspended upon power-on and started by a certain key. This key

is called the trigger. There are three types of triggers that can be set for this recorder.

Key trigger: Pressing the key starts data storage.

External trigger: When the contact input signal is closed, data storage starts.

Alarm trigger: When a specified alarm occurs, data storage starts.

The pre-trigger function, which means that data is always collected in the leading part

of the event file, is useful when data needs to be collected before the trigger occurs.

1 - 5

1.1.5 Alarm Function

Alarm Types

The following six alarm types can be set:

High limit (H), low limit (L), differential high limit (h), differential low limit (l), rateof-change on increase (R), and rate-of-change on decrease (r) alarms

Alarm Preferences

The following preferences can be specified for alarms.

Preference Description

Hysteresis Activates/inactivates the hysteresis of 0.5% of span.

Alarm output relay (option) Outputs the contact signal linking with an alarm status.

Re-annunciation of subsequent alarm (option) Us ing a sing le al arm r elay , re-a lert s the occurrence of a

Fail/memory end output (option) The relay contact output on the rear panel alerts the occurrence

1.1.6 Calculation Functions

The following calculations can be specified.

Function Description

Differential computation Calculates the difference between the measured values of two channels.

Linear scaling Used to convert an input value to fit a different unit system.

Square root Extracts the square root of an input value.

subsequent alarm (re-flashing) during occurrence of an alarm.

of a system error and when the memory is almost full.

1.1.7 Other Functions

Function Description

Communication functions (option) RS-422A interface added.

Remote control (option) This option allows the event trigger (start of event data collection), writing

of time-axis marks, and time adjustment functions to be controlled remotely

by contact input.

1 - 6

1.2 Component Names and Functions

1.2 Component Names and Functions

1.2.1 Front Panel

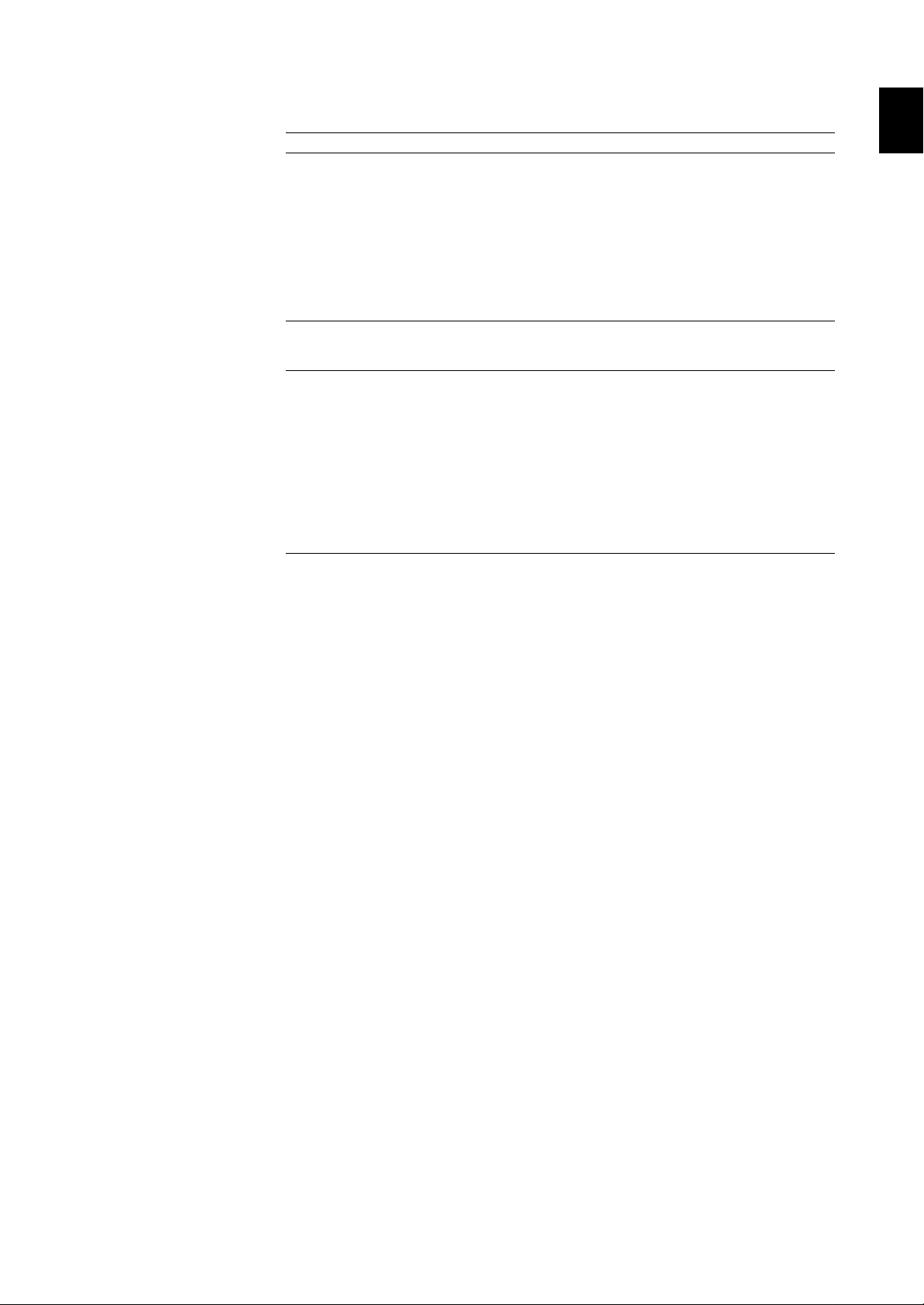

When the operation panel cover is closed

a

b

VIEW RECORDER VR200

c

a. LCD Panel

Displays the trend graphs and the digital readouts of the measured data.

b. Label

Specified by the user to identify the signal corresponding to each channel.

c. Operation Panel Cover

To access the power switch or panel keys or to insert or eject the floppy disk, pull the

cover open by placing a finger in the recess at the top of the cover. Always keep the

cover closed other than when performing these operations.

1. OVERVIEW OF VR200

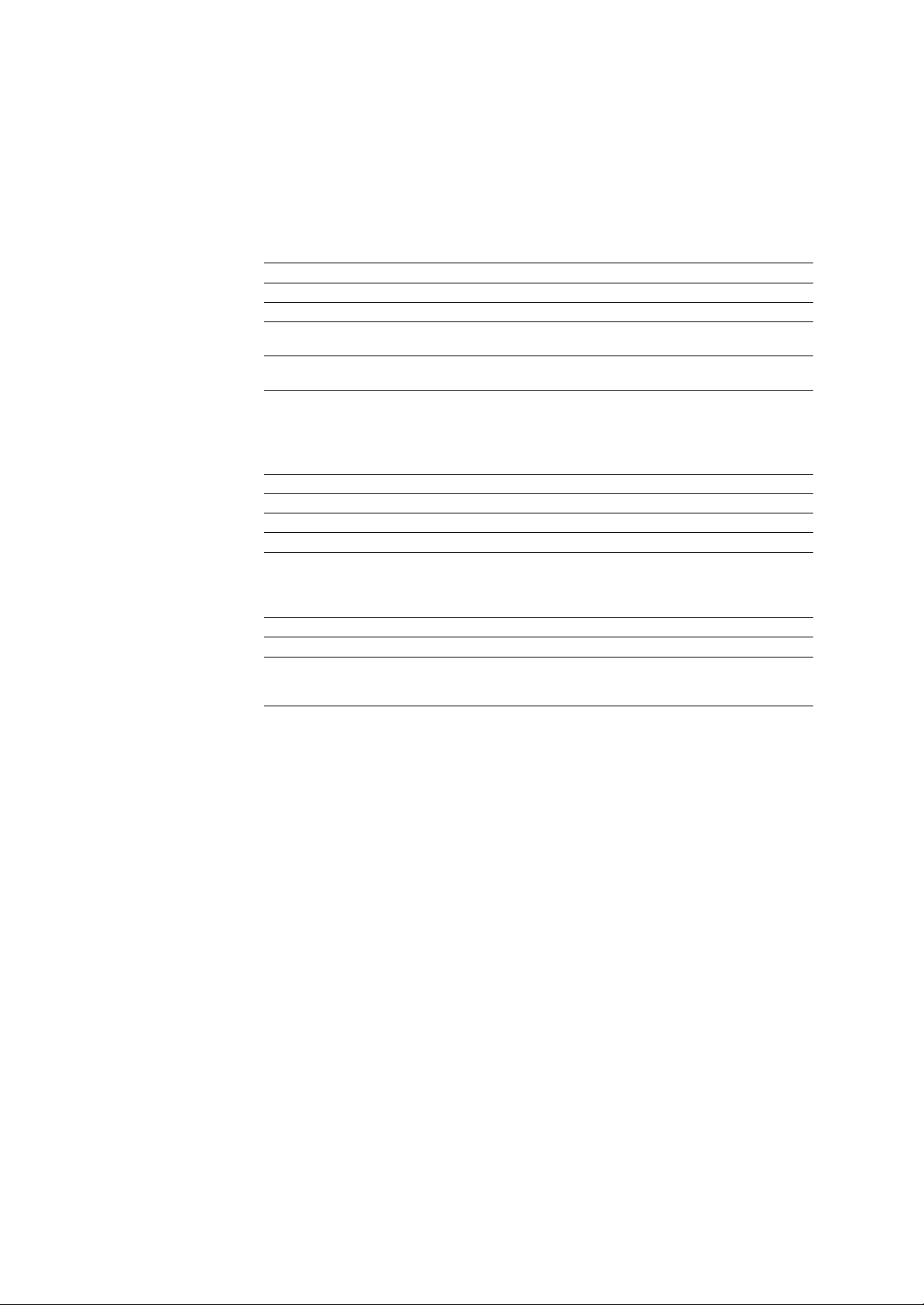

When the operation panel cover is opened

d

POWER

MENU

ESC ACK

e

DISP

g

f

h

d. Panel Keys

Used to switch the screen and mode, select the menu, and enter data and characters.

e. Power Switch

Used to turn the power on and off.

f. Access Lamp

Indicates that the floppy disk is being accessed.

g. Floppy Disk Drive

Used to save the measured data, setup parameters, etc. to a floppy disk.

h. Eject Button

Used to eject the floppy disk.

1 - 7

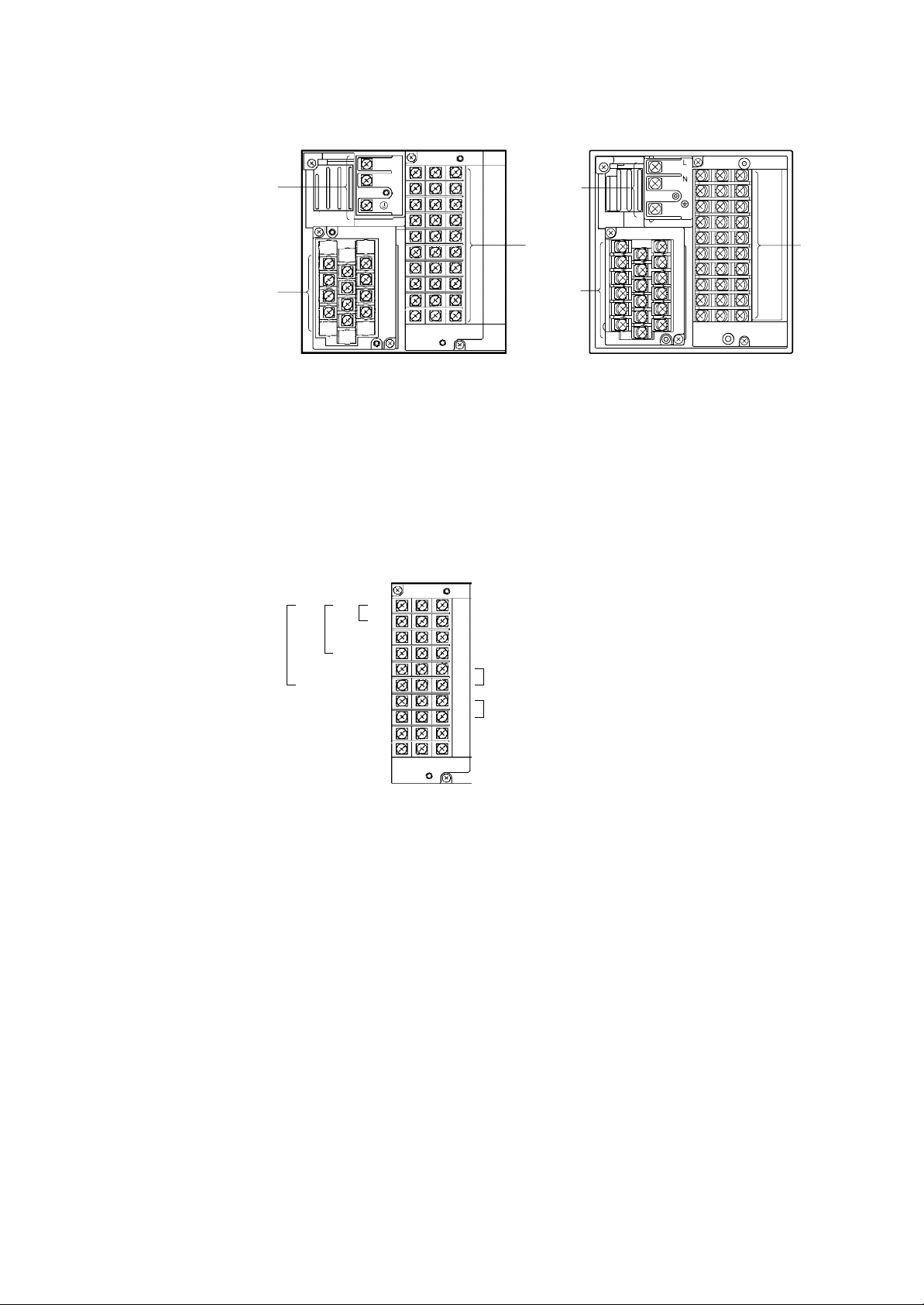

1.2.2 Rear Panel

VR204 VR206

L

i

/B

j

N

+/A

-/b

1

2

3

4

k

Terminal screw: ISO M4 screw, nominal length 6 mm

i. Power Terminals

Connect the power and protection grounding cables.

j. Input Terminals

Connect the input signal cables.

k. Option Terminals

Connect the input/output signals for optional functions.

i

+/A

/b

-/B

1

2

j

3

4

5

6

k

/A3

Alarms

/A2

/A1

1

2

3

4

5

6

7

8

9

10

Fail/memory end

Remote control signal

1 - 8

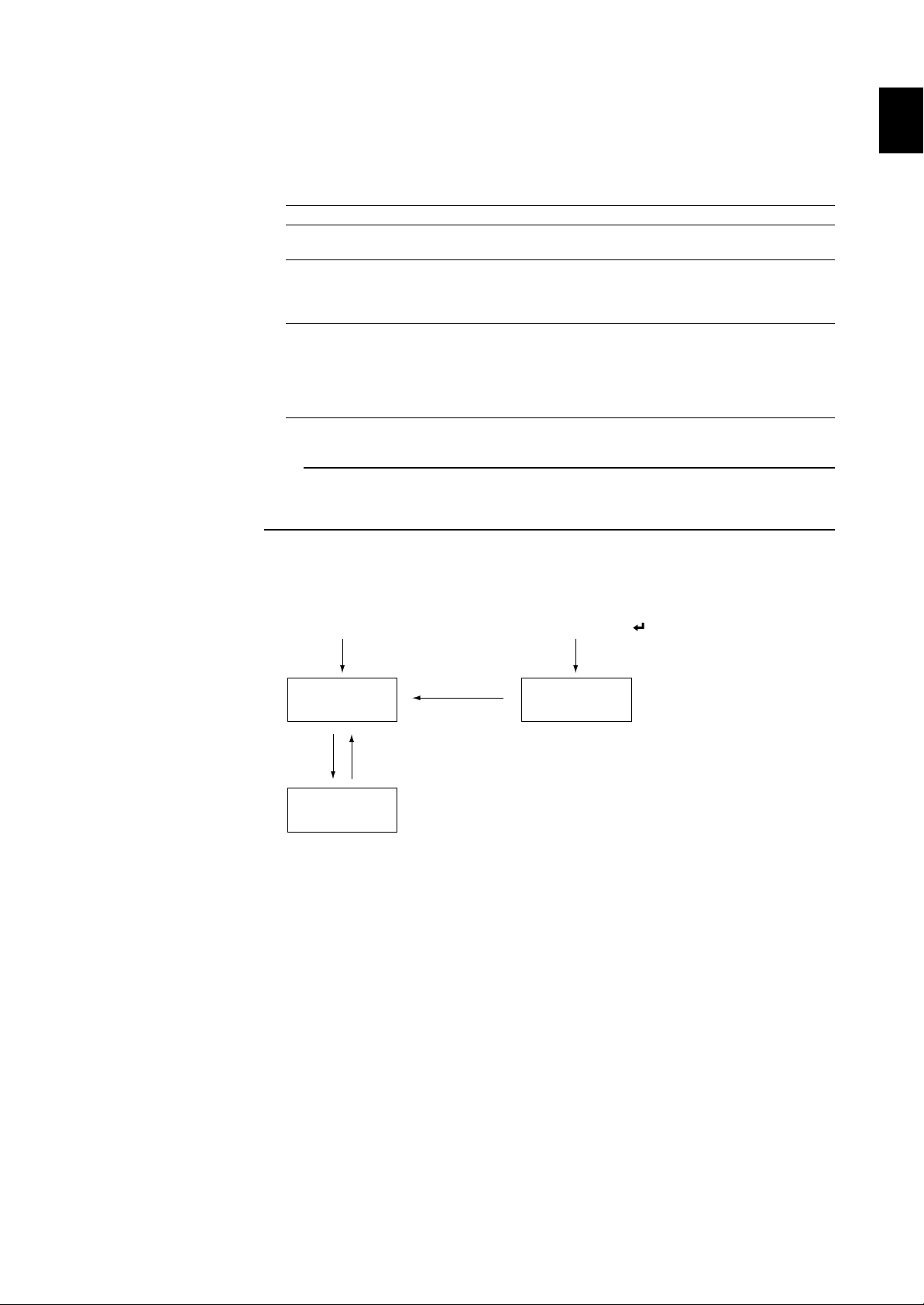

1.3 Run Mode

Power on Power on while pressing the [ ] key.

Operation Mode

Quit setup

SETUP Mode

SET Mode

Keep pressing the MENU key for three seconds.

1.3 Run Mode

1.3.1 Modes

There are three modes of operation of this recorder, and the available screens and valid

keys depend on the mode.

Mode Description Valid Operations

Operation mode Normal run mode. Selected • Monitoring and operation

SET mode Used to set parameters such as input ranges • Basic setting

SETUP mode Used to set the operation environment for the • Settings of operation environment

Note

• If a password is set, the password must be entered when entering the SET mode.

• Modifying the input range or waveform span rate clears the measured data stored in the internal memory, as does modifying a

setting in the SETUP mode.

• Measurement, waveform (trend graph) display, and alarm detection are not performed in the SETUP mode.

1.3.2 Mode Transition

The figure below shows the transitions between the operation, SET, and SETUP modes.

1. OVERVIEW OF VR200

automatically when the power is turned on. • Storing and saving the measured data

and waveform span rate. Pressing the MENU • Operations on floppy disk and files

key for three seconds in the operation mode • Measured data can be stored in memory,

switches the mode to SET. but not saved on a floppy disk.

recorder such as inputting method and data • Displaying, storing, or saving the

storage method. Turning on the power while measured data is not allowed.

pressing the [↵] key starts up the recorder in the

SETUP mode.

1 - 9

1.4 Display Format

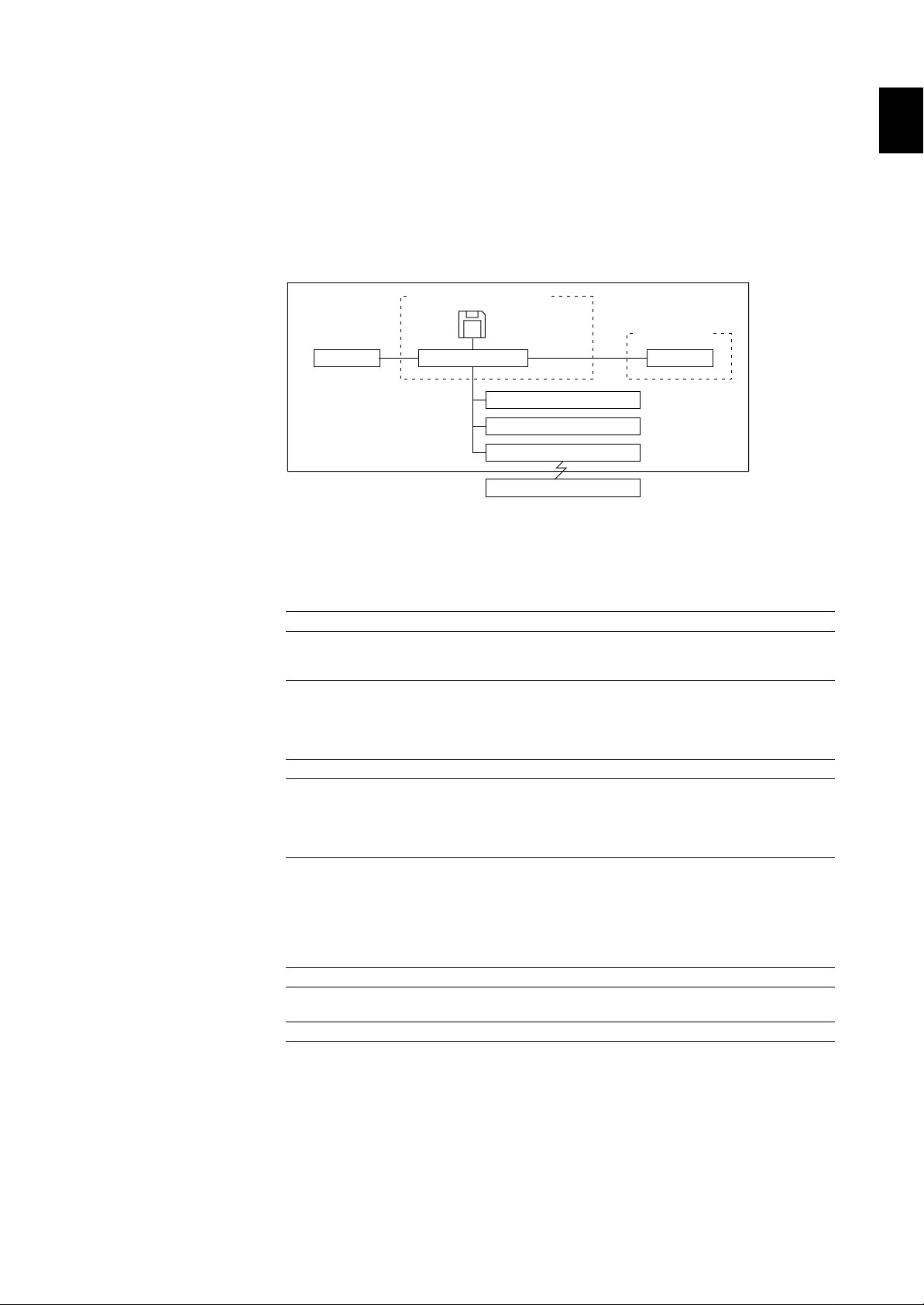

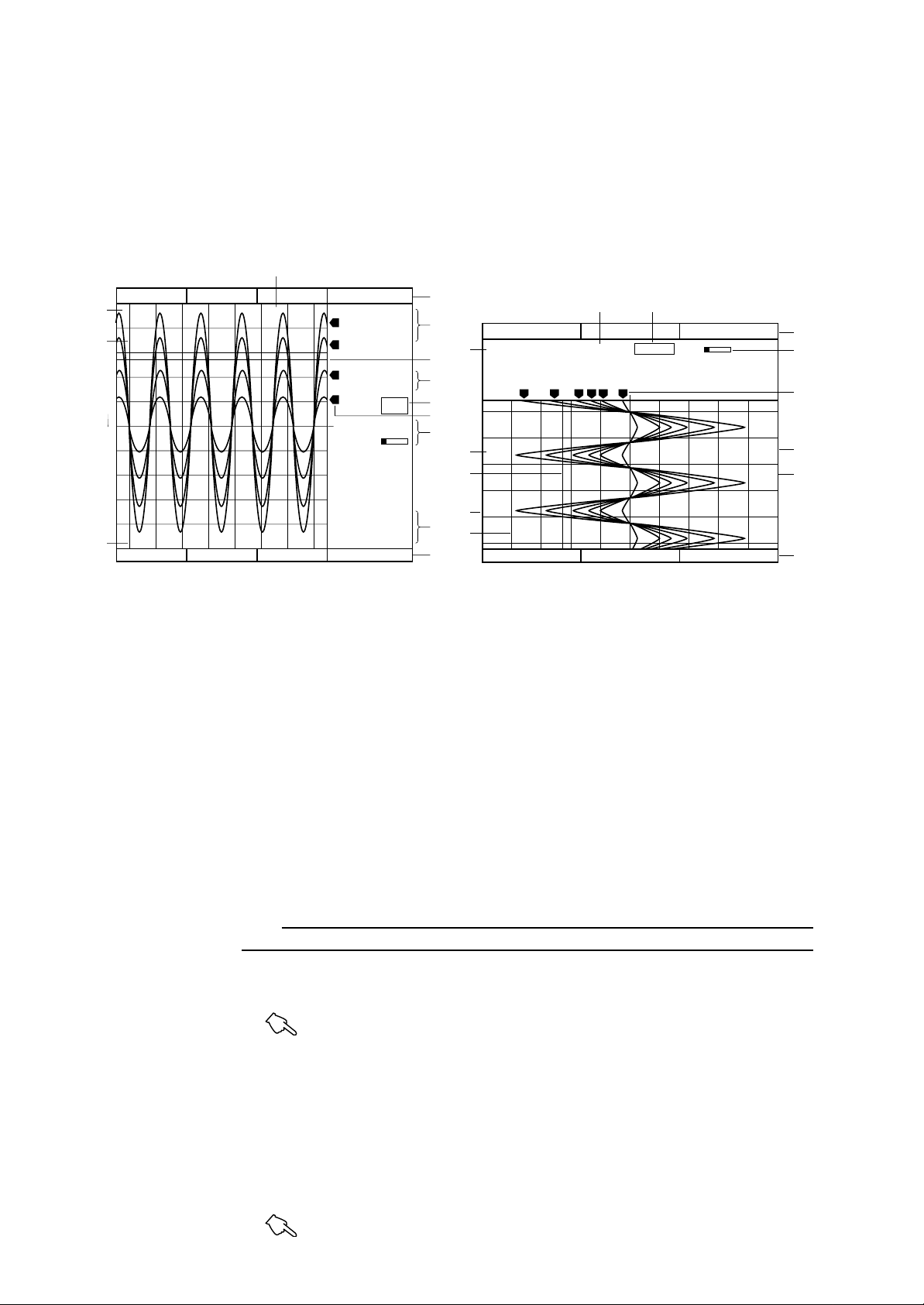

1.4.1 Waveform display

Waveform display

When four channels are used and the direction of

waveform display is horizontal

k

82.79 181.11 143.70 1.310

l

30 min/DIV

MEM=26hour

j

i

°C °C

13:2513:23 13:27 13:29

Pa kl/h V

H

2

1

3

4

100.00

200.00

200.00

6.000

97/02/05

13:30:40

ALM

Memory

1/16

0.00

-100.00

0.00

-6.000

a. Digital Indications

Displays the current measured value of each channel at the update period of 1 second

(or 2 seconds for the VR206 if the A/D integration frequency is set as 100 ms).

If 6 channels are defined to be used, the values for channels 1 to 3 or channels 4 to 6

are displayed. To switch over the channels to be displayed, press the MENU key.

When 3 or 4 channels are used:Only the digital values are displayed. The

When 1 or 2 channels are used:The digital values and engineering units are

When six channels are used and the direction of waveform

display is vertical

a

b

c

d

97/02/05 13:50:25 MEM=25hour

21.35H - 64.62 61.93

k

e

ALM

1/16

d

2 1 3 4 65

e

f

g

100.00

13:50

1ch

0.00

b

13:48

c

6ch

-20.00

13:46

i

b

j

h

kl/hPa

engineering units are displayed in h at the bottom.

displayed together. When the display of tag

numbers is set on, each column for the engineering

unit is split into two rows and the tag number and

unit are displayed in the upper and lower rows,

respectively. (See also Section 4.7.4.)

200.00

30 min/DIV

100.00

30 min/DIV

20.00

30 min/DIV

a

g

f

b

l

V

h

1 - 10

b. Scale Values

The upper and lower limits of recording scale for all channels are displayed. If

scaling computation is used, the values displayed are the scale values after scaling

computation.

Note

In the trend graph, all measured values are displayed in 0-100% ranges corresponding to the (vertical or horizontal) scales defined.

c. Trip Level

A horizontal line used to note a particular level

For details on how to draw this line, see Section 4.7.5, “Trip Level (TRIP) Setting.”

d. Time Indication

When 3, 4 or 6 channels are used, the current time is displayed here. When 1 or 2

channels are used, the current time is displayed in h at the bottom. The display

format is as follows:

Nov.10.95 15:20:00

e. Alarm (ALM) Indication

Displays the alarm when an alarm occurs. The behavior of the alarm indication

varies depending on the setting.

For details on the behavior of the alarm indication, see Section 3.3, “Resetting an Alarm

Output.”

1.4 Display Format

f. Current Value Pointers

Indicates the current values of all channels at the update period of 125 ms (VR202/

VR204), 1 s or 2 s (VR206).

g. Memory Status Indicator

Shows how much area of memory is occupied when the measured data are collected

into the event file by the key trigger.

h. Engineering Unit (or Time Indication)

When 3, 4 or 6 channels are used: The engineering unit for each current value

indication (a) is displayed. When the display of

tag numbers is set on, each column is split into

two rows and the tag number and unit are

displayed in the upper and lower rows,

respectively. (See also Section 4.7.4.)

If 6 channels are defined to be used, the measured

values for channels 4 to 6 may be displayed when

the MENU key is pressed.

When 1 or 2 channels are used:The current time is displayed in the format described

in d above.

i. Time-axis Values

The beginning time of the division is displayed for every other division in the format

hh:mm.

When the direction of waveform display

is horizontal

13:2513:23 13:27 13:29

1. OVERVIEW OF VR200

Displays the time of this point.

j. Grid

Grids are displayed at intervals corresponding to the specified number of divisions

for the scale axis and at the waveform span rate for the time axis. The grid moves

together with the trend graph.

Note

The grid lines of the time axis are usually displayed at every interval of the selected waveform span rate. However, if the power

is switched off and on during the measurement, the trends (waveforms) start to be traced again continuously from the point of time

of the power-off and this causes the interval of the grid lines to be different from the waveform span rate in this case.

k. Display of Remaining Time Before Overwriting Measured Data (or Re-

maining Time Until Memory Becomes Full If Sampling Mode Is Set As

Trigger-on)

If the sampling mode is not set as trigger-on:

This field displays the remaining time until the measured data start being overwritten

after saving data to an FDC. When the data are saved to an FDC, the displayed time

is reset. If the entire data storage memory is used for one event file, no information

is displayed while the recorder is waiting for the trigger. The remaining time is

displayed as ‘MEM=99hour,’ which then shows the time in minutes when the

remaining time is less than one hour. When the display shows ‘MEMORY FULL,’

the measured data is currently being overwritten.

If the sampling mode is set as trigger-on (and if the entire data storage memory is

used for one event file):

This field displays the remaining time until the memory becomes full; however, no

information is displayed while the recorder is waiting for the trigger. When the

memory becomes full, data sampling to the memory stops.

l. Waveform span rate

Displayed only during the horizontal display of the trend display. You can set

whether or not to display the waveform span rate in the SET mode.

When displaying the processing mode When displaying the message

0.00

-100.00

0.00

13:31:29 13:33 13:35 13

PUSH TO MARK MESSAGE1 DATA SAVING DONE

-6.000

13:33 13:35 13:37 13:39

mn

0.00

-100.00

0.00

-6.000

1 - 11

m.Processing Mode Display

Pressing the DISP key while the standard screen is displayed switches the processing

mode and displays the processing mode at the bottom of the screen.

n. Message Display

Displays operation messages, alarm messages, and error messages for the user

during operation.

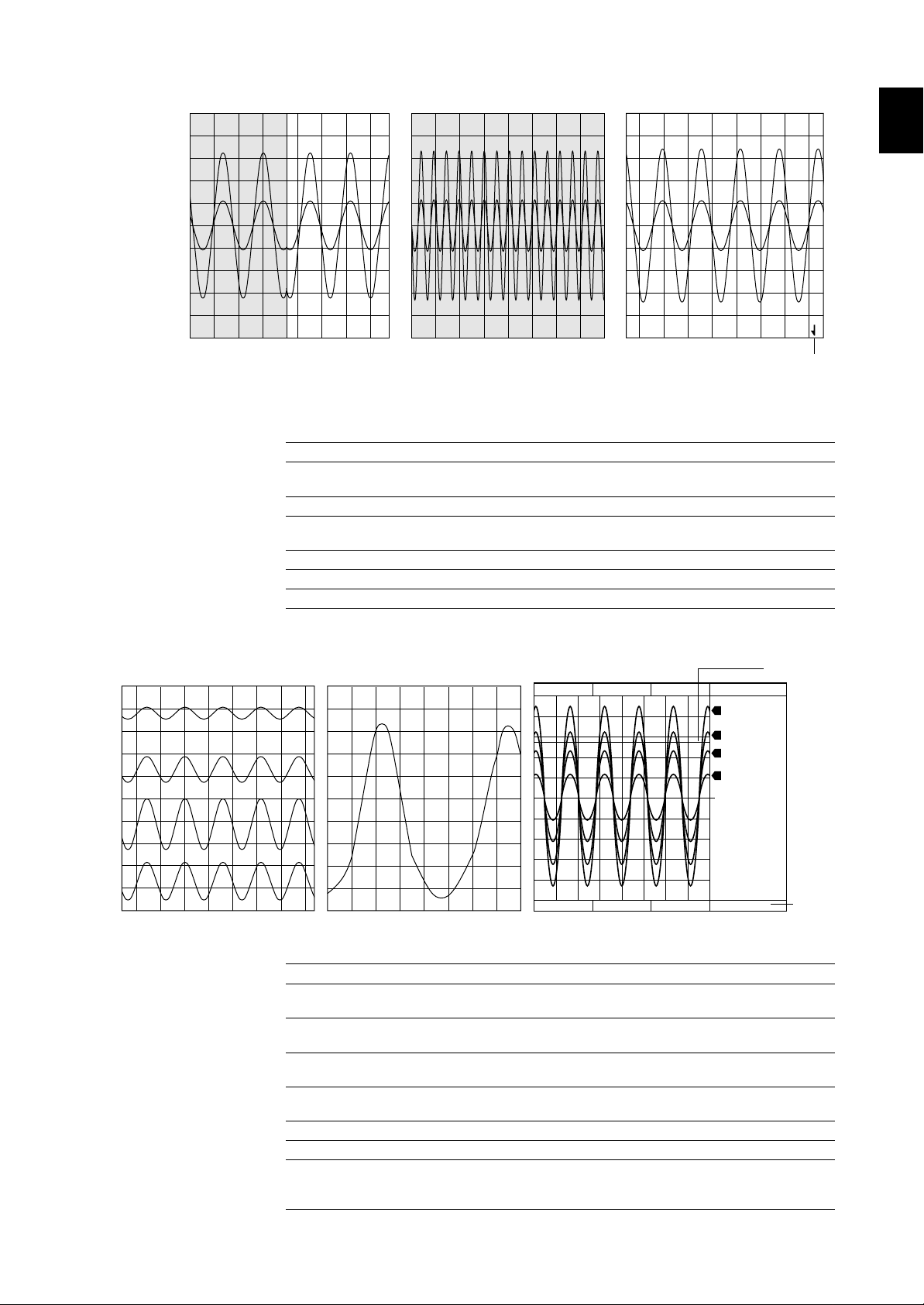

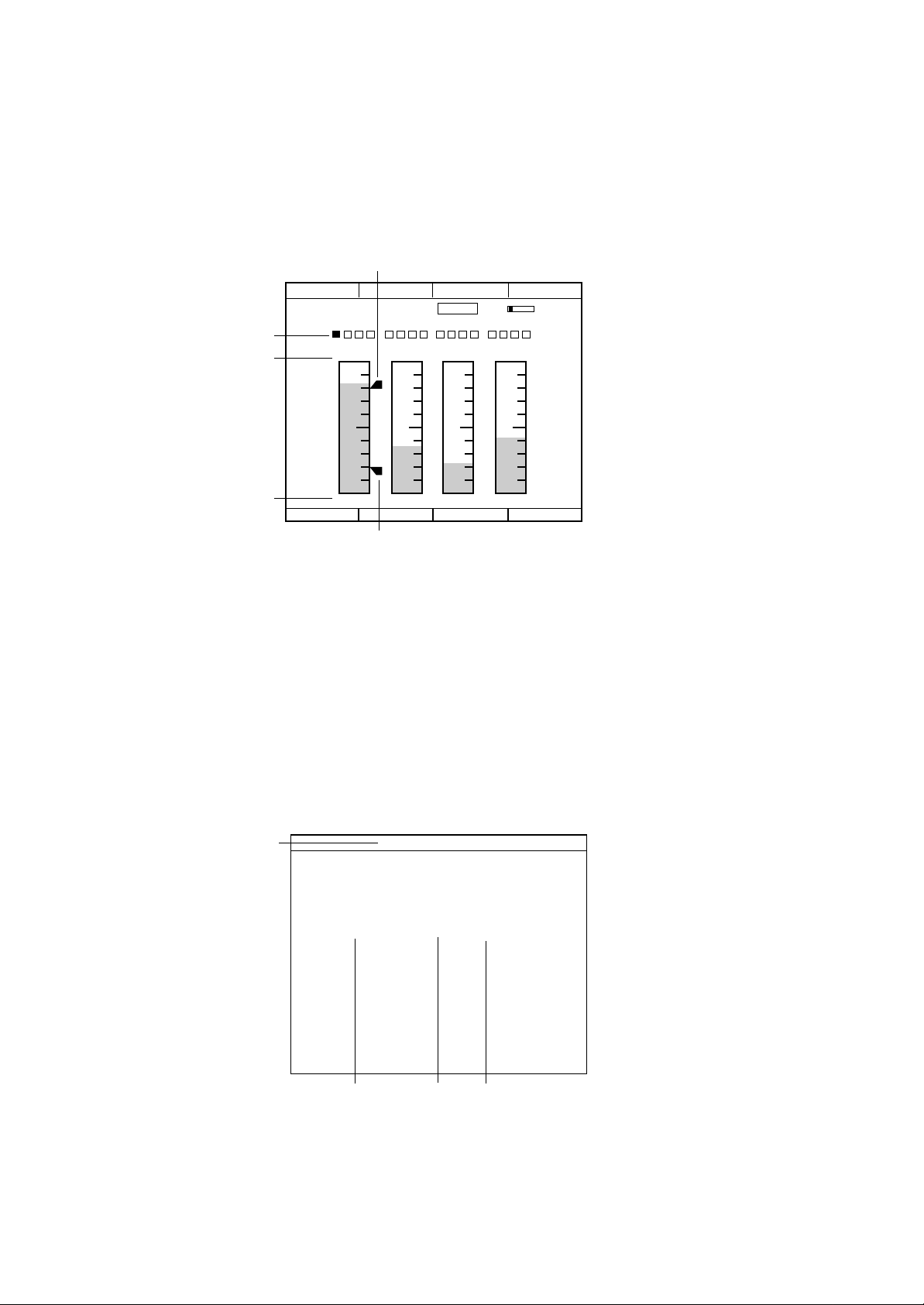

• Bar graph display

d

1.362H

98/06/05 13:50:25 1/16ALM

c

a

b

V

- 0.552

1ch 2ch 3ch 4ch

[ V ] [ V ] [ V ] [ V ]

2.000 2.000 2.000 2.000

-2.000 -2.000 -2.000 -2.000

V

e

- 1.256

V

- 0.268

V

a. Upper limit of scale

Displayed in green when the alarm is reset and red when it is occurring.

b. Lower limit of scale

Displayed in green when the alarm is reset and red when it is occurring.

c. Alarm condition display

Displays the alarm condition of each alarm level for each channel.

Unfilled rectangle: No alarm setting

Green rectangle: Alarm reset

Red rectangle: Alarm in progress

d. High limit alarm point

e. Low limit alarm point

• Digital value display

a

98/06/26 15:07:28

1 - 0. 5 4 2 V

2 1. 8 5 2 V

3 - 0. 8 9 5 V

4 0. 8 9 5 V

b

c

a. Date and time

b. Channel number

Displays channel numbers or tags.

d

1 - 12

c. Measured data

Displayed in red during an alarm.

d. Unit

• Information display

Displays the internal memory condition and the past alarm information.

1.4 Display Format

1. OVERVIEW OF VR200

- 0.552

INFORMATION

V

f

g

- 1.256

MESSAGE NUM

0/99

V

h

- 0.268

c

d

V

i

98/06/05 13:50:25

a

b

V

1.362H

DATA(E1+D) FD SAVE DATA QTY

DIAPLAY DATA : 0% (67/71400) 67

EVENT DATA : 12% (3685/30000) 3685

ALARM SUMMARY(1/1)

A20 CH1 1H 06/25 10:25:36 06/25 11:12:23

A19 CH3 3H 06/11 06:14:14 06/11 07:47:26

A18 CH1 2L 06/11 05:33:15 06/11 05:55:36

A17 CH4 1H 06/10 23:26:56 06/11 03:26:41

A16 CH1 1H 06/06 12:11:23 06/06 13:06:22

A15 CH2 2L 06/06 10:23:25 06/06 11:06:12

A14 CH1 1H 06/05 09:02:44 06/05 09:10:11

A13 CH2 1L 06/03 22:13:33 06/03 22:30:28

A12 CH2 1L 06/02 12:56:32 06/02 13:06:23

A11 CH1 2L 06/01 02:23:56 06/01 03:02:46

e

a. Memory condition of the display data file

After saving to the floppy disk, the number of newly measured data points, the

number of data points that can be saved, and the percentages are displayed.

b. Memory condition of the event file

After saving to the floppy disk, the number of newly measured data points, the

number of data points that can be saved, and the percentages are displayed.

c. Number of messages

Displays the number of messages that are currently written and the number of

messages that can be written.

d. The number of data points to save to the floppy disk.

e. Alarm number

Displayed in order from the oldest alarm occurrence.

f. Channel number

g. Alarm level and alarm type

h. Time of alarm occurrence

i. Time of alarm reset

• List display screen

Displays the setting parameters of the SET mode and SETUP mode. If a SET mode

setting is changed on the list display screen, the setting is immediately updated on

the list.

1 - 13

1.4.2 Screen in SET Mode

82.79 181.11 143.70 1.310

13:2513:23 13:27 13:29

SET= RANGE

Menu Display

Displays the menus available in the set mode. Warning and error messages for

parameter setting are also displayed here.

Note

All display contents other than the bottom field are the same as those in the operation mode.

1.4.3 Screen in the SETUP Mode

MEM26hour

100.00

2

1

3

4

200.00

200.00

6.000

97/02/05

13:30:40

0.00

-100.00

0.00

-6.000

1 - 14

SETUP= ALARM

Menu Display

Displays the menus available in the setup mode. Warning and error messages for

parameter setting are also displayed here.

Note

Except for the bottom field, nothing is displayed on the LCD.

1.5 How to Use the Panel Keys

SET=RANGE

Set value: The entry field is highlighted.

Menu

01:MODE=

Previously set value

1.5 How to Use the Panel Keys

1.5.1 Keys Used in Operation Mode

The following five keys are used in the operation mode.

Key Description in This Manual Function

MENU

ACK

DISP

MENU key Changes the mode to SET if this key is kept pressed for three

ACK key Used to acknowledge the alarm currently displayed (when the

[←] key On the normal operation screen, used to switch the standard

[→] key processing mode or operation message, used to select or

DISP key Each time this key is pressed while the standard screen is

1.5.2 Keys Used in SET and SETUP Modes

SET Menu and Entry Value

The user interface in the SET and SETUP modes is interactive: a menu appears on the

bottom of the screen and prompts entry of the necessary data. All data can be entered

using the panel keys. If the set value you entered needs another associated parameter to

be set, the screen automatically changes to prompt entry of that associated parameter.

The display usually consists of two parts:

1. OVERVIEW OF VR200

seconds.

If 6 channels are defined to be used, pressing this key changes

the channels for which the measured values are to be

displayed.

alarm is not recovered: changes from blinking to lit; when

already recovered: changes to off). Also resets the alarm

output relay (option). This key is valid only when the hold

type is selected for the alarm behavior (see Section 3.3).

screen to the past-data reference screen. While displaying the

execute the processing.

displayed, the processing mode switches in the sequence of

standard, writing of time-axis marks, zooming of time-axis,

activation of manual trigger (if the “key-trigger” is set), and

then back to standard.

In this manual, the shaded entry field as shown below denotes that the actual display

shows the value you set previously.

The display ‘*SET OK*’ or ‘*XXX SET*’ (XXX is the value you entered) appears

when all the necessary parameters have been entered successfully for a menu item and

means that settings for that menu item has been completed. The following five panel

keys are used for data entry and, in the SET and SETUP mode, the functions pictured on

the right of (not “on”) the individual keys are valid.

1 - 15

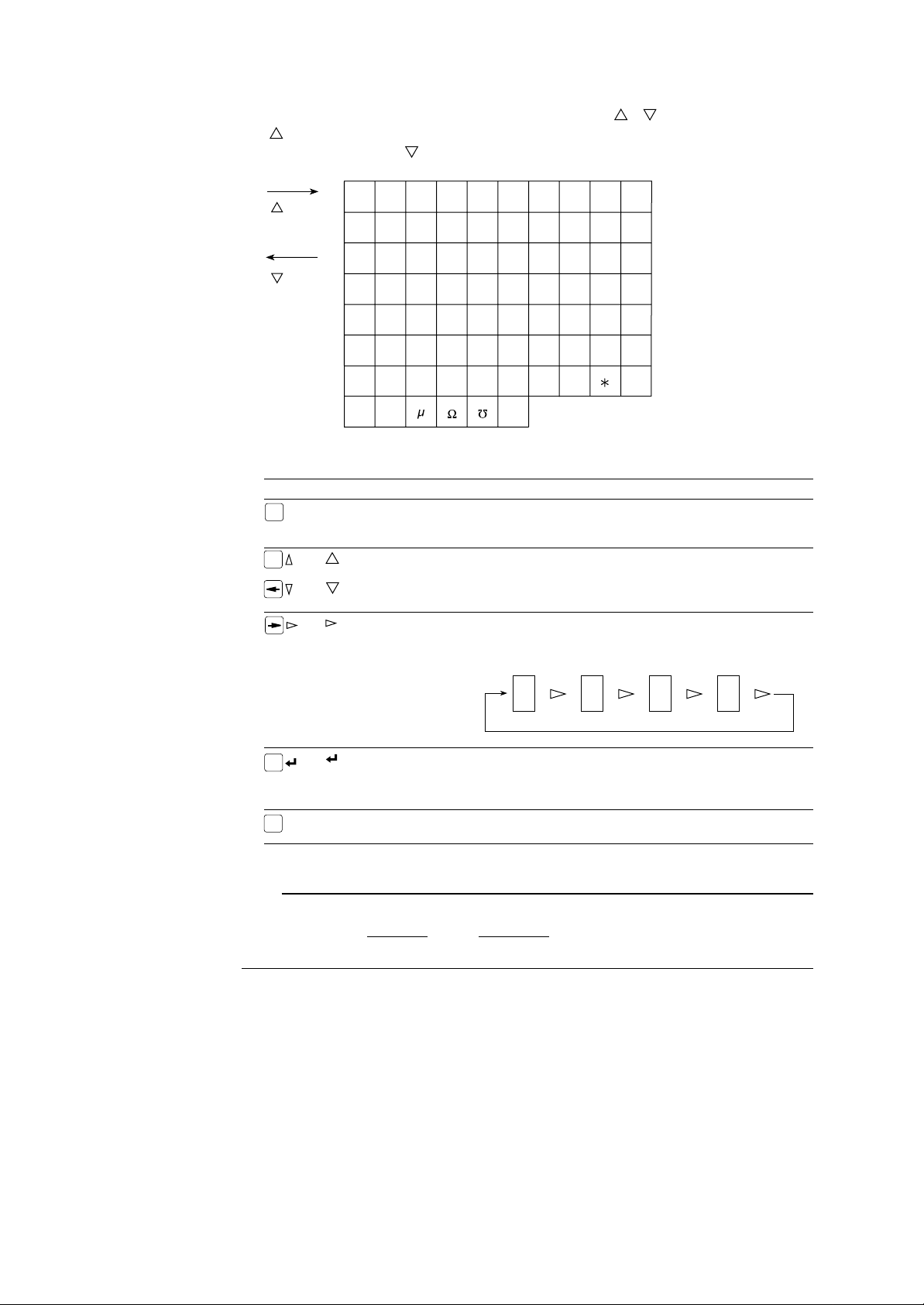

Entry of Alphanumeric Characters

To enter alphanumeric characters, use the UP/DOWN ([ ]/[ ]) keys. Pressing the

[ ] key calls up the alphanumeric characters on the entry field in the sequence as

shown below and the [ ] key reverses the sequence.

[ ]key

ABCDEFGHI J

KLMNOPQRST

UVWXYZa b c d

[ ]key

ef ghi j

opqr st uvwx

yz01234567

89#%()

. °

Panel Keys Used

Key Description in This Manual Functions

MENU

ACK

ESC key Used to abandon the setting before the ‘*SET OK*’ (or ‘*XXX

ESC

SET*’) display appears. The display will return to the primary

level in the menu, ‘SET=xxx’ or ‘SETUP=xxx.’

[ ] key Used to move through multiple selections. In the case of setting

messages or units for example, these keys are used to select an

[ ] key alphanumeric character in a digit where the entry cursor is located.

UP calls the next choice, DOWN calls the previous choice.

[ ] key Used to move the entry cursor to the next digit while entering a

value. Since there is no backspace key provided, this key will move

to the first digit after the last digit.

kl mn

+- /

DISP

[ ] key Used to confirm your highlighted entry. After pressing this key,

you will be prompted to enter the next parameters. If there are two

values to be set on one display, pressing this key to confirm the first

set value then highlights and enables entry of the other parameter.

MENU

MENU key To change the mode back to the operation mode, keep pressing this

key for three seconds.

Note

When entering a numeric value, be sure to enter all digits including the decimal point. The entered number is placed at the last

digit.

Bad entry: 2. 0.02 (For a fixed decimal point)

Good entry: 2.00 2.00 (For a fixed decimal point)

Value entered Value identified

1 - 16

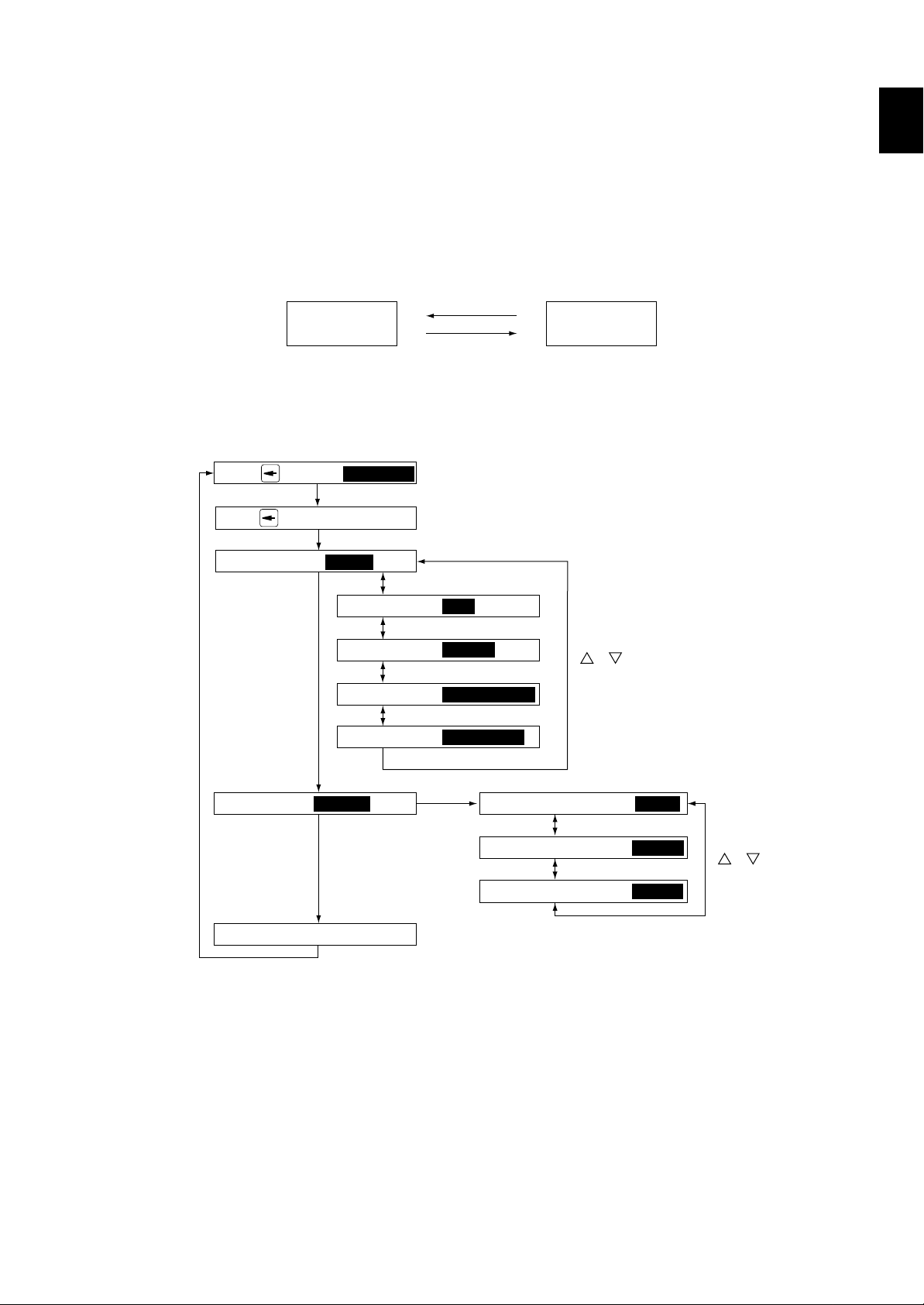

1.6 Flow of Operation and Setting

1.6 Flow of Operation and Setting

1.6.1 Operation Mode

In the operation mode, the switching between the standard screen and past-data

reference screen differs from the other operations. The following shows the flows of

these two types of operation.

Screen Switching

Standard screen

Other Operations

PUSH TO MARK MESSAGE1

PUSH TO TRIGGER

DISPLAY MODE: TREND

[←] / [→] key

reference screen

[DISP] key

(or after a specified time has elapsed)

*1

(Section 3.5, “Writing the Message”)

*2

(Section 3.7, “To Start Storing the Measured Data by Manual Trigger”)

Past-data

Display mode switching

(Section 3.4, “Referencing

the Past Measured Data”)

1. OVERVIEW OF VR200

DISPLAY MODE: BAR

DISPLAY MODE: DIGITAL

[DISP]

key

DISP WINDOW: NORMAL/5.5min DISP WINDOW: NORMAL/5.5 min

Standard screen

*1: Displayed only when the message menu display (MESSAGE PANEL) is set to ON in the SET mode.

*2: Displayed only when the “key trigger” is set.

*3: Displayed only when the display mode is set to trend.

The example above shows the display sequence of the display span time called up when the direction of the waveform display is

set as vertical. If it is set as horizontal, the display sequence is 8, 24, and then 40 minutes.

Fixed to “5.5 minutes” (8 minutes) if the VR200 has the computation function.

DISPLAY MODE: INFORMATION

DISPLAY MODE: PARAMETER

*3 *3

[→]key

DISP WINDOW: NORMAL/16.5 min

DISP WINDOW: NORMAL/27.5 min

[ ]/[ ] key

(Section 3.6,

“Zooming/Reducing

the Time Axis”)

*3

[ ]/[ ] key

*3

If the VR200 has the computation function, “MATH START”/“MATH STOP”/“MATH

CLEAR” is displayed after the manual trigger.

1 - 17

Loading...

Loading...