Page 1

User ’s Guide

http://www.omega.com

e-mail: info@omega.com

V R 2 0 0

A P P L I C A TION SOFTW A R E

Data Viewer Instruction Manual

Page 2

OMEGAne t®On-Line Service Internet e-mail

h t t p : / / w w w.omega.com i n f o @ o m e g a . c o m

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (001) 800-826-6342 FAX: (001) 203-359-7807

En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

SM

SM

SM

Servicing Europe:

Benelux: Postbus 8034, 1180 LAAmstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311 8 9 9 FAX: 420 (69) 631111 4

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Cert i f i e d Northbank, Irlam, Manchester

M44 5EX, United Kingdom

Tel: +44 (0) 161 777-6611 FAX: +44 (0) 161 777-6622

Toll Free in United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

a p p l y. OMEGA is constantly pursuing certification of its products to the European New Appro a c h

D i rectives. OMEGA will add the CE mark to every appropriate device upon cert i f i c a t i o n .

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

Forward

Notes

Trademarks

Thank you for purchasing the VR200-SW Data Viewer for Windows95.

This manual describes the precautions, functions, the operating procedures in using this software

on Windows95. Please read this manual thoroughly beforehand to ensure proper use.

Afterwards, keep the manual in a safe place for quick reference whenever a question arises.

For information regarding the precautions, functions, and operating procedures of the View

Recorder VR100/VR200 and the operating procedures of Windows95, refer to the corresponding

manuals.

• The contents of this manual are subject to change without prior notice as a result of

improvements in the software’s performance and functions. Display contents illustrated in this

manual may differ slightly from what actually appear on your screen.

• Every effort has been made in the preparation of this manual to ensure the accuracy of its

contents. However, should you have any questions of find any errors, please contact OMEGA.

• The copy or reproduction of all or any part of the contents of this manual without OMEGA’s

permission is strictly prohibited.

• It is forbidden to use this software on two or more computers simultaneously. It is also

forbidden for two or more users to use this software.

• It is forbidden to lease or rent this software to a third person.

• OMEGA will not guarantee the condition of the software, except for physical damage to the

original disk, once the software packaging is removed.

• OMEGA will not be responsible for any damage caused directly or indirectly as a result of this

software.

• MS, MS-DOS is a registered trademark of Microsoft Corporation.

• Windows is a trademark of Microsoft Corporation.

• Lotus 1-2-3 is a registered trademark of Lotus-Development Corporation.

• Other product names are trademarks or registered trademarks of their corresponding companies.

All Rights Reserved, Copyright © 1998

1

Page 4

2

Page 5

Contents

Index

1

2

3

4

Forward.................................................................................................................................................. 1

Product Overview .................................................................................................................................4

VR200-SW Data Viewer Software ................................................................................................................ 4

Files Created by VR100 or VR200 ................................................................................................................ 4

System Requirements Necessary for Operation ............................................................................................ 4

Before Setup .......................................................................................................................................................................... 5

Setting up the Software .................................................................................................................................................... 6

Chapter 1 Displaying the Measured Data

1.1 Starting and Exiting the Software .........................................................................................................1-1

1.2 Opening a File.......................................................................................................................................1-2

1.3 Changing the Waveform Display Settings............................................................................................1-5

Setting the Details of the Waveform Display ....................................................................................1-5

Selecting the Waveform Display Zone Type ..................................................................................... 1-8

Setting Display Limits on the Displayed Waveform ....................................................................... 1-10

1.4 Changing the Time Axis Scale of the Waveform Display .................................................................1-11

1.5 Reading the Measured Value with the Cursor ....................................................................................1-13

Reading the Measured Value with the Cursor .................................................................................1-13

Appending User-defined Marks/Deleting Marks/Resetting Marks .................................................1-15

Copying Measured Data to the Clipboard........................................................................................1-17

1.6 Displaying Digital Values...................................................................................................................1-18

Displaying Digital Values ................................................................................................................ 1-18

Reading the Measured Value with the Cursor while Displaying Digital Values.............................1-19

Copying Measured Data to the Clipboard while Displaying Digital Values ................................... 1-20

1.7 Saving the Display Settings ................................................................................................................1-21

1.8 Opening TLOG Interval Timeout Data File .......................................................................................1-22

1.9 Displaying Information on TLOG Interval Timeout Data File ..........................................................1-24

Chapter 2 Converting the Displayed Data

2.1 Converting the Data Format..................................................................................................................2-1

2.2 File Format of the Converted Data .......................................................................................................2-3

Chapter 3 Printing the Measured Data with an External Printer

3.1 Setting up the Printer ............................................................................................................................3-1

3.2 Print Previewing....................................................................................................................................3-2

3.3 Printing the Displayed Waveform or Digital Values ............................................................................ 3-3

Chapter 4 Error Messages

4.1 Troubleshooting ....................................................................................................................................4-1

4.2 Error Messages and Corrective Actions ...............................................................................................4-2

Index

3

Page 6

Product Overview

VR200-SW Data Viewer Software

This VR200-SW Data Viewer Software consists of the following software.

• Beagle for VR

This software enables you to display, convert, and print the data saved to the floppy disk by

VR100 or VR200, on the PC. It is capable of displaying waveforms and digital values, making

cursor measurements, converting the measurement data to ASCII/Lotus/Excel formats, and

printing the measured data.

Files Created by VR100 or VR200

• Event File (xxx.dat)

File containing the event data sampled at the specified sampling interval.

The event data can be displayed, converted to a different data format, or printed using this

software.

• Display data file (xxx.dat)

File containing the data used to display the waveform on the LCD screen of the VR100 or

VR200.

The display data can be displayed, converted to a different data format, or printed using this

software.

• Information file (xxx.inf)

File containing event, power failure, and alarm information in ASCII format.

This file is opened for obtaining event, power failure, and alarm information with this software.

• Setting list file (xxx.lst)

File containing a list of settings in ASCII format. Not used by this software.

• Setting file (xxx.pnl, xxx.pns)

File containing setting values for the VR100 or VR200 in ASCII format. Not used by this

software.

System Requirements Necessary for Operation

• Personal computer

Personal computer on which Windows95 can run.

CPU: 80486DX4 or higher (Pentium 120 Mhz or higher recommended)

Memory: 16 MB of more (24 MB or more recommended)

•OS

Windows 95

• Floppy disk drive

3.5 inch 1.44 MB (MS-DOS compatible). Floppy disk also used in setting up this software.

• Hard disk

15 MB of free disk space or more

• Display

Display supported by Windows95 with analog RGB and 32000 colors or more (65536 colors or

more recommended).

• Printer

Printer supported by Windows95

• Mouse

Mouse supported by Windows95

4

Page 7

Before Setup

• Backing up the System Floppy Disk

• Procedure on Backing up the System Floppy Disk

Please make a back up floppy disk (2HD 1.44 MB) of the original system floppy disk which

you have purchased. From this point, use the backup floppy disk for setup and for other tasks.

Also, when setting up the software, set the floppy disk’s write protect switch to allow writing.

From the MS-DOS prompt in Windows or in DOS, type the command, “diskcopy a: a:” (when

the floppy disk drive is “a”) and execute the backup. Then, follow the instructions on the

screen.

5

Page 8

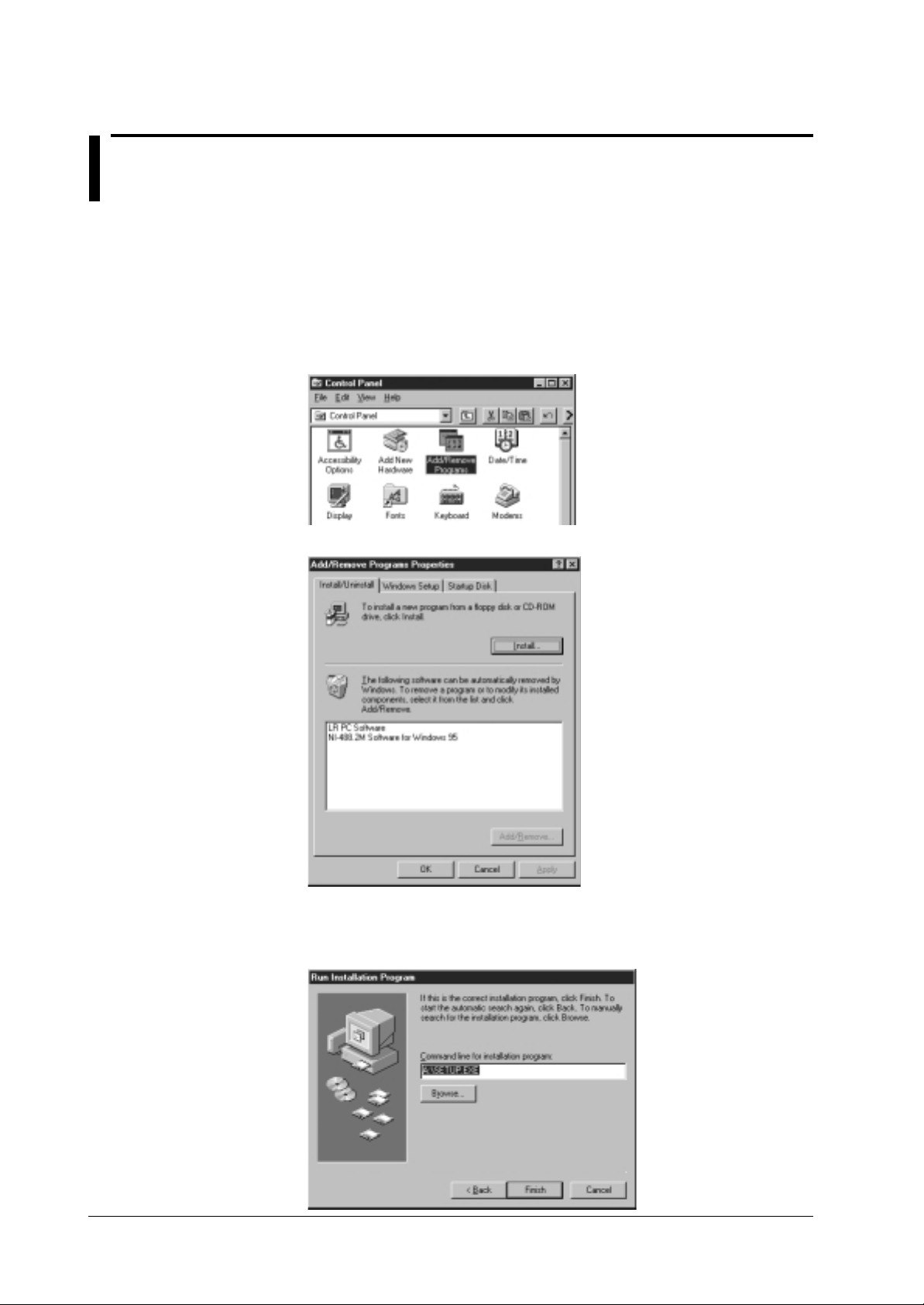

Setting up the Software

Operation

To setup the VR200-SW Data Viewer Software (Beagle for VR), start the setup program by

following the steps below.

1. Turn the computer on and start Windows95.

2. Click the “Start” button and point to “Settings.” Open the “Control Panel” and double click

“Add or Remove Programs.”

3. Click “Install” on “Install/Uninstall.” The installer starts.

4. Set the system floppy disk (backup copy) in the floppy disk drive and click “Next.”

5. Check that the “Command line for installation program” textbox is set to “a:\setup.exe” and

click “Finish.”

6

Page 9

Setting up the Software

6. Follow the setup program instructions. Click “Next.”

7. The setup program asks where to install the software. If you wish to change the destination,

click “Browse...” and enter a new location. After setting the destination, click “Next.”

7

Page 10

Setting up the Software

Explanation

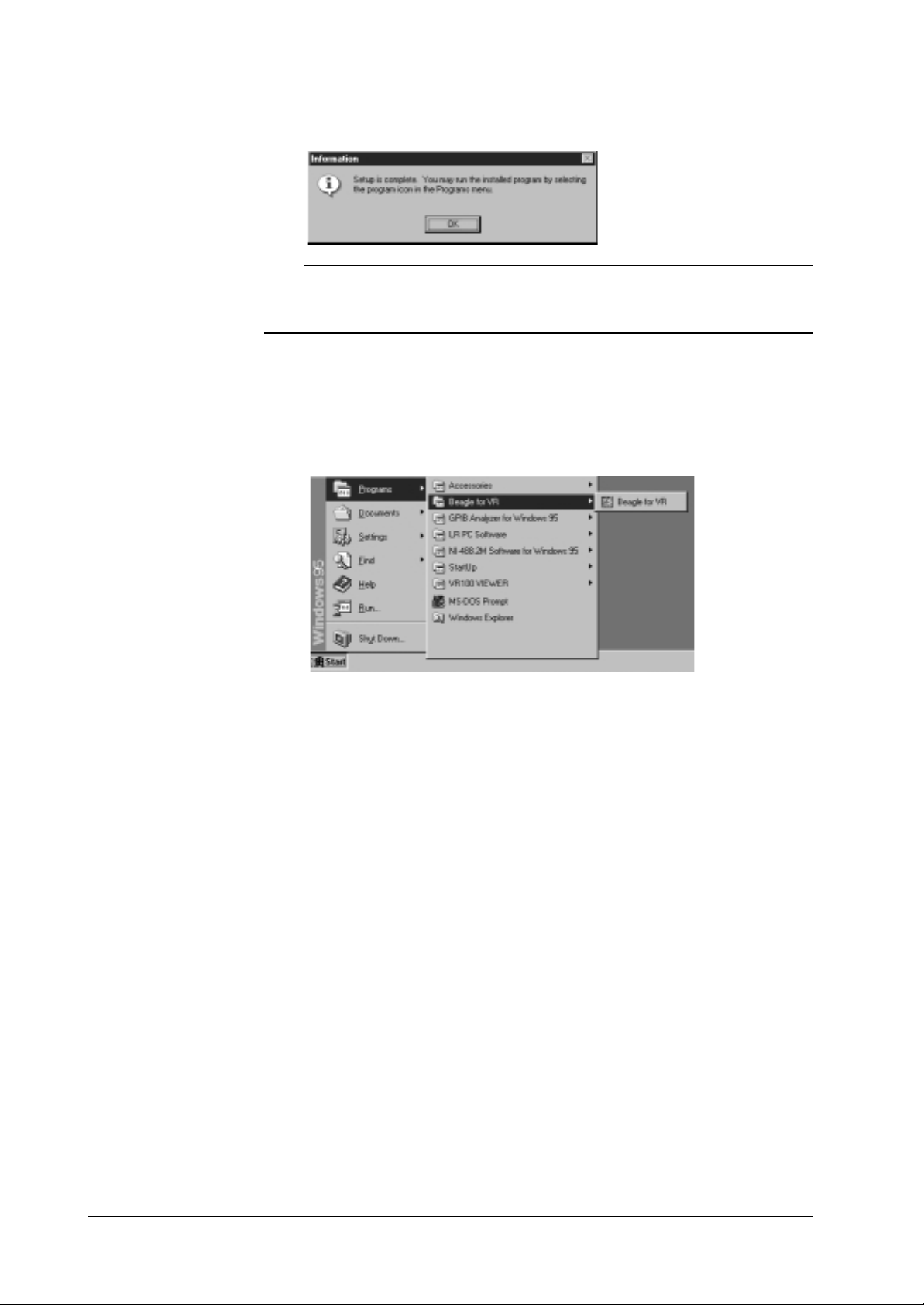

8. If the installation completes correctly, the following message is displayed. Click “OK.”

Note

The following folders are created when this software is setup correctly.

• Destination folder\Program: Contains the VR200-SW Data Viewer software

• Destination folder\Sample: Contains sample data files.

Creating the “Beagle for VR” folder

When this software is setup correctly, “Beagle for VR” folder is created automatically. This

“Beagle for VR” folder is automatically registered in the “Program” menu of the “Start” menu as

shown below.

8

Page 11

1

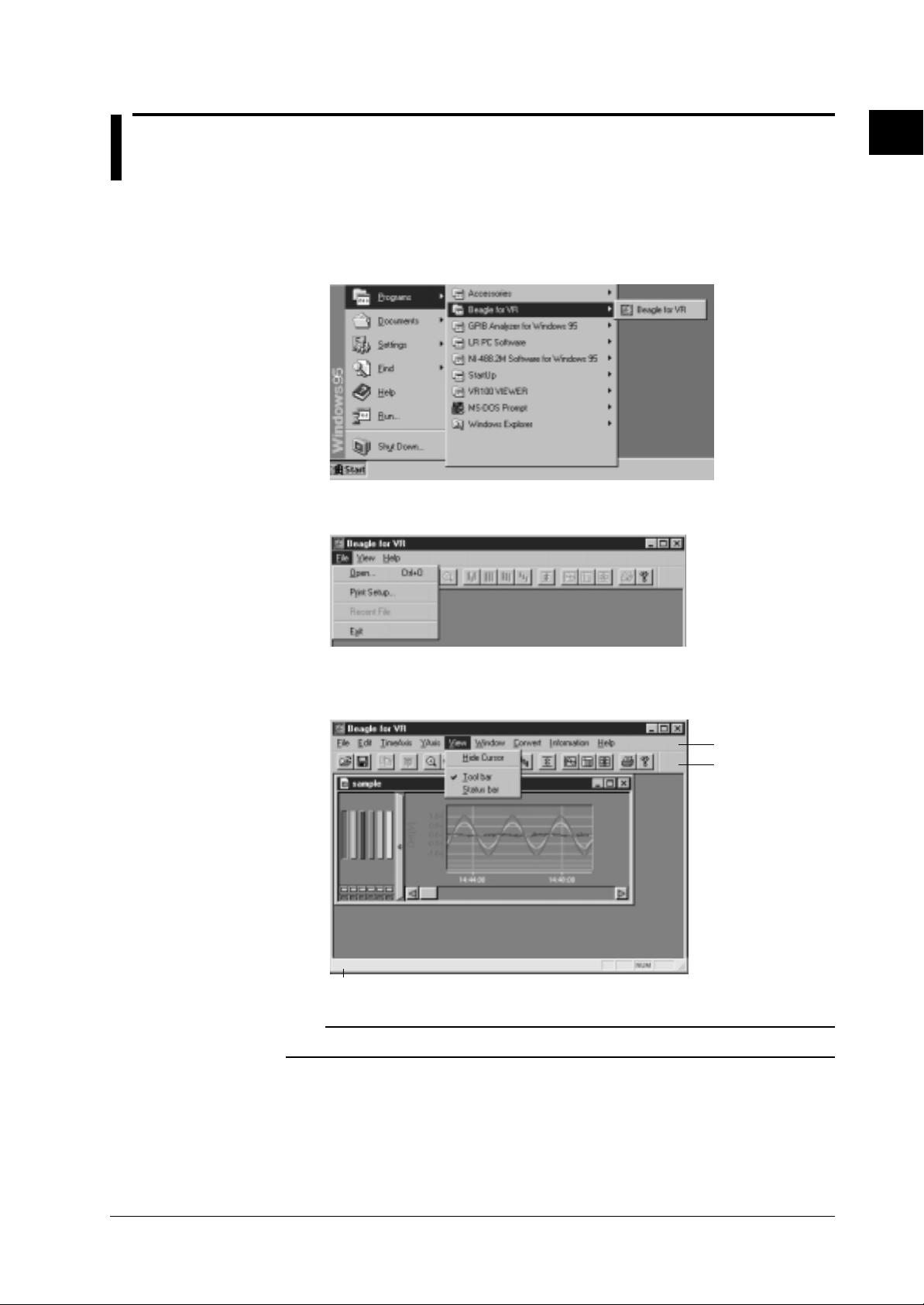

1.1 Starting and Exiting the Software

Status bar

Menu bar

Tool bar

Operation

• Starting the software

Click the “Start” button, and point to “Programs.” Next, point to the “Beagle for VR” folder,

then click “Beagle for VR” to start the software.

• Exiting the software

Select either “File”- “Exit” from the menu bar or “Close” on the window.

Displaying the Measured Data

• Displaying the tool bar/status bar

To display the tool bar, select “View” then “Tool bar” from the menu bar.

To display the status bar, select “View” then “Status bar” from the menu bar.

Note

The tool bar and status bar are displayed upon starting the software.

1-1

Page 12

1.2 Opening a File

• Opening a File

After starting the software, the measured data can be read in and the waveform can be

displayed by following the steps below.

Operation

1. Select “File” then “Open” from the menu bar, or click the file open icon on the tool bar.

File open icon

2. Select the file to display from the “File name” list box.

Select a file with “.dat.” extension. Select the appropriate folder (location of the file) and the

file type as necessary.

Up One Level

Create New Folder

List

Details

3. Click “Open” and the waveform is displayed.

Note

• The number of files that can be opened simultaneously depends on the memory size and free disk space

on the PC.

• When saving files on the VR100 or VR200, if the data file name is set to auto-setting or auto-increment,

event files become “Exxx.dat” and display data files become “Dxxx.dat.”

• It is convenient to copy the data file from the floppy disk to the hard disk for use.

1-2

Page 13

1

Operation

Explanation

1.2 Opening a File

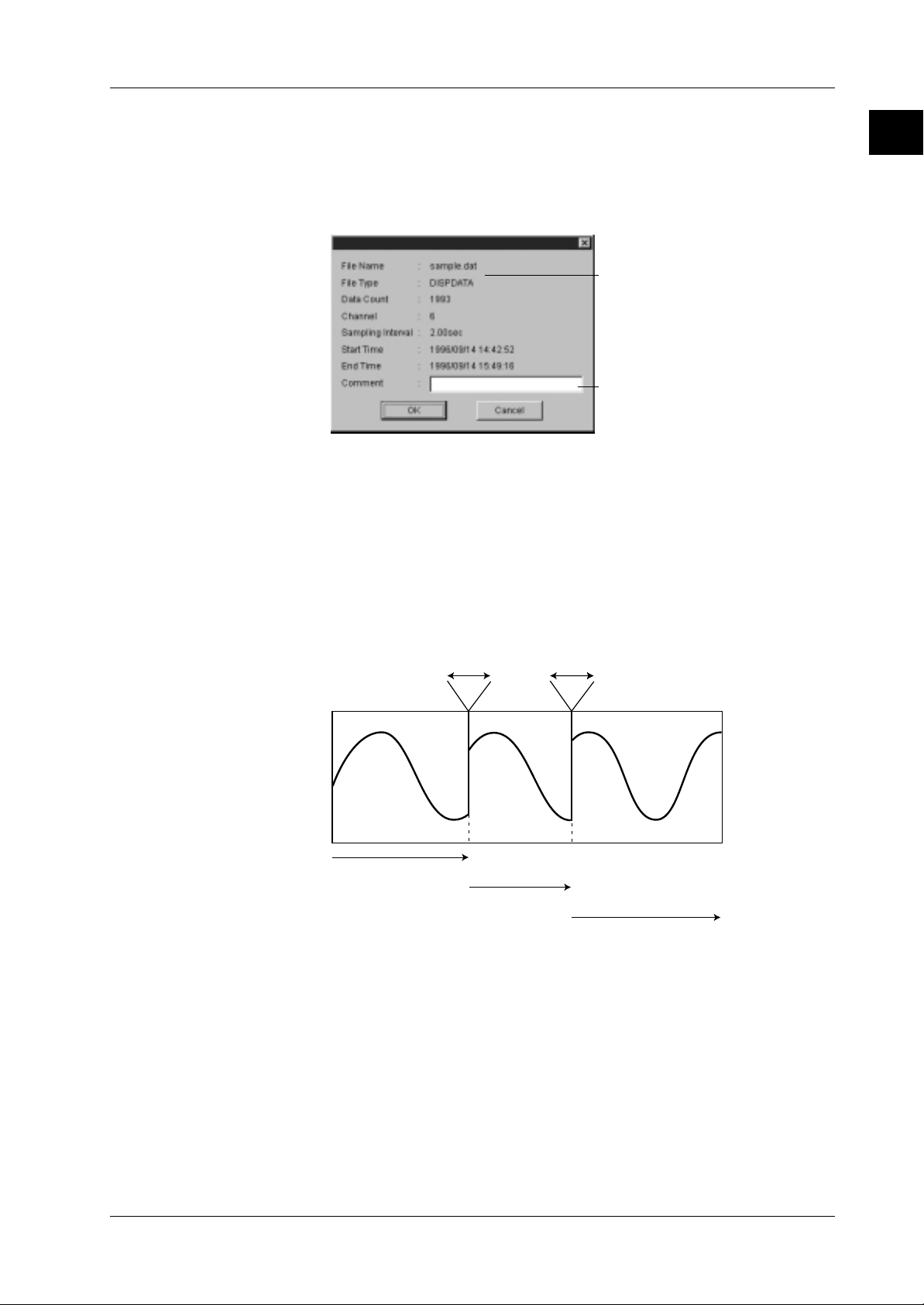

• Viewing the file information

You can view the file information of the displayed waveform by following the steps below.

Displaying the Measured Data

Select “Information” then “File information” from the menu bar. Information similar to the one

shown below is displayed.

When displaying an event file

:Event data

When displaying a display data file

:Display data

Display/enter comments

• Displaying event files containing power failure information data

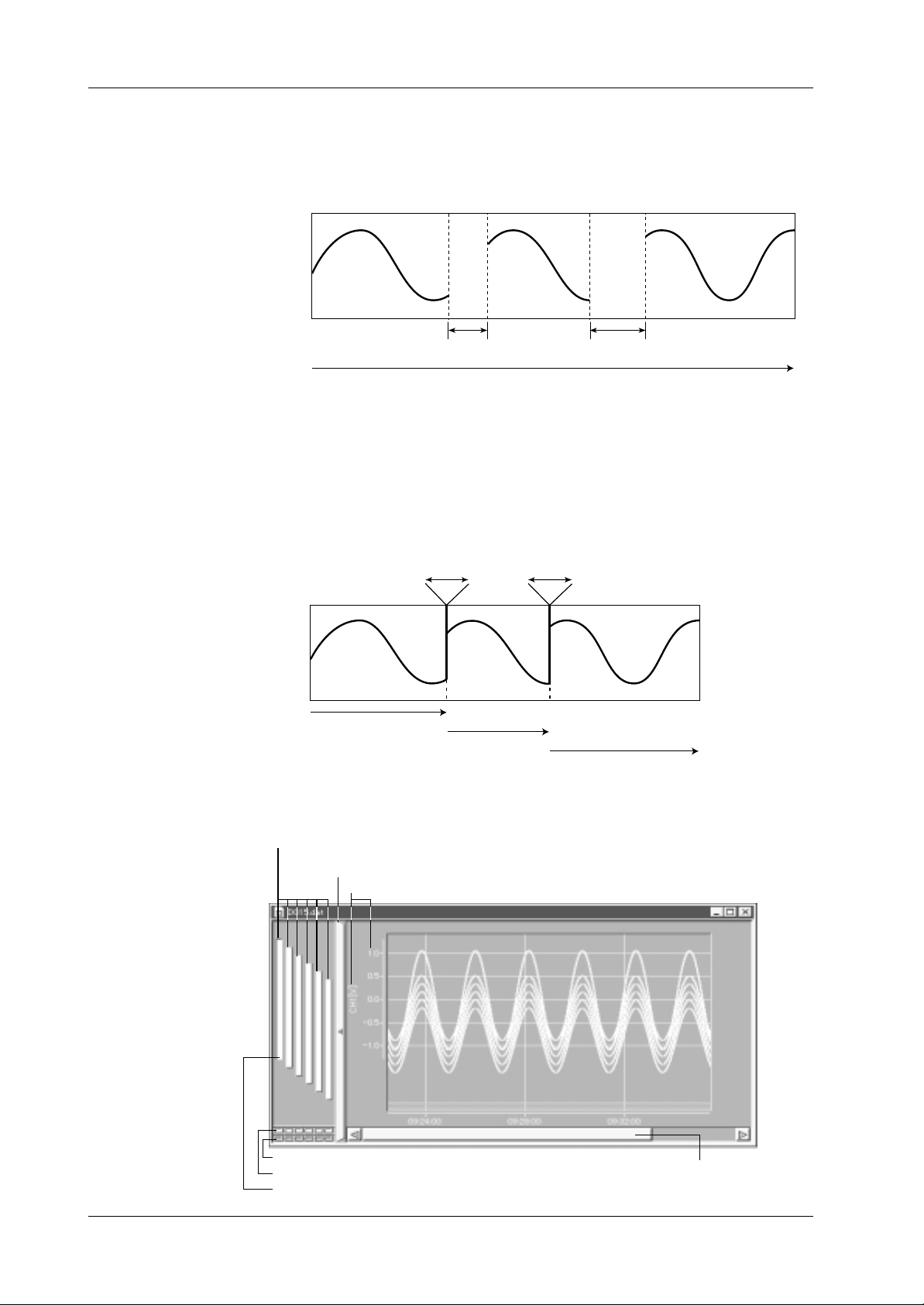

• When displaying an event file containing power failure information data, the waveform data

is displayed with incorrect time information. (The time of the measurement before the power

failure is shifted by the amount of time of the power failure duration.)

• When displaying the waveform of an event file containing power failure information data,

the data indicating the power failure duration is displayed as one point with a value larger

than the range on the top edge of the waveform display area. This is displayed as one point

with a value larger than the range on the digital value display.

The case with two power failure information data

power failure power failure

Displayed with the time

shifted by the duration

of the power failure

Displayed with

the time shifted

by the duration

of the power

failure

Displayed with correct time

1-3

Page 14

e

1.2 Opening a File

• Displaying display data files containing power failure information data

• When the information file containing power information data exists in the same folder as the

display data file, the power failure duration is displayed with a blank section. (The measured

data is displayed with correct time information.)

The case with two power failure information data

power failure power failure

time

• When the information file containing power failure information data does not exists in the

same folder as the display data file, the data indicating the power failure duration is displayed

as one point with a value larger than the range on the top edge of the waveform display area.

This is displayed as one point with a value larger than the range on the digital value display.

(The measured data is displayed with incorrect time information. The time of the

measurement before the power failure is shifted by the amount of time of the power failure

duration.)

The case with two power failure information data

power failure power failure

Displayed with the time

shifted by the duration

of the power failure

Displayed with

the time shifted

by the duration

of the power

failure

Displayed with correct time

• Waveform display example

Click to select the active waveform (waveform for which tags, units, and scale ar

Click to zoom in or zoom out on the waveform display area.

Display of tag, unit, and scale of the active waveform

Alarm display On/Off (CH1, CH2, CH3, CH4, CH5, CH6)

Waveform display On/Off (CH1, CH2, CH3, CH4, CH5, CH6)

Waveform zone display

displayed. Ch1, CH2, CH3, CH4, CH5, CH6)

Scroll the displayed

waveform in the time

axis direction

1-4

Page 15

1

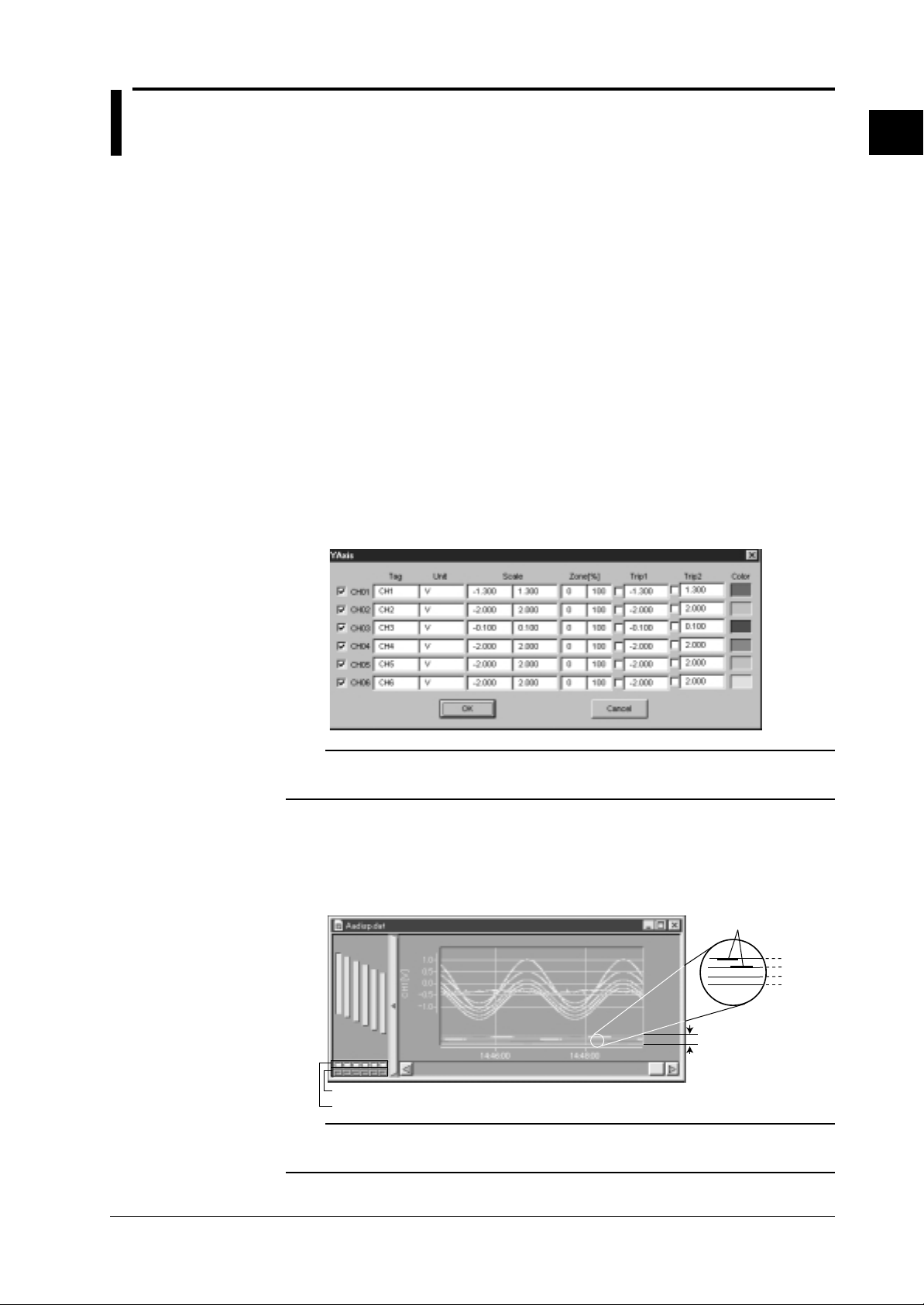

1.3 Changing the Waveform Display Settings

Setting the Details of the Waveform Display

While displaying the waveform, you can change the settings of the following items by following

the steps below.

• Waveform display On/Off, Alarm display On/Off

• Tag

• Unit

• Scale

Sets the display range in order to display the measured waveform with an appropriate scale.

• Zone

Sets the display position on the waveform display area (zone). When displaying multiple

waveforms, you can position each waveform so that it does not overlap.

• Trip Point

Sets the position of the horizontal line used to mark a certain value on the waveform display

area. Also, sets the display of this line On/Off.

• Display color

Sets the color of the displayed waveform.

Operation

1. Select “Yaxis” then “Detail...” from the menu bar.

Displaying the Measured Data

Note

When displaying the waveform from a data file saved on a VR100 or VR200 4CH input model, the settings

for CH5 and CH6 can not be changed

• Turning the waveform display On/Off, and alarm display On/Off

2. To turn the waveform display On/Off, click each checkbox for the channels, or click each

channel button on the lower left corner of the waveform display area.

3. To turn the alarm display On/Off, click each channel button on the lower left corner of the

waveform display area.

Alarm generation

Displays alarm

Alarm display On/Off (CH1, CH2, CH3, CH4, CH5, CH6)

Waveform display On/Off (CH1, CH2, CH3, CH4, CH5, CH6)

Note

Alarms (maximum of 4 alarms per channel) generated on the VR100 are displayed at the bottom of the

waveform display area with the same color as the waveform color for each channel.

Level 1

Level 2

Level 3

Level 4

1-5

Page 16

1.3 Changing the Waveform Display Settings

• Setting tags

4. Enter characters in the “Tag” text box for each channel.

• Setting units

5. Enter characters in the “Unit” text box for each channel.

• Setting the scale

6. Set the scale value for each channel. Text box on the left is the minimum value and the

text box on the right is the maximum value.

Note

Input range is from -999999 to 999999.

• Setting zones

7. Sets the zone for each channel in terms of percentages of the waveform display area. Text

box on the left is the minimum value and the text box on the right is the maximum value.

Note

• The input range for the minimum value is from 0 to 99 % and the input range for the maximum value is

from 1 to 100 %.

• The bottom of the display area is 0 % and the top is 100 %.

• Displaying trip point 1 and trip point 2

8. Click the “Trip1” and “Trip2” check boxes for each channel.

9. Input the display positions of trip point 1 and trip point 2 for each channel.

Note

• Trip points can be set to any value within the scale range for each channel.

• Trip point 1 is red and trip point 2 is yellow.

• The actual trip points displayed on the waveform display are the trip points for the active waveform.

• The display position of a trip point can be changed by dragging the trip point displayed on the right of the

waveform display area.

• Setting the color of the waveform

10. Click the “color” button for each channel.

1-6

11. Set the color.

12. Click “OK.”

13. Click “OK” on the “YAxis” dialog box.

The waveforms and trip points are displayed according to the settings.

Page 17

1

Explanation

Display of tag, unit, and scale of the active waveform

Click to zoom in or zoom out the waveform display area.

Trip point 1

Trip point 2

Click to select the active waveform

(waveform for which tags, units, and scale are displayed. Ch1, CH2, CH3, CH4, CH5, CH6)

Alarm display On/Off (CH1, CH2, CH3, CH4, CH5, CH6)

Waveform display On/Off (CH1, CH2, CH3, CH4, CH5, CH6)

Waveform zone display

Displays

alarm

Scroll the displayed waveform

in the time axis direction

1.3 Changing the Waveform Display Settings

• Waveform display example

Displaying the Measured Data

1-7

Page 18

1.3 Changing the Waveform Display Settings

Selecting the Waveform Display Zone Type

While displaying the waveform, you can select the waveform display zone type as shown, by

following the steps below.

• User zone: Displays according to the position of the zones specified in the “YAxis” “Detail” setting.

• Auto zone: Displays by dividing the waveform display area in equal parts according to the

number of waveforms being displayed.

• Full zone: Displays all waveforms in full zone.

• Slide zone: Displays each waveform by sliding the waveform from the top to bottom of the

waveform display area.

Operation

• To display using user zone: Point to “YAxis” - “Zone” then select “User Zone” from the

menu bar, or click the user zone icon on the tool bar.

• To display using auto zone: Point to “YAxis” - “Zone” then select “Auto Zone” from the

menu bar, or click the auto zone icon on the tool bar.

• To display using full zone: Point to “YAxis” - “Zone” then select “Full Zone” from the menu

bar, or click the full zone icon on the tool bar.

• To display using slide zone: Point to “YAxis” - “Zone” then select “Slide Zone” from the

menu bar, or click the slide zone icon on the tool bar.

User zone icon

Full zone icon

Slide zone icon

Auto zone icon

Explanation

• Example of the waveform display using user zone (when Zone is set to 20 to 80 %)

Zone:80%

100%

Zone:20%

• Example of the waveform display using auto zone (when number of displayed waveforms is 6)

1-8

Page 19

1

1.3 Changing the Waveform Display Settings

• Example of the waveform display using full zone

• Example of the waveform display using slide zone

Displaying the Measured Data

1-9

Page 20

Set to the minimum value of the scale

Set to the maximum value of the scale

1.3 Changing the Waveform Display Settings

Setting Display Limits on the Displayed Waveform

While displaying the waveform, you can set limits on the waveform display by following the

steps below. The display range of the waveform in the Y axis direction is limited to the minimum

and maximum scale values set in the “YAxis”- “Detail”. Measured values which are smaller than

the minimum are set to the minimum value and the measured values which are larger than the

maximum are set to the maximum value and displayed.

Operation

Select “YAxis” then “Limit” from the menu bar or click the limit icon on the tool bar.

Explanation

• Display example when limit is set on the displayed waveform

Limit icon

• Display example when limit is not set on the displayed waveform

1-10

Page 21

1

1.4 Changing the Time Axis Scale of the Waveform

Operation

Display

• Displaying the entire waveform

• Zooming in or zooming out on the waveform display by setting the scale factor

• Zooming in or Zooming out on the waveform display by selecting the scale factor

• Arbitrarily zooming in or zooming out on the waveform display

• Displaying the entire waveform

Displaying the Measured Data

While displaying the waveform, you can change the settings of the following items by following

the steps below.

The waveform is zoomed in or zoomed out in the time axis direction, to display the entire

waveform.

Set a desired scale factor to zoom in or zoom out on the waveform display in the time axis

direction.

Select the scale factor to zoom in or zoom out on the waveform display in the time axis

direction.

Waveform is zoomed in or zoomed out arbitrarily and displayed.

Select “TimeAxis” then “View All” from the menu bar to display the entire waveform.

• Zooming in or zooming out on the waveform display by setting the scale factor

1. Select “TimeAxis” then “Set Scale” from the menu bar.

To zoom in on the display

To zoom out on the display

2. When zooming in on the waveform display, enter the scale factor in the upper box and click

the upper radio button. When zooming out on the waveform display, enter the scale factor in

the lower box and click the lower radio button.

3. Click “OK.”

The waveform is displayed zoomed in or zoomed out in the time axis direction.

Note

• The range for zooming in on the waveform: 1 to 20 times (Integer values)

• The range for zooming out on waveform: 1/1 to 1/1000 times (Denominator: Integer values)

1-11

Page 22

1.4 Changing the Time Axis Scale of the Waveform Display

• Zooming in or zooming out on the waveform display by selecting the scale factor

Selecting “TimeAxis” then “XXX” (scale factor) from the menu bar zooms in or zooms out on

the waveform display in the time axis direction. (Selecting a scale factor larger than 1 results in

zooming in; a scale factor smaller than 1 results in zooming out.)

• Arbitrarily zooming in or Zooming out on the waveform

To zoom in on the waveform display, select “TimeAxis” then “Zoom In” from the menu bar or

click the zoom in icon on the tool bar. To zoom out on the waveform display, select

“TimeAxis” then “Zoom Out” from the menu bar or click the zoom out icon on the tool bar.

The waveform is displayed zoomed in or zoomed out in the time axis direction.

Zoom in icon

Zoom out icon

Explanation

• Scale factor for zooming in and zooming out on the waveform display

The waveform can be zoomed into or zoomed out of in the time axis direction by changing the

number of data* per line** on the time axis. The relation between the scale factor and the

number of data per line is as follows

Scale Relation between the number of data and line

1/1000 1000 data per line

1/500 500 data per line

1/200 200 data per line

1/100 100 data per line

1/50 50 data per line

1/20 20 data per line

1/10 10 data per line

1/5 5 data per line

1/2 2 data per line

1 1 data per line

2 1 data per every 2 lines

5 1 data per every 5 lines

10 1 data per every 10 lines

20 1 data per every 20 lines

* 1 data: 1 set of maximum and minimum data in the case of a display data file.

** 1 line: 1 vertical line on the screen

1-12

Page 23

1

1.5 Reading the Measured Value with the Cursor

Reading the Measured Value with the Cursor

While displaying the waveform, the measured data at the position specified by the cursor can be

read by following the steps below. There are two types of cursors: cursor A and cursor B. The

measured data at cursor A and cursor B and the difference between cursor A and cursor B can be

displayed.

Operation

1. In the waveform display area, set the mouse pointer to the position for reading the measured

data, click and drag the mouse to the position you wish to read to. The point where you first

clicked the mouse is cursor A and the point where you dragged the mouse to is cursor B.

2. Select “Window” then “Display Cursor Value” from the menu bar or click the display cursor

value icon on the tool bar. Cursor value dialog box opens and the time and the measured

values at the positions specified with the cursors are displayed. To make a fine adjustment in

the cursor position, click the arrows in the data number in the cursor value dialog box. The

cursor moves in units of 1 data.

Display cursor value icon

Displaying the Measured Data

Move the cursor in units of 1 data

Difference between the measured value

at cursor position A and the measured value

at cursor position B

Note

• To select the beginning to the end of the measured data, it is convenient to use “Edit” then “Select All”

from the menu bar.

• To clear the cursors from the waveform display area, select “View” then “Hide Cursor” from the menu

bar.

• In the case of event files, a value larger than the range is displayed when reading the measured data

during a power failure with the cursor. In the case of display data files, blank is displayed.

1-13

Page 24

1.5 Reading the Measured Value with the Cursor

Explanation

• Example displaying cursors

cursor A

cursor B

1-14

Page 25

1

1.5 Reading the Measured Value with the Cursor

Appending User-defined Marks/Deleting Marks/Resetting Marks

While displaying the waveform, you can add a mark at any desired position along the time axis by

following the steps below. Also, you can delete marks (trigger mark, event marks, user-defined

marks) displayed at the top of the waveform display area. Furthermore, you can reset the marks

to the condition saved with the VR100 or VR200 (only trigger mark and event marks are

displayed). The three types of marks are as follows:

• Trigger mark: Indicates the trigger point when the measurement was made with the VR100

or VR200.

• Event mark: Indicates the event marks added with the VR100 or VR200.

• User-defined mark: Marks added by the user with this software.

Operation

• Appending user-defined marks

1. Move the mouse cursor to the position you wish to add the user-defined mark and click the

mouse. Cursor is displayed.

2. Select “Edit” - “Append Mark...” from the menu bar or click the add user-defined mark icon

on the tool bar.

add user-defined mark icon

Displaying the Measured Data

3. Enter a label for the user-defined mark in the text box.

4. Click “OK.”

Above the waveform display area at the position where the cursor is displayed, the label for

the user-defined mark is displayed. You can display any number of marks by repeating steps

1 through 4.

Note

• You can not add an user-defined mark when the position of cursor A does not match that of cursor B.

• To rename a mark label, double click the mark you wish to rename, and carry out the steps from step 3.

Double click the mark you wish to rename

1-15

Page 26

1.5 Reading the Measured Value with the Cursor

• Deleting Marks

1. Set using cursor A and cursor B, the range in which you wish to delete the marks on the

waveform display area.

Refer to “Reading the Measured Value with the Cursor” (page 1-13) for instructions on

setting cursor A and cursor B.

2. Select “Edit” then “Delete Mark” from the menu bar.

Trigger mark, event marks, and user-defined marks in the specified range are deleted.

• Resetting Marks

Select “Edit” then “Reset Mark” from the menu bar.

Only trigger mark and event marks which were deleted are displayed. User-defined marks

are not displayed.

Explanation

• Example of Mark Display

Event mark User-defined mark

Trigger mark

1-16

Page 27

1

Copying Measured Data to the Clipboard

While displaying the waveform, you can copy the measured data in the range specified by the

cursor to the clipboard by following the steps below.

Operation

1. Set the range you wish to copy the measured data to the clipboard in the waveform display

area using cursor A and cursor B.

Refer to “Reading the Measured Value with the Cursor” (page 1-13) for instructions on

setting cursor A and cursor B.

2. Select “Edit” then “Copy” from the menu bar or click the copy icon on the tool bar. The

measured data is copied to the clipboard.

Copy icon

Note

• The maximum number of data that can be copied to the clipboard is 1000 data points. For display data

files, this constitutes 1000 sets of maximum and minimum data points.

• The number of channels copied to the clipboard is the number of all the channels saved in the data file.

(It does not depend on the On/Off condition of the waveform display.)

1.5 Reading the Measured Value with the Cursor

Displaying the Measured Data

Explanation

• Example of copying the event file to the clipboard

Date/time of measurement

CH1 Measured value

CH2 Measured value

CH6 Measured value

• Example of copying the display data to the clipboard

Measured value(CH1 min. value,CH1 max. value, ...

Date/time of measurement

CH1 min. value CH2 min. value

CH6 min. value, CH6 max. value)

CH1 max. value

CH2 max. value

Measured value

(CH1, ..., CH6)

Power failure

information data

Power failure information data

1-17

Page 28

1.6 Displaying Digital Values

Displaying Digital Values

The measured data can be displayed in digital value format by following the steps below.

Operation

Select “Window” then “Display Digital” or click the digital value display icon on the tool bar.

A separate window for displaying digital values opens, and the measured data is displayed in

digital value format.

Note

When the digital value display window is maximized and you wish to return to the waveform display,

select “Window” then “Display graph” or click the graph display icon on the tool bar.

Explanation

• Example of digital value display

Date/time of measurement

Data number

Ch1 min. value

Graph display icon

Digital value display icon

Ch1 max. value

1-18

Page 29

1

1.6 Displaying Digital Values

Reading the Measured Value with the Cursor while Displaying Digital Values

While displaying the digital values, you can read the measured data at the position specified with

the cursor by following the steps below. There are two types of cursors: cursor A and cursor B.

The measured data at cursor A and cursor B and the difference between cursor A and cursor B can

be displayed.

Operation

1. While displaying the digital values, set the mouse pointer to the Date[No.] item of the

measured data you wish to read, click and drag the mouse down to the next position. The

point where you first clicked the mouse is cursor A and the point where you dragged the

mouse to is cursor B.

Click at

cursor A

position

Drag to

cursor B

position

Displaying the Measured Data

2. Select “Window” then “Display cursor value” or click the cursor value display icon on the

tool bar. Cursor value dialog box opens and the time and the measured values at the

positions specified with the cursors are displayed. To make a fine adjustment in the cursor

position, click the arrows in the data number in the cursor value dialog box. The cursor

moves in units of 1 data.

Cursor value display icon

Move the cursor in units of 1 data

Difference between the measured value

at cursor position A and the measured value

at cursor position B

Note

• To select the beginning to the end of the measured data, it is convenient to use “Edit” then “Select All”

from the menu bar.

• To clear the cursor from the waveform display area, select “View” then “Hide Cursor” from the menu

bar.

• In the case of event files, a value larger than the range is displayed when reading the measured data

during the power failure with the cursor. In the case of display data files, blank is displayed.

1-19

Page 30

1.6 Displaying Digital Values

Copying Measured Data to the Clipboard while Displaying Digital Values

While displaying the waveform, you can copy the measured data in the range specified by the

cursor to the clipboard by following the steps below.

Operation

1. Set the range you wish to copy the measured data to the clipboard on the Data[No.] items

using cursor A and cursor B.

Refer to “Reading the Measured Value with the Cursor while Displaying Digital Values”

(page 1-19) for instructions on setting cursor A and cursor B.

2. Select “Edit” then “Copy” from the menu bar or click the copy icon on the tool bar. The

measured data is copied to the clipboard.

Copy icon

Note

• The maximum number of data that can be copied to the clipboard is 1000 data points. For display data

files, this constitutes 1000 sets of maximum and minimum data points.

Explanation

• Example of copying the event file to the clipboard

Date/time of measurement

CH1 Measured value

CH2 Measured value

CH6 Measured value

• Example of copying the display data to the clipboard

Measured value(CH1 min. value,CH1 max. value, ...

Date/time of measurement

CH1 min. value CH2 min. value

CH6 min. value, CH6 max. value)

CH1 max. value

CH2 max. value

Measured value

(CH1, ..., CH6)

Power failure

information data

1-20

Power failure information data

Page 31

1

1.7 Saving the Display Settings

While displaying the waveform or the digital values, you can save the display settings to a file by

following the steps below. There is only 1 file for saving the display settings.

Operation

Select “File” then “Save Display Settings” from the menu bar or click the save display settings

icon on the tool bar.

The display settings are saved to the file.

Save display settings icon

Note

• Extension “.vrv” is automatically added to the filename of which the waveform or the digital values is

displayed, as the destination filename.

• The items saved to the file are shown below.

Comment

Position of cursor A and cursor B

On/Off condition of the display waveform limit.

On/Off condition of the alarm display

YAxis detail items (On/Off condition of waveform display, tag, unit, scale, zone, trip point 1, trip point 2,

and color)

Mark information

• If you wish to display the data file as it was originally saved by the VR100 or VR200, delete the display

settings file “xxx.vrv” then reopen the data file.

Displaying the Measured Data

Explanation

• Display settings file

The display settings which are changed with this software are saved to the display settings file

“xxx.vrv.” When the data file which has had the display settings saved is reopened, it is

automatically displayed using the displayed settings. The display settings file can be overwritten

any number of times.

1-21

Page 32

1.8 Opening TLOG Interval Timeout Data File

If statistical computation (TLOG) is performed on the VR200 model with the computation

function, you will open the TLOG interval timeout data file containing the following information.

Start time of computation, unit and decimal point information on each channel.

TLOG interval timeout time and the measured/computed data at that time on each channel.

Stop time of computation and the measured/computed data at that time on each channel.

Operation

1. Select “File” then “Open...” from the menu bar, or click the file open icon on the tool bar.

File open icon

2. Select the filename from the “Filename:” list box. Select a file with “.tlg” extension. Also,

select the appropriate folder and file type as necessary.

Go up one folder

Create new folder

List files

3. Clicking “Open” displays the table.

Data Block

Computation start time

TLOG Interval Timeout Time

Computation stop time

Channel number

Note

The number of files that you can open simultaneously depends on the memory size and free disk space on

the personal computer.

It is convenient to copy the data file from the floppy disk to the hard disk and use the file on the hard disk.

1-22

Page 33

1

Explanation

1.8 Opening TLOG Interval Timeout Data File

Capabilities of the software

This software is capable of doing the following:

Convert data format (see chapter 2).

Print to an external printer (see chapter 3).

Display information from the TLOG interval timeout data file (see section 1.9).

Displaying the Measured Data

1-23

Page 34

1.9 Displaying Information on TLOG Interval

Timeout Data File

Displays computation start and stop times of the TLOG interval timeout data file currently being

displayed for each data block.

Operation

1. Select “Information” then “About the TLOG file...” from the menu bar. The information

about the TLOG interval timeout data file is displayed.

1-24

Page 35

2

2.1 Converting the Data Format

p

While displaying the waveform or the digital values, the measured data can be converted to 3

different data formats—ASCII, Lotus, or Excel format—by following the steps below.

Operation

1. Select “Convert” then “XXX” from the menu bar. (“XXX” is either ASCII, Lotus, or Excel

format.)

2. In the XXX conversion dialog box, enter the range for converting the data(start and end

points) and the step number(e.g. Entering “3” converts every 3 data). If you wish to convert

all the data in the specified range, enter “1” for the step number. Click all the check boxes

for the channels you wish to convert.

End point for converting

Start point for converting

Converting the Displayed Data

Convert Channel(s)

Destination filename

number

Ste

3. When changing the destination folder or the filename, click “File...”

Select or enter the destination filename in the “File name” text box. Select the folder or the

file type as necessary. Then, click “Save.”

4. Click “OK” in the XXX conversion dialog box.

The measured data is converted to the specified data format and saved to the file.

When changing the destination filename

Up One Level

Create New Folder

List

Details

Note

The data range to be converted with each XXX conversion dialog box is automatically set to the range

specified by cursor A and cursor B. (When the data range is not set with the cursor or when the cursor is

turned off (deleted), the data number for the start point is automatically set to 0 and the data number for the

end point is automatically set to the last number represented by -1.)

2-1

Page 36

2.1 Converting the Data Format

• ASCII conversion dialog box

• Lotus conversion dialog box

• Excel conversion dialog box

Note

• The destination filename automatically takes on the file name of the displayed waveform plus the

extension to distinguish the different data formats. Extensions are “.prn” for ASCII format, “.wj2”

(Version 2.0 or later) for Lotus format, and “.xls” (Version 4.0 or later) for Excel formats.

• For Lotus 1-2-3 and Excel, there is a limit on the number of data points that can be handled. This

software does not limit the number of data points that can be converted. Therefore, make sure to set the

number of data points equal to or less than the maximum data number allowed by these software. Also,

when the available memory is low, there are cases when the data can not be read even when the number

of data points is less than the limit.

2-2

Page 37

2

2.2 File Format of the Converted Data

Explanation

Converting the data according to the steps described in Section 2.1, data are created in the format

shown below.

• ASCII Conversion File

• Event file

Title

Start time for conversion

End time for conversion

Sampling interval

Data count

Channel number

"Date","Time","msec",unit

Date

Time Measured valueTime(msec)

Power failure information data

• Display data file

Title

Start time for conversion

End time for conversion

Sampling interval

Data count

Channel number

"Date","Time","msec",unit

Converting the Displayed Data

Time

Time(msec)Date

Measured value

Power failure information data

Note

• When converting an event file containing power failure information data, the waveform data does not get

converted with correct time information. (The time of the measurement before the power failure is

shifted by the amount of time of the power failure duration.)

When converting a display data file containing power failure information, it is converted with correct

time information.

• In the case of event files, the measurement data during the power failure is converted to a value larger

than the range. In the case of display data files, blanks are inserted for the duration of the power failure.

2-3

Page 38

2.2 File Format of the Converted Data

• Lotus Conversion File

This file has the format that can be read by Lotus 1-2-3.

• Event file

ABCDEFG

1

VR Series

2

Start Time

3

End Time

4

Sampling Interval

5

Data Count

6

7

Data.

8

09/14

9

09/14

10

09/14

11

09/14

12

09/14

13

09/14

• Display data file

Time

14:04:22

14:04:24

14:04:26

14:04:28

14:04:30

14:04:32

1996/09/14

1996/09/14

2.000 sec

6

Ch.

msec

0

0

0

CH1

V

-

-

-

0

0

0

0.663

0.574

0.489

14:04:22.000

14:04:32.000

CH2

V

-

0.574

-

0.489

-

0.395

CH3

V

-

0.003

-

0.003

0.004

CH4

V

0.004

0.005

0.005

ABCDEFG

1

VR Series

2

Start Time

3

End Time

4

Sampling Interval

5

Data Count

6

7

8

9

10

11

12

13

Data.

09/14

09/14

09/14

09/14

09/14

09/14

Time

13:59:58

13:59:59

14:00:00

14:00:01

14:00:02

14:00:03

1996/09/14

1996/09/14

1.000 sec

6

Ch.

msec

0

0

0

0

0

0

CH1

V

0.521

0.566

32.639

0.023

-

-

0.025

0.080

13:59:58.000

14:00:03.000

CH2

V

0.524

0.569

32.639

0.019

-

0.029

-

0.079

CH3

V

0.004

0.003

32.639

0.003

-

0.004

-

0.004

CH4

V

0.531

0.575

32.639

0.017

-

0.037

-

0.086

Note

• When converting an event file containing power failure information data, the waveform data does not get

converted with correct time information. (The time of the measurement before the power failure is

shifted by the amount of time of the power failure duration.)

When converting a display data file containing power failure information, it is converted with correct

time information.

• In the case of event files, the measurement data during the power failure is converted to a value larger

than the range. In the case of display data files, blanks are inserted for the duration of the power failure.

2-4

Page 39

2

• Excel Conversion File

This file has the format that can be read by Excel.

• Event file

2.2 File Format of the Converted Data

ABCDEFG

1

VR Series

2

Start Time

3

End Time

4

Sampling Interval

5

Data Count

6

7

Data.

8

09/14

9

09/14

10

09/14

11

09/14

12

09/14

13

09/14

• Display data file

Time

14:04:22

14:04:24

14:04:26

14:04:28

14:04:30

14:04:32

ABCDEFG

1

VR Series

2

Start Time

3

End Time

4

Sampling Interval

5

Data Count

6

7

8

9

10

11

12

13

Data.

09/14

09/14

09/14

09/14

09/14

09/14

Time

13:59:58

13:59:59

14:00:00

14:00:01

14:00:02

14:00:03

1996/09/14

1996/09/14

2.000 sec

6

Ch.

msec

0

0

0

CH1

V

-

-

-

0

0

0

1996/09/14

1996/09/14

1.000 sec

6

Ch.

msec

0

0

0

0

0

0

CH1

V

32.639

-

-

0.663

0.574

0.489

0.521

0.566

0.023

0.025

0.080

14:04:22.000

14:04:32.000

CH2

V

-

0.574

-

0.489

-

0.395

CH3

V

-

0.003

-

0.003

0.004

13:59:58.000

14:00:03.000

CH2

V

0.524

0.569

32.639

0.019

-

0.029

-

0.079

CH3

V

0.004

0.003

32.639

0.003

-

0.004

-

0.004

CH4

V

0.004

0.005

0.005

CH4

V

0.531

0.575

32.639

0.017

-

0.037

-

0.086

Converting the Displayed Data

Note

• When converting an event file containing power failure information data, the waveform data does not get

converted with correct time information. (The time of the measurement before the power failure is

shifted by the amount of time of the power failure duration.)

When converting a display data file containing power failure information, it is converted with correct

time information.

• In the case of event files, the measurement data during the power failure is converted to a value larger

than the range. In the case of display data files, blanks are inserted for the duration of the power failure.

2-5

Page 40

3

3.1 Setting up the Printer

You can set setup the printer by following the steps below.

Operation

1. Select “File” then “Printer Setup...” from the menu bar.

Note

If there is a file already opened, the menu shown above will also have a print menu.

2. Set the printer, orientation, and paper.

Printing the Measured Data with an External Printer

Explanation

To set the printer, follow the procedures according to the system configuration you are using.

3-1

Page 41

3.2 Print Previewing

You can preview the layout before printing by following the steps below.

Operation

1. Select “File” from the menu bar to display the file menu.

Print menu has been added to the file menu shown in Section 1.2.

2. Select “Print Preview.”

3. Click the appropriate buttons to operate the print preview.

Execute print

Show next page

Show previous page

Display 1 page only/2 pages simultaneously

Zoom in

Zoom out

Explanation

Close

Note

• Print preview begins with the first data in the file.

• There are cases when the actual print is slightly different from what is displayed in the print preview.

For information regarding the operation of the print preview, refer to the instruction manual for

your system.

3-2

Page 42

3

3.3 Printing the Displayed Waveform or Digital

Values

You can print the displayed waveform or the digital values by following the steps below.

Operation

1. Select “File” then “Print...” from the menu bar or click the print icon on the tool bar.

print icon

3. Set the printer, orientation, and paper.

Printing the Measured Data with an External Printer

Note

The range for printing is set using cursor A and cursor B, when displaying the waveform or the digital

values. For instructions on setting cursor A and cursor B when displaying the waveform, refer to “Reading

the Measured Value with the Cursor” (page 1-13). For instructions on setting cursor A and cursor B when

displaying the digital values, refer to “Reading the Measured Value with the Cursor while Displaying

Digital Values” (page 1-19).

3-3

Page 43

3.3 Printing the Displayed Waveform or Digital Values

Explanation

• Print example when displaying the waveform

• Print example when displaying the digital values

3-4

Page 44

4

4.1 Troubleshooting

When there is a message displayed on the screen, refer to Section 4.2 “Error Messages and Corrective Actions” (page 4-2).

Problem Possible cause/Corrective Action

Unable to read floppy disk. Check the format type of the floppy disk.

Unable to setup software Check that there is 15 MB or more free disk space.

Error Messages

4-1

Page 45

4.2 Error Messages and Corrective Actions

• Operation Confirmation Messages

Displayed when confirming an operation.

Message Explanation

Correct time can not be displayed because there is no Displayed when the information file (.inf) does not exist in the same folder as

information file. Continue? the data file.

Correct time can not be displayed because the display data Displayed when more than 10 power failure data existed when saving the

file contains more than 10 power failure data. Continue? measured data on VR100 or VR200.

Correct time can not be displayed because the event file Displayed when the event file contains power failure data. (The event file

contains power failure data. Continue? can not be displayed with correct time information.)

• Error messages

Shown in the following figure are displayed when attempting to set invalid values or when the instrument is in an abnormal

condition. If errors persist even after carrying out the corrective actions, please contact OMEGA Engineering.

Error Message Corrective Action

File open error. Check the data file that is being read.

File read error. Check the data file that is being read.

File write error. Floppy disk is protected or the disk is corrupt.

Insufficient memory. Check the amount of free disk space and delete unnecessary files.

Not OMEGA standard format. Check the data file that is being read.

Not VR100 measured data. Select a file saved by VR100 or VR200.

Invalid information in information file. Select a file saved by VR100 or VR200. (The file was not saved by VR100 or

Data created using external sampling signal. Data file created using external sampling signal can not be read.

No information file. If the information file (.inf) exists, copy the information file in the same

Memory allocation error. Exit the program immediately. Exit the program immediately.

VR200, or the file is corrupt.)

folder as the data file before opening.

4-2

Page 46

Index

Index

A Page

Alarm display ..................................................................... 1-5, 1-7

Alarm display On/Off........................................ 1-4, 1-5, 1-7, 1-21

Arrow button ..................................................................1-13, 1-19

ASCII

Conversion ..................................................................... 2-1, 2-2

Conversion file ...................................................................... 2-3

Auto zone .................................................................................. 1-8

Auto zone icon........................................................................... 1-8

B Page

Backup .......................................................................................... 5

C Page

Channel

Channel number .................................................................... 2-3

Number of .................................................................... 1-3, 1-17

Clipboard ........................................................................1-17, 1-20

Closing....................................................................................... 1-1

Color ......................................................................... 1-5, 1-6, 1-21

Comment .......................................................................... 1-3, 1-21

Control panel ................................................................................ 6

Conversion data ................................................................. 2-3~2-5

Number of ............................................................................. 2-3

Conversion start/end points ................................................2-1, 2-2

Converting data formats .....................................................2-1, 2-2

Copy ............................................................................... 1-17, 1-20

Copy icon .......................................................................1-17, 1-20

Cursor ........................................... 1-13~1-17, 1-19~1-21, 2-1, 3-3

Deleting ...................................................................... 1-13, 1-19

Cursor value display ???.................................................1-13, 1-19

Cursor value icon ??? ..................................................... 1-13, 1-19

D Page

Data conversion format

ASCII .................................................................................... 2-3

Excel...................................................................................... 2-5

Lotus...................................................................................... 2-4

Data count...........................................................................1-3, 2-1

Data file ........................................................... 1-2, 1-5, 1-17, 1-21

Data number ........................................................... 1-13, 1-19, 2-1

Data types .................................................................................. 1-3

Digital value display.......................................................1-18, 1-20

Digital value display icon ........................................................ 1-18

Display data ............................................................................... 1-3

Display data file............................................4, Chapter 1, 2-3~2-5

Display limit ............................................................................ 1-10

Display settings file ................................................................. 1-21

E Page

End point ............................................................................2-1, 2-2

Entire display........................................................................... 1-11

Error Messages .......................................................................... 4-2

Event data .................................................................................. 1-3

Event file ......................................................4, Chapter 1, 2-3~2-5

Event mark .....................................................................1-15, 1-16

Excel

Conversion ..................................................................... 2-1, 2-2

Conversion file ...................................................................... 2-5

Exiting the program ................................................................... 1-1

Extension .................................................................. 1-2, 1-21, 2-2

F Page

Index

File format

ASCII .................................................................................... 2-3

Excel...................................................................................... 2-5

Lotus...................................................................................... 2-4

File information ......................................................................... 1-3

File name .................................................................... 1-2, 1-3, 2-1

File open icon ............................................................................ 1-2

Folder............................................................... 8, 1-1, 1-2, 1-4, 2-1

Free disk space ........................................................... 1-2, 2-2, 4-1

Full zone .............................................................................1-8, 1-9

Full zone icon ............................................................................ 1-8

I page

Information file...................................................................... 4, 1-4

Installing ................................................................................... 6~8

Installing/Uninstalling .................................................................. 6

Installing/Uninstalling the program.............................................. 6

L Page

Limit ...............................................................................1-10, 1-21

Limit icon ................................................................................ 1-10

Lotus

Conversion ..................................................................... 2-1, 2-2

Conversion file ...................................................................... 2-4

M Page

Mark

Deleting ......................................................................1-15, 1-16

Event mark ................................................................. 1-15, 1-16

Information.......................................................................... 1-21

Resetting.....................................................................1-15, 1-16

Trigger mark...............................................................1-15, 1-16

User-defined mark......................................................1-15, 1-16

Memory size .............................................................................. 1-2

Menu bar.................................................................................... 1-1

Index-1

Page 47

Index

O Page

Opening ..................................................................................... 1-2

Operation confirmation message ............................................... 4-2

P Page

Power failure information ................................... 1-3, 1-4, 2-3~2-5

Power failure information data ............................... 1-17, 1-20, 2-3

Print .................................................................................... 3-3, 3-4

Print icon ................................................................................... 3-3

Print preview ............................................................................. 3-2

Printer setup............................................................................... 3-1

R Page

Range ..................................................................................1-3, 1-4

S Page

Sampling interval ...............................................................1-3, 2-3

Save display settings icon ??? ................................................. 1-21

Saving display settings ............................................................ 1-21

Scale ......................................................................... 1-5~1-7, 1-21

Scale factor setting .................................................................. 1-11

Scrolling ............................................................................. 1-4, 1-7

Select all .........................................................................1-13, 1-19

Selecting active waveforms ................................................1-4, 1-7

Setting the color, Color setting .................................................. 1-6

Slide zone ........................................................................... 1-8, 1-9

Slide zone icon .......................................................................... 1-8

Start and end time of measurement ........................................... 1-3

Start point ........................................................................... 2-1, 2-2

Starting/Exiting the program ..................................................... 1-1

Status bar ................................................................................... 1-1

Step ..................................................................................... 2-1, 2-2

System floppy disk ................................................................... 5, 6

System requirements .................................................................... 4

U Page

Unit .................................................................... 1-5~1-7, 1-21, 2-3

User zone ................................................................................... 1-8

User zone icon ........................................................................... 1-8

User-defined mark .......................................................... 1-15, 1-16

User-defined mark add icon ??? .............................................. 1-15

W Page

Waveform

Zoom in/zoom out ......................................................1-11, 1-12

Waveform display

Color..................................................................... 1-5, 1-6, 1-21

On/Off ........................................................... 1-4, 1-5, 1-7, 1-21

Scale ..................................................................... 1-4~1-7, 1-21

Tag........................................................................ 1-4~1-7, 1-21

Trip point.............................................................. 1-5~1-7, 1-21

Unit....................................................................... 1-4~1-7, 1-21

Zone...................................................................... 1-4~1-7, 1-21

Zone type........................................................................1-8, 1-9

Waveform display icon ........................................................... 1-18

Y Page

Y axis detail setting ............................................................1-5, 1-6

Z Page

Zone .......................................................................... 1-5~1-7, 1-21

Selecting type .................................................................1-8, 1-9

Setting ............................................................................1-8, 1-9

Zoom in .......................................................................... 1-11, 1-12

Zoom in icon ........................................................................... 1-12

Zoom in/zoom out on waveform display area ....................1-4, 1-7

Zoom out ........................................................................ 1-11, 1-12

Zoom out icon ......................................................................... 1-12

T Page

Tag ............................................................................ 1-5~1-7, 1-21

Time axis

Entire display ...................................................................... 1-11

Scale factor .......................................................................... 1-11

Selecting ..................................................................... 1-11, 1-12

Setting ................................................................................. 1-11

Zoom in/out ................................................................1-11, 1-12

Time axis scale factor .............................................................. 1-11

Title ........................................................................................... 2-3

Tool bar ..................................................................................... 1-1

Trigger mark ...................................................................1-15, 1-16

Trip point .................................................................. 1-5~1-7, 1-21

Troubleshooting......................................................................... 4-1

Index-2

Page 48

WARRANT Y/ DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 25 months f rom date of purchase. OMEGA Warranty adds an additional one (1) month grace

period to the normal two (2) year product war r a n t y to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be re t u rned to the factory for evaluation. OMEGA’s Customer Serv i c e

D e p a rtment will issue an Authorized Return (AR) number immediately upon phone or written re q u e s t .

Upon examination by OMEGA, if the unit is found to be defective, it will be re p a i red or replaced at no

c h a rge. OMEGA’sWARRANTY does not apply to defects resulting from any action of the purc h a s e r, including but not limited to mishandling, improper interfacing, operation outside of design limits,

i m p roper re p a i r, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corro s i o n ;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s c o n t rol. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

R E P R E S E N T ATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A P A R TICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

L I A B I L I T Y : The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this or d e r , whether based on contract, war r a n t y , negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

a c t i v i t y, medical application, used on humans, or misused in any way, OMEGA assumes no re s p o n s i b i l i t y

as set forth in our basic WA R R A N TY/DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA h a rmless from any liability or damage whatsoever arising out of the use of the

P roduct(s) in such a manner.

RETURN REQUEST S / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPA RTMENT (IN ORDER TO AV O I D

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1 . P u rchase Order number under which the pro d-

uct was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our

customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1998 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, re p ro-

duced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior

written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

consult OMEGA

Page 49

W h e r e Do I Find Everything I Need for

P r ocess Measurement and Control?

OMEGA…Of Course!

T E M P E R AT U R E

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & A s s e m b l i e s

Wi re: Thermocouple, RTD & Thermistor