Page 1

www.omega.com

e-mail: info@omega.com

User’s Guide

TQ504

Torque Transducer

Shop online at

Page 2

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Rudé armády 1868, 733 01 Karviná 8

TEL: +420 (0)69 6311899 FAX: +420 (0)69 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

INDEX

1. Applications and typical attributes ............................................... Page 1

2. Description of the measurement system ...................................... Page 1

2.1 Mechanical design ................................................................. Page 1

2.2 Electrical design ..................................................................... Page 2

2.3 Angle-of-rotation transducer ............................................... Page 3

3. Electrical connection of the torque transducer ............................ Page 4

3.1 Connector pin assignments .................................................. Page 5

3.1.1 Signals, angle outputs ........................................................... Page 6

3.2 Laying of the output signal cables ...................................... Page 6

3.3 Placement of conductors in cable ........................................ Page 6

4. Mechanical installation of the torque transducer........................ Page 8

4.1 Suggestions for installation .................................................. Page 8

5. Mechanical calibration ..................................................................... Page 9

5.1 Assembly of a simple calibrating setup ............................ Page 10

5.2 Sample calculation of lever arm length............................. Page 10

5.3 Electrical calibration ............................................................. Page 11

6. Maintenance...................................................................................... Page 11

7. Troubleshooting guide for transducer shaft............................... Page 12

See Data Sheet for technical specifications

TQ504 Torque Transducer

i

Page 4

1. Applications and typical attributes

• Torque transducer with inductive angular position measurement system.

• Measurement of constant and variable torques.

• Torque measurement on a rotating shaft.

• For laboratory, production and quality assurance applications.

• Built- in instrument amplifier.

• Built- in angle-of-rotation transducer.

2. Description of the measurement system

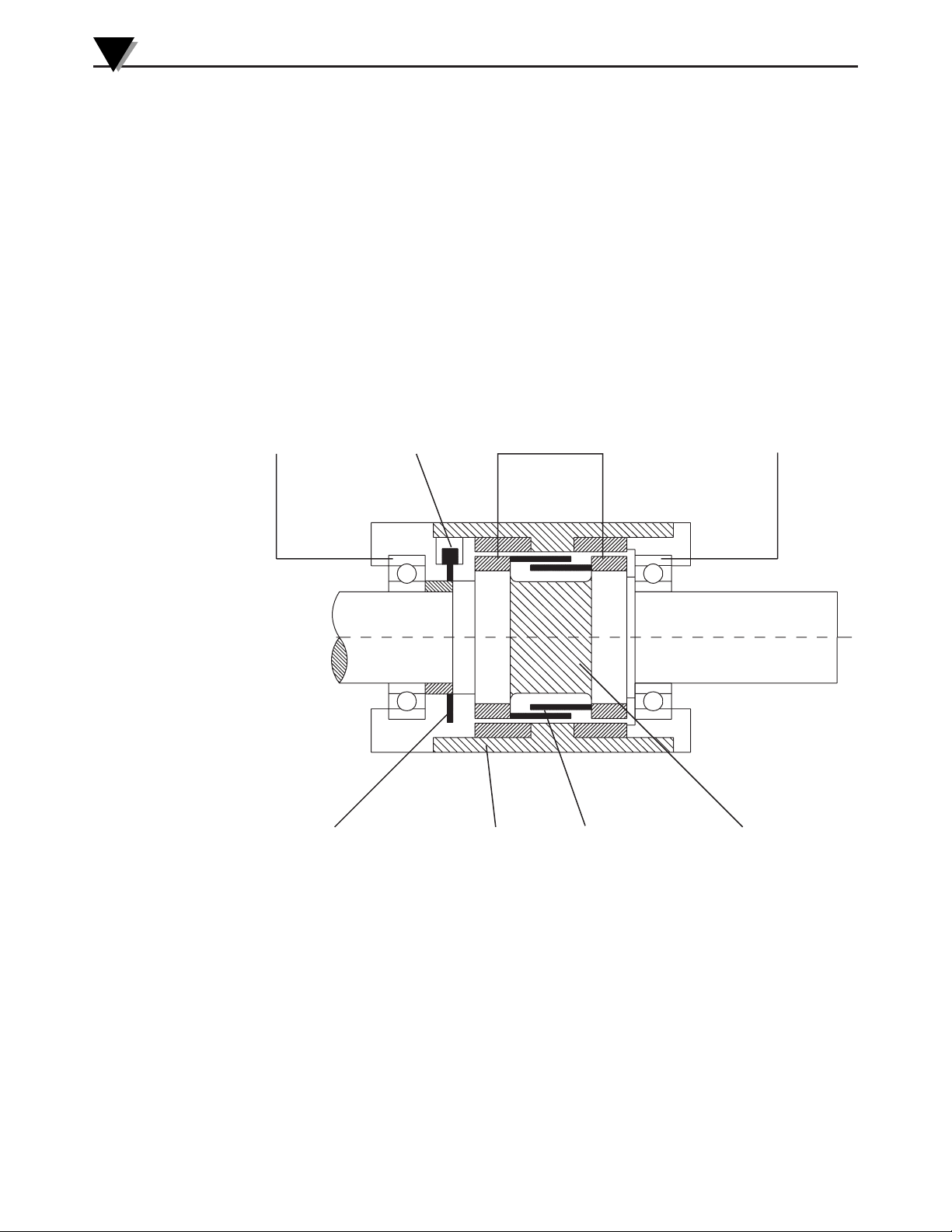

2.1 Mechanical design

• The transducer consists of a stator through which a bearing-mounted shaft

passes.

• A certain length of the shaft is utilized to convert the torque into a proportional

torsional angle.

• This torsional angle or angle of twist is measured between the two ends of this

shaft length by an inductive (wave-form) angular position measurement

system.

• The inductive angular position measurement system converts the angle of

twist into a proportional electrical signal.

TQ504 Torque Transducer

1

Bearing

Angular

Sensor

Pulsedisk Stator Inductive (wave-

Rotary

transformers

form) angular

position measure-

ment system

Bearing

Torsion

length

Page 5

• The electrical power for operation of the inductive angular position

measurement system, which rotates along with the shaft, is provided by means

of a rotary transformer.

• The electrical output signal, which is proportional to the torque, is transferred

to the stator by a second rotary transformer.

• The connection box on the stator contains the electronics, the power supply

unit, and the instrument amplifier.

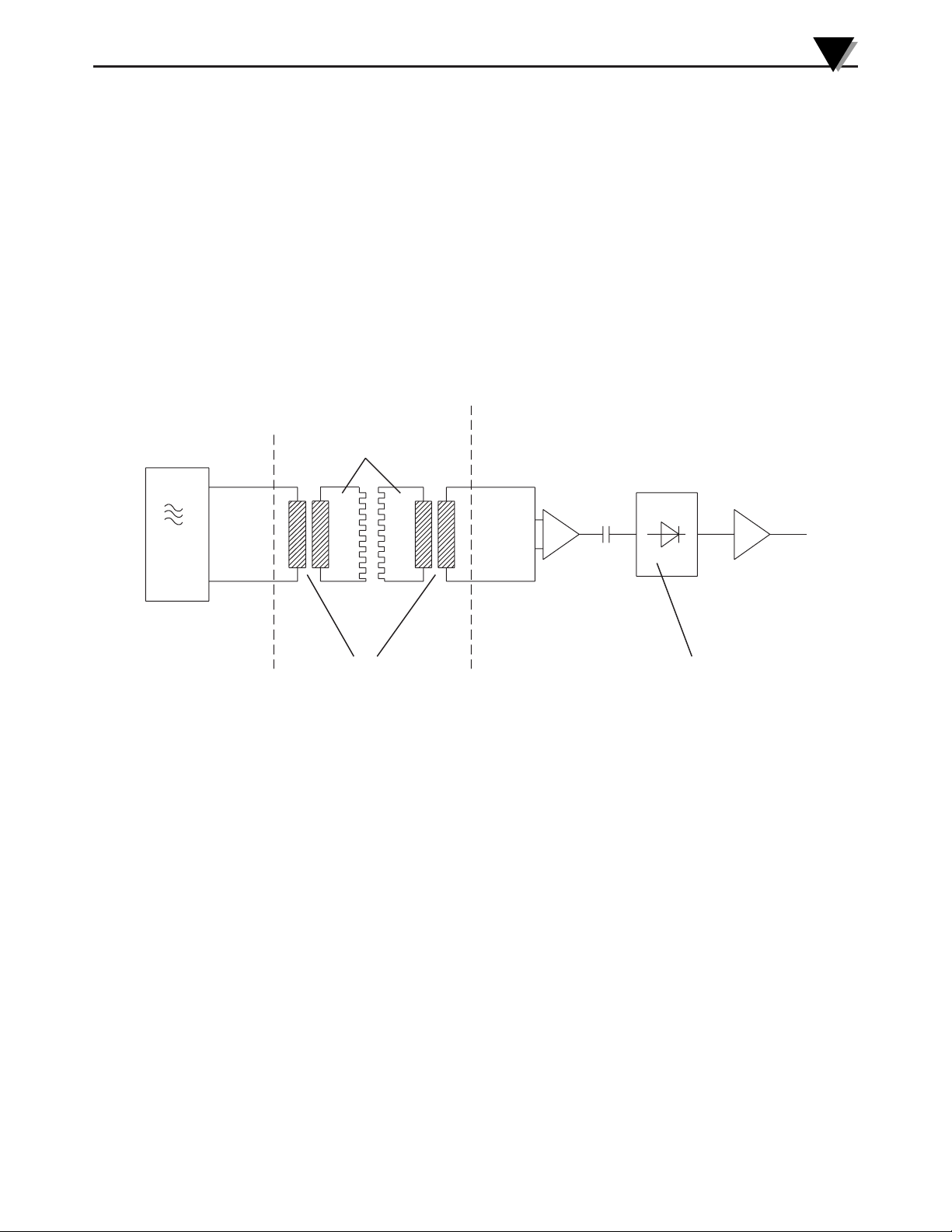

2.2 Electrical design

The built-in electronics comprise the following functional groups:

• Oscillator for generation of the AC input voltage

• Preamplifier for the output signal

• Phase-sensitive rectifier for conversion of the AC output signal into a DC

voltage

• Output amplifier

TQ504 Torque Transducer

2

Mechanical part

of transducer

Inductive (waveform) angular

Oscillator

120kHz

position measurement system

Preamplifier

Output

amplifier

Rotary transformers Phase-sesitive

rectifier

Page 6

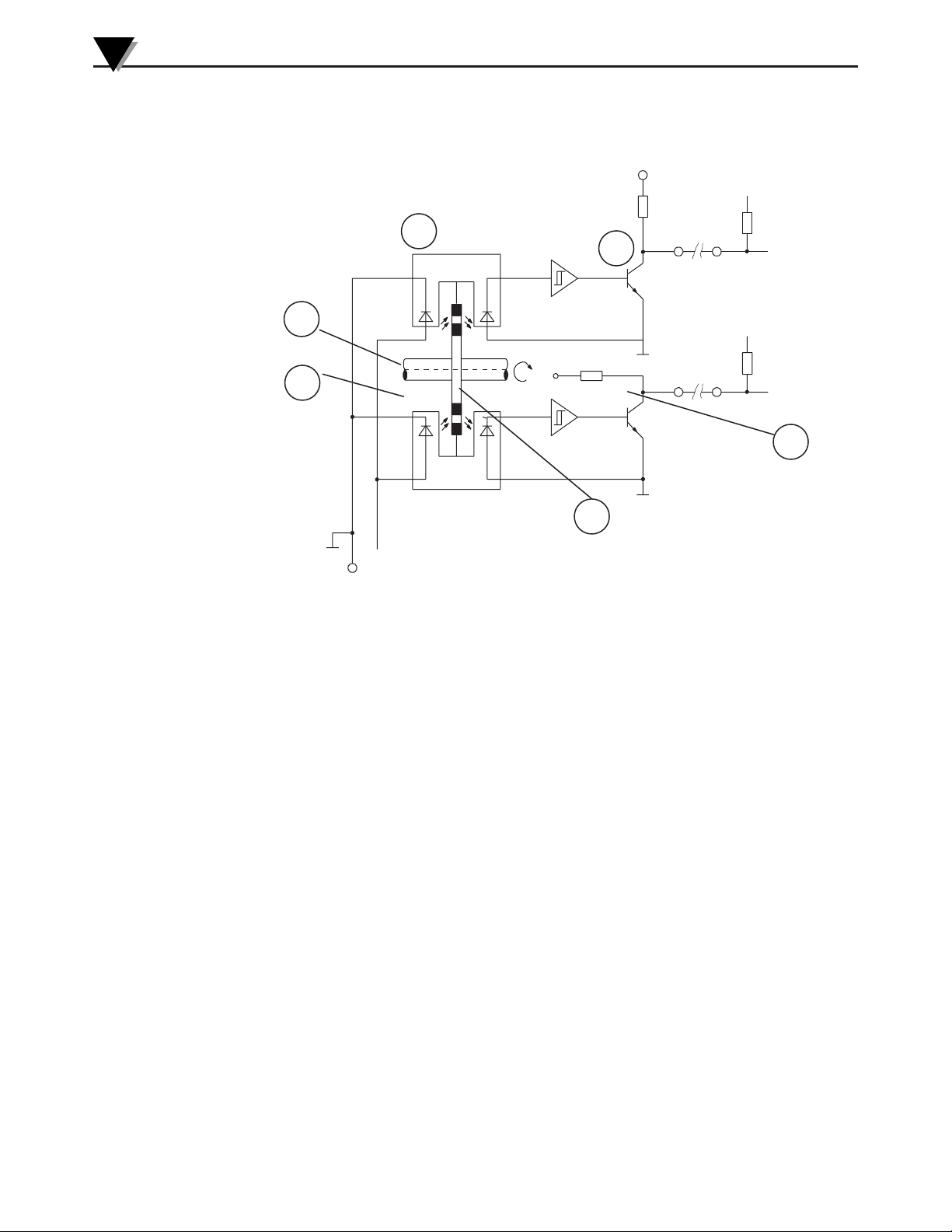

2.3 Angle-of-rotation transducer

Schematic of angle-of-rotation measurement system

1. Rotating shaft

2. Encoder disk

3. Double-arm photoelectric barrier

4. Open-collector output (external pull-up resistor required)*

Features:

• 360 slots in the encoder disk

• Two double-arm photoelectric barriers 90° apart.

• Number of pulses generated proportional to angle of rotation.

* The ohmic value of the resistor depends on the maximum speed of rotation and

the cable length (e.g. 1500 rpm and a 4 m cable, R=3.3kΩ).

TQ504 Torque Transducer

3

+

+5

V

+5

V

1

3

E

3

B

4

0

V

5V

V

0

2

intern

+5

V

4

Page 7

3. Electrical connection of the torque transducer

• Cable type: at least 12 conductors, e.g. LIYCY 12 x 0.14

• Max. cable length: 15 m

TQ504 Torque Transducer

4

Connector

Shielded

cable

To power supply

and to display

Transducer

Page 8

3.1 Connector pin assignments

Description of interface for Type, art.-no.: 7203

Angle outputs: open collector outputs with internal 10kΩ pull-up to +Vop

Built in connector: Binder Series 680, type 09-0331-80-12 or equivalent

Cable diagram with plugs on both sides

TQ504 Torque Transducer

5

Top view of connector on

transducer

Function Pin Description

supply voltage A -U

B

-10.5..-16V, ≤ 30mA

angle output

B <1 360 impulse per revolution duty cycle

50/50 ±20%

moment output

CU

a

±5V bei ±Md

nenn

on ≥ 2k_

+5V at calibration

Ri=10_, output short circuit proof acc.

GND

moment output D GND GND Reference for U

a

supply voltage

E GND GND Reference for Ub, R

kod

, Kal, <1),

<2

supply voltage F +U

b

+10,5V..+16V, ≤ 30mA

angle output

G <2 Signal 90°lagging to signal on Pin B

on rotation to the right

speed puls output H - 60-pulse / rotation

free J

calibration input

K Kal Off: 0V – 2V; On: 3,5V – 30V

Input impendence: > 100 k_

measuring range coding

LR

kod

free

shield M not used in the transducer

Page 9

3.1.1 Signals, angle outputs

3.2 Laying of the output signal cables

-Note on safety-

• Do not lay together with control lines or lines carrying a high

current.

• Do not lay close to strong electromagnetic fields, e.g. those of transformers,

welding equipment, contactors, motors, etc.

• If the above is unavoidable, the cables must be laid in grounded heavygage

steel conduit.

• At the transducer, lay the cables in a sling in order to prevent vibrationinduced damage to them.

3.3 Placement of conducters in cable

In order to prevent the measurement signal being distorted by the angle pulses,

the corresponding conductors should be separated within the cable.

TQ504 Torque Transducer

6

1

0V

t

2

0V

t

Positive pulse

Option

Pulse 90° phase-shifted with

respect to angle

Example application:

Detection of direction of

rotation (clockwise/counterclockwise)

Page 10

The cable length has virtually no influence on the measurement signal, but in the

case of the angle outputs the external pull-up resistances must be properly

adjusted.

TQ504 Torque Transducer

7

Example: 10-conductor cable

0V

0V

cal.

R

rod

–15V

+15V

V

out

+V

op

10k_

Connection cable

max. 15m

+V

op

Pull-up-resistanceR

R

(kΩ)

10

at n

= 1500 rpm

max

Resistance

1

2 10 1(m)

Cable length

Page 11

4. Mechanical installation of the torque transducer

Transducer with fixed stator:

2 holes are provided in the transducer housing for this purpose.

• Use displaceable couplings as both shaft ends that are capable of

accommodating angular, radial and axial misalignment.

• Good results have been obtained with miniature couplings stiff against torsion

such as those described in data sheet 8303.

At torques of 50 Nm or greater, it is also possible to install the transducer

without fixed stator:

• In this case, use flexible couplings at both ends.

Caution: during installation no impermissibly high torques may be

allowed to arise between the two ends of the torque transducer shaft.

4.1 Suggestions for installation

Transducer with fixed stator and couplings able to accommodate angular, radial

and axial misalignment at both ends.

TQ504 Torque Transducer

8

Coupling able to accommodate radial, angular and

axial misalignment

Shaft Shaft

Torquetransducer

Cable

connection

Attachment

angle

Coupling able to accommodate radial, angular and

axial misalignment

BearingBearing

Page 12

Transducer installed without fixed stator, with flexible coupling at each end.

This type of installation is possible at torques of 50 Nm and greater.

5. Mechanical calibration

To perform this, a calibration setup with lever arm and weights is needed to

create a torque.

Steps for calibration:

a) Apply the rated torque to the transducer, then remove the load again.

b) Precisely adjust the transducer to the zero point.

c) Apply a known torque to the transducer.

d) Set the indicator to the proper value.

Recording of a calibration curve:

a) Calibrate the transducer as described above.

b) Progressively apply greater torques to the transducer in steps of 1/10 up to

the full rated torque. Then gradually remove the torque in the same way. At

each step, wait at least 30 seconds for the torque reading to stabilize, and then

record.

TQ504 Torque Transducer

9

Torquetransducer

Bearing

Shaft Shaft

Flexible coupling

Cable

connection

Bearing

Page 13

5.1 A simple calibrating setup

5.2 Sample calculation of lever arm length

TQ504 Torque Transducer

10

L=

Mt

m - g

eg. m = 1 kg. Mt = 10 Nm

L=

10Nm sec

2

1 kg _ 9.80665

= 1,0197 m

Lever arm

KK

Lever arm

bearing

K = coupling able to accommodate

axial and radial misalignments

Countersupport

Lever armTorque transducer

Bearing for lever

arm (double

bearing)

Weight

(calibrated)

Mt = torque

L = required lever arm length

m = required mass

g = 9.80665 m/sec2 - normal gravitational

acceleration (varies slightly from place to place)

Mt

M

L

Page 14

5.3 Electrical calibration

A calibration control facility is integrated in the transducer to permit electrical

calibration.

Procedure for electrical calibration:

• Remove all mechanical loads from the transducer (no torque).

• Apply the calibration voltage Vc to pin K referenced to pin E.

• An output signal corresponding to the rated torque will be emitted.

6. Maintenance

• Type IE transducers require virtually no maintenance.

• The service life expectancy of the bearings within the rated temperature range

is approx. 20,000 hours.

• The service life expectancy of the bearing within the operating temperature

range is approx. 10,000 hours.

• The bearings can only be replaced in the factory.

• For high-precision applications: recalibrate the transducer once annually

(calibration at the factory or using an appropriate calibration setup).

• Once a month, check the cable connectors to make sure that they are securely

seated.

• Check the cables for damage once a month.

TQ504 Torque Transducer

11

5V

CAL

+Vs

GND

Transducer

+5V

Page 15

7. Troubleshooting guide for transducer shaft

TQ504 Torque Transducer

12

Problem Probable causes Remedial action

Shaft does not rotate

Bearings are defective due to:

freely

a) Torsional or flexional vibrations

b) Excessive axial or radial loads Return to factory

c) Old or soiled bearings

d) Bent shaft

Zero point displacement Rotational vibration Readjust zero point on

≤ 2 % Shock forces instrument amplifier

Zero offset between 2%

Transducer has been overloaded The zero point can be

and 5% of range

Shock forces recalibrated once at

Rotational vibration the instrument amplifier

Transducer has

Transducer has been overloaded

hysteresis between

by changing loads or rotational Return to factory

clockwise and counter-

Rotation vibration

clockwise torque

Page 16

NOTES:

TQ504 Torque Transducer

13

Page 17

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

ARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2002 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

Page 18

M2958/0602

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...