Page 1

Operating Instructions

Rotary Torque Transducer

Model TQ 503 (with standard square connections)

Model TQ 503 X (including rangle measurement)

Model TQ 503 R (with shaft ends)

Operating Instructions no. 1333

Model TQ 503

Operating Instructions no. 1333

Page 1 / 17

Page 2

Contents

1. Contents

2. Application and key features

3. Description

3.1 Mechanical design

3.2 Electrical design

3.3 Rotation angle measuring system (only version X)

4. Electrical connections

4.1 Description of interfaces

4.2 Installing the signal lead

5. Using the torquemeter

5.1 Version Q, X

5.2 Version R

6. Static calibration

6.1 Making a simple calibration device

6.2 Calculation example for lever arm length

7. Maintenance

8. Repairs

See datasheet for technical details.

Operating Instructions no. 1333

Page 2 / 17

Page 3

2. Application and key features

· Torquemeter with strain gauges

· Signal transfer by sliprings

· Measurement of constant and variable torque

· Measurement of torque from the rotating shaft

· Integrated system for rotation angle measurement (only version X)

· Suitable for laboratory use and quality control

· Ideal for use with power tools

· Primarily suitable for low speed ranges

· Suitable for momentary measurement of torque (intermittent duty)

Operating Instructions no. 1333

Page 3 / 17

Page 4

3. Description

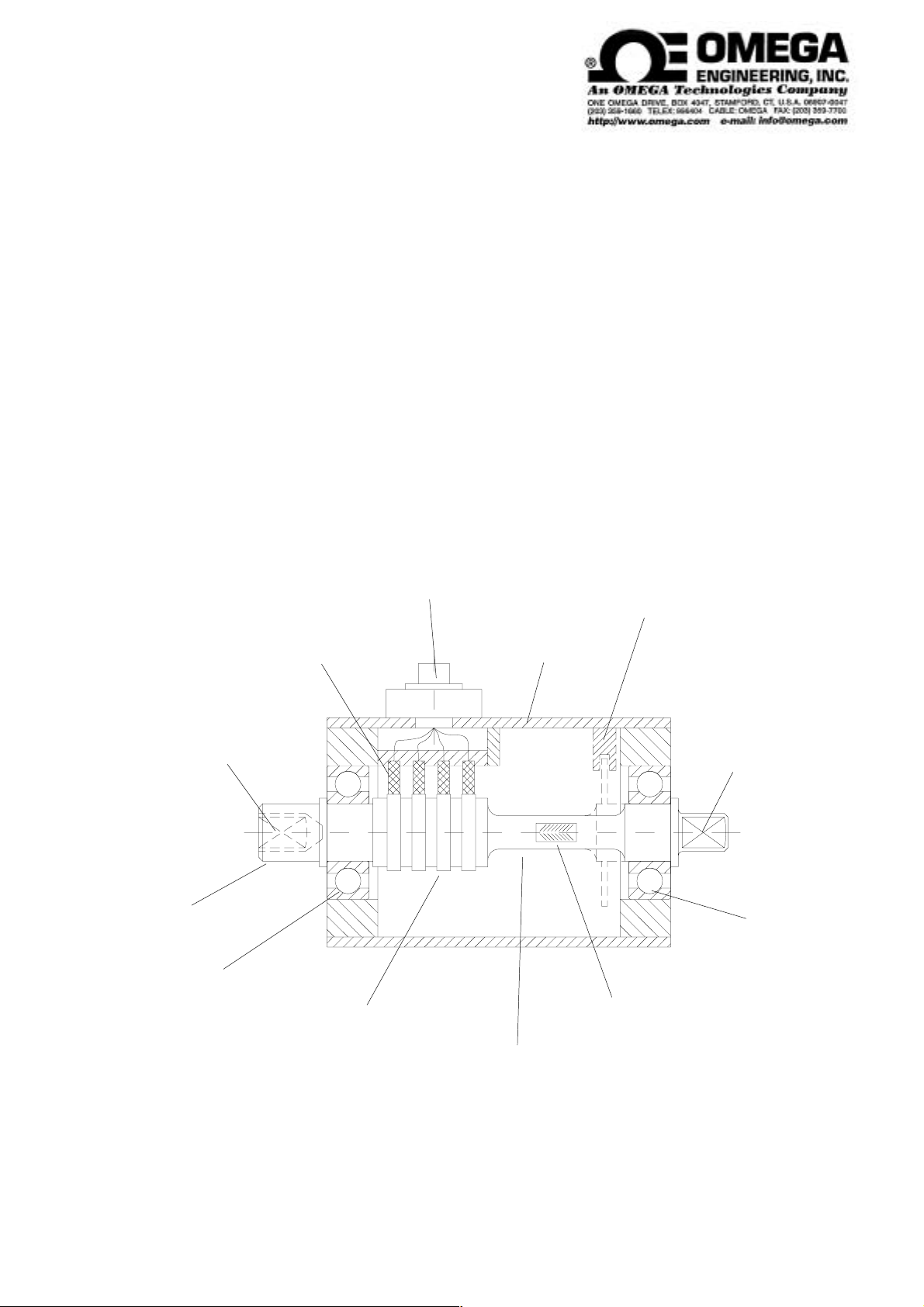

3.1 Mechanical design

Torquemeters type SD comprise a rotating shaft mounted on bearings inside a housing. The shaft has a

necked section - called the torsion zone - to which strain gauges are attached and connected in a full

bridge circuit. Sliprings and brushes provide the link between rotor and housing with two sliprings

carrying the electric power supply to the strain gauges on the rotating shaft. Two other sliprings serve to

transfer the measuring signals from the rotating shaft to the stationary housing. The full bridge circuit is

connected directly through the sliprings and brushes to the lead connector which is mounted on the

housing of the torquemeter.

In version X torquemeters an optical rotation angle measurement system is integrated. It consists of a

pulse disk on the rotating shaft with 360 light-dark stripes. Two light barriers are installed into the stator.

Inside the torquemeter there is a small electronics for processing of the angle pulses.

Square socket

(version Q / X)

or hexagon socket

(version H)

or shaft end with

feather key slots

(version R)

Shaft

Bearing

Brushes

Slip rings

Lead connector

Rotation angle

measuring system

(only version X / HA)

Housing

Square end

(version Q / X)

or hexagon end

(version H)

or shaft end with

feather key slots

(version R)

Bearing

Strain gauges

Torsion zone

Operating Instructions no. 1333

Page 4 / 17

Page 5

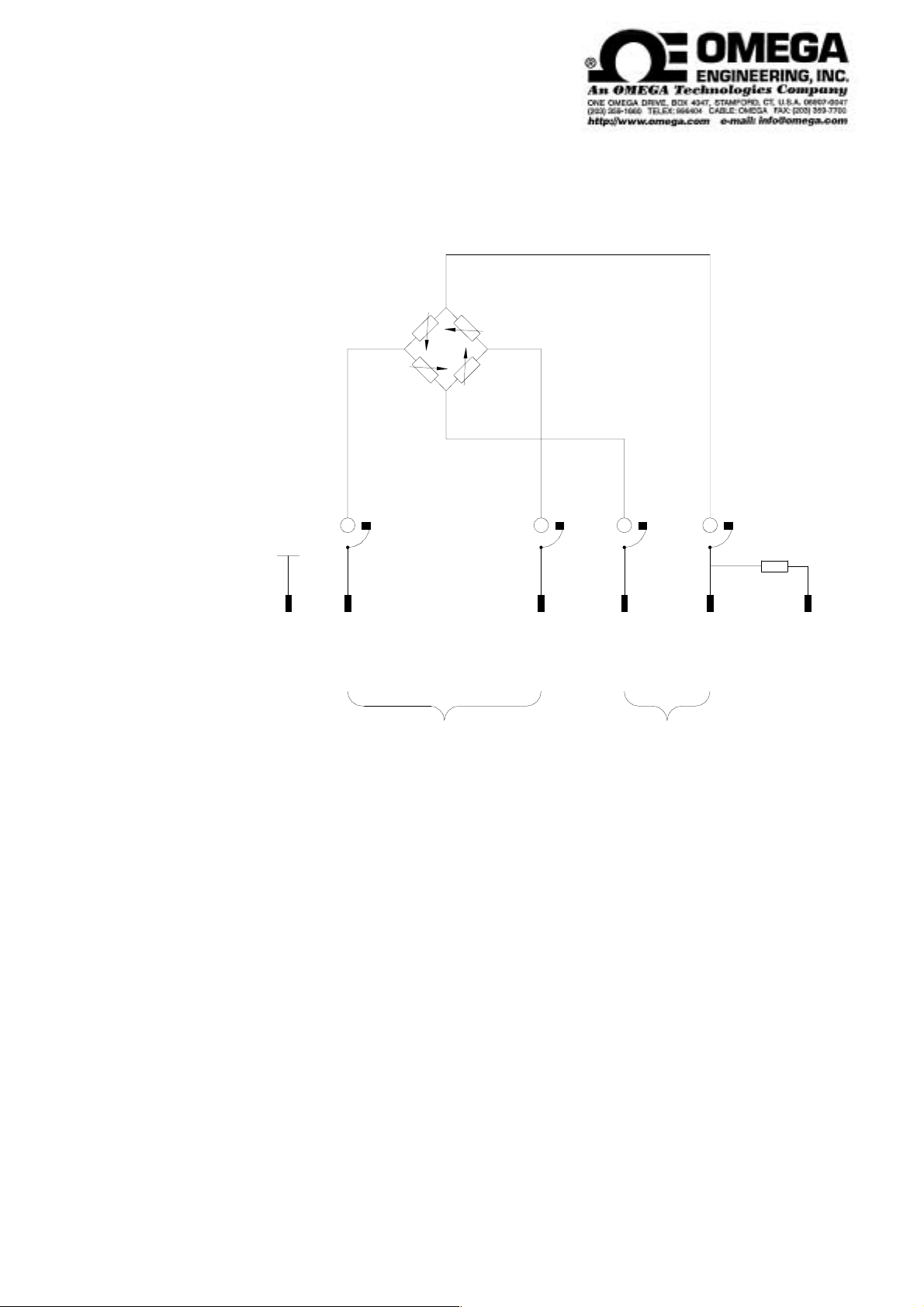

3.2 Electrical design

Shield

R4R3

R2 R1

S4S3S2S1

Version Q, R, H:

Version QA:

Version H

(special design):

U

B

R1 ... R4 = Gauges for measuring mechanical strain

S1 ... S4 = Sliprings with brushes

Signal leads

654213

KDCBAM

FDCBAE

Calibration

voltage

Operating Instructions no. 1333

Page 5 / 17

Page 6

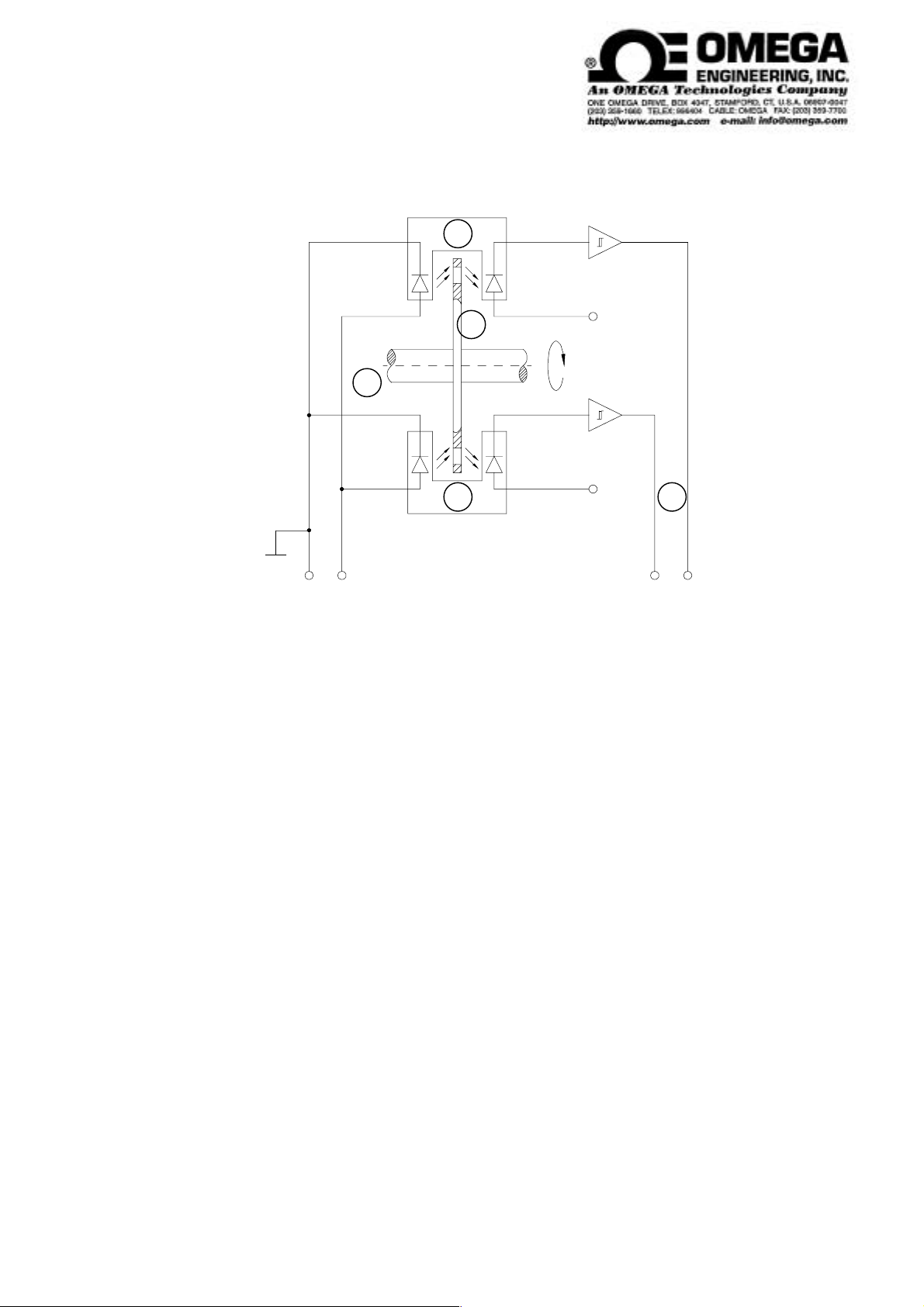

3.3 Rotation angle measuring system (only version X)

3

2

1

3

+5V0V

FEHG

Diagram showing the design of the rotation angle measuring system

1 rotating shaft

2 pulse disk

3 forked light barrier with LED and photo diode

0 V

4

4 operation amplifier

Features

- 360 light-dark stripes on the pulse disk

- two forked light barriers shifted by phase angle 90°

- pulse number proportional to the rotation angle

Operating Instructions no. 1333

Page 6 / 17

Page 7

Adjustment for angle-pulse output (only version X)

with drive on square socket

sense of rotation cw

Output Pin G

Output Pin H

Label M for

Measuring side.

Side with bearings

W

drive side

View W:

Size RSize Q/R

Sense of rotation

Operating Instructions no. 1333

Page 7 / 17

Page 8

4. Electrical connections

Lead connector

Shielded

lead

To power supply unit and display

Torquemeter (all versions)

Shielded lead of 0,25 mm² (version X: 0.14 mm²) cross section

Factory-calibrated with 5 m of lead. A change in length of 2.5 m will cause an error of

approximately 1 %

Operating Instructions no. 1333

Page 8 / 17

Page 9

4.1 Description of interfaces

E

ADF

Versions Q / R / H:

Function Pin Description Top view built-in plug

- Power supply 1 e.g. -6 V DC

+ Power supply 2 e.g. +6 V DC

Shield 3 not connected

+ Signal 4 2 mV/V approx. 350 W *)

- Signal 5 2 mV/V approx. 350 W *)

- Power supply 6 100% calibration

(Calibration voltage) causes 100% signal

Version X:

Function Pin Description Top view built-in plug

- Power supply A Strain gauge full bridge

+ Power supply B

+ Signal C

- Signal D

0 V E Rotation angle pulses

+ 5 V ± 10 % F

Pulse l, leading, TTL G

Pulse r, lagging, TTL H

0 V I

- Power supply K 100% calibration

(Calibration voltage) causes 100% signal

Shield M not connected

Version H (special design):

Function Pin Description Top view built-in plug

+ Power supply A e.g. +6 V DC

- Power supply B e.g. -6 V DC

- Signal C e.g. 2 mV/V approx. 350 W *)

+ Signal D e.g. 2 mV/V approx. 350 W *)

Shield E not connected

- Power supply F 100% calibration

(Calibration voltage) causes 100% signal

B

C

*) customized, see calibration certificate

Operating Instructions no. 1333

Page 9 / 17

Page 10

4.2 Installing the signal lead

Do not run the lead parallel to power cables or control circuits.

Do not place the lead close to equipment producing strong electromagnetic fields,

e.g. transformers, welders, contactors, electric motors, etc.

If such situations cannot be avoided, run the lead inside earthed steel conduit.

Make a loop in the lead when fixing it at the torquemeter so that it is not damaged by vibration.

Operating Instructions no. 1333

Page 10 / 17

Page 11

5. Using the torquemeter

5.1 Versions Q, X and H

Torquemeters of version Q and X have square connections for plug-in tools acc. to DIN 3121

Torquemeter of version H have hexagon connections acc. to DIN 3126, form E/F.

The torquemeters are plugged on to the drive spindle as shown below.

Application examples:

motor /

el. or pneum.

wrench

Lead

connector

Torquemeter

Type SD

Versions Q / X Version H

Lead

connector

socket spanner / bit

Operating Instructions no. 1333

Page 11 / 17

Page 12

5.2 Version R

The torquemeter is adapted to th measuring application by couplings.

For a free floating installation we recommend two torsioally rigid half couplings.

Application example:

Torquemeter

Motor

Test

specimen

Operating Instructions no. 1333

Page 12 / 17

Page 13

6. Static calibration

This procedure requires the use of a calibration device with a lever arm and weights for producing

specific values of torque.

The calibration procedure is as follows:

a) Apply the rated value of torque to the torquemeter and then remove it again.

b) Adjust the zero reading accurately.

c) Apply a known value of torque to the torquemeter.

d) Adjust the displayed reading to the corresponding value.

Plotting a calibration curve

a) Calibrate the torquemeter as described above.

b) Apply torque in 1/10 steps up to the full rated value and then remove it again in the same way.

A delay of at least 30 seconds must be allowed between the individual 1/10 steps so that each

reading can stabilize before it is recorded.

Operating Instructions no. 1333

Page 13 / 17

Page 14

6.1 Making a simple calibration device

Torquemeter

Lever armLever arm

KK

Lever arm

bearing

K = Loose half-couplings

Counter bearing Lever arm bearing

(duplex)

Weight

(calibrated)

Operating Instructions no. 1333

Page 14 / 17

Page 15

6.2 Calculation example for lever arm length

Mt

L=

m x g

Mt = Torque

L = Length of lever arm required

m = Mass required

g = 9.80665 m/s² (= standard gravity - varies with location)

Mt

Example: m= 1 kg

Mt = 10 Nm

10 Nm s

2

è L = = 1,0197 m

1 kg x 9,80665 m

m

L

Operating Instructions no. 1333

Page 15 / 17

Page 16

7. Maintenance

Gradual wear of the brushes and sliprings produces an electrically-conductive dust inside the

torquemeter which might cause an electrical short between the sliprings and cause instability of

the zero reading during rotation. Therefore, it is important to clean the torquemeter regularly.

The recommended cleaning cycle is approximately 106 revolutions

In order to clean the interior, loosen the 4 fixing screws and remove the cover plate

Use a soft linen cloth, a fine hair brush or oil-free compressed air to clean the dust from the

sliprings and the spaces between them

Carefully clean the brushes and the plastic part with the springs using a hair brush or oil-free

compressed air

Version X: Be careful when cleaning, do not scratch the pulse wheel.

Also clean the lead connector

Measure the brush thickness; it should be more than 0.5 mm. New brushes can only be fitted at

the factory.

Replace the cover plate carefully and re-tighten the fixing screws

Check the torquemeter:

Zero reading stable during rotation.

Produce a torque by twisting the meter by hand and note the reading.

If the torquemeter is used for precision work it should be recalibrated every year (either at the

factory or by means of a suitable calibration device)

Operating Instructions no. 1333

Page 16 / 17

Page 17

8. Repairs

Fault Cause Remedy

Shaft stiff to turn Bearing defect due

to:

a) Torsional or

flexural vibration

b) High axial or

radial loads

c) Worn bearings

d) Bent shaft

Zero shift less than

2%

Zero shift between

approx. 2 and 5% of

full scale

Hysteresis between

clockwise and

anticlockwise torque

Torsional vibration

Torsional shock

Torquemeter has been

overloaded

Torsional vibration

Torsional shock

Torquemeter overloaded by high

alternating loads or

torsional vibration

Return to factory

The zero reading can

be readjusted at the

display

The zero reading can

be readjusted once at

the display

Return to factory

Zero unstable during

rotation

Angle pulses roll out

(only version X)

Sliprings and/or

brushes dirty

Pulse disk and optical sensor

are soiled by coal dust

Operating Instructions no. 1333

Open and clean the

torquemeter

(see section 7)

Clean carefully

Page 17 / 17

Loading...

Loading...