Page 1

®

®

User’s Guide

Shop online at

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

MADE IN UNITED KINGDOM

®

OS150 USB

IR Temperature Sensors

Page 2

®

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

Servicing North America:

U.S.A.:

ISO 9001 Certified Stamford CT 06907-0047

Canada: 976 Bergar

One Omega Drive, Box 4047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

Customer Service: 1-800-622-2378/1-800-622-BEST

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

Mexico:

En Espan˜ol: (001) 203-359-7803

FAX: (001) 203-359-7807

e-mail: espanol@omega.com

info@omega.com.mx

®

®

®

Servicing Europe:

Benelux: Managed by the United Kingdom Office

Czech Republic:

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

It is the policy of OMEGA Engineering, Inc.to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European

New Approach Directives. OMEGA will add the CE mark to every appropriate device upon

certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Toll-Free: 0800 099 3344TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omegaeng.nl

Frystatska 184, 733 01 Karvina´ , Czech Republic

Tel: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Tel: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

Page 3

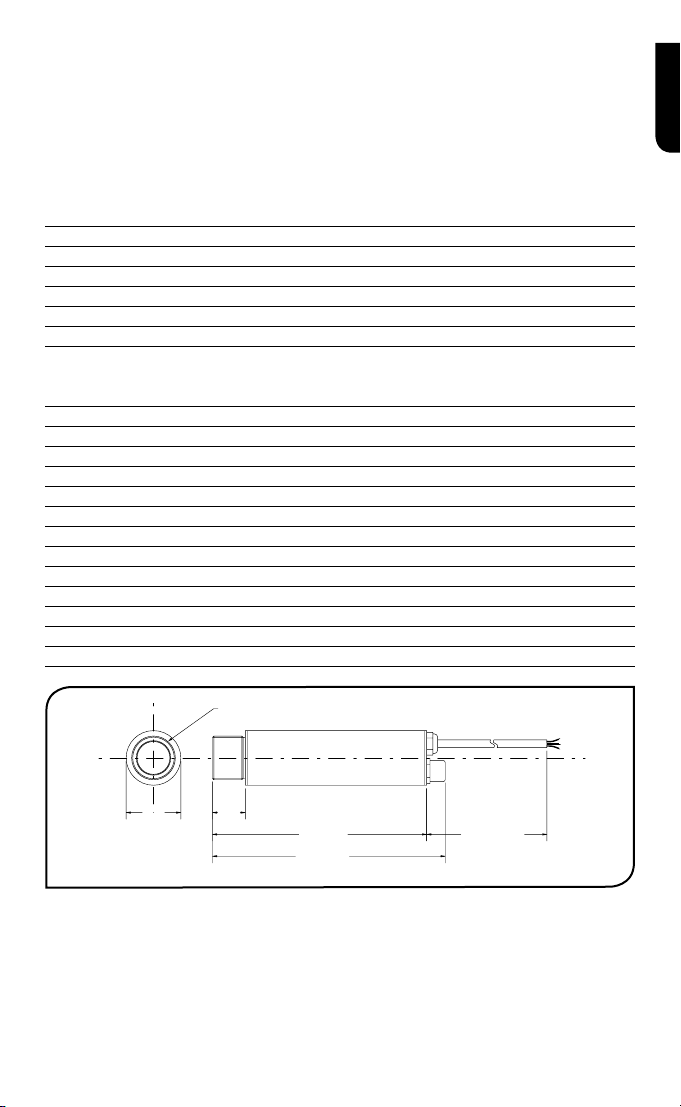

OS150-USB Series non-contact infrared sensors measure temperatures from -40°C to

3.8 (98.0)

4.2 (106.5)

0.6

(15.0)

1.0 (25.0)

M20 x 1mm

36.0 (1000.0)

(standard length)

1000°C and provide a linear 4 to 20mA output. The 2-wire signal is compatible with

almost any indicator, controller, recorder, data logger etc., without the need for special

interfacing or signal conditioning. They are suitable for most materials such as food,

paper, textiles, plastics, leather, tobacco, pharmaceuticals, chemicals, rubber, coal and

asphalt.

Specification

GENERAL

Temperature Range -40°C to 1000°C

Output 4 to 20mA

Accuracy ±1% of reading or ±1°C whichever is greater

Repeatability ±0.5% of reading or ±0.5°C whichever is greater

Emissivity adjustable 0.1 to 1.0

Response Time 240ms (95% response)

Field-of-View 15:1 (OS151-USB)

30:1 (OS301-USB)

ø5mm@100mm (OS801-USB)

Spectral Response 8 to 14µm

Supply Voltage 24Vdc (28Vdc max.)

Sensor Voltage 6Vdc min.

Maximum Loop Impedance 900 Ohms

MECHANICAL

Construction Stainless Steel

Dimensions 25mm diameter x 106.5mm

Cable Length 1m

Weight with Cable 170g

ENVIRONMENTAL

Environmental Rating IP65

Ambient Temperature Range 0°C to 70°C

Relative Humidity 95% maximum non-condensing

english

acceSSorieS

A range of accessories to suit different applications and industrial environments is available. These may be ordered at any time and added on-site. The accessories consist

of the following parts .

Fixed mounting bracket

Adjustable mounting bracket

Air purge collar

Laser sighting tool

›

3

Page 4

optionS

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

15

32

48

0.6

1.2

1.9

0 19.7 39.4

0 500 1000

Spot Dia.

(inches)

Spot Dia.

(mm)

Spot Dia.

(inches)

Spot Dia.

(mm)

Spot Dia.

(inches)

Spot Dia.

(mm)

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

15

48

82

0.6

1.9

3.2

0 19.7 39.4

0 500 1000

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

15

5

15

0.6

0.2

0.6

0 3.9 7.9

0 100 200

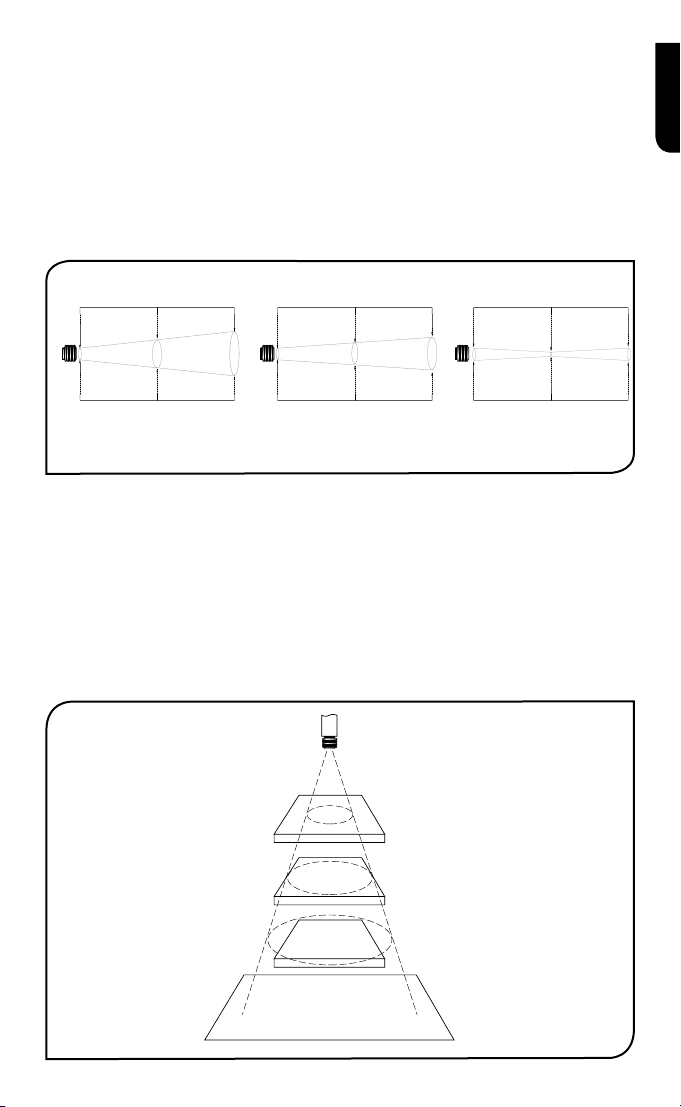

D:S 30:1D:S 15:1

Sensor

BEST

GOOD

INCORREC

Background

Target greater

than spot size

Target equal to

spot size

Target smaller

than spot size

The following options are available. Options are factory installed and must be ordered

english

with the OS150-USB sensor.

Air/water cooled housing

Certificate of calibration

Longer cable (30 m max.)

optical cHart

The optical chart below indicates the nominal target spot diameter at any given distance from the sensing head and assumes 90% energy.

OS151-USB OS301-USB OS801-USB

inStallation

The installation process consists of the following stages:

Preparation

Mechanical installation

Electrical installation

Please read the following sections thoroughly before proceeding with the installation.

preparation

Ensure that the sensor is positioned so that it is focused on the target only.

4

›

T

Page 5

DISTANCE AND SPOT SIZE

12.0

45.0

50.0 50.0

40.0

9.0

15.0

25.0 25.0

Ø20.0

60° Rotation 60° Rotation

60° Rotation

9.0

48.0

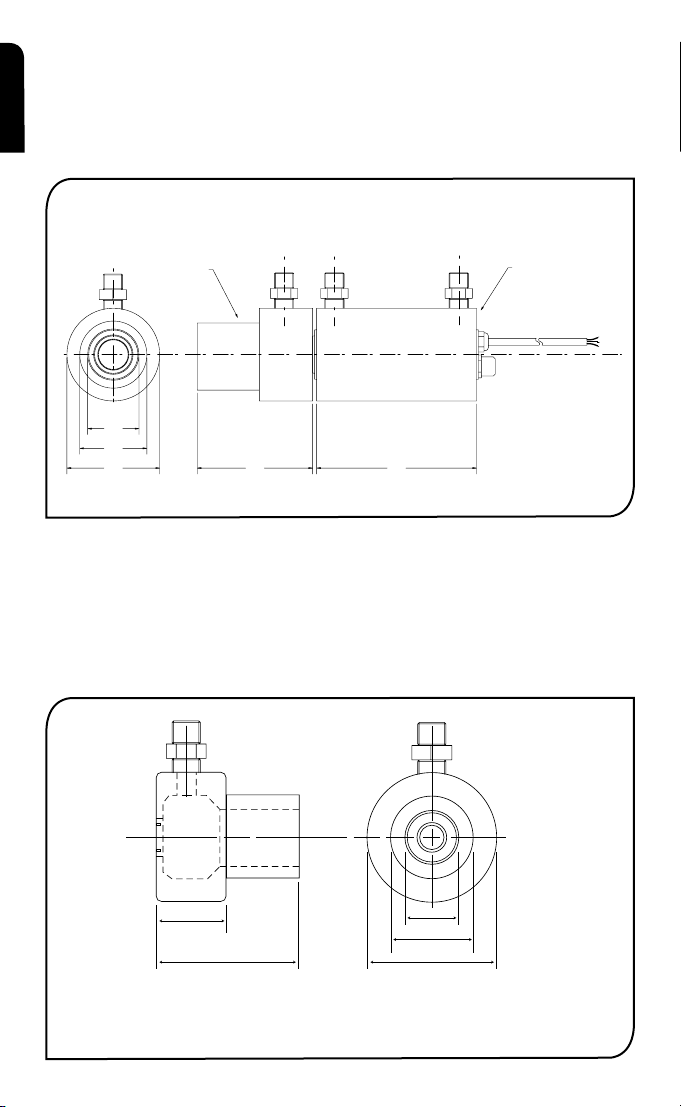

Fixed Bracket (FBL) Adjustable Bracket (ABL)

2 x Mounting Holes M4 Clearance 2 x Mounting Holes M4 Clearance

9.0

24.024.0

The size of the area (spot size) to be measured determines the distance between the

sensor and the target. The spot size must not be larger than the target. The sensor

should be mounted so that the measured spot size is smaller than the target.

AMBIENT TEMPERATURE

The sensor is designed to operate in ambient temperatures from 0°C to 70°C. For

ambient temperatures above 70°C, an air/water-cooled housing will be required.

Avoid thermal shock. Allow 20 minutes for the unit to adjust to large changes in ambient temperature.

ATMOSPHERIC QUALITY

Smoke, fumes or dust can contaminate the lens and cause errors in temperature

measurement. In these types of environment the air purge collar should be used to

help keep the lens clean.

ELECTRICAL INTERFERENCE

To minimise electromagnetic interference or ‘noise’, the sensor should be mounted

away from motors, generators and such like.

WIRING

Check the distance between the sensor and the indicating/controlling device. If necessary, the OS150-USB sensor can be ordered with a longer cable attached.

POWER SUPPLY

Be sure to use a 24Vdc (22mA) power supply.

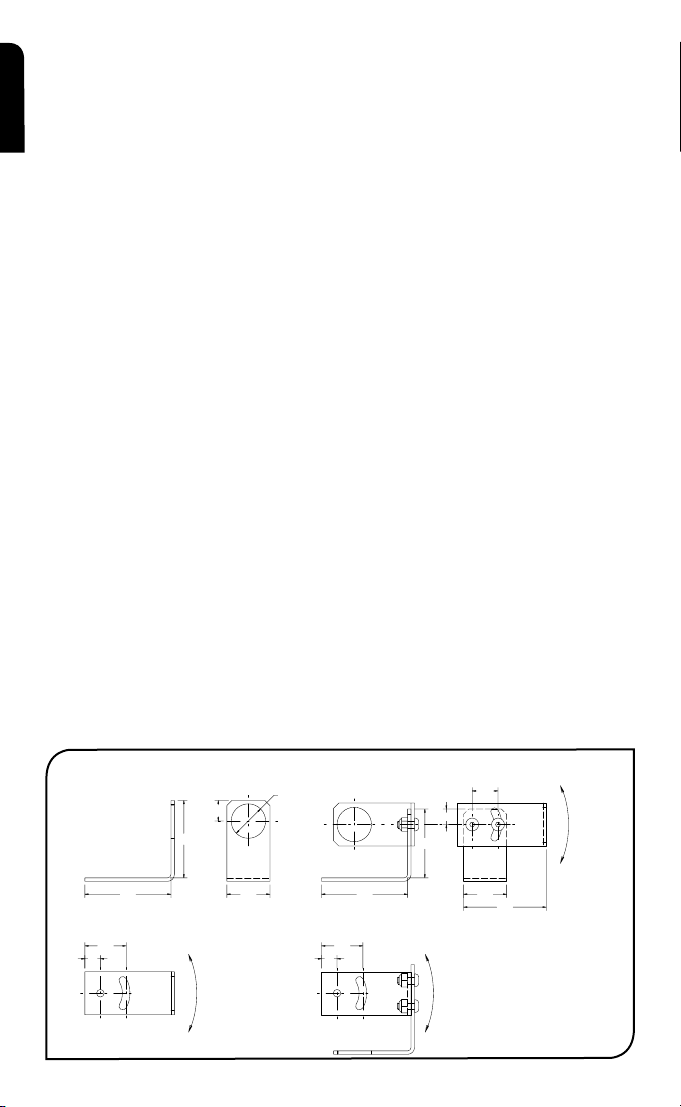

mecHanical inStallation

All sensors come with a 1m cable and a mounting nut. The sensor can be mounted

on brackets or cut outs of your own design, or you can use the fixed and adjustable

mounting bracket accessories which are shown below.

english

›

5

Page 6

AIR/WATER COOLED HOUSING

26.0

34.0

47.0 58.5 81.0

1/8 BSP Water/Air Connections

Air Purge Collar

Water/Air Cooling Jacket

1/8 BSP Air connection

27

58.5

26

34

47

The air/water cooled housing shown below allows the sensor to withstand high ambient

english

temperatures. It is equipped with two 1/8” BSP fittings. Water temperature should be 10°C

to 27°C for efficient cooling. Chilled water below 10°C is not recommended. To avoid

condensation, the air purge collar should be used with the water-cooled housing. Water

flow rate should not be more than 0.5 to 1.5 litres/min.

AIR PURGE COLLAR

The air purge collar below is used to keep dust, fumes, moisture, and other contaminants away from the lens. It must be screwed in fully. Air flows into the 1/8” BSP fitting

and out of the front aperture. Air flow should be no more than 5 to 15 litres/min.

Clean or ‘instrument’ air is recommended.

6

›

Page 7

electrical inStallation

+-

-

+

Display/

Controller

Red

Black

(Blue)

Power Supply

+-

-

+

Display/

Controller

Red

Black

(Blue)

Power Supply

PC

PC

N/C

USB

USB

The sensor to electronics cable is a 1m, PVC cable. One end is attached, at the factory,

to the sensor head. The other end has a pair of wires and a shield (ground) wire.

WIRING

The OS150-USB sensor can be used in 3 different ways as shown below. To use the

4-20mA output, connect the OS150-USB sensor to the controller/indicator with the

24Vdc power supply in the loop using the following table and connection diagram as

a guide. The maximum loop impedance is 900 ohms. Note: The OS150-USB sensor

must be grounded at only one point, either the cable shield or the sensor housing.

Output Wire No. Wire Colour Function

4 to 20mA 1 Red Power supply + / signal +

2 Black (Blue) Power supply - / signal 3 Bare Shield ground

Alternatively, to use the USB output, connect the OS150-USB sensor to a PC using

the cable provided. No external power supply is required when using the USB output.

The OS150-USB sensor can also be used with both the 4-20mA loop and USB connected, provided that the negative terminal of the 24Vdc power supply being used is

not grounded. Note: The OmegaSoft software must be installed before connect-

ing the sensor to a PC.

english

›

7

Page 8

omegaSoft Software

SYSTEM REQUIREMENTS

english

• OmegaSoft software is designed to run under Windows. Suitable versions are

Windows 2000, Windows XP, Windows Vista and Windows 7.

• The recommended minimum computer specification is:

Intel Pentium processor

VGA display with 640x480 resolution

USB 2.0 port

INSTALLATION

1. Insert the disk provided

2. Installer should run automatically (if not, select the appropriate drive and double click

on Setup.exe)

3. Follow the on-screen instructions

NOTE Do not connect the OS150-USB Sensor to the PC before the software is

installed

CONNECTING THE OS150-USB SENSOR TO A PC

1. Connect the circular connector on the USB cable provided to the OS150-USB sensor

2. Connect the USB A connector on the USB cable provided to an available USB 2.0

port

3. Double click on the OmegaSoft desktop icon

NOTE Do not disconnect the USB cable before closing down the OmegaSoft

program

configuration

• Setting Temperature Units

Temperature units can be set on the main temperature panel by pressing °C or °F.

• Setting Output Processing

The temperature range for the 4 to 20mA output, the averaging period and the peak/

valley hold processing can be set by using the main program menu to select:

[Setup] → [Output Processing]

The temperatures corresponding to 4 and 20mA can then be set (minimum –40°C,

maximum 1000°C, minimum span 100°C, maximum span 1000°C).

To minimise the the effects of temperature fluctuations, noise etc on the output

signal, the averaging period can be set between 0 and 60 seconds.

If required, Hold Processing can be applied by setting hold mode to Peak Hold or

Valley Hold and setting a hold period between 0 and 1200 seconds.

• Setting Target Emissivity

To set an Emissivity value for the OS150-USB Sensor, use the main program menu

to select:

[Setup] → [Emissivity]

Emissivity can then be set to a value between 0.1 and 1.0, or selected from a pre-

set list of materials by selecting [Data].

8

›

Page 9

• Setting Reflected Temperature Compensation

To enable and set reflected temperature compensation, use the main program menu

to select:

[Setup] → [Reflection Compensation]

Reflected temperature compensation can be enabled/disabled using [Compensate

for Reflected Temperature], and when enabled the temperature value can be set

between -40 and 1000°C.

operation

Once the sensor is in position and the appropriate power, air, water, and cable connections are secure, the system is ready for continuous operation by completing the

following simple steps:

1. Turn on the power supply

2. Turn on the instrument or PC

3. Read / monitor the temperature

IMPORTANT

Be aware of the following when using the sensor:

• If the sensor is exposed to significant changes in ambient temperature (hot to cold,

or cold to hot), allow 20 minutes for the temperature to stabilise before taking or

recording measurements.

• Do not operate the sensor near large electromagnetic fields (e.g. around arc welders

or induction heaters).

Electromagnetic interference can cause measurement errors.

• Wire must be connected only to the appropriate terminals.

maintenance

Our customer service representatives are available for application assistance, calibration, repair, and solutions to specific problems. Contact our Service Department before

returning any equipment. In many cases, problems can be solved over the telephone.

If the sensor is not performing as it should, try to match the symptom below to the

problem. If the table does not help, call Omega for further advice.

english

TROUBLESHOOTING

Symptom Probable Cause Solution

No output No power to sensor Check power supply

Erroneous temperature Incorrect wire connection Check wire colour codes

Erroneous temperature Faulty sensor cable Verify cable continuity

Erroneous temperature Field of view obstruction Remove obstruction

LENS CLEANING

Keep the lens clean at all times. Any foreign matter on the lens would affect measurement accuracy. Blow off loose particles (if not using the air purge accessory) with an

air ‘puffer’.

›

9

Page 10

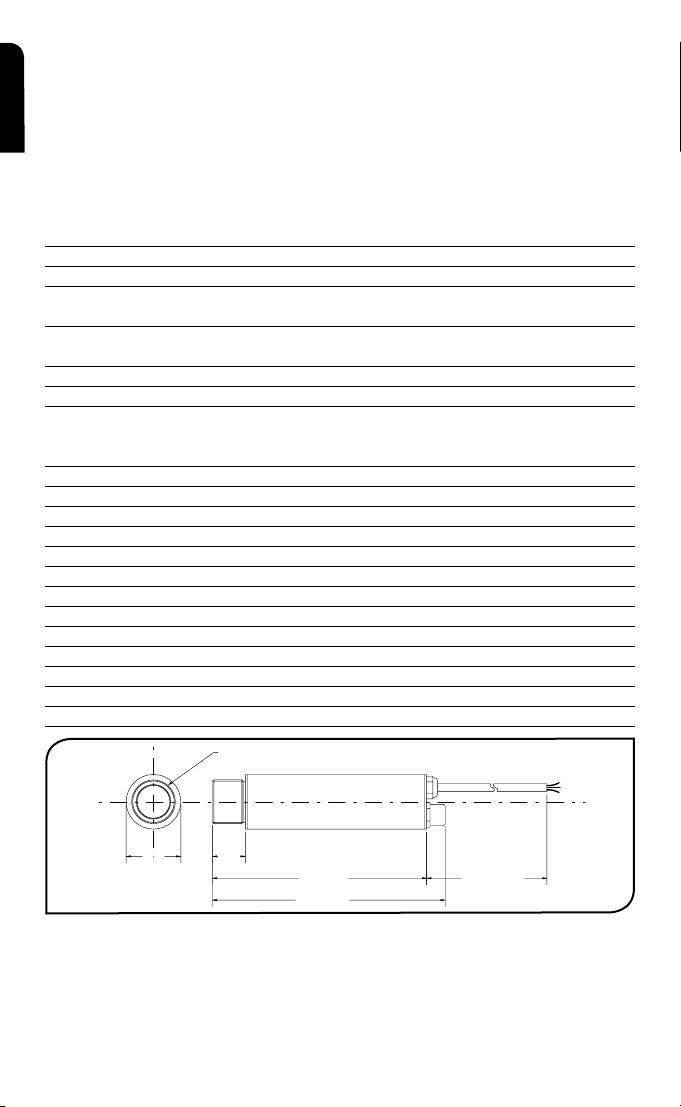

La série OS150-USB des détecteurs à infrarouge sans contact mesure les tempéra-

3.8 (98.0)

4.2 (106.5)

0.6

(15.0)

1.0 (25.0)

M20 x 1mm

36.0 (1000.0)

(standard length)

tures de -40°C à 1000°C et fournit une sortie linéaire de 4 à 20mA. Le signal bifilaire

français

est compatible avec presque tous les indicateurs, contrôleurs, enregistreurs, consignateurs de données, etc., sans avoir besoin d’interfaces ou de conditionnements de

signal particuliers. Ils conviennent à la plupart des matériaux tels que la nourriture, le

papier, les textiles, les plastiques, le cuir, le tabac, les produits pharmaceutiques, les

produits chimiques, le caoutchouc, le charbon et l’asphalte.

SpécificationS

GÉNÉRALES

Echelle de température -40°C à 1000°C

Sortie 4 à 20mA

Précision ± 1% de la mesure ou ± 1°C, celui qui est le

plus important

Fidélité ± 0,5% de la mesure ou ± 0,5°C, celui qui est

le plus important

Emissivité réglable de 0,1 à 1,0

Temps de réponse 240ms (réponse 95%)

Champ de visée 15:1 (OS151-USB)

30:1 (OS301-USB)

ø5mm@100mm (OS801-USB)

Réponse spectrale 8 à 14µm

Voltage d’alimentation 24V cc (max. 28V cc)

Voltage du détecteur Min. 6V cc

Impédance en boucle maximale 900 Ohms

MÉCANIQUES

Construction Acier inoxydable

Dimensions 25mm diamètre x 106.5mm

Longueur du câble 1m

Poids avec câble 170g

ENVIRONNEMENTALES

Catégorie environnementale IP65

Echelle de température ambiante 0°C à 70°C

Humidité relative Maximum 95% non condensée

acceSSoireS

Une gamme d’accessoires pour convenir aux différentes applications et environnements industriels est disponible. Les accessoires peuvent être commandés à tout

moment et ajoutés sur place. Ils consistent en :

Un support de fixation fixe

Un support de fixation réglable

Un collier de purge d’air

Outil de visée laser

10

›

Page 11

Détecteur

LE MEILLEUR

BON

PAS BON

Fond

Cible plus grand

que la grandeur

du point

Cible même

grandeur que

le point

Cible plus petit

que la grandeur

du point

optionS

Distance : Détecteur / objet (inches)

Distance : Détecteur / objet (mm)

15

32

48

0.6

1.2

1.9

0 19.7 39.4

0 500 1000

Diamètre

du point

(inches)

Diamètre

du point .

(mm)

Diamètre

du point

(inches)

Diamètre

du point .

(mm)

Diamètre

du point

(inches)

Diamètre

du point .

(mm)

Distance : Détecteur / objet (inches)

Distance : Détecteur / objet (mm)

15

48

82

0.6

1.9

3.2

0 19.7 39.4

0 500 1000

Distance : Détecteur / objet (inches)

Distance : Détecteur / objet (mm)

15

5

15

0.6

0.2

0.6

0 3.9 7.9

0 100 200

D:S 30:1D:S 15:1

Les options suivantes sont disponibles : Les options sont installées en usine et doivent

être commandées avec le détecteur OS150-USB.

Boîtier refroidi à l’air/eau

Certificat de calibrage

Câble plus long (30 m max.)

taBleau optiQue

Le tableau optique ci-dessous indique le diamètre du point cible nominal à n’importe

quelle distance de la tête de détection et assume 90% d’énergie.

OS151-USB OS301-USB OS801-USB

inStallation

Le processus d’installation consiste aux étapes suivantes :

Préparation

Installation mécanique

Installation électrique

Il faut lire les sections suivantes attentivement avant de commencer l’installation.

français

préparation

S’assurer que le détecteur est mis en place pour qu’il ne se concentre que sur la cible.

›

11

Page 12

DISTANCE ET TAILLE DU POINT

12.0

45.0

50.0 50.0

40.0

9.0

15.0

25.0 25.0

Ø20.0

Rotation 60° Rotation 60°

Rotation 60°

9.0

48.0

Support fixe Support réglable

2 x trous de montage, jeu M4 2 x trous de montage, jeu M4

9.0

24.024.0

La taille de la zone (taille du point) qui doit être mesurée détermine la distance entre le

français

détecteur et la cible. La taille du point ne doit pas être plus grande que la cible. Le

détecteur devrait être monté de façon à ce que la taille du point mesuré est plus petite

que la cible.

TEMPÉRATURE AMBIANTE

Le détecteur est conçu pour fonctionner en températures ambiantes de 0°C à 70°C.

Pour les températures ambiantes supérieures à 70°C, un boîtier refroidi à l’air/eau est

nécessaire.

Eviter les chocs thermiques. Allouer 20 minutes au thermomètre, pour qu’il s’adapte à

d’importantes fluctuations de température ambiante.

QUALITÉ ATMOSPHÉRIQUE

La fumée, les vapeurs ou la poussière peuvent contaminer la lentille et provoquer des

erreurs dans la mesure de température. Dans ces genres d’environnement, le collier

de purge d’air devrait être utilisé pour aider à garder la lentille propre.

INTERFÉRENCE ÉLECTRIQUE

Pour réduire l’interférence électromagnétique ou ‘bruit’, le détecteur devrait être monté

à l’écart de moteurs, générateurs, et autres appareils similaires.

CÂBLAGE

Vérifier la distance entre le détecteur et l’appareil d’indication / de contrôle. Si nécessaire, le détecteur OS150-USB peut être commandé avec un câble attaché plus long.

ALIMENTATION ÉLECTRIQUE

S’assurer qu’une alimentation électrique de 24Vcc (22mA) est utilisée.

inStallation mécaniQue

Tous les détecteurs sont fournis avec un câble d’un mètre et un boulon de fixation. Le

détecteur peut être monté sur un support ou sur des découpes de votre propre conception ou bien les accessoires de support fixe et réglable, qui sont montrés ci-dessous, peuvent être utilisés.

12

›

Page 13

BOÎTIER REFROIDI À L’AIR/EAU

26.0

34.0

47.0 58.5 81.0

1/8 BSP Raccords Air/Eau

Collier de purge d’air

Boîtier refroidi à l’air/eau

27

58.5

26

34

47

1/8 BSP Raccord Air

Le boîtier refroidi à l’air/l’eau montré ci-dessous permet au détecteur de resister à des

temperatures ambiantes élevées. Il est équipé de deux emmanchements de 1/8’’ BSP.

La température de l’eau devrait être entre 10°C et 27°C pour un refroidissement efficace.

L’eau refroidie en dessous de 10°C n’est pas recommandée. Pour éviter la condensation, le collier de purge d’air devrait être utilisé avec le boîtier refroidi à l’eau. Le débit

d’eau ne devrait pas dépasser 0,5 à 1,5 litres/min.

COLLIER DE PURGE D’AIR

Le collier de purge d’air ci-dessous est utilisé pour garder la poussière, les vapeurs,

l’humidité et autres contaminants à l’écart de la lentille. Il doit être entièrement vissé.

L’air s’écoule dans l’emmanchement de 1/8’’ BSP et sort par l’ouverture frontale. Le

débit d’air ne devrait pas dépasser 5 à 15 litres/min.

français

Il est recommandé d’utiliser de l’air propre ou pour les appareils.

13

›

Page 14

inStallation èlectriQue

+-

-

+

Afficheur/

Contrôleur

Rouge

Noir

(Bleu)

Alimentation électrique

+-

-

+

Afficheur/

Contrôleur

Rouge

Noir

(Bleu)

Alimentation électrique

PC

PC

N/C

USB

USB

Le câble du détecteur est un câble en PVC d’1m. Une extrémité est attachée, à

l’usine, à la tête du détecteur. L’autre extrémité a deux câbles et un fil de terre.

français

CÂBLAGE

Il est possible d’utiliser le détecteur OS150-USB de trios façons. Pour utiliser uniquement la sortie 4-20mA, connecter le détecteur OS150-USB à l’afficheur/contrôleur à

l’aide de l’alimentation 24Vdc dans la boucle suivant le tableau et le schema de

câblage ci-dessous. L’impédance de boucle maximale est de 900 ohms. Nota: Il faut

que le détecteur OS150-USB soit connecté à la terre à un seul point, soit au

blindage du câble, soit au boîtier du détecteur.

Sortie No de câble Couleur de câble Fonction

4 à 20mA 1 Rouge Alimentation électrique + / signal +

2 Noir (Bleu) Alimentation électrique - / signal 3 Nu Fil de terre

Pour utiliser uniquement la sortie USB, connecter le détecteur OS150-USB à un PC à

l’aide du cable fourni. Aucune autre source d’alimentation n’est nécessaire lorsque l’on

utilize la sortie USB. On peut également utiliser le détecteur OS150-USB avec la boucle 4-20mA et l’USB connectés, pourvu que la borne negative de l’alimentation 24Vdc

en utilization n’est pas reliée à la terre. Nota: Il faut installer le logiciel Omega avant

de connecter le détecteur à un PC.

14

›

Page 15

omegaSoft Software

SPÉCIFICATIONS DU SYSTÈME.

• Le logiciel OmegaSoft est conçu pour fonctionner sur Microsoft Windows. Les ver-

sions appropriées sont Windows 2000, XP, Vista et 7

• Les spécifications informatiques minimales recommandées sont :

Processeur Intel Pentium

Ecran VGA avec une résolution 640x480

USB 2.0 port

INSTALLATION

1. Insérer le dique fourni

2. Le programme d’installation devrait se mettre en marche automatiquement. (Si ce

n’set pas le cas, sélectionner le lecteur approprié et cliquer sur Setup.exe)

3. Suivre les consignes affichées

NOTA Le détecteur OS150-USB ne doit pas être connecté au PC avant

l’installation du logiciel

CONNECTION DU DÉTECTEUR OS150-USB À UN PC

1. Relier le connecteur circulaire sur le cable USB fourni au détecteur OS150-USB

2. Insérer le connecteur USB A sur le cable USB fourni dans un port USB 2.0 disponible.

3. Double-cliquer sur l’icône OmegaSoft

NOTA Il ne faut pas déconnecter le cable USB avant de fermer le logiciel

OmegaSoft

configuration

• Sélection de l’unité de temperature.

On sélectionne l’unité de temperature en appuyant sur le bouton °C ou °F sur le

console de temperature principal.

• Réglage du traitement de sortie

Les limites de temperature pour la sortie 4 à 20mA, la période de calcul de la moy-

enne ainsi que le traitement de la retenue en crête ou en creux, sont réglés à l’aide

du menu principal en sélectionnant:

[Setup] → [Output Processing]

On peut alors régler les temperatures qui correspondent à 4 et 20mA (minimum

-40°C, maximum 1000°C, étendue minimale 100°, étendue maximale 1000°).

Afin de minimiser les effets des variations de temperature, des interferences et

autres incidents sur le signal de sortie, la période de calcul de la moyenne peut être

réglée entre 0 et 60 secondes.

Si besoin est, le traitement de retenue peut s’effectuer en réglant le mode retenue

à Retenue de la Crête ou Retenue du Creux, et en fixant une période de retenue

entre 0 et 1200 secondes.

• Réglage de l’émissivité de la cible

Pour fixer une valeur d’émissivité pour le détecteur OS150-USB, aller au menu

principal du programme et sélectionner:

[Setup] → [Emissivity]

Il est alors possible de fixer une valeur d’émissivité entre 0,1 et 1,0, ou bien, une

valeur peur être sélectionnée d’une liste de materiel préfixée en sélectionnant

[Data].

• Réglage de la compensation pour la température réfléchie

Pour activer et régler la compensation pour la temperature réfléchie, aller au menu

principal du programme et sélectionner:

15

français

›

Page 16

[Setup] → [Reflection Compensation]

La compensation pour la temperature réfléchie peut être activée/désactivée à l’aide

français

de [Compensate for Reflected Temperature], et, une fois activée, la temperature

peut être réglée entre -40° et 1000°C.

fonctionnement

Une fois que le détecteur est en place et que les connexions appropriées

d’alimentation, d’air, d’eau et de câbles sont bien fixées, le système est prêt pour

fonctionner en continu en complétant les simples étapes suivantes :

1. Mettre en route l’alimentation électrique

2. Mettre en marche l’instrument ou le PC

3. Lire / contrôler la température

IMPORTANT

Il faut faire attention aux suivants lors de l’utilisation du détecteur :

• Si le détecteur est exposé à des changements significatifs de température ambiante

(chaud à froid, ou froid à chaud), avant de prendre ou d’enregistrer des mesures

attendre 20 minutes que la température se stabilise.

• Ne pas faire fonctionner le détecteur près d’importants champs électromagnétiques

(par exemple autour d’un arc de soudage ou d’appareils chauffants à induction).

Des interférences électromagnétiques peuvent provoquer des erreurs de mesure.

• Le câble ne doit être relié qu’à des terminaux appropriés.

entretien

Les représentants du service clientèle sont disponibles pour aider, calibrer, réparer et

résoudre des problèmes particuliers. Contacter le service technique avant de retourner l’équipement. Dans beaucoup de cas, les problèmes peuvent être résolus par

téléphone. Si le détecteur ne fonctionne pas comme il le devrait, essayer de faire correspondre le symptôme ci-dessous au problème. Si le tableau n’aide pas, appeler

Omega pour plus de renseignement.

DIAGNOSTIC DE DÉFAILLANCES

Symptôme Cause probable Solution

Pas de sortie Pas d’alimentation au détecteur Vérifier l’alimentation

électrique

Température erronée Connexion incorrecte du câble Vérifier les codes de couleurs

du câble

Température erronée Câble du détecteur défaillant Vérifier la continuité du câble

Température erronée Obstruction champs de vue Retirer l’obstruction

NETTOYAGE DE LA LENTILLE

Garder la lentille propre à tout moment. Toute matière étrangère sur la lentille affecterait

la précision de la mesure. Souffler les particules libres (si l’accessoire de purge d’air

n’est pas utilisé) avec un ‘soufflet’.

16

›

Page 17

Die OS150-USB-Serie kontaktfreier Infrarotsensoren misst Temperaturen zwischen

3.8 (98.0)

4.2 (106.5)

0.6

(15.0)

1.0 (25.0)

M20 x 1mm

36.0 (1000.0)

(standard length)

-40°C und 1000°C und liefert eine lineare 4 – 20mA Leistung. Das über 2 Drähte

geleitete Signal ist mit fast jedem Anzeigegerät, Controller, Aufnahmegerät,

Messwerterfassungsgerät usw. kompatibel. Eine besondere Schnittstelle oder

Signalverarbeitung ist nicht erforderlich. Die OS150-USB-Sensoren sind für die

meisten Materialien wie Nahrungsmittel, Papier, Textilien, Kunststoffe, Leder, Tabak,

Arzneimittel, Chemikalien, Gummi, Kohle und Asphalt geeignet.

Spezifikation

ALLGEMEIN

Temperaturbereich -40ºC bis 1000ºC

Leistung 4 bis 20mA

Messunsicherheit ±1% des Messwerts oder ±1ºC (je nachdem,

welcher Wert größer ist)

Wiederholgenauigkeit ±0,5% des Messwerts oder ±0,5ºC (je nachdem,

welcher Wert größer ist)

Emissionsvermögen regulierbar von 0,1 bis 1,0

Reaktionszeit 240ms (95% Reaktion)

Bildfeld 15:1 (OS151-USB)

30:1 (OS301-USB)

ø5mm@100mm (OS801-USB)

Spektralempfindlichkeit 8 bis 14µm

Speisespannung 24V Gleichstrom (28V Gleichstrom max.)

Sensorspannung 6V Gleichstrom min.

Maximaler zykl. Scheinwiderstand 900 Ohm

MECHANISCHE DATEN

Konstruktion Rostfreier Stahl

Abmessungen 25mm Durchmesser x 106.5mm

Kabellänge 1m

Gewicht mit Kabel 170g

UMWELTBESTIMMUNGEN

Umwelttechnische Einstufung IP65

Umgebungstemperaturbereich 0ºC bis 70º

Relative Feuchte höchstens 95%, ohne Kondensation

deutsch

zuBeHör

Eine Reihe von Zubehörteilen für unterschiedliche Anwendungen und industrielle

Umgebungen sind erhältlich.

Die Zubehörteilen können jederzeit bestellt und vor Ort installiert werden. Die folgenden

Zubehörteile sind lieferbar:

17

›

Page 18

Feste Halterung

Sensor

AM BESTEN

GUT

FALSCH

Hintergrund

Ziel größer als

Zielpunktgröße

Ziel entspricht

Zielpunktgröße

Ziel kleiner als

Zielpunktgröße

Entfernung: zwischen Sensor und Gegenstand (inches)

Entfernung: zwischen Sensor und Gegenstand (mm)

15

32

48

0.6

1.2

1.9

0 19.7 39.4

0 500 1000

Zielpunktdurchmesse

(inches)

Zielpunktdurchmesser

(mm)

Zielpunktdurchmesse

(inches)

Zielpunktdurchmesser

(mm)

Zielpunktdurchmesse

(inches)

Zielpunktdurchmesser

(mm)

Entfernung: zwischen Sensor und Gegenstand (inches)

Entfernung: zwischen Sensor und Gegenstand (mm)

15

48

82

0.6

1.9

3.2

0 19.7 39.4

0 500 1000

Entfernung: zwischen Sensor und Gegenstand (inches)

Entfernung: zwischen Sensor und Gegenstand (mm)

15

5

15

0.6

0.2

0.6

03.97.9

0 100 200

D:S 30:1D:S 15:1

Verstellbare Halterung

Luftspülmanschette

deutsch

Laserzielgerät

OptiOnen

Die folgenden Optionen sind verfügbar. Die Optionen werden werksmäßig installiert

und müssen zusammen mit dem OS150-USB-Sensor bestellt werden.

Luft-/wassergekühltes Gehäuse

Eichbescheinigung

Längeres Kabel (max. 30 m)

optiScHeS Diagramm

Das optische Diagramm unten gibt den nominellen Zielpunktdurchmesser in einer

beliebigen Entfernung vom Messkopf an. Es werden 90% Energie angenommen.

r

r

OS151-USB OS301-USB OS801-USB

r

inStallation

Der Installationsprozess besteht aus den folgenden Phasen:

Vorbereitung

Mechanische Installation

Elektrische Installation

Bitte lesen Sie sich die folgenden Abschnitte sorgfältig durch, bevor Sie mit der

Installation beginnen.

vorBereitung

Achten Sie darauf, dass der Sensor nach dem Aufstellen nur auf das Ziel weist.

18

›

Page 19

ENTFERNUNG UND ZIELPUNKTGRÖSSE

12.0

45.0

50.0 50.0

40.0

9.0

15.0

25.0 25.0

Ø20.0

60° Drehung 60° Drehung

60° Drehung

9.0

48.0

Feste Halterung Verstellbare Halterung

2 x Befestigungsbohrungen M4-Gewinde 2 x Befestigungsbohrungen M4-Gewinde

9.0

24.024.0

Die Größe des Messbereichs (Zielpunktgröße) bestimmt die Entfernung zwischen Sensor

und Ziel. Die Zielpunktgröße darf die Zielgröße nicht übersteigen. Der Sensor sollte so

aufgestellt werden, dass die gemessene Zielpunktgröße kleiner ist als das Ziel.

UMGEBUNGSTEMPERATUR

Der Sensor ist für Umgebungstemperaturen zwischen 0°C und 70°C konzipiert. Bei

Umgebungstemperaturen über 70ºC ist ein luft-/wassergekühltes Gehäuse erforderlich.

Vermeiden Sie Wärmeschocks. Warten Sie 20 Minuten, damit sich das Gerät an

starke Veränderungen in der Umgebungstemperatur gewöhnen kann.

LUFTQUALITÄT

Rauch, Dämpfe oder Staub können die Linse verunreinigen und zu Fehlern bei der

Temperaturmessung führen. In derartigen Umgebungen sollte die Luftspülmanschette

verwendet werden, damit die Linse sauber bleibt.

ELEKTRISCHE STÖRUNGEN

Um elektromagnetische Störungen oder “Lärm” auf ein Minimum zu reduzieren, sollte der

Sensor entfernt von Motoren, Generatoren und ähnlichen Geräten aufgestellt werden.

VERKABELUNG

Überprüfen Sie die Entfernung zwischen dem Sensor und dem Anzeige-/Steuergerät.

Bei Bedarf kann der OS150-USB-Sensor mit längerem Kabel geliefert werden.

NETZSPANNUNG

Achten Sie darauf, dass Sie 24V Gleichstrom (22mA) verwenden.

mecHaniScHe inStallation

Alle Sensoren werden mit einem 1m langem. Kabel und einer Befestigungsmutter

geliefert. Der Sensor kann an Halterungen oder Ihrem Eigendesign befestigt werden.

Oder verwenden Sie die unten abgebildeten festen und verstellbaren Zubehörteile für

die Halterung.

deutsch

›

19

Page 20

LUFT-/WASSERGEKÜHLTE GEHÄUSE

26.0

34.0

47.0 58.5 81.0

1/8-BSP-Wasser-/Luftverbindungen

Luftspülmanschette

Luft-/Wassergekühlte gehäuse

1/8-BSP-Luftverbindung

27

58.5

26

34

47

Aufgrund des im Folgenden dargestellten luft-/wassergekühlten Gehäuses kann der

Sensor hohen Umgebungstemperaturen standhalten. Der Sensor ist mit zwei 1/8-Zoll-

deutsch

Bsp-Verbindungsstücken ausgestattet. Um eine wirksame Kühlung zu gewährleisten,

sollte die Wassertemperatur zwischen 10ºC und 27ºC betragen. Gekühltes Wasser

unter 10ºC ist nicht zu empfehlen. Um Kondensation zu vermeiden, sollte die

Luftspülmanschette in Verbindung mit dem wassergekühlten Gehäuse eingesetzt werden.

Den Wasserdurchfluss sollte nicht mehr als 0,5 bis 1,5 Liter/Min. betragen.

LUFTSPÜLMANSCHETTE

Die unten abgebildete Luftspülmanschette hält Staub, Dämpfe, Feuchtigkeit und

andere Verunreinigungen von der Linse fern. Die Manschette muss vollständig eingeschraubt werden. Luft strömt in das 1/8-Zoll-Bsp-Verbindungsstück und aus der vorderen Öffnung. Der Luftstrom sollte nicht mehr als 5 bis 15 Liter/Min. betragen.

Es wird reine Luft oder “Hilfsluft” empfohlen.

20

›

Page 21

elektriScHe inStallation

+-

-

+

Display/

Controller

Rot

Schwarz

(Blau)

Stromzuführung

+-

-

+

Display/

Controller

Rot

Schwarz

(Blau)

Stromzuführung

PC

PC

N/C

USB

USB

Das Sensorkabel ist ein 1m langes PVC-Kabel. Ein Ende wird werksmässig am Messkopf

befestigt. Das andere Ende ist mit einem Drahtpaar und einem Abschirmdraht (Erdungsdraht)

versehen.

VERKABELUNG

Der OS150-USB-Sensor kann auf drei verschiedene Arten benutzt werden. Um

lediglich den 4-20mA-Ausgang zu nutzen, schließen Sie den OS150-USB-Sensor an

das Display / den Controller mit der 24 V-Gleichstromzufuhr im Stromkreis an, verwenden Sie dabei die folgende Tabelle und das Anschlussdiagramm als Richtwert. Der

maximale zyklische Scheinwiderstand beträgt 900 Ohm. Nota: Der OS150-USB-

Sensor darf nur an einem Punkt geerdert sein, nämlich entweder an der

Kabelabschirmung oder am Sensorgehäuse

Leistung Kabel Kabelfarbe Funktion

4 bis 20mA 1 Rot Stromzuführung+ /Signal +

2 Schwarz (Blau) Stromzuführung - /Signal 3 Blank Abschirmung (Erdung)

Um nur den USB-Ausgang zu benutzen, schließen Sie den OS150-USB-Sensor an

einen PC an, verwenden Sie dabei das mitgelieferte Kabel. Wenn der USB-Ausgang

verwendet wird, ist keine externe Stromversorgung erforderlich. Der OS150-USBSensor kann auch benutzt werden, wenn er sowohl an den 4-20mA-Ausgang als auch

an den USB-Ausgang angeschlossen wurde, vorausgesetzt dass der Minuspol der

verwendeten 24 V-Gleichstromzufuhr nicht geerdet ist. Hinweis: Die OmegaSoft-

Software muss installiert werden, bevor der Sensor an einen PC angeschlossen

wird.

deutsch

21

›

Page 22

omegaSoft Software

SyStemanforderungen

• Die OmegaSoft-Software wurde für Microsoft Windows entwickelt und ist mit den

deutsch

Versionen Windows 2000, XP, Vista und 7

• Der Rechner sollte mindestens die folgenden Spezifikationen aufweisen:

Intel 486-Prozessor

VGA-Monitor mit einer Auflösung von 640 x 480 Pixel

USB-Port 2.0

InStallatIon

1. Legen Sie die mitgelieferte CD ein.

2. Der Installer müsste automatisch starten (wenn nicht, wählen Sie das richtige Laufwerk

aus und doppelklicken Sie auf Setup.exe).

3. Folgen Sie den Anweisungen auf dem Bildschirm.

HINWEIS Schließen Sie den OS150-USB-Sensor nicht an den PC an, wenn die

Software noch nicht installiert ist.

ANSCHLIESSEN DES OS150-USB-SENSORS AN EINEN PC

1. Stecken Sie den Rundstecker des mitgelieferten USB-Kabels in den OS150-USB-Sensor.

2. Stecken Sie den USB-A-Stecker des mitgelieferten USB-Kabels in einen freien USB-Port 2.0.

3. Doppelklicken Sie auf das OmegaSoft-Symbol auf dem Desktop.

HINWEIS Ziehen Sie das USB-Kabel erst nach Beenden des

OmegaSoft-Programms heraus.

konfiguration

• Einstellen der Temperatureinheiten

Temperatureinheiten können auf dem Haupttemperaturanzeigegerät durch Drücken

von °C oder °F eingestellt werden.

• Einstellen der Datenausgabe

Der Temperaturbereich für den 4 bis 20mA-Ausgang, die durchschnittliche Dauer und

die Speicherung des Höchst- und Tiefstwerts können im Hauptprogrammmenü

eingestellt werden:

[Setup] → [Output Processing]

Die Temperaturen, die 4 und 20mA entsprechen, können eingestellt werden (Minimum

–40°C, Maximum 1000°C, Mindestspanne 100°C, Höchstspanne 1000°C).

Um die Auswirkungen von Temperaturschwankungen, Lärm usw. auf das Ausgabesignal

möglichst gering zu halten, kann die durchschnittliche Dauer auf einen Wert zwischen

0 und 60 Sekunden eingestellt werden.

Wenn erforderlich, kann der Speichermodus auf Speicherung des Höchstwerts oder

Speicherung des Tiefstwerts und die Dauer der Speicherung auf einen Wert zwischen

0 und 1200 Sekunden eingestellt werden.

• Einstellen des Zielemissionsvermögens

Um das Emissionsvermögen für den OS150-USB-Sensor einzustellen, wählen Sie im

Hauptprogrammmenü aus:

[Setup] → [Emissivity]

Das Emissionsvermögen kann auf einen Wert zwischen 0.1 und 1.0 eingestellt oder

aus einer vorgegebenen Materialliste ausgewählt werden, indem [Data] gewählt wird.

• Einstellung der Kompensation der reflektierten Temperatur

Um die Kompensation der reflektierten Temperatur zu aktivieren und einzustellen,

wählen Sie im Hauptprogrammmenü aus:

[Setup] → [Reflection Compensation]

Die Kompensation der reflektierten Temperatur kann mit [Compensate for Reflected

Temperature] aktiviert/deaktiviert werden; wenn sie aktiviert wurde, kann der

Temperaturwert auf -40 bis 1000°C eingestellt werden.

22

›

Page 23

BetrieB

Wenn der Sensor aufgestellt ist und die entsprechenden Strom-, Luft-, Wasser- und

Kabelanschlüsse gesichert sind, kann das System mit den folgenden einfachen

Schritten auf Dauerbetrieb eingestellt werden:

1. Die Stromversorgung einschalten

2. Schalten Sie das Gerät oder den PC ein.

3. Die Temperatur ablesen / überwachen

WICHTIG

Achten Sie beim Einsatz des Sensors auf die folgenden Punkte:

• Wenn der Sensor erheblichen Temperaturschwankungen ausgesetzt wird (heiss zu

kalt oder kalt zu heiss), sind 20 Minuten zulässig, damit sich die Temperatur vor der

Temperaturnahme oder -aufzeichnung stabilisieren kann.

• Betreiben Sie den Sensor nicht in der Nähe großer elektromagnetischer Felder (z.B.

von Lichtbogenschweißgeräten oder Induktionsheizgeräten). Elektromagnetische

Störungen können zu Messfehlern führen.

• Die Kabel dürfen nur mit den korrekten Anschlüssen verbunden werden.

wartung

Unsere Kundendienstmitarbeiter können bei Anwendungen, kalibrierung, Reparaturen

und Lösung konkreter Probleme helfen. Setzen Sie sich bitte mit unserer

Kundendienstabteilung in Verbindung, bevor Sie Geräte zurücksenden. Häufig können

Probleme telefonisch gelöst werden.

Wenn der Sensor nicht ordnungsgemäß funktioniert, versuchen Sie, das unten aufgeführte Symptom dem entsprechenden Problem zuzuordnen. Wenn die Tabelle nicht

weiterhilft, kann Ihnen Omega möglicherweise telefonisch weitere Tipps geben.

STÖRUNGSSUCHE

Symptom Wahrscheinliche Ursache Lösung

Keine Stromleistung Keine Stromzufuhr an Sensor Stromanschluss

überprüfen

Falsche Temperatur Falscher Kabelanschluss Kabelfarbcode überprüfen

Falsche Temperatur Fehlerhaftes Sensorkabel Kabelkontinuität

überprüfen

Falsche Temperatur Blickfeld blockiert Blockierung entfernen

deutsch

REINIGEN DER LINSE

Halten Sie die Linse stets sauber. Fremdkörper auf der Linse würden die Messgenauigkeit

beeinträchtigen. Blasen Sie lose Partikel mit einem Gebläse von der Linse (sofern Sie

nicht die Luftspülmanschette verwenden).

23

›

Page 24

La serie OS150-USB, sensores de infrarrojos sin necesidad de contacto, miden tem-

3.8 (98.0)

4.2 (106.5)

0.6

(15.0)

1.0 (25.0)

M20 x 1mm

36.0 (1000.0)

(standard length)

peraturas de -40ºC a 1000ºC y proporcionan una salida lineal de 4 a 20mA. La señal

de dos hilos es compatible con casi cualquier indicador, controlador, registrador, tabu-

español

lador electrónico de datos, etc., sin necesidad de una interconexión especial o acondicionamiento de señal. Son adecuados para la mayoría de las materias, tales como

alimentos, papel, telas, plásticos, cuero, tabaco, medicinas, productos químicos,

caucho, carbón y asfalto.

caracteríSticaS

GENERAL

Gama de temperaturas -40ºC a 1000ºC

Salida 4 a 20mA

Precisión ±1% de lectura o ±1ºC, la cifra que sea mayor

Repetibilidad ±0,5% de lectura o ±0,5ºC, la cifra que sea mayor

Emisividad ajustable de 0,1 a 1,0

Tiempo de respuesta 240ms (95% respuesta)

Campo visual 15:1 (OS151-USB)

30:1 (OS301-USB)

ø5mm@100mm (OS801-USB)

Respuesta espectral 8 a 14µm

Tensión de alimentación 24Vcc (máx. 28Vcc)

Tensión del sensor mín. 6Vcc

Impedancia máxima de circuito 900 Ohmios

MECÁNICA

Construcción Acero inoxidable

Dimensiones 25mm de diámetro x 106.5mm

Longitud de cable 1m

Peso con cable 170g

AMBIENTE

Valoración ambiental IP65

Gama de temperatura ambiental 0ºC a 70ºC

Humedad relativa 95% máximo sin condensación

acceSorioS

Se encuentra disponible una gama de accesorios para las distintas aplicaciones y

ambientes industriales. Los accesorios pueden pedirse en cualquier momento y añadirse en el mismo recinto. Éstos consisten en las piezas a siguientes:

Consola fija para el montaje

Consola regulable de montaje

Aro de purga de aire

Herramienta óptica láser

24

›

Page 25

Sensor

MEJOR

BUENO

INCORRECTO

Fondo

Diana superior al

tamaño del punto

Diana igual al

tamaño del punto

Diana inferior al

tamaño del punto

Distancia: sensor a objeto (inches)

Distancia: sensor a objeto (mm)

15

32

48

0.6

1.2

1.9

0 19.7 39.4

0 500 1000

Diámetro del

punto de diana

(inches)

Diámetro del

punto de diana

(mm)

Diámetro del

punto de diana

(inches)

Diámetro del

punto de diana

(mm)

Diámetro del

punto de diana

(inches)

Diámetro del

punto de diana

(mm)

Distancia: sensor a objeto (inches)

Distancia: sensor a objetot (mm)

15

48

82

0.6

1.9

3.2

0 19.7 39.4

0 500 1000

Distancia: sensor a objeto (inches)

Distancia: sensor a objeto (mm)

15

5

15

0.6

0.2

0.6

0 3.9 7.9

0 100 200

D:S 30:1D:S 15:1

opcioneS

Se encuentran a disposición las siguientes opciones. Las opciones son instaladas en

la fábrica y deben pedirse con el sensor OS150-USB.

Caja de enfriamiento por aire/agua

Certificado de calibración

Cable más largo (máx. de 30 m)

cuaDro Óptico

El cuadro óptico de debajo indica el diámetro nominal del punto de diana a una distancia dada de la cabeza sensora y asume 90% de energía.

OS151-USB OS301-USB OS801-USB

inStalaciÓn

El proceso de instalación consiste en las siguientes etapas:

Preparación

Instalación mecánica

Instalación eléctrica

Leer las siguientes secciones con detenimiento antes de proceder a la instalación.

preparaciÓn

Asegurarse de que el sensor se coloca de manera que esté enfocando solamente a la

diana.

español

›

25

Page 26

DISTANCIA Y TAMAÑO DE LA ZONA DE MEDICIÓN

12.0

45.0

50.0 50.0

40.0

9.0

15.0

25.0 25.0

Ø20.0

Rotación 60° Rotación 60°

Rotación 60°

9.0

48.0

Soporte fijo Soporte regulable

2 x Holgura de orificios de montaje M4 2 x Holgura de orificios de montaje M4

9.0

24.024.0

El tamaño de la zona de medición a medir determina la distancia entre el sensor y la

diana. El tamaño de la zona de medición no debe ser mayor que el de la diana. El

español

sensor debe ser instalado de manera que la zona de medición determinada sea menor

que la diana.

LA TEMPERATURA AMBIENTE

El sensor está diseñado para funcionar en temperaturas ambientes desde 0ºC hasta

70ºC. Para las temperaturas ambientes superiores a 70ºC, se hará necesario una caja

de enfriamiento por aire/agua.

Evitar un cambio brusco de temperatura. Dejar pasar 20 minutos para que la unidad

se ajuste a los grandes cambios de temperatura ambiente.

CALIDAD ATMOSFÉRICA

Los humos o el polvo pueden contaminar la lente y causar errores en la medición de

la temperatura. El aro de purga de aire debe usarse en ambientes de este tipo para

ayudar a mantener la lente limpia.

INTERFERENCIA ELÉCTRICA

Para reducir al mínimo la interferencia electromagnética o el “ruido”, el sensor debe ser

instalado alejado de motores, generadores o similares.

CONEXIONES ELÉCTRICAS

Comprobar la distancia entre el sensor y el dispositivo indicador/controlador. Si es

necesario, el sensor OS150-USB se puede pedir con el cable que viene adosado, más

largo.

SUMINISTRO ELÉCTRICO

Asegurarse de usar un suministro eléctrico de 24Vcc, (22mA).

inStalaciÓn mecánica

Todos los sensores vienen con 1 metro de cable y una tuerca de montaje. El sensor

puede ser instalado en una consola o dispositivos de diseño propio, o puede usar los

accesorios de consola fija y regulable de montaje que se muestran debajo.

26

›

Page 27

26.0

34.0

47.0 58.5 81.0

Conexiones de agua/aire de BSP

(hilo de rosca en paralelo de British Standards)

de 1/8 de pulgada.

Aro de purga de aire

Caja de enfriamiento por aire/agua

Conexiones de aire de BSP

(hilo de rosca en paralelo de British Standards)

de 1/8 de pulgada.

27

58.5

26

34

47

CAJA DE ENFRIAMIENTO POR AIRE/AGUA

La caja de enfriamiento por aire/agua mostrada a continuación permite al sensor

soportar temperaturas ambientes elevadas. Se encuentra equipado de dos accesorios

BSP (hilo de rosca en paralelo de British Standards) de 1/8 de pulgada. La temperatura del agua debe ser de 10ºC a 27ºC para un enfriamiento eficaz. No se recomienda agua fría por debajo de los 10ºC. Para evitar una condensación, el aro de purga

de aire debe usarse con la caja de enfriamiento por agua. El caudal de agua no debe

ser superior a 0,5 a 1,5 litros/min.

ARO DE PURGA DE AIRE

El aro de purga de aire a continuación se usa para mantener el polvo, los humos, la

humedad y otros contaminantes alejados de la lente. Debe atornillase completamente. El aire fluye hacia adentro del accesorio BSP de 1/8 de pulgada y hacia afuera

de la abertura frontal. El flujo de aire no debe ser superior a 5 a 15 litros/min.

español

Se recomienda aire limpio o “para instrumentos”.

27

›

Page 28

inStalaciÓn eléctrica

+-

-

+

Indicador/

Controlador

Rojo

Negro

(Azul)

Suministro eléctrico

+-

-

+

Indicador/

Controlador

Rojo

Negro

(Azul)

Suministro eléctrico

PC

PC

N/C

USB

USB

El cable desde el sensor a los componentes electrónicos es de PVC, de 1 metro. Uno

de los extremos es adosado, desde fábrica, a la cabeza sensora. El otro extremo tiene

español

un par de hilos y un hilo conductor armado (a tierra).

CONEXIONES ELÉCTRICAS

El sensor OS150-USB puede utilizarse de tres formas distintas. Para utilizar sólo la

salida 4-20mA, conecte el sensor OS150-USB al indicador/controlador con el suministro eléctrico 24 Vcc del circuito utilizando la tabla y diagrama de conexiones siguientes como guía. La impedancia máxima del circuito es de 900 ohmios. Nota: El

sensor OS150-USB debe ser conectado a la tierra en un único punto, en el

blindaje del cable o en la carcasa del sensor.

Salida Nº hilo Color de hilo Función

4 a 20mA 1 Rojo Sum. Elec. + / señal +

2 Negro (Azul) Sum. Elec - / señal 3 Desnudo Hilo conductor armado a tierra

Para utilizar sólo la salida USB, conecte el sensor OS150-USB al PC con el cable

suministrado. No se necesita suministro eléctrico externo para usar la salida USB. El

sensor OS150-USB también puede utilizarse con el circuito 4-20mA y el USB

conectados, siempre que el terminal negativo del suministro eléctrico 24 Vcc utilizado

no esté conectado a tierra. Aviso: antes de conectar el sensor a un PC debe

instalar el software OmegaSoft.

28

›

Page 29

omegaSoft Software

requISItoS del SIStema.

• El software OmegaSoft está diseñado para ser ejecutado en Microsoft Windows. Las

siguientes son versiones adecuadas: Windows 2000, XP, Vista y 7

• Las características de ordenador mínimas recomendadas son:

Procesador Intel 486

Pantalla VGA con una resolución de 640 x 480

Puerto USB 2.0

InStalacIón

1. Inserte el disco suministrado

2. El instalador debería ejecutarse automáticamente (si no lo hace, seleccione la

unidad apropiada y haga doble clic en Setup.exe)

3. Siga las instrucciones que se ofrecen en pantalla

AVISO No conecte el sensor OS150-USB al PC antes de instalar el software

CONEXIÓN DEL SENSOR OS150-USB AL PC

1. Conecte el conector circular del cable USB suministrado al sensor OS150-USB

2. Conecte el conector USB A del cable USB suministrado a un puerto USB 2.0

disponible

3. Haga doble clic en el icono OmegaSoft del escritorio

AVISO No desconecte el cable USB antes de cerrar el programa OmegaSoft

configuraciÓn

• Ajuste de unidades de temperatura

Las unidades de temperatura pueden ajustarse en el panel principal de temper-

aturas pulsándose en °C o °F.

• Ajuste de procesamiento de salida

El rango de temperatura para la salida 4 a 20mA, el período medio y el procesa-

miento de asimiento Peak/valley pueden ajustarse mediante el menú del programa

principal para seleccionar:

[Configuración] → [Procesamiento de salida]

A continuación pueden ajustarse las temperaturas correspondientes a 4 y 20mA

(mínimo –40°C, máximo 1000°C, intervalo mínimo 100°C, intervalo máximo 1000°C).

Para minimizar los efectos de fluctuación de la temperatura, ruidos, etc. en la señal

de salida, el período medio debe ajustarse entre 0 y 60 segundos.

Si es necesario, puede aplicarse el Procesamiento de asimiento mediante el ajuste

del modo de asimiento a Asimiento del pico o

Asimiento del valle o y el ajuste de un período de asimiento de entre 0 y 1200

segundos.

• Ajuste de Emisividad de la diana

Para establecer un valor de Emisividad para el sensor OS150-USB, utilice el menú

principal del programa para seleccionar:

[Configuración] → [Emisividad]

A continuación, la Emisividad puede ajustarse en un valor de entre 0,1 a 1,0, o

seleccionarse desde una lista predefinida de materiales si se selecciona [Datos].

• Ajuste de Compensación de temperatura reflejada

Para habilitar y ajustar la compensación de temperatura reflejada, utilice el menú

principal del programa para seleccionar:

[Configuración] → [Compensación de reflexión]

La compensación de temperatura reflejada puede habilitarse/deshabilitarse en

[Compensar temperatura reflejada], y cuando se habilita, el valor de temperatura

puede ajustarse entre -40 y 1000°C.

29

español

›

Page 30

funcionamiento

Una vez que el sensor está en posición y el suministro eléctrico, el aire, el agua y las

conexiones de cables apropiadas están seguras, el sistema está listo para el funcion-

español

amiento continuo, una vez se completen los sencillos pasos siguientes:

1. Encender el suministro eléctrico

2. Encienda el instrumento o PC

3. Leer / controlar la temperatura

IMPORTANTE

Prestar atención a lo siguiente al usar el sensor:

• Si el sensor se expone a cambios significativos de temperatura ambiental (de

caliente a fr’o o de fr’o a caliente), dejar pasar 20 minutos para que la temperatura

se estabilice antes de tomar o registrar temperaturas.

• No hacer funcionar el sensor cerca de grandes campos electromagnéticos (ejem-

plo, cerca de soldadoras por arco o calentadores por corrientes de inducción). Las

interferencias electromagnéticas pueden causar errores de medición.

• Los hilos deben ser conectados solamente a las terminales apropiadas.

mantenimiento

Nuestros representantes de servicio al cliente están a su disposición para asistirles en

aplicaciones, calibración, reparación y soluciones a problemas específicos. Contactar

nuestro Departamento de servicio antes de devolver el equipo. En muchos casos, los

problemas pueden resolverse por teléfono. Si el sensor no funciona como debiera, intentar encontrar el síntoma de entre los siguientes para identificar su problema. Si la tabla no

le sirve de ayuda, llamar a Omega para mayor asistencia.

IDENTIFICACIÓN DE PROBLEMAS

Síntoma Causa probable Solución

No funciona No hay suministro eléctrico al sensor Comprobar el

suministro eléctrico

Temperatura errónea Conexión de cables incorrecta Comprobar los códigos

de color de los cables

Temperatura errónea Cable sensor defectuoso Confirmar la continuidad

de los cables

Temperatura errónea Obstrucción del campo visual Retirar obstrucción

LIMPIEZA DE LA LENTE

Mantener la lente limpia en todo momento. Cualquier materia extraña en la lente afectaría la precisión de medición. Soplar las partículas sueltas (si no se usa el accesorio

de purga de aire) con un ‘soplador’ de aire.

30

›

Page 31

I pirometri ottici della Serie OS150-USB misurano senza contatto la temperatura da

3.8 (98.0)

4.2 (106.5)

0.6

(15.0)

1.0 (25.0)

M20 x 1mm

36.0 (1000.0)

(standard length)

-40°C a +1000°C fornendo una uscita lineare da 4 a 20 mA. L’uscita a 2 fili è compatibile con la maggior parte degli indicatori, regolatori e registratori, ecc. senza dovere

interporre interfacce o condizionatori di segnali esterni. Sono idonei per la maggior

parte di materiali quali: alimentari, tessili, plastiche, pelli, tabacchi, prodotti farmaceutici e chimici, gomma, carbone, asfalto, ecc.

Dati tecnici

GENERALE

Campo di misura da -40ºC a 1000ºC

Uscita da 4 a 20mA

Precisione ±1% della lettura o ±0,5°C al massimo

Ripetibilità ±0,5% della lettura o ±0,5°C al massimo

Coefficiente di emissione regolabile (via software) da 0,1 a 1,0

Tempo di risposta 240 ms (risposta al 90%)

Risoluzione ottica 15:1 (OS151-USB)

30:1 (OS301-USB)

ø5mm@100mm (OS801-USB)

Banda spettrale da 8 a 14µm

Alimentazione 24Vcc (28Vcc max.)

Voltaggio sensore 6Vcc min.

Impedenza massima circuito 900 Ohm

MECCANICA

Contenitore Acciaio inossidabile

Dimensioni 25mm diametro x 106.5mm

Lunghezza standard del cavo 1m

Peso (incluso il cavo) 170g

AMBIENTALI

Grado di protezione IP65

Temperatura operativa da 0ºC a 70ºC

Umidità relativa 95% max senza condensa

italiano

acceSSorI

Sono disponibili diversi accessori adatti a differenti applicazioni nel settore industriale.

Questi accessori, acquistabili anche in un secondo tempo e applicabili in campo sono:

Squadretta di fissaggio fissa

Squadretta di fissaggio regolabile

Collare per la pulizia

Puntatore laser

opzioni

31

›

Page 32

Sensore

OTTIMO

BUONO

NON CORRETTO

Sfondo

oggetto più

grande della

dimensione spot

oggetto

uguale alla

dimensione spot

oggetto più

piccolo della

dimensione spot

Distanza: Sensore dall’oggetto (inches)

Distanza: Sensore dall’oggetto (mm)

15

32

48

0.6

1.2

1.9

019.7 39.4

0 500 1000

Diametro

nominale

(inches)

Diametro

nominale

(mm)

Diametro

nominale

(inches)

Diametro

nominale

(mm)

Diametro

nominale

(inches)

Diametro

nominale

(mm)

Distanza: Sensore dall’oggetto (inches)

Distanza: Sensore dall’oggetto (mm)

15

48

82

0.6

1.9

3.2

019.7 39.4

0 500 1000

Distanza: Sensore dall’oggetto (inches)

Distanza: Sensore dall’oggetto (mm)

15

5

15

0.6

0.2

0.6

0 3.9 7.9

0 100 200

D:S 30:1D:S 15:1

Sono disponibili le seguenti opzioni che eventualmente devono essere precisate

all’atto della ordinazione.

italiano

Camicia di raffreddamento aria/acqua

Certificato di taratura

Cavo con lunghezza maggiorata (max 30 m)

Diagrammi ottici

I diagrammi qui sotto riportati indicano (in mm e pollici) la grandezza minima

dell’oggetto (target) alle varie distanze per una corretta misura

OS151-USB OS301-USB OS801-USB

inStallazione

Il processo di installazione consiste delle seguenti fasi:

Preparazione

Installazione meccanica

Installazione elettrica

Si prega di leggere interamente le seguenti sezioni prima di procedere all’installazione.

preparazione

Assicurarsi che il sensore pirometrico sia posizionato in modo di essere focalizzato

sull’oggetto di cui si deve misurare la temperatura

DISTANZA E DIMENSIONE SPOT

32

›

Page 33

In base al cono utile (spot) che parte dal sensore ( vedi disegno nella pagina prece-

12.0

45.0

50.0 50.0

40.0

9.0

15.0

25.0 25.0

Ø20.0

Rotazione 60° Rotazione 60°

Rotazione 60°

9.0

48.0

Squadretta fissa Squadretta regolabile

Fori di montaggio M4 Fori di montaggio M4

9.0

24.024.0

dente) la dimensione dell’area da misurare determina la distanza tra sensore e oggetto.

L’oggetto non deve essere più grande dello spot, in questo caso si deve allontanare il

sensore dall’oggetto fino che lo stesso risulta uguale o più piccolo dello spot.

TEMPERATURA AMBIENTE

Il sensore può lavorare a temperatura ambiente compresa tra 0°C e 70°C. Per temperatura ambiente superiore si deve usare la camicia di raffreddamento.

Evitare shock termici. Aspettare circa 20 minuti per adeguare il sensore pirometrico

alla temperatura dell’ambiente.

QUALITA’ ATMOSFERICA

Se nell’ambiente l’aria è impregnata di fumo o di impurità usare il collare di raffreddamento per pulire l’ottica del sensore.

INTEEFERENZE ELETTRICHE

Per evitare interferenze e disturbi causati dai campi elettromagnetici posizionare il

sensore lontano da motori, cavi di alta tensione, ecc.

CABLAGGIO

Controllare la distanza tra il sensore pirometrico e l’utilizzazione. In caso di distanza

maggiore di 1m precisare la lunghezza opzionale del cavo.

ALIMENTAZIONE

Controllare che l’alimentazione sia 24 Vcc (22mA)

inStallazione meccanica

I sensori sono forniti con cavo di 1 m e dado di fissaggio per il montaggio

sulla parte terminale filettata tramite squadrette fisse o regolabili

come quelle fornibili dalla casa e qui sotto riportate:

italiano

33

›

Page 34

26.0

34.0

47.0 58.5 81.0

Connessioni aria/acqua BSP 1/8”

Flangia spurgo aria

Alloggiamento aria/acqua raffreddata

Connessione aria BSP 1/8”

27

58.5

26

34

47

CAMICIA DI RAFFREDDAMENTO ARIA/ACQUA

Questa opzione deve essere montata in fabbrica sul sensore e permette di

italiano

sopportare elevate temperature ambiente. L’acqua (o l’aria compressa) viene fatta

defluire tramite i 2 manicotti BSP 1/8” di ingresso e di uscita. Con acqua tra 10°C e

27°C si può installare il sensore ad una temperatura ambiente di 200°C/250°C.

si raccomanda di non usare acqua fredda al di sotto di 10°C per evitare

condensa sull’ottica. In questo caso si può usare il collare di pulizia (vedi sotto). La

portata d’acqua non deve superare 0,5 a 1,5 litri/min.

COLLARE DI PULIZIA AD ARIA

Con questo accessorio tramite il suo manicotto BSP 1/8” si può insufflare aria compressa (portata raccomandata tra 5 e 15 litri/min.). L’aria fuoriesce dalla superficie

frontale del collare tenendo pulita l’ottica retrostante il collare montato sul sensore. Il

montaggio del collare sul sensore è a vite sull’interno filettato.

L’aria compressa inviata deve essere pulita e filtrata.

34

›

Page 35

inStallazione elettrica

+-

-

+

Combinatore/

indicatore

Rosso

Nero

(Blu)

Alimentazione

+-

-

+

Combinatore/

indicatore

Rosso

Nero

(Blu)

Alimentazione

PC

PC

N/C

USB

USB

Dal sensore fuoriesce un cavo in PVC lungo un metro (standard).

Sul capo libero del cavo vi sono due fili di collegamento e un cavo schermato.

CABLAGGIO

Il sensore pirometrico OS150-USB può essere usato in 3 modi diversi.

1) collegando soltanto l’uscita 4-20 mA all’utilizzazione (display, regolatore, ecc.)

2) collegando soltanto l’uscita USB al PC

3) collegando entrambe le uscite (max impedenza 900 Ohm)

NOTA BENE: Il OS150-USB deve essere messo a terra solo su un punto: o sul

cavo schermato o dal contenitore del sensore.

Uscita N cavo Colore Filo Funzione

4-20mA 1 Rosso Alimentazione+ / segnale +

2 Nero (Blu) Alimentazione- / segnale 3 cavo schermato Messa a terra

Connettere la porta USB del sensore pirometrico a un PC immettendo il cavo a connettore dato in dotazione. Nell’utilizzo di entrambe le uscite, 4-20mA e USB, il sensore

deve essere messo a terra solo con il cavo schermato e non collegando a terra il polo

negativo del sensore. NOTA BENE: Il software OmegaSoft deve essere installato

sul PC prima di connettere il sensore al PC.

italiano

35

›

Page 36

Software omegaSoft

PREREQUISITI NECESSARI

italiano

• Il Software “OmegaSoft” è compatibile con Windows 2000, XP, Vista e 7

• Al PC sul quale va applicato sono richieste le seguenti minime prestazioni:

Processore Intel Pentium

Schermo VGA con risoluzione di 640x480

Porta di ingresso tipo USB 2.0

INSTALLAZIONE

1. Inserire il CD fornito di dotazione con il sensore pirometrico

2. Installato deve partire in automatico. Se no, cliccare su Setup.exe

3. Seguire le istruzioni riportate

ATTENZIONE: Non connettere il sensore prima dell’installazione del SW sul PC.

CONNESSIONE DEL SENSORE

1. Inserire sul sensore pirometrico il suo cavo USB

2. Connettere il cavo USB sulla porta del PC

3. Fare un doppio click sull’icona del OmegaSoft

ATTENZIONE: Non disconnettere il cavo USB prima della chiusura del programma.

configurazione

• Selezionare l’unità di temperatura premendo su °C o °F

• Selezione dell’uscita

Si può selezionare la scheda della temperatura (inizio scala: 4mA, fondo scala:

20mA), la temperatura media di un determinato periodo, valori di picco. Sul menù

principale selezionare:

[Setup] → [Output Processing]

Fare attenzione che il min intervallo (span) preselezionabile è 100°C e il max è 1000

°C. Per minimizzare gli effetti della fluttuazione della temperatura e dei disturbi il

periodo per la misurazione della media può essere preselezionato tra 0 e 60 sec.

Usando la funzione “Hold” i valori di picco max e min si possono preselezionare in

un intervallo di tempo tra 0 e 120 sec.

• Selezione dell’emissività

Ogni corpo presenta un fattore di emissività diverso (tra 0,1 e 1,0) in base al calore,

alla lucentezza al tipo di superficie. Il OS150-USB può venire selezionato

sull’emissività dell’oggetto in esame tra 0,1 e 1,0 via software:

[Setup] → [Emissivity]

• Compensazione della temperatura riflessa

Questa funzione può essere abilitata o disabilitata

[Setup] → [Reflection Compensation]

La compensazione può essere scelta nell’intervallo -40°C +1000°C

36

›

Page 37

funzionamento

Installato il sensore e collegato alla rete elettrica ed eventualmente ai circuiti di raffreddamento, si procede a:

1 Accendere l’alimentazione (accertarsi che sia 24 Vcc!

2. Dare tensione all’utilizzazione (es. visualizzatore)

3. Leggere e controllare la temperatura sul visualizzatore e/o sul PC

AVVERTENZE

• Se la temperatura della zona nel quale è installato il sensore è superiore (o inferiore)

alla temperatura ambiente di 10/24°C attendere circa 20 minuti per il tempo di

stabilizzazione necessario per avere misure affidabili

• Non azionare il sensore in prossimità di consistenti campi elettromagnetici (p.e.

vicino ad archi voltaici o forni a induzione). I disturbi elettromagnetici possono

causare errori rilevanti della misura

• Accertarsi in anticipo che i cablaggi elettrici siano fatti sui terminali giusti.

manutenzione

Salvo che per una periodica pulizia dell’ottica il OS150-USB non richiede una particolare manutenzione. In caso di cattivo funzionamento chiedere all’agente locale consigli per l’eliminazione del problema avvalendosi della sottostante tabella diagnostica.

Solo in caso di non risolvere il problema dopo questo contatto rimandare il sensore alla

Casa o all’agente locale per un più approfondito controllo.

IDENTIFICAZIONE DEI PROBLEMI I

Problema Causa probabile Soluzione

Manca l’uscita Sensore non alimentato Controllo alimentazione

Misura non corretta Fili mal collegati Controllo colore del filo

Misura non corretta Cavo sensore difettoso Verifica continuità del cavo

Misura non corretta Ostruzione campo visivo Rimuovere ostruzione

italiano

PULIZIA DELL’OTTICA

Mantenere la lente sempre pulita. Depositi sulla lente influenzano la misura. Se il sensore non è dotato del collare di pulizia e vi sono particelle solide usare un getto di aria

o un panno bagnato d’acqua non contenente abrasivi.

37

›

Page 38

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 37 months from date of purchase. OMEGA’s WARRANTY

adds an additional one (1) month grace period to the normal three (3) year product

warranty to cover handling and shipping time. This ensures that OMEGA’s customers

receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s

Customer Service Department will issue an Authorized Return (AR) number immediately

upon phone or written request. Upon examination by OMEGA, if the unit is found to be

defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply

to defects resulting from any action of the purchaser, including but not limited to

mishandling, improper interfacing, operation outside of design limits, improper repair, or

unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having

been tampered with or shows evidence of having been damaged as a result of excessive

corrosion; or current, heat, moisture or vibration; improper specification; misapplication;

misuse or other operating conditions outside of OMEGA’s control. Components in which

wear is not warranted, include but are not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products.

However, OMEGA neither assumes responsibility for any omissions or errors nor

assumes liability for any damages that result from the use of its products in

accordance with information provided by OMEGA, either verbal or written.

OMEGA warrants only that the parts manufactured by the company will be as

specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED,

EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of

purchaser set forth herein are exclusive, and the total liability of OMEGA with

respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price

of the component upon which liability is based. In no event shall OMEGA be

liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used:

(1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation

or activity; or (2) in medical applications or used on humans. Should any Product(s) be used

in or with any nuclear installation or activity, medical application, used on humans, or

misused in any way, OMEGA assumes no responsibility

WARRANTY / DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA

and hold OMEGA harmless from any liability or damage whatsoever arising out of the use

of the Product(s) in such a manner.

as set forth in our basic

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service

RETURN REQUESTS/INQUIRIES

Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST

OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE

DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number

should then be marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging

to prevent breakage in transit.

FOR WARRANTY

have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the

product under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2011 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, pho-

tocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole

or in part, without the prior written consent of OMEGA ENGINEERING, INC.

RETURNS, please

FOR NON-WARRANTY REPAIRS,

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the

product, and

3. Repair instructions and/or specific problems

relative to the product.

consult OMEGA

Page 39

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Data Logging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

SM

M5068/1211

Loading...

Loading...