Page 1

Table of Contents

Part 1 Introduction

1.1 General 5

1.2 System Features 7

1.3 Instrument Specifications 9

1.4 Performance Specifications 12

Part 2 Mounting

2.1 General Mounting 13

2.2 Wall Mounting 14

2.3 Pipe Mounting 14

2.4 DIN Rail Mounting 16

2.5 Integral Mounting 16

2.6 Panel Mounting 16

Part 3 Electrical Installation

3.1 General 20

3.2 Two-Wire Configuration 20

3.21 Load Drive Capability

22

3.3 115/230 VAC Configuration 23

3.4 115/230 VAC w/ 2 Relays Configuration 25

3.5 Battery-Powered Configuration 27

Part 4 Sensor Connection

4.1 General 31

4.2 ORE-45P Sensor Connection 32

4.3 Combination Electrode Connection 33

4.4 External Temperature Compensators 34

4.5 Long Cable Length Issues 35

Part 5 Operation

5.1 User Interface 38

5.11 Keys

5.12 Display

5.2 Software 41

5.22 Default Menu

5.23 Calibration Menu

5.24 Configuration Menu

5.25 Diagnostics Menu

5.21 Software Navigation

39

39

41

44

45

46

54

Rev. B, 05/02

ORTX-45

2

Page 2

Table of Contents (continued)

Part 6 Calibration

6.1 Overview and Methods 59

6.11 Sensor Slope

6.12 Sensor Offset

6.14 1-Point Calibration Explained

6.13 2-Point Calibration Explained

60

60

61

61

6.2 Performing a 2-Point Calibration 62

6.3 Performing a 1-Point Calibration 64

6.4 Temperature Calibration 66

6.5 TC Factor Calibration 67

Part 7 Service and Maintenance

69

7.1 System Checks 71

7.2 Instrument Checks 72

7.3 Display Messages 73

Rev. B, 05/02

ORTX-45

3

Page 3

Table of Contents (continued)

Diagrams and Illustrations

Figure 1-1

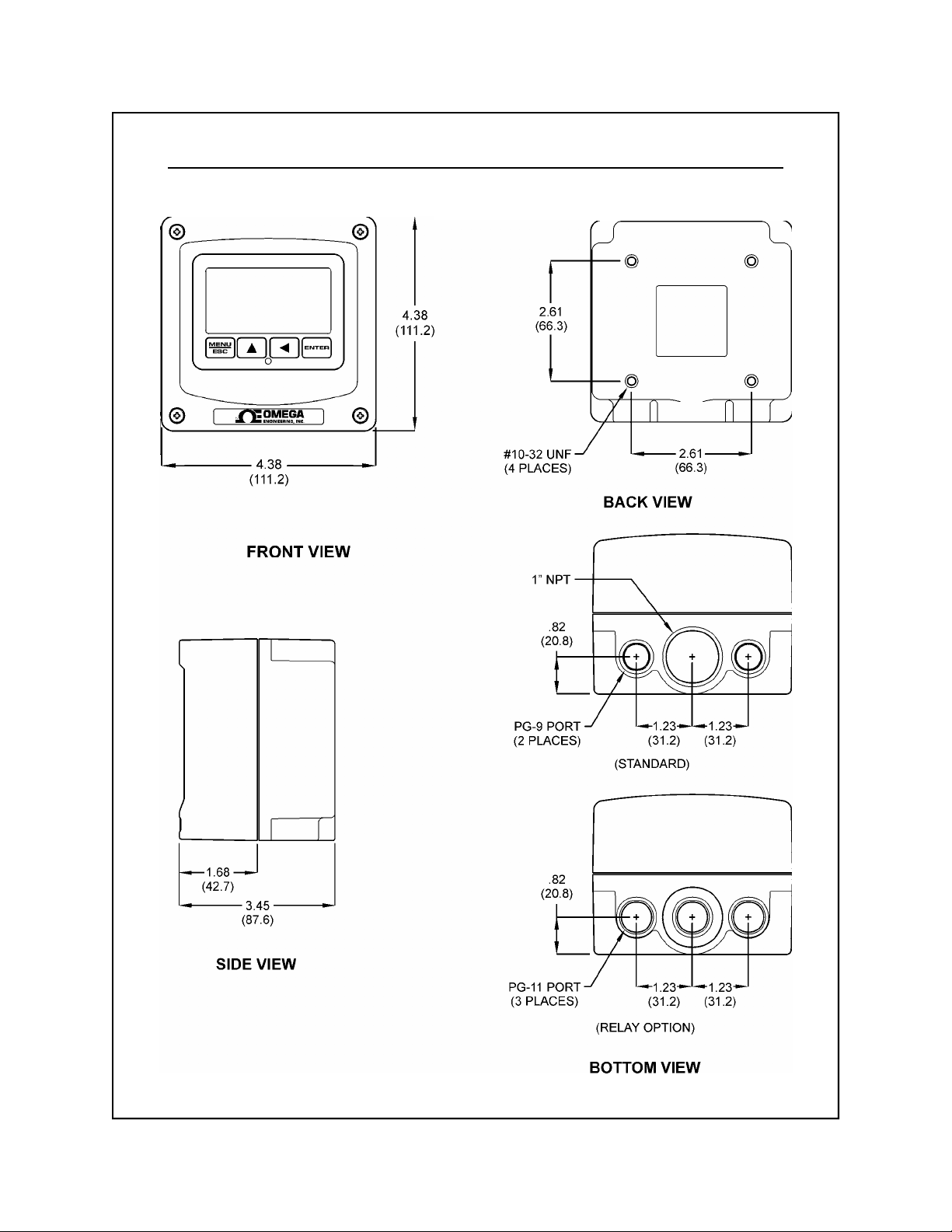

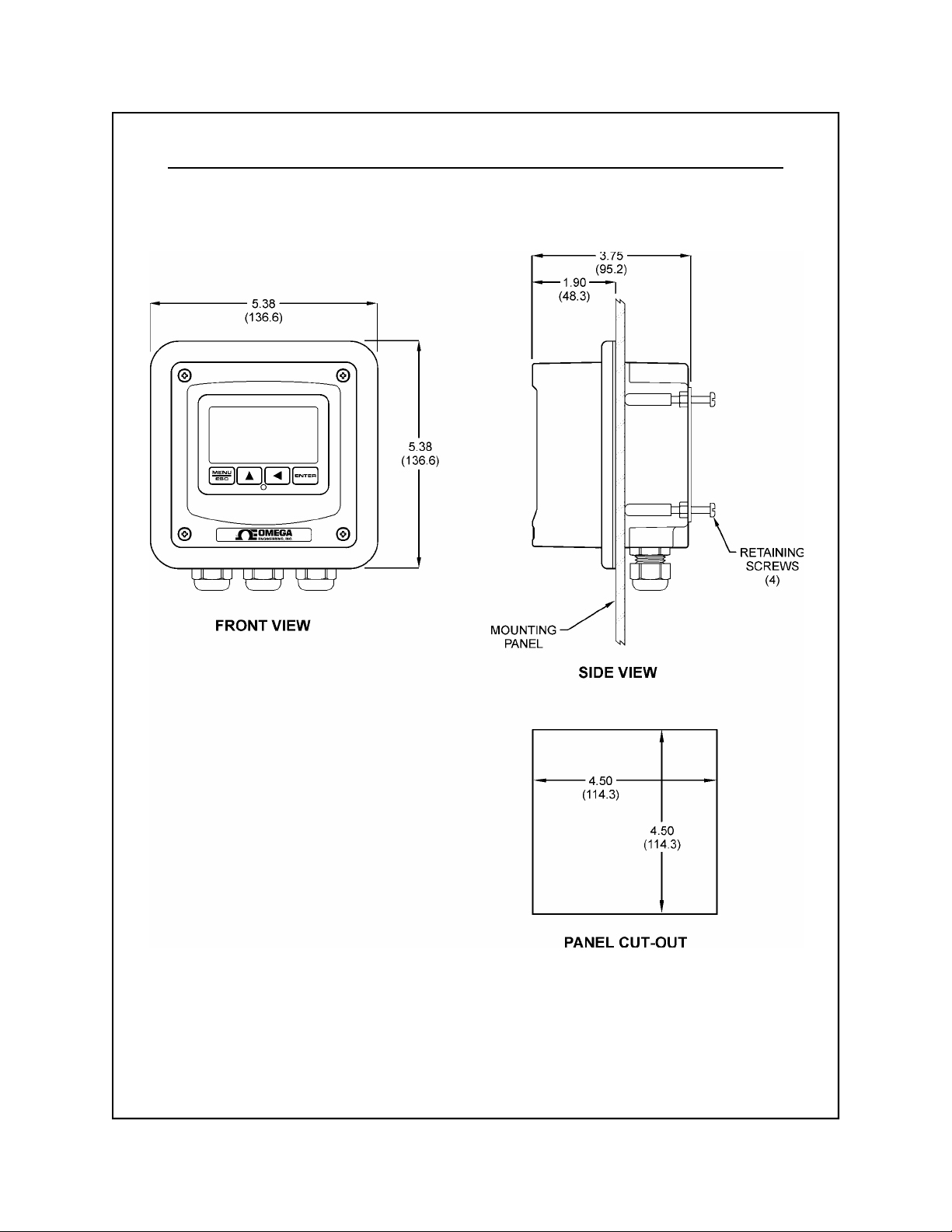

Figure 1-2 Specifications - Views 11

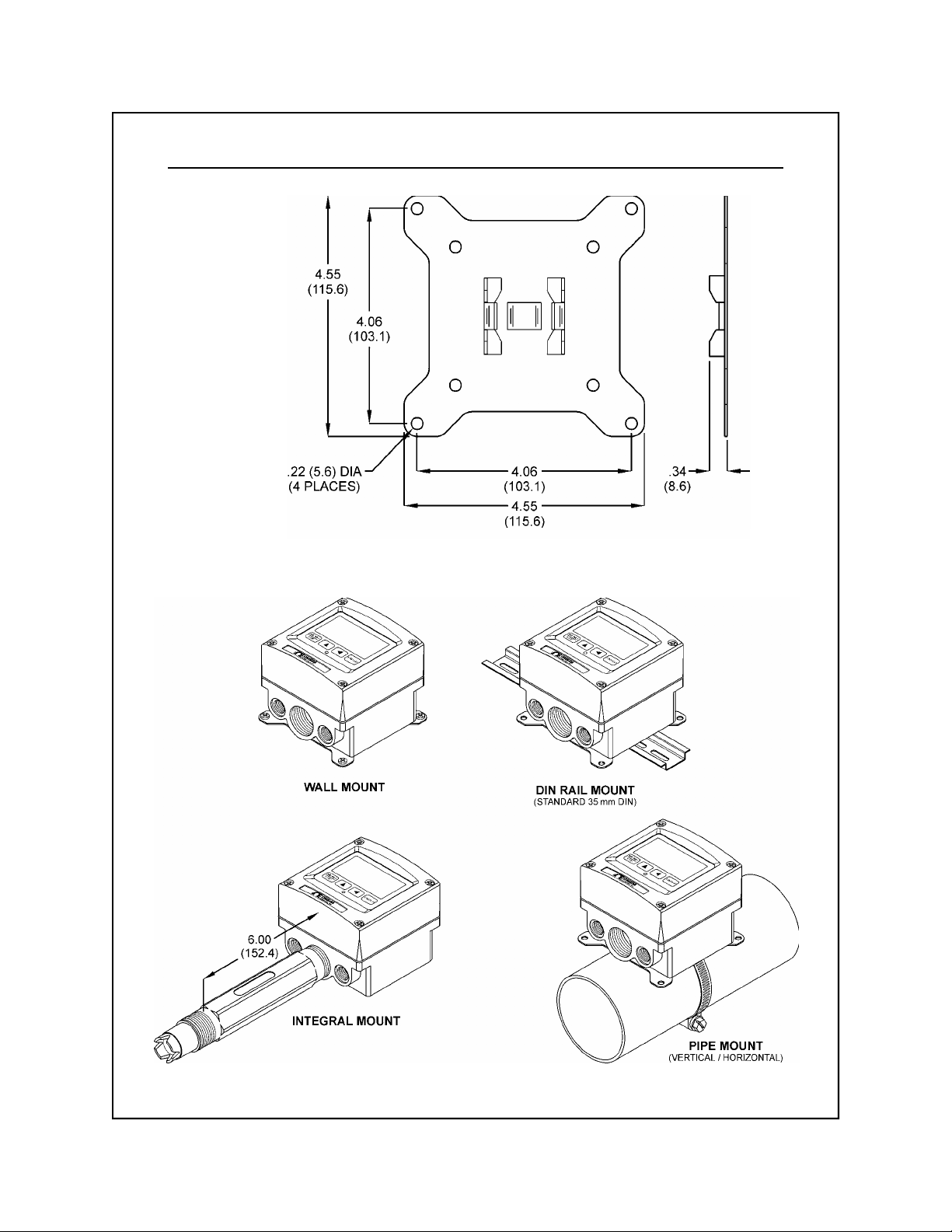

Figure 2-1 Multi-Purpose Bracket 15

Figure 2-2 ORTX-45 Mounting Configurations 15

Figure 2-3

Figure 2-4

Figure 2-5 115/230 VAC Panel Mount and Cut-out 19

Figure 3-1 Loop Power Connection 21

Figure 3-2 Line Power Connection 24

Figure 3-3

Figure 3-4

Figure 3-5 Relay Contacts 27

Figure 3-6 DC Battery Board Connection 28

Figure 4-1 Bulkhead Connection 31

Figure 4-2

Figure 4-3

Combination Electrode 33

Figure 4-4 External Temperature Compensators 34

Figure 4-5

Three-Wire RTD Connection 37

Figure 5-1

Figure 5-2 Software Map 43

Figure 5-3 Control Relay Example 49

Figure 5-4

Figure 7-1 ORTX-45 Assembly Diagram 69

Figure 7-2

ORTX-45 Configurations 6

2-Wire Integral Mount Detail 17

2-Wire Panel Mount and Cut-out 17

Line Power w/ Relays Connection 26

Relay Cable Connection 26

Sensor Cable Connections, ORE-45P 32

Sensor Cable Connections,

Junction Box Connection and

User Interface 38

Alarm Relay Example 50

ORTX-45 Assembly, optional 70

Rev. B, 05/02

ORTX-45

4

Page 4

Part 1 - Introduction

1.1 General

The Model ORTX-45 ORP monitor/analyzer provides an

extremely versatile measurement system for monitoring

and control of ORP (oxidation/reduction potential, also

known as REDOX) over the range of –1000 mV to +2000

mV. The instrument is offered standard as a looppowered transmitter for 2-wire DC applications. Since this

system configuration operates over only two low-voltage

wires, it is ideal for remote monitoring applications where

line power is either unavailable or prohibitively expensive

to run.

With an optional plug-in card, the instrument may also be

configured for 115/230 VAC operation. This configuration

is ideal when line power is located close to the point of

installation, and only a single isolated 4-20 mA output is

required.

An optional plug-in card is also available that provides

dual relay output, and two 4-20 mA outputs (one for ORP

and one for temperature) to convert the instrument to an

ORP controller. This card must be used with the 115/230

VAC option. This option expands the output capability of

the controller for applications that require relay-setpoint

functionality.

Note:

Rev. B, 05/02

An optional plug-in card is available that converts the

instrument into a robust, view-only, portable measurement system that operates on one 9 VDC battery. In this

configuration, all of the standard features of the basic 2wire transmitter are functional with the exception that the

instrument does not output a 4-20 mA current. Since this

system utilizes the same high performance ORE-45P

sensor as the standard configurations, it is a very robust

portable monitoring system. It can be used on its own, or

it can be used with other permanently installed ORTX-45

continuous monitoring systems to simplify calibration by

using the calibrate-by-reference method.

Due to the high-degree of flexibility of the **TX-45 system

options, it is important to note areas of the operating

manual that detail these optional features. The software

features for the relay output option and battery option only

appear when those modules are connected and the

system has been re-powered.

ORTX-45

5

Page 5

Part 1 - Introduction 1.1 General

In all configurations, the ORTX-45 displays mV, sensor

temperature, and output loop current on the secondary

line of the custom display. The instrument may be used

directly with either the high performance Quantum series

of sensors or with standard combination-style electrodes.

The Model ORTX-45 offers maximum mounting flexibility.

A bracket is included with each unit that allows mounting

to walls, pipes, panels, or DIN rail. In addition, the system

is designed to be integral mounted. Integral mounting is

an ideal solution for tight spaces where no mounting exists

except for atop the sensor.

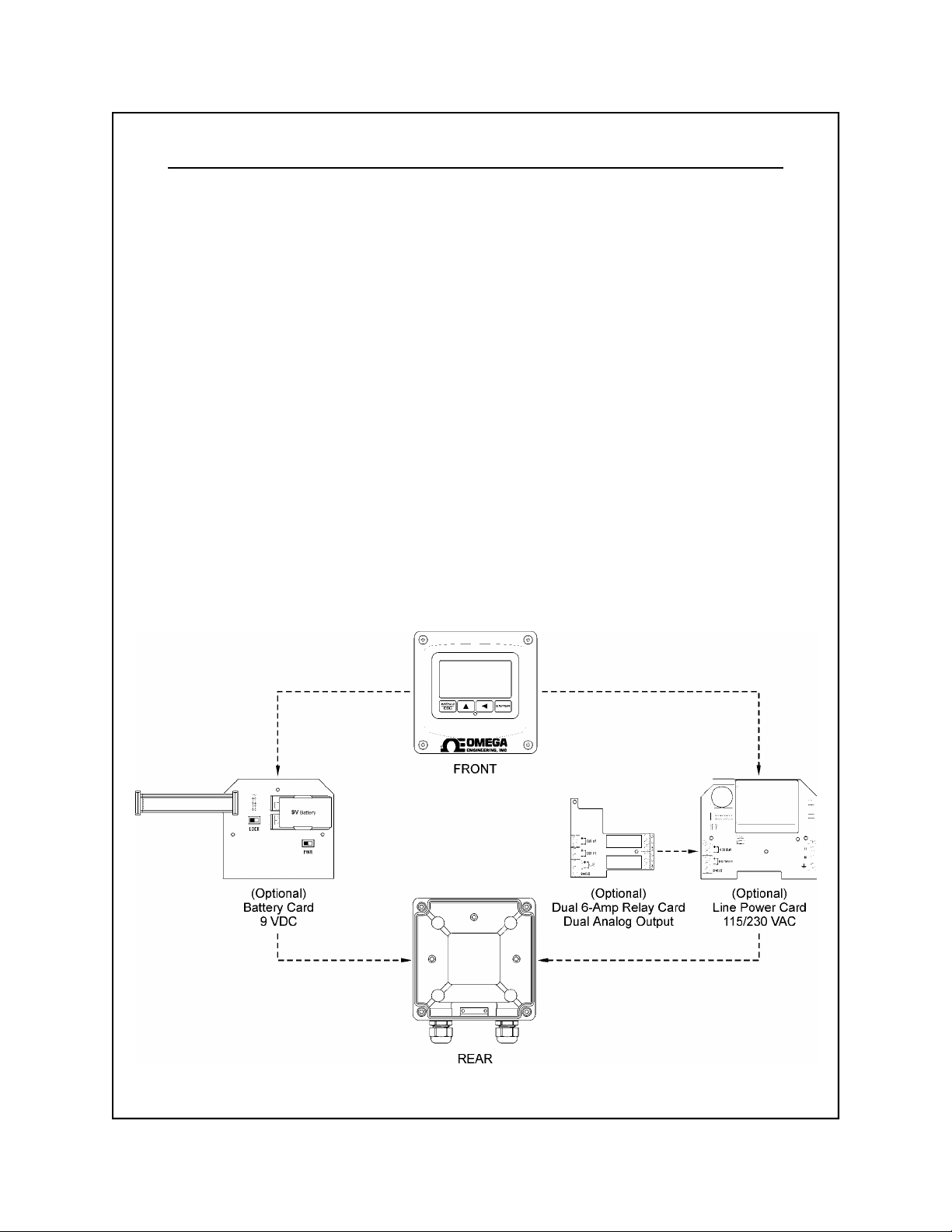

Figure 1-1 illustrates the configuration possibilities for the

ORTX-45 monitor/analyzer system. At any time, options

can be added or removed from the standard unit. The

system software automatically recognizes the options on

power-up and properly enables those new features. This

allows the basic 2-wire module to be stocked as a spare

part for any of the measurement systems.

Rev. B, 05/02

Figure 1-1 ORTX-45 Configurations

ORTX-45

6

Page 6

Part 1 - Introduction 1.2 System Features

1.2 System Features

•

Standard main module is designed to be a fully isolated,

loop powered instrument for 2-wire DC applications.

Protected from surge and brownout. Optional integral

power supply card for 115/230 VAC operation, and

optional battery power supply card for portable applications are available.

• Output Hold, Output Simulate, Output Alarm, and

Output Delay Functions. All forced changes in output

condition include bumpless transfer to provide gradual

return to on-line signal levels and to avoid system

control shocks on the main analog output (ORP).

• Optional plug-card provides dual SPDT relay operation.

Software settings for relay control mode include setpoint, deadband, phase, delay, and failsafe. Software

controls automatically appear in menu list when

hardware option card is plugged in and system power

is applied.

•

Selectable HI-LO alarm “band” mode feature on Relay

A. This feature allows the User to select two set points

on the same relay, so that a high and low limit alarm

can be established on one set of contacts.

•

Selectable Output Fail Alarm feature allows system

diagnostic failures to be sent to external monitoring

systems.

• Selectable Probe Timer feature on Relay B allows

connection of probe cleaner hardware or other accessories that require timed periodic relay contacts.

• Large, high contrast, custom Super-Twist display

provides excellent readability even in low light conditions.

The secondary line of display utilizes 5×7 dot matrix

characters for clear display of messages, avoiding

cryptic segmented character messages. Two of four

measured parameters may be on the display simultaneously.

Rev. B, 05/02

ORTX-45

7

Page 7

Part 1 - Introduction 1.2 System Features

•

Sensor diagnostics monitor glass breakage, sensor

leaks, and RTD condition. Diagnostic messages

provide a clear description of any problem with no

confusing error codes to look up. Messages are also

included for diagnosing calibration problems.

• Flexible two-point and sample calibration methods.

To provide high accuracy, all calibration methods include stability monitors that check temperature and main

parameter stability before accepting data.

• Selectable Pt1000 or Pt100 temperature inputs.

Systems can also be hard-configured for three-wire

elements. Temperature element can be user calibrated.

• Security lock feature to prevent unauthorized tampering

with instrument settings. All settings can be viewed while

locked, but they cannot be changed.

High reliability, microprocessor based system with

•

non-volatile memory back-up that utilizes no batteries.

Low mass, surface mount PCB construction containing

no user adjustment potentiometers. All factory calibrations stored in non-volatile EEPROM.

Rev. B, 05/02

ORTX-45

8

Page 8

Part 1 - Introduction 1.3 Instrument Specifications

1.3 Instrument Specifications, ORTX-45 (common to all variations)

Enclosure

NEMA 4X, IP66, polycarbonate, stainless steel hardware,

weatherproof and corrosion resistant,

HWD: 4.4" (112 mm) × 4.4" (112 mm) × 3.5" (89 mm)

Mounting Options Wall, panel, pipe, DIN rail, or integral-sensor (DC only)

Conduit Openings

Standard: 2 - PG-9 openings, 1 - 1" NPT center opening,

cordgrips and plug included.

Relay option: 3 - PG-11 openings, plugs included

Weight

DC transmitter configuration: 1 lb. (0.45 kg)

Line-powered unit: 1.5 lb. (0.68 kg)

Display

Large, high-contrast, Super-Twist (STN) LCD;

4-digit main display with sign, 0.75" (19.1 mm) seven-

segment characters;

12-digit secondary display, 0.3" (7.6 mm) 5×7 dot

matrix characters

Keypad 4-key membrane type with tactile feedback, polycar-

bonate with UV coating, integral EMI/static shield and

conductively coated window

Ambient Temperature Service, -20 to 60 °C (-4 to 140 ºF)

Storage, -30 to 70 °C (-22 to 158 ºF)

Ambient Humidity 0 to 95%, non-condensing

Location

EMI/RFI Influence

Designed for hazardous and non-hazardous areas

Designed to EN 61326-1

Output Isolation 600 V galvanic isolation

Filter Adjustable 0-9.9 minutes additional damping to 90%

step input

Temperature Input Selectable Pt1000 or Pt100 RTD with automatic

compensation

Rev. B, 05/02

ORTX-45

9

Page 9

Part 1 - Introduction 1.3 Instrument Specifications

Instrument Specifications, ORTX-45 (NOT common to all variations)

»Basic 2-Wire Transmitter:

Power

DC Cable Max. Length

DC Cable Type

Insertion Loss 15.5 VDC

16-35 VDC (2-wire device)

3000 feet (914 meters)

Belden twisted-pair, shielded

»115/230 VAC Option:

Power

4 kV line isolation

Fuse

115/230 VAC ± 10%, 50/60 Hz

250 mA slow-blo on hot line, auto-reset secondary

»115/230 VAC Option + Dual Relays Option:

Power

Fuse

Relays Electromechanical:

Dual SPDT, 6 amp @ 250 VAC, 5 amp @ 24 VDC contacts.

Dual SPST (N.O.) 0.06-2.0 Amp @12-280 VAC, RMS

Dual SPST (N.O.) 3 Amp @ 60 VDC

Software selection for setpoint, phase, delay, deadband,

Analog Outputs

115/230 VAC ± 10%, 50/60 Hz

250 mA slow-blo on hot line, auto-reset secondary

Solid State (AC):

Solid State (DC):

hi-lo alarm, and failsafe. A-B indicators on main LCD.

Dual 4-20 mA current loops, one for main parameter and

one for temperature. Max load 500 Ohms on main and 500

Ohms on temperature.

»Battery Option:

Power

Auto-OFF Time

Low Battery Indication

Battery Life Normal Use (2-4 hours per week), 4-6 months

Continuous operation, 10-14 days

Rev. B, 05/02

Generic 9 VDC alkaline battery

2 hours after no keypress

6.75 VDC

ORTX-45

10

Page 10

Part 1 - Introduction 1.3 Instrument Specifications

Inches (mm)

Rev. B, 05/02

Figure 1-2 Specifications - Views

ORTX-45

11

Page 11

Part 1 - Introduction 1.4 Performance Specifications

1.4 Performance Specifications, ORTX-45

(common to all variations)

Displayed Parameters

Main input, -1000 to +2000 mV

Loop current, 4.00 to 20.00 mA

Sensor temperature, -10.0 to 110.0 °C (14 to 230 ºF)

Main Parameter Range -1000 mV to +2000 mV

Input Impedance

Repeatability

Sensitivity

0.1% of span or better

0.05% of span

Greater than 10

13

Ohms

Non-linearity 0.1% of span

Stability 0.05% of span per 24 hours, non-cumulative

Temperature Drift Span or zero, 0.02% of span/°C

Warm-up Time

Instrument Response Time

7 seconds to rated performance

6 seconds to 90% of step input at lowest setting

Max. Sensor-Instrument

Distance

3000 ft. (914 meters) w/ preamp,

30 ft. (9.1 meters) w/o preamp

Sensor Types Omega ORP w/ preamp, 5 wire input (Model ORE-45P),

or combination style ORP electrode w/ TC - 2 wire input

Rev. B, 05/02

ORTX-45

12

Page 12

Part 2 - Mounting

2.1 General

All **TX-45 Series Instruments offer maximum mounting

flexibility. A bracket is included with each unit that allows

mounting to walls, pipes and DIN rail. In all cases, choose

a location that is readily accessible for calibrations. Also

consider that it may be necessary to utilize a location

where solutions can be used during the calibration process.

To take full advantage of the high contrast display, mount

the instrument in a location where the display can be

viewed from various angles and long distances.

The two-wire version of the instrument is ideal for remote

mounting applications where line power in unavailable and

expensive to run, or in locations where only low-voltage

wiring is allowed. The 115/230 VAC powered version of

the instrument is designed to be used where line power is

already available. The portable version can be used for

survey measurements or for calibration checks of a larger

number of permanently installed units.

Locate the instrument in close proximity to the point of

sensor installation - this will allow easy access during

calibration. Sensor-to-instrument distances of over 3000

feet are possible with the high performance Omega

ORE-45P sensor, but this is not generally recommended

since it may hamper access to sensor during calibration.

The sensor-to-instrument distance for combination style

electrodes must not exceed 30 feet.

Rev. B, 05/02

For long distance installations (50 feet or more), standard

sensor cable (10 feet) in combination with a junction box

and interconnect cable is recommended. Sensors with

extremely long cables can be cumbersome to remove for

cleaning or service. It is much more convenient to remove

or replace a sensor with only 10 feet of cable when a

junction box is used. It is also far more economical.

In general, the location should be relatively dry and clean

with little or no vibration, and the ambient temperature

must be within the operating temperature limits of the

instrument. Avoid areas where the instrument may be

frequently splashed with corrosive process materials.

Particularly in the integral mount version, excessive vibration

or heat from the process line may degrade the reliability of

the system.

ORTX-45

13

Page 13

Part 2 - Mounting 2.1 General

Note: Never leave the instrument case open for ex-

tended periods of time. This can allow corrosive

materials to attack the circuitry of the system.

Due to the high flexibility of the instrument design, some of

the mounting features change based on the option boards

that may be installed. For example, the panel mounting

implementation is different for the 115/230 VAC controller

because the rear of the enclosure must be used. A

special flange must be used to seal the entire enclosure

to the panel. In the 2-wire transmitter configuration, just

the front of the enclosure can be mounted. In addition, the

115/230 VAC must not be integral mounted. Carefully

study all mounting configurations.

2.2 Wall

Mounting

2.3 Pipe

Mounting

Any of the instrument configurations may be wall mounted

(see Figures 2-1 and 2-2 for details). The multi-purpose

bracket is attached to the rear of the enclosure using the

four provided pan head screws. The protrusion side of the

multi-purpose bracket should face into the depression on

the rear of the instrument enclosure. The instrument is

then attached to the wall using the four outer mounting

holes in the bracket.

For the pipe mounting configuration, the multipurpose

bracket is attached to the rear of the enclosure with the

four provided screws. The protrusion on the bracket must

face outward. The bracket may be rotated for proper

alignment prior to mounting (see Figures 2-1 and 2-2 for

details).

Once the bracket is fastened to the rear of the enclosure, the

provided pipe clamp must be completely opened and slipped

through the two slots in the multi-purpose mounting bracket.

The clamp is then looped around the pipe, re-attached, and

tightened.

Rev. B, 05/02

ORTX-45

14

Page 14

Part 2 - Mounting 2.3 Pipe Mounting

Inches (mm)

Figure 2-1 Multi-Purpose Bracket

Rev. B, 05/02

Figure 2-2 ORTX-45 Mounting Configurations

ORTX-45

15

Page 15

Part 2 - Mounting 2.4 DIN Rail Mounting

2.4 DIN Rail

Mounting

2.5 Integral

Mounting

For the DIN rail mounting configuration, the multipurpose

bracket is attached to the rear of the enclosure with the

four provided screws. The protrusion on the bracket must

face outward. The bracket may be rotated for proper

alignment prior to mounting (see Figures 2-1 and 2-2 for

details).

Once the bracket is fastened to the rear of the enclosure,

the unit must be slid onto the DIN rail. It does not lock into

place. Therefore, if the unit is removed for service or

replacement, it must be slid off of the DIN rail, or the front

half of the controller can be removed and replaced since

all of the electronics in the 2-wire configuration reside in

the front half.

Only the 2-wire configuration may be mounted directly on

the back of the Model ORE-45P sensor (see Figures 2-2

and 2-3 for details).

Note: Do not attempt to integral mount the 115/230

VAC configuration. This configuration is not

designed to be mounted directly to the sensor.

2.6 Panel

Mounting

Rev. B, 05/02

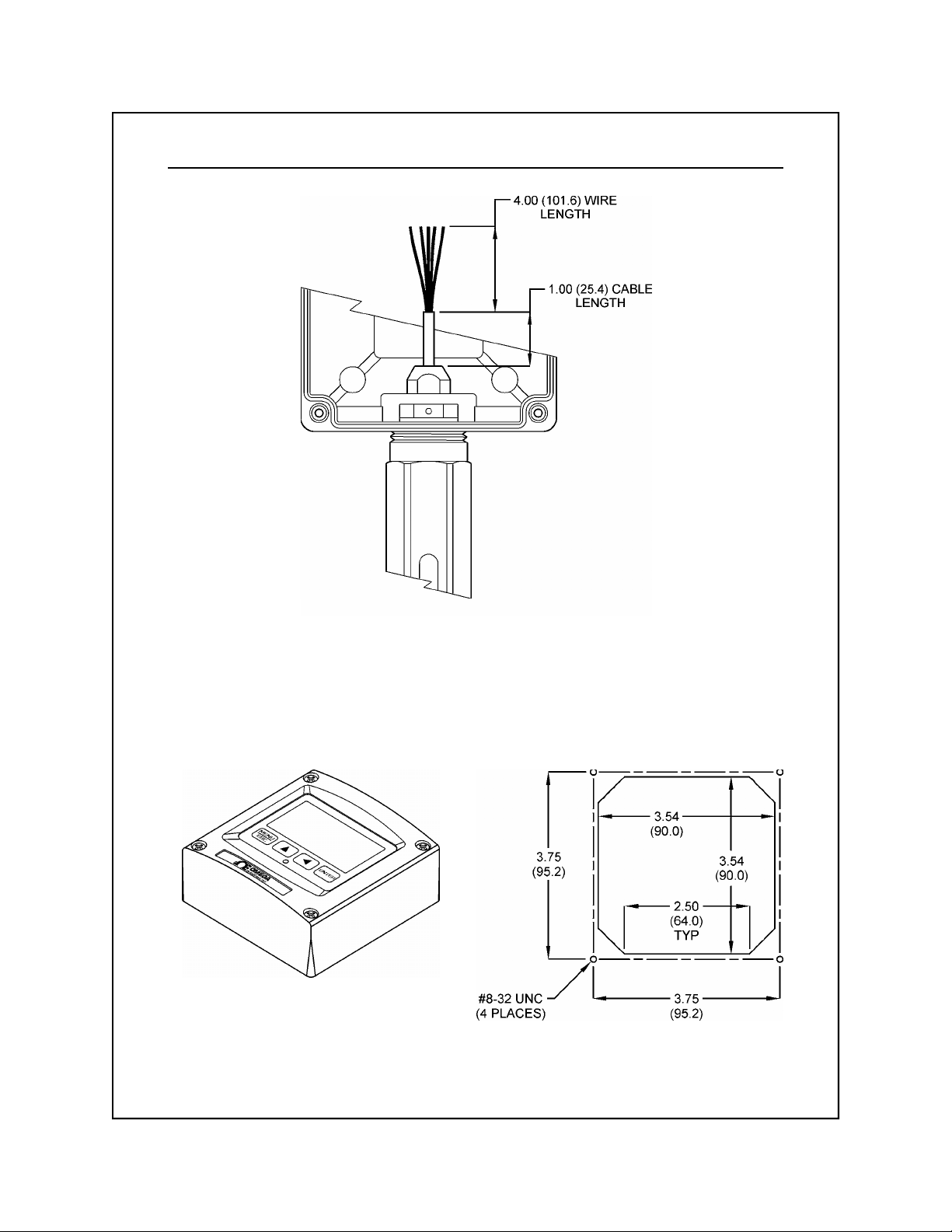

For an integral mount connection, the sensor cable must

be cut substantially to fit into the instrument enclosure.

Cut and strip the sensor cable as shown in Figure 2-3.

Screw the sensor fully into the enclosure base before

completing wiring connections.

The instrument may also be panel mounted in two different

ways:

In the 2-wire configuration, the front half of the enclosure

may be separated and mounted by itself, as shown in

Figure 2-4. Note that the rear of the instrument enclosure

is not utilized in this mounting scheme. Holes must be

drilled at the perimeter of the panel cut-out that allow the

enclosure screws to pass through and be retained on the

back side. User-supplied #8-32 nuts are used to fasten

the instrument from the back. The FIP instrument gasket

remains intact during this mount to seal to the panel.

ORTX-45

16

Page 16

Part 2 - Mounting 2.6 Panel Mounting

Inches (mm)

Inches (mm)

Figure 2-3 2-Wire Integral Mount Detail

Figure 2-4 2-Wire Panel Mount and Cut-out

Rev. B, 05/02

ORTX-45

17

Page 17

Part 2 - Mounting 2.6 Panel Mounting

In the full enclosure configuration (necessary with the

115/230 VAC card option), the entire enclosure is panelmounted using a special optional sealing flange.

The sealing flange must first be attached to the enclosure.

Remove the enclosure hinge by bending one of the hinge

legs inward toward the center of the enclosure with a

pair of needle nose pliers. Once it is loose, slide the

hinge leg out the opposite side. When completed, remove

the two hinge retainer screws and hinge plate assembly.

Fasten the flange to the rear half of the enclosure using

the four hex retainers. The flange gasket material must

face towards the rear of the enclosure. Re-install the

hinge and hinge plate assembly onto the flange using the

two hinge screws. Re-attach hinge pins to the front half of

the enclosure by bending the hinge pin leg with a pair of

needle nose pliers. The flange is now installed. Seal up

the finished enclosure by tightening down the four enclosure

screws prior to mounting.

A different cut-out is required for this configuration, as

shown in Figure 2-5. Once the cut-out has been completed,

insert the flanged enclosure through the cut-out. The

mounting bracket is then attached to the rear of the enclosure

as shown. Install the four tension screws through the four

mounting holes in the bracket, and place the no-slip

rubber boots on each screw. Tighten all screws down to

seal the enclosure flange onto the panel.

Rev. B, 05/02

ORTX-45

18

Page 18

Part 2 - Mounting 2.6 Panel Mounting

Inches (mm)

Rev. B, 05/02

Figure 2-5 115/230 VAC Panel Mount and Cut-out

ORTX-45

19

Page 19

Part 3 - Electrical Installation

3.1 General

The instrument may be powered in several ways, depending on the option features installed. The 2-wire version is

a 16-35 VDC powered transmitter. The integral 115/230

VAC version and relay version require line power. Please

verify the type of unit before connecting any power.

WARNING: Do not connect AC line power to the 2-

wire module. Severe damage will result.

Important Notes:

1. Use wiring practices that conform to all national, state

and local electrical codes. For proper safety as well as

stable measuring performance, it is important that the

earth ground connection be made to a solid ground

point from TB1. The power supply contains a single

¼-Amp slo-blo fuse on the H Terminal.

2. Do NOT run sensor cables or instrument 4-20 mA

output wiring in the same conduit that contains AC

power wiring. AC power wiring should be run in a

dedicated conduit to prevent electrical noise from

coupling with the instrumentation signals.

3.2 Two-Wire

Configuration

Rev. B, 05/02

In the two-wire configuration, a separate DC power supply

must be used to power the instrument. The exact connection

of this power supply is dependent on the control system

into which the instrument will connect. See Figure 3-1 for

further details. Any general twisted pair shielded cable

can be used for connection of the instrument to the power

supply. Route signal cable away from AC power lines,

adjustable frequency drives, motors, or other noisy electrical

signal lines. Do not run sensor or signal cables in conduit

that contains AC power lines or motor leads.

ORTX-45

20

Page 20

Part 3 - Electrical Installation 3.2 Two-Wire Configuration

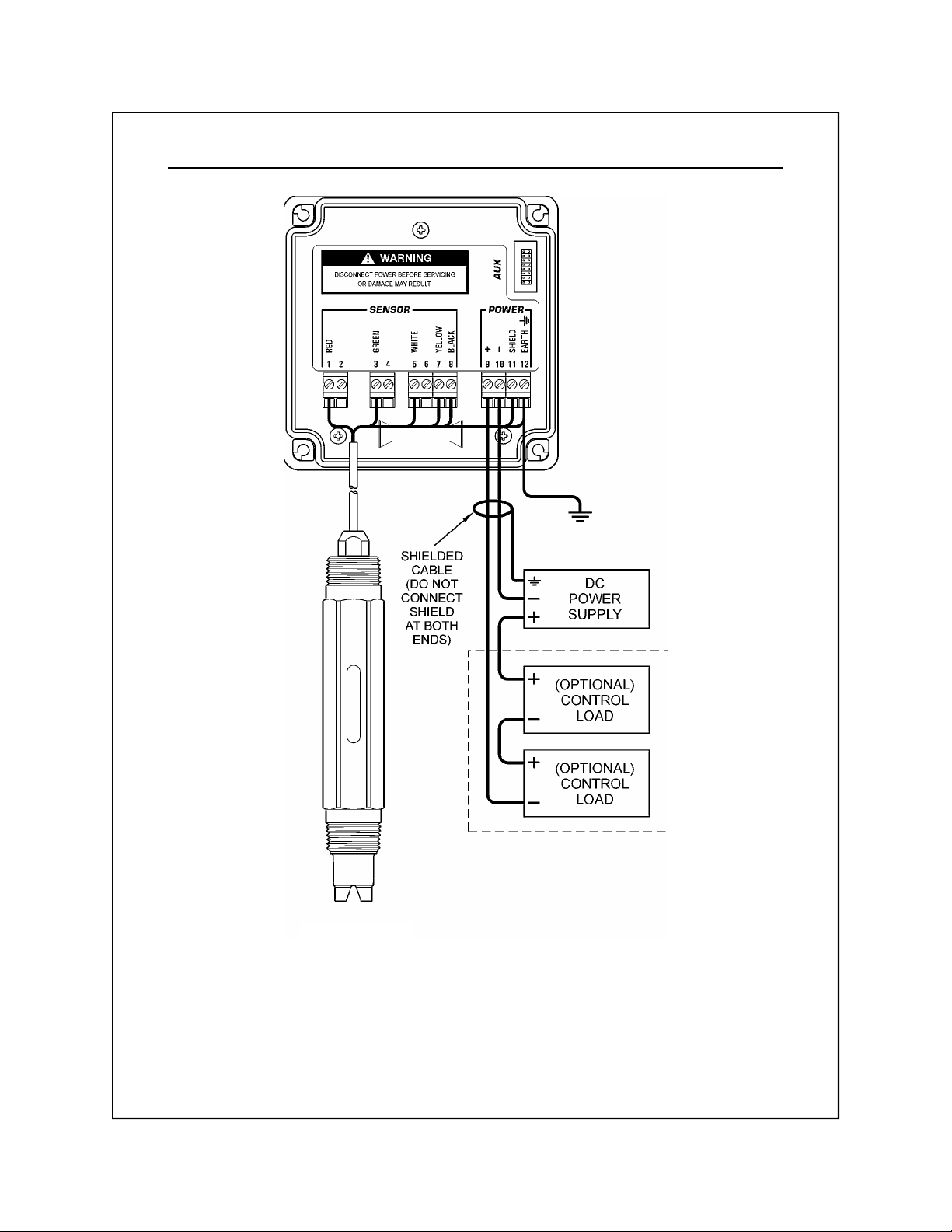

ORE-45P SENSOR

Notes: 1. Voltage between Terminals 9 and 10 MUST be between 16 and 35 VDC.

2. Earth ground into Terminal 12 is HIGHLY recommended. This connection can greatly

improve stability in electrically noisy environments.

Figure 3-1 Loop Power Connection, Omega ORE-45P Sensor and ORTX-45 Transmitter

Rev. B, 05/02

ORTX-45

21

Page 21

Part 2 - Installation 3.2 Electrical-2 wire Version Part 3 - Electrical Installation 3.21 Load Drive Capability

3.21 Load Drive

Capability

The amount of resistance that the analog output can drive

in the 115/230 VAC version is fixed. However, in the twowire configuration, the load-drive level is dependant on the

DC supply voltage provided to the controller.

The two-wire instrument can operate on a power supply

voltage of between 16 and 35 VDC. The available load

drive capability can be calculated by applying the formula

V/I=R, where V=load drive voltage, I=maximum loop

current (in Amperes), and R=maximum resistance load (in

Ohms).

To find the load drive voltage of the two-wire ORTX-45,

subtract 16 VDC from the actual power supply voltage

being used (the 16 VDC represents insertion loss). For

example, if a 24 VDC power supply is being used, the load

drive voltage is 8 VDC.

The maximum loop current of the two-wire ORTX-45 is

always 20.00 mA, or .02 A. Therefore,

(Power Supply Voltage - 16)

R

=

.02

MAX

Rev. B, 05/02

For example, if the power supply voltage is 24 VDC, first

subtract 16 VDC, then divide the remainder by .02.

8/.02 = 400; therefore, a 400 Ohm maximum load can be

inserted into the loop with a 24 VDC power supply.

Similarly, the following values can be calculated:

Power Supply Voltage

Total Load (Ohms)

(VDC)

16.0 0

20.0 200

24.0 400

30.0 700

35.0 950

ORTX-45

22

Page 22

Part 2 - Installation 3.3 Electrical—115/230 vac Version Part 3 - Electrical Installation 3.3 115/230 VAC Configuration

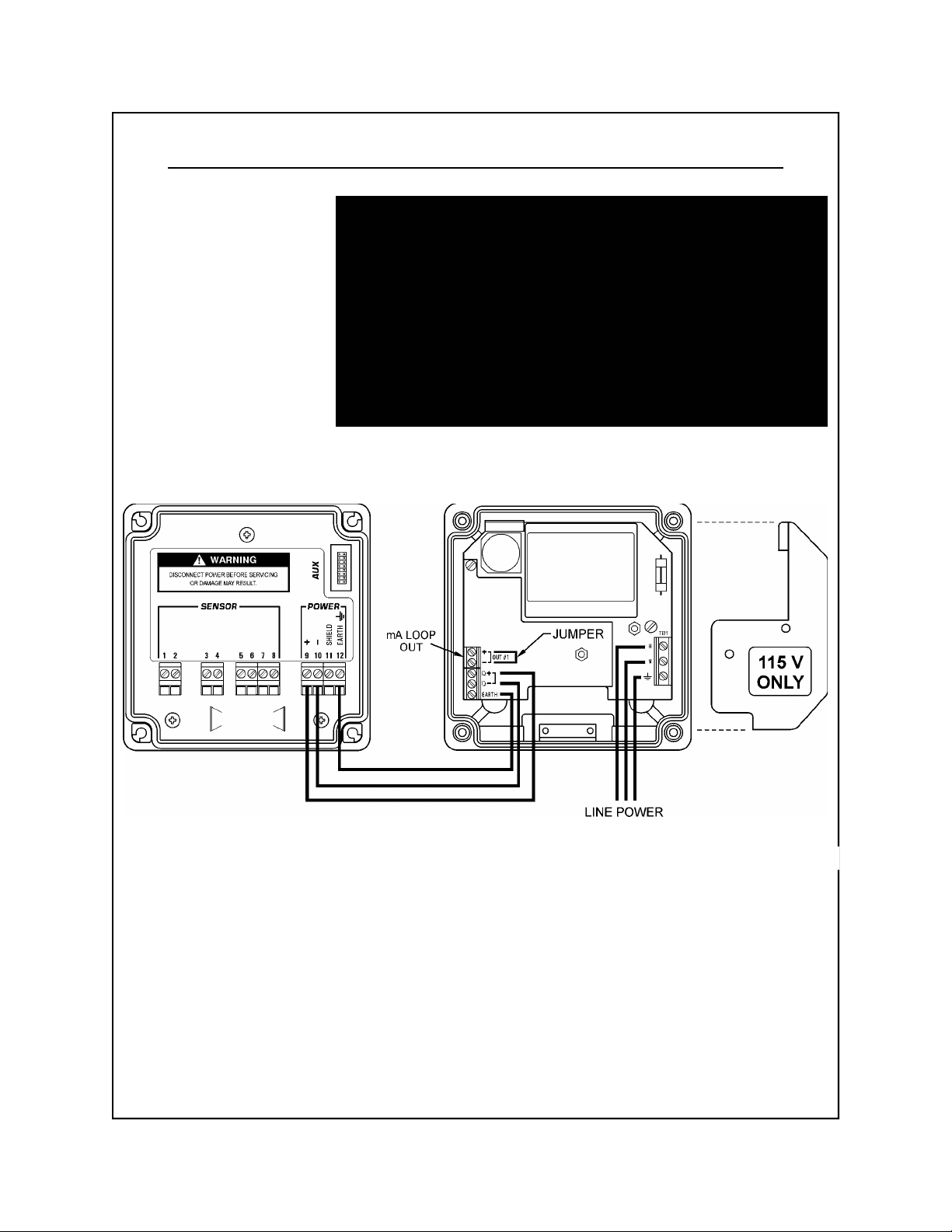

3.3 115/230 VAC

Configuration

In the 115/230 VAC configuration, a DC power supply is

mounted into the inside rear of the enclosure. The power

supply must be ordered with the proper operating voltage.

Verify that the unit requires either 115 VAC or 230 VAC

before installing. Also verify that power is fully disconnected

before attempting to wire.

Connect HOT, NEUTRAL, and GROUND to the matching

designations on terminal strip TB1.

If the unit was ordered with the integral power supply

installed, a connection will also be present from terminal

strip

to the ORTX-45 module. If the power supply

TB2

was ordered separately and installed later, this last

connection at TB2 must be made at this time as shown in

Figure 3-2.

The analog output from the system is present at terminal

TB1. The loop-load limitation in this configuration is 500

Ohms maximum. If the analog output will not be connected

to other instruments, these two terminals must remain

shorted for proper operation.

Note: If not using the 4-20 mA output, a wire short

must exist between terminals (+) and (-) for

proper operation.

Rev. B, 05/02

ORTX-45

23

Page 23

Part 2 - Installation 2.2 Electrical—115/230 VAC Version Part 2 - Installation and Operation 2.3 Electrical

Part 3 - Electrical Installation 3.3 115/230 VAC Configuration

WARNING

Disconnect line power voltage BEFORE connecting

line power wires to Terminal TB1 of the power supply.

The power supply accepts only standard three-wire

single phase power. The power supply is configured

for either 115 VAC or 230 VAC operation at the factory at

time of order, and the power supply is labeled as

such. Do NOT connect voltages other than the labeled

requirement to the input.

Rev. B, 05/02

Figure 3-2 Line Power Connection

The power strip,

, allows up to 14 AWG wire. A wire

TB1

gauge of 16 AWG is recommended to allow for an easy

pass-through into the PG-9 ports when wiring.

ORTX-45

24

Page 24

Part 2 - Installation 3.4 Electrical—Relay Version Part 3 - Electrical Installation 3.4 115/230 VAC w/ 2 Relays Configuration

3.4 115/230 VAC

w/ 2 Relays

Configuration

In the 115/230 VAC w/ relays configuration, a DC power

supply is mounted into the inside rear of the enclosure.

The power supply must be ordered with the proper operating

voltage. Verify that the unit requires either 115 VAC or

230 VAC before installing. Also verify that power is fully

disconnected before attempting to wire.

Connect HOT, NEUTRAL, and GROUND to the matching

designations on terminal strip TB1.

If the unit was ordered with the integral power supply

installed, a connection will also be present from terminal

strip

to the ORTX-45 module. If the power supply

TB2

was ordered separately and installed later, this last connection at TB2 must be made at this time.

The analog outputs from the system are present at terminal TB2. The loop-load limitation in this configuration 400

Ohms maximum. If the analog output will not be connected to other instruments, these two terminals must remain shorted for proper operation.

Note: If not using the 4-20 mA output #1, a wire

short must exist between terminals (+) and(-)

for proper operation.

Rev. B, 05/02

WARNING

Disconnect line power voltage BEFORE connecting

line power wires to Terminal TB1 of the power supply.

The power supply accepts only standard three-wire

single phase power. The power supply is configured

for either 115 VAC or 230 VAC operation at the factory at

time of order, and the power supply is labeled as

such. Do NOT connect voltages other than the labeled

requirement to the input.

ORTX-45

25

Page 25

Part 3 - Electrical Installation 3.4 115/230 VAC w/ 2 Relays

ORP LOOP

OUT

Figure 3-3 Line Power w/ Relays Connection

Also in the line-power w/ relays configuration, a special

cable is connected under the power supply that runs to the

AUX connector on the main part of the instrument. The

cable is retained by a clip mounted under the AUX connector

on the shield. Under the power supply, the black wire in

the cable should be facing PIN 2. On the AUX connector,

the white wire should be in the upper left corner (see

Figure 3-4 for further details).

Rev. B, 05/02

Figure 3-4 Relay Cable Connection

ORTX-45

26

Page 26

Part 2 - Installation 2.33 Electrical—Relay Version Part 3 - Electrical Installation 3.4 115/230 VAC w/ 2 Relays Part 2 - Installation 2.2 Electrical—115/230 VAC Version Part 2 - Installation and Operation 2.3 Electrical Part 3 - Electrical Installation 3.4 115/230 VAC w/ 2 Relays

Relay Contacts

Two sets of SPDT relay contacts are provided on the relay

option board. None of the relay contacts are powered.

The user must supply the proper power to the contacts.

For applications that require the same switched operating

voltage as the ORTX-45 (115 or 230 V), power may be

jumpered from the power input terminals at

Figure 3-5 Relay Contacts

TB1

.

3.5 Battery-Powered

(Portable)

Configuration

Rev. B, 05/02

In the battery-powered version, the instrument is converted to

a display-only portable unit. The battery option card

cannot be used with any other option cards. All of the

normal software functions are active in the portable unit.

In addition, there are several unique hardware features

which are described in detail here.

Note: Do not attempt to connect external DC or AC

power supplies to the portable unit or severe

damage will result.

ORTX-45

27

Page 27

Part 3 - Electrical Installation 3.5 Battery-Powered Configuration

Installation

ORTX-45 TRANSMITTER

To install the battery board, open the ORTX-45 instrument

enclosure and place the board into the rear of the enclosure

as shown in Figure 3-6. The board should be oriented

such that the header connector P1 is located in the upper

left corner of the enclosure. Fasten the circuit board into

the enclosure at the three indicated mounting points using

the three #4 screws included with the kit. Once the board

is fastened, connect the power cable from header connector

P1 on the battery board to the header located in the AUX

port of the instrument. The blue wire on the ribbon cable

should face down and correspond to the white polarity dot

designating pin 1 on the header connector P1. Finally,

install one alkaline 9 VDC battery into battery holder B1.

Since the header connector is below the shield plate, it

helps to bend the connector “out” slightly on the ribbon

cable before inserting it.

Rev. B, 05/02

Figure 3-6 DC Battery Board Connection

ORTX-45

28

Page 28

Part 2 - Installation 3.5 Electrical—Portable Version Part 3 - Electrical Installation 3.5 Battery-Powered Configuration

Operation

Two hardware switches are located on the battery board:

the power switch S2-PWR and the lock switch S1-LOCK.

The PWR switch disconnects the 9 VDC battery and is

only used to disconnect the battery if the system is not to

be used for a long period of time (> 3 months or storage).

Otherwise, leave this switch in the ON position. The

LOCK switch selects between two different modes of

operation: the normal/off mode or locked/on mode. When

LOCK is in the normal/off mode, the system functions

normally and turns on by holding the MENU key on the

front keypad for 5 seconds. Thereafter, the system will

turn off automatically after 2 hours if no keys are pressed.

When LOCK is in the ON mode, the system is permanently

on and will not turn off. This mode is used for extended

operation.

With the system in normal mode (LOCK = OFF), an alkaline

battery will provide approximately 5 months of noncontinuous operation. Specifically, this would represent

periodic operation of the unit of less than 10 hours per

week. When the system is in locked mode (LOCK = ON),

an alkaline battery will provide approximately 10-14 days

of continuous operation. Installing a 9 VDC lithium battery

instead of alkaline will increase operation time in all

modes by 4x. These projections are dependant upon

which instrument the battery board is operating and the

ambient temperature (higher temperatures will shorten

battery life span).

Rev. B, 05/02

The "B" icon will flash on the LCD when the instrument

requires battery replacement. If the battery is not replaced,

eventually the unit will not turn on in the normal operating

mode. This low-battery indicator functions only when

LOCK = OFF.

ORTX-45

29

Page 29

Part 2 - Installation 3.5 Electrical—Portable Version Part 3 - Electrical Installation 3.5 Battery-Powered Configuration

Notes

Several important points to remember when operating the

instrument with the battery board option:

1. To turn the unit ON, press and hold the MENU key for

5 seconds. The unit will turn off automatically after 2

hours if no keys are pressed.

2. NEVER connect an external power source to the instrument power terminals when the battery board is

installed. Severe damage can result.

3. The 4-20 mA output is not functional when the battery

board is connected. To restore 4-20 mA output

functionality, the battery board must be removed.

4. When using the instrument for portable measurements,

be aware of the time required to achieve stable

readings from particular sensors. In most cases,

sensor primary measurements require stable temperature

readings for accurate temperature compensation. The

user must allow adequate time for the sensor to temperature equilibrate with the solution being measured.

Due to the heavy-duty construction of the ORE-45P

sensor, they may require up to 15 minutes to fully

temperature equilibrate with solutions at temperatures

that are considerably different from the initial sensor

temperature.

Rev. B, 05/02

5. Set the PWR switch to OFF if the unit will not be operated

for an extended period of time, or if it is to be stored.

ORTX-45

30

Page 30

Part 4 - Sensor Connection

4.1 General

The sensor cable can be routed into the enclosure through

one of the provided cord-grip retainers, or through a

properly sized conduit connection. Adapters are available

to convert the PG-9 type opening into a 1/2” NPT type

opening.

If the cord-grip devices are used for sealing the cable,

make sure the cord-grips are snugly tightened after

electrical connections have been made to prevent moisture

incursion. If not using the integral mount method, the

center conduit hole of the enclosure should be plugged

with the provided 1" NPT plug.

When stripping cables, leave adequate length for connections in the transmitter enclosure, as shown below.

Rev. B, 05/02

Figure 4-1 Bulkhead Connection

If the instrument is ordered with the Relay Option Board

installed, the enclosure includes three PG-11 cord grips to

allow for the additional wiring going into the enclosure.

ORTX-45

31

Page 31

Part 4 - Sensor Connection 4.2 ORE-45P Sensor Connection

4.2 ORE-45P Sensor

Connection

Figure 4-2 Sensor Cable Connections, Omega ORE-45P

The sensor cable can be quickly connected to the

ORTX-45 terminal strip by matching the wire colors on

the cable conductors. Route signal cable away from AC

power lines, adjustable frequency drives, motors, or other

noisy electrical signal lines. Do not run sensor or signal

cables in conduit that contains AC power lines or motor

leads. See Figure 4-2 for details on connecting the highperformance Omega sensor (Model ORE-45P).

Rev. B, 05/02

Note: Only the custom 6-wire shielded interconnect

cable must be used when connecting the Model

ORE-45P sensor to the instrument. This highperformance, double shielded, polyethylene

jacketed cable is specially designed to provide

the proper signal shielding for the sensor used

in this system. No substitutions can be made.

Substituted cables may cause problems with

system performance.

For optimum electrical noise rejection performance,

connect the innermost cable shield to the terminal marked

Shield

the terminal marked

on the instrument; connect the outermost shield to

Earth

. In addition, the earth terminal

should also be grounded to a nearby source of electrically

clean ground. Do not allow shield wires to short together.

ORTX-45

32

Page 32

Part 4 - Sensor Connection 4.3 Combination Electrode Connection

4.3 Combination

Electrode

Connection

The ORTX-45 may also be used with non-amplified simple

combination electrodes (see Figure 4-3). Note that a wire

jumper must be installed from Terminal 3 to Terminal 8.

The user must also select Sensor Type 2 within the Config

Menu (see Section 5.24). The maximum sensor-toinstrument cable length will be severely limited (30-50

feet) with electrodes of this type. The length will depend

on the specific electrode impedance and the quality of

interconnect cable provided by the manufacturer.

Rev. B, 05/02

Figure 4-3 Sensor Cable Connections, Combination Electrode

ORTX-45

33

Page 33

Part 4 - Sensor Connection 4.4 External Temperature Compensators

4.4 External

Temperature

Compensators

The Omega ORE-45P sensor includes an integral Pt1000

RTD. The Omega **TX-45 series instruments also allow

user-supplied external Pt1000 or Pt100 elements to be

connected to the temperature input, as shown in Figure

4-4. Note that when using the Pt100 connection, sensor

cable length will be limited to 40 feet due to the high cable

resistance error associated with the lower resistance

output of Pt100 RTD elements. In other words, cable

resistance represents a higher percentage of error signal

when using a lower-resistance RTD.

Rev. B, 05/02

Figure 4-4 External Temperature Compensators

ORTX-45

34

Page 34

Part 4 - Sensor Connection 4.5 Long Cable Length Issues

4.5 Long Cable

Length Issues

Cable Resistance

Very long sensor cable runs (> 400 feet) with relatively

low-Ohm resistive temperature sensors can suffer from

accuracy problems related to additive cable resistance as

well as instability of cable resistance over temperature. In

such cases, a three or four-wire connection method allows

these types of errors to be removed from the measurement.

Although the ORTX-45 is configured as a two-wire RTD

input for ease of connection, the transmitter may be

easily configured as a three-wire element if desired. The

three-wire connection allows the instrument to eliminate

errors caused by changes in the resistance of very long connection leads.

In addition to cable resistance, sensor cable lengths

greater than 400 feet may degrade the electrode diagnostic

signals, resulting in false trips. If this occurs, the glass

diagnostic may be switched off without affecting the remaining system diagnostics. See Section 5.25 for further

details.

The Pt1000 temperature element in the Omega ORE-45P

sensor is a high accuracy, Class A tolerance element.

Tolerance of this element is 0.06% at 0°C, or 0.1°C. In

the standard connection the RTD is configured as a twowire element. The sensor cable on the Model ORE-45P

sensor has a lead resistance of approximately 0.0277Ω/ft

at 68°F. The lead length for the RTD is twice as long as

the sensor cable since two leads are attached to the RTD

element in the sensor. Therefore, 100 feet of sensor

cable represents a possible uncalibrated measurement

error of 200 × 0.0277Ω/ft = 5.54Ω. Since the Pt1000 RTD

has a slope of 0.00385Ω/Ω/°C, this calculates to

5.54Ω/3.85 = 1.44°C. Therefore, this length of sensor

cable can represent a severe error for instruments that do

not allow the user to calibrate temperature. Using the

standard two-wire connection, the ORTX-45 transmitter

allows the user to calibrate out these errors up to

approximately 400 feet of sensor cable.

Rev. B, 05/02

ORTX-45

35

Page 35

Part 4 - Sensor Connection 4.5 Long Cable Length Issues

Cable

Temperature Shift

Three-Wire RTD

Connection

In addition to cable length errors, the user must consider

the effects of temperature changes on the sensor cable

itself. The wire in the ORE-45P sensor is copper, and the

temperature coefficient for copper is 0.00393/°C. When

mounted indoors, the effects of temperature change over

the entire length of cable are negligible. However, long

lengths of cable mounted outdoors may undergo appreciable

shifts in resistance over temperature, causing large errors.

Using the temperature coefficient, 100 feet of cable can

result in an error of approximately 0.3°C over a 50°C

change from standardization. This type of error cannot be

calibrated out. It can only be removed by utilizing the

three-wire connection scheme (see below). However, this

error is unusual in that the entire cable length must

change by the same temperature.

For sensor cable distances of 400 feet or more, a threewire RTD connection will produce the highest accuracy

measurement. This connection requires the use of a

junction box. To configure the instrument for a three-wire

connection, the metal PCB shield over the terminal strips

must be carefully removed by first removing the three

retaining screws, then gently prying the shield upward and

slightly pushing the terminal strips through the opening in the

shield. Once the shield has been removed, the user must

cut a small white jumper J1 in the lower-right section of

the top scaling board. Replace the shield and connect the

Model ORE-45P sensor as shown in Figure 4-5. If the

two-wire connection is desired at any time after this

change has been made, the user must install a wire

jumper between terminals 6 and 7 on the transmitter.

Rev. B, 05/02

ORTX-45

36

Page 36

Part 4 - Sensor Connection 4.5 Long Cable Length Issues

ORTX-45 TRANSMITTER

When utilizing the 3-wire RTD connection, a wire jumper

*

must be made between the yellow and blue wires in the

junction box as shown. The blue wire on the connecting

sensor cable must be attached to Terminal 6 in the

ORTX-45 Transmitter as shown. In addition, a jumper

on the scaling board must also be removed. Refer to

Page 36 for further details.

Connecting sensor cable lengths can be up to 400 feet

with a 2-wire RTD connection, and up to 3,000 feet with a

3-wire RTD connection.

When utilizing the junction box connection, the blue wire

on the connecting sensor cable must be attached to

Terminal 6 on the ORTX-45 Transmitter, as above. However, the blue wire on the ORE-45P Sensor cable is not

used.

Use ONLY the provided sensor interconnect cable between

the transmitter and the junction box.

Figure 4-5 Junction Box Connection and Three-Wire RTD Connection

Rev. B, 05/02

ORTX-45

37

ORE-45P SENSOR

Page 37

Part 5 - Operation

5.1 User Interface

The user interface for the ORTX-45 instrument consists of

a custom display and a membrane keypad. All functions

are accessed from this user interface (no internal jumpers,

pots, etc.).

Rev. B, 05/02

(Display shown with all segments ON)

Figure 5-1 User Interface

ORTX-45

38

Page 38

Part 5 - Operation 5.11 Keys

5.11 Keys

All user configuration occurs through the use of four

membrane keys. These keys are used as follows:

MENU/ESC

To scroll through the menu section

headers or to escape from anywhere in

software. The escape sequence allows

the user to back out of any changes in a

logical manner. Using the escape key

aborts all changes to the current screen

and backs the user out one level in the

software tree. The manual will refer to this

key as either MENU or ESC, depending

upon its particular function.

UP

(arrow)

To scroll through individual list or display

items and to change number values.

LEFT

(arrow)

To move the cursor from right to left during

changes to a number value.

ENTER To select a menu section or list item for

change and to store any change.

5.12 Display

Main Parameter

Rev. B, 05/02

The large custom display provides clear information for

general measurement use and user configuration. There

are three main areas of the display: the main parameter

display, the secondary message line, and the icon area.

During normal operation, the main parameter display

indicates the present process input with sign and units.

This main display may be configured to display any of the

main measurements that the system provides. During

configuration, this area displays other useful set-up information to the user.

ORTX-45

39

Page 39

Part 5 - Operation 5.12 Display

Lower Line

Icon Area

During normal operation, the lower line of the display

indicates user-selected secondary measurements that the

system is making. This also includes calibration data from

the last calibration sequence and the instrument model

number and software version. During configuration, the

lower line displays menu items and set-up prompts to the

user. Finally, the lower line will display error messages

when necessary. For a description of all display messages,

refer to Section 7.3.

The icon area contains display icons that assist the user in

set-up and indicate important states of system functions.

The CAL, CONFIG, and DIAG icons are used to tell the

user what branch of the software tree the user is in while

scrolling through the menu items. This improves software

map navigation dramatically. Upon entry into a menu, the

title is displayed (such as CAL), and then the title disappears

to make way for the actual menu item. However, the icon

stays on.

HOLD

FAIL

Rev. B, 05/02

The HOLD icon indicates that the current output of the instrument has been put into output hold. In this case, the

output is locked to the last input value measured when the

HOLD function was entered. HOLD values are retained

even if the unit power is cycled.

The FAIL icon indicates that the system diagnostic

function has detected a problem that requires immediate

attention. This icon is automatically cleared once the

problem has been resolved.

ORTX-45

40

Page 40

Part 5 - Operation 5.12 Display

Relay Area A/B

5.2 Software

The relay area contains two icons that indicate the state of

the system relays (if the relay card is installed). If the

battery board is installed instead, the B icon indicates that

the battery voltage is at a low level. The battery power

option and the relay option cannot be installed together.

The software of the ORTX-45 is organized in an easy to

follow menu-based system. All user settings are organized under four menu sections: Measure, Calibration

[CAL], Configuration [CONFIG], and Diagnostics [DIAG].

Note: The default Measure Menu is display-only and has no

menu icon.

5.21 Software

Navigation

Rev. B, 05/02

Within the CAL, CONFIG and DIAG menu sections is a list

of selectable items. Once a menu section (such as

CONFIG) has been selected with the MENU key, the user

can access the item list in this section by pressing either

the ENTER key or the UP arrow key. The list items can

then be scrolled through using the UP arrow key. Once

the last item is reached, the list wraps around and the first

list item is shown again. The items in the menu sections

are organized such that more frequently used functions

are first, while more permanent function settings are later

in the list. See Figure 5-2 for a visual description of the

software.

ORTX-45

41

Page 41

Part 5 - Operation 5.21 Software Navigation

Each list item allows a change to a stored system variable.

List items are designed in one of two forms: simple single

variable, or multiple variable sequence. In the single

variable format, the user can quickly modify one parameter for example, changing temperature display units from °F

to °C. In the multiple variable sequence, variables are

changed as the result of some process. For example, the

calibration of ORP generally requires more than one piece

of information to be entered. The majority of the menu

items in the software consist of the single variable format

type.

Any data that may be changed will be flashing. This

flashing indicates user entry mode and is initiated by

pressing the ENTER key. The UP arrow key will increase

a flashing digit from 0 to 9. The LEFT arrow key moves

the flashing digit from right to left. Once the change has

been completed, pressing ENTER again stores the variable

and stops the flashing. Pressing ESC aborts the change

and also exits user entry mode.

The starting (default) screen is always the Measure Menu.

The UP arrow key is used to select the desired display.

From anywhere in this section the user can press the

MENU key to select one of the four Menu Sections.

The UP arrow icon next to all list items on the display is a

reminder to scroll through the list using the UP arrow key.

Rev. B, 05/02

ORTX-45

42

Page 42

(

)

(

)

)

y

Part 5 - Operation 5.21 Software Navigation

MENU

SECTIONS

Te mp er atu re

Loop Cu rrent (ORP- #1)

Loop Current (°C/°F- #2)

*

Sensor Offset

Model/Version

**

LIST

ITEMS

Start

MEASURE

(displ ay only)

mV

Tim er Sta tu s

MENU

ESC

Relay A= FAIL

CAL CONFIG DIAG

ENTER ENTER ENTER

or

Cal ORP

Cal Temp

Cal TC Fact

MENU

ESC

Set 4mA

Set 20mA

Set 4mA (°C/°F- #2

*

or

Entry Lock

*

Set Delay

Relay A= AL

Setpnt A- HI

*

Delay A- HI

*

Setpnt A- LO

*

Delay A- LO

*

Phase A

*

Relay A= CON

Setpnt A

*

Delay A

*

Phase A

*

ORP- #1

ORP- #1

(°C/°F- #2)Set 20mA

MENU

ESC

or

Set Hold

Fault List

Sim Out

Fail Out

Glass Diags

Failsa fe

*

Rly A Mode

*

Rly B Mode

*

Default All

MENU

ESC

Rev. B, 05/02

Relay B= FAIL

Relay B= SENS

Tim er B ON

*

Relay B= CON

Setpnt B

*

Delay B

*

Phase B

*

Contrast

Displa

Temp Un its

Temp Input

Select TC

Sensor Type

Figure 5-2 Software Map

ORTX-45

43

Functions enabled

*

with Relay Option Card

Enabled with Relay

**

Option Card when

timer is enabled

(Relay B = SENS)

Page 43

Part 5 - Operation 5.21 Software Navigation

To select a list item for modification, first select the proper

menu with the MENU key. Scroll to the list item with the

UP arrow key and then press the ENTER key. This tells

the system that the user wishes to perform a change on

that item. For single item type screens, once the user

presses the ENTER key, part or all of the variable will

begin to flash, indicating that the user may modify that

variable using the arrow keys. However, if the instrument

is locked (see Section 5.24), the instrument will display the

message Locked! and will not enter user entry mode.

The instrument must be unlocked by entering the proper

code value to allow authorized changes to user entered

values. Once the variable has been reset, pressing the

ENTER key again causes the change to be stored and the

flashing to stop. The message Accepted! will be displayed

if the change is within pre-defined variable limits. If the

user decides not to modify the value after it has already

been partially changed, pressing the ESC key aborts

the modification and returns the entry to its original stored

5.22 Default Menu

In a menu item which is a multiple variable sequence type,

once the ENTER key is pressed there may be several

prompts and sequences that are run to complete the

modification. The ESC key can always be used to abort

the sequence without changing any stored variables.

The default menu for the system is a display-only measurement menu. This menu has no changeable list items and no

navigation icon. When left alone, the instrument will automatically return to this menu after approximately 30 minutes.

While in the default menu, the UP arrow key allows the

user to scroll through the secondary variables on the lower

line of the display, including temperature, current output,

offset data from the last calibration, model number/software

version, and timer status for Relay B (if enabled). Variables

displayed on the lower line will not duplicate the main

display (i.e., the instrument cannot show mV on both the

main and secondary displays).

Rev. B, 05/02

ORTX-45

44

Page 44

Part 5 - Operation 5.22 Default Menu

The timer status screen is only displayed if the probe timer

feature is enabled (available with optional Relay Card), by

setting Relay B Mode =

SENS

(see Section 5.25). The

screen shows the present phase of the timer, as well as how

much time is left before the next phase.

Note: A timer wash cycle can be manually started by

pressing and holding the ENTER key for a few

seconds while viewing the timer status screen in

the Default Menu. The timer must be in the

“OFF” state to allow a manual start (“T” is not

flashing on the display). After this forced cycle,

the system will return to normal.

A display test (all segments ON) can be actuated by

pressing and holding the ENTER key while viewing the

model/version number on the lower line of the display.

5.23 Calibration Menu

[CAL]

Cal ORP

Cal Temp

Cal TC Factor

The calibration menu contains items for frequent calibration

of user parameters. There are three items in this list: Cal

ORP, Cal Temp, and Cal TC Factor.

The ORP calibration menu offers two choices for calibration

of ORP: 2-point and 1-point (sample) methods. See Part 6 Calibration for more details.

The temperature calibration function allows the user to

adjust the offset of the temperature response by a small

factor of ±5 °C. The temperature input is factory calibrated to

very high accuracy. However, very long cable lengths and

junction boxes may degrade the accuracy of the temperature

measurement in some extreme situations. Therefore, this

feature is provided only as an adjustment. Modifying the

present temperature calibration is not recommended since

it can be very difficult to obtain a highly accurate and

stable reference solution as a reference. See Part 6 Calibration for more details.

This function is intended to give the user direct control of

the temperature calibration offset value without having to perform an entire temp cal procedure. See Part 6 - Calibration

for more details.

Rev. B, 05/02

ORTX-45

45

Page 45

Part 5 - Operation 5.24 Configuration Menu

5.24 Configuration

Menu

[CONFIG]

Entry Lock

Set 4 mA

[ORP]

The Configuration Menu contains all of the general user

settings:

This function allows the user to lock out unauthorized

tampering with instrument settings. All settings may be

viewed while the instrument is locked, but they cannot be

modified. The Entry Lock feature is a toggle-type setting;

that is, entering the correct code will lock the transmitter

and entering the correct code again will unlock it. The

code is preset at a fixed value. Press ENTER to initiate

user entry mode and the first digit will flash. Use arrow

keys to modify value.

The ORTX-45 lock/unlock code is

1452. Press ENTER to toggle lock setting once code is

correct. Incorrect codes do not change state of lock

condition.

This function sets the main 4 mA current loop output point

for the instrument. When the Relay Option Board is installed,

the display will read

Set 4 mA #1

. The value stored for

this point may be higher or lower than the value stored for

the 20 mA point. The entry value is limited to a value

between –1000 and +2000 mV, and the 4 mA and the 20

mA point must be at least 100 mV away from each other.

Press ENTER to initiate user entry mode, and the value

will flash. Use arrow keys to modify value; range is –1000

to +2000 mV. Press ENTER to store the new value.

Set 20 mA

[ORP]

Rev. B, 05/02

This function sets the 20 mA current loop output point for

the instrument. When the Relay Option Board is installed,

the display will read

Set 20 mA #1

. The value stored for

this point may be higher or lower than the value stored for

the 4 mA point. The entry is limited to a value between –1000

and +2000 mV, and the 20 mA point and the 4 mA point

must be at least 100 mV away from each other. Press

ENTER to initiate user entry mode, and the value will

flash. Use arrow keys to modify value; range is –1000 to

+2000 mV. Press ENTER to store the new value.

ORTX-45

46

Page 46

Part 5 - Operation 5.24 Configuration Menu

*Set 4 mA #2

[temp]

*Set 20 mA #2

[temp]

ONLY AVAILABLE WITH RELAY OPTION BOARD

.

This function sets the second 4 mA current loop output

point for the transmitter. The value stored for this point

may be higher or lower than the value stored for the 20

mA point. The entry value is limited to a value between 0

and 110 °C, and the 4 mA and the 20 mA point must be at

least 10 °C units away from each other. Press ENTER to

initiate user entry mode, and the value will flash. Use

arrow keys to modify value; range is 0.0 to 110.0 °C.

Press ENTER to store the new value. The optional temperature output is a monitoring type output. It does not

include bumpless transfer, simulate, or fail mode features.

However, HOLD does affect this output.

ONLY AVAILABLE WITH RELAY OPTION BOARD.

This function sets the second 20 mA current loop output

point for the transmitter. The value stored for this point

may be higher or lower than the value stored for the 4 mA

point. The entry is limited to a value between 0 and 110 °

C, and the 20 mA point and the 4 mA point must be at

least 10 °C units away from each other. Press ENTER to

initiate user entry mode, and the value will flash. Use

arrow keys to modify value; range is 0.00 to 110.0 °C.

Press ENTER to store the new value. The optional temperature output is a monitoring type output. It does not

include bumpless transfer, simulate, or fail mode features.

However, HOLD does affect this output.

Set Delay

Rev. B, 05/02

The delay function sets the amount of damping on the

instrument. This function allows the user to apply a first

order time delay function to the ORP measurements being

made. Both the display and the output value are affected

by the degree of damping. Functions such as calibration

are not affected by this parameter. The calibration routines

contain their own filtering and stability monitoring functions

to minimize the calibration timing. Press ENTER to initiate

user entry mode, and the value will flash. Use the arrow

keys to modify value; range is 0.1 to 9.9 minutes.

Press ENTER to store the new value.

ORTX-45

47

Page 47

Part 5 - Operation 5.24 Configuration Menu

*Setpnt A

*Hyst A

*Delay A

ONLY AVAILABLE WITH RELAY OPTION BOARD.

This function establishes the setpoint, or “trip” point for

Relay A. The entry value is limited to a value between –1000

and +2000 mV. Press ENTER to initiate user entry mode,

and the value will flash. Use arrow keys to modify value;

range is –1000 and +2000 mV. Press ENTER to store the

new value.

ONLY AVAILABLE WITH RELAY OPTION BOARD.

This function establishes the hysteresis, or “deadband”,

for Relay A. Hysteresis is most often used to control relay

chattering; however, it may also be used in control

schemes to separate between the ON/OFF trip points of

the relay. Press ENTER to initiate user entry mode, and

the value will flash. Use the arrow keys to modify value;

range is +5 mV to +2000 mV. Press ENTER to store the

new value.

ONLY AVAILABLE WITH RELAY OPTION BOARD.

This function places an additional amount of time delay on

the trip point for Relay A. This delay is in addition to the

main delay setting for the controller. The entry value is limited to a value between 0 and 999 seconds. Press ENTER

to initiate user entry mode, and the value will flash. Use

arrow keys to modify value; range is 0 to 999 seconds.

Press ENTER to store the new value.

Rev. B, 05/02

See Figure 5-3 for a visual description of a typical control

relay application.

ORTX-45

48

Page 48

Part 5 - Operation 5.24 Configuration Menu

When value rises to ≥ +600 mV, relay closes.

ON

+600 mV

PHASE: HI

+500 mV

OFF

When value falls to ≤ +500 mV, relay opens.

Settings:

Setpoint: +600 mV

Hyst: +100 mV

Delay: 000

Failsafe: OFF

When value falls to ≤ +600 mV, relay closes.

OFF

+700 mV

PHASE: LO

+600 mV

ON

HYSTERESIS

}

"DEAD BAND"

HYSTERESIS

}

"DEAD BAND"

OR

OR

*Phase A

When value rises to ≥ +700 mV, relay opens.

Figure 5-3 Control Relay Example

ONLY AVAILABLE WITH RELAY OPTION BOARD.

This function establishes the direction of the relay trip.

When phase is HI, the relay operates in a direct mode.

Therefore, the relay energizes and the LCD indicator

illuminates when the mV value

exceeds

the setpoint.

When the phase is LO, the relay energizes and the LCD

indicator illuminates when the mV drops

below

the setpoint.

The failsafe setting does have an impact on this logic.

The description here assumes that the failsafe setting is

OFF. Press ENTER to initiate user entry mode, and the

entire value will flash. Use the UP arrow key to modify the

desired value; selections include HI for direct operation or

for reverse operation. Press ENTER to store the new

LO

value.

Rev. B, 05/02

ORTX-45

49

Page 49

Part 5 - Operation 5.24 Configuration Menu

*Setpnt A-HI

*Hyst A-HI

*Delay A-HI

*Setpnt A-LO

*Hyst A-LO

*Delay A-LO

PHASE: HI

Settings:

Setpoint A-HI: +600 mV

Hyst A-HI: +100 mV

Delay A-HI: 000

Setpoint A-LO: +200 mV

Hyst A-LO: +100 mV

Delay A-LO: 000

ONLY AVAILABLE WITH RELAY OPTION BOARD.

If Relay A Mode is set to Alarm Mode, AL (see Section

5.25), then the following settings will appear in the Config

Menu list automatically. In this mode, two setpoints can

be selected on the same relay, to create an alarm band.

Phase HI selection causes the relay to energize outside of

the band, and Phase LO causes the relay to energize

inside of the band. This feature enables one relay to be

used as a control relay while the other is used as a HILO Alarm relay at the same time.

See Figure 5-4 for a visual description of a typical

alarm relay application.

+600 mV

+500 mV

OFF

+300 mV

+200 mV

When value rises to ≥ +600 mV, relay closes,

until value falls back to ≤ +500 mV.

ON

HYST - HI

}

HYST - LO

}

ON

When value falls to ≤ +200 mV, relay closes,

until value rises back to ≥ +300 mV.

When value falls to ≤ +600 mV, relay closes,

until value rises back to ≥ +700 mV.

Rev. B, 05/02

OFF

+700 mV

+600 mV

PHASE: LO

+200 mV

+100 mV

OFF

Figure 5-4 Alarm Relay Example

ORTX-45

50

HYST - HI

}

ON

HYST - LO

}

When value rises to ≥ +200 mV, relay closes,

until value falls back to ≤ +100 mV.

Page 50

Part 5 - Operation 5.24 Configuration Menu

*Setpnt B

*Hyst B

*Delay B

*Phase B

*Timer B ON

*Timer B OFF

*Timer B HOLD

ONLY AVAILABLE WITH RELAY OPTION BOARD.

If Relay B Mode is set to CON (see Section 5.25), then

Relay B will function identically to Relay A. Relay B settings

will appear in the CONFIG menu list automatically.

ONLY AVAILABLE WITH RELAY OPTION BOARD

If Relay B Mode is set to

SENS

(see Section 5.25), these

.

timer settings will appear in the menu list automatically.

Relay B will toggle ON and OFF based on the time settings

entered by the user. The timer ON setting controls the

amount of time that Relay B is engaged (N.O. contact

closed), and the timer OFF setting controls the amount

of time that Relay B is released (N.O. contact open).

The timer HOLD setting allows an output hold time to be

entered into the ON/OFF cleaning cycle. This hold time

allows the outputs to stabilize back to normal readings before

the outputs are changed. Using this feature allows the

unit output to appear undisturbed by the cleaning action of

the hardware.

Rev. B, 05/02

Example: If the timer-ON setting is 5 minutes, the timerOFF setting is 1 hour, and the timer-HOLD setting is 2

minutes, the following sequence will occur: At the instant

the timer is enabled, or data for ON/OFF/HOLD is modified,

the “OFF” time period begins. Once the 1-hour OFF

period ends, the outputs will be put in HOLD and relay B

will engage for 5 minutes (ON time). After the 5 minutes

have expired, relay B will be released but the hold will stay

locked in for an additional 2 minutes (HOLD time), retaining

the original output signals. Then, the entire cycle will

repeat - the output hold will be released and relay B will

stay off for 1 hour, etc.

Since most cleaning cycles will typically occur daily or

weekly, it is most likely that the OFF time will be set to a

number like 24 hours or perhaps as much as 168 hours

(approximately 1 week). If the HOLD timer function is set

to 0, the output hold function is released immediately as

relay B is released.

ORTX-45

51

Page 51

Part 5 - Operation 5.24 Configuration Menu

Note: The sensor wash timer is not based on a “real-

time” clock circuit. Therefore, the time accuracy is

only within approximately 10 minutes per day.

If the B mode selection is changed from

SENS

to

FAIL

or

CON while the probe washer is in mid-cycle (and the

HOLD is enabled), the HOLD must be turned off manually

to return all of the outputs to normal operation. A flashing

"T" will be seen on the lower line of the display next to

temperature while the probe cleaner function is operating.

The entry value for each timer setting has a maximum value

of 10 minutes/999 hours/999 minutes for the ON/OFF/

HOLD functions, respectively. Press ENTER to initiate

user entry mode, and the entire value will flash. Use

arrow keys to modify the desired value. Press ENTER to

store the new value.

Note: A timer wash cycle can be manually started by

pressing and holding the ENTER key for a few

seconds while viewing the timer status screen in

the Default Menu. The timer must be in the

“OFF” state to allow a manual start (“T” is not

flashing on the display). After this forced cycle,

the system will return to normal.

Contrast

Rev. B, 05/02

This function sets the contrast level for the display. The

custom display is designed with a wide temperature

range, Super-Twist Nematic (STN) fluid to provide the

highest possible contrast ratio and widest viewing angle

under all conditions. Contrast control of this type of display is

generally not necessary, so contrast control is provided as

a means for possible adjustment due to aging at extreme

ranges. In addition, the display has an automatic temperature compensation network. Press ENTER to initiate

user entry mode, and the value will flash. The contrast

value is not updated until the new value is entered. Use

arrow keys to modify the value; range is 0 to 9 (0 being

lightest). Press ENTER to store the new value.

ORTX-45

52

Page 52

Part 5 - Operation 5.24 Configuration Menu

Display

Temp Units

Temp Input

This function allows the user to change the measurement

in the primary display area. The user may select between

sensor millivolts, sensor temperature, or output current.

Using this function, the user may choose to put temperature

in the main display area and mV on the secondary, lower

line of the display. Press ENTER to initiate user entry

mode, and the entire value will flash. Use the UP arrow

key to modify the desired display value. Press ENTER to

store the new value.

This function sets the display units for temperature. Press

ENTER to initiate user entry, and the entire value will flash.

Use the UP arrow key to modify the display value. The

choices are °F and °C. Press ENTER to store the new value.

This function allows the user to manually lock the temperature at a fixed value of 25 °C. Once locked at 25 °C, a small

appears next to the temperature value on the lower line of

m

the display to indicate to the user that the system is in manual

lock mode. All temperature compensation is defeated when

in manual lock mode. Press ENTER to initiate user entry,

and the entire value will flash. Use the UP arrow key to

modify the value; selections are SENS for sensor input or

for fixed at 25 °C. Press ENTER to store the new value.

F25

Select TC

Sensor Type

Rev. B, 05/02

This function allows the user to select either a Pt1000 or

Pt100 platinum RTD temperature element. The Pt1000

element is the standard element in all high performance

Omega **E-45P sensors; it is the recommended temperature

sensing element for all measurements. The Pt100 selection

is provided as an alternative for use with existing combination-style sensors. Press ENTER to initiate user entry mode,

and the entire value will flash. Use the UP arrow key to modify the desired value. Press ENTER to store the new value.

This function sets the sensor input type. This selection is

critical for control of the internal diagnostics and compensation factors. Press ENTER to initiate user entry mode,

and the entire value will flash. Use the UP arrow key to

modify the desired value. Selections are 1 for Quantum

sensor, and 2 for combination electrode. Press ENTER to

store the new value.

ORTX-45

53

Page 53

Part 5 - Operation 5.25 Diagnostics Menu

5.25 Diagnostics

Menu [DIAG]

Set Hold

The diagnostics menu contains all of the user settings that

are specific to the system diagnostic functions, as well as

functions that aid in troubleshooting application problems.

The Set Hold function locks the current loop output values

on the present process value. This function can be used

prior to calibration, or when removing the sensor from the

process, to hold the output in a known state. Once HOLD

is released, the outputs return to their normal state of

following the process input. The transfer out of HOLD is

bumpless on the main output #1 (ORP) - that is, the

transfer occurs in a smooth manner rather than as an

abrupt change. An icon on the display indicates the

HOLD state, and the HOLD state is retained even if power

is cycled. Press ENTER to initiate user entry mode, and

entire value will flash. Use the UP arrow key to modify the

desired value, selections are ON for engaging the HOLD

function, and

ENTER to store the new value.

Note:

When the Relay Option Board is installed, the Set

to disengage the function. Press

OFF

Hold function holds BOTH current levels, as well as ALL

relay settings. When the Set Hold function is released,

the transfer is bumpless only on the ORP output (current

loop #1).