Omega Products ORE-45P Installation Manual

Table of Contents

Part 1 Introduction

1.1 General 3

1.2 Sensor Features 3

1.3 Sensor Specifications 4

1.4 Important Notes 5

Part 2 Installation

2.1 General 6

2.2 Electrical 8

Part 3 Maintenance and Troubleshooting

3.1 Cleaning the Sensor 10

3.2 Replacing the Saltbridge 11

3.3 Troubleshooting 12

Diagrams and Illustrations

Figure 1-1

Figure 2-1

Monitor/Analyzer 6

Figure 2-2 ORE-45P Sensor Styles 7

Figure 2-3 Cable Description 8

Figure 2-4

ORTX-45 Monitor/Analyzer 9

Figure 3-1

Reference Buffer 11

ORE-45P Sensor Dimensions 5

Integral Mount to ORTX-45

Wiring Diagram, ORE-45P Sensor and

Replacing the Saltbridge and

Rev. C, 05/03

ORE-45P

2

Part 1 - Introduction

1.1 General

1.2 Sensor Features

The Model ORE-45P ORP Sensor measures the

oxidation/reduction potential (also known as REDOX) of

aqueous solutions in industrial and municipal process

applications. It is designed to perform in the harshest of

environments, including applications that poison conventional

ORP sensors. All seals are dual o-ring using multiple

sealing materials. The sensor is designed for use with the

Omega ORTX-45 Monitor/Analyzer.

•

A high volume, dual junction saltbridge is utilized to

maximize the in-service lifetime of the sensor. The

annular junction provides a large surface area to minimize

the chance of fouling. Large electrolyte volume and

dual reference junctions minimize contamination of the

reference solution. Saltbridge is replaceable.

• The reference element of the sensor is a glass pH

electrode immersed in a reference buffer solution.

This glass reference system greatly increases the

range of sensor applications.

• An integral preamplifier is encapsulated in the body of

the sensor. This creates a low impedance signal output

which ensures stable readings in noisy environments

and increases the maximum possible distance between

sensor and analyzer to 3,000 feet (914 meters).

• System diagnostics warn the user in the event of

electrode breakage, loss of sensor seal integrity or

integral temperature element failure.

•

Pt1000 RTD. The temperature element used in this

sensor is highly accurate and provides a highly linear

output.

Rev. C, 05/03

ORE-45P

3

Part 1 - Introduction 1.3 Sensor Specifications

1.3 Sensor Specifications,

ORE-45P

Measuring Range

Sensitivity

Stability

0.2 mV

2 mV pH per 24 hours, non-cumulative

-1000 to +2000 mV

Wetted Materials PEEK, ceramic, titanium, glass, Viton, platinum or gold,

EDPM (316 stainless steel with 316SS body option)

Temperature Compensation Pt1000 RTD

Sensor Cable 6 Conductor (5 are used) plus 2 shields,

15 feet (4.6 meters) length standard

Temperature Range -5 to 95 °C (23 to 203 °F)

Pressure Range

Maximum Flow Rate

0 to 100 psig

10 feet (3 meters) per second

Max. Sensor-Analyzer

Distance

3,000 feet (914 meters)

Mounting options 1” NPT convertible, 1¼” insertion, 1½” or 2” sanitary style

Weight 1 lb. (0.45 kg)

Notes: 1. The type of hardware used to mount the sensor may limit the maximum temperature

and pressure ratings. Please consult the hardware manufacturer’s specifications

to obtain the relevant temperature and pressure rating information.

2. The maximum flow rate specification is lower for process solutions with low ionic

conductivity or high suspended solids concentration. High flow rates in low ionic

conductivity processes may cause a measurement error due to static electrical

discharge.

Rev. C, 05/03

ORE-45P

4

Part 1 - Introduction 1.3 Sensor Specifications

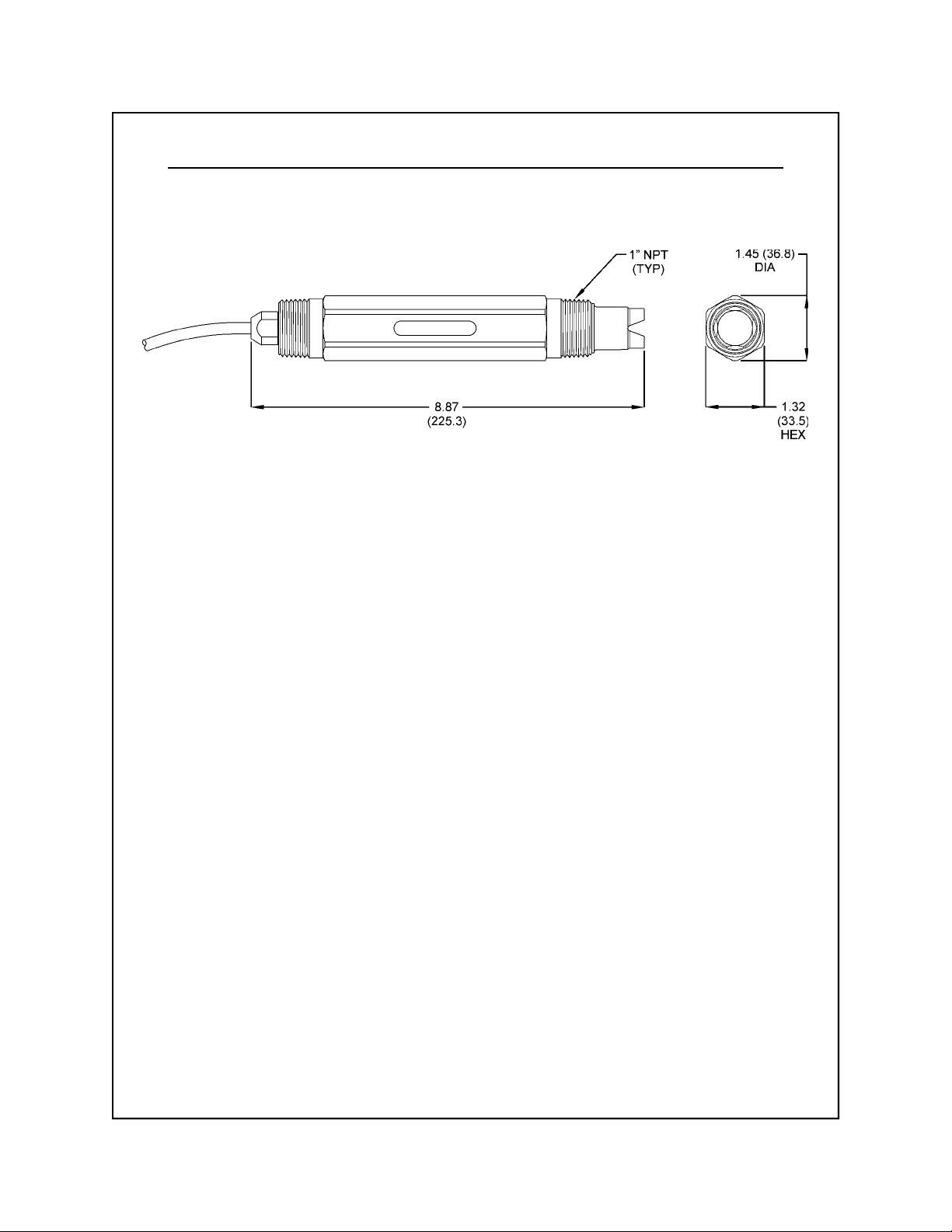

Inches (mm)

Figure 1-1 ORE-45P Sensor Dimensions (standard, convertible-style)

1.4 Important Notes

1. The ORE-45P process electrode contains glass and

can break if not handled properly. Should the electrode

ever break, USE CAUTION when handling the sensor

to avoid serious cuts.

2. The electrode must be wetted at all times to ensure

proper functionality. ORE-45P sensors are shipped

with a fluid-filled cap over the electrode to enable

immediate use (remove cap before installing, save for

storage and shipping). Electrodes that have dried

out for any reason should be hydrated for 24 hours to

restore full functionality.

3. Hydrofluoric acid (HF) will dissolve conventional glass

electrodes. Please contact the factory when the

process application involves this or any other questionable substance.

4. A platinum measuring electrode is standard. However,

DO NOT use platinum electrode in process applications

containing cadmium (Cd), nickel (Ni), tin (Sn), or zinc

(Zn). A gold electrode is available for these applications (contact factory for details).

Rev. C, 05/03

5. Likewise, DO NOT use gold electrode in process

applications containing cyanide (CN-).

ORE-45P

5

Loading...

Loading...