Page 1

User’s Guide

http://www.omega.com

e-mail: info@omega.com

OM-USCAN SERIES

Datalogger

1

Page 2

OMEGAnetSM On-Line Service

http://www.omega.com

Internet e-mail

info@omega.com

Servicing

North America:

USA:

ISO 9001 Certified

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada:

976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: canada@omega.com

For immediate technical or

application assistance:

USA and Canada:

Sales Service: 1-800-826-6342 /

1-800-TC-OMEGA

Customer Service: 1-800-622-2378 /

1-800-622-BEST

Engineering Service: 1-800-872-9436 /

1-800-USA-WHENSM TELEX: 996404

EASYLINK: 62968934 CABLE: OMEGA

Mexico and Latin America:

Tel: (95) 800-TC-OMEGA

FAX: (95) 203-359-7807

En Espan~ol: (203) 359-1660 ext: 2203

e-mail: espanol@omega.com

SM

SM

SM

2

Page 3

Contents

A

B

C

D

1.

2.

3.

Datalogger Construction 4

Specifications 5

Interface Specification 6

Accuracy of Measurement 7

System Requirements 9

Installing the Software 9

Installing the Datalogger 10

4.8

4.81

4.82

4.821

4.822

4.823

4.83

4.84

4.9

4.91

Single-Channel Graphic 27

Smooth and Zoom 29

Display Mode 30

Trace Settings 31

Axis Settings 31

Examples 32

Inspect 33

Save ASCII 34

Twin-Channel Graphic 35

Mathem. Combinations 36

4.

4.1

4.2

4.3

4.4

4.5

4.6

4.61

4.62

4.63

4.64

4.65

4.7

Software 11

Starting Up the Software 11

Com Port 12

Test & Clear Data 15

Put to Sleep 16

Datalogger Identification 17

Setup 20

Active Sensor 21

External Sensor 21

Sampling Rate 21

Delay 22

Scanning 24

Read Out 25

5.

6.

Troubleshooting 37

Language Editor 38

Index of Key Words 45

3

Page 4

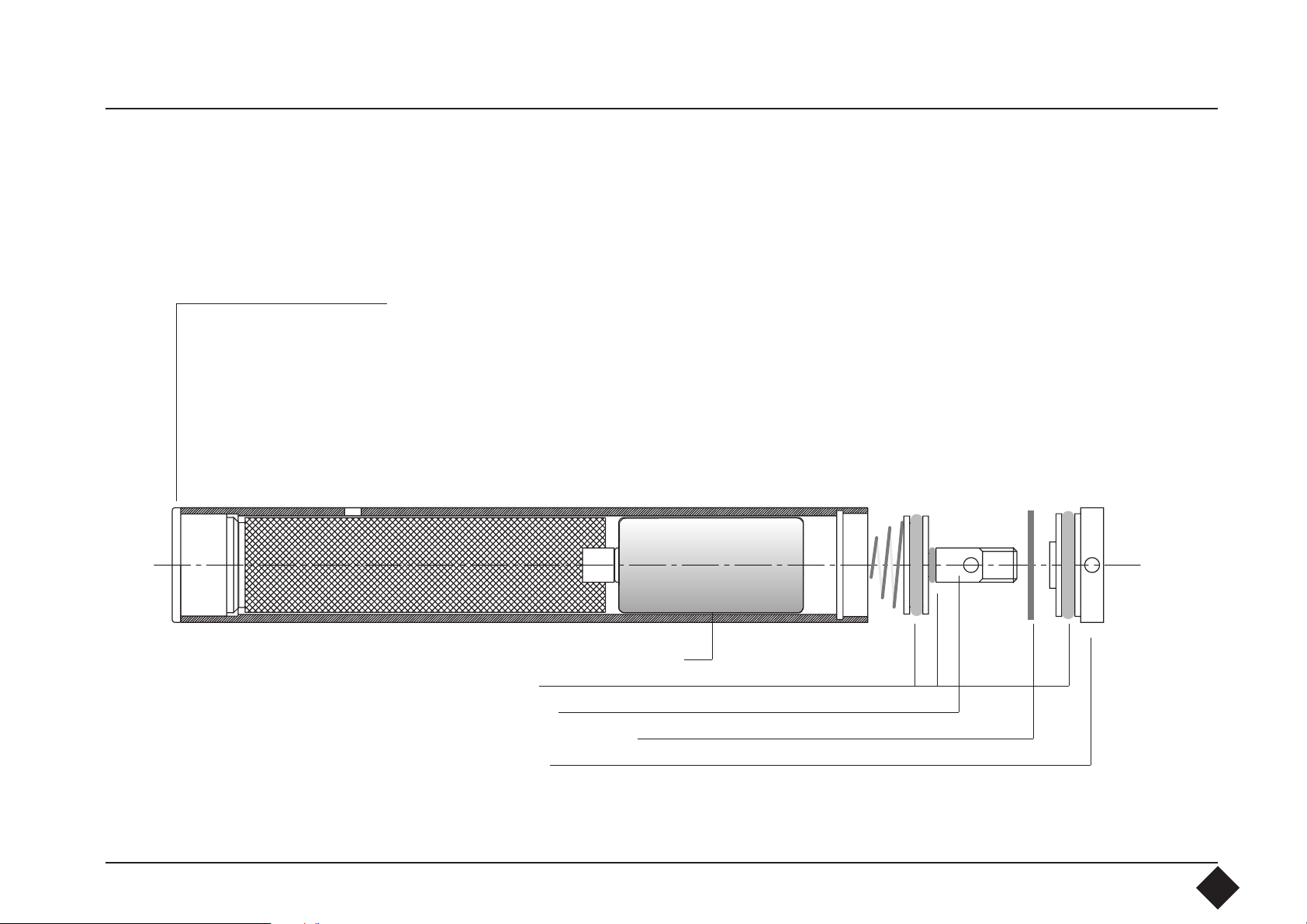

A Datalogger

Construction

Connection socket for interface and external sensors. We recommend that

the protective cap is screwed on to protect the contacts.

Protective Cap

+ Battery -

2/3 AA, 3V lithium battery

O-ring seals

Battery cover

Retaining ring BN823

Cap contents

4

Page 5

B Specifications Internal sensor Precision high-temperature conductor (NTC)

Range: -22°F to 158°F (-30°C to 70°C)

External sensor Precision high-temperature conductor (NTC)

Range: -40°F to 248°F (-40°C to 120°C)

Interchangeability +/- 0.36°F (+/- 0.2°C) in the range from

32°F to 158°F (0°C to 70°C)

Memory depth 64k words, 16 bits

Sampling interval Single-channel: 10 seconds to 20 minutes in 9 steps

Twin-channel: 20 seconds to 40 minutes in 9 steps

Scan Mode: 16 seconds scanning interval

Recording period 3.87 days to 454.5 days

Time base Quartz with ± 5 minutes/year deviation

Interface RS232 with 4800 Baud transmission speed

Data format ASCII or binary (selectable)

5

Page 6

Storage: 2/3 AA lithium battery, replaceable by the user.

Minimum life 2.5 years at 10 sec sampling rate.

In Sleep Mode 9 years (77°F / 25°C)

Recommended battery:

e.g. Sanyo Lithium CR 17335S, 3 V, 1700 mA at 77°F / 25°C

Working range: 32°F to 158°F (0°C to 70°C)

-40°F to 185°F (-40°C to 85°C)

Case: Stainless steel, watertight IP68, up to 10 bar pressure

above atmospheric

Shock: resistance: up to 300 g maximum

C Interface Specification Interface: Connects to PC by 9-channel D-Sub sleeve plug

RS232: Baud rate: 4800 Baud, 8 bits, 1 stop bit, no parity

Scan Mode: 300 Baud. 8 bits, 1 stop bit, no parity

Batteries: 9 V E-Block (IEC: 6F22) alkaline or similar

Battery life 20 hours

Can run from external power source via 9 V universal

power unit regardless of the polarity.

6

Page 7

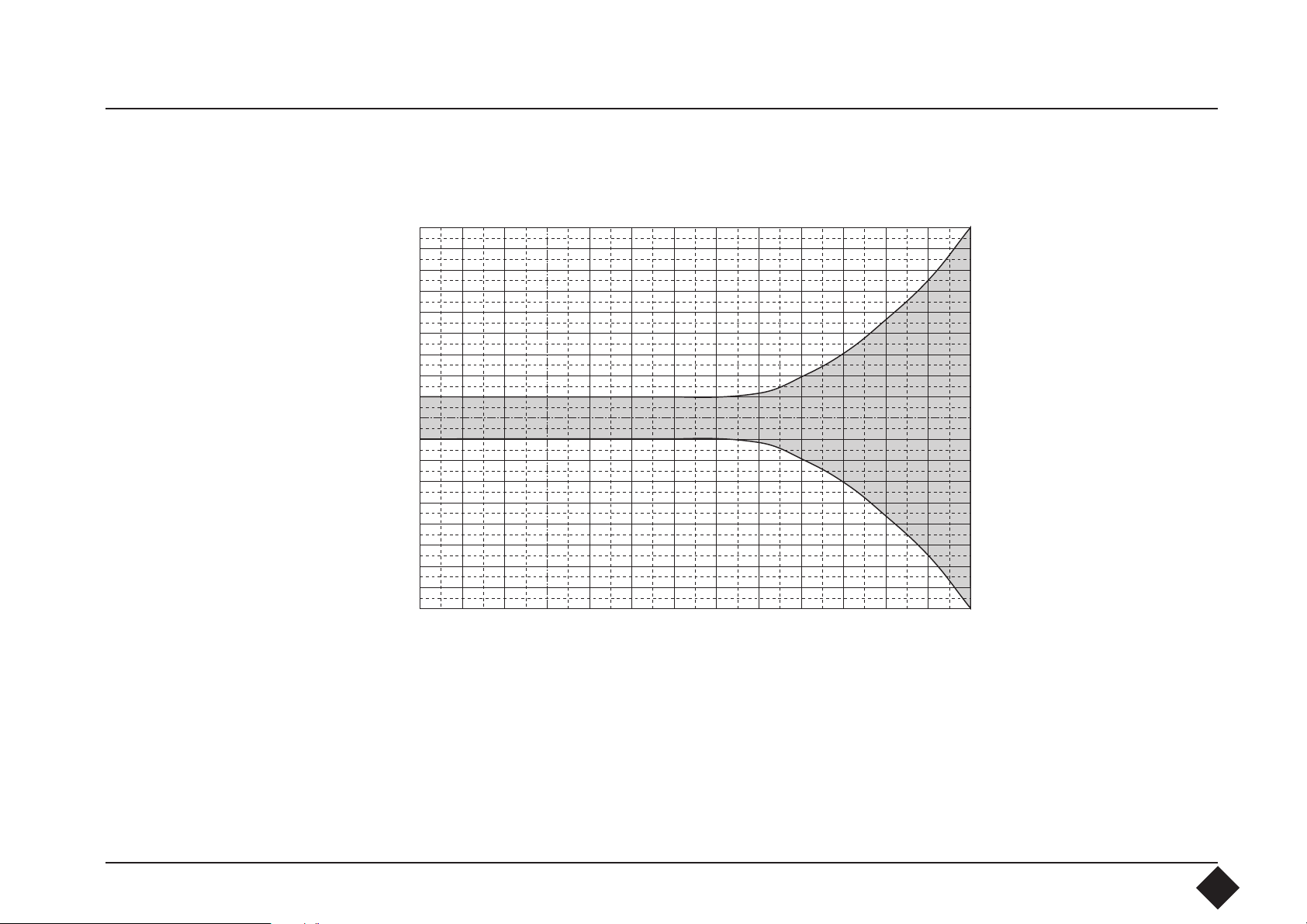

D Accuracy of Measurement

2.88°

2.16°

1.44°

0.72°

0°

-0.72°

Devation (°F)

-1.44°

-2.16°

-2.88°

-22° - 4°

14° 32° 50° 68° 86° 104° 122° 140° 158° 176° 194° 212°F

Measuring Temperature

7

Page 8

The NTC measuring sensor is accurate to ± 0.36°F (±0.2°C). Due to the negative

temperature coefficients, the resistance increases exponentially at higher temperatures, and consequently even the high resolution of the data transducer is no

longer sufficient to keep consistently to the accuracy of ± 0.36°F (±0.2°C).

The diagram shows how

resolution increases as

temperature rises.

216

180

At -22°F (-30°C), the

resistance is 177kOhm and

at 248°F (120°C) only

144

0.38kOhm. A change of

temperature of 18°F

108

(10°C) at -22°F (-30°C)

Temperature °F

72

causes a change of

resistance of 80kOhm and

36

at 248°F, only 0.057kOhm.

8

Page 9

1. System

Requirements

IBM PC compatible PC 80386/33 or higher with minimum 8 MBytes RAM

(Pentium with 16 MBytes recommended):

- SVGA graphics board, 640x480

- At least 5 MBytes available space on the hard disk

- a free communication port: COM1, COM2, COM3 or COM4 (RS232 port)

- Mouse to run the program easily

- Microsoft Windows 3.1 / Windows 95 / Windows 98 / Windows NT 4.0.

If using Microsoft Windows 3.11, please use the updated "Serial.386 Driver for

Windows/TM for Workgropups Rev. Date 3/94".

2. Installing the

Software

Windows 3.1x:

Start Windows. Open Program Manager and click on "File". In the "File"

window, select "Run ...". Now insert the program floppy disk into drive A or B.

In the "Run ..." command window write "A:setup" or, correspondingly, "B:setup"

and confirm the entry with the "OK" button. If you are not selecting any other

directory, confirm the directory recommended. Installation now proceeds

automatically.

Windows 95 / 98 / NT4.0:

Start Windows. Click on "Start" and choose "Run". Insert floppy disk into drive

A or B. In the "Run" command window write "A:\setup.exe"or "B:\setup.exe"

and confirm the entry with the "Enter" key. If you are not selecting any other

directory, confirm the directory recommended.

Installation now proceeds automatically.

9

Page 10

3. Installing the

Datalogger

The datalogger can only be connected to the computer via the interface

supplied. The interface ensures fast, reliable communication between the

datalogger and the computer and does not take power from the datalogger

battery. Connect the interface to a free Com Port using the cable supplied. Note

the Com Port number to enable you to select it in the software. If your Com Port

has a 25-channel plug, you will need a 25 to 9-pin D-Sub adapter, obtainable from

any computer retailer.

N.B.: When you have connected the interface to the computer, switch the

interface ON. The function is displayed by the red LED. Be sure to switch on the

interface before connecting the datalogger to the interface. If you have already

connected the datalogger by mistake, remove it and reconnect it with the

interface switched on. If you do not follow this sequence, the datalogger

battery is drained unnecessarily and communication between the computer and

the datalogger is not possible. By following the setup sequence described, the

datalogger is switched to its normal state when connected, and is thus ready for

communication. In addition, the datalogger is supplied with power by the

interface to meet the requirements of the interface.

10

Page 11

4. Software

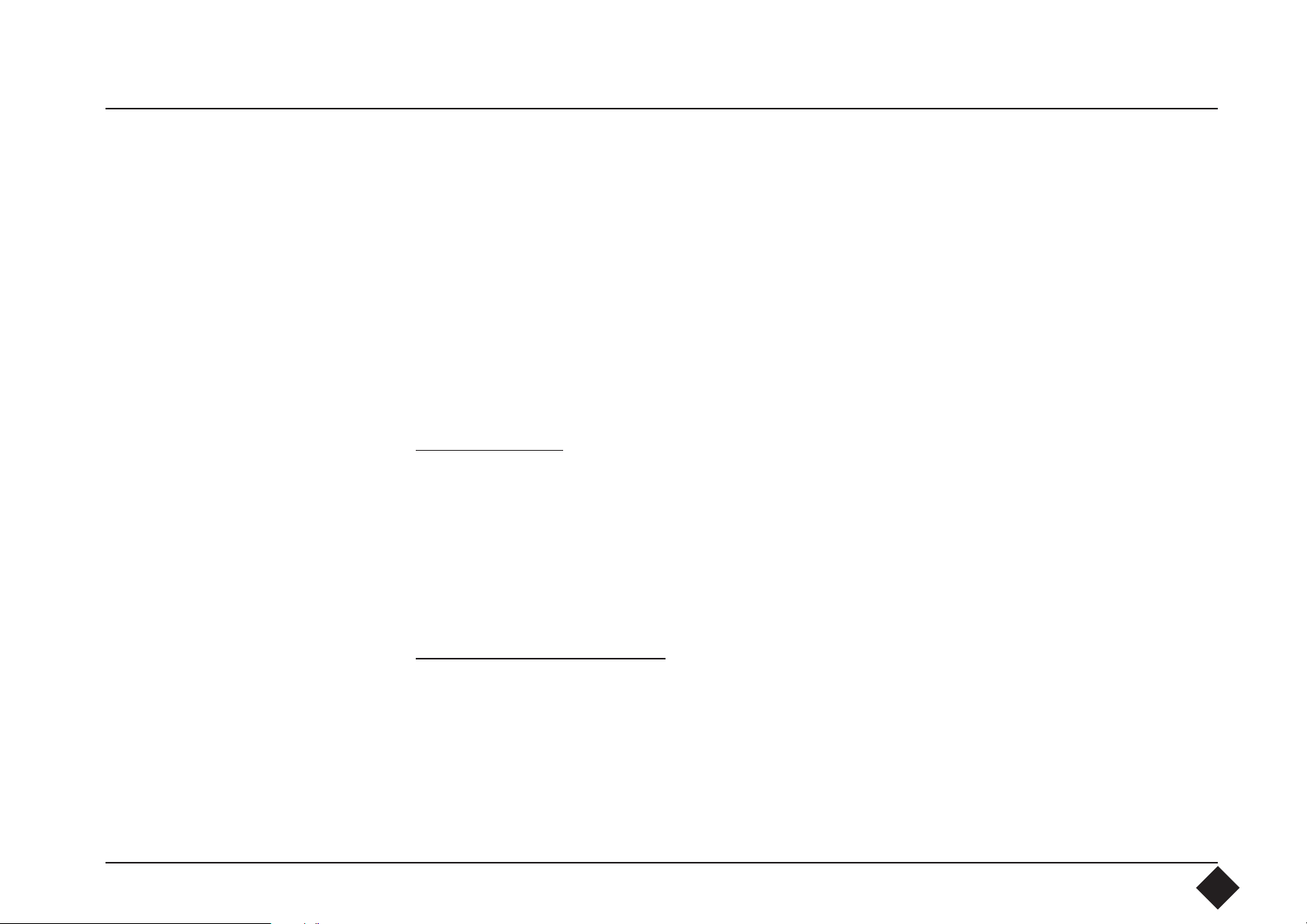

4.1 Starting Up the

Software

When installing the software, the software opens a new program group in your

Windows program with its own icon. Start the software by clicking twice on the

icon. Once the software has been loaded, the software will display the following

opening menu:

µScanT

11

Page 12

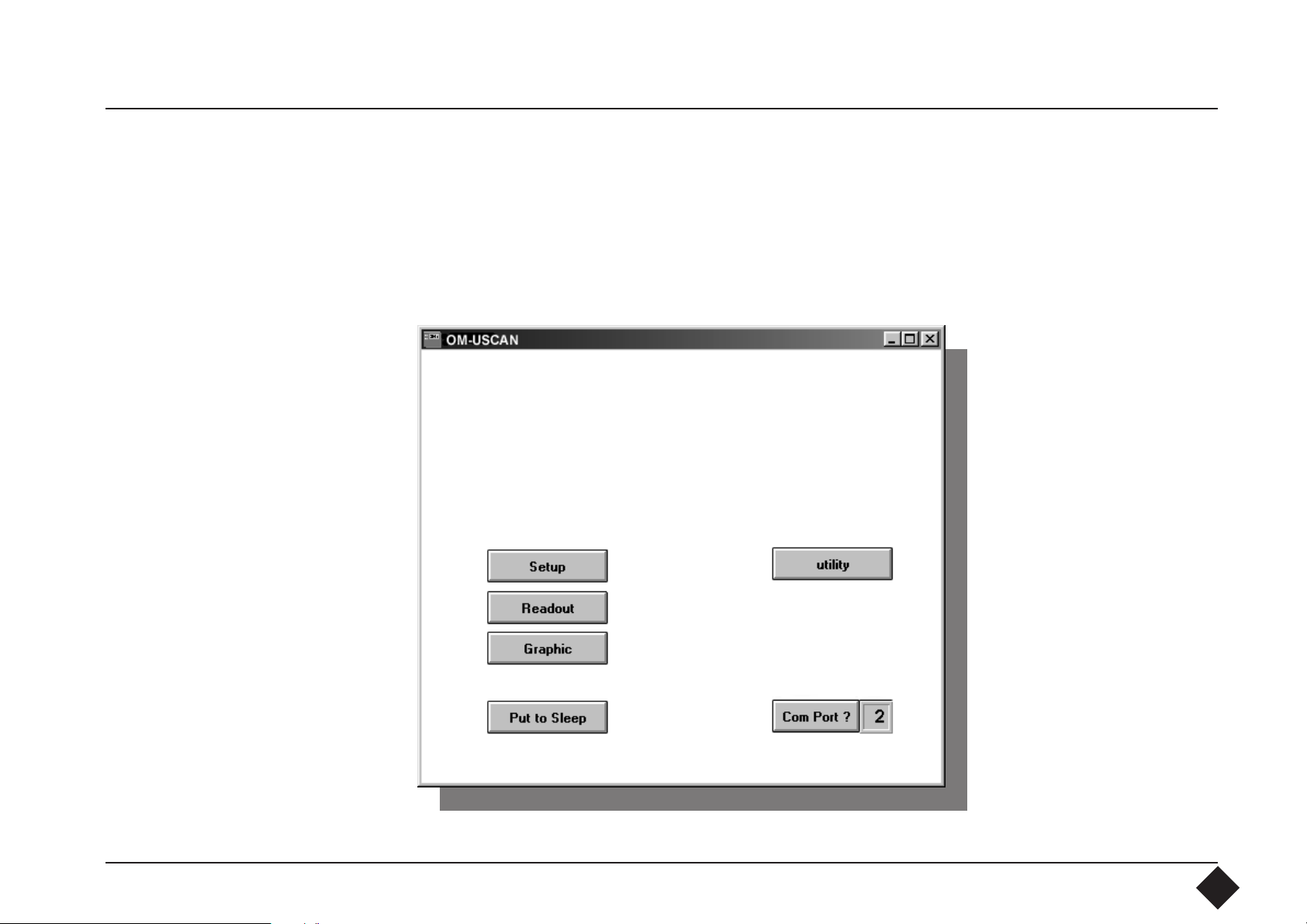

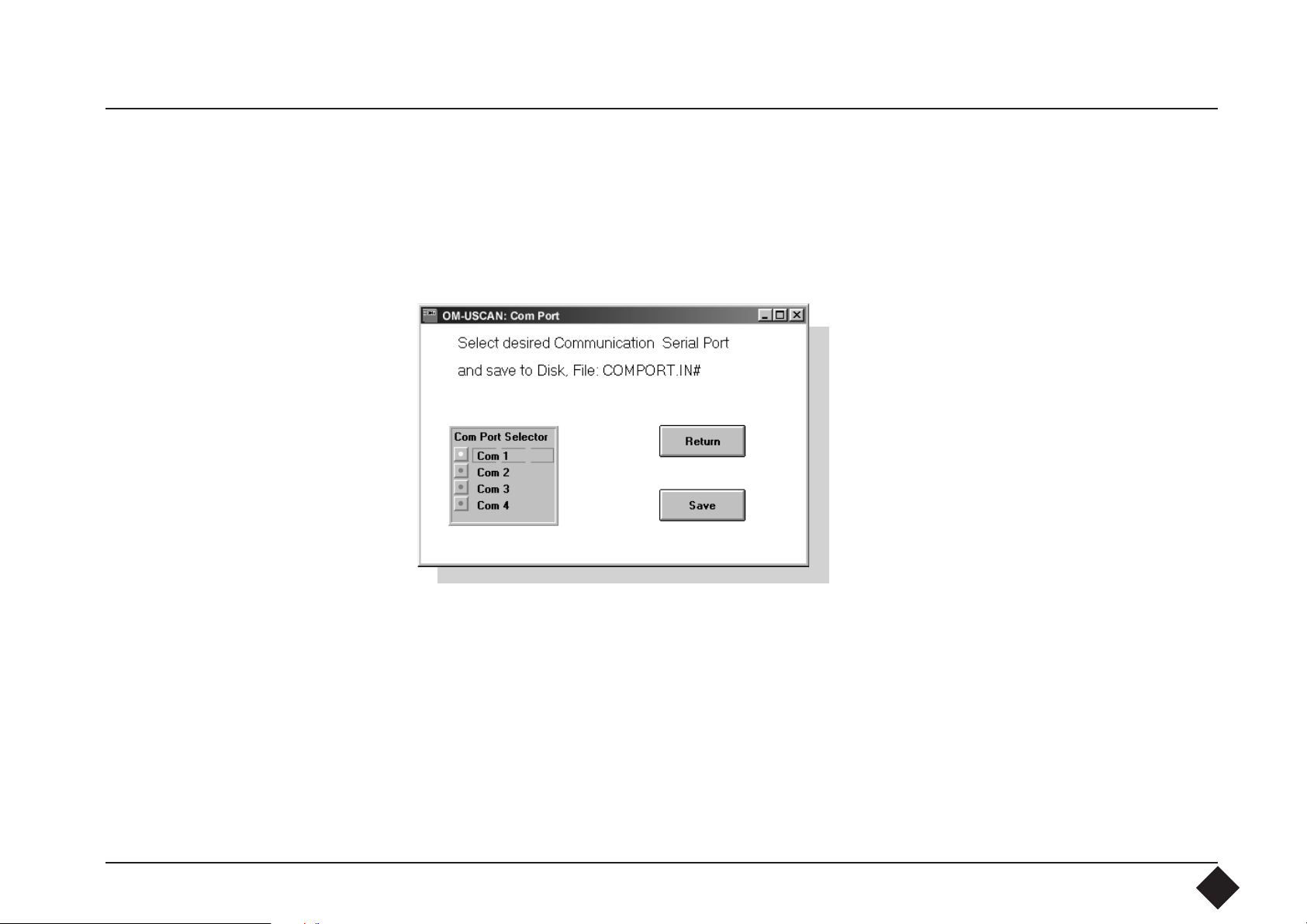

4.2 Com Port

First select the Com Port to which you have connected the interface. To do this,

move the mouse pointer to the appropriate "utility" key. This key will show you

a new key "Change Com Port". Move again the mouse pointer to the "Change

Com Port" key and activate the port by clicking with the mouse.

12

Page 13

Save the selected Com Port by clicking on the "Save" key.

13

Page 14

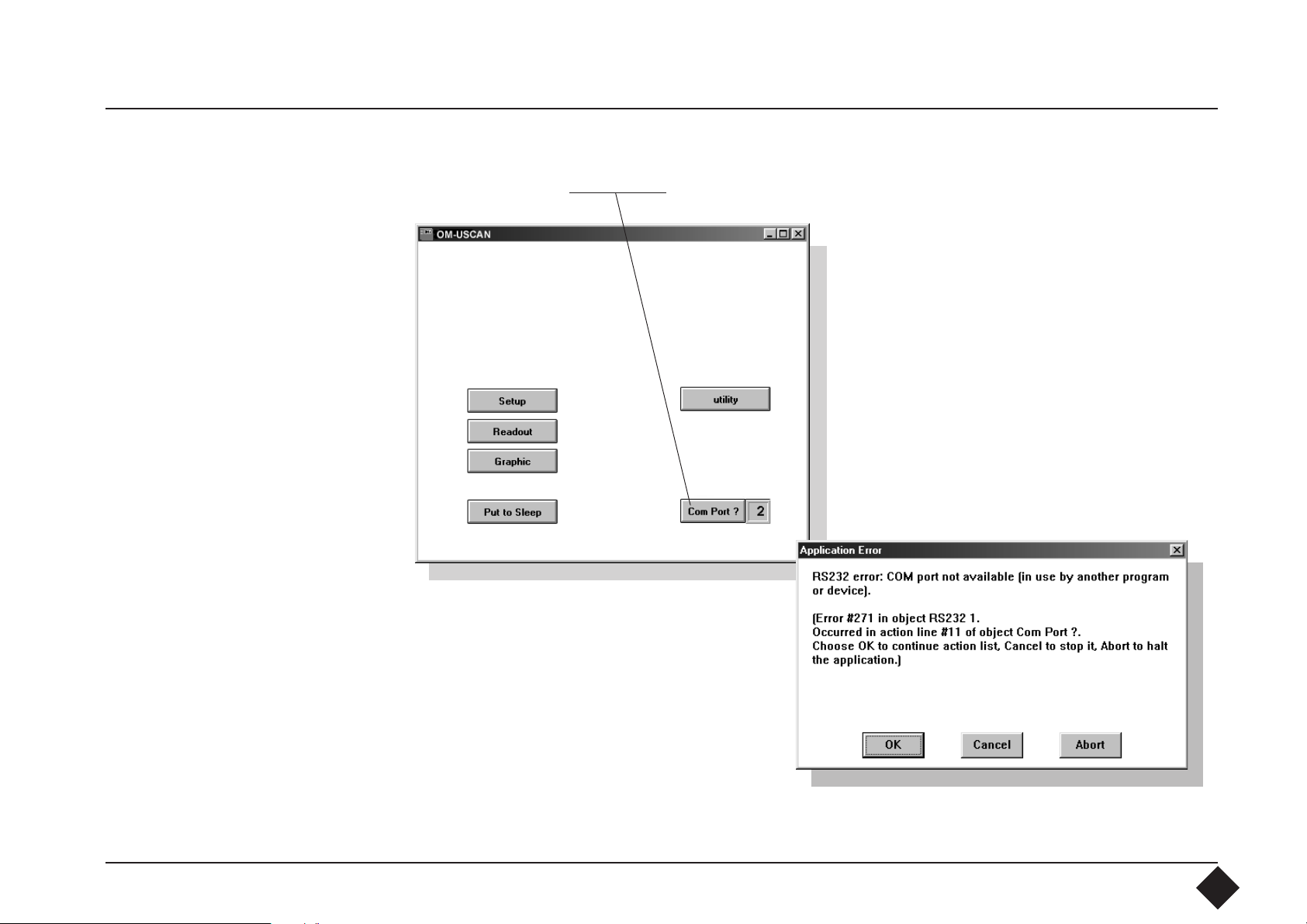

Return to the main window and activate the new Com Port by moving the mouse

cursor to the "Com Port?" key and click on with the mouse.

An error occurs, if the port is in use

by another program or device. Please

repeat the steps again and select the

correct port.

14

Page 15

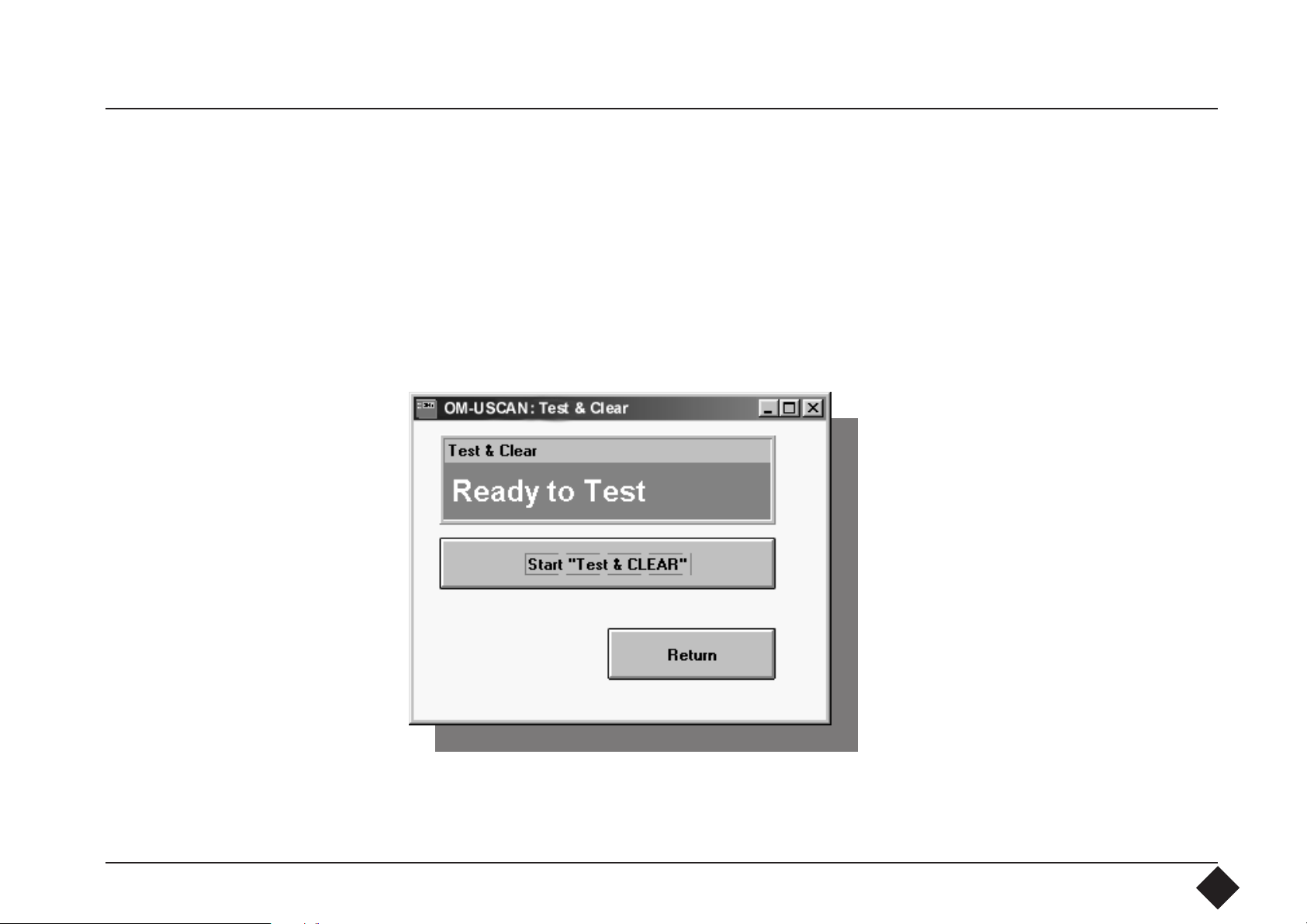

4.3 Test & Clear Data By clicking with the mouse on the “Test & Clear” key, you will start a datalogger

test program, which tests the internal function of the datalogger. This tests and

then clears all the memory cells. Never use this program after capturing data with

the datalogger, because it would then be lost before evaluation. Start the

program by clicking with the mouse on the “Test & Clear” key. The display shows

the test status. Exit the test by clicking on the “Return to Main” key.

15

Page 16

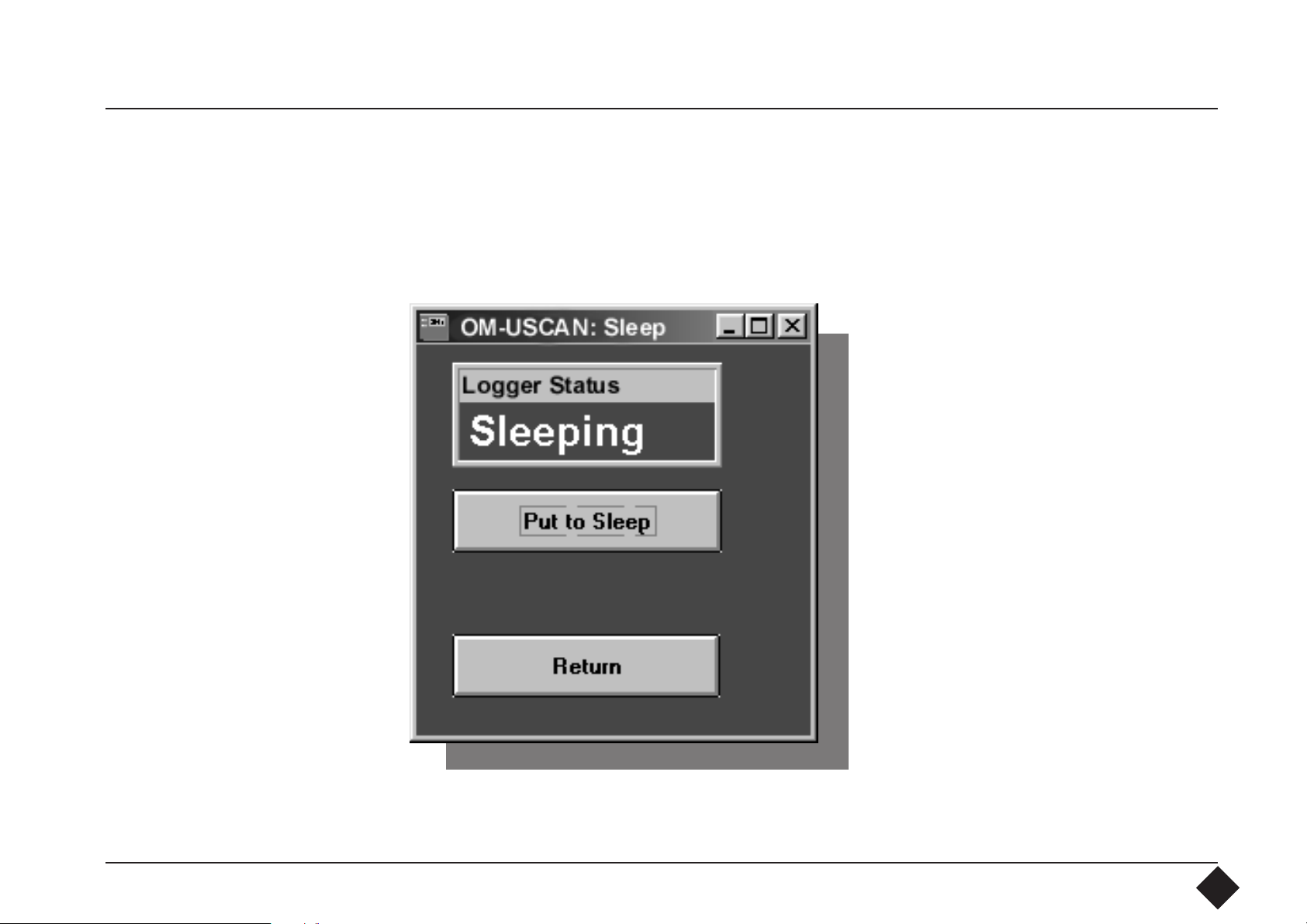

4.4 Put to Sleep If you do not use the datalogger for some time, select the Sleep Mode to conserve

the battery. When in Sleep Mode, the datalogger uses less than 17 µA. Start this

program by activating the “Put to Sleep” key in the Main Menu and pressing this

key again in the Submenu. Then disconnect the datalogger from the interface

and put it aside.

To awake the datalogger again,

reconnect it to the interface. The

connection process reactivates the

datalogger ready for communication.

16

Page 17

4.5 Datalogger

Identification

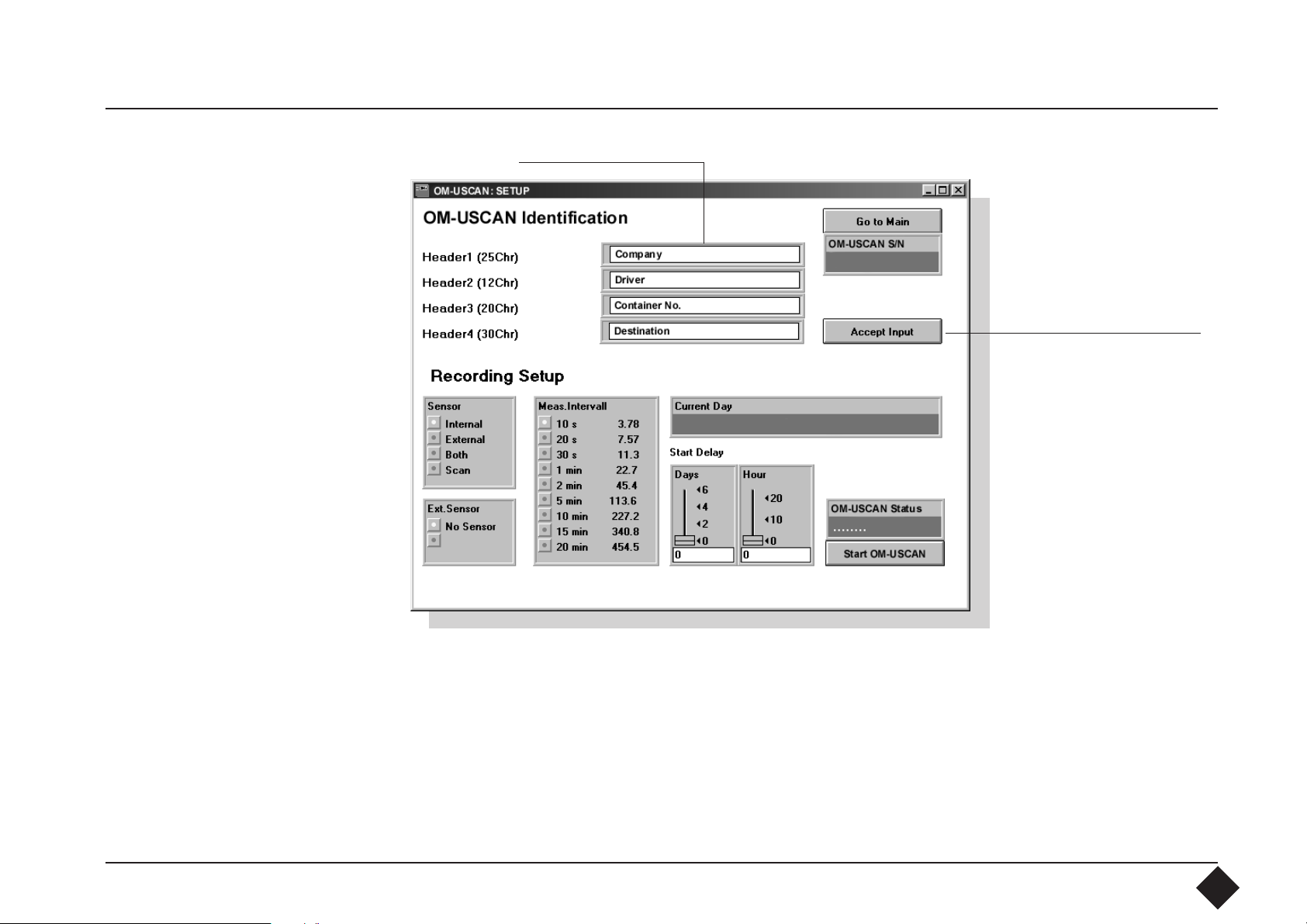

To start using the datalogger, the Setup program has to be started. Do this by

clicking with the mouse on the “Setup” key in the Main Menu. This will open the

“OM-USCAN Setup” window. This window contents two parts. One part is the

datalogger identification with the serial number of the datalogger.

17

Page 18

The flexibility of the datalogger software allows you to create your own

application header to indentify after data recording unequivocal your datalogger.

(Please refer to part 6 Language Editor.) As an application example we created a

header as follow:

First line: Company

Second line: Driver

Third line: Container No.

blank fields for data entry

Fourth line: Destination

In the blank field on the

right side you can enter now

your desired infor-mation.

Don´t use the character "&",

this character is used as a

control character and will

terminate any further input.

18

Page 19

Example:

confirm entry

To charge the datalogger with the header information you have to click with the

mouse on the "Accept Input" key. If you start the datalogger without confirmation,

the old header is kept in memory. To test the content of a previous header please

go to the "Readout" menu. This menu will show you the present header. If you like

to keep it unchanged, go directly to the datalogger setup menu without

confirmation by the "Accept Input" key. The software charges now the datalogger

with the data and afterwards reads out the data for correctness test.

19

Page 20

4.6 Datalogger Setup

The second part of the setup window is intended to charge the datalogger

with recording parameters as sampling-time-intervals, kind of sensor used, start

delay and timing mark.

To select the setup

conditions you will

find the corresponding information

under following

items:

4.61 Active

Sensor

4.62 External

Sensor

4.63 Sampling

Rate

4.64 Start Delay in Days

start Hour

20

Page 21

4.61 Active Sensor

The datalogger can operate either with the built-in sensor or an external sensor

or with both sensors in parallel. If data are recorded by two sensors, the memory

capacity is halved and the sampling intervals doubled.

Use the “Active Sensor” window to select whether you want to measure with the

built-in sensor or an external sensor. The external sensor should be connected to

the plug after starting up the datalogger. If you want to measure with both at

once, use the mouse to select the “Both” key.

You will find information about the "Scanning Mode" under 4.65

4.62 External Sensor

4.63 Sampling Rate

If you are working with two sensors at the same time, the “External Sensor”

window will offer “Temperature”.

Use this window to select the measuring interval, i.e. the intervals of time at which

you want to record data. The total recording time (in days) may be read alongside

the Sampling Rate. Measuring can be halted at any time, however.

21

Page 22

4.64 Delay A "Start Delay" can be selected by using the Sliders for "Start Hour" and "Day

Delay". As starting time the next full time period of the indicated actual time will

be used. If you select for example 12 as "Start Hour" and the "Actual Time" is

09:20:54, the "Start Delay" will be 02:39:06. If the value of "Start Hour" is less than

the "Actual Time", no start delay will be added. In this case, 1 day must be added.

Start Hour Start Delay in Days

22

Page 23

Once you have checked all the inputs, the datalogger can be programmed and

started by means of the "Start OM-USCAN" key. To be quite sure that the

communication and start sequence has been successful, the datalogger software

shows you the status of communication and state of the datalogger. When the

datalogger is in measuring mode a window opens and show the "OM-USCAN

Setup confirmation". The display indicates "OK>>>OK>>>OK>>>....". After this

message you can disconnect the

datalogger from the interface.

Note that a reconnection of the

datalogger will cause a reset.

Status message and

"Start OM-USCAN" key

23

Page 24

4.65 Scanning

Direct scanning of data is possible by using an external sensor. In this mode the

datalogger must be connected to the interface and the sensor must be linked up

to the corresponding socket. The scanning program communicates directly to the

datalogger by using a baud rate of 300 baud. The sampling interval is 16 seconds.

Please use the "Scan Stop" switch to halt scanning. The datalogger can be resetted

by reconnection.

24

Page 25

4.7 Read Out

When measuring has been completed or is halted, you can read out the data

by means of this part of the program and store it on hard disk or floppy.

The “Read Out” window gives you details of the datalogger identification, the

recording mode and start of measuring.

25

Page 26

If you want to transfer and store data from the datalogger, click with the mouse on

the “File” key. Give the recorded trace a name under which you will be able to find

it again easily in Graphic. As soon as the PC starts the read out process, the green LED

on the interface lights up, indicating that data are being output by the datalogger.

Data transfer may take up to 10 minutes, depending on the quantity of data. When

the green LED goes out, transfer is completed. You can only proceed the evaluation

by clicking with the mouse on the “Graphic” key.

26

Page 27

4.8 Single-Channel

“Graphic”

The Graphic program allows you to represent the data stored beforehand

graphically. The main operating features with a single-channel display are shown

in the illustration below. (see 4.8 for two-channel display)

Return to main menu

Call up data file

Convert data to ASCII

More information

“Inspect” graphic

OM-USCAN serial number

Header data

Setup time and date

Start delay

Total recording time

27

Page 28

Click with the mouse on the File window and select a Data File. This may take

some time, depending on the quantity of data. If the raw data have been

linearized, the following screen will appear:

(C)95 by P.T.C AG ,Switzerland

28

Page 29

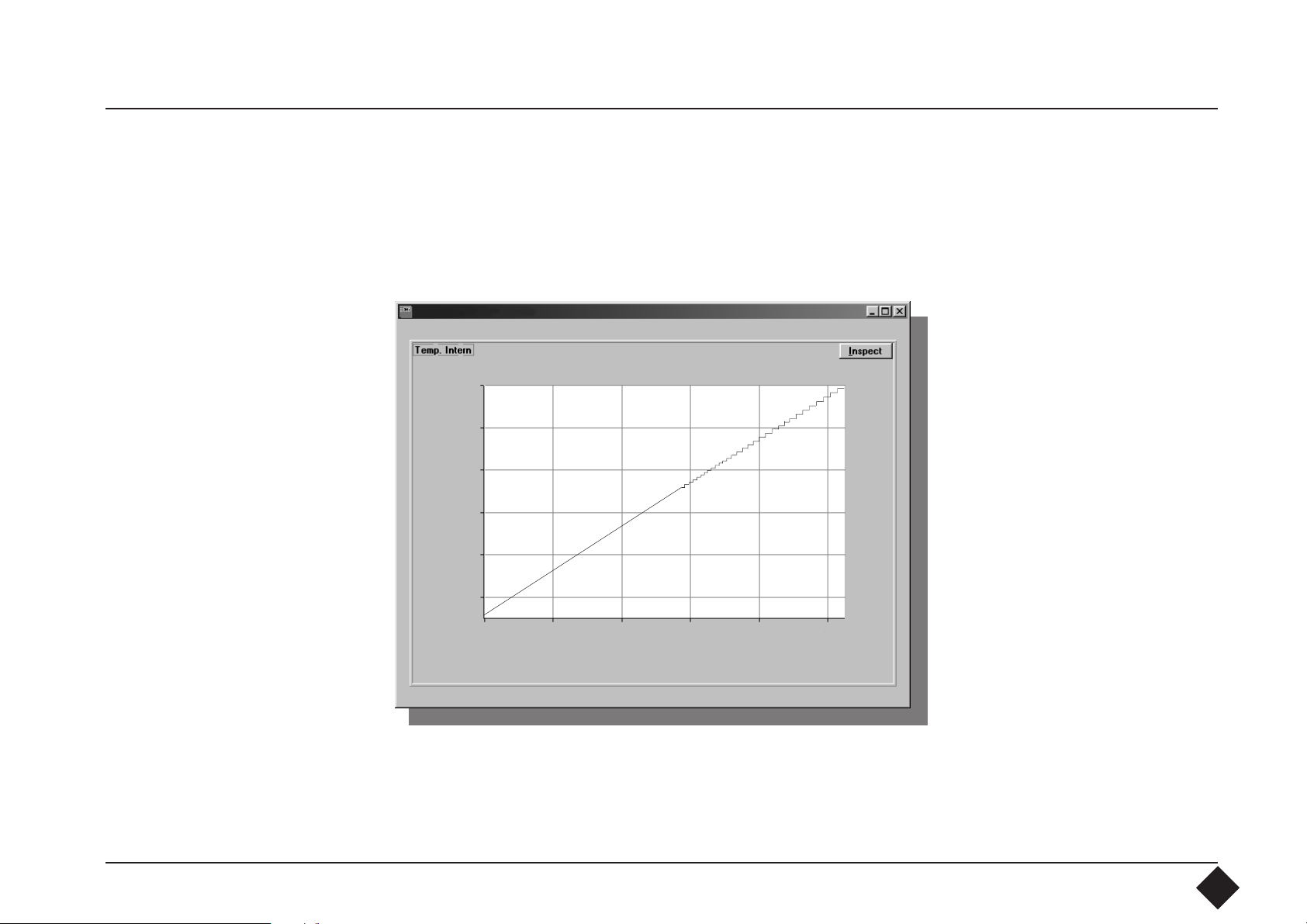

4.81 Smooth and

Zoom

The Smooth function allows you to smooth the data. This is done by using "n"

points around the actual point to form an average. Use the mouse to move the

slide between n=1 and 100. The smooth function will not be activated until you

call up the data file again. Same worth for the zoom function. Select the zoom

button and the zoom limits as a window and recall the file.

"n" slide

Zoom option with

window limits

29

Page 30

4.82 Display Mode By clicking twice on Graphic you can change various display parameters:

Confirm the changes

Trace display mode

Trace display

Axis display

30

Page 31

4.821 Trace Settings These windows allow you to

change the colour of the axes

and traces and also the grid

interval and trace section.

4.822 Axis Settings

31

Page 32

4.823 Examples

“Bar 1st trace” display

Free choice of axis

32

Page 33

4.83 “Inspect” The “Inspect” window allows you to enlarge and reduce sections.

“File”: print the diagram

“Edit”: export the diagram

“Zoom”: enlarge and reduce

the section

33

Page 34

4.84 “Save ASCII”

This function linearizes the raw data and stores them in ASCII, allowing these data

to be further processed by any programs. The first few lines look like this:

Single-channel Twin-channel

X Y XY1Y2

0.05 5.038

0.053 5.199

0.056 5.362

0.058 5.519

0.061 5.626

0.064 5.764

0.067 5.88

0.069 5.961

0.072 6.035

0.075 6.138

0.078 6.197

0.081 6.243

0.083 6.303

0.086 6.34

0.089 6.37

0.092 6.416

0.094 6.446

0.097 6.469

0.1 6.521

X = time axis in hours

Y = ordinate in °C

0.003 26.234 25.368

0.006 26.396 25.375

0.008 26.485 25.375

0.011 26.567 25.375

0.014 26.567 25.298

0.017 26.485 25.298

0.019 26.485 25.222

0.022 26.485 68.745

0.025 26.508 70.381

0.028 26.59 68.745

0.031 26.598 72.141

0.033 26.688 78.259

0.036 26.793 88.388

0.039 26.922 82.412

0.042 26.412 5.795

0.044 24.61 -4.578

0.047 22.803 -9.084

0.05 20.825 -11.265

0.053 18.91 -12.442

34

Page 35

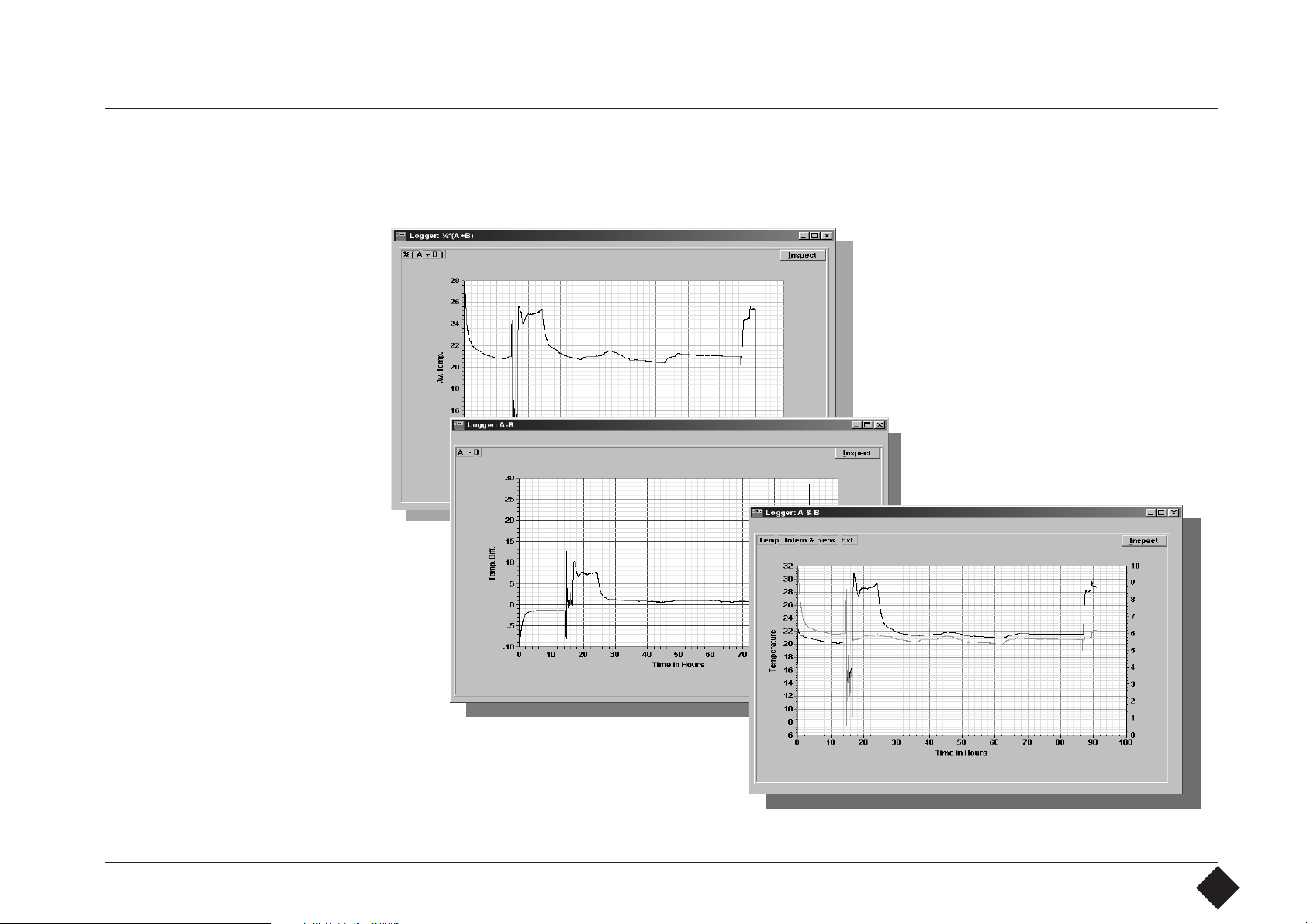

4.9 Twin-Channel

“Graphic”

If you have recorded data with both, the internal and the external sensor, Graphic

will automatically display them in two separate diagrams. The operating features

are different from those in the single-channel display and mathematical

combinations for the two traces have been added to allow connections to be made

visible.

Operation for

mathematical

combinations.

35

Page 36

4.91 Mathematical Combinations

Average of the two traces

Superimposed traces

36

Page 37

5. Troubleshooting

Wrong Com Port.

Time Out Delay: 10 seconds

This message appears if the PC cannot communicate with the datalogger.

The reasons may be the following:

- Wrong COM Port selected:

=> check the COM Port

=> check the RS232 cable

- The datalogger is not in communication mode:

=> check if the interface is switched on and reconnect the datalogger

to the interface for resetting.

=> check the 9 Volt Battery of the interface.

37

Page 38

6. Language Editor

The OM-USCAN Software give you the possibility to change the key words in any

window. So you can adapt the program exactly to your needs. The language editor

can only be opened by a protection code in order to prevent any unauthorized and

unintentional manipulation of existing key words. Open the language editor by

the appropriate key word and

confirm by clicking on "Code OK".

A wrong code brings you back to

the main window.

38

Page 39

The right code opens a new window where you can select the window you like

to modify.

39

Page 40

When you open for example the Startup window you can see several blank fields

right of the English key words. In this field you can enter now your desired key

words. Do not terminate your entry by a carriage return, change only with the

mouse to the next field. Blank fields will be displayed in the window as blank. If you

only like to make correction on some fields, please use an ordinary text editor. After

all fields have been labeled, move the mouse cursor to "File".

The data will be saved

under "setscan.in#".

Do not change the file

name.

Now you can test the

setup window by

clicking with the

mouse on the "Return" key in order to

go back to the main

window.

Any text and language can be entered into these fields.

40

Page 41

If you find now any error in the text it is unnecessary to go back to the language

editor and fill out all fields again. A simpler way is to use the editor from Windows.

Change to the Program-Manager and click twice on the "Editor" icon. Open the

directory, where you have installed the OM-USCAN software. Open the file

"setscan.in#".

Now you can modify and correct all text between the " ". Do not clear the" "

control characters. After correction please save the data under same file. Then go

back to the OM-USCAN software and test the changes.

41

Page 42

The language editor is subdivided into the following windows:

Window Use

- Start up Main-Window

- Setup Record Setup the datalogger for data recording

- Readout Readout the recorded data fom datalogger

- Graphic Show the recorded data in a graphic

- Sleep Put datalogger into sleep mode to save power

- Test & Clear Test datalogger communication and function

For each window a separated data file exists. This enables simpler handling of

language data. The relation between the different windows and data files is as

follows:

Window File

- Start up setscan.in#

- Setup Record record.in#

- Readout readout.in#

- Graphic grafic.in#

- Sleep sleep.in#

- Test & Clear t&c.in#

42

Page 43

As you have seen you can modify and correct any OM-USCAN window and

translate to the destination language. The most important window is the setup

window where you can adapt your needs for header. Four lines are available for

the header. If you use the language editor all lines must be filled in. But if you only

like to modify "Header 1" to "Header 4", it´s simpler to use the Windows Editor

to change the four lines.

Header 1

Header 2

Header 3

Header 4

43

Page 44

To modify the four header lines, please open the "record.in#" file.

In this file you see, where the header information is placed:

Header 4

Header 3

Header 2

Header 1

OM-USCAN Identification Company Driver Container No. Destination

OM-USCAN Setup Condition Sensor Interval,External,Both,Scan Mode

Ext. Sensor No Sensor, ;Temperature,Humidity;Ext.only, ; Return

OM-USCAN Serial No. Actual Date/Time Start Delay Days Start Hour

No Delay OM-USCAN Status Waiting Measuring Input O.K. Set Start Delay

Sampl.Interval

Now change with the editor the header info, for example:

OM-USCAN Identification User Name Street City Country

OM-USCAN Setup Condition Sensor Interval,External,Both,Scan Mode

Ext. Sensor No Sensor, ;Temperature,Humidity;Ext.only, ; Return

OM-USCAN Serial No. Actual Date/Time Start Delay Days Start Hour

No Delay OM-USCAN Status Waiting Measuring Input O.K. Set Start Delay

Sampl.Interval

Do not touch any " , ; " . They are used as controlling characters.

Finally save the file and restart the software.

44

Page 45

Index of Key words

A

Accuracy of measurement 7

Active sensor 20, 21

Actual time 22

Awake the Datalogger 16

Axis display 30

Axiss settings 31

B

Batteries 6

Battery 10

Battery cover 4

Blank fields for data entry 18

C

Call up data file 27

Case 6

Change Com Port 12

Character "&" 18

Code 39

Com Port 10, 12

Com Port? 14

Confirm the changes 30

Connection socket 4

Construction 4

Contents 3

Convert data to ASCII 27

Correct all text 41

D

Data format 5

Day delay 22

Delay 22

Difference 36

Direct scanning 24

Display mode 30

Display parameters 30

Driver for Windows 9

E

Editor from Windows 41

Enlarge and reduce the section 33

Export the diagram 33

External Sensor 5, 20, 21

G

Grafic.in# 42

Graphic, grafic.in# 42

Graphic program 27

Grid 31

H

Header 18, 43

Header data 27

Header information 19

I

Identification 25

Input O.K. 19

Inspect 33

Inspect graphic 27

Installing the Datalogger 10

Installing the software 9

Interchangeability of sensor 5

Interface 6

interface light 26

Interface RS232 5

Interface specification 6

Internal sensor 5

L

Language editor 38

M

Manipulation of existing key words 38

Mathematical combinations 35, 36

45

Page 46

Measuring interval 21

Memory 5

Moisture 21

More information 27

O

O-ring seals 4

P

Parameters 30

Polarity 6

Previous header 19

Print the diagram 33

Program manager 9

Protective cap 4

Put to sleep 16

Q

Quartz 5

R

Read out 25

Readout, readout.in# 42

Readout.in# 42

Record.in# 42, 44

Recording period 5

Recording time 21

Resistance 8

Retaining ring 4

RS232 6

S

Sampling interval 5, 21, 24

Sampling Rate 20, 21

Sampling-time-interval 20

Save ASCII 34

Scan mode 5

Scan stop 24

Scanning 24

Select a data file 28

Serial number 17, 27

Serial. 386 driver 9

Setscan.in# 42

Setup 20

Setup record, record.in# 42

Setup time and date 27

Shock 6

Single-channel 5

Single-channel display 27

Single-channel “Graphic” 27

Sleep, sleep.in# 42

Sleep Mode 16

Sleep.in# 42

Smooth and zoom 29

Smooth function 29

Software 11

Specification 5

Start delay 22, 27

Start delay in days 20

Start hour 20, 22

Start up, setscan.in# 42

Starting up the software 11

Status message 23

Storage 6

Strip Chart display 32

Superimpose 36

System requirements 9

T

t&c.in# 42

Temperature 21

Test & clear, t&c.in# 42

Test & clear data 15

Time base 5

Total recording time 27

Trace display 30

46

Page 47

Trace display mode 30

Trace settings 31

Transfer and store data 26

Troubleshooting 37

Twin-channel “Graphic” 35

Twin-channel: 5

U

Universal power unit 6

W

Wrong Com Port 37

Z

Zoom button 29

47

Page 48

48

Page 49

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 25 months from date of purchase. OMEGA Warranty adds an

additional one (1) month grace period to the normal two (2) year product warranty to cover

handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage on

each product.

If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s

Customer Service Department will issue an Authorized Return (AR) number immediately upon

phone or written request. Upon examination by OMEGA, if the unit is found to be defective it

will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects

resulting from any action of the purchaser, including but not limited to mishandling, improper

interfacing, operation outside of design limits, improper repair, or unauthorized modification.

This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows

evidence of being damaged as a result of excessive corrosion; or current, heat, moisture or

vibration; improper specification; misapplication; misuse or other operating conditions outside

of OMEGA’s control. Components which wear are not warranted, including but not limited to

contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes

liability for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only that the

parts manufactured by it will be as specified and free of defects. OMEGA MAKES

NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER,

EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES

INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The

remedies of purchaser set forth herein are exclusive and the total liability of OMEGA

with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of

the component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any

nuclear installation or activity, medical application, used on humans, or misused in any way,

OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER language,

and additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability

or damage whatsoever arising out of the use of the Product(s) in such a manner.

49

Page 50

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA...Of Course!

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor

Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN

AND FORCE

䡺⻬

Transducers & Strain Gauges

䡺⻬

Load Cells & Pressure Gauges

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW /LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters

& Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Tester & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators

& Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition &

Engineering Software

䡺⻬

Communications-Based

Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM

& Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater

Treatment

䡺⻬

pH, Conductivity & Dissolved

Oxygen Instruments

M - 3327

50

Page 51

Servicing

Benelux:

Postbus 8034, 1180 LA Amstelveen,

The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

Czech Republic:

Ostravska 767, 733 01 Karvina

Tel: 42 (69) 6311899 FAX: 42 (69) 6311114

e-mail: czech@omega.com

France:

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly

pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every

appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

Europe:

Germany/Austria:

Daimlerstrasse 26, D-75392

Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

United Kingdom: ISO 9002 Certified

• 25 Swannington Road, Broughton Astley,

Leicestershire, LE9 6TU, England

Tel: 44 (1455) 285520 FAX: 44 (1455) 283912

• P.O. Box 7, Omega Drive, Irlam,

Manchester, M44 5EX, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR)

NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING

DELAYS). The assigned AR number should then be marked on the outside of the return package and on

any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. P.O. number under which the product was

PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our

customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1996 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced,

translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without prior written consent

of OMEGA ENGINEERING, INC.

FOR

NON-WARRANTY REPAIRS, consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. P.O. number to cover the COST

of the repair,

2. Model and serial number of product, and

3. Repair instructions and/or specific problems

relative to the product.

51

Loading...

Loading...