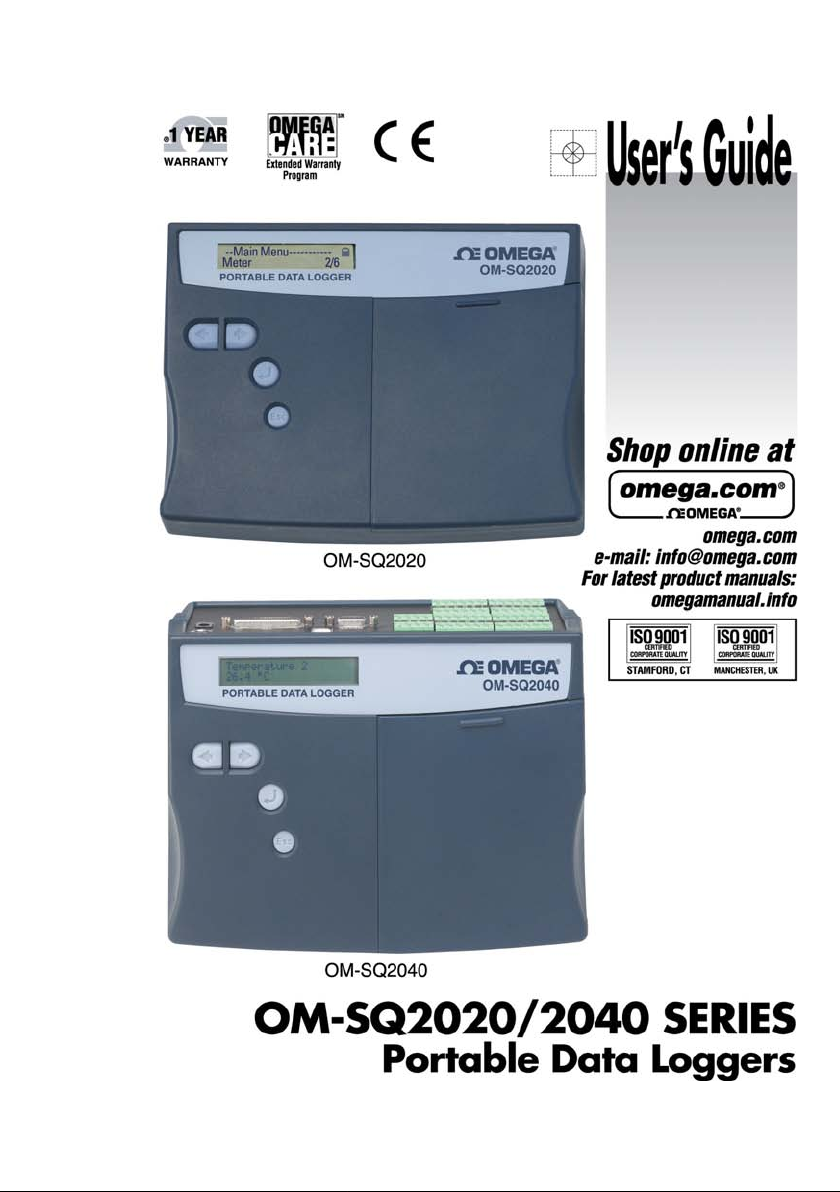

Page 1

Page 2

Page 3

1. Hardware Checklist............................................................................3

2. General Information...........................................................................4

3. Communicating with your Logger ...................................................5

4. Quick Start Example..........................................................................8

5. Download Process Explained.........................................................12

6. Menu and Navigation.......................................................................13

7. Connections.....................................................................................15

8. Accessories......................................................................................17

9. Specifications...................................................................................19

Contents

After reading this guide please refer to the Help contents within

OMEGALOG® (press F1) for further details on your logger and

how to use it with the software.

28923 Version 1.2 - October 08

Page 3

Page 4

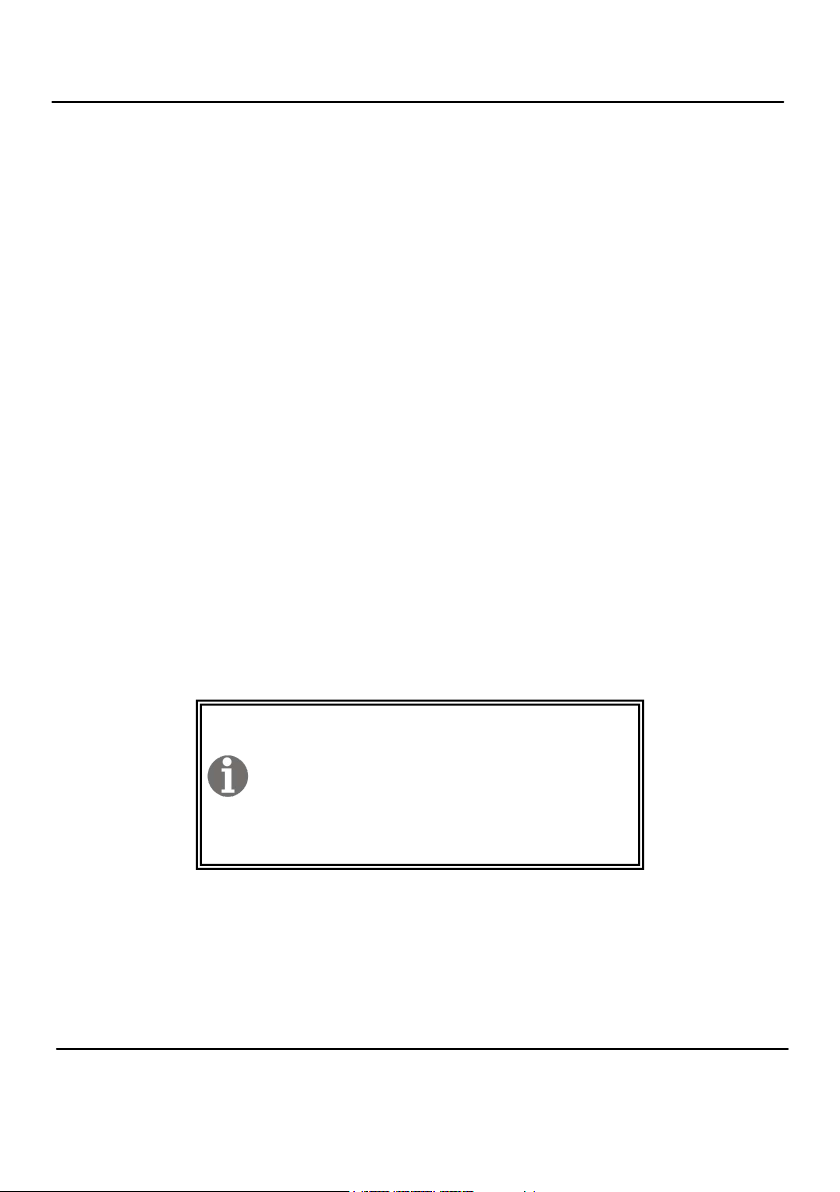

1. Hardware Checklist

B

D

C

A

E

H

F

G

A) OM-SQ2020/2040 Logger

B) CD containing software

C) User’s Guide (this booklet)

D) USB Cable (OM-SQ-USB-CABLE)

E) Mounting bracket/stand for logger

F) Batteries, 6 x AA

G) Current shunt resistors for 4 to 20mA inputs, 10R x 4

(OM-SQ-CS)

H) Connectors: 6 way x 4 (OM-SQ-TB6), 4 way (OM-SQ-TB4),

3 way (OM-SQ-TB3), with cable ties

Note: OM-SQ2040 Logger is supplied with 4 extra 6 way

connectors as above (OM-SQ-TB6).

Version 1.2 - October 08 28923

Page 4

Page 5

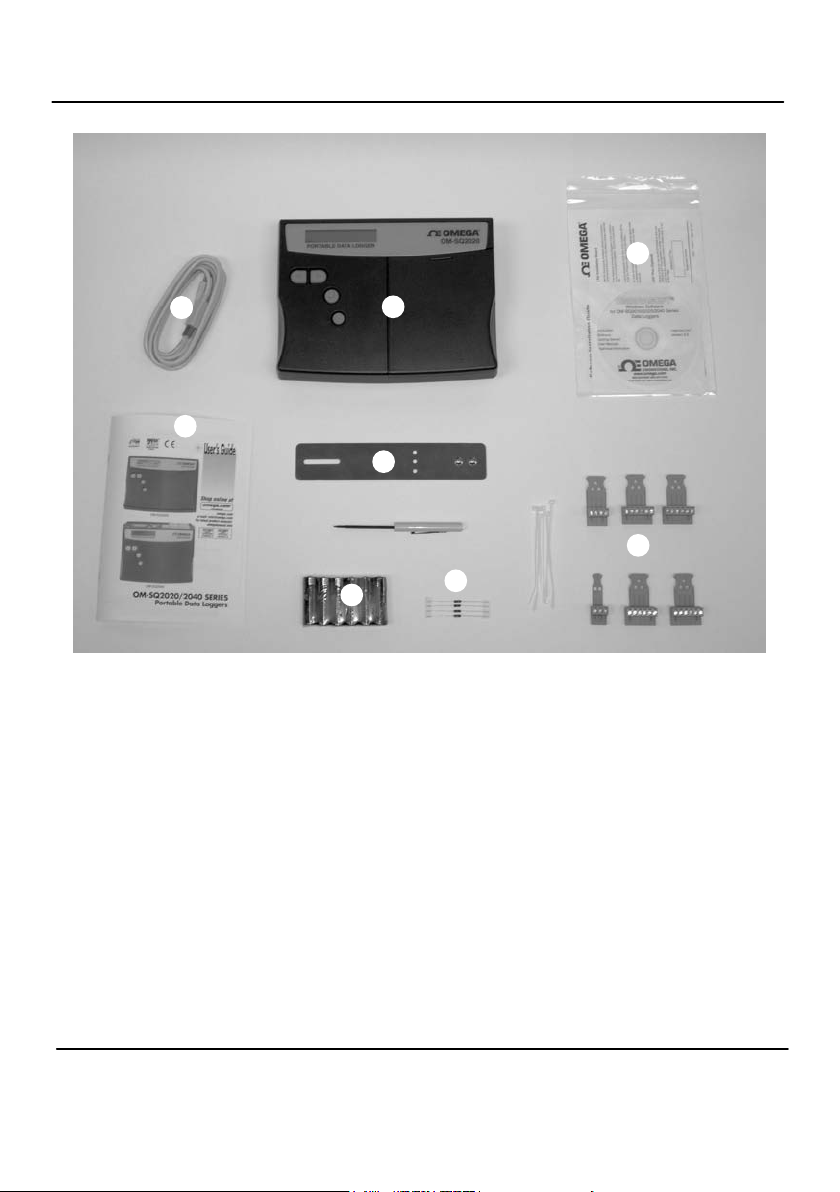

2.1 Installing the batteries

The OM-SQ2020/2040 uses six AA size alkaline batteries located under the removable cover shown below. To insert new or change the existing batteries:

1. Open the battery cover by pushing down and sliding as shown.

2. Insert six AA* batteries, ensuring the correct polarity.

3. Refit the battery cover

* It is recommended that all replacement batteries are of the same manufacturer, type

and condition.

2. General Information

2.2 Power indicator

Battery indicator

When logging please ensure that the batteries in the unit have sufficient capacity to

complete the logging task. This can be checked via the battery indicator located in the

top right of the display.

HIGH LOW

CAPACITY CAPACITY

External power indicator

The logger may be powered from an external source (10-18V DC)

Important: To ensure data protection in the case of an unexpected

power loss, please ensure that batteries are fitted whilst the unit is

operational.

28923 Version 1.2 - October 08

Page 5

Page 6

3. Communicating with your Logger

3.1 Installing the Software

For detailed installation instructions please see the supplied ‘Software Installation Guide’

supplement. For quick installation please see the steps below;

1. Ensure you have administration rights on the PC you wish to install software on

2. Ensure any current OMEGA applications are closed

3. Insert the CD into the CD\DVD drive of your computer and wait for it to autorun*

4. Follow the on screen installation wizard

* If after a few minutes autorun has not occurred select the Run option from the Windows

Start Menu. In the Command Line box, type d:\setup and press enter (where d:\ is your

CD\DVD drive, modify if required)

Important: Please ensure the software is installed before connecting the

OM-SQ2020/2040 data logger.

3.2 Connecting your OM-SQ2020/2040 Data Logger

You can connect to your logger by using one of the following methods;

1. Serial (RS232), including serial adaptors

2. USB

3. Ethernet (where fitted)

Please see below for more information.

Serial (RS232)

For information on using serial adaptors please see the OMEGALOG® help file. If using a

straight serial (RS232) cable, connect one end to the serial port on the logger and the other

end to the PC’s serial port. Once connected you are ready to begin communications.

Version 1.2 - October 08 28923

Page 6

Page 7

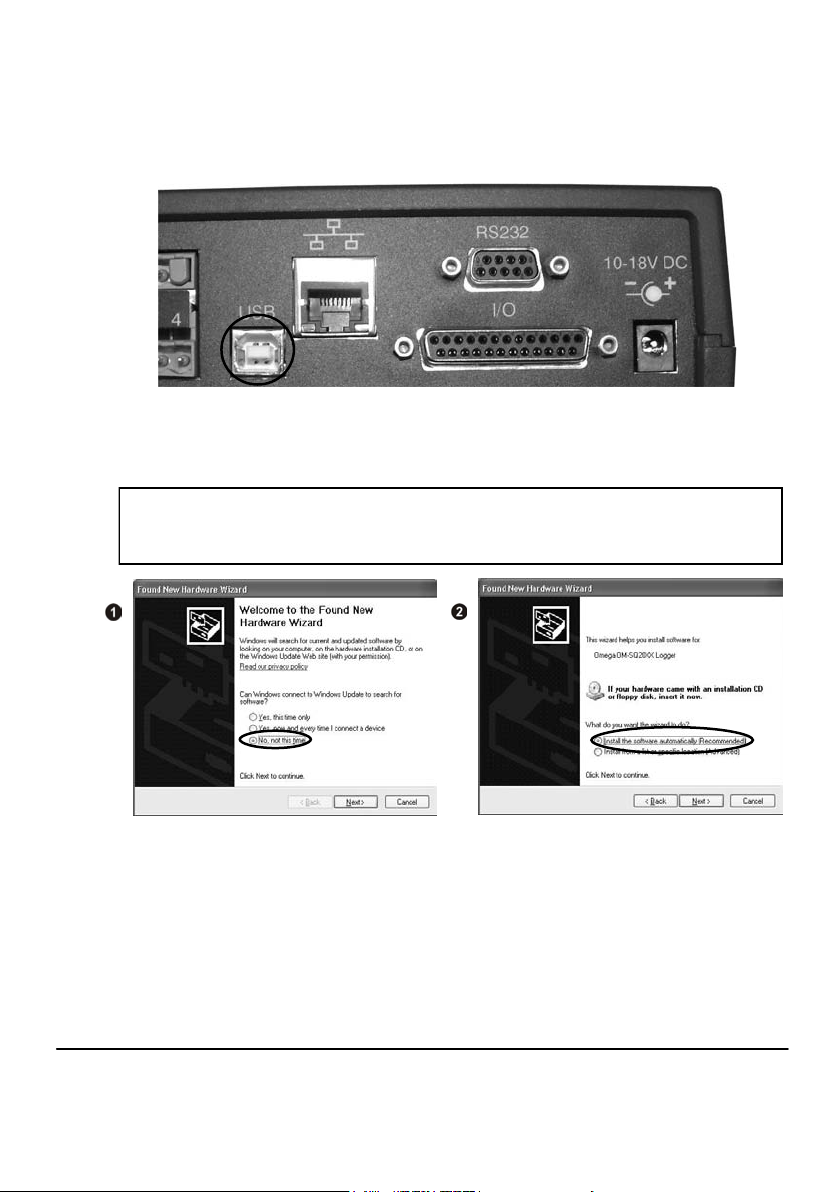

USB

Connect one end of the supplied USB lead to the USB port on the logger and the other end

to a USB port on the PC.

On detection of the logger the PC will launch the driver installation wizard.

Win 2000/XP - During the installation the USB drivers were pre-installed so the wizard will

automatically locate the driver. On the ‘Found New Hardware Wizard’ select ‘No, not this

time’ and for all the other screens select ‘Next’ to complete the installation.

28923 Version 1.2 - October 08

Page 7

Page 8

Win 98SE - Select Search for the best driver for your device (Recommended), Click

Next and follow the instructions illustrated below.

Select Continue Anyway on the Hardware Installation warning which refers to Windows

Logo testing. Once the driver installation has completed you are ready to communicate to

your logger.

If you experience any problems refer to Troubleshooting->20XX USB Drivers in OMEGALOG® help.

Ethernet

Before using the Ethernet connection please read the configuration manual which can be

found under ‘~\OMEGALOG\Manuals\OM-SQ20XX Inbuilt Ethernet Configuration.pdf’

where ‘~\OMEGALOG’ is the installation directory of OMEGALOG®. Connect your Ethernet

network to the Ethernet port on the logger.

Ethernet is only available when the logger is connected via an external power

supply.

Version 1.2 - October 08 28923

Page 8

Page 9

4. Quick Start Example

After installing OMEGALOG® an example setfile will be installed within the

OMEGALOG® installation directory. The example file will log the internal temperature of

the logger. In order to familiarise yourself with the logger the novice user may find this

example Setup useful.

4.1 Startup OMEGALOG® and Select Logger Type

Click on the shortcut icon on your desktop to launch OMEGALOG® or select it from

your start menu. When the OMEGALOG® Assistant is loaded, ensure the correct logger

Type and communication method is selected.

Logger type can be viewed from the OMEGALOG® Assistant, if you need to make any

changes select Logger Selection from the toolbar or run the Communication Wizard.

(Note: the default communication method is USB and you will need to change this via

the Communication Wizard if you are using any of the other communication methods).

4.2 Synchronise Logger & PC

It is advisable to start by synchronising the Logger clock with the PC clock. See step 1

and 2 below:

Synchronise clocks:

From the Logger

From

OMEGALOG® Assistant

click on Logger

Setup.

28923 Version 1.2 - October 08

Setup screen select

the Logger Control

tab.

Click on Set

Logger Time to PC

Time, click OK on the

confirmation screen.

Page 9

Page 10

4.3 Running Quick Start Demo

In the OMEGALOG®

Assistant click ‘Logger

Setup’ to enter the Logger Setup

screen. From here open the

demo setfile using File -> Open

and select the appropriate file for

your logger type.

The Logger

Setup screen

is now visible,

from here you

will be able to

set up your

logging

requirements.

Within the

Actual

Channels tab

scroll down the

Sensor Type

column to Ref.

Junction 1.

This is the

input you will

be reading in

this example.

The Job

Description

can be used to

describe your

setup.

Version 1.2 - October 08 28923

Page 10

Page 11

Click

to send

setup to

logger

and start

logging. Let the unit

log for a few

minutes.

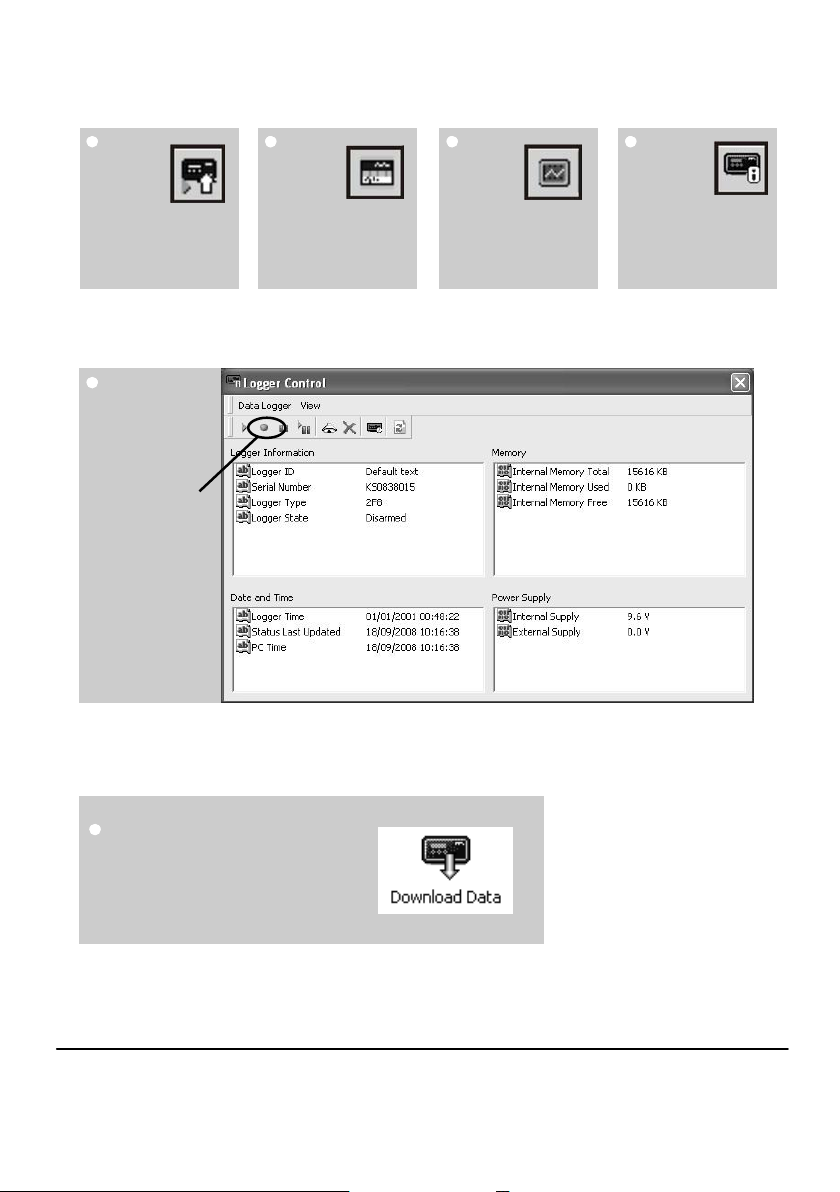

In the Logger

Control window

you can view

relevant

information on

the state of the

logger. To stop

logging click on

the stop button.

Click for

OMEGALOG®

Assistant.

Click

if you

wish to

meter

the input

in Real Time.

Click on

Logger

Control

icon to

pause or stop the

logging process.

To Download the logger

click on the ‘Download Data’

icon from the OMEGALOG®

Assistant.

28923 Version 1.2 - October 08

Page 11

Page 12

In this screen you can now download the Data File and invoke the Export Wizard or

download the Data File via Analysis* (See page 10 for further information).

The data File is given a unique name

(e.g. 28162735.D20). An explanation of

the file name is shown on the right; this

shows the date and start time

In this example you will download and view the Data in the Analysis* window. Start by

selecting the Data File and Graph Data action, then click Download Selected File(s).

You will be prompted to save the Data file, then the data will be converted for viewing.

Once the decoding has

taken place the Analysis File

Description window will be

presented, click OK to view

your Data.

*Available with OMEGALOG® Plus only.

Version 1.2 - October 08 28923

Page 12

Page 13

5. Download Process Explained

Logger

Data Files

Data File

in

external

MMC/SD

card

(.d20)

Reader

(.d20)

Analysis

Analysis File

(Plus Only)

OMEGALOG®

Microsoft Excel

(.xls)

Export

(.csv)

Comma Separated Values

The Diagram above shows the download process. Data in the logger is written to the internal

memory and may be downloaded by OMEGALOG®.

Before the data can be viewed it must be converted by OMEGALOG® for Analysis or exported

to .csv or .xls format depending on the PC software being used.

The conversion process can be performed in one of three ways within OMEGALOG®:

from OMEGALOG® Assistant->Analysis->Export Data File

automatically when using the download Data button from OMEGALOG®*

or from the Logger Data Analysis screen by selecting File->Import Data menu*

Once the file has been downloaded it can be double clicked to open it with the program specified

under ‘Tools’, ‘Preferences’, ‘File Association Action’.

*Available with OMEGALOG® Plus only.

28923 Version 1.2 - October 08

Page 13

Page 14

6. Menu and Navigation

6.1 Control Panel

The illustration below shows the navigation controls in more detail.

NAVIGATION

LEFT

To use the OM-SQ2020/2040 control panel

press , the opening display will be

shown (see right). The display timeout is

preset to 10 seconds, however this can

be changed by selecting the

Configuration tab within the Logger Setup

window of OMEGALOG®.

RIGHT

NAVIGATION

ENTER/CONFIRM &

POWER ON

ESCAPE/BACK

(reverts to previous

Menu)

Version 1.2 - October 08 28923

Page 14

Page 15

6.2 Control panel menu

Detailed below is a basic explanation of the top menu structure. For more information on

the whole menu structure please refer to the Help->Help Content->Loggers within

OMEGALOG®.

6.3.1 Log Control

In this menu you can Arm (activate) or

Disarm (deactivate) the logger.

6.3.2 Meter

Here you can view each channel in Real

Time (at 1-2Hz). Use the enter key to auto

scroll through the channels.

6.3.3 Status

The Status menu gives you access to

information relating to the logger such as

memory and power supply voltage. You

can also override the alarm outputs in

here.

6.3.4 Setup

This contains menus for setting up

Language, Time & Date and the

opportunity to store and recall Setups.

6.3.5 Data Files

This menu allows you to copy data files to

an external memory card (if fitted) and

delete the data files held within the

loggers memory.

6.3.6 Tools

The Tools menu contains maintenance

type functions such as querying the

software version of the logger,

performing a self test and resetting the

logger.

28923 Version 1.2 - October 08

Page 15

Page 16

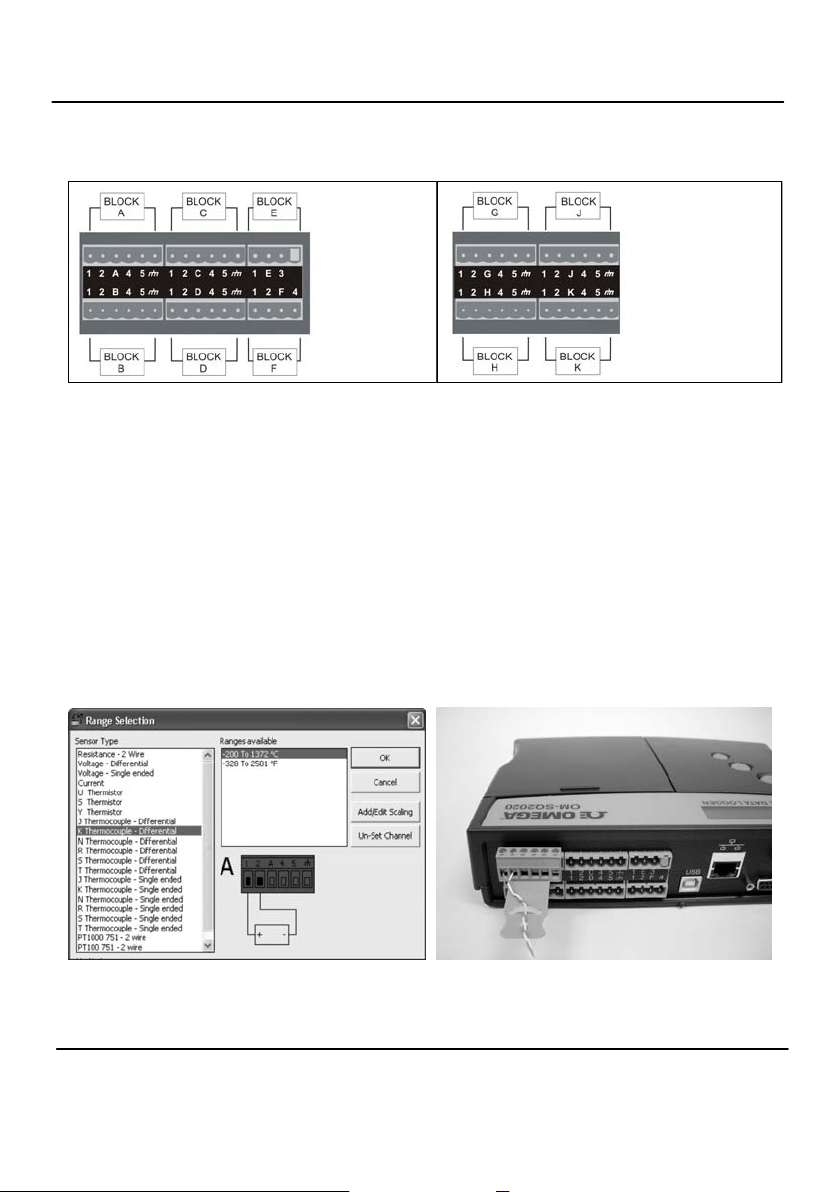

Analog Inputs

7. Connections

Rear view of

ANALOG

connectors

NOTE: Blocks G to K as shown above are

only available on OM-SQ2040 loggers.

As the wiring configuration is dependant upon the sensor type used, it is displayed in OMEGALOG®

during the setup. Follow the wiring diagram to attach the required sensor. If you would like to print

the diagrams in more detail or view at a later stage select ‘File > Print from Logger Setup’.

The example below shows the actual K type differential thermocouple sensor connected to the OMSQ20XX logger from the wiring diagram to the left.

Rear view of

ANALOG

connectors

Version 1.2 - October 08 28923

Page 16

Page 17

Sensor Power Wiring

Unregulated Logger

Supply Output

Regulated 5V Output

I/O Socket Wiring

ALARM

O/P

SLOW PULSE

I/P 1-2

Block E

EVENT/STATE

FAST PULSE

I/P 1-2

I/P 1-8

Negative

Auxiliary Output

Max. 500mA

PIN 1

+ve -ve

V1(+ve)

V1(-ve)

High Voltage Input

Block F

Pin Connection

1 Event/State Input 1

2 Event/State Input 2

3 Event/State Input 3

4 Event/State Input 4

5 Event/State Input 5

6 Event/State Input 6

7 Event/State Input 7

8 Event/State Input 8

9 Ground

10 Alarm Output A

11 Alarm Output B

12 Alarm Output C

13 Alarm Output D

14 Auxiliary Output +ve

15 Auxiliary Output +ve

16 Auxiliary Output -ve

17 Auxiliary Output -ve

18 Ground

19 Ground

20 Ground

21 Fast Pulse Input 1

22 Fast Pulse Input 2

23 Slow Pulse Input 1

24 Slow Pulse Input 2

25 No Connection

V2(-ve)

V2(+ve)

External Memory Card Reader

The external MMC/SD card slot is located inside the

battery compartment.

28923 Version 1.2 - October 08

Page 17

Page 18

8. Accessories

OMEGA Engineering supplies a wide range of accessories to compliment the range of

OM-SQ2020\2040 data loggers. These include GSM Modem and Ethernet converters and wireless adapter as shown below, all of which allow you to contact any OM-SQ2010 data logger remotely or where no land line exists. All are very easy to install and connect directly to the logger

via RS232. If you need any further details or wish to make a purchase please contact OMEGA

Engineering.

Ethernet

GSM

Wireless

RS232 to Ethernet Converter consisting of adaptor box and modem setup

Cable. Ethernet configuration software is suitable for Windows 2000 and XP

only.

GSM Modem kit comprising of modem, data logger connection cable, power

lead and antenna with 3m lead. A data-enabled SIM card will also be required

from your network service provider.

Wireless Adaptor comprising of an RS232 adaptor for connecting the logger

to the PC at baud rates up to 115K2 with a range of up to 200 metres using the

2.4GHz frequency band. The kit is supplied with all connecting leads.

Note: Power supplies (OM-SQ-UNIV-ADAP) need to be ordered separately

Version 1.2 - October 08 28923

Page 18

Part No:

OM-SQ-NET-ADAP

OM-SQ-GSM-KIT

OM-SQ-RF-ADAP

Page 19

Part No:

Software packages for set-up, transfer and data analysis:

OMEGALOG® Plus

Provides full data analysis, on-line graphing, meter to Excel and

export to Excel OM-SQ-SOFT-PLUS

OMEGALOG® Plus Multi-User License

Unlimited use of OMEGALOG® within a single organization. OM-SQ-SOFT-PLUS-LIC

Calibration Certificates for OM-SQ2020/2040 series (all ranges)

Note: Test and Calibration Certificates are traceable to National

Standards

OM-SQ2010 OM-SQ2020-CAL

OM-SQ2040 OM-SQ2040-CAL

Power supplies

100-240V AC 50/60Hz supplied with 3-single fit mains plugs for UK,

Euro, and US OM-SQ-UNIV-ADAP

As OM-SQ-UNIV-ADAP but supplied with 1m flying lead OM-SQ-UNIV-ADAP-1

Current Shunts

Pack of 4 precision resistors for 4-20mA analog channels OM-SQ-CS

Cables for connecting data loggers to computers/modems.

Data Logger to PC serial port OM-SQ-SER-CABLE

Data Logger to PC USB port OM-SQ-USB-CABLE

Terminal blocks

Plug-in terminal blocks with cable restraint

3-way OM-SQ-TB3

4-way OM-SQ-TB4

6-way OM-SQ-TB6

28923 Version 1.2 - October 08

Page 19

Page 20

9. Specifications

ANALOG INPUTS

Basic accuracy (5-45°C): ..............................................± (0.05% readings + 0.025% range)

Common mode rejection: ...........................................................................................100dB

Input impedance: ...................................................................................................> 1MOHM

Linearity: ..................................................................................................................0.0015%

Series mode line rejection:...........................................................................50/60Hz 100dB

DIGITAL INPUTS

Zero input voltage....................................................................... 0 to 0.5V (or shorted input)

One input voltage..................................................................2.7 to 5V (or open circuit input)

Input protection......................................will turn on below about -0.5V and above about 6V

ANALOG-DIGITAL CONVERSION

Type: ....................................................................................................................Sigma-Delta

Resolution: .....................................................................................................................24bit

Sampling rate: ..................................................................Up to 20/100 readings per second

Note: 100Hz Mode not available on 1F8 models

ALARM OUTPUTS.......................................................................4 x open drain FET (18V 0.1A Max)

SENSOR POWER SUPPLY..............................Regulated 5 VDC (50mA) or supply voltage (100mA)

TIME AND DATE...........................................................................................In built clock in 3 formats

SCALING DATA.......................................................Displays readings in preferred engineering units

MEMORY

Internal: ...............................................................................16Mb (Up to 1,800,000 readings)

External:....................................................... Up to 256Mb removable MMC/SD memory card

RESOLUTION.................................................................................................Up to 6 significant digits

PROGRAMMING/LOGGER SET-UP..................... ..........OMEGALOG® or OMEGALOG® Plus software

COMMUNICATION.......................................................................................USB 1.1 and 2.0 / RS232

External options: .......................................................................GSM, Ethernet and wireless

POWER SUPPLY

Internal:............................................................................................6*x AA Alkaline batteries

External: ..........................................10-18VDC Reverse polarity and over-voltage protected

* Maximum operating temperature for supplied alkaline batteries is 50°C

Version 1.2 - October 08 28923

Page 20

Page 21

POWER CONSUMPTION @ 9V

Sleep mode: ..............................................................................................................<600µA

Logging: ..............................................................................................................40 - 120mA

DIMENSIONS AND WEIGHT

2020 Logger

Dimensions: ...................................................................................W235 x D175 x H55 mm

Weight: ............................................................................................................Approx 1.2kgs

Enclosure material: ...................................................................................................... ABS

2040 Logger

Dimensions: ...................................................................................W235 x D175 x H92 mm

Weight: .............................................................................................................Approx1.5kgs

Enclosure material:........................................................................................................ABS

MEMORY MODES (internal only)............................................................Stop when full or overwrite

DISPLAY AND KEYPAD

2 line x 20 character LCD

OPERATING ENVIRONMENT ...................................................................................-30°C to +65°C

Windows is a registered trademark of Microsoft

Corporation in the United States and other countries.

Due to our policy of continuous improvements, specifications may change

without prior notice.

OMEGA Engineering believe that all information declared is correct at the time of issue.

No liability is accepted for errors and omissions.

28923 Version 1.2 - October 08

Page 21

Page 22

Personal Notes:

Version 1.2 - October 08 28923

Page 22

Page 23

Page 24

Loading...

Loading...