Page 1

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gauges

Load Cells & Pressure Gauges

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

M3399/0699

Page 2

OM-LMPLC - User’s Documentation - Omega

User’s Guide

http://www.dasieee.com

e-mail: das@omega.com

OM-LMPLC SERIES

PORTABLE PLC

Page 2 of 47

Page 3

OM-LMPLC - User’s Documentation - Omega

OMEGAnet® On-Line Service Internet e-mail

http://www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGASM

Customer Service: 1-800-622-2378 / 1-800-622-BESTSM

Engineering Service: 1-800-872-9436 / 1-800-USA-WHENSM

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (95) 800-826-6342 FAX: (95) 203-359-7807

En Español: (95) 203-359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in the United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

__________________________________________________________________________________

_

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certification of its products to the European New Approach Directives.

OMEGA will add the CE mark to every appropriate device upon certification.

Page 3 of 47

Page 4

OM-LMPLC - User’s Documentation - Omega

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc.

accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected

applications.

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from

date of purchase. OMEGA Warranty adds an additional one (1) month grace period to the normal one (1) year product warranty to

cover handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an

Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be

defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the

purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or

unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of

having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification;

misapplication; misuse or other operating conditions outside of OMEGA’s control. Components which wear are not warranted,

including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any

omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information

provided by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be as specified and free of

defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT

THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are

exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification,

strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall

OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR

21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s)

be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes

no responsibility as set forth in our basic WARRANTY / DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and

hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S)

TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package

and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

FOR WARRANTY RETURNS,

please have the following informatio n available BEFORE contacting

OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the

product under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest

in technology and engineering. OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1999 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or

reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS, consult OMEGA for current repair charges.

Have the following information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

Table of Contents

TABLE OF CONTENTS...............................................................................................................................................4

TABLE OF FIGURES ....................................................................................................................................................7

TABLE OF TABLES .....................................................................................................................................................7

TABLE OF EXAMPLES ...............................................................................................................................................7

SECTION I - GENERAL INFORMATION................................................................................................................9

Page 4 of 47

Page 5

OM-LMPLC - User’s Documentation - Omega

INTRODUCTION...........................................................................................................................................................9

DESCRIPTION...............................................................................................................................................................9

DOCUMENTATION......................................................................................................................................................9

SAFETY CONSIDERATIONS........................................................................................................................................9

INSTRUMENT IDENTIFICATION...............................................................................................................................9

SECTION II - INSTALLATION................................................................................................................................10

INTRODUCTION.........................................................................................................................................................10

INITIAL INSPECTION ................................................................................................................................................10

POWER REQUIREMENTS..........................................................................................................................................10

BENCH OPERATION..................................................................................................................................................10

PANEL MOUNTING...................................................................................................................................................10

SOFTWARE INSTALLATION ....................................................................................................................................11

SECTION III - OPERATING INSTRUCTIONS .....................................................................................................12

INTRODUCTION.........................................................................................................................................................12

CONTROLS AND INDICATORS .................................................................................................................................12

CONNECTING INPUTS...............................................................................................................................................14

CONNECTING OUTPUTS..........................................................................................................................................15

PROGRAM, RUN, AND PAUSE MODES....................................................................................................................16

RESETTING THE COUNTERS AND PROCEDURE ...................................................................................................17

OM-LMPLC DISPLAYS.............................................................................................................................................17

PROGRAMMING OVERVIEW.....................................................................................................................................19

STEP COMMANDS.....................................................................................................................................................19

Overview...............................................................................................................................................................19

Turn Outputs “On/Off”......................................................................................................................................20

Turn Outputs “On” .............................................................................................................................................20

Turn Outputs “Off”.............................................................................................................................................21

Waiting for Inputs to be “On”..........................................................................................................................21

Waiting for Inputs to be “Off”..........................................................................................................................22

Wait.......................................................................................................................................................................22

End Test................................................................................................................................................................22

Pause Test............................................................................................................................................................22

Jump if Inputs are “On”....................................................................................................................................23

Jump if inputs are “Off”.....................................................................................................................................23

Increase counters................................................................................................................................................23

Count inputs........................................................................................................................................................24

Begin Loop...........................................................................................................................................................25

End Loop..............................................................................................................................................................26

Jump......................................................................................................................................................................26

PROCEDURE WRITER PROGRAMMING SO FTWARE .............................................................................................26

Starting Procedure Writer................................................................................................................................26

Creating a new procedure ................................................................................................................................27

Different Views of your procedure...................................................................................................................27

The Step view.......................................................................................................................................................27

The Sheet View....................................................................................................................................................28

The Output view..................................................................................................................................................29

Editing the custom displays..............................................................................................................................30

Custom Input, Output, and Counter names...................................................................................................31

Modifying onboard counts...............................................................................................................................32

Procedure Writer Options.................................................................................................................................32

Testing your Input and Output wiring............................................................................................................33

Debugging your Procedure..............................................................................................................................34

Printing your procedure...................................................................................................................................34

Documenting your procedure..........................................................................................................................34

Page 5 of 47

Page 6

OM-LMPLC - User’s Documentation - Omega

Saving your procedure......................................................................................................................................35

Opening your procedure...................................................................................................................................35

Reading a Procedure from the OM-LMPLC ..................................................................................................35

Using the procedure Wizard.............................................................................................................................36

OM-LMPLC FIELD PROGRAMMER........................................................................................................................36

Downloading the OM-LMPLC field programmer software into the calculator.....................................37

ADVANCED PROGRAMMING TECHNIQUES ...........................................................................................................38

INTEGRATING THE OM-LMPLC IN A DATA ACQUISITION SYSTEM ..............................................................39

SECTION IV - PRINCIPLES OF OPERATION.....................................................................................................40

INTRODUCTION.........................................................................................................................................................40

STEP CYCLES.............................................................................................................................................................40

SOLID STATE RELAYS.............................................................................................................................................41

SECTION V - MAINTENANCE .................................................................................................................................42

INTRODUCTION.........................................................................................................................................................42

OUTPUT FAILURE .....................................................................................................................................................42

TROUBLESHOOTING.................................................................................................................................................42

SECTION VI - SUPPORT..........................................................................................................................................43

INTRODUCTION.........................................................................................................................................................43

INTERNET WEB SITE...............................................................................................................................................43

APPENDICES...............................................................................................................................................................44

SPECIFICATIONS .......................................................................................................................................................44

SERIAL CABLE WIRING............................................................................................................................................45

RS232 PROTOCOL SUMMARY..................................................................................................................................45

PROCEDURE WRITER - L ICENSE AGREEMENT ....................................................................................................47

Page 6 of 47

Page 7

OM-LMPLC - User’s Documentation - Omega

Table of Figures

FIGURE 1 - OM-LMPLC FRONT PANEL .....................................................................................................................12

FIGURE 2 - REAR OF OM-LMPLC...............................................................................................................................13

FIGURE 3 - OM-LMPLC INPUT CIRCUIT ...................................................................................................................14

FIGURE 4 - TYPICAL OM-LMPLC INPUT WIRING...................................................................................................15

FIGURE 5 - OM-LMPLC OUTPUT CIRUIT FOR AC AND DC...................................................................................15

FIGURE 6 - TYPICAL OM-LMPLC DC OUTPUT WIRING ........................................................................................16

FIGURE 7 - TYPICAL OM-LMPLC AC OUTPUT WIRING........................................................................................16

FIGURE 8 - RESETTING PROCEDURES “COUNT DOWN” WARNING ON THE LCD DISPLAY..............................17

FIGURE 9 - RESETTING PROCE DURES WITH "PROCEDURE" RESET MESSAGE.....................................................17

FIGURE 10 - OUTPUT 2 ACTIVATED AND INPUT 1 ACTIVATED ..........................................................................18

FIGURE 11 - COUNTERS 1-2 DISPLAY .........................................................................................................................18

FIGURE 12 - PROCEDURE INFORMATION DISPLAY..................................................................................................18

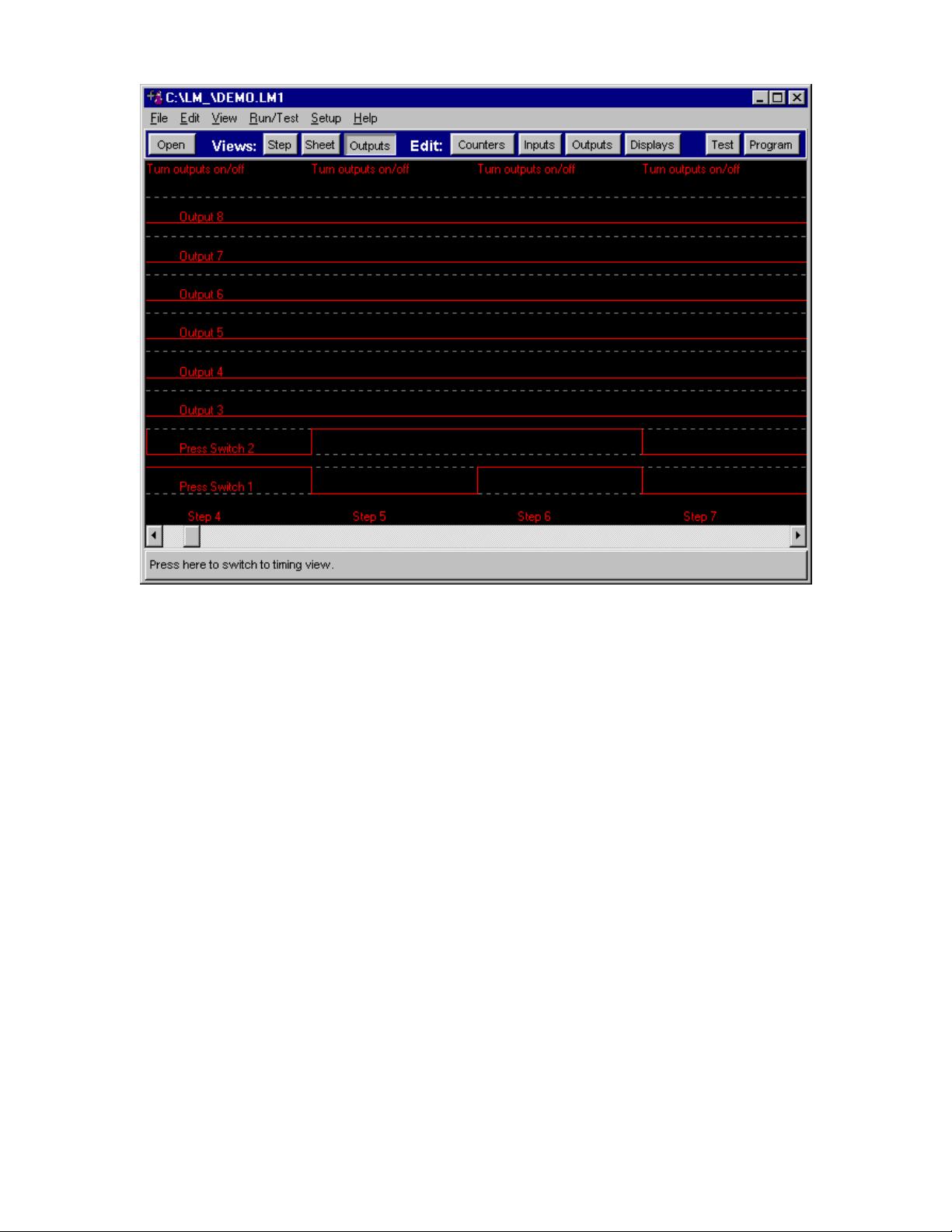

FIGURE 13 - PROCEDURE WRITER STEP V IEW........................................................................................................28

FIGURE 14 - SHEET V IEW.............................................................................................................................................29

FIGURE 15 - OUTPUT V IEW.........................................................................................................................................30

FIGURE 16 - E NTERING CUSTOM DISPLAYS..............................................................................................................31

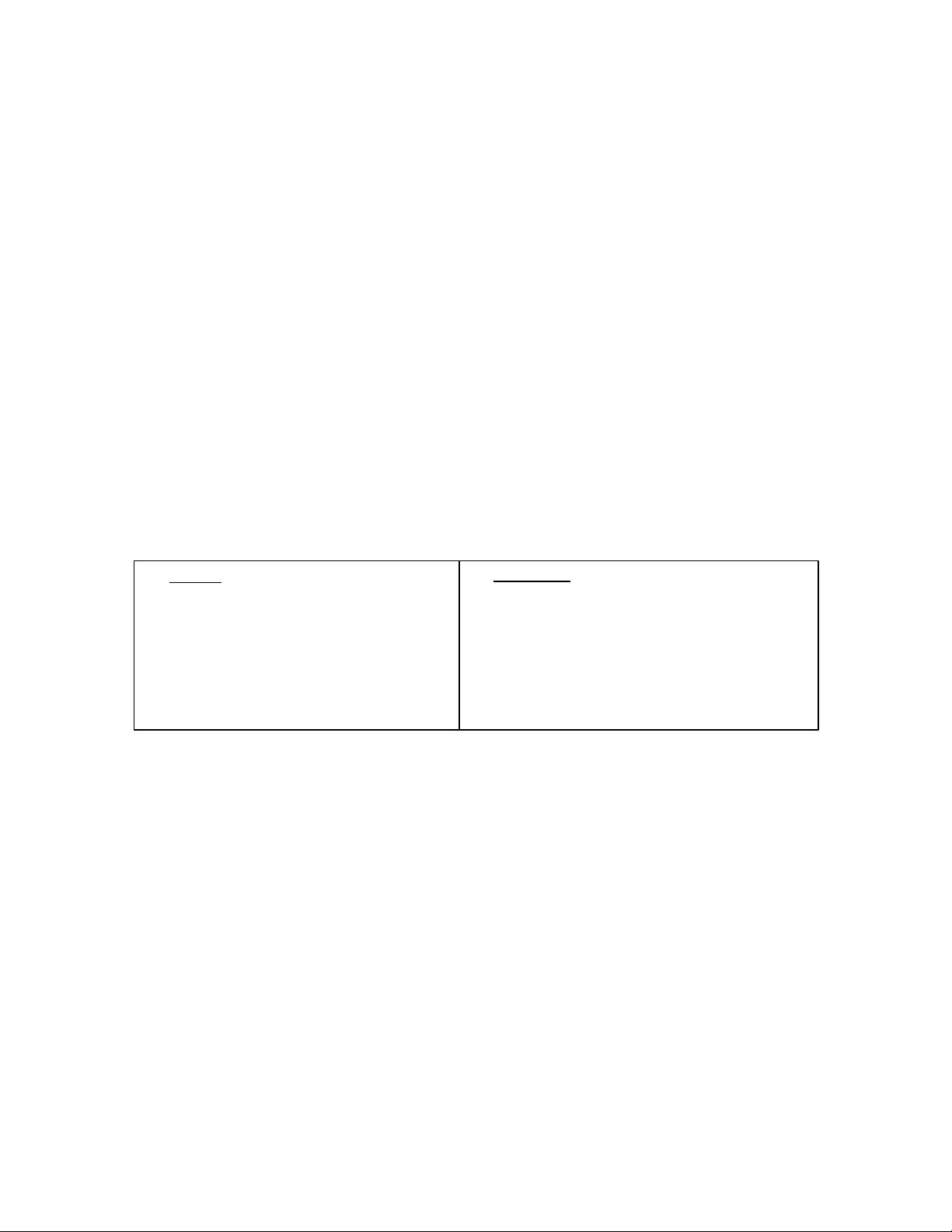

FIGURE 17 - NAMING INPUTS, OUTPUTS, AND COUNTERS....................................................................................31

FIGURE 18 - E DIT CURRENT COUNTS DIALOG..........................................................................................................32

FIGURE 19 - SELECTING A COMM PORT AND OTHER PROCEDURE WRITER OPTIONS.....................................33

FIGURE 20 - TESTING INPUT AND OUTPUT WIRING SCREEN ................................................................................34

FIGURE 21 - READ THE PROCEDURE OUT OF THE PLC TO PRINT IT OUT ..........................................................35

FIGURE 22 - THE MAIN TOOLBAR FOR THE FIELD PROGRAMMER IS ACCESSED THROUGH THE CST BUTTON

.................................................................................................................................................................................36

FIGURE 23 - THE OM-LMPLC FIELD PROGRAMMER ALLOWS PROGRAMMING WITHOUT THE PC................37

FIGURE 24 - SERIAL CABLE WIRING...........................................................................................................................45

Table of Tables

TABLE 1 - SUMMARY OF STEP COMMANDS.............................................................................................................20

TABLE 2 - OM-LMPLC TROUBLE SHOOTING...........................................................................................................42

Table of Examples

All examples are included on the Procedure Writer install disks. Their names are indicated by (filename) in

the following table.

EXAMPLE 1 - TURNING OUTPUTS ON AND OFF WITH THE "OUTPUTS ON/OFF" COMMAND

(EX_ONOFF.LM1)..................................................................................................................................................20

EXAMPLE 2 - RUNNING PARTS WHEN SE LECTED ONLY USING THE TURN OUTPUTS ON COMMAND

(EXTURNON.LM1).................................................................................................................................................21

EXAMPLE 3 - USING INPUTS TO MONIT OR TEST PROGRESS WITH THE WAIT INPUTS COMMAND

(EXWAITIN.LM1)..................................................................................................................................................22

EXAMPLE 4 - RUNNING TWO DIFFERENT TESTS WITH ONE PROCEDURE USING JUMPIF COMMAND

(EXJUMPIN.LM1)...................................................................................................................................................23

EXAMPLE 5 - USING COUNTERS TO TRACK CYCLES (EX_CNTR.LM1)..................................................................23

EXAMPLE 6 - COUNTING INPUTS DIRECTLY WITH THE "COUNT INPUTS" COMMAND (EX_CNTIN.LM1)...24

EXAMPLE 7 - USING "JUMP IF" COMMANDS FOR MORE ADVANCED INPUT COUNTING (EXTCNTIN2.LM1).25

EXAMPLE 8 - USING LOOPS TO CYCLE A SPECIFIC NUMBER OF TIMES (EXLOOP1.LM1)..................................25

Page 7 of 47

Page 8

OM-LMPLC - User’s Documentation - Omega

EXAMPLE 9 - USING MULTIPLE LOOPS FOR HANDLING USER INSPECTIONS (EXLOOP2.LM1).........................26

EXAMPLE 10 - CREATING OR LOGIC WITH MULTIPLE JUMP STEPS....................................................................38

EXAMPLE 11 - IMPLEMENTING AND LOGIC WITH MULTIPLE JUMP STEPS......................................................39

Page 8 of 47

Page 9

OM-LMPLC - User’s Documentation - Omega

Section I - General Information

Introduction

This section gives a general overview on the OM-LMPLC.

Description

The purpose of the OM-LMPLC is to function as a flexible I/O controller for test labs. In contras t with

widely available controllers, the OM-LMPLC was specifically designed for on/off cycling tests such as

pneumatic cycling, electronic power cycling, and other durability testing. Being tailored to the particular

niche market brings features not availa ble on current PLC's. Features usually required for testing such as

cycle counters, ease of use, computer control, and solid state relay outputs.

Documentation

The User’s Documentation is the comprehensive source for information concerning the OM -LMPLC. Use

the Table of Contents, Table of Figures, and Table of Tables to quickly locate the information you require.

Other sources of information include the Procedure Writer’s on-line documentation, the Omega WWW

(World Wide Web) site, and Omega’s Application notes.

Safety Considerations

Although the OM -LMPLC is a low voltage device, the OM-LMPLC could control potentially dangerous test

setups. The OM -LMPLC is not designed for controlling in situations where errors in the control logic could

cause human injury. Please use common sense in your use of the OM -LMPLC and apply standard safety

practices.

Qualified personnel should only perform wiring. Extreme care should be taken when working with dangerous

voltage levels.

When output errors could cause problems, for example if a Solid State Relay fails “On”, it is recommend that

the user installs a output disable circuit on each of the commons of the output connector. OM -LMPLC’s

output enable button on its front panel disables the outputs from the control side only, so if the Solid State

Relay fails “On” the output enable button will not have any affect.

Instrument Identification

On the rear of the OM-LMPLC is an identification number. This label clearly identifies the serial and model

number of the OM-LMPLC.

Page 9 of 47

Page 10

OM-LMPLC - User’s Documentation - Omega

Section II - Installation

Introduction

This section shows how to get started using the OM -LMPLC. This includes initial components inspection,

mounting, installing the programming software, and configuring your PC’s communications port.

Initial Inspection

When you receive your OM-LMPLC, you should have the following:

• Power supply (or) power jack connector

• Serial cable

• Setup disks (2) for the Procedure Writer Software (included in this manual)

• OM-LMPLC

• OM-LMPLC User's Documentation

• Panel mount slides (or) rubber feet and handle

If you do not have any of the above, please contact Omega’s.

Power requirements

The OM-LMPLC comes with its own wall transformer DC power supply or a power jack connector

compatible with the input power connector on the OM-LMPLC. The power jack connector allows you to use

an alternative DC power source. Consult the Specifications in the appendices for information on power

requirements.

Bench Operation

The OM -LMPLC is suitable for bench top operation. However, care should be taken when using the OMLMPLC for controlling dangerous AC voltages. It is recommended that you enclose the OM -LMPLC in a

protective case when working with AC voltages.

Panel Mounting

You can install the OM-LMPLC into a panel. In order to install the OM-LMPLC into a panel, you can use the

panel mount installation kit. Contact Omega’s for more information.

Page 10 of 47

Page 11

OM-LMPLC - User’s Documentation - Omega

Software Installation

Use the two disks included with the OM-LMPLC to install the “Procedure Writer” software. The following

steps describe the installation process.

1. Insert the program disk into a floppy disk drive.

2. Choose “Run” from the file menu of Program Manager if you are using Windows 3.x. If you are using

Windows 95, press start and choose run.

3. Type the drive letter followed by a colon, slash ( \ ) and then “setup”. For example, if you placed the

disk into the “a” drive it would be “a: \setup.exe”

4. Press enter.

5. Follow the instructions as shown in the setup program. The setup will check to see if there is enough

space on your hard drive, install the software, and allow you to choose the directory for locating the

software.

Setting up a free Comm port

Most PCs, both laptop and desktop type, have two Comm ports. Many devices use Comm ports to get data

into and out of your PC. Two of the most prominent devices are mice and modems. Most desktop PCs have

a mouse connected to one of their Comm ports. Most Laptops have a mouse built in which does not use the

external Comm port connector. You must determine which Comm port is not in use. See Setting up a Comm

port on page 32 for more information.

Page 11 of 47

Page 12

OM-LMPLC - User’s Documentation - Omega

Section III - Operating Instructions

Introduction

This section describes how to operate the OM-LMPLC. It includes information about the hardware, software

features, and the OM-LMPLC step commands.

Controls and Indicators

In order to simplify use and reduce cost, the OM -LMPLC’s front panel user interface is extremely simple.

The front panel of the OM -LMPLC has only two buttons, a key-switch, a connector, and a display (Figure

1). The rear panel has connections for the Inputs, Outputs, and the device power. All user interactions occur

through the front panel.

Figure 1 - OM -LMPLC front panel

The Mode push button is used to select the currently viewed display, to remove the OM -LMPLC from

“Pause Mode”, and to reset the procedure and internal counters. The operatio n of the “Mode” button is

defined in the “Program, Run, and Pause Modes” sub-section later in this section.

Page 12 of 47

Page 13

OM-LMPLC - User’s Documentation - Omega

The key-switch selects the operational mode of the OM -LMPLC. The OM-LMPLC has three modes: Pause,

Run, and Programming Mode. The sub-section called “Program, Run, and Pause Modes” clearly defines the

interaction of the key-switch and the different modes.

The output enable push button controls the signal to the OM -LMPLC’s internal hardware output chip that

enables its outputs. The purpose for this switch is so you can quickly disable the outputs. For increased

safety, the output enable switch is independent of the Microprocessor control. When this switch is

depressed, it will show an orange dot. In this state, it will enable the Microprocessor to control the outputs.

Note: The "output enable" safety feature only disables the outputs from the control side. For example, if the

solid state relay failed on (Shorted) this switch would have no effect. For possible dangerous situations an

external shut of f relay should be added on the power side.

The serial connector is where you connect the serial cable with the PC. This is how the OM-LMPLC

communicates with the PC.

The back panel of the OM-LMPLC has the connectors for the outputs, inputs, and power (Figure 2).

Figure 2 - Rear of OM -LMPLC

The power connector is where the proper power source should be connected. This connector has positive

at its center and ground on the outside. Consult specifications for power requirements.

The OM -LMPLC output connector is a ten-position connector. It has two commons located at position 1

and 5. Outputs one through four share position 1 common and outputs four through eight share position 5.

For example connection diagrams see the “Connecting Outputs” sub section later in this section.

The OM -LMPLC input connector is a nine-position connector. Position 1 of the connector is a common to

all eight inputs. For more information on connecting inputs to the OM-LMPLC, see sub-section called

“Connecting Inputs” later in this section.

Page 13 of 47

Page 14

OM-LMPLC - User’s Documentation - Omega

LEDs

DC

Voltage

DC

Sensor

Supply

Input (X)

Connecting Inputs

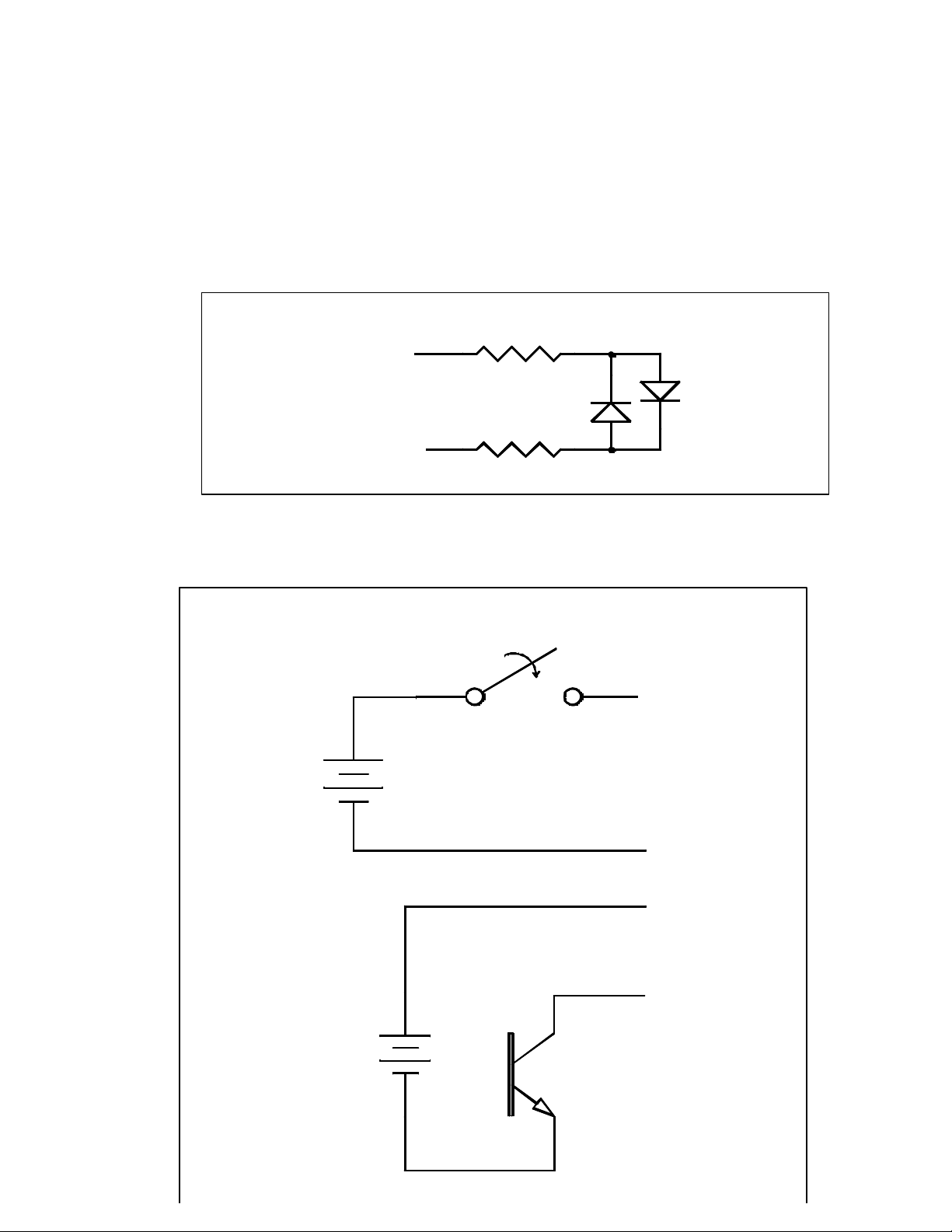

The inputs on the OM-LMPLC are bi -directional LED opto-isolators (Figure 3). You can use any DC voltage

source from 5 to 35 VDC to power the LED to complete the circuit. Wiring for dry contact switches and

transistor output type devices (such as proximity sensors and photo detectors) are shown in

Figure 4.

Input (X)

Input

Common

Figure 3 - OM -LMPLC Input Circuit

Dry Contact Switch

5-35 V

Common

Common

Input (X)

Transistor Output

5-35 V

Page 14 of 47

Sensor such as

Proximity Sensor

or Photo Detector

Page 15

OM-LMPLC - User’s Documentation - Omega

-

Figure 4 - Typical OM -LMPLC Input Wiring

Connecting Outputs

The OM-LMPLC has a 10-position connector for outputs. Outputs are available for DC and AC. Typical

wiring for DC and AC connections is shown in

Figure 6 and Figure 7, respectively.

Output (X)

Crydom Solid

State Relay AC

Type (SCR or

Common (X)

C1=OUT 1-4

C2=OUT 5-8

TRIAC)

Output (X)

Common (X)

C1=OUT 1-4

C2=OUT 5-8

Figure 5 - OM -LMPLC output ciruit for AC and DC

Crydom Solid

State Relay DC

Type (Bipolar

Transistor) Note

polarity

Page 15 of 47

Page 16

OM-LMPLC - User’s Documentation - Omega

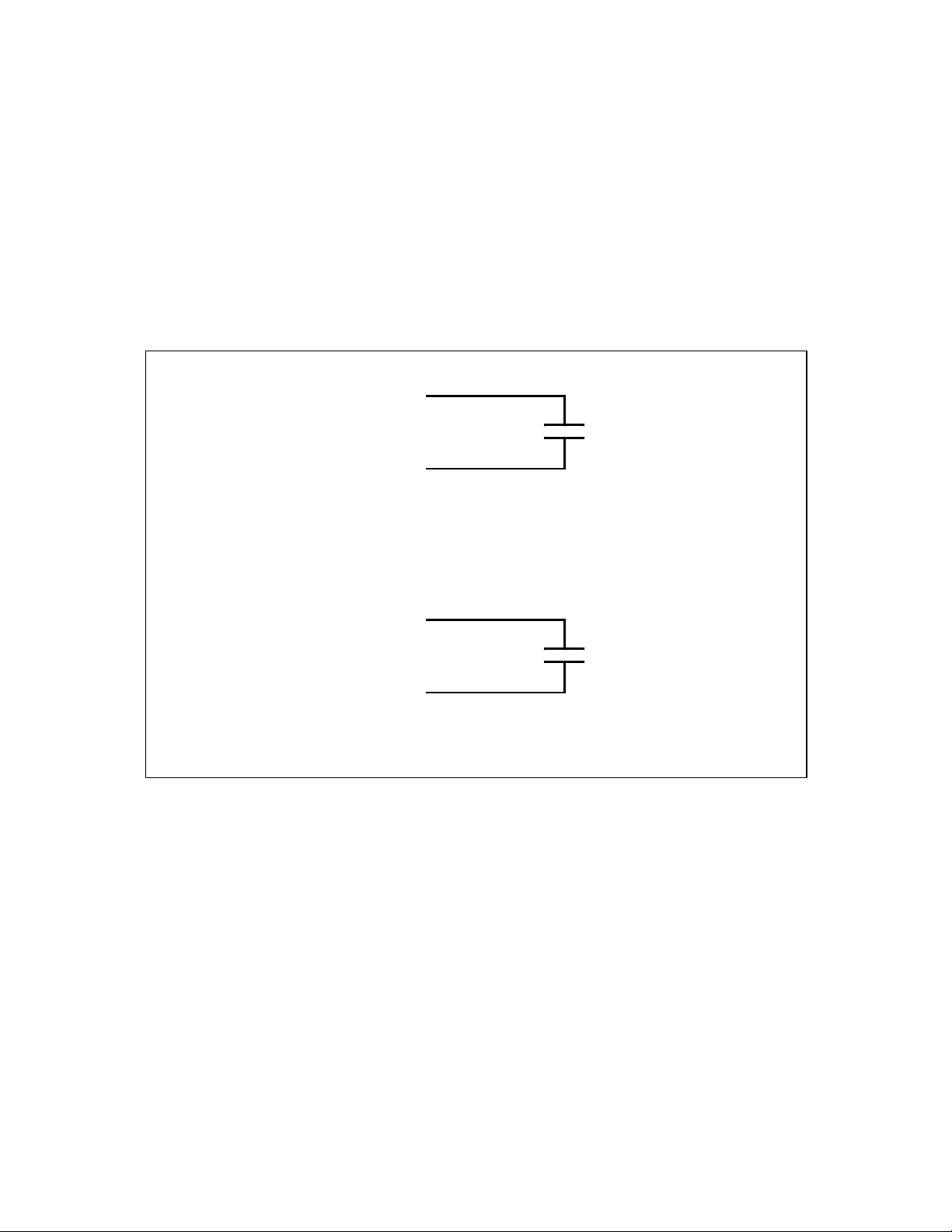

DC Voltage

1 AMP

3-60V

Figure 6 - Typical OM -LMPLC DC Output wiring

DC Load such as

solenoid, relay or

DUT.

Output (X)

Common

AC Load such as a

solenoid, relay or

DUT.

Fuse

120 VAC (Neutral)

120 VAC (Hot)

Figure 7 - Typical OM -LMPLC AC Output wiring

Output (X)

Common

Program, Run, and Pause Modes

The OM -LMPLC operates in three different modes. The modes are the Run mode, Pause mode, and Program

mode. For each mode, the OM-LMPLC behaves differently. The function of the “Mode” button also

changes depending on what operational mode the OM -LMPLC is in. The key-switch is used to change the

operational mode of the OM-LMPLC.

Page 16 of 47

Page 17

OM-LMPLC - User’s Documentation - Omega

When the key-switch is placed in to the “Prog” position, the OM -LMPLC enters program mode. Moving

the switch to the run position places the OM -LMPLC into pause mode. Run mode is then entered from

pause mode by pressing the “Mode” button. In this case, the “Mode” effectively acts as a start button.

The OM -LMPLC will power-up in pause mode if the key-switch is set to the “run” position. This avoids

accidentally running a program on power up.

The program mode is where the OM-LMPLC is programmed and reset. In progra m mode, the “Mode”

button serves two functions. First, pressing the mode button immediately switches to the next display. If

the “Mode” button is held pressed, the OM-LMPLC will begin the reset countdown. See the next section for

more information on rese tting.

Pause mode serves as a temporary mode between the Program and Run mode. In the run mode, the “Mode”

button serves as a Start button. When the mode button is pressed, the OM-LMPLC enters run mode.

Pause mode can also be entered using the “Pause Test” step command.

When the OM -LMPLC enters the run mode, it immediately begins running the program at the current step.

The current step is shown on the program information display. In the run mode, the mode button cycles

through the six displays.

Resetting the Counters and Procedure

You can reset both the on-board counters and the procedure right from the OM-LMPLC’s front panel when

it is in program mode. You have the option to reset only the procedure or both the procedure and the

counters. If you want to reset the counters and not the procedure, you can do this through the “Edit

counters” dialog in the Procedure Writer software.

By holding the “Mode” button for longer than five (5) seconds, the “Reset” count down screen appears

(Figure 8). The OM -LMPLC will begin to count down (this is indicated by the blocks shown). When all the

blocks right of the “Procedure” label disappears, the procedure is reset (this will take approximately 5

seconds). When reset, the re set message appears (Figure 9). After resetting the procedure, the OM-LMPLC

will be counting down to reset the counters in a similar fashion. To cancel resetting, release the mode button

before the OM-LMPLC counts down to zero blocks.

R

e s e t t i n g

P r o c e d u r e

C o u n t e r s

OOOOOOOO OOOOOOOO

Figure 8 - Resetting Procedures “Count Down” warning on the LCD Display

R

e s e t t i n g

P r o c e d u r e R e s e t

C o u n t e r s

OOOOOOOO OOOOOOOO

Figure 9 - Resetting procedures with "Procedure" reset message

OM-LMPLC Displays

Page 17 of 47

Page 18

0 0

0 0

.

0 0

0 0

O

n / O

0

OM-LMPLC - User’s Documentation - Omega

The OM -LMPLC has six standard displays. They are the following: Counters 1-2, Counters 3-4, Counter 5-6,

Counters 7-8, Test information, and Procedure information display. It also has a test complete display and

special displays during programming and procedure resetting.

On each of the six displays, the lower line of the display reflects the Input and Output status of the OM LMPLC (Figure 10). A filled in box indicates an input or output is activated while an empty box indicates

that an output is deactivated. This display is very useful for debugging your test setup. Note, if the output

enable button is not activated, the output reading will not reflect the actual output status.

T e s t B a n n n e r L i n e

C o u n t e r 1

C o u n t e r 2

O OOOOOO OOOOOOO

Figure 10 - Output 2 Activated and Input 1 activated

The top line of all the displays, except for the procedure information display, show the test banner. This is a

custom display setup in the “Procedure Writer” software. This is setup through the “Custom displays”

selection in the “Edit” pull down menu.

Displays Counter 1-2, Counter 3-4, Counter 5-6, and Counter 7-8 show the counter's custom 13-character

description and it's six digit count

T e s t B a n n n e r L i n e

C o u n t e r 1

C o u n t e r 2

O O O O O O O O

Figure 11 - Counters 1-2 display

O O O O O O O O

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

The test information display is a custom display that can be used for general test information. This is setup

through the “Custom displays” selection in Procedure Writer.

The procedure information display shows the information about the current state of the pro cedure (Figure

12). It shows the current step the OM -LMPLC is operating, the name of the command of that step, and the

value information for that step. For example, output type commands will show the time left to complete the

current step. For wait for input type steps, the OM-LMPLC will display the Inputs the OM -LMPLC is

waiting for. Use this screen and a procedure print to debug your tests.

O u t pu t s

S t e p 0 3

A : 0 0 0 0 0 5 B : 0 0 0 0 0 0

O O O O O O O O

Figure 12 - Procedure Information Display

Page 18 of 47

f f

0 0 : 0 0 : 0 0 . 2 5

O O O O O O O O

Page 19

OM-LMPLC - User’s Documentation - Omega

Programming Overview

When you design a test, usually a procedure is developed which shows step by step on how to carry out

the actions for that particular test. By following this procedure, you can carry out the test consistently over

and over again. You start at step number one, then perform step number two, etc. until you arrive at the last

step. Sometimes, you may have to repeat certain steps a number of times.

If you understand the above test procedure analogy you can understand programming the OM -LMPLC.

You define a procedure, which has steps. Each step has a number, and on each step, an action is

performed. The first step, step number one, is performed first. Then, following the logic of the procedure,

each step is performed.

The OM-LMPLC has a small number of actions that can be performed. Each step has one action. A

particular action may require parameters detailing how that action is to be performed. For Example, the

action “Jump to another step” would require a parameter of which step to jump to. The command that turns

outputs on/off needs to know what outputs to turn on/off and a time.

Examples of available actions are the following:

• Turn outputs on and off for a certain time period

• Wait until certain inputs are activated or deactivated

• Jump to different steps if inputs are activated or deactivated

• Increment on board counters

• Count inputs that are activated

• Perform a group of actions a specified number of times (Looping)

• Jump to a different step unconditionally

• Declare an END test to show a display or attract attention with an audible alarm

• Pause the test to wait for operator attention with a optional audible alarm

These commands are explained in detail in the sub-section called “Step Commands”.

A simple example of a procedure to get a glass of water is the following:

1. Turn on Faucet

2. Wait until the glass is full

3. Turn off Faucet

4. End - Now you have a glass of water

First, the OM -LMPLC will turn on the output required to turn on the faucet. Then the OM-LMPLC will wait

until the “glass full’ input is activated. When this happens, it turns off the faucet and stops. You now have

a glass of water .

Step Commands

OVERVIEW

The OM -LMPLC runs a procedure composed of steps. Logically, like any procedure, the OM-LMPLC starts

at step 1 and then follows each step sequentially until its done. Each step has a command associated with

it, which tells the OM -LMPLC to do something meaningful. These commands perform actions such as turn

on outputs, increment counters, or check inputs. A command may have a value and connections to inputs,

Page 19 of 47

Page 20

OM-LMPLC - User’s Documentation - Omega

Turn power off for 5 seconds

outputs or counters. The meaning of the value depends on the particular command. Table 1 below

summarizes the step commands.

Table 1 - Summary of Step Commands

Step command Value Associated with

Turn Outputs “On/Off” Length of time of the step Outputs

Turn Outputs “On” Length of time of the step Outputs

Turn Outputs “Off’ Length of time of the step Outputs

Wait for Inputs to be “On” Length of time out and step Inputs

Wait for Inputs to be “Off” Length of time out and step Inputs

Wait Time to wait None

End Test Beep on or off None

Pause Test Beep on of off None

Jump if Inputs are “On” Step to jump to Inputs

Jump if Inputs are “Off” Step to jump to Inputs

Increment Counters None Counters

Count Inputs None Inputs

Begin Loop Length of the Loop None

End Loop None None

Jump Step to jump to None

TURN OUTPUTS “ON/OFF”

The turn outputs on/off command will activate and deactivate outputs. The Outputs selected will be turned

“on” and the outputs not selected will be turned “off”. The step value for this command indicates how long

the OM -LMPLC will remain performing this step. The procedure information display will show the time

remaining until the OM-LMPLC switches to the next step.

Example 1 demonstrates how this command can be used to cycle power to a device connected to output 1.

On the first step, a "Turn outputs on/off" command is used to turn power on for 5 seconds. Then the "Turn

outputs on/off" is used in step 2 to power off the device for five seconds. Finally, in step 3, the OM-LMPLC

will immediately return to step 1 and repeat the process.

Example 1 - Turning outputs on and off with the "Outputs On/Off" command (ex_onoff.lm1)

Step

no

1 Turn outputs on/off 00:00:05.00 Y N N N N N N N Turn power on for 5 seconds

2 Turn outputs on/off 00:00:05.00 N N N N N N N N

3 Jump to another step Step 1 N N N N N N N N Keep cycling power

Step Command Value 1 2 3 4 5 6 7 8 Comments

TURN OUTPUTS “ON”

This command is nearly the same as “Turn Outputs On/Off” command. The difference is that the selected

inputs are turned “On” without affecting the non-selected outputs.

Page 20 of 47

Page 21

N

NN N

N

NN N

Cycle door 1

N

NN N

cycles

N

NN N

Should we cycle door 2

N

NN N

Cycle door 2

N

NN N

N

NN N

1 second

N

NN N

Turn both outputs on

N

NN N

Example 2 shows how this command can be used. This example shows how, by adding two external

switches, you can control if a part is cycled or not.

Step 1 checks to see if the first switch is not enabled with the" jump if inputs are off" command. If it is not it

jumps to step 4, thereby not turning on output 1 or increasing count 1. At step 4, a similar operation is

performed except that input 2 is examined. Then in step 7, the outputs that are turned on stay on for one

second. Step 8 then turns them off. Finally, in step 9 a jump is made back to step one to repeat the process.

The value of this command is that step 5 will only affect output 2 and nothing else. Therefore, if output 1

was turned on it will still be turned on during step 7. Similarly, if output 2 was turned off output 1 will still be

turned on during step 7.

Example 2 - Running parts when selected only using the Turn Outputs On command (exturnon.lm1)

Outputs Inputs Counters

1 Door 1 Cycle Door 1 Door 1 count

2 Door 2 Cycle Door 2 Door 2 count

Step

no

1 Jump if inputs are off Step 3 Y N N N

2 Turn outputs On only 00:00:00.00 Y N N N

3 Increase a counter(s) N/A Y N N N

4 Jump if inputs are off Step 5 N Y N N

5 Turn outputs On only 00:00:00.00 N Y N N

6 Increase a counter(s) N/A N Y N N

7 Wait 00:00:01.00 N N N N

8 Turn outputs Off only 00:00:01.00 Y Y N N

9 Jump to another step Step 1 N N N N

Step Command Value 1 2 3 4 5 6 7 8 Comments

OM-LMPLC - User’s Documentation - Omega

Should we cycle Door 1

Keep track of door 1

Keep track of door 2

cycles

Allow outputs to be on

Keep cycling

TURN OUTPUTS “OFF”

This command is nearly the same as the “Turn Outputs On/Off” command. The difference is that the

selected inputs are turned “Off” without affecting the non-selected outputs.

WAITING FOR INPUTS TO BE “ON”

When the OM -LMPLC encounters this command, it waits for the selected inputs to be activated. It waits

only a specific length of time called a time out period. If the inputs are activated within this time out period,

the OM -LMPLC continues to the next step immediately. If the inputs are not activated within a time out a

jump is made to the step indicated in this steps value.

The OM-LMPLC checks once every 250 ms for the inputs to be activated. Therefore, inputs must be

activated for 250 ms to guarantee the OM-LMPLC will react. On the procedure information display, it shows

what inputs need to be activated to complete this step, the time remaining to wait for these inputs to be

activated, and a step to jump to.

Page 21 of 47

Page 22

OM-LMPLC - User’s Documentation - Omega

N

NN N

N

NN N

Wait until door is closed

N

NN N

Close the door

N

NN N

Wait until door is closed

N

NN N

Keep Cycling

N

NN N

for technician

N

NN N

In Example 3, the "Wait for inputs on" command is used to provide feedback during door cycling. In step 1,

we turn on the outputs. Then, in step 2, we wait until input one is activated. As soon as it is activated, we

move to step 3. If input 1 is not activated within 10 seconds, a jump to step 6 is made where an alarm is

activated. In step 3 we close the door. Then, in step 4, we wait for it to close. Then, the entire process

repeats by jumping back to step 1.

Example 3 - Using inputs to monitor test progress with the Wait Inputs command (exwaitin.lm1)

Wire List Outputs Inputs Counters

1 Open Door Door Open Count 1

2 Close Door Door Closed Count 2

3 Alarm Count 3

Step

no

1 Turn outputs on/off 00:00:00.00 Y N N N

2 Wait until inputs are on 00:10.00 -> 6 Y N N N

3 Turn outputs on/off 00:00:00.25 N Y N N

4 Wait until inputs are on 00:10.00 -> 6 N Y N N

5 Jump to another step Step 1 N N N N

6 Turn outputs on/off 00:00:00.25 N N Y N

7 Jump to another step Step 6 N N N N

Step Command Value 1 2 3 4 5 6 7 8 Comments

Open the door

Sound Alarm and wait

Keep sounding alarm

until reset

WAITING FOR INPUTS TO BE “OFF”

This command is very similar to the “Waiting for Inputs to be on” except that the selected inputs must be

off or deactivated. On the procedure information display, it shows what inputs need to be off to complete

this step, the time remaining to wait for these inputs to be activated, and a step to jump to.

WAIT

This command simply waits a specified time before going to the next step. This step’s value is the length of

time this step waits.

END TEST

This command suspends execution of the OM -LMPLC and shows the test complete display on to the LCD

screen. You can select whether the OM-LMPLC sounds it's alarm or not for this step.

This step is useful when you need the OM -LMPLC to inform you or other lab personnel that the test is

complete.

PAUSE TEST

This command makes the OM-LMPLC enter pause mode. Pause mode stops the OM-LMPLC procedure and

shows “Press mode to start” message on the OM-LMPLC LCD display. The step value is whether the OM-

Page 22 of 47

Page 23

LMPLC should sound the OM -LMPLC’s internal alarm when this command is activated. The states of the

N

NN N

N

NN N

Push for 1 second

N

NN N

Release for 1 second

N

NN N

Keep cycling

N

NN N

Push for 2 seconds

N

NN N

Release for 2 seconds

N

NN N

outputs are maintained when pause mode is entered.

This command is useful for cycling tests where you must perform a visual inspection of the parts on an

interval. You can use the “Pause Test” command to stop the OM-LMPLC procedure every required number

of cycles and alert you that the test needs service.

JUMP IF INPUTS ARE “ON”

This comma nd will jump to another step instead of going to the following step if inputs are activated. If the

inputs that are selected are all activated when this step is reached, the OM-LMPLC’s next step will be

changed to the step selected for this step command.

Example 4 shows how to use the Jump if command to run two different programs selected by an external

switch. On step 1 a check is made on input 1. If activated, a jump is made to step 5. Otherwise, step 2 is then

executed. Steps 2 and 3 run at a cycle rate of 2 seconds, while 5 and 6 run at a cycle rate of 4 seconds.

Example 4 - Running two different tests with one procedure using JumpIf command (exjumpin.lm1)

Step

no

1 Jump if inputs are on Step 5 Y N N N

2 Turn outputs on/off 00:00:01.00 Y N N N

3 Turn outputs on/off 00:00:01.00 N N N N

4 Jump to another step Step 1 N N N N

5 Turn outputs on/off 00:00:02.00 Y N N N

6 Turn outputs on/off 00:00:02.00 N N N N

7 Jump to another step Step 1 N N N N

Step Command Value 1 2 3 4 5 6 7 8 Comments

OM-LMPLC - User’s Documentation - Omega

Run test 2 if selected

Keep cycling

JUMP IF INPUTS ARE “OFF”

This is the same command as Jump if inputs are ON except the selected inputs should be off in order to

qualify for a jump.

INCREASE COUNTERS

The increment counters command increments one of the OM -LMPLC’s internal on-board counters. For this

command, you must select the counter you wish the OM-LMPLC to increment. This step has no value.

Example 6 shows how the counters can be used to count cycles. On step 1, the device power is turned on.

Then it is turned off in step 2. Finally, in step 3, a counter is incremented to keep track of cycles. This entire

cycle repeats itself because step 4 jumps to step 1.

Example 5 - Using counters to track cycles (ex_cntr.lm1)

Page 23 of 47

Page 24

OM-LMPLC - User’s Documentation - Omega

Increase counter

YYY Y

YYY Y

which are closed

N

NN N

Release all switches

N

NN N

Step

no

1 Turn outputs on/off 00:00:05.00 Y N N N N N N N Turn power on for 5

2 Turn outputs on/off 00:00:05.00 N N N N N N N N Turn power off for 5

3 Increase a counter(s) N/A Y N N N N N N N

4 Jump to another step Step 1 N N N N N N N N Keep cycling power

Step Command Value 1 2 3 4 5 6 7 8 Comments

COUNT INPUTS

When the OM -LMPLC encounters this command it takes the current input reading and then compares it

with the inputs you selected in the Procedure Writer for this command. If one of the inputs you have

selected is activated, it increments a counter. The counter it increments is a direct correlation between the

input number and the counter number. For example, if input 1 was on and selected in procedure writer, then

Counter 1 would be incremented. This command has no value.

Example 6 shows how to use the count inputs command to cycle switches. On step one we actuate all the

switches by turning all outputs on for one second. Then, we count each switch contact that was made

(These are wired to each input). Next, we stop pressing the switch for 1 second. Finally, we repeat the

process by returning to step one.

seconds

seconds

Example 6 - Counting inputs directly with the "Count Inputs" command (ex_cntin.lm1)

Wire list Outputs Inputs Counters

1 Close Sw 1 sw 1 closed sw 1 count

2 Close Sw 2 sw 2 closed sw 2 count

3 Close Sw 3 sw 3 closed sw 3 count

4 Close Sw 4 sw 4 closed sw 4 count

5 Close Sw 5 sw 5 closed sw 5 count

6 Close Sw 6 sw 6 closed sw 6 count

7 Close Sw 7 sw 7 closed sw 7 count

8 Close Sw 8 sw 8 closed sw 8 count

Step

no

1 Turn outputs on/off 00:00:01.00 Y Y Y Y

2 Count the inputs N/A Y Y Y Y

3 Turn outputs on/off 00:00:01.00 N N N N

4 Jump to another step Step 1 N N N N

This command is provided so you can easily setup for counting inputs. If you require increased flexibility,

like incrementing any counter based on any combination of inputs, use Jump if commands combined with

the Increase counter(s) command. Example 7 shows how to do this.

On step 1 we press switch 1. Switch 1 should close and activate input 1. On step 2, the OM -LMPLC checks

to see if input 1 was not activated. If so, it jumps to step 4; therefore, skipping incrementing the count. If

input 1 was activated no jump would occur and step 3 would increment the counter. On step 4, the switch is

released and cycling continues.

Step Command Value 1 2 3 4 5 6 7 8 Comments

Push all switches

Count the switches

Keep cycling

Page 24 of 47

Page 25

Example 7 - Using "Jump If" commands for more advanced input counting (extcntin2.lm1)

N

NN N

N

NN N

increment

N

NN N

Increase sw1 count

N

NN N

Release sw1

N

NN N

timulate DUT

Remove DUT stimulus

ping

End the test

Wire List Outputs Inputs Counters

1 Close sw1 sw1 closed sw 1 count

Step

no

1 Turn outputs on/off 00:00:01.00 Y N N N

2 Jump if inputs are off Step 4 Y N N N

3 Increase a counter(s) N/A Y N N N

4 Turn outputs on/off 00:00:01.00 N N N N

5 Jump to another step Step 1 N N N N

Step Command Value 1 2 3 4 5 6 7 8 Comments

BEGIN LOOP

This command begins a loop. A loop is a series of steps that will be ran a certain number of times. The OMLMPLC supports two concurrent loops. On the procedure information display, these are represented as A

and B. The Procedure Writer checks your procedure’s loops to ensure that you have no more than two

concurrent loops. You must also have one end loop for every begin loop. The most external loop in your

code will always be represented by A and most internal loops will be represented by b. The length of a Loop

is limited to 999,999.

OM-LMPLC - User’s Documentation - Omega

Push sw 1

If not closed skip

Keep cycling

Example 8 shows how a loop can be used to execute a step a specific number of times. On step 1, the loop is

started with a value of 100. Then, steps two and three cycle the DUT. Finally, the end loop command

indicates the loop is complete. This cycle repeats 99 more times. After this, the RoboTechnician moves to

step five and ends the test.

Example 8 - Using loops to cycle a specific number of times (exloop1.lm1)

Step

no

1 Start a loop 000100 N N N NNN N N Run 100 cycles

2 Turn outputs on/off 00:00:00.25 Y N N NNN N N S

3 Turn outputs on/off 00:00:00.25 N N N NNN N N

4 End the Loop N/A N N N NNN N N Keep loo

5 End the Test Beep On N N N NNN N N

6 Jump to another step Step 1 N N N NNN N N

Some times, you may want to perform a specific number of steps inside of a specific number of steps.

Example 9 demonstrates this. On step 1 the outside loop is started. Then, step 2 starts the inner loop. The

Step Command Value 1 2 3 4 5 6 7 8 Comments

Page 25 of 47

Page 26

OM-LMPLC - User’s Documentation - Omega

N

NN N

N

NN N

N

NN N

N

NN N

N

NN N

Keep track of test cycles

N

NN N

Keep looping

N

NN N

inspection

N

NN N

N

NN N

inner loop (steps 3 and 4) cycle the DUT. After 200 iterations, step 7 is executed and RoboTechnician

pauses for the operator to make a visual inspection. When the inspection is complete, the outside loop

causes the inner loop to occur 9 more times. Finally, when the outer loop has exhausted, the test is ended on

step 9. Note the DUT underwent 2000 cycles.

Example 9 - Using multiple loops for handling user inspections (exloop2.lm1)

Step

no

1 Start a loop 000010 N N N N

2 Start a loop 000200 N N N N

3 Turn outputs on/off 00:00:01.00 Y N N N

4 Turn outputs on/off 00:00:01.00 N N N N

5 Increase a counter(s) N/A Y N N N

6 End the Loop N/A N N N N

7 Pause the Test Beep On N N N N

8 End the Loop N/A N N N N

9 End the Test Beep On N N N N

Step Command Value 1 2 3 4 5 6 7 8 Comments

Run 2000 cycles with 10

inspections

Perform an inspection

every 200 cycles

Stimulate DUT for 1 sec

Remove DUT stimulus

for 1 sec

Wait for technician

keep looping

End the test

END LOOP

This command loops to the last begin loop and decreases its count by one. When the begin loops count is

zero, it falls out of the loop and goes to the next step. This step has no value.

JUMP

This command jumps to another step. The step value for this step is the number of the step to jump to.

Procedure Writer programming software

The Procedure Writer software is where you build your OM-LMPLC procedure. The Procedure writer

software allow s you to easily build procedures to control outputs with complex logic. We have attempted to

make “Procedure Writer” very similar to other popular Windows applications so that you will already be

familiar with how it works.

STARTING PROCEDURE WRITER

If you are using Windows 95, select Procedure Writer from the appropriate group in the start menu. For

Windows 3.1 users, double click on the Procedure Writer Icon. This will start the Procedure Writer. After

starting, you have the options to open a existing procedure, start a new procedure, or start a new procedure

using the procedure wizard.

Page 26 of 47

Page 27

OM-LMPLC - User’s Documentation - Omega

CREATING A NEW PROCEDURE

A new procedure can be created by selecting “New” from the file pull down. This will create a new

procedure with cleared custom displays and steps initialized to the default jump command.

DIFFERENT VIEWS OF YOUR PROCEDURE

The procedure writer lets you look at your procedure in three different ways. Each is called a "view". The

three views are the following: step, sheet, and output.

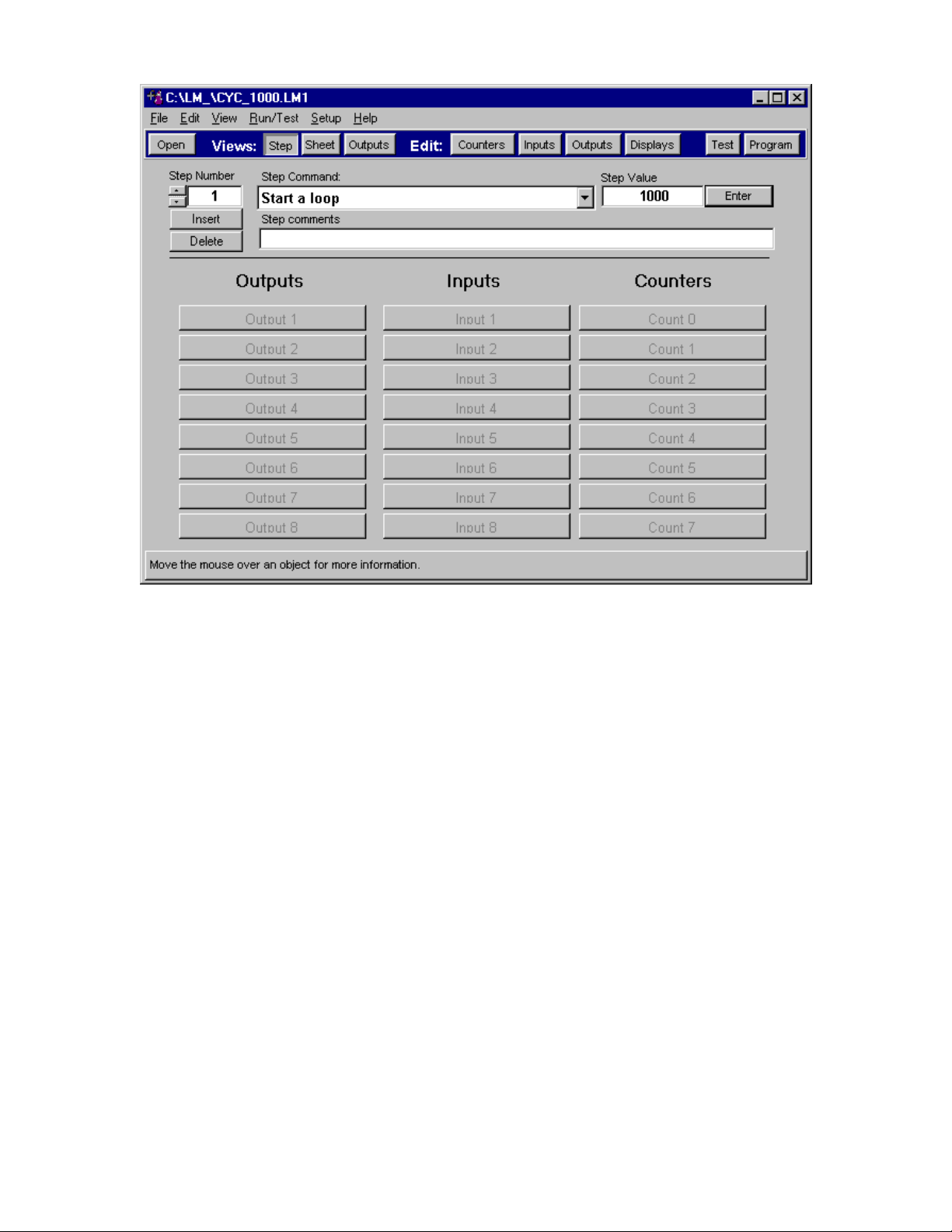

THE STEP VIEW

Step view shows the procedure one step at a time (Figure 13). From this view, the OM -LMPLC procedure

can be completely built. Here you can navigate through the steps, insert steps, delete steps, change the

step action, and add comments.

This view shows all the information about the current step. The current step is indicated by the box under

the "Step Number" label. This view shows the step command, step value, comments and

Input/Output/Counter associati on.

You can navigate the steps by clicking on the up-down arrows under the “step number” caption. Clicking

on the up arrow decreases the step number while clicking the down arrow increases the step number.

You can change the current step command by clicking the down arrow to the right of the current step

command. This will drop down a list of step commands. After selection, “Procedure Writer” will change the

currently displayed value to the selected command's default.

If the step has a value, the “Pro cedure Writer” will allow you to adjust it by clicking on the “Enter” button.

When you click this button, a dialog box will appear allowing you to manipulate that step’s value.

To insert a step before the current step, click on the “Insert” button. Procedure Writer will then ask if it is

okay to delete step 96. Deleting the last step is required because the OM-LMPLC can only execute 96 steps.

To delete the current step, click the “Delete” button. “Procedure Writer” will then verify your delete action.

If you respond with yes, the current step will be deleted.

Note It is important to re-adjust jump steps after insert and delete commands if they are affected.

When a command that requires an output, an input, or a counter the associated buttons will become

enabled. To select the input/output/counter just click the button corresponding to input/output/counter

which you wish to select. A button that is pressed is selected and a button that is not pressed is not

selected.

Add comments to the cur rent step by entering text into box below “Step comments”.

Page 27 of 47

Page 28

OM-LMPLC - User’s Documentation - Omega

Figure 13 - Procedure Writer Step View

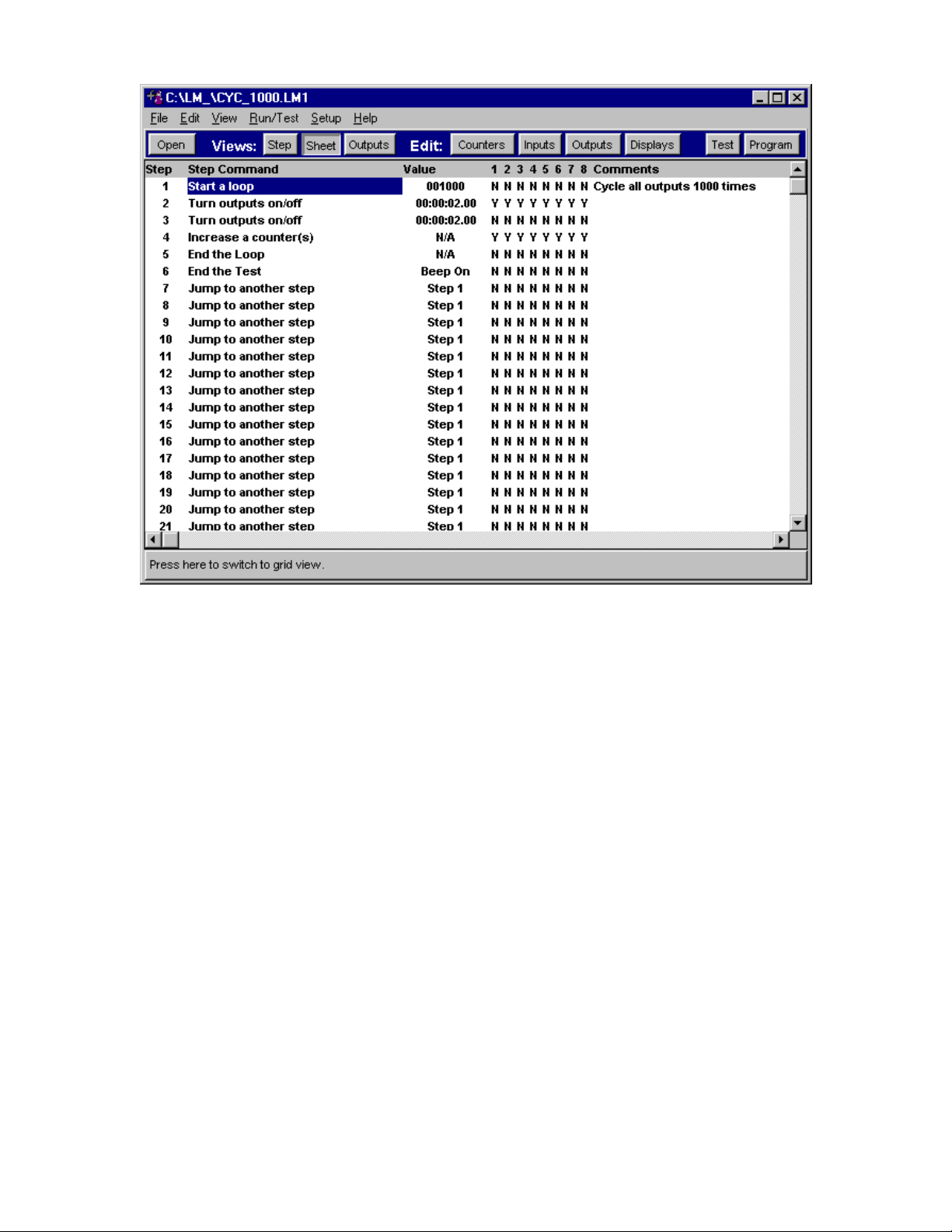

THE SHEET VIEW

The sheet view gives a spreadsheet type view of the procedure (Figure 14). It shows all the steps from 1 to

96. From this view, you can adjust step values and output/input/counter connections. This view is

especially useful for setting up the jump values, since you can immediately see the step you wish to jump to.

To adjust a step’s value, double click on its value. Procedure Writer will then bring up a dialog allowing you

to manipulate this steps value.

To manipulate its outputs/inputs/counters value double click on the column 1-8 to change the value. A “Y”

corresponds to being selected and a “N” corresponds to not being selected.

If you double click on the sheet for anything besides values or output/inputs/counters, Procedure Writer

will switch to step view. The step view’s current step will be the step that was double clicked on in the

sheet view. This provides a quick way to switch to any step in the procedure.

Page 28 of 47

Page 29

OM-LMPLC - User’s Documentation - Omega

Figure 14 - Sheet View

THE OUTPUT VIEW

This view gives graphical view of the outputs by step (Figure 15). This view helps you see relationships

between turning different outputs on and off. Since this representation is by step, this view is not based on

timing.

In complex procedures where a lot of jumping is done, this display may not be meaningful. Only on intervals

where the “Turn Outputs on/off” commands are used will this display accurately reflect the output

relationships.

Page 29 of 47

Page 30

OM-LMPLC - User’s Documentation - Omega

Figure 15 - Output View

EDITING THE CUSTOM DISPLAYS

To enter the custom test information and test complete displays, choose the “Custom Displays…” from the

“Edit” pull down menu. This will show a screen where you can edit the OM -LMPLC’s custom displays

(Figure 16).

The box labeled “Test Banner” is the text that is shown on the top line of most of the OM-LMPLC's screens.

Usually, you will enter a descriptive name for the test you are performing. The test information display’s

line two and three are described here. A simulation of what the test information display would look like is

shown in the yellow box on the right.

The test complete screen is also entered on this screen. Fill in the boxes labeled “Test complete line 2” and

“Test complete line 2” with the information you want shown on the LCD display. This display will be

shown when the OM -LMPLC encounters an “End Test” command. A simulation of what the test complete

display would look like is shown in the yellow box on the right.

Page 30 of 47

Page 31

OM-LMPLC - User’s Documentation - Omega

Figure 16 - Entering Custom Displays

CUSTOM INPUT, OUTPUT, AND COUNTER NAMES

The Procedure Writer allows you to give your outputs, inputs, and counters custom names. This is helpful

while you are building your procedure because you can refer to your outputs, inputs, and counters by name

instead of number. This also is needed for descriptive wire lists and printing. The custom counter names are

displayed on the OM-LMPLC’s LCD display.

You can name them by making the appropriate selection from the edit menu. When you select the in puts,

for example, you will see a screen that allows you to edit the names (Figure 17).

Figure 17 - Naming Inputs, Outputs, and Counters

Page 31 of 47

Page 32

OM-LMPLC - User’s Documentation - Omega

MODIFYING ONBOARD COUNTS

Procedure Writer allows you to preset the OM-LMPLC’s on board counters to any value within their

counting range. This is useful for test samples that may have been pre-cycled and already have cycle

counts. You can also use this feature to reset the counters without resetting the current procedure.

To access this feature, choose “On board counts” from the edit pull down menu. Making this selection

shows the “Edit current counts” dialog (Figure 18 - Edit current counts dialog). Obviously, you need to

have the serial cable attached to read the on-board counts from the OM-LMPLC. To save your changes to

the OM-LMPLC, choose “Ok”. If you wish to keep the current counts, choose “Cancel”.

Figure 18 - Edit current counts dialog

PROCEDURE WRITER OPTIONS

To serve the needs of different users of the OM-LMPLC and Procedure Writer, Procedure Writer has

application options. You can setup the options of the Procedure Writer through the options selection from

the setup pull down. Selecting this pull down will show the options dialog (Figure 19).

Setting up a Comm port

You have to tell the Procedure Writer which Comm port you are using to communicate with the OM-LMPLC.

This is done by selecting “Options” from the “Setup” pull down menu. This selection will show a screen

allowing you to select the Comm port (Figure 19). Select the Comm port from the drop down box and click

ok.

Page 32 of 47

Page 33

OM-LMPLC - User’s Documentation - Omega

Automatically Reset Counts when programmed

The Procedure Writer can automatically reset the OM -LMPLC’s counters when it is programmed. To enable

this feature select the “Automatically reset counters when programmed” in the options dialog. To manually

reset the counters you can use the mode button of the OM-LMPLC or via the “Edit Current Counts” dialog.

Show Adjustment button in the test dialog

You have the option of showing adjustment buttons in the test dialog. These adjustment buttons allow the

user to adjust timing and manipulate the current step shown on the OM -LMPLC. These are provided as an

option because the manipulations are not recorded into the procedure that is on the PC. Therefore, you may

create an inconsistency between the saved procedure on the PC and the procedure in the OM-LMPLC. This

may be unacceptable for organizations that need the documentation features for quality standards.

Figure 19 - Selecting a Comm Port and other Procedure Writer options

TESTING YOUR INPUT AND OUTPUT WIRING

Procedure Writer allows you to test your input and output wiring by manually exercising your outputs. This

is done from the “Test Outputs” screen (Figure 20). You can exercise outputs individually by clicking on

the output buttons. The Inputs are read from the OM-LMPLC a few times a second and are refreshed on the

display.

You also have the option to manipulate the current step’s timing and change the current step of the OM LMPLC. This is done by clicking the buttons in the lower left-hand corner of the test dialog. These buttons

may not appear because they were disabled in the options dialog discussed in the last section.

Page 33 of 47

Page 34

OM-LMPLC - User’s Documentation - Omega

Figure 20 - Testing Input and Output wiring screen

DEBUGGING YOUR PROCEDURE

Follow these steps when you have problems with your procedure. These are the source for the most

common errors in building a OM-LMPLC procedure.

1. Verify output and input wiring using the Test Inputs and Outputs Screen

2. Inspect your procedures Jump type steps and make sure they have correct values

PRINTING YOUR PROCEDURE

The Procedure Writer software allows you to print your procedure. Select “Print…” from the file pull down

menu. A dialog box will be shown allowing you to select the default printer and paper orientation.

DOCUMENTING YOUR PROCEDURE

The Procedure writer can help you document your procedure. From the edit menu, you have three

selections that will transfer procedure information to the Windows clipboard in a tab-separated format.

Then, the information can then be pasted in to your favorite word processor or spreadsheet. For example, in

MS-Word you can paste the procedure, select it, and then convert text to table to turn it into a formatted

table. The selections u nder the edit menu are the following: Copy Current Counts to the clipboard, copy the

procedure to the clipboard, and copy the wire list to the clipboard.

The “Copy current counts to the clipboard” reads the OM-LMPLC’s current counts through the serial cable,

attaches them to the custom names and places them on the Clipboard in a tab-separated format. This feature

Page 34 of 47

Page 35

OM-LMPLC - User’s Documentation - Omega

is very useful if you have counts that exceed the six-digit view on the OM -LMPLC’s PLC display. This

method of reading the counts can read counters up to the internal limit of 16,777,216.

SAVING YOUR PROCEDURE

You can save the current procedure by choosing “Save” from the file pull down menu. If you wish to save

the current procedure to a different name “Choose Save As.”

OPENING YOUR PROCEDURE

You have a few options to opening a previous procedure. The most convenient is to use the Most recent

procedure menu. These are the file names located at the lowest part of the file pull down menu. Other

options are the “Open” selection and the “Open” button on the tool bar.

READING A PROCEDURE FROM THE OM-LMPLC

You can read a procedure from the OM -LMPLC into the PC. To do this, select "Read Program from OMLMPLC" from the Run/Test menu. This will bring up the "Read program from OM-LMPLC" dialog (