Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

OMET-USB SERIES

8, 16 and 32 Channel

Thermocouple Measurement

Systems for the USB Bus

Shop online at

Page 2

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

OMET-USB-73 User Manual USB Data Acquisition

Table of Contents

1 Introduction.................................................................................................................................................1-1

1.1 Features – OMET-USB-73 Commercial Version..........................................................................................1-2

1.2 Operating Systems and API Software..........................................................................................................1-2

1.3 USB 73 Versions..........................................................................................................................................1-3

1.3.1 Temperature Input Series.....................................................................................................................................1-3

1.4 Software Support..........................................................................................................................................1-3

1.5 Contact Details.............................................................................................................................................1-3

2 Getting Started............................................................................................................................................2-1

2.1 Package Items..............................................................................................................................................2-1

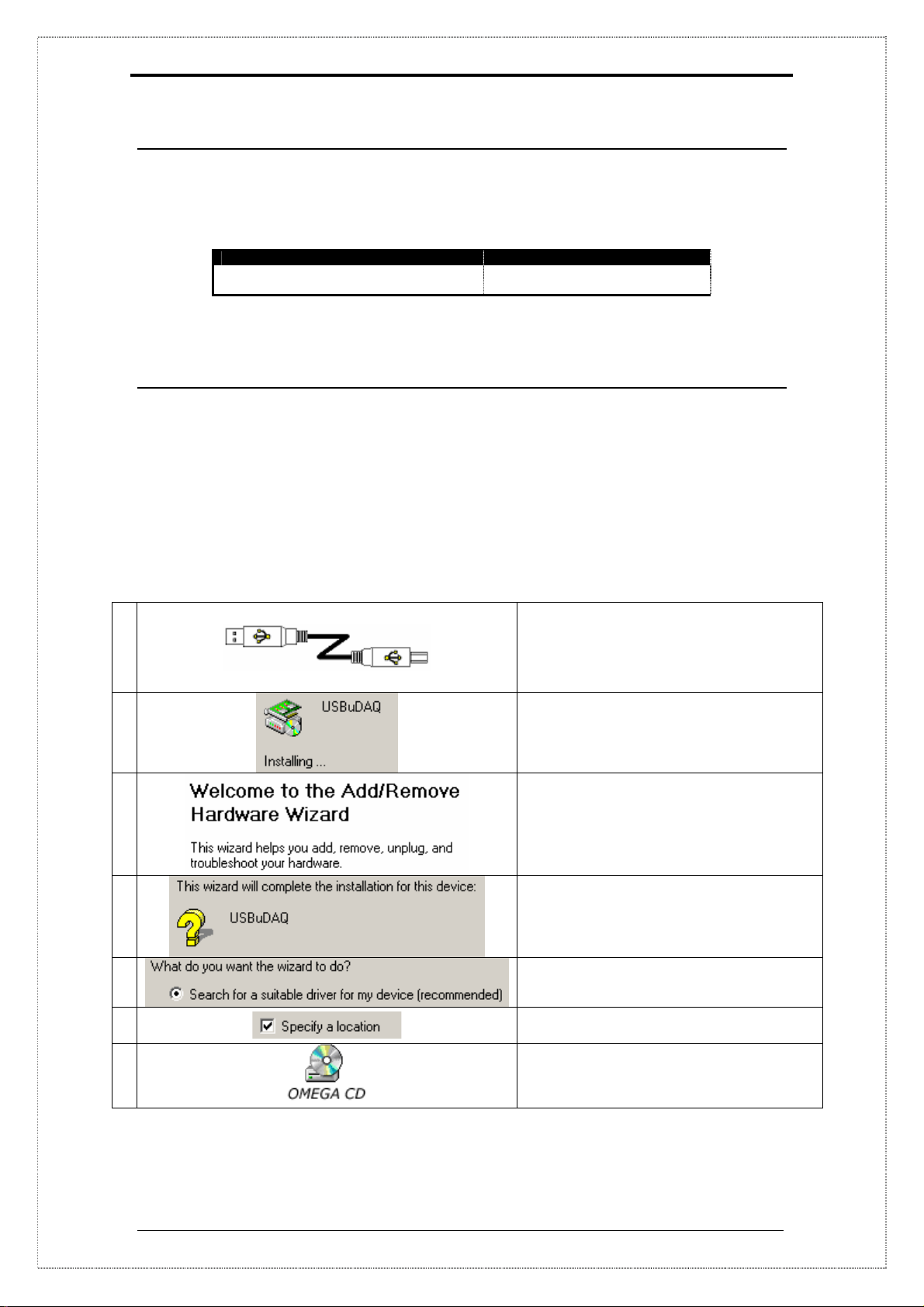

2.2 Operating Systems for Specific Devices ......................................................................................................2-2

2.3 Installation ....................................................................................................................................................2-2

2.3.1 Microsoft Windows PnP Installation (Windows ME, 2000, XP)............................................................................2-2

2.3.2 Linux Installation (Kernel 2.4 and later) - Overview..............................................................................................2-3

2.4 Application Software - OmegaLog................................................................................................................2-3

3 Hardware Interface.....................................................................................................................................3-1

3.1 OMET-USB-73 External Application Connectors.........................................................................................3-1

3.2 Pin Assignments...........................................................................................................................................3-3

3.2.1 OMET-USB-73 DIO Connector – DB25 (M).........................................................................................................3-3

3.2.2 OMET-USB-73 Temperature Input – DB25 (M)...................................................................................................3-3

3.3 Pin Descriptions............................................................................................................................................3-4

3.3.1 Digital Inputs/Outputs (PA0-7, PB0-7, PC0-7)......................................................................................................3-4

3.3.2 Digital Ground (DGND).........................................................................................................................................3-4

3.3.3 Analog Ground (AGND)........................................................................................................................................3-4

3.3.4 Analog Inputs (ACH0-15)......................................................................................................................................3-4

3.3.5 Temperature Inputs (TCH0-7)+-...........................................................................................................................3-4

3.4 Bus Connectors............................................................................................................................................3-4

3.5 Power Supplies, Power Connectors.............................................................................................................3-5

3.6 Application Modules & Accessories..............................................................................................................3-5

3.6.1 Digital I/O Adapter Module – OMET-PC43A2......................................................................................................3-5

3.6.2 Thermocouple Adapter.........................................................................................................................................3-6

4 Software......................................................................................................................................................4-1

4.1 EDR Enhanced Application Program Interface (EDRE API)........................................................................4-1

4.2 The Query Command – EDRE_Query.........................................................................................................4-3

4.3 Digital Inputs/Outputs...................................................................................................................................4-5

Omega Engineering Inc. © Copyright 2005 – www.omega.com i

Page 4

OMET-USB-73 User Manual USB Data Acquisition

4.3.1 Reading the Digital Inputs – EDRE_DioRead......................................................................................................4-5

4.3.2 Writing to the Digital Outputs – EDRE_DioWrite..................................................................................................4-6

4.3.3 Query Codes.........................................................................................................................................................4-8

4.4 Temperature Input – 73 Model.....................................................................................................................4-9

4.4.1 Thermocouple Procedure.....................................................................................................................................4-9

4.4.2 Reading CJC Channel..........................................................................................................................................4-9

4.4.3 Types of Thermocouples....................................................................................................................................4-10

4.4.4 Reading a Thermocouple Channel.....................................................................................................................4-10

4.4.5 Calculating Ambient Temperature......................................................................................................................4-10

4.4.6 Calculating Temperature for Thermocouples.....................................................................................................4-11

5 Calibration Procedure..............................................................................................................................5-13

5.1.1 Calibration - USB 73...........................................................................................................................................5-13

5.1.2 Equipment...........................................................................................................................................................5-13

5.1.3 Calibration Procedure – USB 73........................................................................................................................5-13

A Specifications.................................................................................................................................................I

A.1 Digital Input/Output Characteristics.............................................................................................................I

A.2 Temperature Input Characteristics..............................................................................................................I

A.3 Bus Interface..............................................................................................................................................II

A.3.1 USB 1.1...................................................................................................................................................................II

A.3.2 USB 2.0...................................................................................................................................................................II

A.4 Power Requirements..................................................................................................................................II

A.4.1 USB Devi ces............................................................................................................................................................II

A.5 Environmental / Physical............................................................................................................................II

A.5.1 USB.........................................................................................................................................................................II

A.6 Power Supplies.........................................................................................................................................III

B Related Products and Accessories............................................................................................................IV

B.1 General Adapters......................................................................................................................................IV

B.2 Digital I/O Application Modules.................................................................................................................IV

C Configuration Constants..............................................................................................................................V

C.1 Query Codes..............................................................................................................................................V

C.2 Error Codes...............................................................................................................................................VI

C.3 Digital I/O Return Query Codes.................................................................................................................VI

D Ordering Information...................................................................................................................................VII

Omega Engineering Inc. © Copyright 2005 – www.omega.com ii

Page 5

OMET-USB-73 User Manual USB Data Acquisition

List of Figures

Figure 3-1 OMET-USB-73 Front Side 2-Tier.......................................................................................3-1

Figure 3-2 OMET-USB-73 Front Side 3-Tier.......................................................................................3-1

Figure 3-3 OMET-USB-73 Rear Side 2-Tier....................................................................................... 3-1

Figure 3-4 OMET-USB-73 Rear Side 3-Tier....................................................................................... 3-1

Figure 3-5 OMET-USB-73 DB25 Male Connector................................................................................3-3

Figure 3-6 OMET-USB-73 Connectors..............................................................................................3-4

Figure 3-7 µDAQ Power Connector Pin Assignment............................................................................ 3-5

Figure 3-8 µDAQ Power Socket...................................................................................................... 3-5

Figure 3-9 OMET-PC43A2 Digital I/O Adapter....................................................................................3-6

Figure 3-10 Thermocouple Adapter.................................................................................................. 3-6

Figure 4-1 EDR Enhanced API Design .............................................................................................4-2

Omega Engineering Inc. © Copyright 2005 – www.omega.com iii

Page 6

OMET-USB-73 User Manual USB Data Acquisition

List of Tables

Table 1-1 µDAQ Temperature Versions............................................................................................1-3

Table 2-1 USB Operating System Support......................................................................................... 2-2

Table 3-1 µDAQ Connectors.......................................................................................................... 3-2

Table 3-2 OMET-USB-73 DIO Connector – DB25 (M)..........................................................................3-3

Table 3-3 OMET-USB-73 Input – DB25 (M).......................................................................................3-3

Table 4-1 Digital I/O Assigned Ports................................................................................................. 4-5

Table 4-2 CJC Channels Assigned ..................................................................................................4-9

Table 4-3 Thermocouple Type Table.............................................................................................. 4-10

Table 5-1 Analog Source Requirements..........................................................................................5-13

Table 5-2 General Adapters ............................................................................................................. IV

Table 5-4 Digital I/O Application Modules............................................................................................IV

Table D-1 OMET-USB-73 Ordering Information................................................................................... VII

Omega Engineering Inc. © Copyright 2005 – www.omega.com iv

Page 7

OMET-USB 73 User Manual Data Acquisition

1

1 Introduction

The OMET-USB-73 products consist of two main types, a ‘T’ and ‘R’ version. The ‘T’ version

is designed for reading thermocouples and the ‘R’ for reading RTDs. The main difference

between the two are the fact that the ‘T’ version can only read voltage levels between ±80mV

and the ‘R version inputs between ±2.5V.

The OMET-USB-73 Temperature Input series supports 8, 16 and 32 temperature inputs. The

units come with external adaptors that serve as the connection point for the sensors.

Each unit also has three DIO ports of eight bits.

Omega Engineering Inc. © Copyright 2005 – www.omega.com 1-1

Page 8

OMET-USB 73 User Manual Data Acquisition

1.1 Features – OMET-USB-73 Commercial Version

The OMET-USB-73 series has some very unique features and are listed below:

• USB Revision 1.1 @ full speed and 2.0 compliant @ high speed

• Powered externally

• Intel 8255 compatible digital I/O ports

• 14-bit Analog resolution temperature inputs

• Quick and effortlessly to install

• ABS plastic housing

1.2 Operating Systems and API Software

The OMET-USB-73 has a complete SDK, EDR Enhanced Software Development Kit. This kit

contains a driver for Microsoft® Windows™ and the Linux kernel. Please consult OMEGA

Engineering for the latest information on which specific operating systems are supported.

Current Supported Operating System:

• Microsoft® Windows™ 2000

• Microsoft® Windows™ Millennium Edition

• Microsoft® Windows™ XP

• Microsoft® Windows™ Pocket PC 2003

• Linux Kernel 2.4 and later

The EDR Enhanced SDK serves as a common application and programming interface for all

the units, no matter what the communications protocol. This single property makes the units

easy to program because no knowledge is needed about the specific type of interface. It also

means that the units can be controlled from the same application without any redevelopment

when installing a different device. It also increases the life expectancy of the software

application. The EDR Enhanced SDK comes with complete documentation and examples

programs. For custom software the API is easy to learn shortening the learning curve. It also

means that it’s quicker to go into production.

Omega Engineering Inc. © Copyright 2005 – www.omega.com 1-2

Page 9

OMET-USB 73 User Manual Data Acquisition

1.3 USB 73 Versions

The tables below list the various versions that are available.

1.3.1 Temperature Input Series

• R is RTD

• T is Thermocouple

Feature OMET-USB

73R/T8

Number of digital I/O channels 24 24 24

Number of 8255 compatible ports (8-bit) 3 3 3

Number of temperature channels 8 16 32

Number of CJC channels 1 2 4

Analog input resolution 14-bit 14-bit 14-bit

Maximum sampling speed 100 Hz 100 Hz 100 Hz

Table 1-1 µDAQ Temperature Versions

OMET-USB

73R/T16

OMET-USB

73R/T 32

1.4 Software Support

The OMET-USB-73 series is supported by EDR Enhanced and has an extensive range of

examples. The software will help you to get your hardware going very quickly. It also makes it

easy to develop complicated control applications. All operating system drivers, utility and test

software are supplied on the EDR Enhanced CD-Rom. The latest drivers can also be

downloaded from the Eagle Technology website. For further support information see the

Contact Details section.

1.5 Contact Details

Omega Engineering Inc.

1 Omega Drive

P.O. Box 4047

Stamford, CT 06907 USA

Telephone (800)-848-4286

Fax (203)-359-7700 E-Mail das@omega.com

Website

http://www.omega.com

Omega Engineering Inc. © Copyright 2005 – www.omega.com 1-3

Page 10

OMET-USB 73 User Manual Data Acquisition

2

2 Getting Started

This chapter describes how to install and configure the OMET-USB-73 device for the first

time. Minimal configuration is necessary; almost all settings are done through software.

2.1 Package Items

The package of items differs by device type. Depending on the device type accessories will

be included like power supplies, USB cable and third party devices.

1. OMET-USB-73 unit

2. USB 2.0 compliant peripheral cable

3. Universal power supply

4. Software CD Rom

5. RTD or Thermocouple adaptor unit

6. Software CD Rom

Omega Engineering Inc. © Copyright 2005 – www.omega.com 2-1

Page 11

OMET-USB 73 User Manual Data Acquisition

2.2 Operating Systems for Specific Devices

The USB driver for Windows is a Windows Driver Model (WDM) type that will run on all

modern Windows platforms. Linux has it’s own driver which is exported as a character device.

Windows ME/2000/XP WDM Plug and Play

Linux 2.4 and later Linux Character Device

OS Type Driver Type

Table 2-1 USB Operating System Support

2.3 Installation

The USB installation is different on each operating system type. The installation procedure for

each operating system will be discussed separately for Windows Desktop, Windows Mobile

and Linux.

2.3.1 Microsoft Windows PnP Installation (Windows ME, 2000, XP)

For the Windows PnP installation you will need a PC that can accept a USB device and that is

configured to work with USB devices. Depending on the version you will need either USB 1.1

or USB 2.0.

Find an open USB port and connect your

device with the provide USB cable. Also

1

provide power to your device if it is

externally powered. Only use the provide

power cable or power supply.

2

3

4

5

6

7

Windows will now detect that a new USB

device was attached and request driver to

be supplied.

Click on the next button to start the

process.

The wizard will now need to be supplied

with driver files to for your USB device.

Select the option as indicated and then

the next button.

Only select to specification the location of

the driver files.

The driver is located at

<OMEGACD>\EDRE\Drivers\WDM\USB.

Select the next button to install the driver.

Omega Engineering Inc. © Copyright 2005 – www.omega.com 2-2

Page 12

OMET-USB 73 User Manual Data Acquisition

Depending on the model the last screen

8

will show that the installation was

completed successfully for your particular

device.

2.3.2 Linux Installation (Kernel 2.4 and later) - Overview

The Linux installation can be a bit tricky sometimes. Make sure that the kernel supports USB

devices and that the necessary modules are already loaded or can load on demand. Also

make sure that all kernel source and header files are installed. The Linux driver is available

with complete source and it will be best if it is recompiled to be compatible with the current

kernel version. The source listing on the <OMEGACD>\EDRE\Linux should match the

directory structure on the target system. Drivers can be copied manually to /usr/src/<linux

kernel source>/drivers/edredaq. The USB driver will also be located here. Copy the driver and

read the documentation in the same directory to install the driver.

Also copy the EDR Enhanced shared object and examples. This should be located at

/usr/src/edre. The EDRE source directory contains the source for the API and examples. The

examples directory has samples program specifically for each device. Make sure to install the

EDR Enhanced before trying to build the source code. The header files are located at

usr/include/edre. The header files is also necessary when building the drivers. Please consult

the Linux documentation for complete instructions.

2.4 Application Software- OmegaLog

The EDR Enhanced Software Development Kit CD-Rom comes with OMEGALog OMET for

Windows™. OMEGALog OMET has support for Analog Inputs, Analog Outputs, Digital I/O

and Counter-Timers. It has an oscilloscope function to continuously display incoming analog

data, a signal generator, a power supply, temperature logger and a multifunctional chart

recorder to sample and control signals, analog and digital, at preset intervals.

WaveView can be found on the EDR Enhanced CD-Rom at

<OMEGACD>\EDRE\APPS\WVFW.

Omega Engineering Inc. © Copyright 2005 – www.omega.com 2-3

Page 13

OMET-USB 73 User Manual Data Acquisition

3

3 Hardware Interface

The Hardware Interface chapter will discuss all connectors located on the OMET-USB-73

products. The pin assignments for each connector will also be listed.

The OMET-USB-73 series has connectors for digital I/O and temperature I/O. The OMETUSB-73s make use of only one connector type, a DB25 male. To inter-connect to application

modules there are adapters modules available. A cable is used to connect to these modules.

Screw terminal modules are also available for quick installations. This chapter will also

discuss method of hardware operation, optional accessories and connectable applicatio n

modules.

3.1 OMET-USB-73 External Application Connectors

The OMET-USB-73 is fitted with various DB25 male connectors. The illustrations below show

the different box types. There are two-tier and three-tier models. Depending on the number of

connectors required the box would be either one. The OMET-USB-73 devices use a standard

USB type B connector. The side with the power connector is the rear side of the device. The

pin assignments are the same for all models.

Figure 3-1 OMET-USB-73 Front Side

2-Tier

Figure 3-3 OMET-USB-73 Rear Side

2-Tier

Figure 3-2 OMET-USB-73 Front Side

3-Tier

Figure 3-4 OMET-USB-73 Rear Side

3-Tier

Omega Engineering Inc. © Copyright 2005 – www.omega.com 3-1

Page 14

OMET-USB 73 User Manual Data Acquisition

B = Bottom, M = Middle, T = Top

F = Front, R = Rear

Device Type DB25 (M)

OMET-USB-73T/R8

OMET-73T/R16

OMET-73T/R32

Digital I/O

Port

Assignment

FB (0-2)

FB (0-2)

FB (0-2)

DB25(M)

Analog I/O

FT (CH0-7, CJC0)

FT (CH0-7, CJC0)

RT (CH8-15, CJC1)

FM (CH0-7, CJC0)

RM (CH8-15, CJC1)

FT (CH16-23, CJC2)

RT (CH24-31, CJC3)

Table 3-1 µDAQ Connectors

Box Type

Omega Engineering Inc. © Copyright 2005 – www.omega.com 3-2

Page 15

OMET-USB 73 User Manual Data Acquisition

3.2 Pin Assignments

Figure 3-5 OMET-USB-73 DB25 Male Connector

3.2.1 OMET-USB-73 DIO Connector – DB25 (M)

The table below shows the pin assignments for the DB25(M) digital I/O connectors found on

the OMET-USB-73 devices.

Pin Name Pin Name

1 PA0 14 PA1

2 PA2 15 PA3

3 PA4 16 PA5

4 PA6 17 PA7

5 PB0 18 PB1

6 PB2 19 PB3

7 PB4 20 PB5

8 PB6 21 PB7

9 PC0 22 PC1

10 PC2 23 PC3

11 PC4 24 PC5

12 PC6 25 PC7

13 DGND

Table 3-2 OMET-USB-73 DIO Connector – DB25 (M)

3.2.2 OMET-USB-73 Temperature Input – DB25 (M)

The table below shows the pin assignments for the DB25(M) temperature input connectors

found on the OMET-USB-73 device.

Pin Name Pin Name

1 AGND 14 +8.4V

2 AGND 15 +12V

3 AGND 16 CJC

4 AGND 17 -12V

5 AGND 18 TCH76 TCH7+ 19 TCH6-

7 TCH6+ 20 TCH58 TCH5+ 21 TCH49 TCH4+ 22 TCH310 TCH3+ 23 TCH211 TCH2+ 24 TCH112 TCH1+ 25 TCH013 TCH0+ 26 SHELL – DGND

Table 3-3 OMET-USB-73 Input – DB25 (M)

Omega Engineering Inc. © Copyright 2005 – www.omega.com 3-3

Page 16

OMET-USB 73 User Manual Data Acquisition

3.3 Pin Descriptions

3.3.1 Digital Inputs/Outputs (PA0-7, PB0-7, PC0-7)

These lines are connected to the 3 ports of the 8255 PPI. Each port can be configured as

either an input or an output.

3.3.2 Digital Ground (DGND)

All digital ground signals should be connected to this pin.

3.3.3 Analog Ground (AGND)

All analog inputs should be referenced to AGND. Do not connect AGND and DGND together.

This will create ground loops and instability in the hardware.

3.3.4 Analog Inputs (ACH0-15)

The analog input channels are connected to the analog input sub-system and are used to

measure analog voltages. These signals are referenced to analog ground (AGND).

3.3.5 Temperature Inputs (TCH0-7)+-

Each temperature channel has two input lines for positive and negative. However in all

temperature applications there are always and external modules for thermocouple or RT D

inputs. Their user never connects directly to these pins.

3.4 Bus Connectors

The OMET-USB-73 uses a standard USB Type B connector. The device is supplied with a

USB 2.0 compliant cable. When viewing the OMET-USB-73 device from the rear the USB B

Type connector is located on the right side. In the middle are the indicator light and the power

connector on the left. When the USB device is connected to the PC the USB indicator light

will light up, indicating that USB bus power is present.

Figure 3-6 OMET-USB-73 Connectors

Omega Engineering Inc. © Copyright 2005 – www.omega.com 3-4

Page 17

OMET-USB 73 User Manual Data Acquisition

3.5 Power Supplies, Power Connectors

The commercial OMET-USB-73 units are supplied with an AC power supply.

The AC power supply is a wide AC input voltage range type, 110V to 250V. The AC power

supply also contains a universal socket kit, which makes it possible to connect to any

international power socket. The output voltage is 9V @ 1A maximum.

The polarity of the output connector must be positive on the outside and negative in the

middle.

There is an indicator light to show of the power is present.

Figure 3-7 µDAQ Power Connector Pin Assignment

Figure 3-8 µDAQ Power Socket

3.6 Application Modules & Accessories

The OMET-USB-73 devices support a wide range of standard applications modules. These

application modules can help to simply or easily duplicate installations that can save allot of

time. Application modules and accessories come in many forms. It has support for digital

output control and digital input monitoring for AC and DC.

3.6.1 Digital I/O Adapter Module – OMET-PC43A2

The digital I/O adapter module is used to map digital I/O ports to a usable form. The OMETPC43A2 adapter module makes it possible to connect to application modules, such as solid

relays modules and optical-isolated modules. The OMET-PC43A2 output the 3 x 8-bit ports

(A,B,C) into a combination of port A and B and three separate ports A,B and C. To connect to

the OMET-PC43A2 use a standard DB25M/F cable. Port AB is a standard IDC20 connecter

and port A,B and C standard IDC10 connecters. The OMET-PC43A2 can also be used to

provide external power to application modules. Connect +5V to the external power screw

terminal and it will distribute it to all child models through the various connecters. The table

below shows the pin mappings for the module. When externally powered the power indicator

will light up.

Omega Engineering Inc. © Copyright 2005 – www.omega.com 3-5

Page 18

OMET-USB 73 User Manual Data Acquisition

Figure 3-9 OMET-PC43A2 Digital I/O Adapter

3.6.2 Thermocouple Adapter

The thermocouple adapter is used to interconnect the OMET-USB-73 unit and thermocouple

temperature sensors. The adapter has cold junction compensation (CJC) built-on, which is

necessary to make thermocouple connections. The CJC needs to be calibrated before being

used. The illustration below shows the thermocouple adapter. The adapter has DB25 female

connector that connects directly to the OMET-USB-73 unit. Care must be taken to only

connect to a temperature input connector.

Figure 3-10 Thermocouple Adapter

Omega Engineering Inc. © Copyright 2005 – www.omega.com 3-6

Page 19

OMET-USB 73 User Manual Data Acquisition

4

4 Software

The OMET-USB-73 series are supplied with a complete software package called the EDR

Enhanced Software Development Kit (EDRE SDK). The SDK is supplied with many operating

system drivers, an application program interface (EDRE API), complete documentation and

programming examples for most programming languages.

The software development kit also contains OMEGALog OMET

to provide a generic application solution for data capturing and simple process control. Third

party Interface drivers are also provided for Labview, TestPoint and Agilent VEE Pro.

The Software chapter serves as reference for the EDR Enhanced API exported functions. It

explains how to do common operations to program and control the OMET-USB-73 hardware.

Each supported function is listed for each type of interface. The parameters for each function

are also listed. There are only a few functions, so make sure to have a thorough

understanding of how to use them.

4.1 EDR Enhanced Application Program Interface (EDRE API)

The EDR Enhanced API consist of operating system drivers, Windows dynamic link libraries,

Windows ActiveX controls, Windows .Net components and Linux shared objects. EDRE

Enhanced API has support for Windows 2000/XP/.Net and the Linux kernel.

The EDR Enhanced SDK contains example code to use as reference or starting point for a

custom application. The examples covers topics such as digital I/O reads and writes, and

reading the analog inputs.

The EDRE API hides the complexity of the hardware and makes it really easy to program the

OMET-USB-73 devices. It has functions for each basic sub-system and is real easy to learn.

The EDR Enhanced Application Programming Interface currently support four interface types:

1. Shared Object with exported functions via dynamic link library and shared object

2. EDR Enhanced ActiveX package for Windows platform

3. EDR Enhanced Object interface for Linux and .Net platform

4. EDR Enhanced Device Object interface for Linux and .Net platform

The illustration below shows the EDR Enhanced Application Program Interface design. The

next sections will discuss each sub-system’s functions separately. It will show which functions

each type of interface supports and what parameters are used.

Omega Engineering Inc. © Copyright 2005 – www.omega.com 4-1

Page 20

OMET-USB 73 User Manual Data Acquisition

Figure 4-1 EDR Enhanced API Design

Omega Engineering Inc. © Copyright 2005 – www.omega.com 4-2

Page 21

OMET-USB 73 User Manual Data Acquisition

4.2 The Query Command – EDRE_Query

The query API function is used to retrieve useful information about your device. Appendix C

has a list of query codes that will operate on the OMET-USB-73 devices. The query function

is the most powerful function of the EDR Enhanced API and can tell a lot about your device,

like manufacturing date, the serial number, bus type, revision and device driver version. The

query function can also supply information about the API itself like release version and

number of devices installed.

4.2.1.1 Shared Object and Linked Library Interface

Function Name

Object

Platform

Parameters

Return Error

Error Codes

EDRE_Query

Edrapi.dll / edrapi.so

Linux, Microsoft Windows, Pocket PC 2003

32-bit unsigned integer Serial Number

32-bit unsigned integer Query Code

32-bit unsigned integer Parameter

32-bit signed integer

>=0 Query return value No error

-1 EDRE_FAIL General failure

-3 EDRE_BAD_SN Device with serial

number does not exist

-18 EDRE_BAD_QUERY Invalid query code

4.2.1.2 ActiveX Interface

Function Name

Object

Platform

Related Property

Parameters

Return Value

Error Codes

4.2.1.3 EDR Enhanced Main Object Interface

Function Name

Object

Platform

Parameters

Return Value

Error Codes

Query

EDREUTLX

Microsoft Windows

SerialNumber

32-bit unsigned integer Query Code

32-bit unsigned integer Parameter

32-bit signed long

>=0 Query return value No error

-1 EDRE_FAIL General failure

-3 EDRE_BAD_SN Device with serial

-18 EDRE_BAD_QUERY Invalid query code

Query

EDREObject

Linux

32-bit unsigned integer Serial Number

32-bit unsigned integer Query Code

32-bit unsigned integer Parameter

32-bit signed integer

>=0 Query return value No error

-1 EDRE_FAIL General failure

-3 EDRE_BAD_SN Device with serial

-18 EDRE_BAD_QUERY Invalid query code

number does not exist

number does not exist

Omega Engineering Inc. © Copyright 2005 – www.omega.com 4-3

Page 22

OMET-USB 73 User Manual Data Acquisition

4.2.1.4 EDR Enhanced Device Object Interface

Function Name

Object

Platform

Parameters

Return Value

Error Codes

Query

EDREDevice

Linux

32-bit unsigned integer Query Code

32-bit unsigned integer Parameter

32-bit signed integer

>=0 Query return value No error

-1 EDRE_FAIL General failure

-3 EDRE_BAD_SN Device with serial

number does not exist

-18 EDRE_BAD_QUERY Invalid query code

4.2.1.5 Query example

This example queries the number of devices installed and the serial number of each device.

PSEUDO START

Define APINUMDEV = 5 “See appendix C for list of query codes”

NumDevices of type 32-bit integer

SerialNumber of type 32-bit integer

NumDevices = EDRE_Query(0, APINUMDEV,0)

For d = 0 to NumDevices-1 do

SerialNumber = EDRE_Query(0, APIDEVSN,d)

Next d

PSEUDO STOP

Omega Engineering Inc. © Copyright 2005 – www.omega.com 4-4

Page 23

OMET-USB 73 User Manual Data Acquisition

4.3 Digital Inputs/Outputs

The table below shows all the assigned ports to each device. The digital port makes out an

important part of any automated system. The digital I/O ports are used to control external

equipment logically or to monitor logical conditions. The digital I/O port can be used to switch

high voltage external equipment through controlling external relays and contactors. It can also

be connected external monitoring circuit that indicates conditions logically.

XXX = USB

T=TOP, M=MIDDLE, B=BOTTOM

F=FRONT, R=REAR

2 = 2 TIER BOX, 3 = 3 TIER BOX

Port PPI No

XXX 73R/T

A 0 0 8-bits FB2 Port A

B 0 1 8-bits FB2 Port B

C 0 2 8-bits FB2 Port C

Assigned

Number

Table 4-1 Digital I/O Assigned Ports

Port Width

OMET-

USB-73

Connector

Description

4.3.1 Reading the Digital Inputs – EDRE_DioRead

A single call is necessary to read a digital I/O port. Depending on the interface the result is

either passed through a reference parameter or by the returned code. The digital I/O ports a

self managed, meaning it will automatically configure as inputs when read from. Please note

that due to the identity of the digital I/O devices the output ports will looses its output value

when the a port is configured differently. It’s very important to do the appropriate reads and

writes to ensure the device is in proper configuration before using it. Each interface function is

showed separately in the next section.

4.3.1.1 Shared Object and Linked Library Interface

Function Name

Object

Platform

Parameters

Return Error

Error Codes

EDRE_DioRead

Edrapi.dll / edrapi.so

Linux, Microsoft Windows, Pocket PC 2003

32-bit unsigned integer Serial Number

32-bit unsigned integer Port

Pointer to 32-bit unsigned integer Value

32-bit signed integer

0 EDRE_OK No error

-1 EDRE_FAIL General failure

-3 EDRE_BAD_SN Device with serial

number does not exist

-14 EDRE_BAD_PARAMTER Port value is incorrect

4.3.1.2 ActiveX Interface

Function Name

Object

Platform

Related Property

Parameters

Return Value

Error Codes

Read

EDREDioX

Microsoft Windows

SerialNumber

32-bit signed integer Port

32-bit signed long

>=0 Value read from port No error

-1 EDRE_FAIL General failure

-3 EDRE_BAD_SN Device with serial

number does not exist

Omega Engineering Inc. © Copyright 2005 – www.omega.com 4-5

Page 24

OMET-USB 73 User Manual Data Acquisition

-14 EDRE_BAD_PARAMTER Port value is incorrect

4.3.1.3 EDR Enhanced Main Object Interface

Function Name

Object

Platform

Parameters

Return Value

Error Codes

4.3.1.4 EDR Enhanced Device Object Interface

Function Name

Object

Platform

Parameters

Return Value

Error Codes

DioRead

EDREObject

Linux

32-bit unsigned integer Serial Number

32-bit unsigned integer Port

Pointer to 32-bit unsigned integer Value

32-bit signed integer

0 Value read from port No error

-1 EDRE_FAIL General failure

-3 EDRE_BAD_SN Device with serial

number does not exist

-14 EDRE_BAD_PARAMTER Port value is incorrect

DioRead

EDREDevice

Linux

32-bit unsigned integer Port

Pointer to 32-bit unsigned integer Value

32-bit signed integer

0 Value read from port No error

-1 EDRE_FAIL General failure

-3 EDRE_BAD_SN Device with serial

number does not exist

-14 EDRE_BAD_PARAMTER Port value is incorrect

4.3.2 Writing to the Digital Outputs – EDRE_DioWrite

A single call is necessary to write to a digital I/O port. Depending on the interface type a port

number and value is passed to the function. A returned error code will tell if the function

passed or not. . Please note that due to the identity of the digital I/O devices the output ports

will looses its output value when the a port is configured differently. It’s very important to do

the appropriate reads and writes to ensure the device is in proper configuration before using

it. Each interface function is showed separately in the next section.

4.3.2.1 Shared Object and Linked Library Interface

Function Name

Object

Platform

Parameters

Return Error

Error Codes

EDRE_DioWrite

Edrapi.dll / edrapi.so

Linux, Microsoft Windows, Pocket PC 2003

32-bit unsigned integer Serial Number

32-bit unsigned integer Port

32-bit unsigned integer Value

32-bit signed integer

0 EDRE_OK No error

-1 EDRE_FAIL General failure

-3 EDRE_BAD_SN Device with serial

number does not exist

-14 EDRE_BAD_PARAMTER Either the port or

value is incorrect

Omega Engineering Inc. © Copyright 2005 – www.omega.com 4-6

Page 25

OMET-USB 73 User Manual Data Acquisition

4.3.2.2 ActiveX Interface

Function Name

Object

Platform

Related Property

Parameters

Return Value

Error Codes

Write

EDREDioX

Microsoft Windows

SerialNumber

32-bit signed integer Port

32-bit signed integer Value

32-bit signed integer

0 EDRE_OK No error

-1 EDRE_FAIL General failure

-3 EDRE_BAD_SN Device with serial

number does not exist

-14 EDRE_BAD_PARAMTER Either the port or

value is incorrect

4.3.2.3 EDR Enhanced Main Object Interface

Function Name

Object

Platform

Parameters

DioWrite

EDREObject

Linux

32-bit unsigned integer Serial Number

32-bit unsigned integer Port

32-bit unsigned integer Value

Return Value

Error Codes

32-bit signed integer

0 EDRE_OK No error

-1 EDRE_FAIL General failure

-3 EDRE_BAD_SN Device with serial

number does not exist

-14 EDRE_BAD_PARAMTER Either the port or

value is incorrect

4.3.2.4 EDR Enhanced Device Object Interface

Function Name

Object

Platform

Parameters

Return Value

Error Codes

DioWrite

EDREDevice

Linux

32-bit unsigned integer Port

32-bit unsigned integer Value

32-bit signed integer

0 EDRE_OK No error

-1 EDRE_FAIL General failure

-3 EDRE_BAD_SN Device with serial

-14 EDRE_BAD_PARAMTER Either the port or

number does not exist

value is incorrect

Omega Engineering Inc. © Copyright 2005 – www.omega.com 4-7

Page 26

OMET-USB 73 User Manual Data Acquisition

4.3.3 Query Codes

The digital I/O sub-system can be queried for the number of ports available and the property

of each port. The following query codes are relevant to the digital I/O system.

Name Value Description

DIONUMPORT 400 Query the number of digital I/O ports installed

DIOQRYPORT 401 Query a specific port for its properties. Use PARAM to specify

0 DIOOUTPUT

1 DIOINPUT

2 DIOINOROUT

3 DIOINANDOUT

DIOPORTWIDTH 402 Query a specific port width. Use PARAM to specify the port.

The value returned is the bit width of the port.

4.3.3.1 Query number of ports

PSEUDO START

Dioports of type 32-bit integer

Dioport = EDRE_Query(serialnumber, DIONUMPORT,0)

PSEUDO STOP

the port.

Port is output only

Port is either in or out

Port is input only

Port is in and out

4.3.3.2 Query port type

“Port type can be output, input, in-and-out, in-or-out

PSEUDO START

Port_type of type 32-bit integer

For p = 0 to Dioports-1 do

Port_type = EDRE_Query(serialnumber, DIOQRYPORT,p)

Next p

PSEUDO STOP

4.3.3.3 Query port width in bits

PSEUDO START

Port_width of type 32-bit integer

For p = 0 to Dioports-1 do

Port_width = EDRE_Query(serialnumber, DIOPORTWIDTH,p)

Next p

PSEUDO STOP

Omega Engineering Inc. © Copyright 2005 – www.omega.com 4-8

Page 27

OMET-USB 73 User Manual Data Acquisition

4.4 Temperature Input – 73 Model

The OMET-USB-73 has three different basic temperature models. The OMET-USB-73 is

available in an 8, 16, and 32-channel model.

There are eight channels available on a single DB25 male connector and one cold junction

compensation (CJC) channel. Only a genuine Eagle Technology thermocouple adapter can

be used to interface to the thermocouple inputs. This adapter has a build CJC device and is

necessary to read thermocouple temperatures.

The OMET-USB-73 temperature units also support RTD inputs. If RTDs are used a RTD

adapter must be connected. The RTD adapter has build in support for a 1mA and 10mA

current source. It supports both the two wire and four wire system.

Note that the OMET-USB-73 units are manufactured for either thermocouples or

RTD and cannot be changed by swapping the adapter modules.

4.4.1 Thermocouple Procedure

To read a thermocouple channel a sequence needs to be followed. The step s below shows

what steps to follow the read a thermocouple channel.

1. Read CJC channel

2. Calculate ambient temperature

3. Read thermocouple channel

4. Calculate temperature

4.4.2 Reading CJC Channel

To be able to read and calculate a thermocouple voltage the CJC channel need to be read.

This value is used to calculate the cold-junction-compensation for a thermocouple channel.

A thermocouple adapter’s CJC channel has a circuit that will supply a voltage of 10mV per 1

degree Celsius. The CJC channel is read in the same way as a normal analog channel. The

index of the channel is very important as for a unit can have more than one CJC channel. The

CJC channel must always be read before reading a number of channels on a thermocouple

adapter. The table below shows the CJC channel index for a particular type of device.

XXX = USB

Devices CJC Channels

XXX 73T8

XXX 73T16

R-XXX 73T16

XXX 73T32

R-XXX 73T32

Table 4-2 CJC Channels Assigned

4.4.2.1 Query the CJC channel index

The index of each CJC channel can be queried

PSEUDO START

CJC_channel of type 32-bit integer

Do

CJC_channel = EDRE_Query(serialnumber, ADAMBCHAN,0)

Until CJC_channel < 0

CJC Value Assigned

0 8

CJC Value Assigned

0 16

1 17

CJC Value Assigned

0 32

1 33

2 34

3 35

Omega Engineering Inc. © Copyright 2005 – www.omega.com 4-9

Page 28

OMET-USB 73 User Manual Data Acquisition

PSEUDO STOP

4.4.2.2 Read CJC channel

To read a CJC channel use the EDRE_ADSingle command. For further reference on this

command see the analog input section. The channel must be the CJC channel index. The

Gain and Range parameter are not used.

PSEUDO START

CJC_value of type 32-bit signed integer

CJC_channel of type 32-bit unsigned integer

CJC_channel = 8

error = EDRE_ADSingle(serialnumber, CJC_channel,0,0,pointer of CJC_value)

if error = 0 print CJC_value

else print “Error reading CJC channel”

PSEUDO STOP

4.4.3 Types of Thermocouples

The EDR Enhanced application program interface supports the conversion of many

thermocouple types. The table below lists all the supported types. Each type has its purpose

like wide temperature range or very accurate in a certain range. The constant value is used

when calculating the temperature.

Value Thermocouple Type

0 Type J

1 Type K

2 Type E

3 Type T

4 Type S

5 Type R

6 Type B

7 Type N

8 Type C

Table 4-3 Thermocouple Type Table

4.4.4 Reading a Thermocouple Channel

Reading the thermocouple channel is the same as reading an analog channel or CJC

channel. The channels on the OMET-USB-73models are zero indexed. If the device is a

hybrid that has normal analog channels and temperature channels, the temperat ure channels

will follow the analog channels. As with the reading of the CJC channel the rang e and gain

parameter of the EDRE_ADSingle command is not used.

The example below will read thermocouple channel 0.

PSEUDO START

TC_value of type 32-bit signed integer

error = EDRE_ADSingle(serialnumber, 0,0,0,pointer of TC_value)

if error = 0 print TC_value

else print “Error reading termocpuple channel”

PSEUDO STOP

4.4.5 Calculating Ambient Temperature

After reading the CJC channel the ambient temperature can be calculated. The voltage read

from the CJC channel must be passed to this conversion function. The returned value will be

the temperature in millidegrees.

Omega Engineering Inc. © Copyright 2005 – www.omega.com 4-10

Page 29

OMET-USB 73 User Manual Data Acquisition

4.4.5.1 Shared Object and Linked Library Interface

Function Name

Object

Platform

Parameters

Return Value

Value

4.4.5.2 ActiveX Interface

Function Name

Object

Platform

Related Property

Parameters

Return Value

Value

4.4.5.3 EDR Enhanced Main Object Interface

Function Name

Object

Platform

Parameters

Return Value

Value

EDRE_CalcCJCmC

Edrapi.dll

Microsoft Windows

32-bit signed integer CJC microvolt

32-bit signed integer

Millidegrees

CalcCJCmC

EDREADX

Microsoft Windows

None

32-bit signed integer CJC microvolt

32-bit signed integer

Millidegrees

CalcCJCmC

EDREObject

No support

32-bit signed integer CJC microvolt

32-bit signed integer

Millidegrees

4.4.5.4 EDR Enhanced Device Object Interface

Function Name

Object

Platform

Parameters

Return Value

Value

CalcCJCmC

EDREDevice

No support

32-bit signed integer CJC microvolt

32-bit signed integer

Millidegrees

4.4.6 Calculating Temperature for Thermocouples

After the CJC channel and thermocouple channel was read and the CJC value converted to

millidegrees, the thermocouple temperature can be calculated. The thermocouple type,

thermocouple channel voltage and ambient temperature need to be supplied in order to do

this. The returned value will be in millidegrees.

4.4.6.1 Shared Object and Linked Library Interface

Function Name

Object

Platform

Parameters

Return Value

Value

EDRE_CalcTCmC

Edrapi.dll

Microsoft Windows

32-bit signed integer array Thermocouple type

32-bit signed integer array Thermocouple channel

voltage

32-bit signed integer array Ambient temperature in

32-bit signed integer

Millidegrees

millidegrees

Omega Engineering Inc. © Copyright 2005 – www.omega.com 4-11

Page 30

OMET-USB 73 User Manual Data Acquisition

4.4.6.2 ActiveX Interface

Function Name

Object

Platform

Related Property

Parameters

CalcTCmC

EDREADX

Microsoft Windows

None

32-bit signed integer Thermocouple type

32-bit signed integer Thermocouple channel

voltage

32-bit signed integer Ambient temperature in

millidegrees

Return Value

Value

32-bit signed integer

Millidegrees

4.4.6.3 EDR Enhanced Main Object Interface

Function Name

Object

Platform

Parameters

CalcTCmC

EDREObject

No support

32-bit signed integer Thermocouple type

32-bit signed integer Thermocouple channel

voltage

32-bit signed integer Ambient temperature in

millidegrees

Return Value

Value

32-bit signed integer

Millidegrees

4.4.6.4 EDR Enhanced Device Object Interface

Function Name

Object

Platform

Parameters

CalcTCmC

EDREDevice

No support

32-bit signed integer Thermocouple type

32-bit signed integer Thermocouple channel

voltage

32-bit signed integer Ambient temperature in

millidegrees

Return Value

Value

32-bit signed integer

Millidegrees

4.4.6.5 Example of calculating a thermocouple temperature

The temperature

PSEUDO START

Define TYPE_K 1

CJC_millideg of type 32 signed integer

TC_value of type 32-bit signed integer

TC_millideg of type 32-bit signed integer

TC_millideg = EDRE_CalcTCmC(TYPE_K, TC_value, CJC_millideg)

Print TC_millideg

PSEUDO STOP

Omega Engineering Inc. © Copyright 2005 – www.omega.com 4-12

Page 31

OMET-USB 73 User Manual Data Acquisition

5

5 Calibration Procedure

This chapter deals with calibrating your hardware. Please follow the instruction carefully to

properly calibrate your device.

5.1.1 Calibration - USB 73

If the USB device needs to be calibrated, the software can be found on the EDR Enhanced

SDK CD-Rom. This application provides step-by-step information of how to calibrate your

device. Make sure that you have a high precision calibration voltage source. This will help to

configure your device more accurately.

5.1.2 Equipment

The following calibration equipment is required to calibrate the analog OMET-USB-73 device.

If the calibration equipment does conform to these specifications it will not be possible to

calibrate the device accurately.

5.1.2.1 High Precision Voltage Source

A high precision voltage source is required to generate input analog voltages. The Burster

Digistant Typ 4405 is am example of such a device. The device is used as standard test

equipment to calibrate the µDAQ and Rugged µDAQ device. Make sure the device conform to

its own calibration requirements and that it is serviced regularly. The device requirements are

the following.

Item Specification

Voltage Range 0V to 10V

Type Analog Output

Relative Accuracy 0.1 % of 1 bit in 16384

Accuracy

Table 5-1 Analog Source Requirements

5.1.3 Calibration Procedure – USB 73

1. Install the USB Calibration Software <EDRECD>\EDRE\APPS\OMET-USB-73 CAL

2. Run the USB Calibration Software.

3. Follow the step-by-step information on screen to tune your device.

4. Make sure to save the data to your device.

< 1.2 µV

Omega Engineering Inc. © Copyright 2005 – www.omega.com 5-13

Page 32

OMET-USB 73 User Manual Data Acquisition

±

A

A Specifications

A.1 Digital Input/Output Characteristics

Number of Digital Channels:

Models are: USB

Number of Grouped Channels:

Models are: USB

Compatibility: Intel® 82C55/TTL

D.C Characteristics – PPI 8255 Compatible Ports

Device Channels

73 24

Device PPI

Channels

73 3

Level Min Max

Input Low Voltage -0.5V 0.8V

Input High Voltage 2.0V 5.0V

Output High Voltage 2.4V

Output Low Voltage 0.45V

Output Current 2mA

A.2 Temperature Input Characteristics

Number of Channels

Models are: USB, SRL, BT and Rugged

Resolution 14-bits

Maximum Update Rate – USB 1.1 & USB 2.0 2 milliseconds

Data Transfer – USB 1.1 & USB 2.0 Programmed I/O – USB Bulk Transfer

Input Programmable Ranges

Input Coupling DC

Relative Accuracy

Gain x 1 Offset Error

Gain x 30 Offset Error

1 LSB

±0.305 millivolts

±0.011 millivolts

Omega Engineering Inc. © Copyright 2005 – www.omega.com I

Device Differential

73T8 8

73T16 16

73T32 32

Channel

Gain

1 R

30 T

Channels

Model Bipolar

Range

±2.5V

±83mV

Page 33

OMET-USB 73 User Manual Data Acquisition

A.3 Bus Interface

A.3.1 USB 1.1

Bus Type Universal Serial Bus Revision 1.1

Bus Speed USB Full Speed – 12 Mega bit per second.

Controller USB Serial Interface Endpoint Compliant

Voltage 5V

Endpoints 1 x Control Transfer Endpoint

A.3.2 USB 2.0

Bus Type Universal Serial Bus Revision 2.0

Bus Speed USB High Speed – 480 Mega bit per second.

Controller USB Serial Interface Endpoint Compliant

Voltage 5V

Endpoints 1 x Control Transfer Endpoint

1 x Bulk Transfer Endpoint

1 x Interrupt Transfer Endpoint

1 x Isochronous Transfer Endpoint @ 512kB/s

1 x Bulk Transfer Endpoint

1 x Interrupt Transfer Endpoint

1 x Isochronous Transfer Endpoint @ 512kB/s

A.4 Power Requirements

A.4.1 USB Devices

Device Minimum Typical Maximum Power Source

OMET-USB-73T8 400 mA 450 mA External PSU

OMET-USB-73T16 420 mA 470 mA External PSU

OMET-USB-73T32 820 mA 870 mA External PSU

A.5 Environmental / Physical

A.5.1 USB

Relative Humidity 0% to 90% (non-condensing)

Operating Temperature

Storage Temperature

Housing Type Plastic Casing

Weight – OMET-USB-73T8, OMET-USB-73T16 280g

Weight – OMET-USB73-T32 400g

Dimensions – OMET-USB73-T8, OMET-USB-73T16 Height: 45mm

Dimensions – OMET-USB-73T32 Height: 60mm

0°C to 70°C

-25°C to 120°C

Width: 80mm

Length: 148mm

Width: 80mm

Length: 148mm

Omega Engineering Inc. © Copyright 2005 – www.omega.com II

Page 34

OMET-USB 73 User Manual Data Acquisition

A.6 Power Supplies

Input Type AC

Input Range 110V – 240V

Input Connector Type Multiple to comply with all international wall sockets

Power DC

Output Type DC

Output Voltage 9V

Maximum Output Current 1A

Output Connector Type 5mm DC plug

Regulator Type Switch Mode

Location External/Separate

Indicators Power

Omega Engineering Inc. © Copyright 2005 – www.omega.com III

Page 35

OMET-USB 73 User Manual Data Acquisition

B

B Related Products and Accessories

A whole range of external connectable accessories and application modules supports the

OMET-USB-73 series. These modules are easy to connect too and support DINRAIL

installations. Below is a list of products that are compatible with the OMET-USB-73 devices.

They are broken up sub-sections to cover each type of application.

B.1 General Adapters

There are general adapters that can be used with the OMET-USB-73 devices. These

modules simple map a cable-connector to a screw terminal block.

Adapter Entry

OMET-

ADPT-2526

OMET-

ADPT-20

OMET-

ADPT-910

Connector

DB25 Female DB25M/F To map the main connector to a screw terminal

IDC 20 IDC 20 To connect to digital I/O port A-B on the OMET-

IDC 10

DB9 Female

Cable Possible

clock. This adapter is used to make simple

connections to the unit.

IDC 10

DB9 Female

Table 5-2 General Adapters

To connect 8 channels on the PC52A2

For connecting to digital I/O ports or analog

channels on the OMET-PC43A2 and PC52A2.

Also for connecting to the DB9 on the serial

Usage

PC43A2.

units.

B.2 Digital I/O Application Modules

All Digital I/O application modules are DINRAIL mountable. They are supplied with standard

cables and are easy to connect too. Wide variety is available and care must be taken to select

the correct module for the application.

Adapter Entry

Connector

PC-37 Series IDC10

IDC20

DB25

PC-51-8 IDC10 IDC10 8CH Opto 22 G4 Carrier module

PC-38G IDC10 IDC10 8CH Electro-Mechanical relay module

PC-38H IDC10 IDC10 8CH Reed relay module

PC-38V IDC10 IDC10 8CH TTL Driver module

PC-38W IDC20 IDC20 16CH TTL Driver module

PC-38X DB25 DB25M/F 24CH TTL Driver module

PC-43B IDC20 IDC20 16CH Opto-Isolated inputs

PC-43C DB25 DB25F/M 24CH Opto-Isolated inputs

PC-43E IDC10 IDC10 8CH Opto-Isolated inputs

Cable Application

IDC10

IDC20

DB25M/F

Opto 22 solid state relay modules

Table 5-3 Digital I/O Application Modules

Omega Engineering Inc. © Copyright 2005 – www.omega.com IV

Page 36

OMET-USB 73 User Manual Data Acquisition

C

C Configuration Constants

C.1 Query Codes

Name Value Description

APIMAJOR 1 Query EDRE API major version number.

APIMINOR 2 Query EDRE API minor version number.

APIBUILD 3 Query EDRE API build version number.

APIOS 4 Query EDRE API OS type.

APINUMDEV 5 Query number of devices installed.

BRDTYPE 10 Query a board’s type.

BRDREV 11 Query a board’s revision.

BRDYEAR 12 Query a board’s manufactured year.

BRDMONTH 13 Query a board’s manufactured month.

BRDDAY 14 Query a board’s manufactured da y.

BRDSERIALNO 15 Query a board’s serial number.

DRVMAJOR 20 Query a driver’s major version number.

DRVMINOR 21 Query a driver’s minor version number.

DRVBUILD 22 Query a driver’s build version number.

ADNUMCHAN 100 Query number of ADC channel.

ADNUMSH 101 Query number of samples-and-hold channels.

ADMAXFREQ 102 Query maximum sampling frequency.

ADBUSY 103 Check if ADC system is busy.

ADFIFOSIZE 104 Get ADC hardware FIFO size.

ADFIFOOVER 105 Check for FIFO overrun condition.

ADBUFFSIZE 106 Check software buffer size.

ADBUFFOVER 107 Check for circular buffer overrun.

ADBUFFALLOC 108 Check if software buffer is allocated.

ADUNREAD 109 Get number of samples available.

ADEXTCLK 110 Get status of external clock line – PCI30FG.

ADEXTTRIG 111 Get status of external trigger line – PCI30FG.

ADBURST 112 Check if burst mode is enabled.

ADRANGE 113 Get ADC range.

DANUMCHAN 200 Query number of DAC channels.

DAMAXFREQ 201 Query maximum DAC output frequency.

DABUSY 202 Check if DAC system is busy.

DAFIFOSZ 203 Get DAC FIFO size.

CTNUM 300 Query number of counter-timer channels.

CTBUSY 301 Check if counter-timer system is busy.

DIONUMPORT 400 Query number of digital I/O ports.

DIOQRYPORT 401 Query a specific port for capabilities.

DIOPORTWIDTH 402 Get a specific port’s width.

INTNUMSRC 500 Query number of interrupts sources.

INTSTATUS 501 Queries interrupt system’s status.

INTBUSCONNECT 502 Connect interrupt system to bus.

INTISAVAILABLE 503 Check if an interrupt is available.

INTNUMTRIG 504 Check number times interrupted

Omega Engineering Inc. © Copyright 2005 – www.omega.com V

Page 37

OMET-USB 73 User Manual Data Acquisition

C.2 Error Codes

Name Value Description

EDRE_OK 0 Function successfully.

EDRE_FAIL -1 Function call failed.

EDRE_BAD_FN -2 Invalid function call.

EDRE_BAD_SN -3 Invalid serial number.

EDRE_BAD_DEVICE -4 Invalid device.

EDRE_BAD_OS -5 Function not supported by operating system.

EDRE_EVENT_FAILED -6 Wait on event failed.

EDRE_EVENT_TIMEOUT -7 Event timed out.

EDRE_INT_SET -8 Interrupt in use.

EDRE_DA_BAD_RANGE -9 DAC value out of range.

EDRE_AD_BAD_CHANLIST -10 Channel list size out of range.

EDRE_BAD_FREQUECY -11 Frequency out of range.

EDRE_BAD_BUFFER_SIZE -12 Data passed by buffer incorrectly sized

EDRE_BAD_PORT -13 Port value out of range.

EDRE_BAD_PARAMETER -14 Invalid parameter value specified.

EDRE_BUSY -15 System busy.

EDRE_IO_FAIL -16 IO call failed.

EDRE_BAD_ADGAIN -17 ADC-gain out of range.

EDRE_BAD_QUERY -18 Query value not supported.

EDRE_BAD_CHAN -19 Channel number out of range.

EDRE_BAD_VALUE -20 Configuration value specified out of range.

EDRE_BAD_CT -21 Counter-timer channel out of range.

EDRE_BAD_CHANLIST -22 Channel list invalid.

EDRE_BAD_CONFIG -23 Configuration invalid.

EDRE_BAD_MODE -24 Mode not valid.

EDRE_HW_ERROR -25 Hardware error occurred.

EDRE_HW_BUSY -26 Hardware busy.

EDRE_BAD_BUFFER -27 Buffer invalid.

EDRE_REG_ERROR -28 Registry error occurred.

EDRE_OUT_RES -29 Out of resources.

EDRE_IO_PENDING -30 Waiting on I/O completion

C.3 Digital I/O Return Query Codes

Name Value Description

DIOOUT 0 Port is an output.

DIOIN 1 Port is an input.

DIOINOROUT 2 Port can be configured as in or out.

DIOINANDOUT 3 Port is an input and an output.

Omega Engineering Inc. © Copyright 2005 – www.omega.com VI

Page 38

OMET-USB 73 User Manual Data Acquisition

D

D Ordering Information

For ordering information please contact Omega Engineering directly or visit our website

www.omega.com.

Device USB

OMET-73T8

OMET-73T16

OMET-73T32

OMET-73R8

OMET-73R16

OMET-73R32

USB

1.1

3 3

3 3

3 3

3 3

3 3

3 3

Description

2.0

8 Channel Thermocouple input device

16 Channel Thermocouple input device

32 Channel Thermocouple input device

8 Channel RTD input device

16 Channel RTD input device

32 Channel RTD input device

Table D-1 OMET-USB-73 Ordering Information

Omega Engineering © Copyright 2002-2004 – www.omega.com

Page 39

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

ARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2005 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

Page 40

M4248/1005

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...