Page 1

MTC SERIES

Multi-Pin Thermocouple Connectors

MADE IN

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

Shop online at

Page 2

OMEGAnet®On-Line Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing

certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains,and

reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Czech Republic:

Frystatska 184, 733 01 Karvina

´, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

Germany/Austria:

Daimlerstrasse 26, D-75392

Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

Servicing Europe:

U.S.A. and Canada:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

U.S.A.: ISO 9001 Certified

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Servicing North America:

For immediate technical or application assistance:

Mexico:

En Espan~ol: (001) 203-359-7803

FAX: (001) 203-359-7807

e-mail: espanol@omega.com

info@omega.com.mx

United Kingdom:

ISO 9002 Certified

One Omega Drive

River Bend Technology Centre

Northbank, Irlam

Manchester M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

Canada:

976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

Page 3

i

Table of Contents

Page

Section 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Section 2 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.1 Multi-Pin Connector Bodies . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.2 Thermocouple Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3 Backshell Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Installing the Thermocouple Contacts . . . . . . . . . . . . . . . . . . 8

3.4.1 Contact Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4.2 Contact Insertion into the Connector . . . . . . . . . . . . . . . . . . 10

3.4.3 Contact Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Page 4

1

SECTION 1 INTRODUCTION

1.1 General Description

The OMEGA®Multi-Pin Thermocouple Connectors provide a sturdy

and efficient means of joining multi-wire thermocouple cables. They

can be used with OMEGA Multipair Extension Cable for rapid,

convenient connection and dismantling of apparatus without handling

individual sensors.

The design utilizes a combination of resilient and rigid dielectric

insulators to eliminate internal air voids and prevent the passage of air

and moisture into or through the connector. Connectors can withstand

ambient temperatures up to 392°F (200°C) contributing to an extended

connector life.

The OMEGA Multi-Pin Thermocouple Connectors do not carry a MIL

spec. number; however, they do meet the performance requirements of

MIL-C 26500E and are intermateable with MIL-C 26500 connectors.

1.2 Features

• Thermocouple alloy pins and sockets

• Air and moisture resistant connection

• Rated to 392°F (200°C)

• Removable crimp contacts

• Accepts 20-24 gage wire

• Aluminum shells

• Black anodized finish

• Threaded coupling

Page 5

2

SECTION 2 UNPACKING

Remove the Packing List and verify that all equipment has been

received. If there are any questions about the shipment, please call

OMEGA Customer Service Department.

Upon receipt of shipment, inspect the container and equipment for any

signs of damage. Take particular note of any evidence of rough handling

in transit. Immediately report any damage to the shipping agent.

NOTE:

The carrier will not honor any claims unless all ship ing

material is saved far their examination. After examining

and removing contents, save packing material and carton in

the event reshipment is necessary

SECTION 3 OPERATION

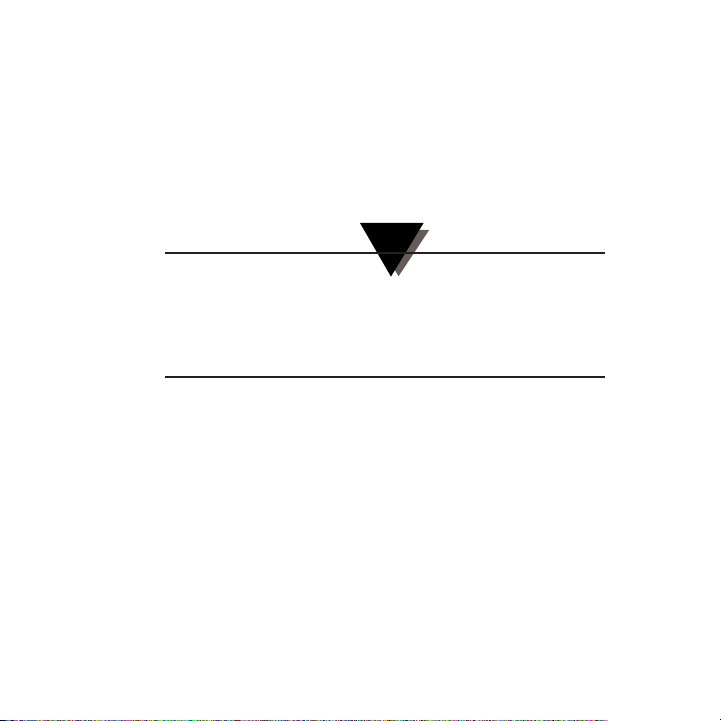

3.1 Multi-Pin Connector Bodies

The contact cavities in the connectors are identified with a spiral guide

line indicating cavity sequence (see Figure 3-1). The first and last

cavities are numbered and every tenth cavity is bracketed. The number

of available cavities are 5, 12, 24, 41, and 55.

Page 6

3

Figure 3-1. Cavity Sequence

Page 7

4

The multi-pin connector bodies come in three styles (plus backshell

cable clamps), MC-male cord, FC-female cord, and FF-female flanged.

A. MC-Male Cord (see Figure 3-2)

In-line cord connectors with threaded couplings. MC style uses

thermocouple alloy pins.

B. Style FC-Female Cord (see Figure 3-3)

In-line cord connectors with threaded couplings. FC style uses

thermocouple alloy sockets.

C. Style FF-Female Flanged (see Figure 3-4)

Rugged flanged body for bulkhead and chassis mounting. It is a

flange mounted receptacle with threaded coupling. FF style uses

thermocouple alloy sockets.

D. Backshell Cable Clamp

Backshell cable clamps provide effective support for the cable at

the male or female connector and prevent twisting and pulling.

3.2 Thermocouple Contacts

The thermocouple contacts must be installed into the multi-pin

connector bodies by the user. Styles FC and FF use the thermocouple

alloy sockets; Style MC uses the thermocouple alloy pins. Pins and

sockets must be matched to thermocouple alloys.

The push-in crimp style contacts are machined from thermocouple

alloy materials and color coded for easy identification. Gold plated

copper (uncompensated) pins and sockets are available for use with

nonthermocouple wire. Sealing plugs are also available to seal unused

positions in lieu of a pin or socket.

Page 8

5

“M” “S” “T” “V”

Number Backshell Coupling Shell Shell

Connector Shell of Clamp Nut Skirt Internal

Body Size Cavities Thread Dia. Dia. Dia.

MTC-5-MC 10 5

9

⁄16-24 UNEF 0.906 0.526 0.444

MTC-12-MC 12 12

3

⁄4-20 UNEF 1.078 0.696 0.614

MTC-24-MC 16 24

15

⁄16-20 UNEF 1.266 0.892 0.810

MTC-41-MC 20 41 13⁄16-18 UNEF 1.510 1.123 1.041

MTC-55-MC 22 55 1

5

⁄16-18 UNEF 1.625 1.248 1.166

Figure 3-2. MC Style Connector

Page 9

6

“M” “R” “S” “T” “Y” “Z”

Number Backshell Coupling Flange Locknut Mounting Mounting

Connector Shell of Clamp Thread Width Flats Hole Hole

Body Size Cavities Thread Dia. Flat

MTC-5-FC 10 59⁄16-24 UNEF11⁄16-24 1.10415⁄16 0.076 0.730

MTC-12-FC 12 123⁄4-20 UNEF7⁄8-24 1.291 11⁄8 0.947 0.917

MTC-24-FC 16 2415⁄16-20 UNEF 11⁄16-18 1.516 15⁄16 1.135 1.105

MTC-41-FC 20 41 13⁄16-18 UNEF 15⁄16-18 1.860 19⁄16 1.385 1.350

MTC-55-FC 22 55 1

5

⁄16-18 UNEF 17⁄16-18 1.954 111⁄16 1.510 1.475

1-3/8 MAX.

1.285

.771

R THREAD M THREAD

1-1/8 MAX. PANEL THICKNESS

.081/.087 SIZES 8 TO 14

.122/.128 SIZES 16 TO 24

Figure 3-3. FC Style Connector

Page 10

7

“M” “R” “S” “T” “Y” “Z”

Number Backshell Coupling FlangeMounting Back Front

Connector Shell of Clamp Thread Width Hole Mounting Mounting

Body Size Cavities Thread Centers Hole Hole

MTC-5-FF 10 59⁄16-24 UNEF11⁄16-24 .937 0.719 0.748 0.572

MTC-12-FF 12 123⁄4-20 UNEF7⁄8-24 1.031 0.812 0.913 0.760

MTC-24-FF 16 2415⁄16-20 UNEF 11⁄16-18 1.250 0.969 1.107 0.948

MTC-41-FF 20 41 13⁄16-18 UNEF 15⁄16-18 1.437 1.156 1.325 1.197

MTC-55-FF 22 55 1

5

⁄16-18 UNEF 17⁄16-18 1.562 1.250 1.452 1.322

.091/.097 SIZES 8 to 14

.122/.128 SIZES 16 TO 24

.125/.116 SIZES 8 to 22

.154/.145 SIZES 24 TO 28

(4) HOLES

1-3/8 MAX. S

S

T

T

1.155

R THREAD M THREAD

Figure 3-4. FF Style Connector

Page 11

8

3.3 Backshell Clamps

(See Figure 3-9, Page 9).

3.4 Installing The Thermocouple Contacts

3.4.1 Contact Termination

Contacts are crimp terminated onto the wire outside the connector

assembly. A specially designed MS standard crimping tool (OMEGA

®

MTC-CT) must be used to properly crimp wires to the pins or sockets.

1. Strip the wire (20 to 24 gage) .170'' to .201''; avoid nicking the wires

or damaging the insulation as it is a functional part of the sealing

system.

2. Insert the stripped wire into the contact pocket until it is visible

through the inspection hole (see Figure 3-6).

3. Fully seat contact in crimp tool positioner.

4. Crimp in one full stroke. (Ratchet action ensures a complete crimp

every time.)

5. Inspect crimp for wire visibility through inspection hole.

Page 12

9

Backshelf Max Max

Clamp Dia. B Length Dia. D Dia. E

MTC-5-SHL

3

⁄4 213⁄8

MTC-12-SHL 1 2 11⁄8

1

⁄2

MTC-24-SHL 11⁄8 21⁄2 11⁄2

5

⁄8

MTC-41-SHL 13⁄8 21⁄2 11⁄2

5

⁄8

MTC-55-SHL 11⁄2 31

5

⁄8

7

⁄8

MTC-5-SHL-A

3

⁄4 2

3

⁄4

1

⁄8

MTC-12-SHL-A 1 2

7

⁄8

3

⁄16

MTC-24-SHL-A 11⁄8 21⁄2 1

5

⁄16

MTC-41-SHL-A 13⁄8 21⁄2 11⁄8

7

⁄16

MTC-55-SHL-A 11⁄2 31

1

⁄8

1

⁄2

LENGTH

DIA. "B"

DIA. "E" DIA. "D"

M THREAD

PER FIGURE 3-2, 3-3, 3-4

SILICONE SEAL CLAMP CAP

BODYO-RING

Figure 3-5. Backshell Clamps

Page 13

10

Figure 3-6. Inserting the Stripped Wire into the Contact

3.4.2 Contact Insertion into the Connector

Once the contacts are property crimped onto the wire, they are inserted

into the appropriate cavity of the connector by means of an insertion

tool (OMEGA’s MTC-IT). Assembly of the contacts into the connector

must be made with reasonable care to avoid damage to the insulation.

1. Lubricate the wire cavities in the back face of insert (on the

connectors) with a very thin film of silicone oil, or equal, before

inserting contacts.

2. Locate contact in insertion tool as shown in Figure 3-7.

3. Align contact with the hole in the rear face of the insert (see Figure

3-8). The alignment of the insertion tool with contact must be

coaxial with the axis of the connector. When the contact has

entered the rear seal portion of the insert, maintain alignment of

contact and tool parallel to and in line with the hole. Insert the

contact to full depth. User will hear contact click-in when seated

fully in retention collet.

4. Remove insertion tool, keeping it aligned with the hole.

Page 14

11

Figure 3-7. Locating Contact into Insertion Tool

Figure 3-8. Aligning Contact

Page 15

12

3.4.3 Contact Removal

A contact is removed from the connector insert with the extraction tool

(OMEGA’s MTC-RT).

1. Set the space sleeve in the proper position for removal of male or

female contact.

2. Place too[ over the contact and insert into the cavity (see Figure

3-9). The alignment of the removal tool with the contact must be

coaxial with the axis of the connector.

3. Exert pressure axially to release retention collet. Spacer sleeve

will shoulder at face of insulation when tool is inserted to proper

depth.

4. Push extraction plunger to force the contact out of the rear of the

insert.

5. Grasp contact or wire at the rear of the insert and pull to

complete extraction.

6. Remove tool axially.

7. After using extraction tool the space sleeve should be set forward

in last notch to protect the end of the plunger guide.

Page 16

13

Figure 3-9. Alignment of Removal Tool

Page 17

14

Notes

1 . MS standard assembly tools are required to properly crimp and

assemble connectors.

2. Match pins and sockets to thermocouple alloys.

Example: A 12 cavity connector carries 6 thermocouple circuits

(pairs) requiring 6 positive alloy pins or sockets, and 6 negative

alloy pins or sockets per connector.

3. Order connectors in mating pairs. Style MC mates with Style FF.

Style MC mates with Style FC.

4. Backshell cable clamps are recommended with each cord style

connector.

Page 18

15

Notes

Page 19

FOR WARRANTY RETURNS, please have the

following information available BEFORE contacting

OMEGA:

1. Purchase Order number under which the

product was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the

latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2006 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or

reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

WARRANTY / DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period

of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to

the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue

an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is

found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

from any action of the purchaser, including but not limited to mishandling, improper interfacing, operation outside of

design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having

been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat,

moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s

control. Components in which wear is not warranted, include but are not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither

assumes responsibility for any omissions or errors nor assumes liability for any damages that result

from the use of its products in accordance with information provided by OMEGA, either verbal or

written. OMEGA warrants only that the parts manufactured by the company will be as specified and

free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND

WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES

INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein

are exclusive, and the total liability of OMEGA with respect to this order, whether based on

contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity,

medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our

basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA

harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING

ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM

OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR

number should then be marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

Page 20

M0192/0306

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor

Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN

AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters

& Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators

& Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition &

Engineering Software

䡺⻬

Communications-Based

Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM

& Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater

Treatment

䡺⻬

pH, Conductivity & Dissolved

Oxygen Instruments

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

Loading...

Loading...