Page 1

MPS11

Melting Point Apparatus

®

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

Shop online at

omega.com

®

User’s Guide

®

MADE IN UNITED KINGDOM

Page 2

Servicing North America:

U.S.A.: OMEGA Engineering, Inc.

ISO 9001 Certified One Omega Drive

P.O. Box 4047

Stamford, CT 06907-0047 USA

Toll-Free: 1-800-826-6342 TEL: (203) 359-1660

FAX: (203) 359-7700 e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec), H7L 5A1 Canada

Toll-Free: 1-800-826-6342 TEL: (514) 856-6928

FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 /1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico/ En Español: 001 (203) 359-7803 FAX: 001 (203) 359-7807

Latin America info@omega.com.mx e-mail: espanol@omega.com

Servicing Europe:

Benelux: Managed by the United Kingdom Office

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184

733 01 Karviná, Czech Republic

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

FAX: +420-59-6311114 e-mail: info@omegashop.cz

France: Managed by the United Kingdom Office

Toll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26

D-75392 Deckenpfronn, Germany

Toll-Free: 0800 6397678 TEL: +49 (0) 7056 9398-0

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

United Kingdom: OMEGA Engineering Ltd.

ISO 9001 Certified

One Omega Drive, River Bend Technology Centre, Northbank

Irlam, Manchester M44 5BD United Kingdom

Toll-Free: 0800-488-488 TEL: +44 (0) 161 777-6611

FAX: +44 (0) 161 777-6622 e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

®

Page 3

Version 1.1

Melting Point

Apparatus

SMP11

Instructions for use

Mode d’emploi

Istruzioni per uso

Instrucciones de funcionamiento

Gebrauchsanweisung

Scientific

heating rate ºC/min

10

Page 4

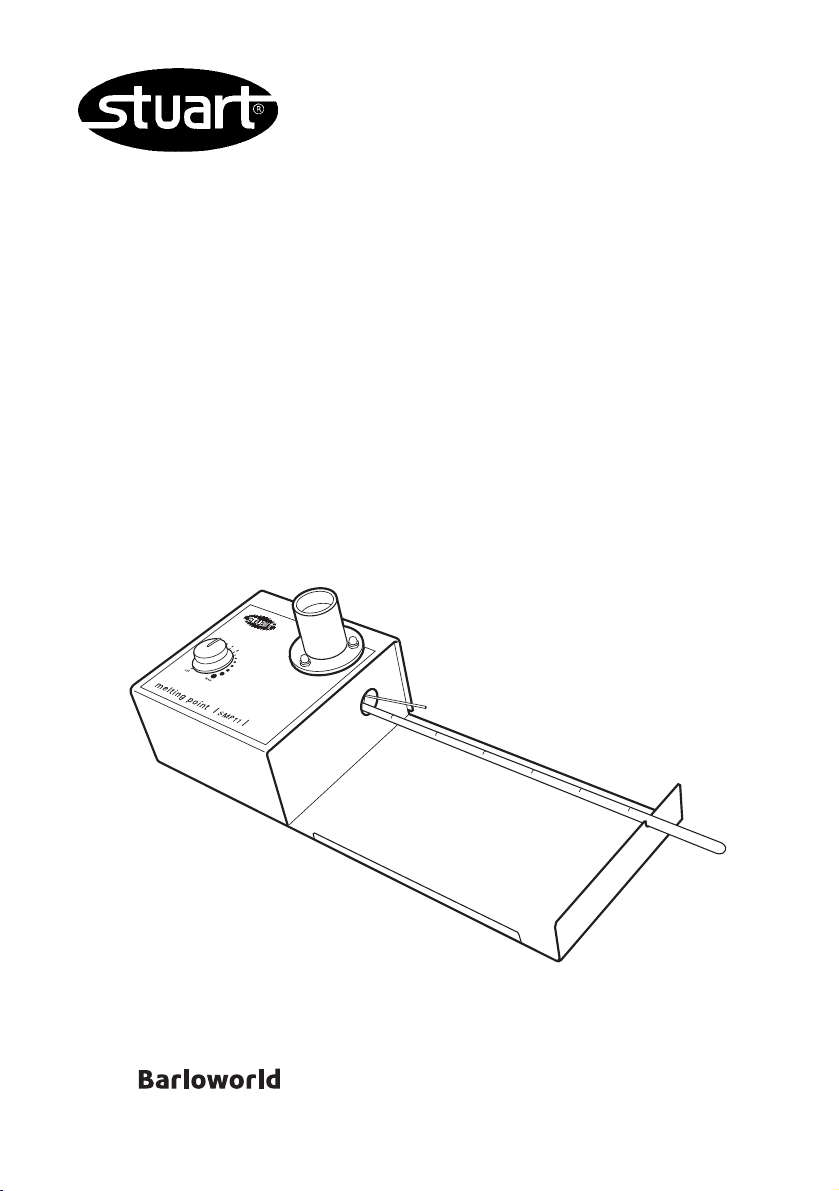

English

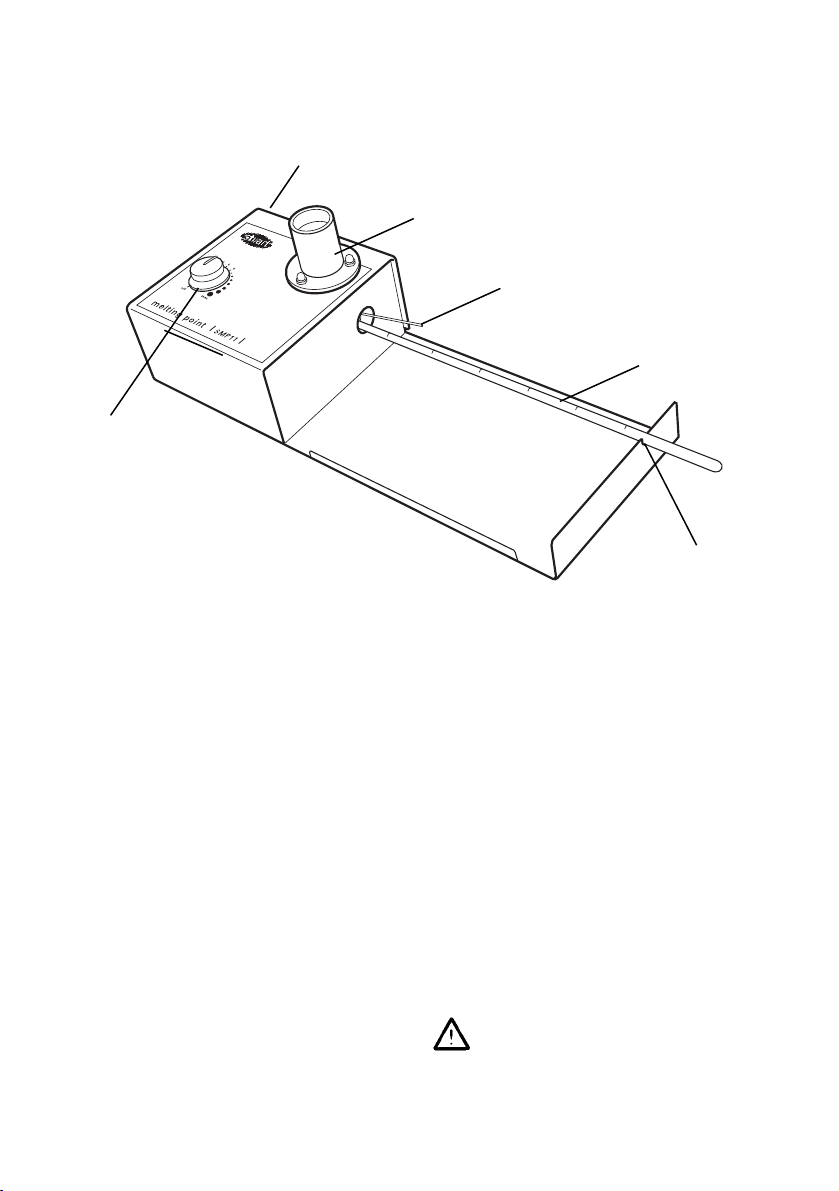

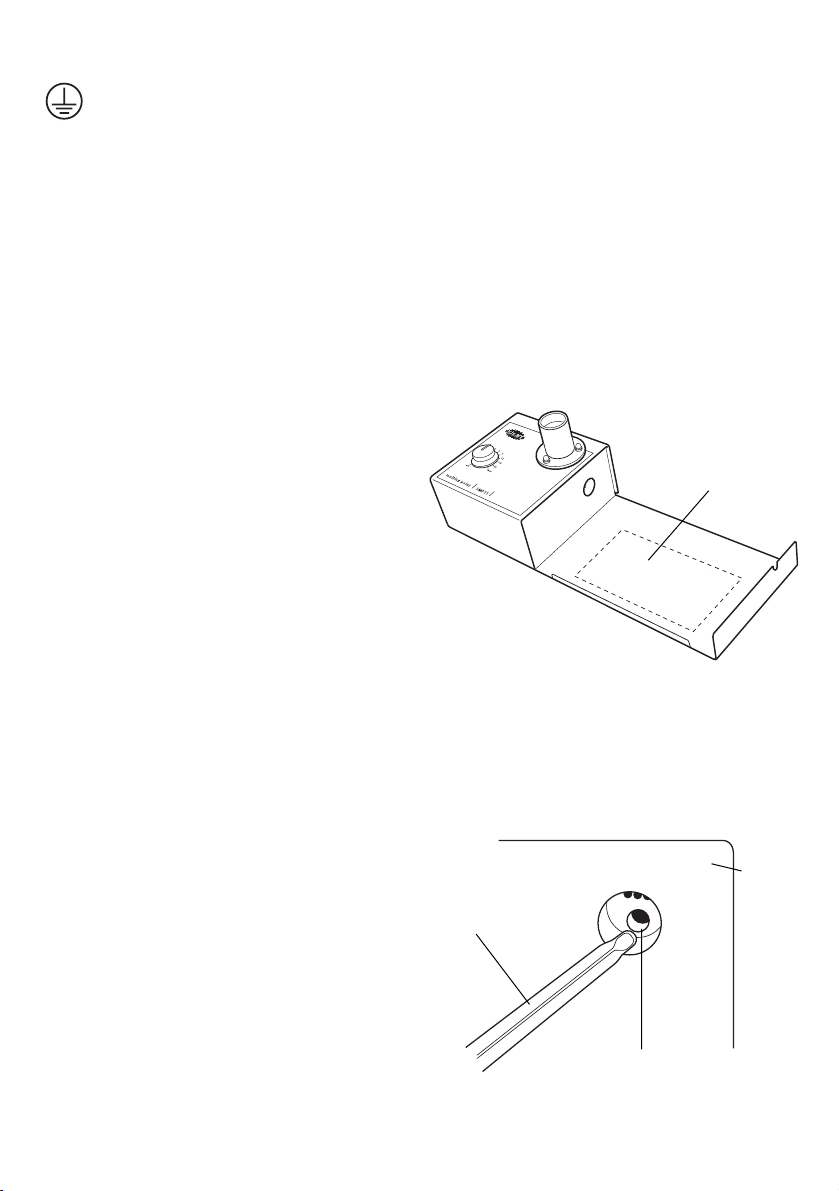

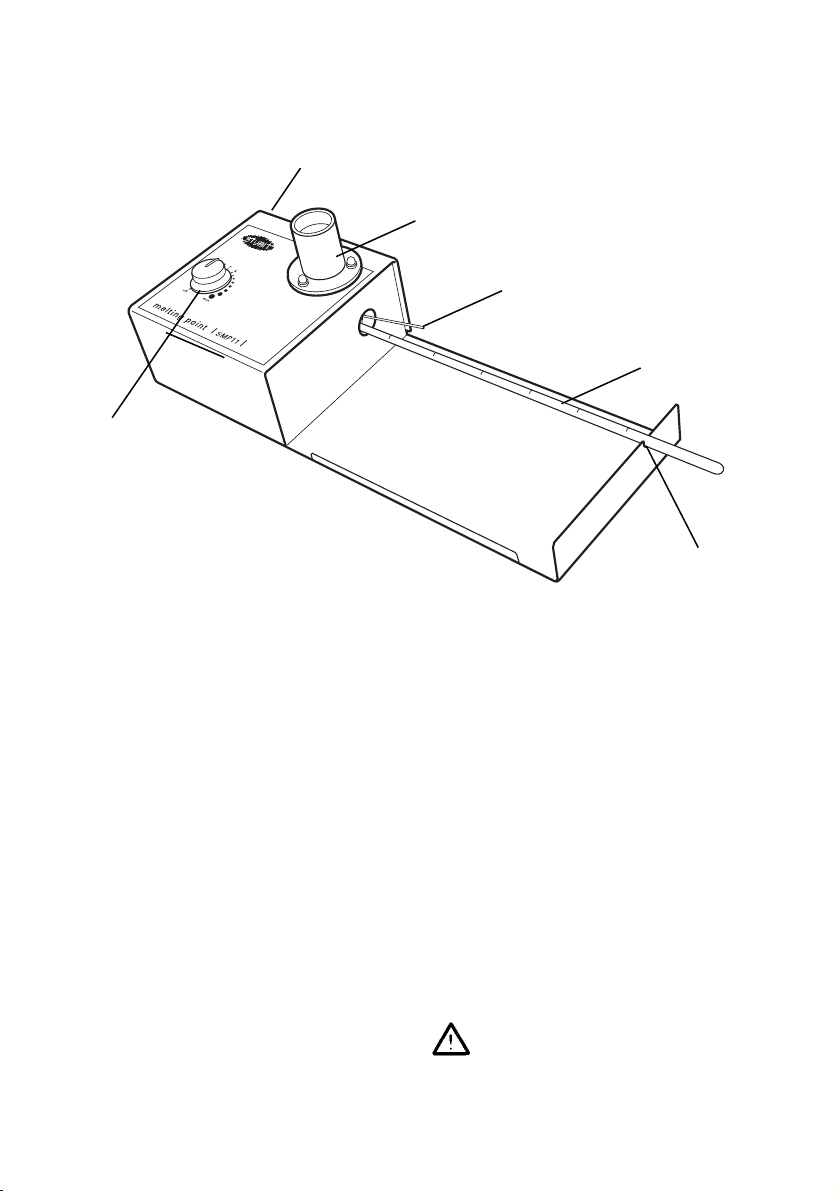

Capillary tube

Heating controller

Thermometer

support

Thermometer

IEC connector

Lens

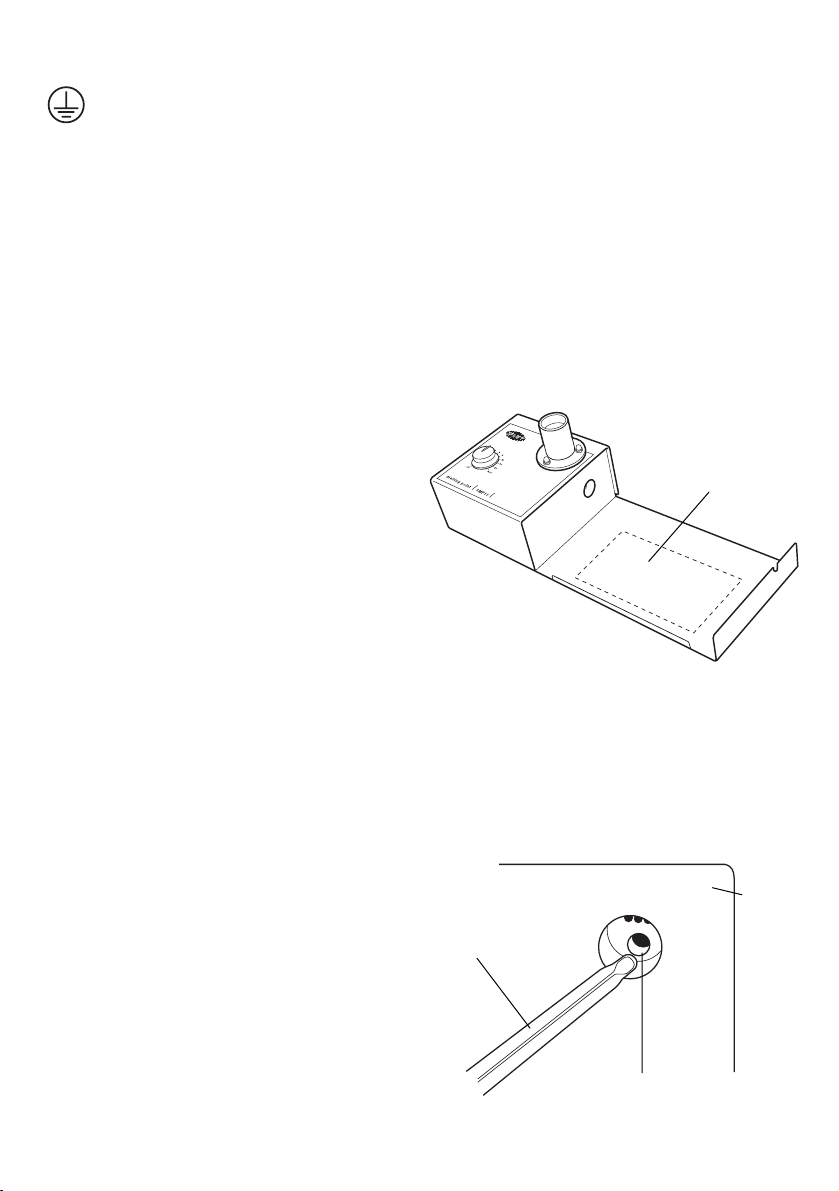

Fig 1

MELTING POINT

APPARATUS

SMP11

Thank you for purchasing this Stuart product.

To get the best performance from the

equipment, and for your own safety, please read

these instructions carefully before use. (For an

illustration of the controls, see Fig 1).

Safety advice before use

This equipment is designed to operate under the

following conditions: -

❖ For indoor use only

❖ Use in a well ventilated area

❖ Ambient temperature +5°C to +40°C

❖ Altitude to 2000m

❖ Relative humidity not exceeding 80%

❖ Mains supply fluctuation not >10%

❖ Overvoltage category II IEC60364-4-443

❖ Pollution degree 2 IEC664

❖ Use with a minimum distance all around of

200mm from walls or other items

If the equipment is not used in the manner

described in this manual the protection

provided by the equipment may be

impaired.

heating rate ºC/min

10

Page 5

1

Electrical installation

THIS EQUIPMENT MUST BE EARTHED

Before connection please ensure that the line

supply corresponds to that stated on the rating

label. Power consumption is 50W.

There is an IEC socket at the rear on the left

hand side of the instrument for connection to

the mains supply, (see figure 1). The unit is

supplied with two mains leads fitted with IEC

plugs for connection to the instrument. One has

a U.K. 3 pin plug and the other has a 2 pin

“Shuko” plug for connection to the mains

supply. Choose the lead appropriate for your

electrical installation and discard the other.

Should neither lead be suitable you should

obtain a moulded lead locally. If this is not

possible, take the lead with the U.K. plug and

replace the plug with a suitable alternative. See

the enclosed instruction sheet for advice on how

to carry out this procedure.

Should the mains lead require replacement a

cable of 1mm

2

of harmonized code H05V V-F

connected to an IEC 320 plug should be used.

N.B. The UK mains lead is protected by a 10A

fuse mounted in the plug top.

The mains lead should be connected to the

instrument BEFORE connection to the mains

supply.

IF IN DOUBT CONSULT A QUALIFIED

ELECTRICIAN

General description

The sample for the melting point test is placed in

a capillary tube and inserted in to the aluminium

block inside the heater. Using the manually

adjustable heating rate, the SMP11 will rapidly

heat samples up to 20°C per minute to the melt

temperature and up to the maximum

temperature of 250°C. An accurate reading to

within 1°C of the melt temperature can be

achieved by using a slower heating rate of

between 1 and 10°C per minute. The sample is

observed through the magnifying lens until the

melt occurs and the melt temperature read from

the thermometer.

Before use

1. The SMP11 is supplied in custom-made

packaging; it is recommended that the

instrument should be kept in this packaging

between uses to maintain it in optimum

condition.

2. (First time only) Once the unit is unpacked,

select the appropriate choice of self adhesive

instruction label from the multi-language set

provided. Peel off the backing and stick the

label onto the large recessed metal area on

the right side of the SMP11 (see Fig 2).

Apply the label carefully using a flat object to

smooth away air bubbles.

Instructions for

use

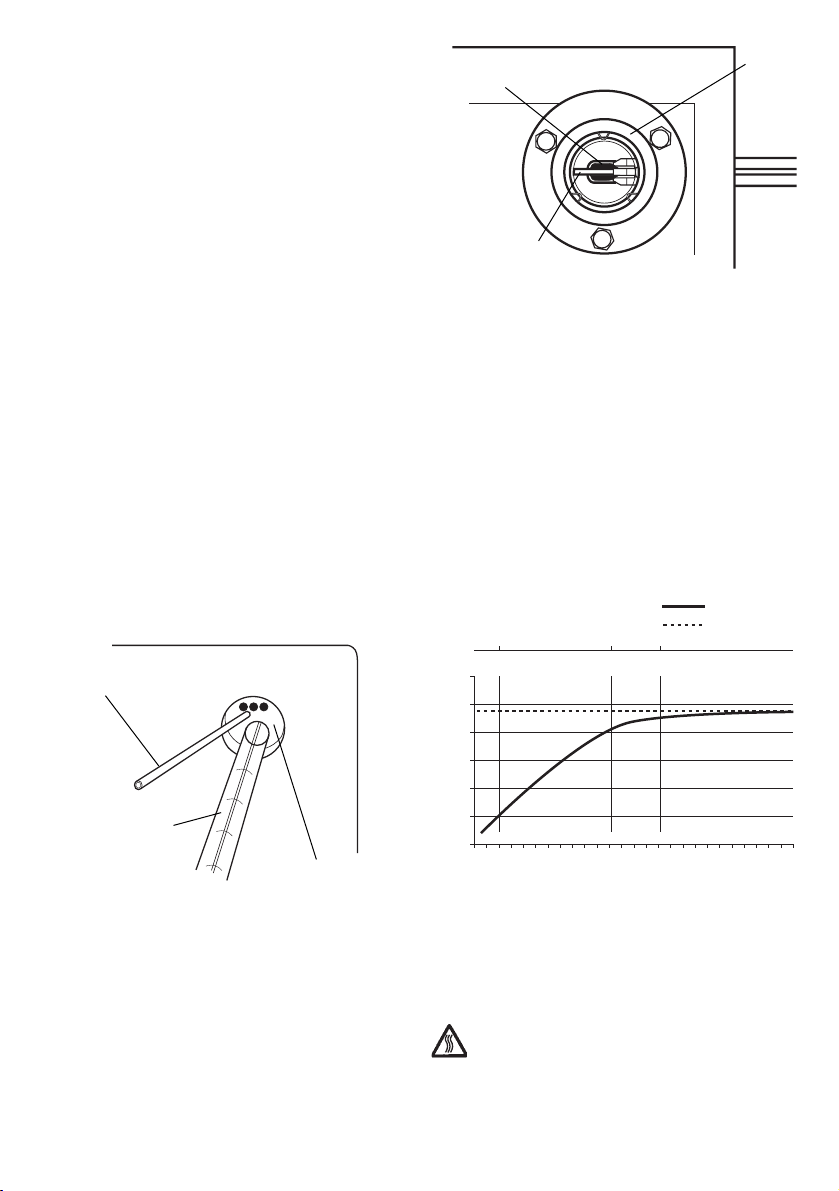

Fig 2

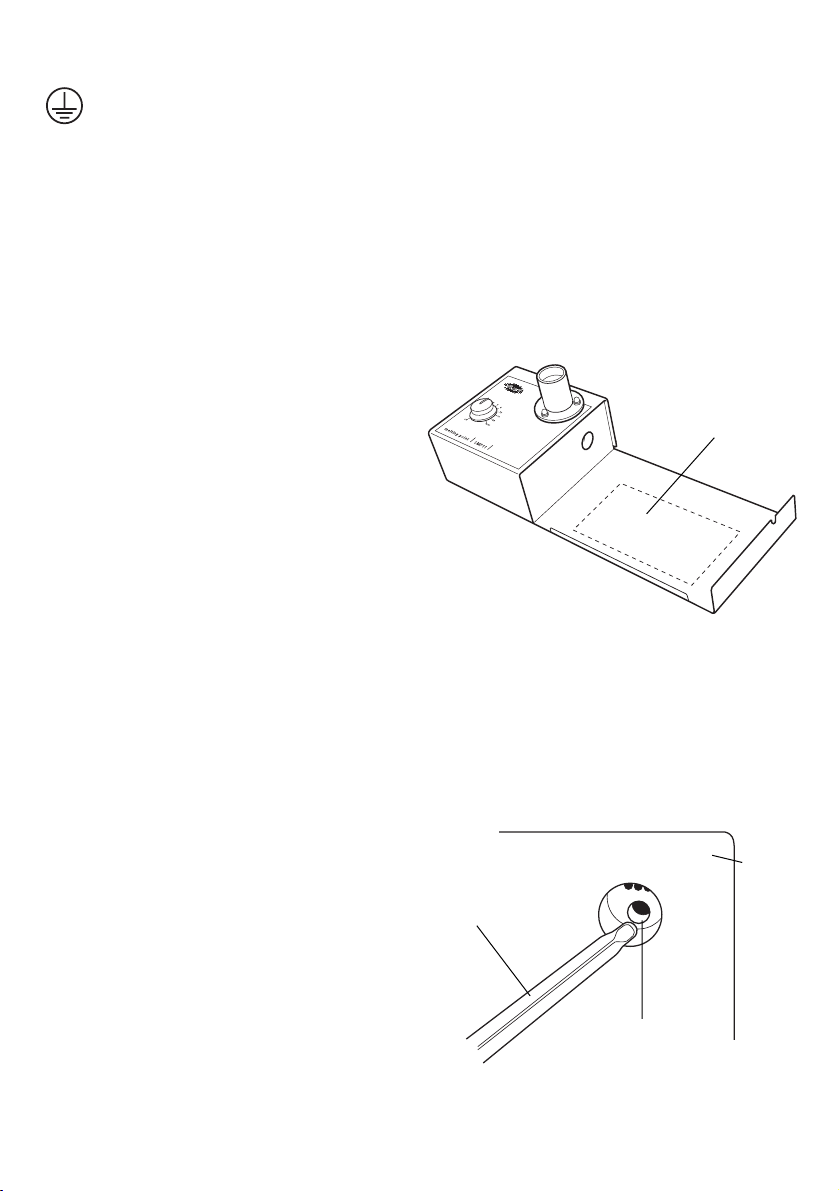

Fig 3

3. Place the unit on a firm, level surface.

4. Insert the bulb of the non-toxic spirit filled

thermometer into the side of the heating

block (see Fig 3), while resting the other end

in the slot on the right hand side.

Thermometer

Heating block

SMP11

Page 6

Measuring a melting point

N.B. If the unit has been used recently the block

may be too hot for your sample. If this is the case

turn the apparatus off and allow the unit to cool

before proceeding. An optional brass cold finger

(ref. SMP1/2) can be inserted into the

thermometer hole; this has the effect of drawing

heat out of the heating block and so considerably

reduces the cooling time.

1. The SMP11 is supplied with a pack of 1.9mm

open-ended capillary tubes. It is recommended

that one end of the tubes should be sealed

with a Bunsen burner flame, by a fully trained

person, prior to use. Alternatively a pack of

capillary tubes that have been sealed on one

end can be purchased from your Stuart

stockist (ref. SMP10/1).

2. Place a small amount of your powdered

sample into the end of a 1.9mm diameter

glass capillary tube.

3. Insert the capillary tube into the side of the

heating block via the holes provided (see Fig

4). A maximum of 3 capillary tubes can be

inserted at any one time.

4. Look down the lens and position the tube so

that the sample can be observed clearly

(see Fig 5).

2

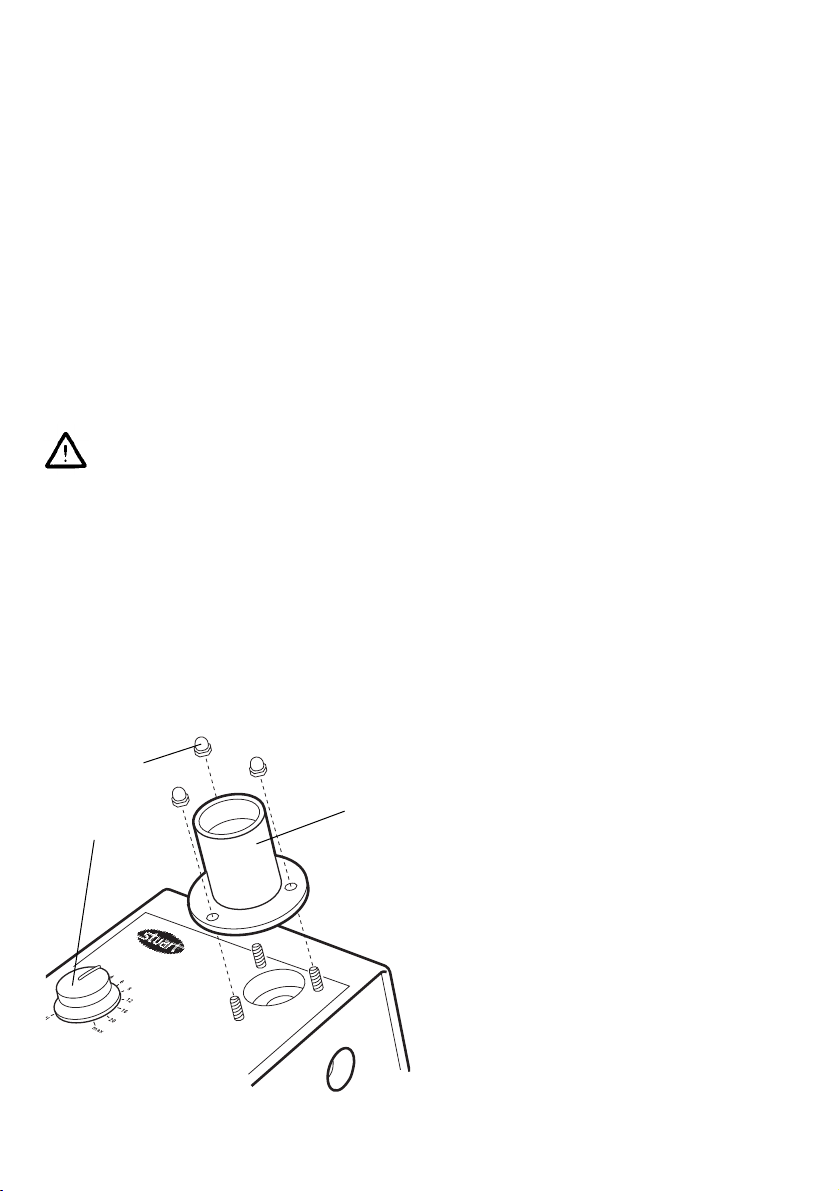

Fig 4

Fig 6

Thermometer

Heating block

Thermometer

Capillary tube

Capillary tube

5. It is assumed that the approximate melting

point range is known, if not a rough run may

be required to gauge the approximate range.

6. In order to achieve a fast and accurate

melting point range it is important to use a

rapid heating rate as the sample heats up

from ambient and a much reduced heating

rate as the sample approaches melt, see Fig

6 for an ideal heating curve for a sample

with a melting point of 240°C.

Fig 5

0

100

150

200

250

300

50

02468101214161820222426

Time (min)

Temperature °C

Max 10°C/min 1°C/min

Dial settings

Block temperature

Melting point

Ideal heating curve

7. Connect to the mains electricity supply.

8. Start by heating the sample at the maximum

rate by setting the heating controller to max.

Lens

Caution: The heating block may be HOT.

Page 7

9. Once the thermometer reaches 60% of the

expected melting point the heating controller

should be reduced to 10°C/min, by turning

the heating controller anti-clockwise.

10. Continue to reduce the heating controller so

that it is on 1°C/min when the sample is

within 15°C of the expected melt.

11. Observe the melt through the eyepiece,

while recording the temperature on the

thermometer; make a note of the melt

temperature.

12. Turn off to begin cooling, or insert the

accessory brass insert to speed up cooling.

Cleaning & Servicing

WARNING: Ensure the unit is

disconnected from the mains electricity

supply and allowed to cool before

attempting any cleaning or servicing.

Cleaning

Periodically clean the instrument using a damp

cloth and mild detergent solution. Do not use

harsh or abrasive cleaning agents.

In the event of any breakage of the thermometer

bulb or capillary tubes disconnect the unit from

the mains supply. Any debris can be removed

simply by unscrewing the dome nuts holding the

3

lens and then lifting the lens out (see Fig 7). The

instrument can then be turned upside down so

that any debris falls out. Once the lens has been

removed the chamber can be cleaned with a

damp cloth or a soft brush.

Servicing

This unit does NOT require routine servicing.

Repairs

There are no user replacement parts on this

instrument. If this unit were to stop working or

malfunction in any way, only suitably qualified

personnel should investigate the problem. Prior

to any internal repairs being undertaken a

service manual should be requested from the

Technical Service Department of Barloworld

Scientific Ltd. quoting both the model and serial

number of your product.

NB: Fuses are mounted in both the live and

neutral line.

Only spare parts supplied or specified by

Barloworld Scientific Ltd. or its agents should be

used. Fitting of non-approved parts may affect

the performance and safety features designed

into the instrument.

If in any doubt, please contact the Technical

Dept. of Barloworld Scientific or the point of

sale.

Barloworld Scientific Ltd.

Stone, Staffordshire ST15 0SA

United Kingdom

Tel: +44 (0) 1785 812121

Fax: +44 (0) 1785 813748

e-mail equipment@barloworld-scientific.com

www.barloworld-scientific.com

Fig 7

Lens

Dome nuts

Heating

controller

Page 8

4

Warranty

Barloworld Scientific Ltd warrants this instrument

to be free from defects in material and

workmanship, when used under normal

laboratory conditions, for a period of three (3)

years. In the event of a justified claim,

Barloworld Scientific will replace any defective

component or replace the unit free of charge.

This warranty does NOT apply if damage is

caused by fire, accident, misuse, neglect,

incorrect adjustment or repair, damage caused

by installation, adaptation, modification, fitting

of non-approved parts or repair by unauthorized

personnel.

Technical Specification

Number of samples Three

Temperature range Ambient to 250°C

Heating rates 1°C to a max of 20°C/min

Dimensions (WxDxH) 370 x 140 x 110 mm

Net weight 1.7 Kg

Electrical supply

SMP11 230V, 50/60Hz, 50W

SMP11/100V/60 100V, 50/60Hz, 50W

SMP11/120V/60 120V, 50/60Hz, 50W

Spares / Accessories

SMP11/1 Spare spirit filled thermometer,

0 to 250°C.

SMP1/2 Brass cooling plug

SMP1/4 Melting point tubes (open both ends)

SMP2/1 Melting point tubes (sealed both ends)

SMP10/1 Melting point tubes (sealed a one end)

Page 9

5

Français

Tube capillaire

Régulation du

chauffage

Support du

thermomètre

Thermomètre

Connecteur IEC

Loupe

Fig 1

APPAREIL A POINT DE

FUSION

SMP11

Merci d’avoir acheté ce produit Stuart. Pour tirer

les meilleures performances de cet appareil, et

pour votre propre sécurité, veuillez lire

attentivement ces instructions avant utilisation

(pour une illustration des commandes, voir Fig.

1).

Conseils de sécurité avant

utilisation

Cet appareil est conçu pour fonctionner dans les

conditions suivantes : -

❖ Utilisation uniquement en intérieur

❖ Utilisation dans un endroit bien ventilé

❖ Température ambiante +5°C à +40°C

❖ Altitude jusqu’à 2000 m

❖ Humidité relative ne dépassant pas 80%

❖ Variation du secteur ne dépassant pas 10%

❖ Catégorie surtension II IEC60364-4-443

❖ Degré de pollution 2 IEC664

❖ Utilisation à une distance minimale de 200

mm de toute paroi ou autre élément

Toute utilisation de cet appareil d’une

façon non décrite dans ce manuel peut

altérer la protection intrinsèque de

l’appareil.

heating rate ºC/min

10

Page 10

6

Installation électrique

CET APPAREIL DOIT ETRE RELIE A LA

TERRE.

Avant de connecter l’appareil, vérifier que

l’alimentation délivrée par le secteur correspond

à celle précisée sur l’étiquette d’identification. La

consommation électrique est de 50 W.

L’appareil possède une prise IEC à l’arrière du

côté gauche pour le raccordement au secteur

(voir figure 1). L’appareil est alimenté par deux

cordons d’alimentation équipés de fiches IEC

pour la connexion de l’appareil. Un des cordons

possède une fiche U.K. à 3 broches et l’autre

une fiche à 2 broches “Shuko” pour le

raccordement au secteur. Choisir le cordon

correspondant à son alimentation électrique et

mettre l’autre de côté.

Si aucun câble ne correspond, se procurer

localement un cordon moulé. Si cela est

impossible, prendre le cordon avec la fiche U.K.

et remplacer la fiche par un dispositif approprié.

Se reporter à la fiche d’instructions jointe pour

des conseils sur la procédure à suivre.

Si le cordon d’alimentation doit être remplacé,

utiliser un câble de 1mm

2

du code harmonisé

H05V V-F connecté à une fiche IEC 320.

N.B. Le cordon d’alimentation UK est protégé

par un fusible de 10 A installé sur le dessus de la

fiche.

Connecter le cordon d’alimentation sur l’appareil

AVANT de le raccorder au secteur.

EN CAS DE DOUTE, CONSULTER UN

ELECTRICIEN QUALIFIE.

Description générale

L'échantillon pour le test portant sur le point de

fusion est placé dans un tube capillaire et inséré

dans le bloc en aluminium à l'intérieur du

réchauffeur. A l'aide de la commande manuelle

de réglage de chauffage, le SMP11 chauffe

rapidement les échantillons jusqu'à 20°C par

minute, pour atteindre une température

maximale de 250°C. Une lecture précise à une

marge d'1°C de la température de fusion peut

être obtenue en utilisant une vitesse de

chauffage inférieure comprise entre 1 et 10°C

par minute. L'échantillon est observé à travers

d'une part une loupe grossissante jusqu'à ce que

la fusion se produise, et d'autre part la lecture de

la température de fusion à partir du

thermomètre.

Instructions

d’utilisation

Fig 2

Fig 3

Thermomètre

Bloc chauffant

SMP11

Avant utilisation

1. Le SMP11 est livré dans un emballage

spécialement adapté ; nous conseillons de

conserver l’appareil dans cet emballage entre

deux utilisations pour le conserver dans un

état optimal.

2. (Première utilisation uniquement) Lorsque

l’appareil est déballé, choisir l’étiquette

d’instructions adhésive appropriée parmi le

choix de langues. Décoller l’arrière et coller

l’étiquette sur la grande zone métallique

creuse du côté droit du SMP11 (voir Fig. 2).

Appliquer délicatement l’étiquette à l’aide

d’un objet plat pour lisser et chasser les

bulles d’air.

3. Placer l’appareil sur une surface plane et

solide.

4. Insérer le bulbe du thermomètre à alcool non

toxique dans le côté du bloc chauffant (voir

Fig. 3), tout en faisant reposer l’autre

extrémité dans l’encoche du côté droit.

Page 11

7

Mesure d’un point de

fusion

N.B. Si l’appareil a été utilisé récemment, le bloc

peut être trop chaud pour l’échantillon. Dans ce

cas, éteindre l’appareil et le laisser refroidir avant

de continuer. Un cylindre de refroidissement en

laiton optionnel (réf. SMP1/2) peut être inséré

dans le trou du thermomètre ; ceci a pour effet

d’extraire la chaleur hors du bloc chauffant et de

raccourcir considérablement le temps de

refroidissement.

1. Le SMP11 est livré avec un paquet de tubes

capillaire de 1,9 mm à extrémités ouvertes. Il

est conseillé de faire sceller par une personne

formée une des extrémités des tubes à l’aide

d’un bec Bunsen avant utilisation. Il est

également possible d’acheter un paquet de

tubes capillaires déjà fermés à une extrémité

auprès d’un distributeur de Stuart (réf.

SMP10/1).

2. Placer une petite quantité de l’échantillon en

poudre dans l’extrémité du tube capillaire en

verre de 1,9 mm de diamètre.

3. Insérer le capillaire dans le côté du bloc

chauffant dans les trous prévus (voir Fig. 4).

3 capillaire maximum peuvent être insérés en

une seule fois.

Fig 4

Fig 6

Thermomètre

Thermomètre

Loupe

Tube capillaire

Tube capillaire

Fig 5

0

100

150

200

250

300

50

02468101214161820222426

Temps (min)

Température °C

Max 10°C/min 1°C/min

Block température

Point de fusion

Courbe de chauffage idéale

4. Observer à travers la loupe et positionner le

tube pour que l’échantillon puissent être

clairement observé (voir Fig. 5).

5. La plage approximative du point de fusion

est supposée connue; sinon, un test rapide

peut être nécessaire pour estimer la plage

approximative.

6. Pour atteindre une plage de point de fusion

rapide et précise, il est important d’utiliser

une vitesse de montée en température

rapide lorsque l’échantillon est chauffé à

partir de la température ambiante, et une

vitesse plus faible lorsque l’échantillon

approche de la fusion. Voir Fig. 6 pour une

courbe de chauffage idéale pour un

échantillon de point de fusion de 240°C.

7. Raccorder l’appareil au secteur.

8. Démarrer en chauffant l’échantillon à la

puissance maximale en réglant le régulateur

de chauffage sur max.

Block chauffant

Attention: Le bloc de chauffage peut

être CHAUD

Page 12

9. Lorsque le thermomètre atteint 60% du

point de fusion estimé, réduire le régulateur

de chauffage sur 10°C/min, en tournant le

régulateur de chauffage dans le sens antihoraire.

10. Continuer à réduire le régulateur jusqu’à ce

qu’il atteigne 1°C/min lorsque l’échantillon

est à 15°C de sa fusion attendue.

11. Contempler la fusion à travers l’oculaire, tout

en observant la température affichée par le

thermomètre ; noter la température de

fusion.

12. Eteindre pour commencer le refroidissement,

ou insérer l'accessoire en laiton pour

accélérer le refroidissement.

Nettoyage et entretien

ATTENTION : vérifier que l’appareil est

déconnecté du secteur et le laisser refroidir

avant d’entreprendre toute action de

nettoyage ou d’entretien.

Nettoyage

Nettoyer périodiquement l’appareil à l’aide d’un

chiffon humide et d’une solution de détergent

doux. Ne pas utiliser de nettoyants durs ou

abrasifs.

En cas de bris du bulbe du thermomètre ou de

tubes capillaires, déconnecter l’appareil du

secteur. Retirer simplement tous les débris en

dévissant les écrous en dôme maintenant la

loupe et en soulevant la loupe pour la retirer

(voir Fig. 7). L’appareil peut à présent être

retourné pour faire tomber tous les débris endehors. Une fois la loupe retirée, il est possible

de nettoyer la chambre avec un chiffon humide

ou une brosse souple.

Entretien

Cet appareil ne nécessite PAS d’entretien de

routine.

Réparations

Cet appareil ne possède aucune pièce

remplaçable par l’utilisateur. Si cet appareil ne

fonctionne plus ou mal d’une façon ou d’une

autre, seules des personnes convenablement

qualifiées sont autorisées à rechercher le

problème. Avant d’entreprendre toute réparation

interne, demander un manuel d’entretien au

Service Technique de Barloworld Scientific Ltd. en

précisant le modèle et le numéro de série du

produit.

NB : les fusibles sont installés sur la ligne sous

tension et le neutre.

Utiliser uniquement les pièces de rechange

fournies ou spécifiées par Barloworld Scientific

Ltd. ou ses agents. L’installation de pièces non

agréées peut affecter les performances et la

sécurité intrinsèques de l’appareil.

En cas de doute, contacter le Service Technique

de Barloworld Scientific ou le point de vente.

Barloworld Scientific France SAS

ZI du Rocher Vert - BP 79

77793 Nemours Cedex

France

Tél: +33 1 64 45 13 13

Fax: +33 1 64 45 13 00

e-mail: bibby@bibby-sterilin.fr

8

Fig 7

Loupe

Ecrous en

dôme

Régulateur

de

chauffage

Page 13

Garantie

Barloworld Scientific Ltd. garantit que cet

appareil est exempt de tout de défaut de

matériaux et de transformation, s’il est utilisé

dans les conditions normales de laboratoire,

pendant une période de trois (3) ans. En cas de

demande justifiée, Barloworld Scientific

remplacera tout composant défectueux ou

remplacera l’appareil gratuitement.

Cette garantie ne s’applique PAS si les

dommages sont le résultat d’un incendie,

accident, mauvaise utilisation, négligence,

réglage incorrect ou réparation, si les dommages

sont causés par une mauvaise installation,

adaptation, modification, mise en place de

pièces non agréées ou réparation par une

personne non habilitée.

Spécifications techniques

Nombre d’échantillons Trois

Gamme de température Ambiante à 250°C

Montée en température

1°C jusqu'à un maximum

de 20°C/min.

Dimensions (LxPxH) 370 x 140 x 110 mm

Poids net 1,7 Kg

Alimentation

SMP11 230 V, 50/60 Hz, 50W

SMP11/100V/60 100 V, 50/60 Hz, 50W

SMP11/120V/60 120 V, 50/60 Hz, 50W

Pièces de rechange / Accessoires

SMP11/1 Thermomètre à alcool de rechange,

0 à 250°C

SMP1/2 Cylindre de refroidissement en laiton

SMP1/4 Tubes pour point de fusion

(ouverts aux deux extrémités)

SMP2/1 Tubes pour point de fusion

(fermés aux deux extrémités)

SMP10/1 Tubes pour point de fusion

(fermés à une extrémité)

9

Page 14

10

Italiano

Tubo capillare

Regolazione

riscaldamento

Supporto

termometro

Te rmometro

Connettore IEC

Oculare

Fig 1

APPARECCHIO PER PUNTO

DI FUSIONE

SMP11

Congratulazioni per l’acquisto di questo prodotto

Stuart. Per ottenere le migliori prestazioni da

questo apparecchio e per garantire la sicurezza

dell’operatore, si consiglia di leggere

attentamente le istruzioni prima dell’uso.

(I componenti sono illustrati in Fig. 1)

Avvertenze di sicurezza

prima dell’uso

Questo prodotto è stato progettato per operare

nelle seguenti condizioni: -

❖ Da utilizzare soltanto in ambienti chiusi

❖ Utilizzare in ambienti ben ventilati

❖ Temperatura ambiente da +5°C a +40°C

❖ Altitudine fino a 2000m

❖ Umidità relativa non superiore a 80%

❖ Oscillazioni di tensione di alimentazione non

superiori a 10%

❖ Categoria di sovratensione II IEC60364-4-443

❖ Livello di inquinamento 2 IEC664

❖ Utilizzare a una distanza minima di 200 mm

da pareti o altri oggetti su tutti i lati.

L’utilizzo dell’apparecchio in maniere

diverse da quelle descritte nel presente

manuale può compromettere le misure di

protezione adottate.

heating rate ºC/min

10

Page 15

Installazione elettrica

QUESTO APPARECCHIO DEVE ESSERE

COLLEGATO A TERRA

Prima di procedere con il collegamento, verificare

che l’alimentazione elettrica di rete corrisponda

ai valori prescritti nella targhetta dati

dell’apparecchio. Potenza assorbita: 50W.

Sul lato posteriore sinistro dell’apparecchio è

presente una presa IEC per il collegamento

all’alimentazione elettrica di rete (v. Fig. 1).

L’apparecchio è fornito con due cavi di

alimentazione di rete dotati di spine a norma

IEC. Un cavo è dotato di spina GB a 3 spinotti e

l’altro è dotato di una spina di tipo Shuko a 2

spinotti, per il collegamento all’alimentazione di

rete. Scegliere il cavo adatto alla propria

situazione e smaltire l’altro cavo.

Nel caso che nessuno dei cavi sia adatto,

ottenere localmente una spina adatta di tipo

termofuso. Se questa soluzione non dovesse

essere possibile, sostituire la spina sul cavo di

tipo britannico con una spina adatta alle proprie

esigenze. Per informazioni su come eseguire

questa procedura, fare riferimento al foglio di

istruzioni allegato.

Nel caso sia necessaria la sostituzione del cavo di

rete, utilizzare cavo da 1mm

2

codice armonizzato

H05V V-F con una spina IEC 320.

N.B. Nel Regno Unito, la spina di alimentazione è

protetta con un fusibile da 10A, montato

all’interno della spina stessa.

Collegare sempre il cavo di alimentazione

all’apparecchio PRIMA di inserire la spina nella

presa di corrente di rete.

IN CASO DI DUBBI, RIVOLGERSI A UN

ELETTRICISTA QUALIFICATO

Generalità

Il campione per la determinazione del punto di

fusione viene collocato all'interno di un tubo

capillare e inserito nel blocchetto in alluminio

all'interno del riscaldatore. Grazie alla

regolazione manuale della rampa di incremento

di temperatura, il modello SMP11 può riscaldare

rapidamente il campione fino a raggiungere il

punto di fusione, con tassi di incremento di

temperatura fino a 20 °C al minuto e una

temperatura massima di 250 °C. Una misura

accurata della temperatura di fusione, con una

precisione di 1 °C, può essere ottenuta

utilizzando un tasso di incremento della

temperatura più lento, compreso fra 1 e 10 °C al

minuto. Il campione viene osservato tramite il

lentino di ingrandimento. Al verificarsi della

fusione, la temperatura potrà essere letta

sull'apposito termometro.

Prima dell’uso

1. Il modello SMP11 è fornito in un imballo

specifico. Si raccomanda di conservare lo

strumento in questo imballo quando non in

uso per mantenerlo in condizioni ottimali.

2. (Solo primo utilizzo) Dopo aver disimballato

l’apparecchio selezionare l’etichetta di

istruzioni adesiva desiderata dal set

multilingua fornito. Rimuovere il dorso di

protezione e applicare l’etichetta sull’area

metallica incavata sul lato destro dello

strumento (v. Fig. 2). Applicare l’etichetta con

attenzione, utilizzando un oggetto piatto per

eliminare eventuali bolle d’aria.

11

Istruzioni per uso

Fig 2

3. Collocare l’apparecchio su di una superficie

piana e robusta.

4. Inserire il bulbo del termometro ad alcool

non tossico nel foro ricavato sul lato del

blocchetto di riscaldamento (v. Fig. 3) e

appoggiarne l’altra estremità nella

scanalatura sulla destra dell’apparecchio.

Page 16

12

Fig 3

Te rmometro

Blocchetto di

riscaldamento

SMP11

Misura del punto di

fusione

N.B. Se l’apparecchio è stato appena utilizzato, la

temperatura del blocchetto può essere troppo

elevata per il campione da misurare. In questo

caso, spegnere l’apparecchio e attenderne il

raffreddamento prima di procedere con la

misura. Eventualmente, inserire l’apposita

barretta in ottone (accessorio opzionale rif.

SMP1/2) nel foro del termometro per facilitare

l’estrazione di calore dal blocchetto di

riscaldamento e accelerare notevolmente il

tempo necessario per il raffreddamento.

1. L’apparecchio SMP11 è fornito con un

pacchetto di tubi capillari da 1,9 mm con le

estremità aperte. Si raccomanda di sigillare

un’estremità dei tubi utilizzando un becco

Bunsen prima dell’uso. Tale operazione dovrà

essere realizzata da una persona

debitamente addestrata. Alternativamente, è

possibile acquistare confezioni di tubi capillari

presigillati presso il proprio rivenditore Stuart

(rif. SMP10/1).

2. Collocare una piccola quantità di campione

polverizzato all’interno dell’estremità di un

tubo capillare in vetro da 1,9 mm di

diametro.

3. Inserire il tubo capillare nel lato del

blocchetto di riscaldamento tramite gli

appositi fori (v Fig. 4). È possibile inserire fino

a 3 tubi capillari contemporaneamente.

4. Servendosi dell’oculare di ispezione, collocare

il tubo nella posizione più adatta a garantire

l’osservazione ottimale del campione (v.

Fig.5).

Fig 4

Te rmometro

Blocchetto di

riscaldamento

Te rmometro

Oculare

Tubo capillare

Tubo capillare

Fig 5

5. Si suppone che il punto di fusione

approssimativo sia in linea di massima

conosciuto. In caso contrario, può essere

necessario effettuare una prova per

determinare la temperatura approssimata.

6. Per ottenere una misura del punto di fusione

rapida e accurata è importante utilizzare un

incremento di temperatura piuttosto rapido

durante la prima fase del riscaldamento del

campione dall’ambiente, rallentando quindi

l’incremento quando la temperatura del

campione si approssima alla temperatura di

fusione. La Fig. 6 illustra la curva di

riscaldamento ideale per un campione con

punto di fusione di 240°C.

Page 17

13

Fig 6

0

100

150

200

250

300

50

02468101214161820222426

Tempo (min)

Temperatura °C

Massimo 10°C/min 1°C/min

Temperatura

Punto di fusione

Curva di riscaldamento ideale

7. Collegare l’apparecchio alla rete di

alimentazione elettrica.

8. Cominciare a riscaldare il campione alla

velocità di incremento massima, impostando

su massimo il regolatore di riscaldamento.

9. Quando la temperatura indicata dal

termometro raggiunge il 60% del punto di

fusione previsto, ridurre la velocità di

riscaldamento a 10 °C/min ruotando il

regolatore in senso antiorario.

10. Continuare a ridurre la velocità di

riscaldamento in maniera che si trovi su

1 °C/min quando la temperatura del

campione è a 15 °C dalla temperatura

prevista di fusione.

11. Osservare la fusione tramite l’oculare e

registrare la temperatura indicata dal

termometro annotando la temperatura di

fusione.

12. Spegnere l'apparecchio per iniziare il

raffreddamento, inserendo eventualmente

l'apposito accessorio in ottone per accelerare

il raffreddamento.

Pulizia e manutenzione

AVVERTENZA: Assicurarsi che

l’apparecchio sia scollegato

dall’alimentazione elettrica prima di

procedere con qualsiasi operazione di

pulizia o manutenzione.

Pulizia

Pulire regolarmente l’apparecchio usando un

panno inumidito con una soluzione di

detergente non aggressivo. Non utilizzare

prodotti per la pulizia abrasivi o aggressivi.

In caso di rottura del bulbo del termometro o del

tubo capillare, scollegare l’apparecchio

dall’alimentazione elettrica. Tutti i residui

possono essere rimossi semplicemente svitando i

dadi a cappellotto che assicurano l’oculare e

rimuovendo quindi l’oculare dalla sua sede (v.

Fig. 7). Rovesciare lo strumento per far cadere

tutti i residui. Dopo aver rimosso l’oculare, pulire

la camera con un panno umido o un pennello o

spazzolino morbido.

Fig 7

Oculare

Dadi a

cappellotto

Regolazione

riscaldamento

Manutenzione

Questo apparecchio non richiede particolari

interventi di assistenza.

Attenzione: il blocco potrebbe essere

già caldo!

Page 18

Specifiche tecniche

Numero di campioni Tre

Campo di temperatura: Da ambiente a 250°C

Velocità di riscaldamento: Da 1°C fino a un

massimo di 20°C/min

Dimensioni (LxPxA) 370 x 140 x 110 mm

Peso netto 1,7 Kg

Alimentazione elettrica

SMP11 230V, 50/60Hz, 50W

SMP11/100V/60 100V, 50/60Hz, 50W

SMP11/120V/60 120V, 50/60Hz, 50W

Ricambi / Accessori

SMP11/1 Termometro ad alcool di ricambio,

0 ~ 250°C.

SMP1/2 Barretta di raffreddamento in ottone

SMP1/4 Tubetti per punto di fusione

(aperti alle due estremità)

SMP2/1 Tubetti per punto di fusione

(chiusi alle due estremità)

SMP10/1 Tubetti per punto di fusione

(chiusi a un’estremità)

Riparazioni

Lo strumento non contiene componenti

sostituibili dall’utilizzatore. In caso di

malfunzionamento o guasto, affidare l’esame

dell’apparecchio unicamente a personale

qualificato. Prima di procedere con eventuali

interventi di riparazione di componenti interni

richiedere il corrispondente manuale di assistenza

dal Dipartimento di Assistenza Tecnica di

Barloworld Scientific Ltd indicando modello e

numero di serie dell’apparecchio.

NB: Sia la fase che il neutro sono dotati di

fusibili.

Utilizzare unicamente parti di ricambio fornite o

specificate da Barloworld Scientific Ltd. o suoi

agenti. L’installazione di parti non approvate può

compromettere il funzionamento adeguato e le

funzioni di sicurezza dello strumento.

In caso di dubbi, rivolgersi al Dipartimento di

Assistenza Tecnica di Barloworld Scientific o al

rivenditore.

Barloworld Scientific Italia Srl

Via Alcide de Gasperi 56

20077 Riozzo di Cerro al Lambro

Milano Italia

Tel: +39 (0)2 98230679

Fax: +39 (0)2 98230211

e-mail: marketing@barloworld-scientific.it

www.barloworld-scientific.it

Garanzia

Barloworld Scientific Ltd garantisce che questo

strumento è esente da difetti di materiali e

lavorazione, se usato in normali condizioni di

laboratorio, per un periodo di tris (3) anni. In

caso di richiesta giustificata, Barloworld Scientific

sostituirà qualsiasi componente difettoso o

l’apparecchio gratuitamente.

La presente garanzia NON si applica in caso di

danni causati da incendio, incidente, uso

improprio, negligenza, regolazione o riparazione

incorretta, danni causati da installazione,

adattamento, modifica, installazione di parti non

approvate o riparazione realizzate da personale

non autorizzato.

14

Page 19

15

Tubo capilar

Controlador de

velocidad de

calentamiento

Soporte para el

termómetro

Te rmómetro

Conector corriente

Lente

Fig 1

Espanol

~

PUNTO DE FUSION

SMP11

Gracias por adquirir este producto de Stuart.

Para obtener las mayores prestaciones del

equipo, y para su seguridad, por favor leerse

cuidadosamente las intrucciones antes de usarlo

(ver ilustración de los controles en fig 1).

Consejos de seguridad

antes de uso.

Este equipo está diseñado sólo para operar en

las siguientes condiciones.-

❖ Uso en locales cerrados, no a la intemperie.

❖ Uso en areas ventiladas

❖ Temperatura ambiente: +5°C a +40°C

❖ Altitud de 2000 m.

❖ Humedad relativa no excederá del 80%

❖ Máxima fluctuación de la corriente >10%

❖ Voltaje categoría II IEC60364-4-443

❖ Grado de interferencias 2 IEC664

❖ Dejar alrededor del equipo al menos una

distancia de seguridad de 200 mm.

Si el equipo no se utiliza bajo las

condiciones descritas en este manual, la

protección de seguridad utilizada en el

aparato puede no funcionar

adecuadamente.

heating rate ºC/min

10

Page 20

Instalacion eléctrica.

ESTE EQUIPO DEBE CONECTARSE A UNA

TOMA DE TIERRA.

Antes de conectar el instrumento a la red,

asegurarse que la tensión es la correcta. Potencia

consumida 50W.

En la parte posterior del instrumento está la

conexión IEC para el cable de corriente (ver fig

1). Esta unidad se suministra con dos cables, uno

con clavija inglesa, y otro con la “Shuko”

Europea, escoger la más apropiada dependiendo

del pais donde se encuentre. Si tiene otro tipo de

clavija, utilice el cable inglés para adaptar su tipo

corrrespondiente, o adquiera otro cable con

clavija IEC 320, teniendo en cuenta que se

requiere al menos 1 m de cable de al menos

1mm

2

de sección.

El cable inglés incorpora un fusible de 10 A en la

propia clavija.

La conexión IEC del cable debe conectarse al

instrumento ANTES de ser enchufado a la

corriente eléctrica.

SI TIENE CUALQUIER DUDA, CONSULTE A UN

ELECTRICISTA CUALIFICADO.

Descripción General

La muestra para la prueba de punto de fusión se

coloca en un tubo capilar y se introduce en el

bloque de aluminio, en el interior del calentador.

La SMP11 utilizará el índice de calentamiento

ajustable manualmente y calentará rápidamente

las muestras hasta 20°C por minuto, hasta la

temperatura de fusión, y hasta una temperatura

máxima de 250°C. Es posible obtener una

lectura exacta con un margen de 1°C de la

temperatura de fusión si se utiliza un índice de

calentamiento más lento, entre 1 y 10°C por

minuto. La muestra se puede observar con la

lupa hasta que se produce la fusión y se lee la

temperatura del termómetro.

Antes de usarse.

1. El punto de fusión SMP11 se suministra en

un embalaje que puede utilizarse

posteriormente entre usos, como protección

suplementaria.

2. (Primera vez sólo) Después de desembalarlo,

escoger la pegatina de las instrucciones

autoadhesivas de su idioma, y pegarla en el

lugar apropiado (ver fig 2). Aplicar la

pegatina con cuidado de no dejar ninguna

burbuja en la superficie, utilizando si es

preciso un objeto plano como alisador.

16

Pegatina de

instrucciones en

el idioma

correspondiente

Fig 2

3. Colocar la unidad en una superficie firme y

plana.

4. Insertar el bulbo del termómetro (de material

no tóxico) dentro del orificio en la parte del

bloque de calentamiento, y descansar el otro

extremo del termómetro en la parte derecha,

en la hendidura corespondiente.

Fig 3

Te rmómetro

Bloque de

calentamiento

SMP11

Page 21

Medida del punto de

fusión.

NOTA DE SEGURIDAD. Si la unidad ha sido

utilizada hace poco, el bloque de calentamiento

interno puede estar demasiado caliente para la

muestra y fundirla prematuramente. En este

caso, desconectar el aparato y dejar que se

enfrie, utilizando si es necesario el accesorio de

enfriamiento opcional (ref. SMP1/2) que se

coloca en el orificio del termómetro.

1. El modelo SMP11 se suministra con una caja

de capilares de 1,9 mm Ø con los dos

extremos abiertos; para el uso debe cerrarse

uno de los extremos con un mechero

bunsen, por una persona entrenada.

Alternativamente puede adquirirse una caja

de capilares cerrados por un extremo (Ref

SMP10/1)

2. Colocar una pequeña cantidad de muestra

pulvurenta o cristalina dentro del capilar

(cerrado por un extremo), poner una

cantidad que no ocupe más de 2 a 3 mm de

altura de capilar.

3. Colocar el capilar ya lleno de muestra, dentro

de uno de los tres orificios del bloque de

calefacción, (ver fig 4).

5. Se asume que normalmente se conoce el

punto de fusión de la muestra, si no es así

deberá realizarse una curva rápida para

determinar el valor aproximado.

6. Para conseguir un rápido y preciso punto de

fusión se aconseja realizar la primera parte

del calentamiento con rampa rápida, hasta

aproximarse al valor que se supone está el

punto de fusión, (ver Fig. 6, para una curva

teórica de determinación de un punto de

fusión a 240ºC).

17

Fig 4

Te rmómetro

Bloque de

calefacción

Te rmómetro

Lupa

Tubo capilar

Tubo capilar

Fig 5

4. Comprobar a través de la lupa de

observación, que la posición, tanto del

termó-metro como de los capilares es similar

a la indicada en la fig 5.

Fig 6

0

100

150

200

250

300

50

02468101214161820222426

Tiempo (min)

Temperatura °C

Máx 10°C/min 1°C/min

Temperatura

Punto di fusión

Curva ideal de

calentamiento

7. Conectar el instrumento a la corriente.

8. Iniciar el calentamiento de la muestra con la

velocidad máxima de calentamiento máx.

(botón al máximo en sentido horario).

AVISO: El bloque de muestras puede

estar caliente.

Page 22

9. Cuando el termómetro indique un 60% del

punto de fusión esperado, cambiar la

velocidad de calentamiento a 10ºC/min

girando el botón de calentamiento en

sentido anti-horario.

10. Continuar reduciendo la velocidad de

calentamiento a 1ºC/min, cuando la

temperatura se acerque 15ºC por debajo del

valor esperado.

11. Observar a través de la lupa, la muestra del

capilar, hasta que se note que se funde,

entonces anotar el valor que marca el

termómetro.

12. Desconecte el equipo para iniciar el

enfriamiento o inserte la pieza de bronce

accesoria para acelerar el enfriamiento.

Limpieza & Mantenimiento

PELIGRO: Asegurarse que la unidad está

desconectada, y fría para realizar cualquier

limpieza o mantenimiento.

Limpieza

Limpiar periodicamente el intrumento, utilizando

un paño de algodón y una solución de

detergente neutro. NO utilizar estropajos ni

agentes limpiadores abrasivos.

En el supuesto de rotura del bulbo del

termómetro o capilares, desconectar de la

corriente la unidad, y proceder a limpiar en

interior, extrayendo los tres tornillos del soporte

de las lentes de la lupa (ver fig 7). El instrumento

puede ponerse boca abajo, para sacar los restos

de vidrio o capilares. Posteriormente puede

limpiarse con un paño suave el interior o las

lentes.

18

Fig 7

Lentes

Roscas ciegas

Controlador de

velocidad de

calentamiento

Mantenimiento

Esta unidad NO requiere ningún mantenimiento

rutinario

Reparaciones

Si la unidad no calienta o se detecta un

problema de mal funcionamiento, sólo personal

cualificado debe investigar el problema. Si se

precisa cualquier pieza interna, dirigirse

directamente al Departamento de Asistencia

Técnica de Barloworld Scientific, facilitando el

número de serie del instrumento.

Nota: Se han colocado fusibles tanto en la linea

de fase como en el neutro.

Sólo pueden usarse piezas originales de

recambio, suministradas por Bibby-Sterilin o sus

agentes autorizados. Colocar piezas no

diseñadas para el intrumento, puede afectar a

las prestaciones del instrumento. Para cualquier

duda, ponerse en contacto con el Departamento

Técnico de Barloworld Scientific, o su agente

autorizado más próximo.

Afora S.A.

Calle Aribau 240

08006 Barcelona

Spain

Tel: +343 93-306 98 00

Fax: +343 93-306 98 23

e-mail: marketing@afora.com

www.afora.com

Page 23

19

Garantía

Barloworld Scientific Ltd garantiza que este

equipo está libre de defectos en el material y la

fabricación cuando se utiliza en condiciones

normales de laboratorio durante un período de

tres (3) años. En caso de una reclamación

justificada, Barloworld Scientific sustituirá los

componentes defectuosos o toda la unidad sin

cargo alguno.

Esta garantía NO cubre los daños ocasionados

por incendio, accidente, uso incorrecto,

negligencia, ajuste o reparación incorrectos,

daños producidos por la instalación, adaptación,

modificación, montaje de piezas no autorizadas

o reparación efectuada por personal no

autorizado.

Especificaciones Técnicas

Número de muestras Tres

Rango de Temperatura Ambiente a 250°C

Velocidades de

calentamiento 1°C hasta un máximo

de 20°C/min

Dimensiones (AnxFxAl) 370 x 140 x 110 mm

Peso Neto 1.7 Kg

Suministro eléctrico

SMP11 230V, 50/60Hz, 50W

SMP11/100V/60 100V, 50/60Hz, 50W

SMP11/120V/60 120V, 50/60Hz, 50W

Recambios / Accesorios

SMP11/1 Termómetro de recambio,

0 to 250°C x 1ºC

SMP1/2 Accesorio de enfriamiento

SMP1/4 Paquete de tubos capilares

(abiertos ambos lados)

SMP2/1 Paquete de tubos capilares

(cerrados ambos lados)

SMP10/1 Paquete de tubos capilares

(un lado cerrado)

Page 24

20

SCHMELZPUNKTBESTIMMUNGSGERÄT

SMP11

Wir bedanken uns für den Kauf dieses Stuart

Produkts. Lesen Sie bitte vor dem Gebrauch

diese Bedienungsanleitung gründlich durch, um

das Gerät optimal nutzen zu können. (Eine

Darstellung der Bedienelemente finden Sie in

Abb. 1).

Sicherheitshinweise vor

dem Einsatz

Dieses Gerät ist für den Einsatz unter folgenden

Bedingungen ausgelegt:

❖ Nur für den Gebrauch in Innenräumen

❖ Für gute Durchlüftung des Raums sorgen

❖ Umgebungstemperatur zwischen

+5° C und +40° C

❖ Höhe: bis zu 2000 m

❖ Relative Feuchte nicht über 80%

❖ Netzspannungsschwankungen nicht über 10%

❖ Überspannungsklasse 2 IEC 6O364-4-443

❖ Verschmutzungsgrad 2 IEC664

❖ Auf einen Mindestabstand von 200 mm zu

Wänden bzw. anderen Geräten achten

Wenn das Gerät nicht entsprechend der

Bedienungsanleitung eingesetzt wird,

können die Schutzfunktionen des Gerätes

beeinträchtigt werden.

Deutsch

Kapillarröhrchen

Heizungsregler

Thermometerhalterung

Thermometer

IEC-Stecker

Lupe

Abb. 1

heating rate ºC/min

10

Page 25

Elektrischer Anschluss

DIESES GERÄT MUSS GEERDET WERDEN

Vor dem Anschluss bitte kontrollieren, ob die

Stromversorgung den Angaben auf dem

Typenschild entspricht. Die Stromaufnahme

beträgt 50 W.

Auf der Geräterückseite befindet sich eine

Europa-Steckdose für den Anschluss des

Netzkabels (siehe Abbildung 1). Das Gerät wird

mit zwei Netzkabeln mit unterschiedlichen

Steckern geliefert. Das eine Kabel besitzt einen

3-poligen Stecker für Großbritannien, während

das andere Kabel mit einem zweipoligen SchukoStecker ausgerüstet ist. Wählen Sie das für Ihren

Standort geeignete Kabel und entsorgen Sie das

andere. Sollten beide Kabel nicht passen,

nehmen Sie bitte das Kabel mit dem GB- Stecker

und schließen Sie den entsprechenden neuen

Stecker an. Dazu muss der angespritzte Stecker

abgeschnitten werden. Dann das Kabel für den

neuen Stecker passend machen und diesen

entsprechend den beiliegenden Anweisungen

anschließen.

Bei einem eventuellen Austausch des Netzkabels

wird ein Kabel vom Typ H05V V-F mit 1mm

2

Adernquerschnitt und Europastecker (IEC 320)

benötigt.

Hinweis: Das GB-Netzkabel ist durch eine 10 A

Sicherung im Stecker selbst geschützt.

Das Kabel muss zuerst am Gerät eingesteckt

werden BEVOR der Anschluss an die

Stromversorgung erfolgt.

IM ZWEIFELSFALL EINEN ELEKTROFACHMANN HINZUZIEHEN

Allgemeine Beschreibung

Die für den Schmelzpunkttest verwendete Probe

wird in einem Kapillarröhrchen platziert und in

den Aluminiumblock im Heizgerät eingeführt.

Das SMP11 heizt die Proben bei einer manuell

einstellbaren Heizrate von bis zu 20°C pro

Minute schnell auf die Schmelztemperatur und

bis zur maximalen Temperatur von 250°C auf.

Eine auf ±1°C exakte Anzeige der

Schmelztemperatur kann unter Verwendung

einer langsameren Heizrate zwischen 1 und 10°C

pro Minute erreicht werden. Die Probe wird bis

zum Schmelzen durch die Vergrößerungslinse

beobachtet, und die Schmelztemperatur wird auf

dem Thermometer abgelesen.

Vor dem Gebrauch

1. Das SMP11 wird in einer speziellen

Verpackung geliefert. Bitte bewahren Sie das

Gerät während des Nichtgebrauchs in dieser

Verpackung auf um einen optimalen Zustand

des Geräts zu gewährleisten.

2. (Für den erstmaligen Einsatz). Nach dem

Auspacken des Geräts wählen Sie bitte das

entsprechende Selbstklebeetikett aus dem

mitgelieferten mehrsprachigen Set aus. Folie

auf der Rückseite abziehen und das Etikett

auf die große Aussparung der

Metalloberfläche rechts am Gerät aufkleben

(siehe Abb. 2). Das Etikett mit einem flachen

Gegenstand so aufdrücken, das keine

Luftblasen verbleiben.

21

Bedienungsanleitung

Abb. 2

3. Das Gerät auf einer festen, ebenen

Oberfläche aufstellen.

4. Den Kolben des giftfreien Thermometers

seitlich in den Heizblock einschieben (siehe

Abb. 3). Das andere Ende des Thermometers

liegt auf der Halterung auf.

Page 26

Messung des

Schmelzpunkts

Hinweis: Falls das Gerät erst vor kurzem

gebraucht wurde, kann es sein, dass der

Heizblock für die nächste Probe zu heiß ist. In

diesem Fall das Gerät ausschalten und zunächst

abkühlen lassen. Um die Abkühlung zu

beschleunigen kann der wahlweise erhältliche

Messing-Kühlfinger (Nr. SMP1/2) kann in die

Thermometeröffnung eingesetzt werden.

1. Das SMP11 wird mit einer Packung beidseitig

offener Kapillarröhrchen (1,9 mm) geliefert.

Wir empfehlen, das Röhrchenende mit einem

Bunsenbrenner vor dem Gebrauch einseitig

zu versiegeln (darf nur durch erfahrenes

Personal erfolgen). Alternativ können

einseitig verschlossene Kapillarröhrchen auch

über Ihrem Stuart Händler bestellt werden

(Nr. SMP10/1).

2. Eine kleine Menge der pulverförmigen Probe

in das 1,9 mm Kapillarröhrchen eingeben.

3. Das Kapillarröhrchen in eine der seitlichen

Öffnungen am Heizblock einsetzen (siehe

Abb. 4). Es können maximal bis zu 3

Kapillarröhrchen gleichzeitig eingesetzt

werden.

4. In die Lupe hineinschauen und das Röhrchen

so verschieben, dass die Probe gut zu sehen

ist (siehe Abb. 5).

22

Abb. 3

Thermometer

Heizblock

SMP11

Abb. 4

Thermometer

Heizblock

Thermometer

Lupe

Kapillarröhrchen

Kapillarröhrchen

Abb. 5

5. Es wird vorausgesetzt, dass der ungefähre

Schmelzpunktbereich bekannt ist.

6. Um den Schmelzpunktbereich schnell und

präzise bestimmen zu können, muss die

Probe zunächst schnell auf Temperatur

gebracht werden, um dann bei Annäherung

an den Schmelzpunkt eine weitaus niedrigere

Heizrate zu verwenden (Abb. 6 zeigt die

ideale Erhitzungskurve für eine Probe mit

einem Schmelzpunkt von 240°C).

Page 27

7. Gerät am Netz anschließen.

8. Die Probe zunächst so schnell wie möglich

erhitzen, indem der Heizungsregler auf max.

eingestellt wird.

9. Sobald das Thermometer 60% des zu

erwartenden Schmelzpunkts erreicht, den

Heizungsregler durch Drehen nach links auf

10°C/Min. drosseln.

10. Den Heizungsregler weiter drosseln, sodass

ein Wert von 1°C/Min. erreicht wird, wenn

der zu erwartende Schmelzpunkt der Probe

innerhalb von 15°C liegt.

11. Die Schmelzung durch die Lupe beobachten

und die auf dem Thermometer angezeigte

Schmelzpunkttemperatur notieren.

12. Schalten Sie das Gerät aus, um den

Abkühlungsprozess zu beginnen, oder

schieben Sie den als Zubehör erhältlichen

Messingeinsatz ein, um eine beschleunigte

Abkühlung zu erreichen.

Reinigung und Wartung

ACHTUNG: Vor allen Reinigungs- und

Wartungsarbeiten das Gerät vom Netz

trennen und abkühlen lassen.

23

Reinigung

In regelmäßigen Abständen das Gerätegehäuse

mit einem feuchten Tuch und einem milden

Reinigungsmittel säubern. Keine starken oder

scheuernden Reinigungsmittel verwenden.

Bei einem Bruch des Thermometers oder der

Kapillarröhrchen das Gerät vom Netz trennen.

Die Bruchstücke können leicht entfernt werden

indem die Hutmuttern der Lupe gelöst werden

um dann die Lupe herauszuziehen (siehe Abb. 7).

Abb. 6

0

100

150

200

250

300

50

024681012 14 16 18 20 22 24 26

Zeit (min)

Temperatur °C

Max 10°C/min 1°C/min

Temperatur

Schmelzpunkt

Ideale Erhitzungskurve

Abb. 7

Lupe

Hutmuttern

Heizungsregler

Das Gerät nun umdrehen, sodass die

Bruchstücke herausfallen können. Anschließend

kann die Heizkammer mit einem feuchten Tuch

oder einem weichen Pinsel gereinigt werden.

Wartung

Für dieses Gerät sind KEINE

Wartungsmaßnahmen erforderlich.

Reparatur

Dieses Gerät enthält keine vom Benutzer zu

wartenden Teile. Eine Reparatur oder Austausch

von Ersatzteilen darf nur von geschultem

Fachpersonal durchgeführt werden. Vor

eventuellen Reparaturarbeiten fordern Sie bitte

ein Wartungshandbuch von der Technischen

Abteilung der Barloworld Scientific Ltd. an

(Modell- und Seriennummer angeben).

Anm.: Phasen- und Nullleiter enthalten getrennte

Sicherungen.

ACHTUNG: Der Probenblock kann heiß

sein.

Page 28

Es dürfen nur Ersatzteile verwendet werden, die

von Barloworld Scientific bzw. dessen

Niederlassungen geliefert wurden. Der Einbau

anderer Teile kann die Sicherheitsfunktionen

dieses Geräts beeinträchtigen.

Im Zweifelsfall wenden Sie sich bitte an die

Technische Abteilung von Barloworld Scientific

Ltd. oder an Ihre Verkaufsstelle.

Barloworld Scientific Ltd.

Stone, Staffordshire ST15 0SA

United Kingdom

Tel: +44 (0) 1785 812121

Fax: +44 (0) 1785 813748

e-mail equipment@barloworld-scientific.com

www.barloworld-scientific.com

Garantie

Barloworld Scientific Ltd gewährleistet, dass

dieses Gerät keine Herstellungs- und

Materialmängel aufweist. Bei Einsatz unter

normalen Laborbedingungen gilt diese Garantie

für drei (3) Jahre. Im Falle einer gerechtfertigten

Reklamation ersetzt Barloworld Scientific das

defekte Teil kostenlos.

Diese Garantie gilt NICHT bei Beschädigung

durch Feuer, Unfall, Missbrauch,

Vernachlässigung, falscher Einstellung oder

Reparatur, Schäden durch Adaptierung bei der

Installation, Modifizierung, Einbau von nicht

zugelassenen Teilen bzw. Reparatur durch

unbefugtes Personal.

24

Technische Daten

Anzahl der Proben Drei

Temperaturbereich Umgebungstemp. bis 250°C

Heizrate 1 bis maximal 20 °C/min

Abmessungen

(B x T x H) 370 x 140 x 110 mm

Nettogewicht 1,7 Kg

Stromversorgung

SMP11 230V, 50/60Hz, 50W

SMP11/100V/60 100V, 50/60Hz, 50W

SMP11/120V/60 120V, 50/60Hz, 50W

Ersatzteile / Zubehör

SMP11/1 Ersatzthermometer (auf Alkoholbasis),

0 bis 250°C.

SMP1/2 Messing-Kühlfinger

SMP1/4 Schmelzpunktröhrchen

(an beiden Enden offen)

SMP2/1 Schmelzpunktröhrchen

(an beiden Enden verschlossen)

SMP10/1 Schmelzpunktröhrchen

(an einem Ende verschlossen

Page 29

These products meet the relevant EC

harmonised standards for radio frequency

interference and may be expected not to

interfere with, or be affected by, other equipment with

similar qualifications. We cannot be sure that other

equipment used in their vicinity will meet these standards

and we cannot guarantee that interference will not occur

in practice. Where there is a possibility that injury,

damage or loss might occur if equipment malfunctions

due to radio frequency interference, or for general advice

before use, please contact the Technical Service

Department of Barloworld Scientific Ltd.

Declaration of Conformity

Scientific

Page 30

INSPECTION REPORT

MODEL SMP11

ELECTRICAL SAFETY

1. Earth continuity

❏

2. Insulation ❏

3. Flash test ❏

FUNCTIONAL

1. Indicators

❏

2. Temperature control ❏

3. Visual acceptance ❏

QUALITY CONTROL INSPECTOR

✓

✓

✓

✓

✓

✓

Barloworld Scientific Ltd

Beacon Road Stone

Staffordshire ST15 0SA

United Kingdom

Tel: +44 (0)1785 812121

Fax: +44 (0)1785 813748

www.barloworld-scientific.com

Barloworld Scientific France SAS

ZI du Rocher Vert - BP 79

77793 Nemours Cedex

France

Tel: +33 1 64 45 13 13

Fax: +33 1 64 45 13 00

e-mail: bibby@bibby-sterilin.fr

Barloworld Scientific Italia Srl

Via Alcide de Gasperi 56

20077 Riozzo di Cerro al Lambro

Milano Italia

Tel: +39 (0)2 98230679

Fax: +39 (0)2 98230211

e-mail: marketing@barloworld-scientific.it

www.barloworld-scientific.it

Barloworld Scientific US Ltd

350 Commerce Drive

Rochester NY 14623

USA

Tel: (800) 828-6595

Fax: (585) 334-0241

www.dynalabcorp.com

Afora S.A.

Calle Aribau 240

08006 Barcelona Spain

Tel: +343 93-306 98 00

Fax: +343 93-306 98 23

e-mail: marketing@afora.com

www.afora.com

Scientific

Page 31

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship

for a period of 37 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1)

month grace period to the normal three (3) year product warranty to cover handling and

shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or

written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired

or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action

of the purchaser, including but not limited to mishandling, improper interfacing, operation outside

of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit

shows evidence of having been tampered with or shows evidence of having been damaged as a

result of excessive corrosion; or current, heat, moisture or vibration; improper specification;

misapplication; misuse or other operating conditions outside of OMEGA’s control. Components in

which wear is not warranted, include but are not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability

for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only that

the parts manufactured by the company will be as specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND

WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED

WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The

remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA

with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a

“Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or

(2) in medical applications or used on humans. Should any Product(s) be used in or with any

nuclear installation or activity, medical application, used on humans, or misused in any way,

OMEGA assumes no responsibility as set forth in our basic WARRANTY / DISCLAIMER language,

and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability

or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN

ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the

outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR WARRANTY

RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the

product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2012 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, repro-

duced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior

written consent of OMEGA ENGINEERING, INC.

Page 32

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

SM

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Data Logging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

M5094/0112

Loading...

Loading...