Page 1

MPS10, MPS20

Melting Point Apparatus

®

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

Shop online at

omega.com

®

User’s Guide

®

MADE IN UNITED KINGDOM

Page 2

Servicing North America:

U.S.A.: OMEGA Engineering, Inc.

ISO 9001 Certified One Omega Drive

P.O. Box 4047

Stamford, CT 06907-0047 USA

Toll-Free: 1-800-826-6342 TEL: (203) 359-1660

FAX: (203) 359-7700 e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec), H7L 5A1 Canada

Toll-Free: 1-800-826-6342 TEL: (514) 856-6928

FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 /1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico/ En Español: 001 (203) 359-7803 FAX: 001 (203) 359-7807

Latin America info@omega.com.mx e-mail: espanol@omega.com

Servicing Europe:

Benelux: Managed by the United Kingdom Office

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184

733 01 Karviná, Czech Republic

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

FAX: +420-59-6311114 e-mail: info@omegashop.cz

France: Managed by the United Kingdom Office

Toll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26

D-75392 Deckenpfronn, Germany

Toll-Free: 0800 6397678 TEL: +49 (0) 7056 9398-0

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

United Kingdom: OMEGA Engineering Ltd.

ISO 9001 Certified

One Omega Drive, River Bend Technology Centre, Northbank

Irlam, Manchester M44 5BD United Kingdom

Toll-Free: 0800-488-488 TEL: +44 (0) 161 777-6611

FAX: +44 (0) 161 777-6622 e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

®

Page 3

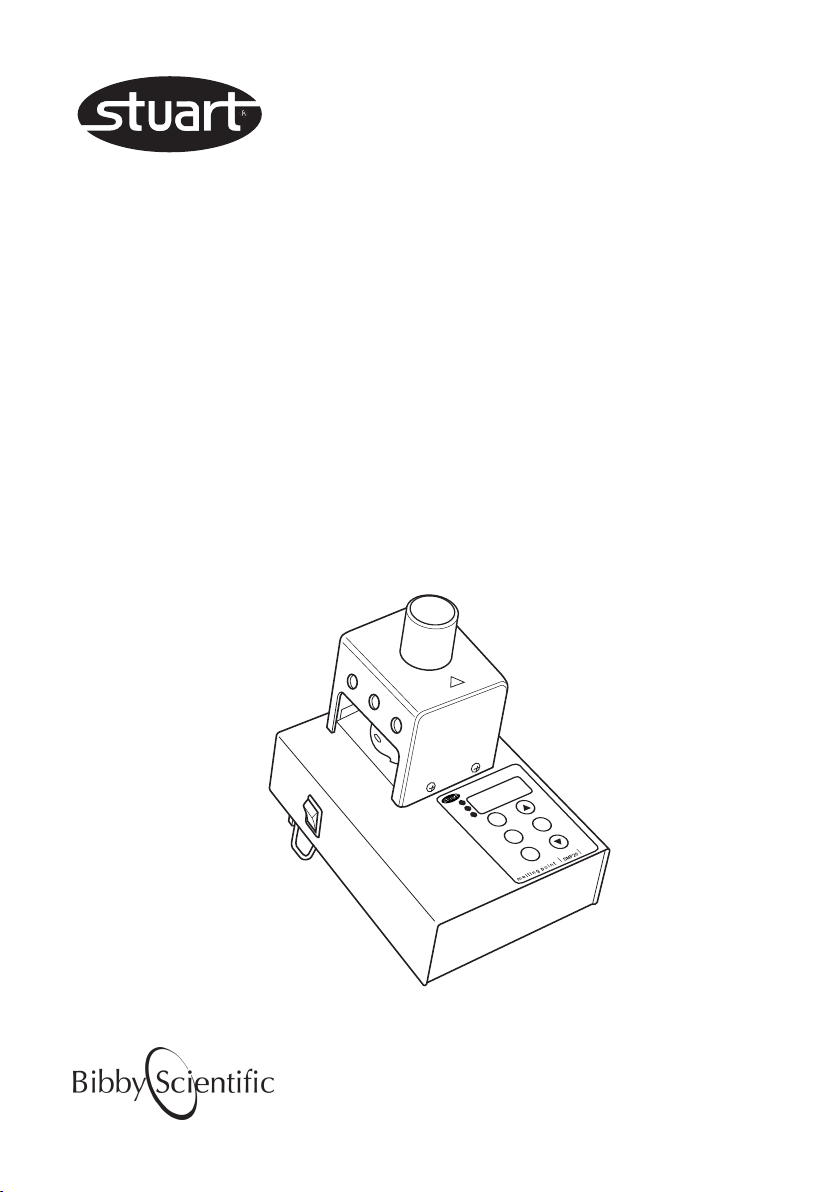

Melting Point

Apparatus

SMP10, SMP20

Instructions for use

Manuel d’utilisation

Istruzioni per l’uso

Instrucciones de funcionamiento

Bedienungsanweisung

ºC

heating

plateau

ramping

start/stop

plateau set

ramp stop

hold

Version 2.0

Page 4

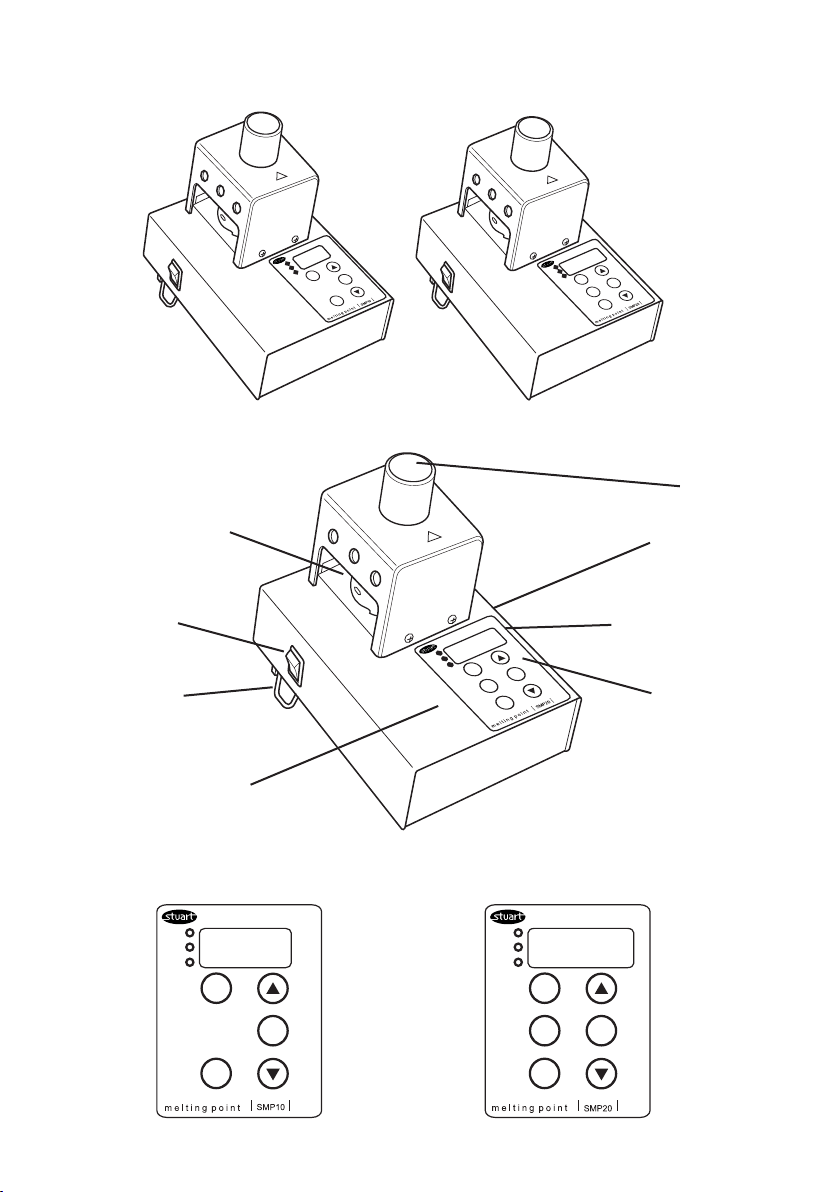

English

ºC

heating

plateau

ramping

stop

plateau set

start

heating

plateau

SMP10 SMP20

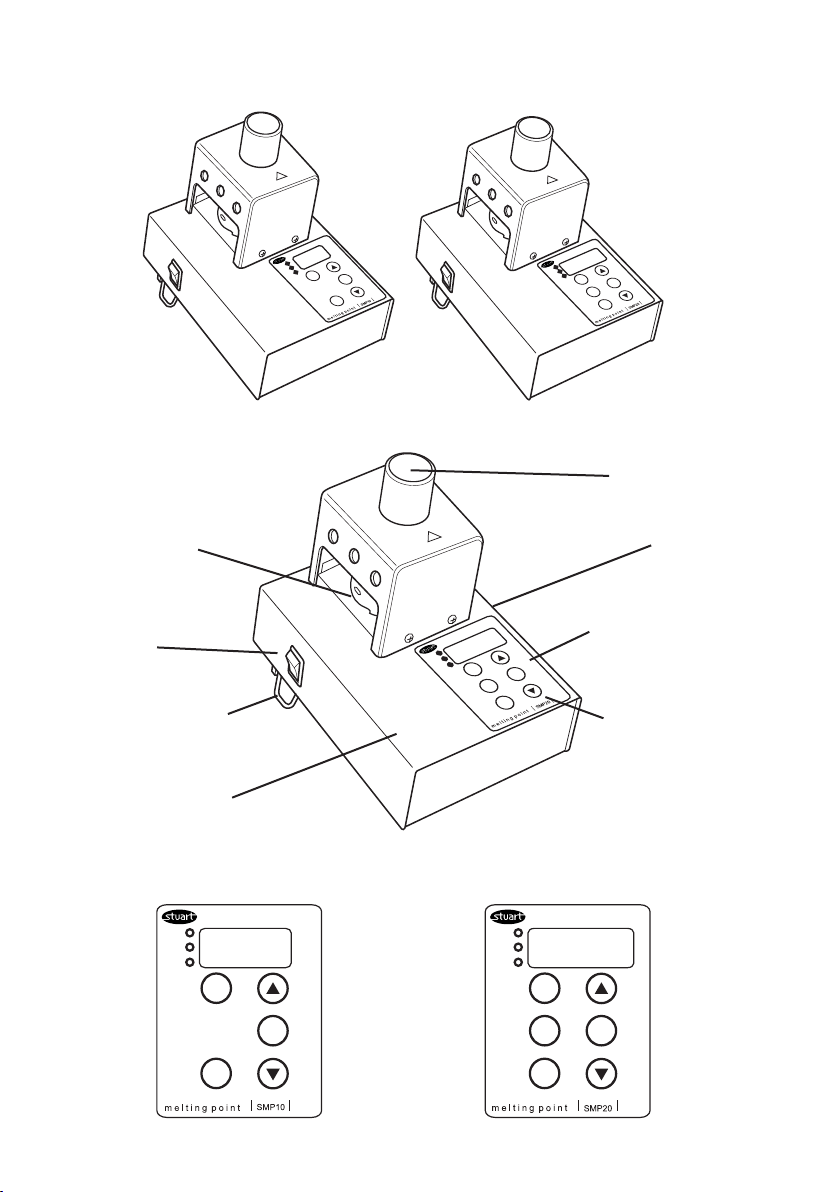

Sample tube holder

Mains on/off

Extendible feet

Instruction fascia

heating

plateau

ramping

ºC

start/stop

plateau set

ramp stop

hold

ºC

ramping

start/stop

ramp stop plateau set

hold

Eye viewer

IEC connector

Temperature display

Control panel

SMP10 Fascia SMP20 Fascia

heating

plateau

ramping

ºC

stop

plateau set

start

heating

plateau

ramping

ºC

start/stop

ramp stop plateau set

hold

2

Page 5

Melting Point Apparatus

SMP10, SMP20

Introduction

Thank you for purchasing this piece of Stuart

equipment. To get the best performance from the

equipment and for your own safety, please read these

instructions carefully before use. Before discarding the

packaging check that all parts are present and correct.

This equipment is designed to operate under the

following conditions:

v For indoor use only

v Use in a well ventilated area

v Ambient temperature range +5°C to +40°C

v Altitude to 2000m

v Relative humidity not exceeding 80%

v Mains supply fluctuation not exceeding 10%

v Overvoltage category II IEC60364-4-443

v Pollution degree 2 IEC664

If the equipment is not used in the manner described

in this manual and with accessories other than those

recommended by Stuart, the protection provided may

be impaired.

Electrical Installation

THIS EQUIPMENT MUST BE EARTHED

Before connection please ensure that the line

supply corresponds to that stated on the rating

label. Power consumption is 70W.

There is an IEC socket at the rear of the right hand

side of the instrument for connection to the mains

supply, (see figure 1). The unit is supplied with two

mains leads fitted with IEC plugs for connection to the

instrument. One has a U.K. 3 pin plug and the other

has a 2 pin “Shuko” plug for connection to the mains

supply. Choose the lead appropriate for your electrical

installation and discard the other. Should neither lead

be suitable you should obtain a moulded lead locally.

If this is not possible, take the lead with the U.K. plug

and replace the plug with a suitable alternative. See

the enclosed instruction sheet for advice on how to

carry out this procedure. Should the mains lead require

replacement a cable of 1mm2 of harmonised code

H05W-F connected to an IEC 320 plug should be used.

N.B. The U.K. mains lead is protected by a 10A fuse

mounted in the plug top. The mains lead should be

connected to the instrument BEFORE connection to the

main supply.

THIS OPERATION SHOULD ONLY BE UNDERTAKEN

BY A QUALIFIED ELECTRICIAN

General Description

The Stuart SMP10 and SMP20 have been designed

for maximum safety and ease of use. The

temperature is selected, measured and displayed

digitally ensuring accuracy and avoiding the need

for a glass thermometer. Two samples can be tested

simultaneously. They are viewed via a magnifying lens

with clear observation aided by built in illumination.

Extendible feet allow the unit to be operated at the

optimum viewing angle. Full access to the block allows

easy cleaning and maintenance.

Before using the unit for the first time

Once the unit is unpacked, select the appropriate

choice of self adhesive instruction label from the multilanguage set provided. Peel off the backing and stick

the label onto the left side of the fascia. Apply the label

carefully using a flat object to smooth away air bubbles.

Principle of Operation

The SMP10 and SMP20 melting point apparatus has

been designed to give both quick and accurate results

as well as maximum convenience in use. Melting point

samples are placed in a glass capillary tube which is

placed in the aluminium block inside the sample

chamber. This block is heated and the sample observed

through the magnifying lens until the melt occurs.

The melting point temperature may then be easily

read from the large LED display. In order to avoid the

necessity to continually watch the sample the SMP10

is equipped with a “plateau” function. This allows

a temperature to be set a few degrees below the

expected melting point. The SMP10 will then heat to

this temperature very rapidly (20°C per minute) and

hold it until the operator is ready to begin measuring. It

can safely be left to do this unattended.

SMP10 only

Once measuring is started the SMP10 will heat slowly

(2°C per minute) from the plateau temperature until

the melt occurs. This slow rate of heating allows very

accurate melting points to be obtained.

SMP20 only

It is possible to adjust the ramp rate of the SMP20,

between 1ºC per minute and 10ºC per minute. This

allows either a fast result to be obtained or a more

accurate slow one

Before Use

Place the unit on a firm, level surface and extend the

feet at the rear of the instrument so that the unit is

at a convenient viewing angle. Connect to the mains

electricity supply and switch on by means of the mains

on/off switch. The actual block temperature will now

be shown on the LED display and the illumination in

the sample chamber will come on.

3

Page 6

Measuring a Melting Point

N.B. If the unit has been used recently the block may

be too hot for your sample. If this is the case press

the stop button and allow the unit to cool before

proceeding.

1. Prepare sample by placing a small amount in the

end of a glass capillary tube.

2. Decide on a suitable plateau temperature. This

should be approximately 10°C below the expected

melting point of the sample.

3. Check that all 3 function lights are extinguished.

If not, press the stop button.

4. Press and hold the plateau set button (the plateau

light will flash). The display will now show the

current plateau temperature.

5. The desired plateau temperature may now be set

using the arrow keys to scroll the display up

or down as required.

6. Release the set button. The new plateau

temperature is now set and all function lights

will go out (The plateau setting can be checked at

any time during operation by pressing and holding

the plateau set button). This action will not

interfere with the operation of the unit).

7. SMP20 only – Decide on an appropriate ramp rate,

between 1ºC per minute and 10ºC/min. Results

obtained at 1ºC per minute will be the most

accurate, while more approximate results can

be obtained faster at higher ramp rates.

Setting the ramp rate is the same procedure as setting

the plateau except you need to use the ramp set button

instead of the plateau set button.

8. Insert the tube into the side of the heating block

via the holes provided. For convenience this can

be done from either side of the block. Look down

the magnifier and position the tube so that the

sample can be observed clearly.

Caution: The heating block may be HOT.

9. Press the start or stat/stop key. The unit will quickly

heat up to the plateau temperature (the heating

light will be illuminated - see figure 1)

10. Once the plateau temperature has been reached

the plateau light will be illuminated as well as

the heating light - see figure 1.

N.B. At low plateau temperatures there may be some

overshoot. Wait until the plateau light comes on before

proceeding in order to ensure that the temperature has

stabilised.

11. Press the start button again. The block will

begin to heat at the pre-set ramp rate (SMP20)

or at the fixed 2°C per minute on the SMP10

(the plateau light will go out and the ramping

and heating lights will both be illuminated - see

figure 1.)

12. Observe the sample until the melt occurs and

record the temperature from the digital display.

13. SMP20 only – It is possible to freeze the

temperature display on the SMP20 using the

hold button. Once pressed the temperature

display will hold (ramping light flashing) to allow

more time to record the melt temperature.

Press hold again to return to the actual block

temperature.

14. After the melt has occurred press the stop or start/

stop button. All function lights will go out and the

unit will cool to ambient temperature.

15. Pressing the start button again will cause

the unit to return to the plateau temperature

instead of ambient. The heating light will come on

even if the temperature is above the plateau and

the unit is, in fact, cooling.

Cleaning & Servicing

WARNING: Ensure the unit is disconnected from

the mains electricity supply and allowed to cool

before attempting any cleaning or servicing.

Cleaning

Periodically clean the instrument using a damp cloth

and mild detergent solution. Do not use harsh or

abrasive cleaning agents. Broken melting point tubes

may be removed from the block simply by pushing

them through with a piece of wire or similar tool.

For access to the block for more thorough cleaning the

sample chamber cover must be removed.

1. Remove the 3 retaining screws and lift off the

cover.

2. Loosen the screw retaining the metal plate but do

not remove completely.

3. Push the plate to one side.

4. The glass window in the top of the block may now

be removed.

Servicing

Any repairs or replacement of parts MUST only be

undertaken by suitably qualified personnel. There are

two replaceable fuses on the rear of the IEC mains

connector. The cause of any fuse failure should be

investigated and corrected.

Proceed as follows:

1) Ensure the unit is disconnected from the mains

supply.

2) Unscrew the four screws on the base of the unit

and remove the base plate. Do not disconnect or

pull on the base earth bonding wire.

4

Page 7

3) Two fuses are mounted on the rear of the IEC

connector (both ‘Live’ and ‘Neutral’ mains

supply leads are fused). These fuses can be

removed and replaced by hand. ALWAYS

replace the fuse by ones of the correct values

shown below:

For 230V, 50Hz - T1A

For 120V, 60Hz - T1.6A

4) Refit the base and four securing screws.

5) It is advisable to perform a ‘PAT’ (Portable

Appliance Test) electrical safety test, or

equivalent, before the unit is put back into

operation.

For a comprehensive list of parts and a Service

Manual required by service engineers conducting

internal repairs, please contact the Technical Service

Department of Bibby Scientific Ltd. quoting both the

model and serial number.

Only spare parts supplied or specified by Bibby Scientific

Ltd. or its agents should be used. Fitting of nonapproved parts may affect the performance and safety

features designed into the instrument. If in any doubt,

please contact the Technical Service Department of

Bibby Scientific Ltd. or the point of sale.

Bibby Scientific Ltd.

Stone, Staffordshire ST15 0SA

United Kingdom

Tel: +44 (0)1785 812121

Fax: +44 (0)1785 813748

e-mail info@bibby-scientific.com

www.bibby-scientific.com

Warranty

Bibby Scientific Ltd. warrants this instrument to be free

from defects in material and workmanship, when used

under normal laboratory conditions, for a period of

three (3) years. In the event of a justified claim Bibby

Scientific will replace any defective component or

replace the unit free of charge. This warranty does NOT

apply if damage is caused by fire, accident, misuse,

neglect, incorrect adjustment or repair, damage caused

by incorrect installation, adaptation, modification,

fitting of non-approved parts or repair by unauthorised

personnel.

Technical Specification

SMP10 SMP20

Number of samples Two Two

Temperature range Ambient to 300°C Ambient to 300°C

Temperature resolution 1°C 0.1ºC

Temperature accuracy ±1°C ±1°C

Display Three digit LED Four digit LED

Sensor PT100 PT100

Ramp rates 20°C / minute to plateau 20°C / minute to plateau

2°C /minute to melt Between 1 and 10ºC/min

Dimensions (WxDxH) 160 x 220 x 170 mm 160 x 220 x 170 mm

Net weight 1.8 Kg 1.8 Kg

5

Page 8

Français

ºC

heating

plateau

ramping

stop

plateau set

start

ºC

heating

plateau

ramping

start/stop

ramp stop plateau set

SMP10 SMP20

Support tube

echantillon

Narche /

Arret

Pieds anovibles

Nobe operatoire

heating

plateau

ramping

ºC

start/stop

plateau set

ramp stop

hold

Affichabe temperature

hold

Loupe d’observation

Enbase cee

Panneau de controle

SMP10 Fascia SMP20 Fascia

heating

plateau

ramping

ºC

stop

plateau set

start

heating

plateau

ramping

ºC

start/stop

ramp stop plateau set

hold

6

Page 9

Appareil de mesure du

point de fusion

SMP10, SMP20

Manuel d’utilisation

Nous vous remercions d’avoir acheté cet appareil Bibby

Scientific. Afin d’en obtenir satisfaction, et pour votre

sécurité, nous vous invitons à lire avec attention les

instructions ci-dessous avant l’utilisation Le matériel

Bibby Scientific est conçu pour fonctionner dans les

conditions suivantes :

v Utilisation en intérieur uniquement

v Utilisation dans une pièce bien aérée

v Température ambiante de +5 °C à +40 °C

v Altitude inférieure à 2 000m

v Humidité relative n’excédant pas 80%

v Fluctuations de l’alimentation électrique

n’excédant pas 10% de la valeur nominale

v Surtension de catégorie II selon la norme CEI

60364-4-443

v Degré 2 de pollution selon la norme CEI 664

Si l’équipement n’est pas utilisé de la façon décrite

dans ce manuel, la protection fournie par l’appareil

peut être altérée.

Installation Électrique

CET ÉQUIPEMENT DOIT ÊTRE RELIÉ À LA

TERRE

Avant le raccordement, assurez-vous que

l’alimentation électrique correspond à celle

indiquée sur l’étiquette de spécifications. La

puissance est de 70 W.

Une embase CEE est située à l’arrière du côté droit

de l’instrument pour le raccordement à l’alimentation

électrique, (voir le schéma 1). L’appareil est fourni

avec deux cordons d’alimentation équipés de fiches

CEE pour le raccordement. L’un de ces cordons est

équipé d’une fiche britannique à 3 broches et l’autre

est équipé d’une fiche « Shuko » à deux broches.

Choisissez le cordon d’alimentation adapté à votre

installation électrique et mettez l’autre de côté. Si ni

l’un ni l’autre ne conviennent, vous devrez alors obtenir

le cordon d’alimentation utilisé dans le pays où vous

vous trouvez. Si ce n’est pas possible, prenez celui

avec la prise anglaise, coupez-la et remplacez-la par

celle correspondant au pays d’utilisation. Voir la feuille

d’instructions incluse pour le montage de cette prise.

Si le cordon d’alimentation doit être remplacé, utilisez

un câble d’ 1mm

connecté à une fiche CEI 320.

2

de type H05W-F (code harmonisé),

Remarque : Le cordon d’alimentation équipé d’une

fiche britannique est protégé par un fusible de 10 A

monté dans la partie supérieure de la fiche. Il doit être

connecté à l’appareil AVANT de le connecter à une

prise secteur.

EN CAS DE DOUTE, CONSULTER UN ÉLECTRICIEN

QUALIFIÉ

Description Générale

Les appareils Stuart SMP10 et SMP20 ont été conçus

pour une sécurité et une facilité d’utilisation maximales.

La sélection de la température, la mesure et l’affichage

sont numériques, ce qui assure une parfaite précision

et permet de ne pas utiliser de thermomètre. Deux

échantillons peuvent être examinés simultanément.

Ils sont visualisés à l’aide d’une lentille grossissante

et d’un éclairage intégré. Les pieds arrières ajustables

permettent d’incliner l’appareil pour obtenir un

champ de vision optimal. Accès total au bloc pour un

nettoyage aisé.

Avant d’utiliser l’appareil pour la première fois:

Une fois déballée, choisissez l’étiquette d’instructions

adhésive appropriée à la langue du pays d’utilisation

parmi celles fournies. Décollez l’étiquette de son

support et collez-la sur le côté gauche de la face avant

de l’appareil. Appliquez celle-ci avec précaution, en

employant un objet plat pour lisser les bulles d’air.

Principe de Fonctionnement

Les appareils à point de fusion SMP10 et SMP20

ont été conçus pour donner des résultats rapides et

précis et fournir un confort d’utilisation maximal. Les

échantillons sont placés dans un tube capillaire en

verre, qui est ensuite placé dans le bloc en aluminium à

l’intérieur de la chambre de mesure. Ce bloc est chauffé

et l’échantillon est observé à travers la loupe jusqu’à ce

que la fusion se produise. La température du point de

fusion peut alors être facilement relevée sur le grand

affichage digital. Afin d’éviter une observation continue

de l’échantillon, les deux appareils sont équipés d’une

fonction “plateau”. Ceci permet de sélectionner une

température située quelques degrés en dessous du

point de fusion prévu. Ces appareils chaufferont alors

très rapidement jusqu’à cette température (20°C par

minute) et la maintiendront jusqu’à ce que l’opérateur

soit prêt à commencer l’analyse. Durant cette montée

en température, l’appareil ne nécessite pas de

surveillance particulière.

SMP10 uniquement

Une fois la mesure commencée, le SMP10 chauffera

lentement (2°C par minute), de la température

de plateau jusqu’à ce que la fusion se produise.

Cette lente montée en température permet une

détermination précise des points de fusion.

7

Page 10

SMP20 uniquement

Il est possible de régler le taux de rampe du SMP20

entre 1°C et 10°C par minute. Cela permet d’obtenir

soit un résultat rapide soit un résultat moins rapide

mais plus précis.

Avant l’emploi

Placez l’appareil sur une surface solide et horizontale et

placez les pieds arrières de l’appareil de sorte que celuici soit dans une position optimale pour l’observation.

Connectez l’appareil à l’alimentation électrique et

mettez l’interrupteur “Marche/Arrêt” en position

“Marche”. La température réelle du bloc sera alors

affichée sur l’écran digital et l’éclairage de la chambre

de mesure s’allumera.

Détermination d’un point de fuszion

Remarque : Si l’appareil a été utilisé récemment, le bloc

peut être trop chaud pour votre échantillon. Si c’est le

cas, appuyez sur la touche “Arrêt” et laissez l’appareil

refroidir avant de poursuivre.

1. Préparez l’échantillon en plaçant un peu de ce

dernier dans l’extrémité d’un tube capillaire en

verre.

2. Choisissez la température de plateau appropriée.

Celle-ci devra être approximativement 10°C au dessous du point de fusion prévu.

3. Vérifiez que les 3 témoins de fonctionnement sont

éteints. Sinon, appuyez sur la touche “Arrêt”.

4. Maintenez la touche de réglage de la température

de plateau enfoncée (le témoin “plateau”

clignotera). L’affichage donnera alors la

température de plateau actuelle.

5. La température de plateau peut maintenant être

sélectionnée en utilisant les touches fléchées Haut

ou Bas pour obtenir celle souhaitée.

6. Relâchez la touche de réglage, la nouvelle

température de plateau est désormais définie et

tous les témoins de fonctionnement s’éteignent

(la température de plateau peut être vérifiée à

tout moment lors du fonctionnement

en maintenant enfoncée la touche de réglage de la

température de plateau. Cette action n’interférera

dans le bon fonctionnement de l’appareil).

7. SMP20 uniquement : Déterminez le taux de rampe

approprié, entre 1°C et 10°C par minute. Les

résultats obtenus à 1°C par minute seront les plus

précis, tandis qu’avec des taux de rampe plus

élevés, les résultats sont obtenus plus rapidement

mais sont plus approximatifs.

Le réglage du taux de rampe suit la même procédure

que le réglage de la température de plateau à

l’exception près qu’il faut utiliser la touche de réglage

du taux de rampe au lieu de celle pour la fonction

“plateau”.

8. Insérez le tube sur un côté du bloc de chauffage

par les orifices prévus à cet effet. Ceci peut être

fait d’un côté ou de l’autre du bloc. Placez le tube

8

de sorte l’échantillon puisse bien être observé.

9. Appuyez sur la touche “Marche” ou “Marche/

Arrêt”. L’appareil chauffera rapidement jusqu’à

la température de plateau (le témoin de chauffage

s’allumera - voir schéma 1).

10. Une fois que la température de plateau a été

atteinte, le témoin “plateau” s’allume tout comme

le témoin de chauffage - voir schéma 1.

Remarque : Avec des températures de plateau

basses, il est possible que des dépassements

surviennent. Attendez jusqu’à ce que le témoin de

la température de plateau s’allume avant

de continuer la procédure afin de vous assurer que

la température est stabilisée.

11. Appuyez de nouveau sur la touche “Marche”. Le

bloc commencera à chauffer avec un taux de

rampe préréglé (SMP20) ou au taux de rampe

déterminé de 2 °C par minute sur le SMP10 (le

témoin de la température de plateau s’éteindra

et les témoins de chauffage et de taux de rampe

s’allumeront - voir schéma 1).

12. Observez l’échantillon jusqu’à ce que la fusion se

produise et notez la température affichée.

13. SMP20 uniquement : Il est possible de figer

l’affichage de la température sur le SMP20 en

appuyant sur la touche de suspension. Une fois

que vous aurez appuyé sur celle-ci, l’affichage

de la température se figera (le témoin du taux de

rampe clignotera) afin de vous laisser plus de

temps pour enregistrer la température de fusion.

Appuyer de nouveau sur la touche de suspension

pour revenir à la température réelle du bloc.

14. Après la fusion, appuyez sur la touche “Arrêt”

ou “Marche/Arrêt”. Tous les témoins de

fonctionnement s’éteindront et l’appareil

redescendra à la température ambiante.

15. Appuyez de nouveau sur la touche “Marche”

ramènera l’appareil à la température de plateau au

lieu de la température ambiante. Le témoin

de chauffage s’allumera même si la température

est au-dessus du plateau, mais l’appareil refroidira.

Nettoyage et Entretien

AVERTISSEMENT : Assurez-vous que l’appareil

n’est plus alimenté et qu’il refroidit avant

d’entamer le nettoyage ou l’entretien.

Nettoyage

Nettoyez régulièrement l’appareil à l’aide d’un chiffon

humide et d’un détergent et doux. N’utilisez pas

de produits nettoyants abrasifs ou corrosifs. Des

tubes capillaires cassés peuvent être enlevés du bloc

simplement en les poussant à travers l’appareil avec

un morceau de fil de fer ou un outil semblable. Pour

accéder au bloc afin d’effectuer un nettoyage plus

complet, le couvercle de la chambre de mesure doit

être enlevé.

Page 11

1. Enlevez les 3 vis de retenue, puis retirez le

couvercle.

2. Desserrez la vis maintenant la plaque métallique

mais ne l’enlevez pas complètement.

3. Poussez la plaque sur le côté.

4. La fenêtre en verre au-dessus du bloc peut

maintenant être enlevée.

Entretien

Toute opération de réparation ou de remplacement

de pièces DOIT être réalisée par un technicien qualifié.

Deux fusibles remplaçables sont situés à l’arrière du

connecteur d’alimentation CEI. La cause de toute

panne d’un fusible doit être recherchée et corrigée.

Seules les pièces détachées fournies ou spécifiées par

Bibby Scientific France ou ses revendeurs doivent être

utilisées. L’installation de pièces non approuvées peut

affecter l’efficacité des dispositifs de sécurité intégrés

à l’appareil. En cas de doute, contactez le service

technique de Bibby Scientific France ou votre revendeur.

Bibby Scientific France SAS

ZI du Rocher Vert - BP 79

77793 Nemours Cedex

France

Tél: +33 1 64 45 13 13

Fax: +33 1 64 45 13 00

e-mail: bibby@bibby-sterilin.fr

Procédez comme suit :

1) Assurez-vous que l’appareil n’est plus alimenté.

2) Dévissez les quatre vis situées à la base de

l’appareil et retirez la plaque de la base. Ne

déconnectez ou ne tirez pas sur le fil de mise à la

terre de la base.

3) Deux fusibles sont montés à l’arrière du

connecteur CEI (les câbles de phase et de neutre

sont équipés de fusibles). Ces fusibles peuvent être

retirés et remplacés à la main. Remplacez

TOUJOURS les fusibles par de nouveaux fusibles

avec les valeurs appropriées comme indiqué ci dessous :

Pour 230 V, 50 Hz : T1A

Pour 120 V, 60 Hz : T1.6A

4) Réinstallez la base ainsi que les quatre vis de

retenue.

5) Il est recommandé d’effectuer un test de sécurité

électrique “PAT” (Portable Appliance Test, contrôle

de sécurité d’appareils portables) ou un test

équivalent, avant de remettre l’appareil en service.

Pour obtenir la liste complète des pièces nécessaires aux

techniciens de maintenance réalisant des réparations

internes, ou pour recevoir un manuel d’entretien,

contactez le service d’assistance de Bibby Scientific

France en mentionnant le numéro de modèle et le

numéro de série.

Caractéristiques techniques

Garantie

Bibby Scientific France garantit cet appareil contre

tout défaut de pièces ou de main-d’œuvre, dans des

conditions d’utilisation normale en laboratoire, pour

une période de trois (3) ans. En cas de réclamation

justifiée, Bibby Scientific France remplacera

gratuitement l’appareil ou tout composant défectueux.

Cette garantie ne s’applique pas si les dommages sont

dus à un incendie, un accident, une inondation, une

négligence ou une utilisation inadéquate. La garantie

ne s’applique pas non plus si l’appareil n’a pas été

installé correctement, réparé par une personne non

qualifiée ou modifié à l’aide de pièces détachées ne

provenant pas de la société Bibby Scientific France.

Cette garantie NE s’applique PAS en cas de dommages

provoqués par un incendie, un accident, une utilisation

inappropriée, une négligence, un réglage incorrect, une

réparation inadéquate, une installation, une adaptation

ou une modification inappropriée, l’installation de

pièces non approuvées ou la réalisation de réparations

par un personnel non autorisé.

SMP10 SMP20

Nombres d’échantillons Deux Deux

Plage de températures Ambiante à 300°C Ambiante à 300°C

Résolution de la température 1°C 0,1°C

Précision de la température ±1°C ±1°C

Affichage Digital à 3 chiffres Digital à 4 chiffres

Capteur PT100 PT100

Taux de rampe 20°C/min jusqu’à la 20 °C/min jusqu’à la

température de plateau température de plateau

2°C/min jusqu’à la fusion Entre 1°C et 10°C/min

Dimensions (L x P x H) 160 x 220 x 170 mm 160 x 220 x 170 mm

9

Page 12

Italiano

ºC

heating

plateau

ramping

stop

plateau set

start

heating

SMP10 SMP20

Blocco porta

campioni

Interruttore

on / off

Appoggio

regolabile

Etichetta istruzioni

heating

plateau

ramping

ºC

start/stop

plateau set

ramp stop

hold

ºC

plateau

ramping

start/stop

ramp stop plateau set

hold

Visore

Alimentazione

Display temperatura

Pannello comandi

10

SMP10 Fascia SMP20 Fascia

heating

plateau

ramping

ºC

stop

plateau set

start

heating

plateau

ramping

start/stop

ramp stop plateau set

hold

ºC

Page 13

Apparecchio per la

misurazione del punto

di fusione

SMP10, SMP20

Istruzioni per l’uso

Vi ringraziamo per avere acquistato questo prodotto

Bibby Scientific. Per ottenere la migliore prestazione

da questo apparecchio, e per la Vostra sicurezza, Vi

preghiamo di leggere attentamente queste istruzioni

prima dell’uso.

L’apparecchio è stato progettato per funzionare nelle

seguenti condizioni:

v Da usarsi solo all’interno

v Da usarsi in un’area ben ventilata

v Intervallo di temperatura da +5°C a +40°C

v Altitudine massima di 2000 metri

v Umidità relativa non superiore a 80%

v Fluttuazioni dell’alimentazione elettrica non

superiori a 10%

v Categoria di sovratensione II IEC60364-4-443

v Grado di inquinamento 2 IEC664

Se l’apparecchio non è usato come specificato ne

presente manuale, la protezione offerta

dall’apparecchio stesso può essere ridotta.

Installazione elettrica

L’APPARECCHIO DEVE ESSERE

COLLEGATO A TERRA.

Prima della connessione, assicurarsi che la linea di

alimentazione corrisponda a quanto indicato sulla

targhetta. La potenza di assorbimento è di 70W.

Nella parte posteriore dell’apparecchio, sul lato

destro, è presente una presa IEC per la connessione

all’impianto di alimentazione (fig.1). Ogni unità viene

fornita con due cavi di alimentazione dotati di spine

IEC per la connessione dell’apparecchio alla rete

elettrica. Un cavo è dotato di spina “Inglese” a 3 pin,

l’altro ha una spina tipo “Shuko” a 2 pin. Scegliere il

cavo più adatto per la connessione e scartare l’altro. In

caso i cavi non fossero adatti all’uso, sarà necessario

provvedere alla loro sostituzione con un modello

alternativo. Qualora non fosse disponibile un cavo

confezionato idoneo, è possibile eventualmente tagliare

la spina inglese e sostituirla,con una di tipo adatto.

Ulteriori istruzioni accluse mostrano come eseguire

questa procedura. In caso di sostituzione del cavo di

alimentazione, sarà necessario utilizzare un cavo da

1 mm2 codificato H05W-F e connesso a una spina

IEC320.

N.B.: Il cavo di alimentazione inglese è protetto da

un fusibile di 10A montato sulla spina. Il cavo di

alimentazione deve essere connesso all’apparecchio

PRIMA di essere collegato all’impianto elettrico.

IN CASO DI DUBBIO, CONSULTARE UN ELETTRICISTA

QUALIFICATO.

Descrizione generale

Gli apparecchi Stuart SMP10 e SMP20 sono stati

progettati per garantire massima sicurezza e semplicità

d’uso. La temperatura viene impostata, misurata e

visualizzata in modo digitale, garantendo accuratezza

ed evitando l’uso di termometri di vetro. Sarà possibile

esaminare due capillari campione contemporaneamente.

I campioni vengono osservati nitidamente tramite

una lente di ingrandimento illuminata, e i piedini di

appoggio regolabili permettono la scelta del migliore

angolo di osservazione. Il completo accesso al blocco

riscaldante permette una facile pulizia e manutenzione

dell’apparecchio.

Prima dell’uso

Una volta aperto l’imballo del Vostro apparecchio,

scegliete l’etichetta adesiva contenente le istruzioni

da applicare all’apparecchio, nella lingua desiderata.

Successivamente applicate l’etichetta sulla parte sinistra

del pannello dei comandi prestando attenzione e

utilizzando un oggetto piatto per eliminare le bolle

d’aria.

Principi di utilizzo

Gli apparecchi SMP10 e SMP20 sono stati progettati per

dare risultati rapidi e accurati garantendo la massima

comodità di impiego. I campioni da fondere devono

essere preparati in capillari di vetro successivamente

introdotti nel blocco di alluminio all’interno della camera.

Mentre il blocco si scalda, il campione viene

osservato attraverso la lente fino alla fusione. La

temperatura di fusione verrà visualizzata sull’ampio

display digitale. Per evitare la continua osservazione del

campione, l’apparecchio SMP10 è stato dotato di una

funzione di “picco”. Ciò permette l’impostazione di una

temperatura di poco inferiore a quella prevista per la

fusione. L’SMP10 raggiunge questa temperatura molto

rapidamente (20°C al minuto) e la mantiene costante

fino a che l’utilizzatore è pronto per l’osservazione.

Durante questa fase non è indispensabile sorvegliare

l’apparecchio.

Solo SMP10

Quando inizia la fase di misurazione, l’SMP10 riscalderà

molto lentamente (2°C al minuto) partendo dalla

temperatura “picco” fino alla fusione del campione.

La ridotta velocità di riscaldamento consente di ottenere

punti di fusione molto accurati.

11

Page 14

Solo SMP20

La rampa dell’SMP20 è regolabile tra 1°C al minuto e

10°C al minuto. Questo permette di ottenere risultati

rapidi, oppure più lenti ed accurati.

Prima dell’uso

Sistemare l’apparecchio su una superficie piana

rigida ed estendere i piedi di appoggio nella parte

posteriore dello strumento fino al livello di angolazione

desiderato.Connettere l’apparecchio all’alimentazione

elettrica e metterlo in funzione con l’apposito pulsante

di accensione/spegnimento. Il display mostra l’attuale

temperatura del blocco, e si accende la luce nella

camera.

Misurazione del punto di fusione

N.B. Se l’unità è stata usata di recente, il blocco

potrebbe essere già caldo. In questo caso premere

il pulsante Stop e attendere il raffreddamento del

blocco.

1. Preparare il campione introducendo la polvere nel

capillare di vetro.

2. Impostare una temperatura “picco” idonea. E’

sufficiente impostare una temperatura di 10°C

inferiore al punto di fusione previsto.

3. Verificare che le 3 spie luminose di funzione siano

spente, altrimenti premere Stop.

4. Premere e mantenere premuto il tasto di

regolazione del picco (la spia di “picco”

lampeggia). Il display mostra ora la temperatura di

picco.

5. Si può ora impostare la nuova temperatura di

picco, utilizzando i tasti freccia su o giù.

6. Rilasciare il pulsante di regolazione: ora la nuova

temperatura di picco è visualizzata, e le spie

di funzione sono spente (la temperatura di picco

può essere controllata in ogni momento,

premendo a lungo il tasto di regolazione del picco.

Ciò non interferisce con il funzionamento

dell’unità).

7. Solo SMP20 – Decidere la velocità di rampa

appropriata scegliendo un valore tra 1°C/min e

10°C/min. I risultati ottenuti con 1°C al minuto

saranno più accurati, mentre impostando velocità

di rampa maggiori si otterranno risultati più

approssimati.

Per impostare la velocità di rampa seguire la procedura

di impostazione del “picco” utilizzando il tasto per la

rampa al posto del tasto per il picco.

8. Inserire il capillare dalla parte laterale del blocco,

attraverso gli appositi fori. Per comodità ciò può

essere fatto da entrambi i lati. Osservare attraverso

la lente e posizionare il capillare fino ad avere la

migliore osservazione.

Attenzione: il blocco potrebbe essere già CALDO!

9. Premere Start o Start/Stop. L’apparecchio riscalderà

velocemente fino alla temperatura di picco

impostata (la spia di riscaldamento è accesa -

fig.1).

10. Raggiunta la temperatura di picco, si accenderà

una seconda spia - fig.1.

N.B.: Se la temperatura di picco è bassa, potrebbe

verificarsi una fluttuazione di temperatura, perciò è

meglio attendere l’accensione della spia di picco, che

assicura la stabilità della temperatura impostata.

11. Premere nuovamente il tasto Start. Il blocco viene

ora scaldato alla velocità di rampa impostata

(SMP20) o alla velocità fissa di 2°C al minuto

(SMP10) (la spia di picco si spegne, le spie di rampa

e riscaldamento restano accese - fig.1.

12. Osservare attentamente il campione fino al

momento della fusione e registrare la relativa

temperatura sul display.

13. Solo SMP20 – E’ possibile bloccare la temperatura

visualizzata utilizzando il tasto Hold. Premendo il

tasto Hold, il valore di temperatura rimane sul

display (la spia di rampa lampeggia) per consentire

di registrare più comodamente la temperatura di

fusione. Premere ancora il tasto Hold per tornare

alla temperatura del blocco.

14. Conclusa la fusione della sostanza campione,

premere Stop o Start/Stop. Tutte le spie luminose

si spengono e l’apparecchio torna alla temperatura

ambiente.

15. Premendo nuovamente Start l’apparecchio tornerà

alla temperatura di picco invece di raffreddarsi. La

spia luminosa di riscaldamento si accenderà anche

se la temperatura è superiore al valore di picco e di

fatto l’apparecchio è in fase di raffreddamento

Pulizia e manutenzione

ATTENZIONE: Assicurarsi che l’apparecchio sia

scollegato all’impianto di alimentazione

elettrica e che il blocco sia sufficientemente

raffreddato prima di procedere a qualsiasi

operazione di pulizia o manutenzione.

Pulizia: pulire periodicamente l’apparecchio usando un

panno morbido e una soluzione detergente leggera.

Non utilizzare agenti detergenti aggressivi o corrosivi.

I capillari eventualmente rotti all’interno del blocco

possono essere facilmente eliminati spingendoli con un

filo rigido od oggetti similari. Per il completo accesso al

blocco riscaldante è necessario rimuovere il coperchio

protettivo:

1. Rimuovere le 3 viti di sicurezza e sollevare il

coperchio.

12

Page 15

2. Svitare la vite che assicura il piatto di metallo senza

rimuoverla completamente.

3. Spingere il piatto di metallo da una parte.

4. Ora si può rimuovere la finestra in vetro sopra il

blocco.

Sono autorizzate le operazioni di sostituzione eseguite

con parti di ricambio originali Bibby Scientific. L’utilizzo

di parti non originali può compromettere la funzionalità

dell’apparecchio e renderne vane le misure di sicurezza.

In caso di dubbio, contattare

Manutenzione: Ogni riparazione o sostituzione

di parti di ricambio DEVE necessariamente essere

effettuata da personale altamente qualificato. Sul retro

del connettore elettrico IEC si trovano due fusibili.

Prima di procedere alla loro sostituzione, individuare e

riparare il guasto che ne ha provocato la rottura. Per

sostituire i fusibili procedere come segue:

1) Controllare che l’unità sia scollegata

dall’alimentazione elettrica.

2) Allentare le quattro viti alla base dell’unità e

togliere la piastra di base. Non scollegare o tirare il

filo di terra.

3) I due fusibili si trovano nella parte posteriore del

connettore IEC (uno per il conduttore di fase e

l’altro per quello di terra) e si possono togliere e

sostituire manualmente. Utilizzare SEMPRE fusibili

di ricambio dell’amperaggio indicato di seguito.

Per 230 V, 50 Hz – T1A

Per 120 V, 60 Hz – T1,6A

4.) Rimontare la base con le quattro viti.

5) È consigliabile eseguire un test si sicurezza elettrica

prima di rimettere in funzione l’unità.

Per una lista completa di ricambi o per richiedere il

manuale di servizio, contattare il Centro di assistenza

della Bibby Scientific Ltd. più vicino, specificando

modello e numero di serie.

Specifiche tecniche

Bibby Scientific Italia Srl

Via Alcide de Gasperi 56

20077 Riozzo di Cerro al Lambro

Milano Italia

Tel: +39 (0)2 98230679

Fax: +39 (0)2 98230211

e-mail: marketing@bibby-scientific.it

www.bibby-scientific.it.

Garanzia

La Bibby Scientific Ltd. garantisce questo apparecchio

come esente da difetti nei materiali e in fase di

fabbricazione, se usato alle normali condizioni di

laboratorio, per un periodo di tre (3) anni. In caso di

reclamo giustificato, la Bibby Scientific sostituirà ogni

componente difettoso o l’intero apparecchio, senza

onere alcuno. Tale garanzia NON verrà applicata in caso

di danni causati da incendi, incidenti, uso non corretto,

negligenza, riparazione non autorizzata, installazione

non corretta, adattamenti non autorizzati, modifiche

non autorizzate,montaggio di parti non originali o

riparazioni eseguite da personale non autorizzato.

SMP10 SMP20

Numero di campioni Due Due

Campo di temperatura Da ambiente a 300°C Da ambiente a 300°C

Risoluzione di temperatura 1°C 0,1ºC

Accuratezza di temperatura ±1°C ±1°C

Display Digitale a tre caratteri Digitale a quattro caratteri

Sensore PT100 PT100

Velocità di rampa 20°C / minuto al picco 20°C / minuto al picco

2°C /minuto alla fusione Tra 1 e 10ºC/min

Dimensioni (LxPxA) 160 x 220 x 170 mm 160 x 220 x 170 mm

Peso netto 1,8 kg 1,8 kg

13

Page 16

Español

ºC

heating

plateau

ramping

stop

plateau set

start

heating

SMP10 SMP20

Ouficios para

muestras

Boton

Paro / Marcha

Patas

plegables

Caratula frontal

heating

plateau

ramping

ºC

start/stop

plateau set

ramp stop

hold

ºC

plateau

ramping

start/stop

ramp stop plateau set

hold

Visore

Conectar de

corriente IEC

Indicadar de

temperatura

Pauel de

contral

14

SMP10 Fascia SMP20 Fascia

heating

plateau

ramping

ºC

stop

plateau set

start

heating

plateau

ramping

start/stop

ramp stop plateau set

hold

ºC

Page 17

Aparato para punto de

SI TIENE DUDAS AL RESPECTO, CONSULTE A UN

ELECTRICISTA CUALIFICADO.

fusión

SMP10, SMP20

Gracias por haber adquirido un producto Bibby

Scientific. Para obtener las máximas prestaciones del

equipo, y para su seguridad, lea detenidamente estas

instrucciones antes de usar el aparato.Este equipo se ha

diseñado para funcionar en las condiciones siguientes:

v Sólo para uso en interior

v Se debe utilizar en un área bien ventilada

v Rango de temperatura ambiente: de +5 °C a +40 °C

v Altitud hasta 2000 m

v Humedad relativa inferior al 80%

v Fluctuación de la alimentación eléctrica inferior al 10%

v Sobretensión de categoría II IEC60364-4-443

v Grado de contaminación 2 IEC664

Si el equipo no se usa de la manera descrita en este

manual, la protección proporcionada por el aparato

puede no ser adecuada.

Instalación eléctrica

ESTE EQUIPO DEBE CONECTARSE A TIERRA.

Antes de la conexión, asegúrese de que la

alimentación de línea corresponde a la que se

muestra en la etiqueta de características. El

consumo energético es de 70 W.

Hay un zócalo IEC en la parte posterior del lado

derecho del instrumento para enchufar a la corriente

(vea la figura 1). La unidad se suministra con dos cables

de alimentación provistos de enchufes IEC que se

conectan al instrumento. Uno de los cables tiene un

enchufe de tres pines (Reino Unido) y el otro dispone

de un enchufe Shuko de dos pines para la conexión a la

red eléctrica. Elija el cable adecuado para su instalación

eléctrica y descarte el otro. Si ninguno de los cables

resulta adecuado, deberá obtener uno adaptado a su

zona. Si no es posible, cambie el enchufe del cable

para el Reino Unido y sustitúyalo por otro que sea

apropiado. Consulte la hoja de instrucciones adjunta

para saber cómo realizar este procedimiento. Si fuera

preciso sustituir el cable de alimentación, deberá

utilizarse un cable de 1 mm

armonizado H05W-F y conectado a un enchufe IEC

320. Nota: El cable de alimentación para el Reino Unido

está protegido con un fusible de 10 A montado en la

parte superior del enchufe. El cable de alimentación

debe conectarse al instrumento ANTES de conectarlo a

la red eléctrica.

2

de sección, con código

Descripción general

El SMP10 y el SMP20 han sido diseñados para la

máxima seguridad y facilidad de uso. La temperatura se

selecciona, mide y visualiza digitalmente, asegurando la

exactitud y sin necesidad de utilizar un termómetro de

vidrio. Pueden medirse dos muestras simultáneamente.

La observación se realiza por medio de una lupa muy

nítida ayudada por un sistema de iluminación. Además,

unas patas regulables permiten un óptimo ángulo de

observación, todo ello situado en un bloque de fácil

acceso para su limpieza y mantenimiento.

Antes de usar la unidad por primera vez

Una vez desembalada la unidad, seleccione la etiqueta

de instrucciones autoadhesiva que corresponda a

su idioma. Despegue el papel de soporte y pegue la

etiqueta en el lado izquierdo del panel frontal. Coloque

con cuidado la etiqueta con la ayuda de un objeto

plano para evitar que queden burbujas debajo.

Principio de funcionamiento

Los aparatos de punto de fusión SMP10 y SMP20 se han

diseñado para poder obtener unos resultados precisos

y rápidos a la vez que con gran facilidad en su uso. Las

muestras para la determinación del punto de fusión

se colocan en un tubo capilar de vidrio, que se coloca

en el bloque de aluminio situado en el interior de la

cámara de muestras. Este bloque se calienta y se observa

la evolución de la muestra a través de la lupa, hasta

que se produce la fusión. La temperatura del punto de

fusión puede leerse fácilmente en el indicador LED. Para

evitar tener que observar constantemente la muestra, el

SMP10 se ha equipado con la función de meseta, que

permite fijar una temperatura unos grados por debajo

del valor de punto de fusión esperado. El SMP10 se

calentará rápidamente hasta dicha temperatura (20 ºC

por minuto) y la mantendrá hasta que el operario esté

preparado para empezar la medición. Se puede dejar

que el aparato actúe solo, sin supervisión, con toda

seguridad.

Solo SMP10

Una vez iniciada la medición, el SMP10 se calentará

lentamente (2 ºC por minuto) desde la meseta de

temperatura hasta que se produzca la fusión de la

muestra. Esta baja velocidad de calentamiento permite

obtener puntos de fusión muy precisos.

Solo SMP20

Es posible ajustar la velocidad de rampa del SMP20

entre 1 ºC por minuto y 10 ºC por minuto. De este

modo, se pueden obtener los resultados de forma

rápida o bien más lenta pero más precisa.

15

Page 18

Antes de usar

Coloque la unidad en un sitio firme y nivelado y

extienda las patas situadas en la parte posterior del

instrumento, de tal modo que la unidad tenga un

cómodo ángulo de visualización. Conectar la unidad

a la corriente eléctrica y encenderla mediante el

interruptor de encendido/apagado. La temperatura

real del bloque se mostrará en el indicador LED y se

iluminará la cámara de muestras.

Medición de un punto de fusión

Nota: Si la unidad acaba de ser usada, el bloque puede

estar demasiado caliente para su muestra. Si éste es el

caso, pulse el botón STOP y deje enfriar la unidad antes

de continuar.

1. Prepare la muestra colocando una pequeña

cantidad al final del tubo capilar de vidrio.

2. Determine una meseta de temperatura adecuada.

Ésta debe estar unos 10 ºC por debajo de la

temperatura de punto de fusión esperada.

3. Compruebe que las tres luces de función estén

apagadas. De lo contrario, pulse el botón STOP.

4. Mantenga pulsado el botón SET de meseta (la luz

de meseta parpadeará). La pantalla mostrará la

meseta de temperatura actual.

5. Ahora puede definir la meseta de temperatura

deseada mediante las teclas de flecha hacia arriba

o hacia abajo.

6. Suelte el botón SET. El nuevo valor de meseta de

temperatura está ahora memorizado y

todas las luces de función se apagarán. Este valor

se puede consultar en cualquier momento

durante el funcionamiento del equipo,

simplemente manteniendo pulsado el botón SET

de meseta. Esta acción no interfiere en nada el

normal funcionamiento de la unidad.

7. Sólo SMP20 – Determine la velocidad de rampa

adecuada, entre 1ºC y 10ºC por minuto. Los

resultados obtenidos a 1ºC por minuto serán los

más precisos, mientras que las velocidades de

rampa más elevadas proporcionarán resultados de

forma más rápida pero aproximados.

Para definir la velocidad de rampa se sigue el

mismo procedimiento que al definir la meseta,

excepto que se necesita utilizar el botón SET de

rampa en lugar del botón SET de meseta.

8. Inserte el tubo en el lateral del bloque de

calentamiento, a través de los orificios existentes.

Para su comodidad, puede hacer esto desde

cualquier lado del bloque. Mire por la lupa y

coloque el tubo de forma que la muestra pueda

observarse con claridad.

Precaución: El bloque de calentamiento

puede estar CALIENTE.

9. Pulse la tecla START o START/STOP. La unidad

se calentará rápidamente hasta llegar a la meseta

de temperatura. La luz de calentamiento se

iluminará (vea la figura 1).

10. Una vez que la meseta de temperatura haya sido

alcanzada, la luz de meseta se iluminará, además

de la luz de calentamiento (vea la figura 1).

Nota: Un valor muy bajo en la meseta de temperatura

puede producir que se sobrepase temporalmente el

valor programado. Espere hasta que la luz de meseta se

encienda; así se asegurará de que la temperatura se ha

estabilizado.

11. Pulse de nuevo el botón START. El bloque

comenzará a calentarse a la velocidad de rampa

predefinida (SMP20) o al valor fijado de 2 ºC por

minuto en el SMP10. La luz de meseta se apagará

y las de calentamiento y rampa se iluminarán (vea

la figura 1).

12. Observe el comportamiento de la muestra hasta

que se produzca la fusión y anote la temperatura

mostrada en la pantalla digital.

13. Sólo SMP20 – Es posible congelar la visualización

de temperatura en el SMP20 mediante el botón

HOLD. Una vez pulsado, se mantendrá la

visualización de temperatura (la luz de

rampa destellará) para tener tiempo para registrar

la temperatura de fusión. Pulse de nuevo el botón

HOLD para volver a la temperatura de bloque real.

14. Después de observar la fusión, pulse el botón

STOP o START/STOP. Todas las luces de función

se apagarán y la unidad se irá enfriando hasta la

temperatura ambiente.

15. Si se pulsa nuevamente el botón START, la unidad

vuelve a la programación de meseta de

temperatura en lugar de la temperatura ambiente.

La luz de calentamiento se encenderá, aunque la

temperatura esté por encima de la meseta y en

realidad la unidad se esté enfriando.

Limpieza y mantenimiento

ADVERTENCIA: Asegúrese de que la unidad está

desconectada de la corriente eléctrica y se ha enfriado,

antes de realizar cualquier acción de limpieza o

mantenimiento.

Limpieza

Limpie periódicamente el instrumento con un paño

humedecido y un detergente suave. No utilice

productos de limpieza agresivos o abrasivos. Los tubos

de punto de fusión rotos se pueden sacar del bloque

simplemente haciendo pasar un alambre u otro objeto

similar. Para acceder al bloque y realizar una limpieza

más profunda, debe desmontarse la cubierta de la

cámara de muestras.

16

Page 19

1. Extraiga los tres tornillos de sujeción y quite la

cubierta.

2. Afloje el tornillo que sujeta la placa metálica, sin

quitarlo del todo.

3. Empuje la placa hacia un lado.

4. Ya puede extraer la ventanilla de cristal de la parte

superior del bloque.

Sólo se deben utilizar piezas de repuesto suministradas

o especificadas por Bibby Scientific Ltd. o sus agentes.

La instalación de piezas no aprobadas puede afectar

al rendimiento y a las funciones de seguridad

incorporadas en el instrumento. Si tiene alguna duda,

póngase en contacto con el departamento de servicio

técnico de Bibby Scientific Ltd. o con el punto de venta.

Mantenimiento

Cualquier reparación o sustitución de piezas que se

efectúe DEBE ser llevada a cabo sólo por personal

cualificado. Hay dos fusibles reemplazables en la parte

posterior del conector de alimentación IEC. La causa

de cualquier fallo en el fusible debe investigarse y

corregirse.

Siga estos pasos:

1) Asegúrese de que la unidad esté desconectada de

la red eléctrica.

2) Desenrosque los cuatro tornillos de la base de la

unidad y extraiga la placa base. No desconecte ni

tire del cable de conexión a tierra de la base.

3) Hay dos fusibles montados en la parte posterior

del conector IEC (los cables de suministro eléctrico

“Fase” y “Neutro” están protegidos por un

fusible). Estos fusibles se pueden extraer y sustituir

manualmente. Sustituya SIEMPRE los fusibles

por otros con los valores correctos, como se indica

a continuación:

Para 230 V, 50 Hz: T1A

Para 120 V, 60 Hz: T1.6A

4) Vuelva a colocar la base y los cuatro tornillos de

fijación.

5) Se recomienda realizar una prueba de seguridad

eléctrica PAT (Portable Appliance Test, prueba de

dispositivos portátiles), u otra equivalente, antes

de volver a poner la unidad en funcionamiento.

Para obtener una lista completa de piezas de

recambio y un manual de servicio para técnicos

de mantenimiento, póngase en contacto con el

departamento de servicio técnico de Bibby Scientific

Ltd., indicando el modelo y número de serie.

Bibby Scientific Ltd.

Stone, Staffordshire ST15 0SA

Reino Unido

Tel.: +44 (0)1785 812121

Fax: +44 (0)1785 813748

C. e.: info@bibby-scientific.com

www.bibby-scientific.com

Garantía

Bibby Scientific Ltd. garantiza que este instrumento

estará libre de defectos de material o fabricación,

siempre que se utilice en condiciones normales de

laboratorio, por un período de tres (3) años. En el

caso de que se presente una reclamación justificada,

Bibby Scientific sustituirá gratuitamente el componente

defectuoso o toda la unidad. Esta garantía NO es válida

para ningún daño causado por incendio, accidente, uso

inadecuado, negligencia, reparación o ajuste incorrecto,

ni para ningún daño causado por una instalación,

adaptación, modificación, instalación de piezas no

aprobadas o reparación llevadas a cabo por personal no

autorizado.

Especificaciones técnicas

SMP10 SMP20

Número de muestras Dos Dos

Rango de temperaturas De ambiente a 300°C De ambiente a 300°C

Resolución de temperatura 1°C 0,1ºC

Precisión de temperatura ±1°C ±1°C

Pantalla LED de tres dígitos LED de cuatro dígitos

Sensor PT100 PT100

Velocidades de rampa 20°C/minuto hasta meseta 20°C/minuto hasta meseta

2°C /minuto hasta fusión Entre 1 y 10ºC/min

Dimensiones (AnxFoxAl) 160 x 220 x 170 mm 160 x 220 x 170 mm

Peso neto 1,8 kg 1,8 kg

17

Page 20

Deutsch

ºC

heating

plateau

ramping

stop

plateau set

start

heating

plateau

SMP10 SMP20

Halter für

Probenröhrchen

Netz

Ein / Aus

ºC

heating

plateau

ramping

start/stop

Aufstellfüße

Fläche für

Bedienungshinweise

plateau set

ramp stop

hold

ºC

ramping

start/stop

ramp stop plateau set

hold

Sichtfenster

IEC Netzanschluß

Temperaturanzeige

Bedienfläche

18

SMP10 Fascia SMP20 Fascia

heating

plateau

ramping

ºC

stop

plateau set

start

heating

plateau

ramping

start/stop

ramp stop plateau set

hold

ºC

Page 21

Schmelzpunktapparat

SMP10, SMP20

Instructions for use

Introduction

Wir bedanken uns für den Kauf dieses Bibby Scientific

Produkts. Lesen Sie bitte vor dem Gebrauch des Geräts

diese Bedienungsanleitung gründlich durch, um das

Gerät optimal nutzen zu können und Ihre eigene

Sicherheit zu gewährleisten.

Dieses Gerät ist für den Einsatz unter folgenden

Bedingungen ausgelegt:

v Nur für den Gebrauch in Innenräumen

v In einem gut durchlüfteten Bereich aufstellen

v Umgebungstemperaturbereich +5°C bis +40°C

v Max. Höhe: 2000 m

v Relative Feuchte nicht über 80%

v Stromversorgungsschwankungen nicht über 10%

v Überspannungsklasse II IEC60364-4-443

v Verschmutzungsgrad 2 IEC664

Wenn das Gerät nicht entsprechend der

Bedienungsanleitung eingesetzt wird, können die

Schutzfunktionen des Geräts beeinträchtigt werden.

Elektrische Installation

DIESES GERÄT MUSS GEERDET WERDEN.

Vergewissern Sie sich vor dem Anschluss,

dass die Netzspannung den Angaben auf

dem Geräteschild entspricht. Die

Leistungsaufnahme beträgt 70W.

An der rechten Geräteseite hinten befindet sich ein

genormter IEC-Anschluss für das Netzkabel (siehe

Abbildung 1). Das Gerät wird mit zwei Netzkabeln mit

IEC-Anschluss geliefert. Das eine Netzkabel ist für den

Anschluss in Großbritannien gedacht und besitzt 3

Anschlussstifte, während das andere Kabel mit einem

Schuko-Stecker mit 2 Anschlussstiften ausgestattet

ist. Wählen Sie das entsprechende Kabel für Ihren

Einsatzort. Das andere Kabel kann dann entsorgt

werden. Sollten beide Kabel ungeeignet sein, müssen

Sie sich das entsprechende Kabel vor Ort besorgen.

Ist dies nicht möglich, so kann ein anderer Stecker

auch an das für Großbritannien gedachte Kabel

montiert werden. Das beiliegende Hinweisblatt enthält

Anweisungen zum Montieren eines anderen Steckers.

Falls das Netzkabel einmal ersetzt werden muss,

sollten Sie ein Kabel mit 1 mm

und IEC 320 Stecker verwenden. Anm.: Das GBNetzkabel besitzt eine oben in den Stecker eingebaute

10A-Sicherung. Das Netzkabel muss

2

Querschnitt (H05W-F)

VOR dem Anschluss an die Stromversorgung zuerst

in das Gerät eingesteckt werden.

IM ZWEIFELSFALL WENDEN SIE SICH BITTE AN

EINEN QUALIFIZIERTEN ELEKTRIKER

Allgemeine Beschreibung

Die Modelle Stuart SMP10 und SMP20 wurden für

höchste Sicherheit und Bedienungsfreundlichkeit

konzipiert. Die Temperatur wird gewählt, gemessen

und dann auf einer Digitalanzeige genau dargestellt,

sodass ein Glasthermometer entfällt. Es können

zwei Proben gleichzeitig geprüft werden. Die

Beobachtung erfolgt durch ein leicht sichtbares

Vergrößerungsglas mit eingebauter Beleuchtung.

Durch die Aufstellfüße kann das Gerät auf den

besten Betrachtungswinkel eingestellt werden. Der

Block ist gut zugänglich, um die Reinigung und

Wartung zu erleichtern.

Vor dem ersten Gebrauch des Geräts

Nach dem Auspacken des Geräts wählen Sie bitte

die entsprechende selbsthaftende Beschilderung aus

dem mitgelieferten Sprachsatz. Dann die Folie auf

der Rückseite abziehen und das Schild vorne links am

Gerät anbringen. Das Schild vorsichtig aufkleben und

etwaige Luftblasen mit einem flachen Gegenstand

wegstreichen.

Funktionsweise

Die Schmelzpunktapparate SMP10 und SMP20

wurden so entworfen, dass sowohl eine schnelle und

genaue Ergebnisermittlung als auch eine einfache

Bedienung möglich ist. Die Schmelzpunktproben

werden in ein Kapillarröhrchen gegeben, an einem

Ende versiegelt und in den Aluminiumblock in

der Probenkammer eingesetzt. Dieser Block wird

dann aufgeheizt und die Probe mit Hilfe des

Vergrößerungsglases kontrolliert, bis die Schmelzung

stattfindet. Die Schmelzpunkttemperatur kann dann

leicht von der großen LED-Anzeige abgelesen werden.

Damit die Probe nicht ständig beobachtet werden

muss, besitzt das SMP10 eine „Plateau“-Funktion.

Damit lässt sich die Temperatur auf ein paar Grad

unter dem zu erwartenden Schmelzpunkt einstellen.

Das SMP10 heizt sich dann sehr schnell auf diese

Temperatur auf (20°C pro Minute) und hält sie so

lange, bis der eigentliche Messvorgang stattfinden

soll. Während dieses Vorgangs kann das Gerät

bedenkenlos unbeaufsichtigt sein.

Nur SMP10

Sobald dann der Messvorgang ausgelöst wird, heizt

sich das SMP10 langsam (2°C pro Minute) weiter

auf, bis der Schmelzpunkt erreicht wird. Durch diese

langsame Aufheizrate lässt sich der Schmelzpunkt

sehr genau bestimmen.

19

Page 22

Nur SMP20

Die Aufheizrate des SMP20 kann auf einen Wert

zwischen 1°C pro Minute und 10°C pro Minute

eingestellt werden. Dies ermöglicht die Erzielung eines

schnellen oder eines langsameren, dafür aber genaueren

Resultats.

Vor dem Gebrauch

Das Gerät auf eine feste, ebene Fläche stellen und

die Füße hinten am Gerät so einstellen, dass ein

geeigneter Betrachtungswinkel gegeben ist. Das Gerät

an die Stromversorgung anschließen und mit dem

Ein/Aus-Schalter anschalten. Es wird nun die aktuelle

Blocktemperatur auf der LED-Anzeige dargestellt.

Gleichzeitig schaltet sich die Beleuchtung der

Probenkammer ein.

Messen des Schmelzpunktes

Anm.: Falls das Gerät erst vor kurzem gebraucht wurde,

kann es sein, dass der Block für die nächste Probe zu

heiß ist. In diesem Fall die Stopp-Taste drücken und das

Gerät abkühlen lassen.

1. Eine kleinere Menge der Probe in das Ende eines

Kapillarröhrchens einsetzen.

2. Eine geeignete Plateau-Temperatur wählen.

Diese sollte etwa 10°C unter dem zu erwartenden

Schmelzpunkt der jeweiligen Probe liegen.

3. Kontrollieren, ob alle 3 Funktionsleuchten aus sind.

Andernfalls die Stopp-Taste drücken.

4. Die Taste „Plateau Set“ drücken und halten (die

Plateau-Leuchte blinkt auf). Auf der Anzeige

erscheint die gegenwärtige Plateau-Temperatur.

5. Die gewünschte Plateau-Temperatur kann nun mit

Hilfe der Pfeiltasten und der Anzeige je nach

Bedarf eingestellt werden.

6. Die Taste „Set“ wieder loslassen. Die neue

Plateau-Temperatur ist nun eingestellt, und alle

Funktionsleuchten erlöschen. (Die Plateau Einstellung kann jederzeit durch Drücken und

Halten der Taste „Plateau Set“ kontrolliert werden,

ohne dass dadurch der Gerätebetrieb beeinflusst

würde.)

7. Nur SMP20 – Eine geeignete Aufheizrate

zwischen 1ºC und 10ºC pro Minute festlegen.

Bei einer Aufheizrate von 1ºC pro Minute sind

die Resultate am genausten, bei höheren

Aufheizraten hingegen lassen sich weniger

genaue, aber schnellere Resultate erzielen. Das

Vorgehen zum Einstellen der Aufheizrate

ist identisch mit dem zum Einstellen der Plateau Temperatur, mit dem Unterschied, dass Sie anstelle

der „Plateau Set“-Taste die „Ramp Set“-Taste

verwenden müssen.

8. Das Röhrchen in eines der Löcher des Heizblocks

einsetzen. Dies ist von beiden Seiten aus möglich.

Durch das Vergrößerungsglas schauen und das

20

Röhrchen so positionieren, dass die Probe deutlich

zu sehen ist.

Achtung: Der Heizblock kann HEISS sein.

9. Die Taste „Start“ bzw. „Start/Stop“ drücken. Das

Gerät heizt sich schnell auf die Plateau-Temperatur

auf (die Heizleuchte ist an - siehe Abbildung 1).

10. Nach Erreichen der Plateau-Temperatur sind

sowohl die Plateau-Leuchte als auch die

Heizleuchte aktiviert - siehe Abbbildung 1)

Anm.: Bei niedrigen Plateau-Temperaturen kann

es zunächst zu einem Überschreiten der

eingestellten Temperatur kommen. Daher warten,

bis das Plateau-Licht aufleuchtet, um sicher zu

sein, dass sich die Temperatur stabilisiert hat.

11. Erneut die Taste „Start“ drücken. Der Bock heizt

sich nun mit der voreingestellten Heizrate (SMP20)

bzw. mit der festgelegten Anstiegstemperatur

von 2°C pro Minute beim SMP10 auf (Dabei

geht die Plateau-Leuchte aus, während die

Leuchten für Anstiegsrate und Heizung aktiviert

sind - siehe Abbildung 1.)

12. Die Probe beobachten, bis die Schmelzung

stattfindet, und dann die Temperatur von der

Digitalanzeige ablesen.

13. Nur SMP20 – Mit der Taste „Hold“ kann die

Temperaturanzeige am SMP20 eingefroren

werden. Bei einmaligem Drücken wird die

Temperaturanzeige eingefroren (die Leuchte für die

Heizrate blinkt), damit Sie mehr Zeit zum

Notieren der Schmelztemperatur haben). Bei

erneutem Drücken von „Hold“ kehrt die Anzeige

zum aktuellen Temperaturwert des Heizblocks

zurück.

14. Nach dem Schmelzen die Taste „Stop“ bzw.

„Start/Stop“ drücken. Alle Funktionsleuchten

gehen aus und das Gerät kühlt sich auf

Umgebungstemperatur ab.

15. Durch erneutes Drücken der Taste „Start“ kehrt

das Gerät auf die Plateau-Temperatur zurück.

Die Heizleuchte leuchtet auf, selbst dann, wenn

die Temperatur über der Plateau-Temperatur liegt

und das Gerät sich in Wirklichkeit abkühlt.

Reinigung & Wartung

WARNUNG: Vor jeglichen Wartungs- oder

Reinigungsarbeiten sicherstellen, dass das

Gerät von der Stromversorgung getrennt ist und

sich ausreichend abgekühlt hat.

Reinigung

Das Gerät in regelmäßigen Abständen mit einem

feuchten Tuch und einem milden Reinigungsmittel

säubern. Keine ätzenden Mittel oder Scheuermittel

zur Reinigung verwenden. Zerbrochene

Schmelzpunktröhrchen können mit einem Stück

Page 23

Draht oder ähnlichem einfach durch den Block

hindurchgeschoben werden. Bei einer umfassenderen

Reinigung des Blocks muss zuerst die Abdeckung der

Probenkammer abmontiert werden:

5) Es wird empfohlen, vor erneuter Inbetriebnahme

des Geräts einen elektrischen Sicherheitstest für

tragbare Geräte („PAT“-Test) oder einen

äquivalenten Test durchzuführen.

1. Die 3 Halteschrauben lösen und die Abdeckung

abnehmen.

2. Die Schraube der Metallplatte lösen, aber nicht

ganz herausnehmen.

3. Die Platte zur Seite schieben.

4. Nun kann das Glasfenster oben aus dem Block

herausgenommen werden.

Wartung

Etwaige Reparatur- oder Austauscharbeiten

MÜSSEN von entsprechend qualifiziertem

Fachpersonal vorgenommen werden. Hinten am

IEC-Netzsteckverbinder sind zwei austauschbare

Sicherungen eingebaut. Bei einem Ausfall einer der

Sicherungen ist die Ursache zu ermitteln und zu

beheben.

Wie folgt vorgehen:

1) Sicherstellen, dass das Gerät von der

Netzstromversorgung getrennt ist.

2. Die Schraube der Metallplatte lösen, aber nicht

ganz herausnehmen.

3. Die Platte zur Seite schieben.

4. Nun kann das Glasfenster oben aus dem Block

herausgenommen werden.

Wartung

Etwaige Reparatur- oder Austauscharbeiten

MÜSSEN von entsprechend qualifiziertem

Fachpersonal vorgenommen werden. Hinten am

IEC-Netzsteckverbinder sind zwei austauschbare

Sicherungen eingebaut. Bei einem Ausfall einer der

Sicherungen ist die Ursache zu ermitteln und zu

beheben.

Wie folgt vorgehen:

1) Sicherstellen, dass das Gerät von der

Netzstromversorgung getrennt ist.

2) Die vier Schrauben am Gerätesockel lösen und die

Bodenplatte abnehmen. Nicht den Erdungsdraht

des Sockels lösen oder daran ziehen.

3) Die beiden Sicherungen sind hinten in den IEC

Steckverbinder eingebaut (der stromführende

Leiter und der Neutralleiter sind gesichert). Die

Sicherungen können per Hand ausgetauscht

werden. Die Sicherungen IMMER durch

Sicherungen mit folgenden Nennleistungen

ersetzen:

Für 230 V, 50 Hz - T1A

Für 120 V, 60 Hz - T1,6A

4) Den Sockel wieder anbringen und die vier

Sicherungsschrauben festziehen.

Eine ausführliche Teileliste und ein Wartungshandbuch

sind über die technische Abteilung der Bibby Scientific

Ltd. erhältlich. Dabei bitte sowohl die Modellnummer

als auch die Seriennummer angeben.

Es dürfen nur die von Bibby Scientific Ltd. gelieferten

bzw. vorgeschriebenen Ersatzteile verwendet werden.

Durch nicht genehmigte Komponenten können sowohl

die Leistung als auch die Sicherheitsfunktionen des

Geräts beeinträchtigt werden. Im Zweifelsfall wenden

Sie sich bitte an die technische Abteilung von Bibby

Scientific Ltd. oder an Ihren Händler.

Bibby Scientific Ltd.

Stone, Staffordshire ST15 0SA

Großbritannien

Tel.: +44 (0)1785 812121

Fax: +44 (0)1785 813748

E-Mail: info@bibby-scientific.com

www.bibby-scientific.com

Garantie

Bibby Scientific Ltd. gewährleistet für einen Zeitraum

von drei (3) Jahren, dass dieses Gerät bei Einsatz

unter normalen Laborbedingungen von Material und

Verarbeitungsfehlern frei ist. Im Falle einer berechtigten

Reklamierung ersetzt Bibby Scientific kostenlos alle

defekten Teile bzw. das gesamte Gerät. Diese Garantie

gilt NICHT, wenn Schäden durch Feuer, Unfall,

Missbrauch, Nachlässigkeit, falsche Einstellung oder

Reparatur, durch unsachgemäße Installation, Adaption,

Modifikation, Montage nicht genehmigter Teile oder

Reparatur durch nicht autorisierte Personen entstanden

sind.

21

Page 24

Technische Daten

SMP10 SMP20

Anzahl der Proben Zwei Zwei

Temperaturbereich Umgebungstemp. bis 300°C Umgebungstemp. bis 300°C

Temperaturauflösung 1°C 0,1ºC

Temperaturgenauigkeit ±1°C ±1°C

Anzeige Dreistellige LED Vierstellige LED

Fühler PT100 PT100

Heizraten 20°C / Minute bis Plateau 20°C / Minute bis Plateau

2°C / Minute bis Schmelzung Zwischen 1 und 10ºC / Minute

Abmessungen (BxTxH) 160 x 220 x 170 mm 160 x 220 x 170 mm

Nettogewicht 1,8 kg 1,8 kg

22

Page 25

This product meets the applicable

EC harmonized standards for radio

frequency interference and may be

expected not to interfere with, or be affected

by, other equipment with similar qualifications.

We cannot be sure that other equipment

used in its vicinity will meet these standards

Declaration of Conformity

and so we cannot guarantee that interference

will not occur in practice. Where there is a

possibility that injury, damage or loss might occur

if equipment malfunctions due to radio frequency

interference, or for general advice before use,

contact the Technical Department of Bibby

Scientific Ltd.

23

Page 26

INSPECTION REPORT

MODEL SMP10

SMP20

ELECTRICAL SAFETY

1. Earth continuity

2. Insulation

3. Flash test

FUNCTIONAL

1. Indicators

2. Temperature control

3. Visual acceptance

QUALITY CONTROL INSPECTOR

Bibby Scientific Ltd

Beacon Road Stone

Staffordshire ST15 0SA

United Kingdom

Tel: +44 (0)1785 812121

Fax: +44 (0)1785 810471

e-mail: info@bibby-scientific.com

www.bibby-scientific.com

Bibby Scientific France SAS

ZI du Rocher Vert - BP 79

77793 Nemours Cedex

France

Tel: +33 1 64 45 13 13

Fax: +33 1 64 45 13 00

e-mail: bsf@bibby-scientific.fr

www.bibby-scientific.com

Bibby Scientific US Ltd

3 Terri Lane Suite 10

Burlington NJ 08016

USA

Tel: 800-225-9243

Fax: 609-589-2571

www.bibby-scientific.com

Bibby Scientific Italia Srl

Via Alcide de Gasperi 56

20077 Riozzo di Cerro al Lambro

Milano Italia

Tel: +39 (0)2 98230679

Fax: +39 (0)2 98230211

e-mail: marketing@bibby-scientific.it

www.bibby-scientific.it

Bibby Scientific (Asia) Ltd

Room 607 Yen Sheng Centre

64 Hoi Yuen Road Kwun Tong

Kowloon Hong Kong

Tel: +852 3583 1581

Fax: +852 3583 1580

e-mail bibby@bibby-scientificasia.com

www.bibby-scientificasia.com

Page 27

WARRANTY/DISCLAIMER