Page 1

MICROMACHINED SILICON

MODULAR PRESSURE SENSOR

Configurable—High Accuracy—High Temperature Performance

For Industrial, Test and Measurement, and Aerospace Applications

Low Pressure from 10 in-H2O to 2.5 psi

and Standard Ranges from 5 to 5000 psi

Metric Ranges: 25 mbar to 350 bar

MM Series Pressure

Transducers

Standard

Optional

Most Popular

Models in Stock!

Fast Delivery for

Thousands of

Configurations!

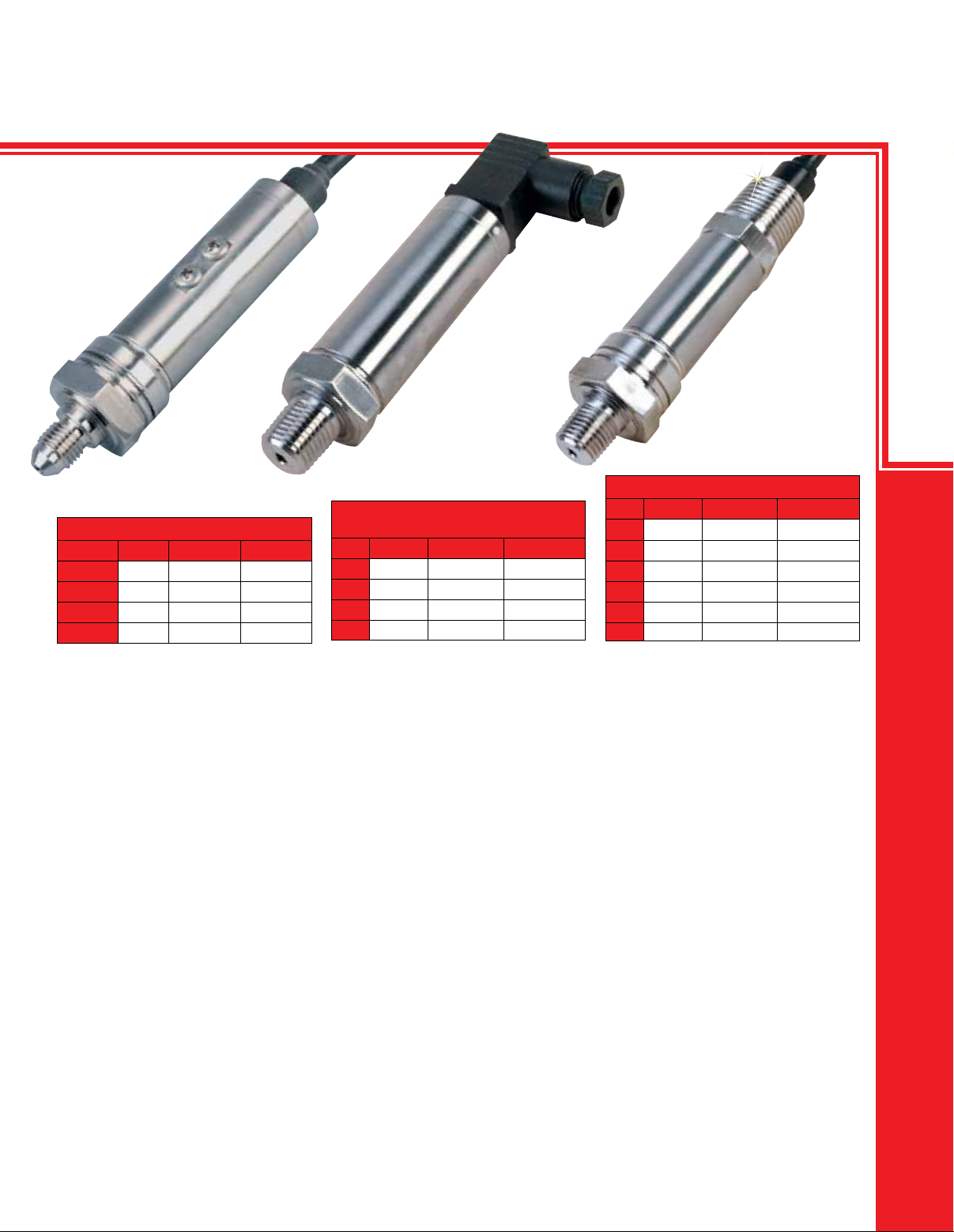

MMG050VP5C0T3A5,

features 50 psig, mV

output, 0.40% accuracy,

cable termination.

B

U Customer Selectable Features

U Fast Delivery

U High Accuracy

U Up to ±0.03% Linearity

Available Accuracies:

±0.05% FS BSL Accuracy

±0.08% FS BSL Accuracy

±0.20% FS BSL Accuracy

±0.40% FS BSL Accuracy

U Premium Temperature

Performance

U Broad Compensated Range

U Gage, Absolute, Barometric, Vacuum,

U Compound and Differential

U 5-Point NIST Traceable Calibration

MMG100C1P5C6T3A5,

features 100 psig

4 to 20 mA output,

0.40% accuracy,

mini DIN termination.

MMG10WVP3C1T2A2,

features 0 to 10 in-H2O,

mV output, 0.08% accuracy,

twist-lock termination.

1 Week Delivery

on Custom

Configurations

All models shown actual size.

MMDWU015VP5C1T3A5,

features 15 psid,

mV output, 0.40% accuracy,

twist-lock termination.

Note: BSL = Best Straight Line.

B-1

Page 2

ONE SOURCE FOR ALL YOUR PRESSURE

MEASUREMENT APPLICATIONS

Gage Pressure

Low Pressure

Absolute Pressure

Differential Pressure

Vacuum Ranges

Compound Ranges

Barometric Pressure

OMEGA has developed a rapid delivery system for

its new Micro Machined Silicon product line.

Adjustable

zero and span

potentiometers

MMG1.0KC1P2J0T3A5P,

1000 psig, 0.05% accuracy,

MMG100C1P5C6T3A5,

4 to 20 mA output,

2 m (6') cable, and

optional potentiometers.

features 100 psig

4 to 20 mA output,

0.40% accuracy,

mini DIN termination.

You can have your pick of pressure ports,

electrical connections, pressure range and units,

thermal range and accuracy and accessories

like trim pots. There are over 1-million possible

combinations. OMEGA can deliver reasonable

quantities of almost any combination within

5 working days. We have an easy-to-use

configurator online at omega.com where you can

select the transducer with the exact specifications

for your project.

We also have the most popular configurations

stocked for same day shipment!

OMEGA’s micro-machined piezoresistive

pressure transducers have a proven record in

high performance commercial, automotive, test

and measurement and aerospace applications.

The piezoresistive process uses strain gages

molecularly embedded into a highly stable silicon

wafer. The silicon wafer is diced into individual

die which each contain a full strain gage bridge.

The die is mounted in a sealed chamber protected

from the environment by glass to metal seals and

a pressure sensitive stainless steel diaphragm. A

small volume of silicone oil transfers the pressure

from the diaphragm to the strain bridge. The

construction provides a very rugged transducer

with exceptional accuracy, stability and thermal

effects.

All models shown

actual size.

MMS20A015C1P31T6A5,

15 psia 4 to 20 mA output,

2" sanitary fitting,

0.08% accuracy,

twist-lock termination.

A unique design ruggedizes the transducers by

providing secondary fluid containment in the event

of a diaphragm rupture.

U Five Accuracies

U Ninety-Two Pressure Ranges

U Ten Electrical Outputs

U Four Thermal Ranges

U Fourteen Pressure Ports

U Five Electrical Terminations

U Over 1,000,000 Combinations!

B-2

Page 3

MM SERIES

MMG1.0KC1P4J0T3A5P,

4 to 20 mA output, 1000

psig, 0.20% accuracy with

CABLE CONNECTION

COLOR mV 5/10V mA

BLACK – EXC Common – EXC

WHITE + SIG + Out + CAL

GREEN – SIG SHUNT SHUNT

RED + EXC + EXC + EXC

COMMON SPECIFICATIONS

G/A/V/CG/BARO

Approvals: RoHS and CE

Calibration: 5-point NIST traceable

Bandwidth: DC to 1 kHz typical

Response Time: < 1 ms

CE Compliant: IEC61326

Emissions: IEC550022 Class B

Electrostatic Discharge Immunity: IEC1000-4-2

EM Field Immunity: IEC61000-4-3

EFT Immunity: IEC61000-4-4

Surge Immunity: IEC61000-4-5

Conducted RF: IEC61000-4-6

Rate Power Frequency Magnetic Field: IEC61000-4-8

Minimum Resistance Between Body and Any Wire:

100 MΩ @ 50 Vdc

Weight: 115 to 200 g (4 to 7 oz) (depending

upon configuration)

Environmental

Operating Temperature: -45 to 121°C (-49 to 250°F)

Protection:

Cable: 2 m (6') IP67

mini DIN: IP65

Twist-Lock and M12: IP65

Conduit 2 m (6') Cable with

Mechanical

Wetted Parts: 316L stainless steel

Media: Compatible with 316L SS

Pressure Cycles: 1 million minimum

potentiometers.

MMG100C1P5C6T3A5,

features 100 psig,

4 to 20 mA output, 0.40%

accuracy, mini DIN

termination.

M12, MINI DIN

AND SOLDER PINS CONNECTION

PIN mV 5/10V mA

1 + EXC + EXC + Supply

2 – EXC Common – Supply

3 + OUT + Output NC

4 – OUT NC NC

1

⁄2 NPT Conduit Fitting: IP67

MMG1.0KC1P2C2T3A5,

features 1000 psig, 4 to 20

mA output, 0.05% accuracy,

cable termination with

conduit fitting.

TWIST-LOCK CONNECTION

PIN mV 5/10V mA

A + EXC + EXC + EXC

B – EXC Common – EXC

C + OUT + OUT + SHUNT

D – OUT + SHUNT + SHUNT

E NC NC NC

F NC NC NC

Long Term Stability (1-Year): ±0.1% FS typical

Shock: 50 g, 11 mS half sine, vertical and horizontal axis

Vibration: 5-2000-5 Hz, 30 minute cycle, curve L, mil-spec

810 figure 514-2-2, vertical and horizontal axis

Overpressure Gage Pressure:

10-in H

1 psi: 6 times span

2.5 psi to 3500 psi: 4 times span

5000 psi: 15,000 psi max

Overpressure Absolute Pressure:

5 psia: 6 times span

2.5 psia to 3500 psia: 4 times span

5000 psia: 15000 psi max

O: 10 times span

2

Secondary Containment

Gage/Diff/Vac/Compound:

10 in-H

15 to 1000 psi: To 3000 psi

1500 to 5000 psi: To 15,000 psi

Absolute/Barometric:

5 to 1000 psi: To 6000 psia

1500 to 5000 psi: To 15,000 psia

O to 5 psi: To 1000 psi

2

Excitation

3 mV/V: 10 Vdc (ratiometric 5 to 10 Vdc)

10 mV/V: 10 Vdc (ratiometric 5 to 10 Vdc)

0 to 5 Vdc: 10 to 30 Vdc @ 10 mA

0 to 10 Vdc: 15 to 30 Vdc @ 10 mA

4 to 20 mA: 9 to 30 Vdc (9 to 20 Vdc above 229°F)

Bipolar Amplifiers: Same as corresponding

outputs from above—compound and some differential

pressure models

B-3

1

⁄2 NPT

B

Page 4

60.97 (2.40)

5.21 (0.20)

ø63.91

(2.52)

PX429S20 2" flange

ø22.25

(0.88)

MM SERIES SANITARY PROCESS SENSORS

Using Micro-Machined Silicon Technology

10 mV/V, 0 to 5 Vdc, 4 to 20 mA Outputs

Gage Pressure: 10 inH2O to 600 psi (25 mb to 41 bar)

Absolute Pressure: 5 to 600 psi (345 mb to 41 bar)

Compound Gage: ±10 inH2O to ±15 psi (±25 mb to ±1 bar)

Vacuum (Negative Gage): 0 to -10 inH2O to 0 to -15 psi

(25 mb to 1 bar)

Barometric Ranges: 0 to 32 inHg to 26 to 32 inHg

Sanitary Pressure Transducers

and Transmitters

®

Standard

in food processing, beverage or

74-03

U High, 0.08% Accuracy

U Solid State Sensor for

Durability

U Excellent Long Term

Stability

U Welded Stainless Steel

Construction

U 316L SS Wetted Parts

U Shock and Vibration Rated

U High Overpressure Rating

U Ruggedized with

Secondary Containment

System

The MM Series micro-machined

silicon transducers with 11⁄2 or

2" sanitary fittings are ideal for

pressure or level CIP applications

ø22.25

5.21 (0.20)

60.97 (2.40)

(0.88)

ø63.91

(2.52)

PX429S20 2" flange

Dimensions: mm (inch)

Ø = Diameter

Mating

connector

included

(not shown)

bio/pharmaceutical applications as

well as industrial applications that

require a rugged, high accuracy

transducer. The micro-machined

silicon sensor provides a transducer

with excellent long term stability.

The modular construction allows for

fast delivery of most configurations

and fittings.

COMMON SPECIFICATIONS

SANITARY

Accuracy: 0.4% to 0.05% best straight

line (linearity, hysteresis and repeatability

combined) compound gage models

calibrated in positive direction only

Calibration: 5-point NIST traceable

calibration with zero and span values,

calibrated in horizontal direction

Zero Balance: ±0.5% FS typical ±1%

max (for ranges ≤2.5 psi ±1% typ. ±2%

max)

Span Setting: ±0.5% FS typical ±1%

max (for ranges ≤2.5 psi ±1% typ. ±2%

max)

5.21 (0.20)

60.97 (2.40)

Twist-lock

style.

or 2 "

2

⁄

TM

ø22.25

(0.88)

ø50.39

(1.98)

Fitting

1

1

Tri-Grip

PX429S15-015GV, shown

smaller than actual size.

PX419S15 1½" flange

mini DIN

style.

Fast Delivery!

Stock to 1 Week

on Most Models

PX419S20-100AV, shown

smaller than actual size.

Operating Temperature Range:

-15 to 115°C (-5 to 240°F)

Compensated Temperature Range:

Ranges ≤ 5 psi: 4.4 to 60°C

(40 to 140°F)

Ranges > 5 psi: -4 to 85°C

(25 to 185°F)

Temperature Compensation:

Zero and Span Shift Over

Compensated Range

Ranges ≤ 25 psi:

Zero: 1.00%

Span: 0.70%

Range = 5 psi:

Zero: 0.80%

Span: 0.50%

Ranges > 5psi:

Zero: 0.50%

Span: 0.50%

26B & 26HB Barometric Range:

Zero: 0.90%

Span: 0.50%

Minimum Isolation Between Case and

Output Terminations:

100M Ω @ 50 Vdc

Pressure Cycles: 1 million, min

Long Term Stability (1-Year): ±0.1%

FS typ.

Shock: 50 g, 11 mS half sine shock,

(under test)

Vibration: ±20 g (under test)

Bandwidth: DC to 1 kHz typical

Response Time: <1 mS

Fill Fluid: NEOBEE M5 food grade

Approved to 3A Sanitary

Specification 74-03

CE Compliant: Meets industrial

emissions and immunity standard

IEC61326 for industrial locations

B-4

Page 5

Conduit backend PX409C

Integral cable backend PX409

Twist-lock backend PX429

5 (0.2)

28

(1.1)

½ NPT TH’D

(gage units only)

MM SERIES SANITARY PROCESS SENSORS

High Accuracy Pressure Transducers

Piezoresistive Design With High Temperature Performance

All images shown

smaller than actual size.

Cable style.

PX409S Series

PX409 Cable Connection

Color mV 5/10V mA

Black – EXC Common – Supply

White + SIG + Output NC

Green – SIG NC NC

Red + EXC + EXC + Supply

Conduit backend PX409C

28

(1.1)

Integral cable backend PX409

5 (0.2)

½ NPT TH’D

mini DIN and M12 style. Twist-lock style.

PX419S Series

PX459S M12

connector.

PX419/PX459 Pinout

Pin mV 5/10V mA

1 + EXC + EXC + Supply

2 – EXC Common – Supply

3 + SIG + Output NC

4 – SIG NC NC

5 (0.2)

Vent with porous plug

(gage units only)

mini DIN backend PX419

5 (0.2)

PX429 Twist-Lock Pinout

Pin mV 5/10V mA

A + EXC + EXC + Supply

B – EXC Common – Supply

C + SIG + Output NC

D – SIG NC NC

E NC NC NC

F NC NC NC

Dimensions: mm (inch)

PX429S Series

NC = No Connection.

2 connector

bacend

Ø 20.2

(0.8)

2

(0.2)

B

Environmental Protection:

IP65 or IP67 depending upon electrical

termination

Pressure Rating:

½ and 2" Tri-GripTM (compatible with

Tri-Clamp®)

OUTPUT SPECIFICATIONS

Specifications (mV/V Output)

Output: 10 mV/V: ratiometric

5 to 10 Vdc

Supply: 5 to 10 Vdc

Vent with porous plug

Fitting: 600 psi using suitable clamp

Over Pressure: 4 x rated pressure to

maximum rated flange pressure

Secondary Containment: 6 x rated

pressure to a maximum of 2000 psi (not

in clamp)

Specifications (Amplified Voltage

Output)

Output/Supply:

0 to 5 Vdc: 10 to 30 Vdc

0 to 10 Vdc: 15 to 30 Vdc

B-5

Wetted Parts:

316L SS

Weight: 285 g (10 oz

Specifications (4 to 20 mA Output)

Output/Supply:

Output: 4 to 20 mAdc

Supply: 9 to 30 Vdc

[9 to 20 Vdc above 105°C (229°F)]

max loop res Ω = (Vs-9) x 50

)

Page 6

ø22.25

(0.88)

ø50.39

(1.98)

PX419S15 1½" flange

60.97 (2.40)

5.21 (0.20)

2 m

(6')

MM SERIES SANITARY PROCESS SENSORS

USB OUTPUT

USB Output Sanitary Fitting Pressure Transducer

Connect Directly to Your PC or Laptop

Gage, Absolute, Compound Gage, Vacuum and Barometric Pressures

10 inH2O to 600 psi (25 mb to 41 bar)

MM Sanitary USB Series

®

Standard

Ranges > 5psi:

74-03

USB SANITARY

SPECIFICATIONS

Accuracy: 0.08% typical best straight

line, 0.14% max (linearity, hysteresis

and repeatability combined) compound

gage models calibrated in positive

direction only

Calibration: 5-point NIST traceable

calibration with zero and span values

calibrated in horizontal direction

Zero Balance: ±0.5% FS typical ±1%

max (for ranges ≤2.5 psi ±1% typical

±2% max)

Span Setting: ±0.5% FS typical

±1% max (for ranges ≤2.5 psi ±1%

typical ±2% max)

Operating Temperature Range:

-15 to 95°C (-5 to 203°F)

Compensated Temperature Range:

Ranges ≤ 5 psi: 4.4 to 60°C

(40 to 140°F)

Ranges > 5 psi: -4 to 85°C

(25 to 185°F)

Temperature Compensation

Zero and Span Shift Over

Compensated Range:

Ranges ≤2.5 psi:

Zero: 1.00%

Span: 0.70%

Range = 5 psi:

Zero: 0.80%

Span: 0.50%

Zero: 0.50%

Span: 0.50%

26B/26HB Barometric Range:

Zero: 0.90%

Span: 0.50%

Minimum Isolation Between Case and

Output Terminations:

100M Ω @ 50 Vdc

Pressure Cycles: 250,000, minimum

Long Term Stability (1-Year): ±0.1%

FS typical

Shock: 50 g, 11 mS half sine shock,

(under test)

Vibration: ±20 g (under test)

Bandwidth: DC to 3 Hz typical

A to D Conversion: 14 bit

Response Time: <1 mS

Fill Fluid: NEOBEE M5 food grade

Approved to 3A Sanitary

Specification 74-03

CE Compliant: Meets industrial

emissions and immunity standard

IEC61326

Environmental Protection: IP65

Pressure Rating:

½ and 2" Tri-Grip

Fitting: 600 psi using suitable clamp

Over Pressure: 4 x rated pressure to

maximum rated flange pressure

Secondary Containment: 6 x rated

pressure to a maximum of 2000 psi (not

in clamp)

Wetted Parts: 316L SS

Weight: 285 g (10 oz)

TM

Dimensions: mm (inch)

Ø = Diameter

FREE SOFTWARE INCLUDED!

Each unit includes free software that

converts your PC into a strip chart

recorder or data logger so readings can

be saved and later printed or exported

to a spread sheet file. Also included are

software drivers for some of the most

popular Laboratory programs

.

B-6

Laptop not

included.

Page 7

MM SERIES

15 psid and below

Conduit backend PX409C

Integral cable backend PX409

Twist-lock backend PX429

mini DIN backend PX419

5 (0.2)

5 (0.2)

5 (0.2)

28

(1.1)

Vent with porous plug

(gage units only)

DIFFERENTIAL PRESSURE MODELS

mV/V, 0 to 5 or 0 to 10 Vdc,

or 4 to 20 mA Outputs

Uni-Directional or Bi- Directional

0-10 inH2O to 0-1000 psid

MM Series

Standard

U Precision Micro-Machined

Silicon Core

U 5-Point NIST Traceable

Calibration

U High Stability, Low

Drift

U Welded Stainless Steel

Construction

U 316L SS Wetted Parts

U Premium Temperature

Performance

U Broad Compensated

Temperature Range

U Durable, 1 Million

Cycle Life

U Ruggedized with

Secondary Containment

U Customized Specifications

Available

COMMON SPECIFICATIONS

DIFFERENTIAL

Accuracy: 0.4% to 0.05% BSL linearity,

hysteresis and repeatability combined

Minimum Resistance Between

Transducer Body

and Any Wire: 100 MΩ

Operating Temperature:

mV/V and 5 to 10 Vdc Output:

-45 to 121°C (-49 to 250°F)

mA Output: -45 to 115°C

(-49 to 239°F)

Compensated Temperature Range:

10 inH

(1 to 185°F)

15 to 1000 psi: -29 to 85°C

(-20 to 185°F)

Thermal Accuracy:

% Span Shift over compensated

temperature range

Zero Span

10 inH

2.5 to 1000 psi: ±0.50 ±0.50%

Pressure Cycles: 1 million minimum

Long Term Stability (1-Year):

±0.1% FS typical

Bandwidth: DC to 1 kHz typical

Response Time: <1 ms

CE Complient: Meets EN1326-1:

2006 for industrial locations

Shock: 50 g, 11 mS half sine,

vertical and horizontal axis

O to 5 psi: -17 to 85°C

2

O to 1 psi: ±1.00% ±1.00%

2

Vibration: 5-2000-5 Hz, 30 minute

cycle, Curve L, Mil-Spec 810 figure

514-2-2, vertical and horizontal axis

Wet Wet:

Wetted Parts: 316L stainless steel

Wet Dry:

Positive Side: 316L stainless steel

Negative Side: Clean, dry, non-ionic

gases

Line/Static Pressure: 500 psi max

applied to both sides simultaneously

Proof Pressure (Differential):

10 inH

1 psi range = 6 times range

2.5 to 750 psi ranges = 4 times range

1000 psi range = 3 times range

Hi Side Containment Pressure

(Differential):

Ranges 10 inH2O to 5 psi: to 1000 psi

Ranges 15 to 1000 psi: to 3000 psi

Pressure Ports: Select

Electrical Terminations:

PX409: 2 m (6') cable

PX409C: 2 m (6') cable with

conduit thread

PX419: mini DIN

(mating connector included)

PX429: Twist-lock,

(mating connector sold separately)

PX459: M12 connector

PX429 Mating Connector:

PT06F10-6S

Weight: 200 g (7 oz) max

O range = 10 times range

2

1

⁄2 NPT

B

Dimensions: mm (inch)

ø = diameter

68.5 (2.7)

Serial # and range

identify high port

ø22.8

(0.9)

50.8 (2.0)

78.7 (3.1)

30 psid and above

22.8 (0.875) hex

each end

¼ - 18 NPT

each end

Serial # and range

identify high port

B-7

71.1 (2.8)

50.8 (2.0)

78.7 (3.1)

ø22.8

(0.9)

25.4 (1.0) hex

each end

¼ - 18 NPT

each end

Page 8

4.3 (0.17)

4.8 (0.19)

4.8 (0.19)

9.4 (0.37)

½ NPT

conduit fitting

included

Code 1

Code 6

Code 0

Code 2

4.3 (0.17)

M12 x 1

Vented

through cable

Ø 20.2

(0.8)

2

(0.2)

2

onnector

4.3 (0.17)

4.8 (0.19)

4.8 (0.19)

9.4 (0.37)

ø22.3

(0.88)

ø22.3

(0.88)

ø22.3

(0.88)

ø22.3

(0.88)

22.2 (0.875)

Wrench

Flats

25 (1)

Wrench

Flats

63.7

(2.51)

65.2

(2.57)

57.1

(2.25)

9.4

(0.37)

49

(1.93)

49.5

(1.95)

Hex

25 (1)

Wrench

Flats

Hex

22.2 (0.875)

Wrench

Flats

Hex

Hex

Hex

Hex

½ NPT

conduit fitting

included

Code 1

Code 6

Code 0

Code 2

Code ME

Code L

Code MC

Code MA

Code J

Code C

Code A

4.3 (0.17)

M12 x 1

Vented

through cable

Ø 20.2

(0.8)

2

(0.2)

2

onnector

4.3 (0.17)

4.8 (0.19)

9.4 (0.37)

½ NPT

conduit fitting

included

4.3 (0.17)

M12 x 1

Vented

through cable

Ø 20.2

(0.8)

2

(0.2)

2

onnector

4.8 (0.19)

9.4 (0.37)

½ NPT

conduit fitting

included

Vented

through cable

Ø 20.2

(0.8)

2

(0.2)

2

onnector

Vented

through cable

Ø 20.2

(0.8)

2

(0.2)

2

4.8 (0.19)

9.4 (0.37)

½ NPT

conduit fitting

included

Vented

through cable

Ø 20.2

(0.8)

2

(0.2)

2

onnector

4.3 (0.17)

4.8 (0.19)

4.8 (0.19)

9.4 (0.37)

ø22.3

(0.88)

ø22.3

(0.88)

ø22.3

(0.88)

ø22.3

(0.88)

22.2 (0.875)

Wrench

Flats

25 (1)

Wrench

Flats

63.7

(2.51)

65.2

(2.57)

57.1

(2.25)

45.2

(1.78)

20.8

9.4

(0.37)

49

(1.93)

49.5

(1.95)

Hex

25 (1)

Wrench

Flats

Hex

22.2 (0.875)

Wrench

Flats

Hex

Hex

Hex

Hex

Male

16.2

(0.64)

17

(0.67)

14

(0.55)

10.6

(0.42)

16.5

(0.65)

14.2

(0.56)

13

(0.51)

M12 x 1.5-6g 9/16-18 UNF-2A G 1/4B-19TPI G 1/8-28TPI 7/16-20 UNJF-2A 1/4-18 NPT 1/8-27 NPT

½ NPT

conduit fitting

included

Code 1

Code 6

Code 0

Code 2

Code ME

Code L

Code MC

Code MA

Code J

Code C

Code A

Code MF

Code M

Code MD

Code MB

Code K

Code D

Code B

4.3 (0.17)

M12 x 1

Vented

through cable

Ø 20.2

(0.8)

2

(0.2)

2

onnector

ELECTRICAL TERMINATION

6-Pin, Vented or

4.3 (0.17)

Non-Vented Bendix

PT06F10-6S mating

connector,

sold separately.

DIMENSIONS

Low Range

Pressure Transducer

<15 psi Units

M12 Connector

5 (0.2)

Pressure Transducer

Ø 20.2

(0.8)

M12 x 1

(gage units only)

Mid Range

Barometric

Transducer

≥15 psi Units

Vent with

porous plug

4-Pin, Vented or Non-

Vented mini DIN

included

4.8 (0.19)

Low Range Differential

Pressure Transducer

<15 psi Units

4-Conductor

Integral Cable, 2 Meter

4.8 (0.19)

Mid Range Differential

Pressure Transducer

Cable with 1⁄2 NPT

Conduit Fitting

≥15 psi Units

ø22.3

(0.88)

57.1

(2.25)

45.2

(1.78)

20.8

(0.82)

Hex

25 (1)

9.4

(0.37)

Wrench

Flats

PRESSURE PORTS*

Male

(0.64)

16.2

ø22.3

(0.88)

22.2 (0.875)

17

(0.67)

Hex

Wrench

Flats

65.2

(2.57)

14

(0.55)

ø22.3

(0.88)

(1.93)

Hex

10.6

(0.42)

49

25 (1)

Wrench

Flats

Hex

63.7

(2.51)

Ø = diameter

Dimensions: mm (inch)

16.5

(0.65)

Hex

ø22.3

(0.88)

22.2 (0.875)

49.5

(1.95)

14.2

(0.56)

Wrench

Flats

Hex

13

(0.51)

Female

Dimensions may vary slightly for ranges >1000 psi.

*

M12 x 1.5-6g 9/16-18 UNF-2A G 1/4B-19TPI G 1/8-28TPI 7/16-20 UNJF-2A 1/4-18 NPT 1/8-27 NPT

12.7

(0.50)

M12 x 1.5-6H 9/16-18 UNF-2B G 1/4B-19TPI G 1/8-28TPI 7/16-20 UNJF-2B 1/4-18 NPT 1/8-27 NPT

18.3

(0.72)

14.2

(0.56)

8

B-8

10.6

(0.42)

(0.67)

17

14.2

(0.56)

14.2

(0.56)

Loading...

Loading...