Page 1

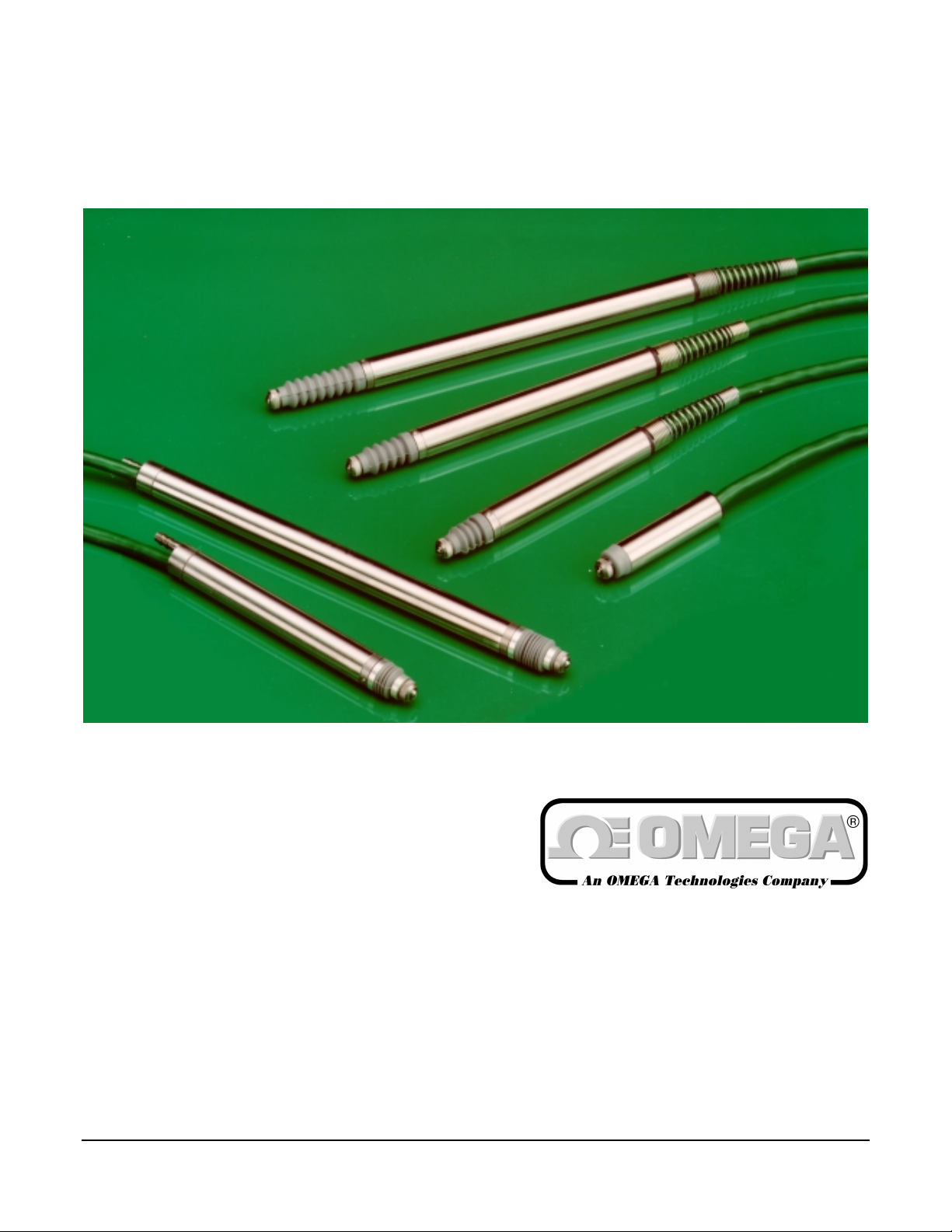

User’s Guide

http://www.omega.com

e-mail: info@omega.com

GP911 Series

Analog Gaging Transducers

GP911 Series M-3337 02/99

Page 1 of 12

Page 2

OMEGAnet® On-Line Service

http://www.omega.com

Internet e-mail

info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified

Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (95) 800-826-6342 FAX: (95) 203-359-7807

En Espan˜ol: (95) 203-359-7803 e-mail: espanol@omega.com

SM

SM

SM

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified

Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in the United Kingdom: 0800-488-488

e-mail:

info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification

of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING

GP911 Series M-3337 02/99

: These products are not designed for use in, and should not be used for, patient-connected applications

Page 2 of 12

.

Page 3

Contents

Product Description 4

Description ....................................................................................................................4

Installation Recommendations......................................................................................4

Electrical Connections for Use with Omega Electronics...............................................7

Location & Clamping........................................................................................4

Tip Tightness ...................................................................................................5

Zero Adjustment............................................................................................... 5

Cable................................................................................................................ 5

Pneumatic Options ..........................................................................................6

Adjustable Pretravel Option ............................................................................6

Environmental Considerations.........................................................................6

Quadrature Resistor......................................................................................... 7

GP911 Series M-3337 02/99

Page 3 of 12

Page 4

Product Description

Description

Omega Gaging Transducers are high precision measurement probes intended

for all Gaging applications demanding high accuracy and a high degree of

repeatability. The one piece parallel body houses a precision linear ball sleeve

bearing assembly, anti-rotation guide and the choice of either a half bridge or a

L.V.D.T. winding, a combination which adds up to an extremely versatile,

accurate and cost effective measurement solution.

Installation Recommendations

Location & Clamping

L.V.D.T. Gaging transducers generally are a reliable and proven technology that

is well established in all areas of manufacturing and quality control. The majority

of the associated problems experienced with their application and use are totally

avoidable, particularly if sufficient thought is given during the initial design stages

of equipment, to the position and clamping methods employed for these

measuring elements.

L.V.D.T.’s being of inductive nature are susceptible to some degree to the

influence of magnetic fields and therefore should be positioned well away from

electric motors, relays and permanent magnets, where this is not possible then

magnetic shielding should be considered as an alternative.

Clamping of the probe body should be carefully considered, ideally the body of

the transducer should be clamped in a pinch or yoke type clamp, if this is not

possible then the introduction of a load spreading bush between body and clamp

is a preferred alternative.

Irrespective of clamping method care must be taken not to overtighten retaining

screws as distortion of the body may prove damaging to the integrity of the

transducer and adversely effect the geometry of the installation.

Where single point screw clamping is adopted then the tightening torque

employed should be limited to that which will give a maximum of 50Kg point load.

The typical maximum torque for an M5x0.8mm or a 10-32UNF screw would be

approximately 0.27Nm.

GP911 Series M-3337 02/99

Page 4 of 12

Page 5

Tip Tightness

Standard measuring tips are factory tightened to a torque of between 0.18Nm

and 0.22Nm, this is sufficient to prevent loosening of the tip in use, but well within

the damage threshold of the anti-rotation mechanism. It is recommended that

replacement tips are tightened to the prescribed torque limits with the shaft fully

retracted. A proprietary thread locking anaerobic sealant may be used sparingly if

desired.

Zero Adjustment

This is best achieved by first positioning the Gage master, zeroing any electrical

offset control, selecting the course set gain and moving the Gaging probe into

contact with the master until the reading comes onto the scale. Gently tighten the

clamp until it is just possible to ”fidget” the probe manually towards the zero

indication.

As zero is approached, the instrument gain may be increased; when the zero

point is within the range of the zero offset controls the clamp must be fully

tightened. Any standard Omega probe used over the whole of its rated stroke

should be mechanically set to within 0.004” (0.10mm) of true zero, if the

measuring range is less than the rated stroke then the setting tolerance may be

increased proportionally to within the limits of the available electrical offset.

Cable

The transducer cable is specially manufactured to company specification to

achieve the optimum balance between flex life, flexibility, chemical resistance,

abrasion resistance and electrical characteristics such as electrostatic screening.

The following precautions will minimize transducer failure due to cable damage.

Cable runs should be positioned well clear of moving components and vulnerable

working areas. If the cable is in a flex situation then a minimum bend radius of 6”

(150mm) should be maintained, the vacuum and pneumatic options should not

be flexed from the transducer cable entry, but should be anchored separately at a

position of 2-3” (50-75mm) from the end cap.

Specials

All non-pneumatic probes are provided with a cable strain relief spring as

standard. This feature allows the user to retrospectively install a right angle cable

outlet to aid space or cable routing restrictions.

1.181”

30.0mm

Dimension

0.315”

8.0mm

0.335”

8.5mm

GP911 Series M-3337 02/99

Page 5 of 12

Page 6

Pneumatic Options

The Gaging tip of pneumatic probes is normally biased in the inward direction

and extension of the tip is achieved by applying air pressure to the probe nozzle.

Air pressure may be varied within the specified limits to achieve the desired tip

force at zero. The pneumatic probes are designed to be leak free and of small

volume to minimize the air flow requirements and maintain a consistent tip force.

Care must be taken not to damage the bellows seal as the satisfactory operation

of the probe is entirely dependent on this component. A working clearance

around the bellows equivalent to a 0.375” (9.5mm) dia. hole is desirable. To

maximize the working life of the probes the air supply should be both clean and

dry; i.e. filtered to better than 0.0002” (5 microns) and with a relative humidity of

less than 60%.

Operating Pressure Range for Standard Products : 0.4 Bar (6 psi) to 1.0 Bar (14

psi)

Vacuum Option

The Gaging tip of the vacuum operated probes is normally biased in the outward

direction and retracted by the application of negative pressure within the

specified ranges at the probe nozzle. Care must be taken not to damage the

bellows seal as the satisfactory operation of the probe is entirely dependent on

this component. Probes may be operated from a pumped system or individually

from a hand operated bulb.

Operating Pressure for Standard Products : 0.27 Bar (4 psi) maximum

Adjustable Pretravel Option

The option for adjustable pretravel is provided to maximize probe life and

minimize component damage where side application of the Gaged component is

necessary. Pretravel should be adjusted for minimum lift of the probe tip

necessary for a satisfactory Gaging operation within the tolerance of the Gaged

component.

Pretravel should only be adjusted using the spanner provided.

The pretravel adjustment is not provided as a means of fine mechanical zero

control, although it is possible to be used as such. Excessive use of the facility for

zero adjustment can result in loss of electrical datum, resulting in possible

damage to the internal stops.

Environmental Considerations

All non-pneumatic Gaging probes are specified to operate from +14°F to 176°F

(-10°C to +80°C) and all pneumatic probes from 41°F to 176°F (+5°C to +80°C).

At the low temperature extremes it may be necessary, due to stiffening, to

remove the rubber gaiter to achieve satisfactory operation. In this case the

atmosphere must be both clean and dry. However, continued operation without

the gaiter is not recommended due to the damage caused by the ingress of dirt.

Use of the transducer without the gaiter invalidates warranty. Omega probes are

designed to withstand the rigors of in-process Gaging and will operate

satisfactorily in the presence of copious amounts of coolants and cleaning

solvents.

GP911 Series M-3337 02/99

Page 6 of 12

Page 7

Electrical Connections for Use with Omega Electronics

Quadrature Resistor

These are supplied, where necessary to minimize residual voltage at null and

should be fitted as follows:

L.V.D.T

phase (see calibration sheet for details). Yellow wire is not connected in optional

factory fitted plugs.

.: Between yellow and white or yellow and green depending on

Half-Bridge

for details).

LVDT

Case

: Between yellow and red or yellow and blue (see calibration sheet

BLACK

CABLE SCREEN

BLUE

+

-

WHITE

YELLOW

GREEN

RED

GP911 Series M-3337 02/99

Page 7 of 12

Page 8

This Page Intentionally Left Blank

GP911 Series M-3337 02/99

Page 8 of 12

Page 9

This Page Intentionally Left Blank

GP911 Series M-3337 02/99

Page 9 of 12

Page 10

This Page Intentionally Left Blank

GP911 Series M-3337 02/99

Page 10 of 12

Page 11

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period

13 months

of

normal

from date of purchase. OMEGA Warranty adds an additional one (1) month grace period to the

one (1) year product warranty

to cover handling and shipping time. This ensures that OMEGA’s

customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department

will issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by

OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY

does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This

WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of having been

damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification;

misapplication; misuse or other operating conditions outside of OMEGA’s control. Components which wear are

not warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither

assumes responsibility for any omissions or errors nor assumes liability for any damages that result

from the use of its products in accordance with information provided by OMEGA, either verbal or written.

OMEGA warrants only that the parts manufactured by it will be as specified and free of defects. OMEGA

MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR

IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total

liability of OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon

which liability is based. In no event shall OMEGA be liable for consequential, incidental or special

damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity,

medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in

our basic WARRANTY / DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold

OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a

manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR)

NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING

DELAYS). The assigned AR number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage

in transit.

WARRANTY

FOR

RETURNS, please have the

following information available BEFORE contacting

OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

NON-WARRANTY

FOR

REPAIRS, consult OMEGA for

current repair charges. Have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the

repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems relative

to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1999 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior

written consent of OMEGA ENGINEERING, INC.

GP911 Series M-3337 02/99

Page 11 of 12

Page 12

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gauges

Load Cells & Pressure Gauges

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

GP911 Series M-3337 02/99

Page 12 of 12

Loading...

Loading...