Page 1

®

ALL PLASTIC VorTex FLowMeTer

For CorroSIVe LIquIdS

FV-200 Series

Standard

U No Moving Parts

U Corrosion Resistant

U 6 to 51 mm (

U High Temperature

[95°C (203°F)]

Models Available

U NIST Certificate

The FV-200 Series meter utilizes

vortex-shedding technology to

provide a repeatable flow

measurement accurate to 1% of

full scale. The meter has no

moving parts, and any potential for

fluid contamination is eliminated

by the meter’s corrosion-resistant

all plastic construction. The meter

includes a compact 2-wire (4 to

20 mA) or 3-wire pulse transmitter

(optional), contained within a

conveniently replaceable plug-in

electronics module. All electronics

are housed in a corrosion-resistant

enclosure. Unlike meters containing

metal or moving parts, the FV-200

is perfect for aggressive or easily

contaminated fluids. Applications

range from ultra-pure water to highly

corrosive chemicals and slurries

Operation of the FV-200 vortex

flowmeter is based on the vortex

shedding principle. As fluid moves

around a body, vortices (eddies) are

formed and move downstream.

They form alternately, from one

side to the other, causing pressure

fluctuations. These are sensed by

a piezoelectric crystal in the sensor

tube, and are converted to a 4 to

20 mA, or pulse signal. The

frequency of the vortices is directly

proportional to the flow rate. This

results in extremely accurate and

repeatable measurements using no

moving parts.

Another advantage of utilizing a

FV-200 vortex flowmeter is that there

are no gaskets or elastomers in the

meter. Therefore, one need only be

concerned with the thermoplastic

material used in body construction.

1

⁄4 to 2") Sizes

In a thermoplastic piping system,

the material chosen for the flowmeter

should match that of the pipe

wherever possible.

Many factors may affect the

capability of a meter to measure

the flow of specific fluids accurately.

Different solutions have varying effects on meters. For instance, heavy

particle suspension will wear down

internal parts on some meters or

cause sensing inaccuracies for

non-obtrusive metering systems.

For vortex flowmeters, high

viscosities tend to dampen the

formation of vortices and reduce the

effective range. Particles and internal

bubbles do not usually affect

vortex meters. Slurries containing grit

can wear down the bluff body over a

period of time. Also, long fibers can

catch and build up on the bluff,

decreasing accuracy. Standard

factory calibration is for tap water at

32 SSU (1 CST) viscosity and

ambient temperature. Viscosity

above 1 CST will raise the minimum

readable flow rate, reducing

FV-211, shown smaller

than actual size.

rangeability. The effect is linear to

viscosity. No adjustments are

required for specific gravities up

to 2.0. Liquids with high specific

gravities will adversely affect the

permissible amount and duration

of over range flow.

SPECIFICATIONS

Measured: Liquids

Connection:

Wetted Material: PVC, CPVC or PVDF

depending on model number

Turndown Ratio: 12.1

(except

Accuracy: ±1% of full scale,

4 to 20 mA or ±2% of full scale,

frequency pulse (“-P” option)

Repeatability: ±0.25% actual flow

Output Signal: 4 to 20 mA or

frequency pulse (source-sink driver;

1A source/ 1.5A sink; typical output

resistance 10 Ω)

Power Supply: 13 to 30 Vdc

Enclosure: NEMA 4X (IP 66)

Response Time: 2 seconds minimum,

step change in flow

1

⁄4 to 2 NPT thread

1

⁄4" meter size; 8.1)

G-5

Page 2

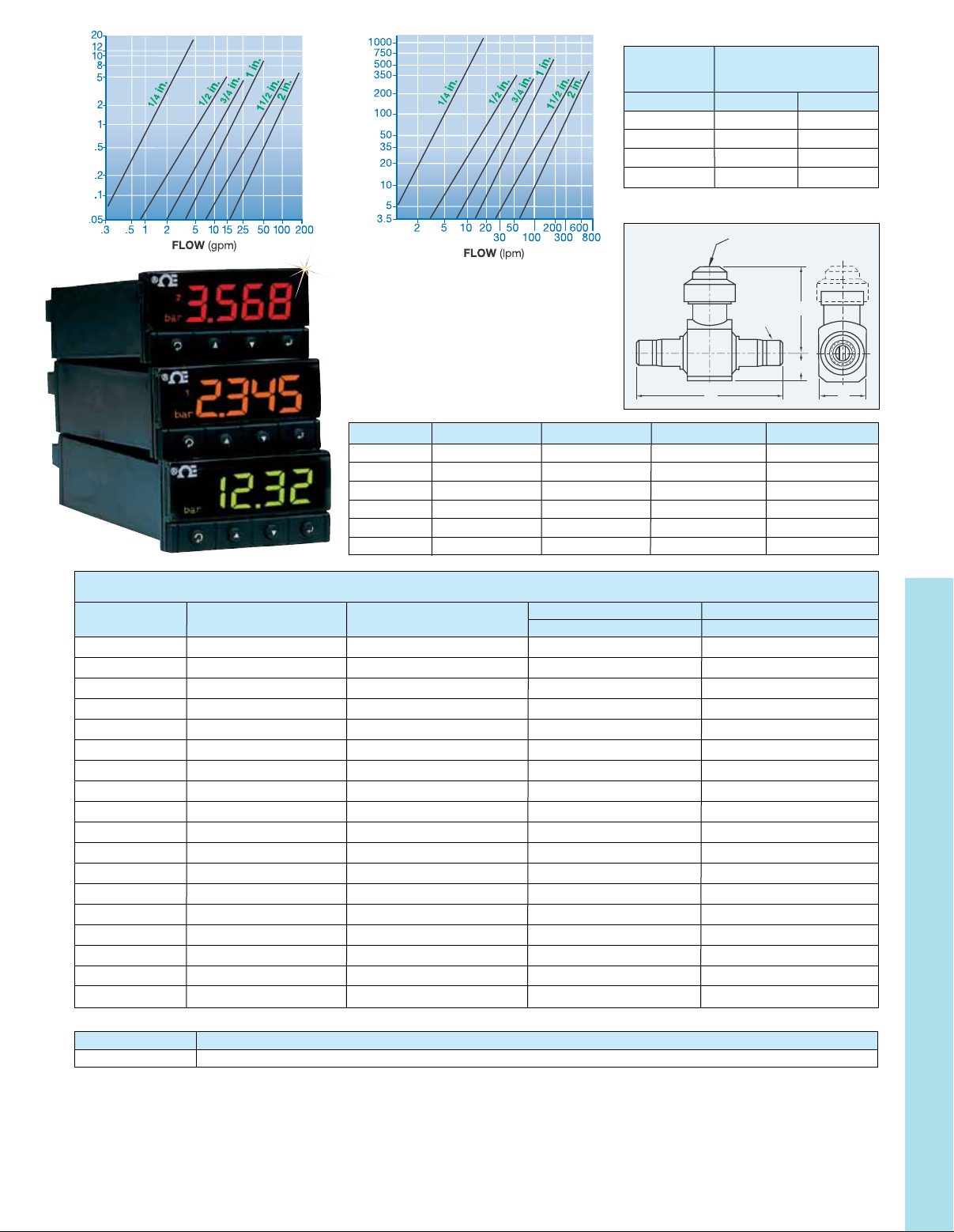

PORD ERUSSERP )rabilliM(

Pressure—Temperature Ratings

Maximum Maximum

Fluid Operating Pressure

PORD ERUSSERP )disp(

PORD ERUSSERP )rabilliM(

DPi32, shown smaller

than actual size. visit

omega.com/dpi_series

for more information.

Temperature bar (PSIG)

°C (°F) PVC CPVC

95 (203)* NR 1.6 (24)

66 (150) NR 4.3 (63)

38 (100) 6.4 (93) 8.3 (120)

21 (70) 10.3 (150) 10.3 (150)

*(-HT) models only

½ NPT female

conduit connection

A

NPT

B

C

Dimensions: mm (inch)

Size, NPT A B C D

¹⁄₄ 97 (3.81) 45 (1.75) 133 (5.25) 64 (2.50)

¹⁄₂ 97 (3.81) 45 (1.75) 181 (7.13) 64 (2.50)

³⁄₄ 97 (3.81) 45 (1.75) 194 (7.63) 64 (2.50)

1 100 (3.92) 45 (1.75) 204 (8.03) 64 (2.50)

1¹⁄₂ 99 (3.90) 51 (2.00) 213 (8.37) 64 (2.50)

2 109 (4.31) 51 (2.00) 213 (8.37) 64 (2.50)

To Order Visit omega.com/fv-200_series for Pricing and Details

Connection, Minimum Flow Maximum Flow

Model No. NPT Size Construction LPM (GPM) LPM (GPM)

FV-211 ¹⁄₄ PVC 2.3 (0.6) 18.9 (5)

FV-212 ¹⁄₂ PVC 4.7 (1.3) 56.8 (15)

FV-213 ³⁄₄ PVC 7.9 (2.1) 94.6 (25)

FV-214 1 PVC 15.8 (4.2) 189.3 (50)

FV-215 1¹⁄₂ PVC 31.5 (8.3) 378.5 (100)

FV-216 2 PVC 63.1 (16.7) 757.1 (200)

FV-221 ¹⁄₄ CPVC* 2.3 (0.6) 18.9 (5)

FV-222 ¹⁄₂ CPVC* 4.7 (1.3) 56.8 (15)

FV-223 ³⁄₄ CPVC* 7.9 (2.1) 94.6 (25)

FV-224 1 CPVC* 15.8 (4.2) 189.3 (50)

FV-225 1¹⁄₂ CPVC* 31.5 (8.3) 378.5 (100)

FV-226 2 CPVC* 63.1 (16.7) 757.1 (200)

FV-231 ¹⁄₄ PVDF* 2.3 (0.6) 18.9 (5)

FV-232 ¹⁄₂ PVDF* 4.7 (1.3) 56.8 (15)

FV-233 ³⁄₄ PVDF* 7.9 (2.1) 94.6 (25)

FV-234 1 PVDF* 15.8 (4.2) 189.3 (50)

FV-235 1¹⁄₂ PVDF* 31.5 (8.3) 378.5 (100)

FV-236 2 PVDF* 63.1 (16.7) 757.1 (200)

Accessory

Model No. Description

PSU-93 Unregulated 24 Vdc power supply

Comes complete with 5 point NIST certificate and operator’s manual.

For units with a pulse output add a “-P” to the model number, no additional charge.

* For high temperature CPVC or PVDF add suffix “-HT” to model number, for additional cost

Ordering Examples: FV-213,

FV-226-P, 2 NPT, CPVC vortex with pulse output.

FV-231-P-HT,

1

⁄4 NPT, PVC vortex with pulse output and high temperature option.

3

⁄4 NPT, PVC vortex flowmeter and DPi32, 1⁄32 DIN digital display.

G-6

D

G

Loading...

Loading...