Page 1

FPD1000-HP SERIES

HIGH PRESSURE

Positive Displacement Flowmeters

Page 2

Page 3

To the owner:

Thank you for purchasing an OMEGA FPD

Series Flowmeter. Please take a few minutes to read through the manual before installing and operating your meter. If you

have any problems with the meter, refer to

the Maintenance and Troubleshooting sections of the manual.

This manual contains connection and operating instructions for the OMEGA FPD

Series meters with pulse outputs. This includes the following models:

FPD1202-HP FPD1203-HP

The OMEGA FPD Series flowmeter has incorporated the oval rotor principal into its

design. This has proven to be a reliable and

highly accurate method of measuring flow.

Exceptional repeatability and high accuracy

over a wide range of fluid viscosities and

flowrates are features of the OMEGA FPD

Series flowmeter design. With low pressure

drop and high pressure rating, means the

OMEGA FPD Series flowmeters are suitable for both gravity and pump (in-line) applications.

INSTALLATION

1. Use thread sealant on all pipe threads.

2. Ensure the meter is installed so that

rotor shafts are always in a horizontal

plane (See Figure 1). Flow is bi-directional.

Figure 1

DO NOT install

meter this way.

3. OMEGA recommends use of flexible

connections.

4. Extreme care must be taken when installing the meter. Pipe strain or overtightening meter connections can

cause meter damage.

PULSER DETAILS

IMPORTANT INFORMATION

Please read this information

!

▲

carefully before use!

Before use, confirm the fluid to be used is

compatible with the meter or consult with

OMEGA for advice.

To prevent damage from dirt or foreign

matter, OMEGA recommends a Y or basket type 200 mesh strainer be installed as

close as possible to the inlet side of the

meter. (If required, contact OMEGA for further information.)

To prevent damage to the meter, slowly fill

the system with fluid. This will prevent damage caused by air purge.

NOTE: Failure to do this could damage the

meter.

For pump applications, turn off the pump

at the end of each day.

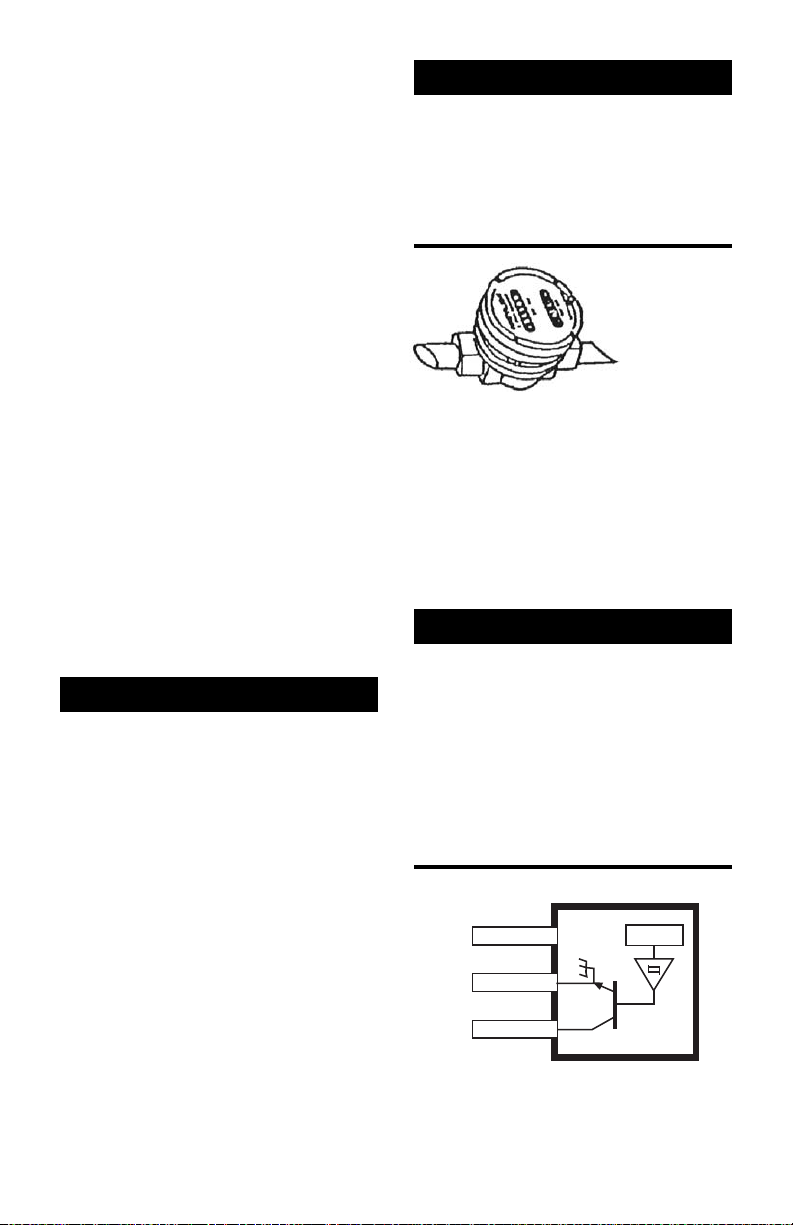

Hall Effect Sensor Specifications

•4.5 V to 24 V (4.6 - 9 mA) operation

needs only an unregulated supply.

•Open collector 25 mA output NPN

(Current Sink) compatible with digital

logic.

•Reverse battery precaution.

Figure 2

Supply

Signal

Ground

12 3

Hall Effect Sensor Wiring Details

V

cc

(HP Models Only)

X

1

Page 4

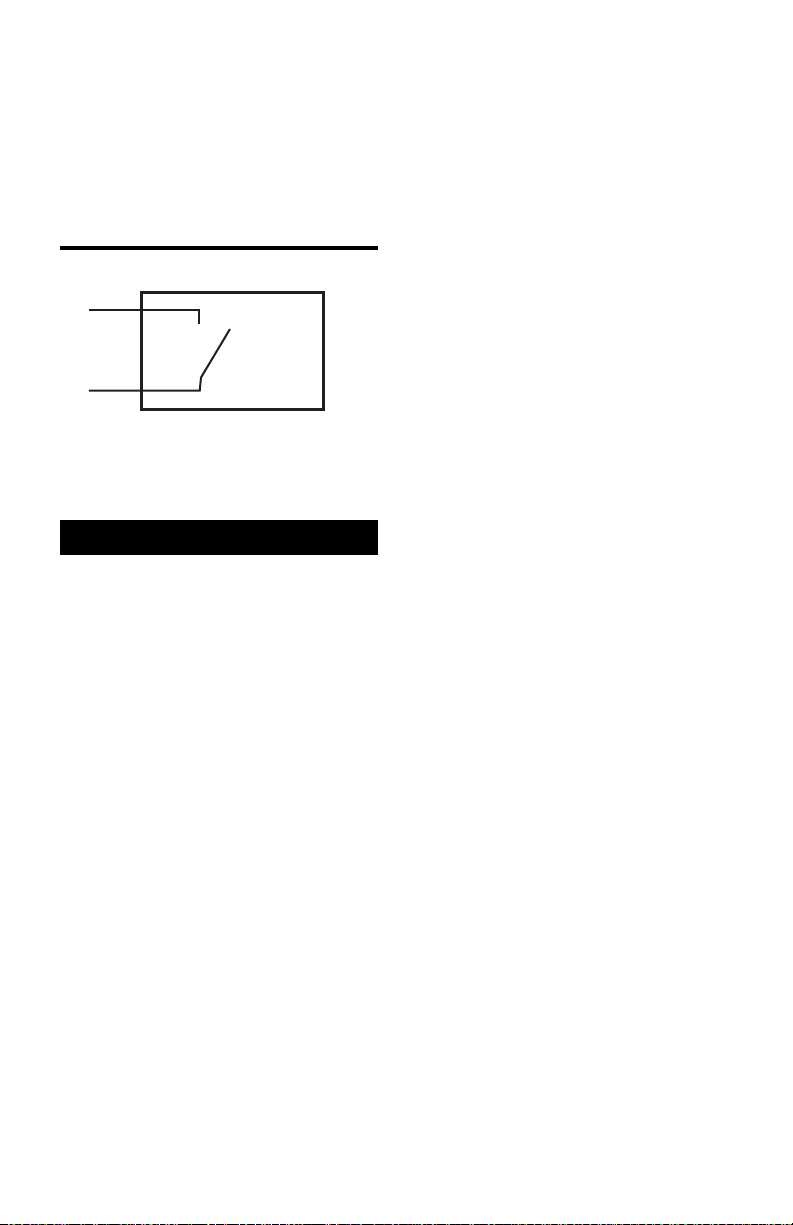

Reed Relay Specifications

•Two wire SPST N/O.

•Switching voltage 150 VDC; maximum

current 0.25 Amps.

•Rating 3 watts.

•Duty cycle 20% ON, 80% OFF.

Figure 3

12

Reed Switch Wiring Details

(HP Models Only)

MAINTENANCE

Disassembly:

1. Ensure the fluid supply to the meter has

been disconnected, and the line pressure has been released before disassembly.

2. Remove the four screws and remove the

pulser cap.

3. Remove the gasket.

4. Remove eight screws and remove the

meter cap.

5. Remove O-ring and inspect. Replace Oring if damaged.

6. Remove rotors, clean and inspect. Replace rotors if damaged.

7. To remove the PCB, remove the two

screws.

NOTE: Reed Switch PCB’s cannot be re-

moved.

Reassembly:

1. Replace rotors into the meter body. The

rotors should be at 90 degrees to each

other.

2. Lightly rotate the rotors by hand. They

must rotate freely.

3. Install O-ring.

4. Replace the meter cap and tighten the

eight screws uniformly to 35Nm (25 Ft.

Lbs.).

5. Replace the pulser cap and tighten the

four screws.

2

Page 5

TROUBLESHOOTING

Symptom Probable Cause Corrective Action

FLUID WILL NOT 1. Foreign matter blocking Dismantle meter, clean rotors. Strainer must

FLOW THROUGH rotors be fitted in-line.

THE METER

REDUCED FLOW 1. Line strainer partially Clean strainer.

THROUGH THE blocked

METER

METER READING 1. Fluid flowrate is too low See specifications for minimum and

INACCURATE or too high maximum flowrates.

METER NOT 1. Faulty Hall Effect sensor Replace meter cap for Reed Switch models,

GIVING A PULSE or Reed Switch replace PCB for Hall Effect models.

SIGNAL

2. Line strainer blocked Clean strainer.

3. Damaged rotors Replace rotors. Strainer must be fitted in-line.

4. Meter connections over- Re-adjust connections.

tightened

2. Fluid is too viscous Maximum viscosity 1000 centipoise.

2. Air in fluid. Bleed air from system.

3. Excess wear caused by Check meter for damage. Install correctly.

incorrect installation

2. Faulty magnet Replace rotors.

3

Page 6

DISPLAY PARTS LISTING

3

Model: FPD1202-HP

4

TERMINAL

BLOCK

2

7

1

u = Recommended Spare Parts to stock.

Bold Text = Indicates Stainless Steel model parts.

Item Rec. Part or Set

No. Qty. Parts (Order from this column only) Part Description

11 MS1NS Meter Body Assembly NPT

28 u MS367S Bolt Set - Socket Head

31 MS170H Pulser Cap (BSP)

31 MS170HN Pulser Cap (NPT)

44 uMS115S Bolt Set - Socket Head

61 MS3HES Meter Cap & Hall Effect Assembly

61 MS3HPS Meter Cap & Reed Switch Assembly

72 uMS6-1S Rotor Set (Stainless Steel)

81 u BS029V O-Ring (Viton)

81 u BS029TE O-Ring (Kalrez)

91 MS300HS Gasket

10 1 MS284S Screw Sets

9

10

6

8

*

*

Reed Switch & Hall Effect are unavailable without meter cap.

*

4

Page 7

SPECIFICATIONS

Pulse Meter Models

Flow Ranges (LPM or GPM)

Above 5 centipoise 2 to 100 / 0.53 to 26.4

Below 5 centipoise 5 to 100 / 1.32 to 26.4

Accuracy of Reading ± 1%

Maximum Viscosity 1000 Centipoise

Maximum Operating Pressure 55160 kPa / 8000 PSI / 551 Bar

Maximum Operating Temperature 120°C / 248°F

Pulse Type Hall Effect Sensor / Reed Switch

Pulses per Litre/Gallons 1000 / 3785

Meter Dimensions 86mm Dia. / 3.4” Dia. (Meter Body)

83mm / 3.25” (Port Face to Face)

Weight 3.3 kg / 116 oz.

5

Page 8

DISPLAY PARTS LISTING

3

Model: FPD1203-HP

4

TERMINAL

9

BLOCK

10

2

7

1

u = Recommended Spare Parts to stock.

Bold Text = Indicates Stainless Steel model parts.

Item Rec. Part or Set

No. Qty. Parts (Order from this column only) Part Description

11 MS2NS Meter Body Assembly NPT

28 u MS367S Bolt Set - Socket Head

31 MS170H Pulser Cap (BSP)

31 MS170HN Pulser Cap (NPT)

44 uMS115S Bolt Set - Socket Head

61 MS3HES Meter Cap & Hall Effect Assembly

61 MS3HPS Meter Cap & Reed Switch Assembly

72 u MS7-1ES Rotor Set (S/Steel) - Hall Effect

72 uMS7-1RS Rotor Set (S/Steel) - Reed Switch

72 uMS7-1HES Rotor Set (S/Steel) - Hall Effect, High Visc.

72 uMS7-1HRS Rotor Set (S/Steel) - Reed Switch, High Visc.

81 u BS029V O-Ring (Viton)

81 u BS029TE O-Ring (Kalrez)

91 MS300HS Gasket

10 1 MS284S Screw Sets

6

8

*

*

Reed Switch & Hall Effect are unavailable without meter cap.

*

6

Page 9

SPECIFICATIONS

Pulse Meter Models

Flow Ranges (LPM or GPM)

Above 5 centipoise 15 to 500 / 4.0 to 132

Below 5 centipoise 25 to 500 / 6.0 to 132

Accuracy of Reading ± 1%

Maximum Viscosity

Maximum Operating Pressure 55160 kPa / 8000 PSI / 551 Bar

Maximum Operating Temperature 120°C / 248°F

Pulse Type Hall Effect Sensor / Reed Switch

Pulses per Litre/Gallons 400 / 1514

Meter Dimensions 86mm Dia. / 3.4” Dia. (Meter Body)

Weight 3.3 kg / 116 oz.

Unless high viscosity rotors are fitted.

*

*

1000 Centipoise

83mm / 3.25” (Port Face to Face)

7

Page 10

Page 11

Page 12

M-4125 / 0405

Loading...

Loading...