Page 1

Flow 6.25 GPM

Total 1234567.8>

IS O9002

CERTIFIED

CORPORATE QUALITY

MANCHESTER, UK

ISO 9001

CERTIFIED

CORPORATE QUALITY

STAMFORD, CT

User’s Guide

Shop online at

www.omega.com

e-mail: info@omega.com

FP90 SERIES

Flow Transmitters

Page 2

OMEGAnet® Online Service Internet e-mail

www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certifi ed Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Español: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Rudé arm

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certifi ed Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-48

e-mail: sales@omega.co.uk

.

dy 1868, 733 01 Karvin. 8

®

®

®

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certifi cation of its products to the European New Approach Directives.

OMEGA will add the CE mark to every appropriate device upon certifi cation.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifi cations without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

OMEGA FP90 Series Flow Transmitter Instructions

Page 3

Omega FP90 Series Flow Transmitter Instructions

Flow 6.25 GPM

Total 1234567.8>

• Remove power to unit before wiring input and

output connections.

• Follow instructions carefully to avoid personal

injury.

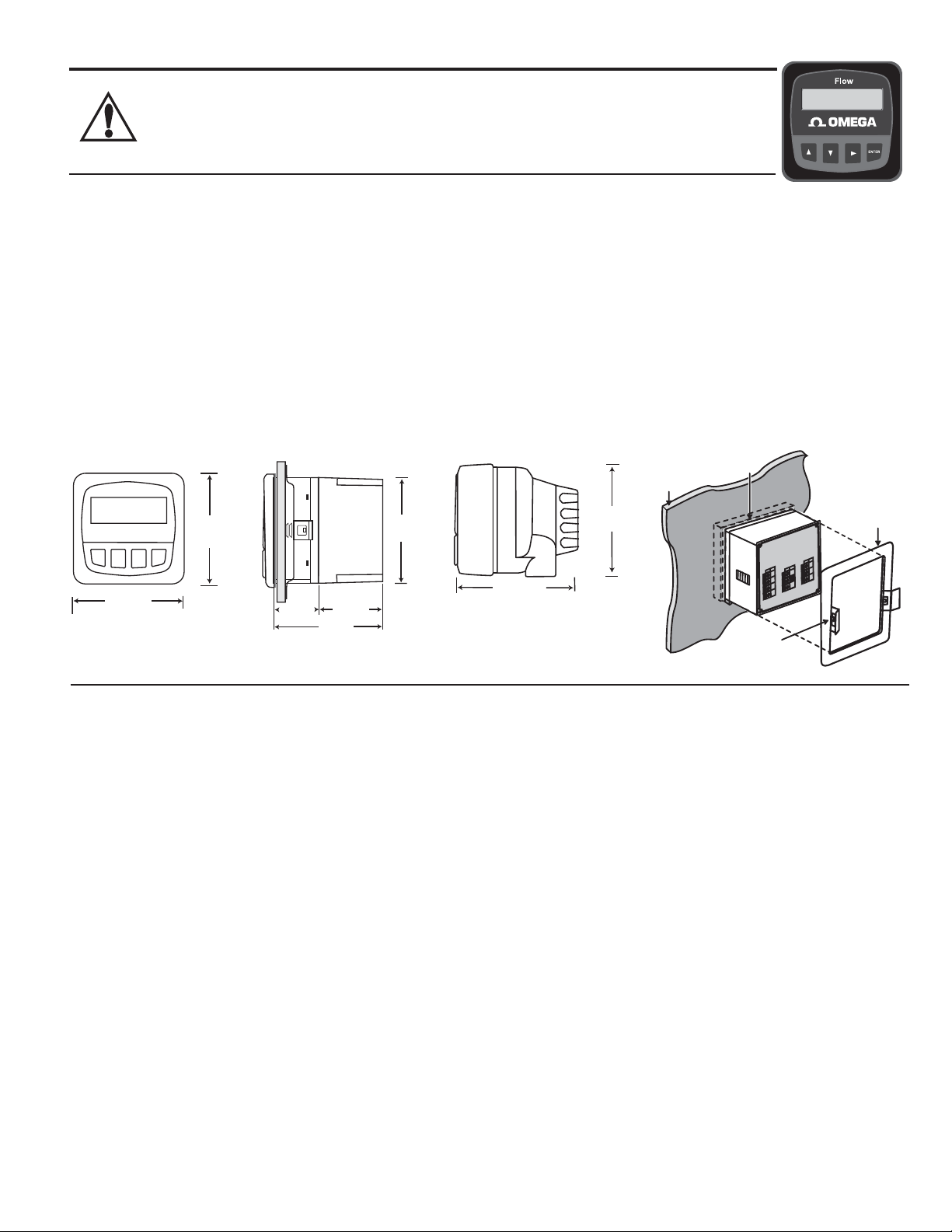

Installation

FP90 series transmitters are available in two styles: panel mount and fi eld mount. The panel mount is supplied with the necessary

hardware to install the transmitter. This manual includes complete panel mounting instructions.

Field mounting requires one of two separate mounting kits. The FP90IM integral kit joins the sensor and instrument together into a

single package. The FP90UM Universal kit enables the transmitter to be installed virtually anywhere.

Detailed instructions for integral mounting or other fi eld installation options are included with the FP90IM Integral kit or the

FP90UM Universal kit.

Panel Installation

1. The panel mount transmitter is designed for installation using a 1/4 DIN Punch. For manual panel cutout, an adhesive

template is provided as an installation guide. Recommended clearance on all sides between instruments is 1 inch.

2. Place gasket on instrument, and install in panel.

3. Slide mounting bracket over back of instrument until quick-clips snap into latches on side of instrument.

4. To remove, secure instrument temporarily with tape from front or grip from rear of instrument. DO NOT RELEASE.

Press quick-clips outward and remove.

96 mm

(3.8 in.)

FRONT VIEW

Field Mount &

Panel Mount

96 mm

(3.8 in.)

41 mm

(1.6 in.

)

SIDE VIEW

Panel Mount

Optional

Rear

Cover

56 mm

(2.2 in.)

97 mm

(3.8 in.)

92 mm

(3.6 in.)

Specifi cations

General

Accuracy: ±0.5 Hz

Enclosure:

• Rating: NEMA 4X/IP65 front

• Case: PBT

• Panel case gasket: Neoprene

• Window: Polyurethane coated polycarbonate

• Keypad: Sealed 4-key silicone rubber

• Weight: Approx. 325g (12 oz.)

Display:

• Alphanumeric 2 x 16 LCD

• Update rate: 1 second

• Contrast: User selected, 5 levels

• Thermal sensitivity shift: ±0.005% of reading per °C

Electrical

• Power: 12 to 24 VDC ±10%, regulated,

21 mA max current

Sensor Input:

• Range: 0.5 to 1500 Hz

• Sensor power: 2-wire: 1.5 mA @ 5 VDC ± 1%

3 or 4 wire: 20 mA @ 5 VDC ± 1%

• Optically isolated from current loop

• Short circuit protected

Current output:

• 4 to 20 mA, isolated, fully adjustable and reversible

• Max loop impedance: 50 Ω max. @ 12 V

325 Ω max. @ 18 V

600 Ω max. @ 24V

OMEGA FP90 Series Flow Transmitter Instructions

Contents

1. Installation

2. Specifi cations

3. Electrical Connections

4. Menu Functions

gasket on

front side

panel

96 mm

(3.8 in.)

102 mm

(4.0 in.)

SIDE VIEW

Field Mount w/

Integral kit

• Update rate: 100 ms

• Loop accuracy: ±0.03 mA

Open-collector output: Hi, Lo, Frequency, Pulse Programmable

• Optically isolated, 50 mA max. sink, 30 VDC max. pull-up

voltage.

• Maximum pulse rate: 300 pulses per minute

• Hysteresis: Adjustable

Relay outputs (2 sets mechanical SPDT contacts):

• Hi, Lo, Frequency, Pulse Programmable (300 pulses/min max)

• Maximum voltage rating: 5 A @ 30 VDC, 5 A @ 250 VAC

resistive load

• Hysteresis: User adjustable

Environmental

• Operating temperature: -10 to 70°C (14 to 158°F)

• Storage temperature: -15 to 80°C (5 to 176°F)

• Relative humidity: 0 to 95%, non-condensing

• Maximum altitude: 2000 m (6562 ft)

• Insulation category: II

• Pollution degree: 2

Standards and Approvals

• CE

• Immunity: EN50082-2

• Emissions: EN55011

• Safety: EN61010

• Manufactured under ISO 9001 and ISO 14001

of panel

quick-clip

mounting

9

8

6

4

7

3

5

2

1

bracket

page 1

Page 4

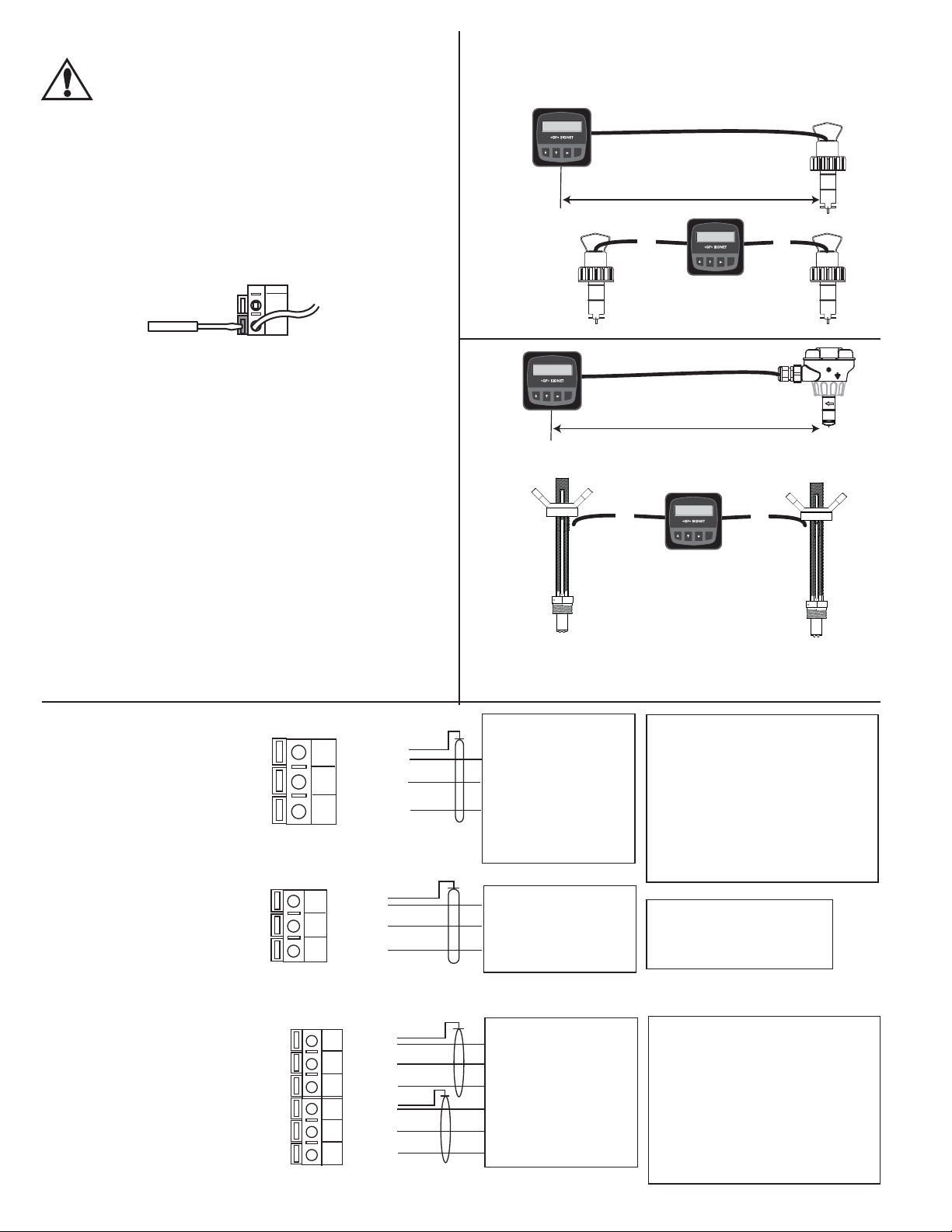

Electrical Connections

Caution: Failure to fully open terminal jaws before

removing wire may permanently damage instrument.

Wiring Procedure

1. Remove 0.5 - 0.625 in. (13-16 mm) of insulation from wire

end.

2. Press the orange terminal lever downward with a small

screwdriver to open terminal jaws.

3. Insert exposed (non-insulated) wire end in terminal hole

until it bottoms out.

4. Release orange terminal lever to secure wire in place.

Gently pull on each wire to ensure a good connection.

Maximum cable length is 200 ft. for FP5100, FP5200, FP5300,

FP6000 and any sinusoidal fl ow signal.

FP90-1, -2

Flow

Flow 6.25 GPM

Total 1234567.8>

ENTER

≤ 200 ft. (61 m)

FP90-3

Flow

Flow1: 6.25 GPM

B

Flow2: 9.75 GPM

ENTER

A

2

1

Wiring Removal Procedure

1. Press the orange terminal lever downward with a small

screwdriver to open terminal jaws.

2. When fully open, remove wire from terminal.

Wiring Tips:

• Do not route sensor cable in conduit containing AC power

wiring. Electrical noise may interfere with sensor signal.

• Routing sensor cable in grounded metal conduit will help

prevent electrical noise and mechanical damage.

• Seal cable entry points to prevent moisture damage.

• Only one wire should be inserted into a terminal. Splice

double wires outside the terminal.

Sensor Input Connections

FP90-1 Terminals

Sensr Gnd

9

(SHIELD)

Sensr IN

8

(RED)

Sensr V+

7

(BLACK)

FP90-2 Terminals

Sensr Gnd

13

(SHIELD)

Sensr IN

12

(RED)

Sensr V+

11

(BLACK)

A ≤ 200 ft. (61 m)

B

≤ 200 ft. (61 m)

FP90-1, -2

Flow

Flow 6.25 GPM

Total 1234567.8>

ENTER

≤ 1000 ft. (300 m)

FP90-3

Flow

Flow1: 6.25 GPM

B

Flow2: 9.75 GPM

ENTER

A

A ≤ 1000 ft. (305 m)

B

≤

1000 ft. (305 m)

Maximum cable length is 1000 ft. for FP-5600/FP8501,FP2540/

FP3-1500, FMG-3000 and FMG-550 and any square wave fl ow

signal.

No Aux Power:

FP-5100

FP-5200

FP-5300

FP-6000

FP-8500

FP-8501

Aux Power for FP90-1:

FP-5060

FP-5600

FP-8500A

FP-8501A

FP-2541

FMG-3000 Series Magmeter

FMG-550 Series magmeter

Any Open Collector pulse input

All sensors

Aux Power for FP90-2 must

always be connected to

provide relay power.

page 2

FP90-3 Terminals

Snsr 2 Gnd

16

(SHIELD)

Snsr 2 IN

15

(RED)

Snsr 2 V+

14

(BLACK)

Snsr 1 Gnd

13

(SHIELD)

Snsr 1 IN

12

(RED)

Snsr 1 V+

11

(BLACK)

No Aux Power:

FP-5100

FP-5200

FP-5300

FP-6000

FP-8500

FP-8501

Aux Power for FP90-3:

FP-5060

FP-5600

FP-8500A

FP-8501A

FP-2541

FMG-3000 Series Magmeter

FMG-550 Series magmeter

Any Open Collector pulse input

OMEGA FP90 Series Flow Transmitter Instructions

Page 5

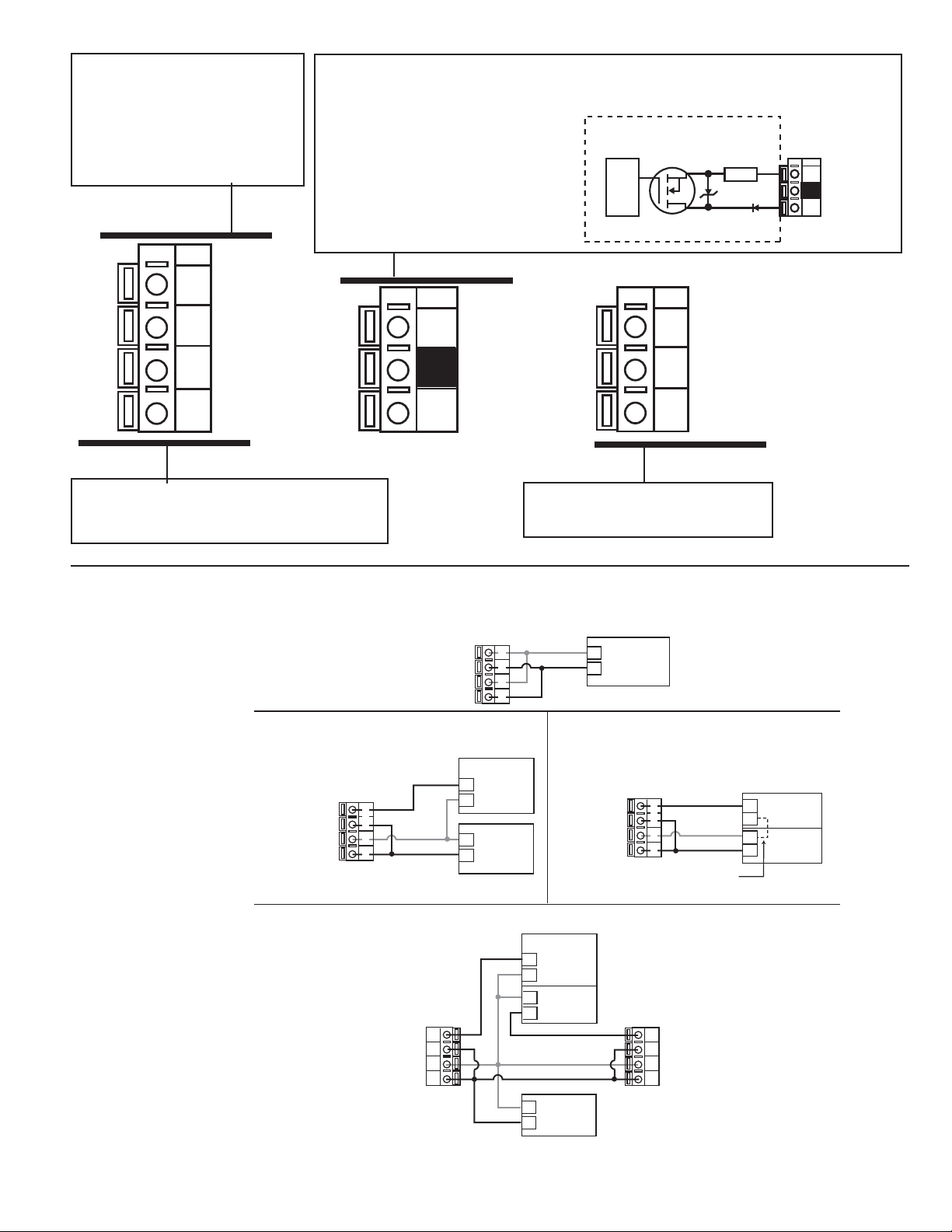

FP90-1 rear terminals

Internal open-collector

output circuit

Output --

Output +

Isolation

15Ω

S

D

Terminals 3 and 4: Loop Power

12-24 VDC ±10% system power

and current loop output.

Max. loop impedence:

50 Ω max. @ 12 V

325 Ω max. @ 18 V

Terminals 5 and 6: Open-collector Output

A transistor output, programmable (see CALIBRATE menu) as:

• High or Low with adjustable hysteresis

• Volumetric pulse

• Frequency based on fl ow rate

• May be disabled (Off) if not used.

600 Ω max. @ 24 V

System Pwr

4

Loop -

System Pwr

3

Loop +

AUX

2

Power -

AUX

1

Power +

Terminals 1 and 2: AUXILIARY power

12-24 VDC ±10% Used only if the fl ow sensor

requires more than 1.5 mA current.

6

5

Output -

Output +

Sensr Gnd

9

(SHIELD)

Sensr IN

8

(RED)

Sensr V+

7

(BLACK)

Terminals 7-9: Flow sensor input

See next page for more information.

FP90-1 System Power/Loop Connections

Stand-alone application, no current loop used

System Pwr Loop -

System Pwr Loop +

AUX Power -

* See AUX POWER Note

Connection to a PLC/Recorder, separate supply

Transmitter

Terminals

System Pwr Loop -

System Pwr Loop +

AUX Power -

AUX Power +

* See AUX POWER Note * See AUX POWER Note

Example: Two transmitters connected to PLC/Recorder with separate power supply

Auxiliary Power note:

AUXILIARY power is used only if the flow sensor requires more than 1.5 mA current.

4

4

3

3

2

2

1

1

System Pwr Loop -

System Pwr Loop +

AUX Power -

AUX Power +

AUX Power +

Transmitter 1

Terminals

4

3

2

1

Transmitter

Terminals

4

4

3

3

2

2

1

1

PLC or Recorder

+

Loop Input

4-20 mA

-

Power

-

Supply

12-24 VDC

+

+

Connection to a PLC with built-in power supply

System Pwr Loop -

System Pwr Loop +

AUX Power -

AUX Power +

PLC or Recorder

+

Channel 1

4-20 mA in

-

-

Channel 2

4-20 mA in

+

Power

-

Supply

12-24 VDC

+

Power

Supply

12-24 VDC

Transmitter

Terminals

4

4

3

3

2

2

1

1

PLC

Transmitter 2

Terminals

4

System Pwr Loop -

4

3

System Pwr Loop +

3

2

AUX Power -

2

1

AUX Power +

1

* See AUX POWER Note

Internal

Connection

PLC Terminals

Loop Input

+

4-20 mA

-

Power

-

Supply

+

12-24 VDC

OMEGA FP90 Series Flow Transmitter Instructions

page 3

Page 6

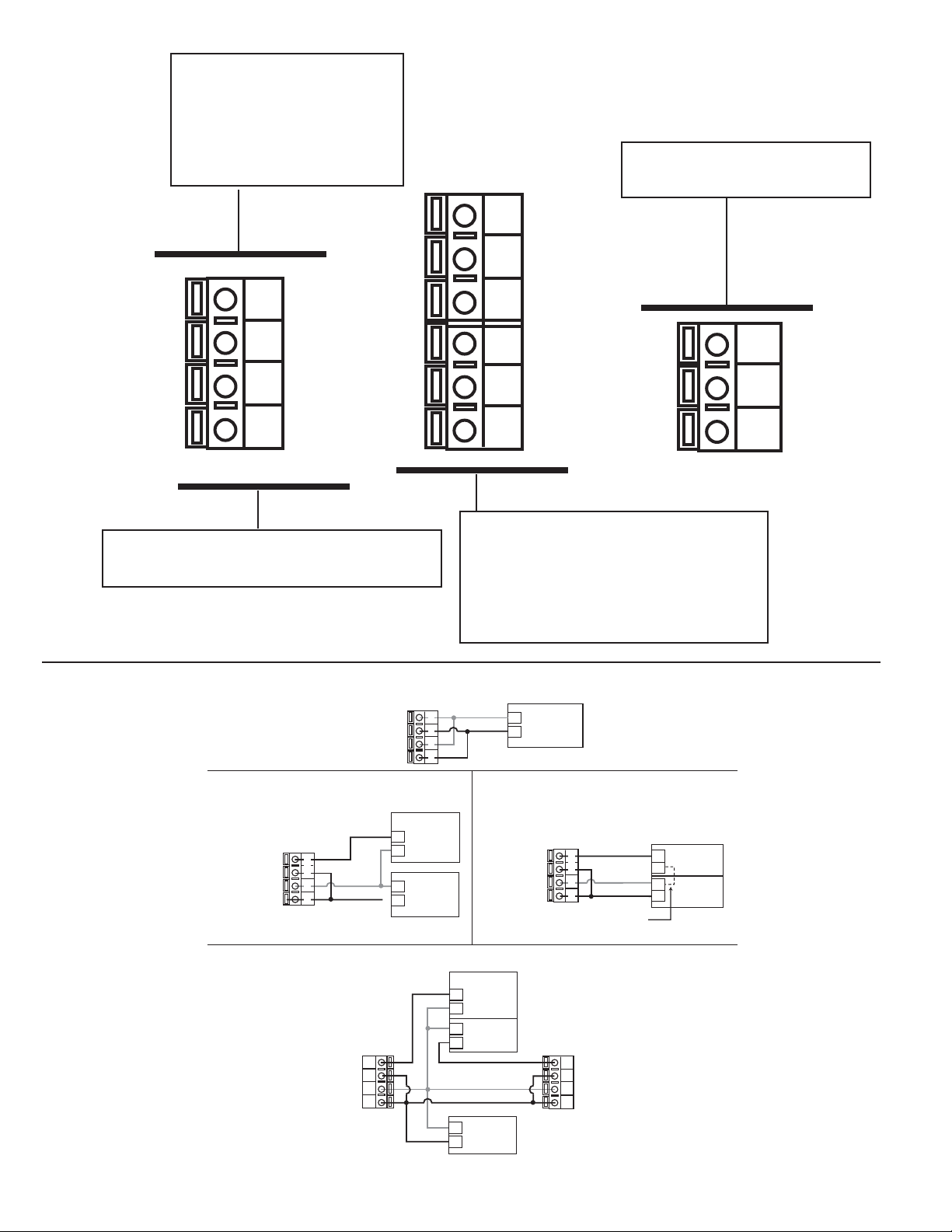

FP90-2 Wiring

Terminals 3 and 4: Loop Power

12-24 VDC ±10% system power

and current loop output.

Max. loop impedance:

50 Ω max. @ 12 V

325 Ω max. @ 18 V

600 Ω max. @ 24 V

10

9

Terminals 11-13: Flow sensor input

See next page for more information.

Relay 2

(NO)

Relay 2

(COM)

System Pwr

4

Loop -

System Pwr

3

Loop +

AUX

2

Power -

AUX

Power +

1

Terminals 1 and 2: AUXILIARY power

12-24 VDC ±10% provides power for relay operation.

Stand-alone application, no current loop used

System Pwr Loop -

System Pwr Loop +

AUX Power -

* See AUX POWER Note

AUX Power +

Transmitter

Terminals

Relay 2

8

(NC)

Relay 1

7

(NO)

Relay 1

6

(COM)

Relay 1

5

(NC)

Terminals 5-10: Relay Outputs

Two sets mechanical SPDT contacts,

programmable (see CALIBRATE menu) as:

• High or Low with adjustable hysteresis

• Volumetric pulse based on totalizer

• May be disabled (Off) if not used.

4

4

3

3

2

2

1

1

+

Power

Supply

12-24 VDC

13

12

11

Sensr Gnd

(SHIELD)

Sensr IN

(RED)

Sensr V+

(BLACK)

page 4

Connection to a PLC/Recorder, separate supply

Transmitter 1

Terminals

4

3

2

1

PLC or Recorder

+

Loop Input

4-20 mA

-

Power

-

Supply

12-24 VDC

+

Transmitter

Terminals

System Pwr Loop -

System Pwr Loop +

AUX Power -

AUX Power +

* See AUX POWER Note

Example: Two transmitters connected to PLC/Recorder with separate power supply

Auxiliary Power note:

• AUXILIARY Power is required for all systems where relays are used.

4

4

3

3

2

2

1

1

System Pwr Loop -

System Pwr Loop +

AUX Power -

AUX Power +

Connection to a PLC with built-in power supply

Transmitter

AUX Power -

AUX Power +

Transmitter 2

Terminals

Terminals

* See AUX POWER Note

System Pwr Loop -

System Pwr Loop +

* See AUX POWER Note

PLC or Recorder

+

Channel 1

4-20 mA in

-

-

Channel 2

4-20 mA in

+

Power

-

Supply

12-24 VDC

+

PLC Terminals

4

4

3

3

2

2

1

1

PLC

4

System Pwr Loop -

4

3

System Pwr Loop +

3

2

AUX Power -

2

1

AUX Power +

1

Internal

Connection

+

-

+

Loop Input

4-20 mA

Power

Supply

12Ð24 VDC

OMEGA FP90 Series Flow Transmitter Instructions

Page 7

1

Internal open-collector

output circuit

Outputs

Isolation

15Ω

S

D

2

_

+

FP90-3 Wiring

Terminals 3-6: Loop Power

12-24 VDC ±10% system power

and current loop outputs.

Max. loop impedance:

50 Ω max. @ 12 V

325 Ω max. @ 18 V

600 Ω max. @ 24 V

Terminals 7-10: Open-collector Outputs

Two transistor outputs, programmable (see CALIBRATE menu) as:

• High or Low with adjustable hysteresis

• Pulse based on Volume.

• Frequency based on fl ow rate

• May be disabled (Off) if not used.

Loop 2-

6

Loop 2+

5

System Pwr

4

Loop -

System Pwr

3

Loop +

AUX

2

Power -

AUX

1

Power +

10

9

8

7

Terminals 1 and 2: AUXILIARY power

Used only if the fl ow sensor requires more than 1.5 mA current.

Refer to your fl ow sensor specifi cations for this information.

Stand-alone application, no current loop used

System Power Loop 1 –

System Power Loop 1 +

Loop 2 –

Loop 2 +

AUX Power –

AUX Power +

Tra ns mitter

Terminals

6

5

4

3

2

1

NC

NC

Output 2-

Output 2+

Output 1-

Output 1+

Power

–

Supply

+

12–24 VDC

Snsr 2 Gnd

16

(SHIELD)

Snsr 2 IN

15

(RED)

Snsr 2 V+

14

(BLACK)

Snsr 1 Gnd

13

(SHIELD)

Snsr 1 IN

12

(RED)

Snsr 1 V+

11

(BLACK)

Terminals 11-16: Flow sensor inputs

See Sensor Input section for more information.

OMEGA FP90 Series Flow Transmitter Instructions

Connection to a PLC/Recorder , separate supply

Tra ns mitter

Terminals

Loop 2 –

Loop 2 +

System Power Loop 1 –

System Power Loop 1 +

AUX Power –

AUX Power +

Example: T wo transmitters connected to PLC/Recorder with separate power supply

System Power Loop 1 –

System Power Loop 1 +

6

5

4

3

2

1

Loop 2 –

Loop 2 +

AUX Power –

AUX Power +

Tra nsm itter 1

Terminals

6

5

4

3

2

1

PLC or R ecorder

+

Channel 2

4-20 mA

–

Channel 1

–

4-20 mA

+

Power

–

Su pply

+

12–24 VDC

Auxiliary Power Note:

Auxiliary power is necessary for flow sensors that require more than 1.5 mA of current.

Connection to a PLC with built-in power supply

System Power Loop 1 –

System Power Loop 1 +

AUX Power –

AUX Power +

PLC or R ecorder

+

Channel 1

4-20 mA in

–

+

Channel 2

4-20 mA in

–

–

Channel 3

4-20 mA in

+

–

Channel 4

4-20 mA in

+

Power

–

Supply

+

12–24 VDC

Loop 2 –

Loop 2 +

Tra ns mitter

Terminals

6

5

4

3

2

1

Tra nsm itter 2

Terminals

Internal

Connection

PLC

Loop 2 –

6

Loop 2 +

5

System Power Loop 1 –

4

System Power Loop 1 +

3

AUX Power –

2

AUX Power +

1

PLC Terminals

Channel 2

+

4-20 mA

–

Channel 1

+

4-20 mA

–

Power

–

Supply

+

12–24 VD C

page 5

Page 8

Hysteresis

Time

Low Setpoint

Process

Relay energized

Relay deenergized

Hysteresis

Time

High Setpoint

Process

Open Collector and Relay Outputs

Flow 6.25 GPM

Total 1234567.8>

The open collector and relay outputs can be used as a switch that

responds when the fl ow rate moves above or below a setpoint,

or it can be used to generate a pulse that is relative to the fl ow

volume or to the fl ow rate.

Low (Open Collector or Relay output)

Output triggers when the fl ow rate is less than the setpoint.

The output will deenergize when the fl ow rate moves above the

setpoint plus the hysteresis value.

High (Open Collector or Relay output)

Output triggers when the fl ow rate is greater than the setpoint.

The output will deenergize when the fl ow rate drops below the

setpoint plus the hysteresis value.

Frequency (Open Collector only)

Output is a pulse stream that is based on the input fl ow sensor

signal. The input frequency can be divided by any value from 1 to

254.

Pulse (Open Collector or Relay output)

Output is a pulse based on the volume of fl uid that passes the

sensor. Set any value from 0.0001 to 99999.

VIEW menus

• During normal operation, the FP90 displays the VIEW menu.

• When using the CALIBRATE or OPTIONS menus, the FP90 will return to the VIEW menu if no activity occurs for 10 minutes.

• To select the item you want displayed, press the UP or DOWN arrow keys. The items will scroll in a continuous loop. Changing the

display selection does not interrupt system operations.

• No key code is necessary to change display selection.

• Output settings cannot be edited from the VIEW menu.

View Menu for FP90-1

Display Description

Monitor the fl ow rate and the resettable totalizer. Press the RIGHT ARROW key to reset

the totalizer. If the totalizer is locked, you will need to enter the Key Code fi rst.

Lock or Unlock the totalizer in the OPTIONS menu.

This is the permanent View display.

Monitor the Permanent Totalizer value.

Monitor the 4-20 mA Loop output.

Monitor date for scheduled maintenance or date of last calibration.

0.0 GPM

Total: 12345678 >

All of the displays below are temporary. After ten minutes the display will return to the permanent display.

Perm: 12345678

Gallons

Loop Output:

12.00 mA

Last CAL:

6-16-09

page 6

OMEGA FP90 Series Flow Transmitter Instructions

Page 9

View Menu for FP90-2

Display Description

0.0 GPM

Total: 12345678 >

Monitor the fl ow rate and the resettable totalizer. Press the RIGHT ARROW key to reset

the totalizer. If the Reset is locked, you will need to enter the Key Code fi rst. Lock or

Unlock the totalizer in the OPTIONS menu. This is the permanent View display.

All of the displays below are temporary. After ten minutes the display will return to the permanent display.

Perm: 12345678

Gallons

Loop Output:

12.00 mA

Last CAL:

6-16-09

Monitor the Permanent Totalizer value.

Monitor the 4-20 mA Loop output.

Monitor date for scheduled maintenance or date of last calibration.

View Menu for FP90-3

Display Description

Flow1: 123.4 GPM

Flow2: 567.8 GPM

Delta Flow:

10.5 GPM

All of the VIEW displays below are temporary.

The permanent display will return after ten minutes.

Tot1: 1234567.8

Tot2: 123456.78 >

Perm1: 1234567.8

Gallons

Perm2: 123456.78

Gallons

Loop 1 Output:

12.00 mA

Loop 2 Output:

12.00 mA

Last CAL

6-16-09

Monitor the fl ow rate of Channel 1 and Channel 2 simultaneously.

This is a permanent display.

Monitor the delta fl ow rate (Channel 1 rate - channel 2 rate = Delta Flow)

This is a permanent display.

Monitor channel 1 and channel 2 Resettable Totalizers. Press the RIGHT ARROW key to

reset the totalizer. If Reset is locked, you must enter Key Code. Lock or Unlock function is

in OPTIONS menu.

Monitor channel 1 Permanent Totalizer.

Monitor channel 2 Permanent Totalizer.

Monitor the 4-20 mA Loop 1 output.

Monitor the 4-20 mA Loop 2 output.

Monitor date for scheduled maintenance or date of last calibration.

OMEGA FP90 Series Flow Transmitter Instructions

page 7

Page 10

FP90 series Editing Procedure:

OPTIONS

CALIBRATE

VIEW

2s 5s

Press &

hold for

access:

ENTER

20.0 G

Output Setpnt:

2

0.00 GPM

Output Setpnt:

1

0.00 GPM

ENTER

Output

Setpnt:

1

0

.00

GPM

Output Setpnt:

1

9

.00 GPM

Output Setpnt:

Saving

Output

Setpnt:

19.00 GPM >

20.0 GPM >

Output Setpnt:

GPM >

Flow Units:

CALIBRATE: ----

Enter Key Code

CALIBRATE: *---

Enter Key Code

CALIBRATE: **-Enter Key Code

CALIBRATE: ***Enter Key Code

GPM >

Flow Units:

Step 1. Press and hold ENTER key:

• 2 seconds to select the CALIBRATE menu

• 5 seconds to select the OPTIONS menu.

Step 2. The Key Code is UP-UP-UP-DOWN keys in sequence.

• After entering the Key Code, the display will show the fi rst item in the selected menu.

Step 3. Scroll menu with UP or DOWN arrow keys.

Step 4. Press RIGHT ARROW key to select menu item to be edited.

• The fi rst display element will begin fl ashing.

Step 5. Press UP or DOWN keys to edit the fl ashing element.

• RIGHT ARROW key advances the fl ashing element.

Step 6. Press ENTER key to save the new setting and return to Step 3.

Notes on Step 1:

• The View Menu is normally displayed.

• The CALIBRATE and OPTIONS menus require a KEY CODE.

Notes on Step 2:

If no key is pressed for 5 minutes while display is showing "Enter

Key Code", the display will return to the VIEW menu.

Notes on Steps 3 and 4:

• Refer to pages 9-14 for complete listing of menu items and their use.

• From the Step 3 display, pressing the UP and DOWN keys simultaneously will

return the display to the VIEW menu.

• If no key is pressed for 10 minutes, display will also return to the VIEW menu.

Step 3: Finished Editing?

Press the UP and DOWN keys simultaneously after

saving the last setting to return to normal operation.

First item in CALIBRATE menu

Step 3

Step 4

Notes on Steps 5 and 6:

• All output functions remain active during editing.

• Only the fl ashing element can be edited.

• RIGHT ARROW key advances the fl ashing element in a continuous loop.

• Edited value is effective immediately after pressing ENTER key.

• If no key is pressed for 10 minutes unit will restore the last saved value and return to step 3.

• Step 6 (pressing ENTER key) always returns you to Step 3.

• Repeat steps 3-6 until all editing is completed.

page 8

Press the UP and DOWN keys simultaneously while

any element is fl ashing. This will recall the last

Step 5: Made an Error?

saved value of the item being edited and return you

to Step 3.

Step 5

Step 6

OMEGA FP90 Series Flow Transmitter Instructions

Page 11

CALIBRATE and OPTIONS menus

The following pages contain the CALIBRATE and OPTIONS menus for each version of the FP90 Flow Transmitter. Be sure you are

using the correct menu:

• FP90-1: Single-channel Loop Flow Transmitter with one open-collector output

• FP90-2: Single-channel Loop Flow Transmitter with 2 SPDT relays

• FP90-3: Dual-channel Loop Flow Transmitter with two open-collector outputs

Calibrate Menu for FP90-1

Display

(Factory settings shown)

Flow Units:

GPM >

Flow K-Factor:

60 >

Total Units:

Gallons >

Total K-Factor

60 >

Loop Range: GPM

000.00 → 100.00 >

Output Mode:

Low >

Output Setpnt:

10.0 GPM >

Output Hys:

5.0 GPM >

Output Volume:

100.00 Gallons >

Output PlsWdth:

0.1 Seconds >

Output Freq.:

Divide by 1 >

Last CAL:

6-16-09

The fi rst two characters set the Flow Rate units of measure. They have no effect on calculations. They

may be any alpha or numeric character, upper or lower case.

The last character sets the Flow rate Timebase. Select S (seconds), M (minutes), H (hours) or D

(days).

This setting tells the transmitter how to convert the input frequency from the fl ow sensor into a fl ow

rate. The K-factor is unique to the sensor model and to the pipe size and schedule. Refer to data in the

sensor manual for the correct value. Limits: 0.0001 to 99999. (The K-factor cannot be set to 0)

This setting identifi es the Totalizer units. It has no effect on any calculation. It serves as a label only.

Each character can be any alpha or numeric selection, upper or lower case.

This setting tells the transmitter how to convert the input frequency from the fl ow sensor into a

volumetric total. It also is used as the basis for the Open Collector pulse mode.

The setting is usually the same as the Flow K-factor, or different by x10 or x100. Limits: 0.0001 to

99999. (The K-factor cannot be set to 0)

Select the minimum and maximum values for the 4-20 mA Current loop output. The FP90 will allow any

values from 0.0000 to 99999.

Select the desired mode of operation for the Open Collector output. Options available are High, Low,

volumetric Pulse, or Frequency. The signal may be disabled if not used.

In Low or High Mode, the Open Collector output will be deactivated when the Flow rate reaches this

value. Be sure to modify this setting if you change the Flow Units.

The Open Collector output will be deactivated at Setpoint ± Hysteresis, depending on High or Low

Setpoint selection. (See details on page 6.)

In Pulse mode, the Open collector output will generate one pulse when this volume of fl ow passes the

sensor. The measurement is based on the Total K-factor. The FP90 will allow any value from 0.0000 to

99999.

In Pulse mode, this setting defi nes the duration of the Open Collector output pulse. The FP90 allows

any value from 0.1 seconds to 999.9 seconds.

In Frequency mode, the Open Collector output will simulate the sensor frequency, divided by this

setting. The FP90 allows any value from ÷1 to ÷254.

Use this “note pad” to record important dates, such as annual recertifi cation or scheduled maintenance.

Description

OMEGA FP90 Series Flow Transmitter Instructions

page 9

Page 12

Options Menu for FP90-1

Display

(Factory settings shown)

Contrast:

3 >

Averaging:

Adjust the LCD contrast for best viewing. A setting of 1 is lower contrast, 5 is higher. In

general, select lower contrast if the display is in warmer ambient surroundings.

OFF provides the most instantaneous output response to changes in fl o w .

Options are 8 seconds, 20 seconds, 50 seconds or 120 seconds.

Longer averaging produces more stable display and output response.

O >

Loop Adjust:

4.00 mA >

Loop Adjust:

20.00 mA >

Output Active:

Low >

Test Loop:

>

Adjust the minimum and maximum current output. The display value represents the

precise current output.

Adjustment limits:

• 3.80 mA < 4.00 mA > 5.00 mA

• 19.00 mA < 20.00 mA > 21.00 ma

Use this setting to match the system output to any external device.

Active HIGH: This setting is used to turn a device (pump, valve) ON at the setpoint.

Active LOW: This setting is used to turn a device OFF at the setpoint.

Press UP and DOWN keys to manually order any output current value from 3.6 mA to

21.00 mA to test the output loop.

Test Output:

>

Press UP and DOWN keys to manually toggle the Open Collector output state.

Description

page 10

OMEGA FP90 Series Flow Transmitter Instructions

Page 13

Calibrate Menu for FP90-2

Display

(Factory settings shown)

Description

Flow Units:

GPM >

Flow K-Factor:

60.00 >

Total Units:

Gallons >

Total K-Factor

60 >

Loop Range: GPM

000.00 → 100.00 >

Relay1 Mode:

Low >

Relay1 Setpnt:

10.0 GPM >

Relay1 Hys:

5.0 GPM >

Relay1 Volume:

100.00 Gallons >

Relay1 PlsWdth:

0.1 Seconds >

Last CAL:

6-16-09

The fi rst two characters set the Flow Rate units of measure. They have no effect on calculations. They

may be any alpha or numeric character, upper or lower case.

The last character sets the Flow rate Timebase. Select S (seconds), M (minutes), H (hours) or D (days).

This setting tells the transmitter how to convert the input frequency from the fl ow sensor into a fl ow

rate. The K-factor is unique to the sensor model and to the pipe size and schedule. Refer to data in the

sensor manual for the correct value. Limits: 0.0001 to 99999. (The K-factor cannot be set to 0.)

This setting identifi es the Totalizer units. It has no effect on any calculation. It serves as a label only.

Each character can be any alpha or numeric selection, upper or lower case.

This setting tells the transmitter how to convert the input frequency from the fl ow sensor into a

volumetric total. It also is used as the basis for the volumetric Pulse mode.

The setting is usually the same as the Flow K-factor, or different by x10 or x100. Limits: 0.0001 to

99999. (The K-factor cannot be set to 0.)

Select the minimum and maximum values for the 4-20 mA Current loop output. The FP90 will allow any

values from 0.0000 to 99999.

Select the desired mode of operation for relay 1. Options available are High, Low or volumetric Pulse.

The signal may be disabled if not in use.

In Low or High Mode, the relay output will be activated when the Flow rate reaches this value. Be sure

to modify this setting if you change the Flow Units.

Relay 1 will be deactivated at Setpoint ± Hysteresis, depending on High or Low Setpoint selection.

(See details on page 6.)

In Pulse mode, the relay output will generate one pulse when this volume of fl ow passes the sensor.

(The measurement is based on the Total K-factor.) The FP90 will allow any value from 0.0000 to

99999.

In Pulse mode, this setting defi nes the duration of the relay pulse. The FP90 allows any value from 0.1

seconds to 999.9 seconds.

Use this “note pad” to record important dates, such as annual recertifi cation or scheduled maintenance.

All Relay settings repeat for Relay 2.

OMEGA FP90 Series Flow Transmitter Instructions

page 11

Page 14

Options Menu for FP90-2

Display

(Factory settings shown)

Contrast:

Adjust the LCD contrast for best viewing. A setting of 1 is lower contrast, 5 is higher.

Select lower contrast if the display is in warmer ambient surroundings.

3 >

Flow Decimal:

***.** >

Total Decimal:

********. >

Averaging:

O >

Set the decimal to the best resolution for your application. The display will automatically

scale up to this restriction.

Select *****., ****.*, ***.**, **.*** or *.****

Set the totalizer decimal to the best resolution for your application.

Select ********., *******.*, or ******.**

OFF provides the quickest output response to changes in fl o w .

Options are 8 seconds, 20 seconds, 50 seconds or 120 seconds.

Longer averaging produces more stable display and output response.

Total Reset:

Lock O >

Loop Adjust:

4.00 mA >

Loop Adjust:

20.00 mA >

Test Loop:

Locked: The Key Code must be entered to reset the resettable totalizer.

Unlocked: No key code required to reset the resettable totalizer.

Adjust the minimum and maximum current output. The display value represents the

precise current output.

Adjustment limits:

• 3.80 mA < 4.00 mA > 5.00 mA

• 19.00 mA < 20.00 mA > 21.00 ma

Use this setting to match the system output to any external device

Press UP and DOWN keys to manually order any output current value from 3.6 mA to

21.00 mA to test the output loop.

>

Description

Test Relay 1:

>

Press UP and DOWN keys to manually toggle the state of relay 1.

Repeat for relay 2.

page 12

OMEGA FP90 Series Flow Transmitter Instructions

Page 15

Calibrate Menu for FP90-3

Display

(Factory settings shown)

Flow1 Units:

GPM >

Flow1 K-Factor:

60.000 >

Total1 Units:

Gallons >

Total1 K-Factor

60.00 >

Loop1 Source:

Flow1 >

Loop1 Range: GPM

000.00 > 100.00 >

Output1 Source:

Flow1 >

Output1 Mode:

Low >

Output1 Setpoint

10.0 GPM >

Output1 Hys:

5.0 GPM >

Output1 Volume:

100.00 Gallons >

Output1 Pulsewdth:

0.1 Seconds >

Output1 Freq.:

Divide by 1 >

Last Cal

The fi rst two characters set the Flow Rate units of measure. They have no effect on calculations.

They may be any alpha or numeric character, upper or lower case.

The last character sets the Flow rate Timebase. Select S (seconds, M (minutes, H (hours) or D (days)

This setting tells the transmitter how to convert the input frequency from the fl ow sensor into a fl ow rate.

The K-factor is unique to the sensor model and to the pipe size and schedule. Refer to data in the sensor

manual for the correct value. Limits: 0.0001 to 99999. (The K-factor cannot be set to 0)

This setting identifi es the Totalizer units. It has no effect on any calculation. It serves as a label only. Each

character can be any alpha or numerical selection, upper or lower case.

This setting tells the transmitter how to convert the fl ow sensor signal into a volumetric total. It also is

used as the basis for the Open Collector pulse mode.

The setting is usually the same as the Flow K-factor, or different by x10 or x100.

Limits: 0.0001 to 99999. (The K-factor cannot be set to 0)

Select the input source to be associated with Loop output #1:

Flow sensor #1, Flow sensor #2, or Delta Flow

Select the minimum and maximum values for the Current loop output #1.

The FP90 will allow any values from 0.0000 to 99999.

Select the input source for Open Collector output #1: Flow sensor #1, Flow sensor #2, or Delta Flow

Select the mode of operation for Open Collector output #1.

Options available are High, Low, Pulse (volumetric), or Frequency (based on rate).

The signal may be disabled if not in use.

In Low or High Mode, this Open Collector output will be activated when the Flow rate reaches this value.

Be sure to modify this setting if you change the Flow Units.

The Open Collector output will be deactivated at Setpoint ± Hysteresis, depending on High or Low

Setpoint selection.

In Pulse mode, Open collector output #1 will generate one pulse when this volume of fl ow passes the

sensor. (The measurement is based on the Total1 K-factor)

The FP90 will allow any value from 0.0000 to 99999.

In Pulse mode, this setting defi nes the duration of Open Collector output pulse #1. The FP90 allows any

value from 0.1 seconds to 999.9 seconds.

In Frequency mode, Open Collector output #1 will simulate the sensor frequency, divided by this value.

The FP90 allows any value from ÷1 to ÷254.

Use this “notepad” to record important dates, such as annual recertifi cation or scheduled maintenance.

6-16-09 >

All functions labeled "1" will repeat for channel 2.

Description

OMEGA FP90 Series Flow Transmitter Instructions

page 13

Page 16

Options Menu for FP90-3

Display

(Factory settings shown)

Contrast:

3 >

Flow1 Decimal

***.** >

Total1 Decimal

********. >

Averaging 1

O >

Adjust the LCD contrast for best viewing. A setting of 1 is lower contrast, 5 is higher.

Select lower contrast if the display is in warmer ambient surroundings.

Set the decimal to the best resolution for your application. The display will automatically

scale up to this restriction.

Select *****., ****.*, ***.**, **.*** or *.****

Set the totalizer decimal to the best resolution for your application.

Select ********., *******.*, or ******.**

OFF provides the quickest output response to changes in fl o w .

Options are 8 seconds, 20 seconds, 50 seconds or 120 seconds.

Longer averaging produces more stable display and output response.

Description

Total Reset

Lock O >

Loop1 Adjust:

4.00 mA >

Lock Off : No key code required to reset the resettable totalizer.

Lock On : The Key Code must be entered to reset the resettable totalizer.

Adjust the minimum and maximum current output. The display value represents the

precise current output.

Adjustment limits:

• 3.80 mA < 4.00 mA > 5.00 mA

• 19.00 mA < 20.00 mA > 21.00 ma

Use this setting to match the system output to any external device.

Loop1 Adjust:

20.00 mA >

Output1 Active:

Low >

Test Loop1:

Active HIGH: This setting is used to turn a device (pump, valve) ON at the setpoint.

Active LOW: This setting is used to turn a device OFF at the setpoint.

Press UP or DOWN keys to manually order any output current value from 3.6 mA to

21.00 mA to test current loop output #1.

>

Press UP or DOWN keys to manually toggle the state of open collector output #1.

Test Output 1:

>

All functions labeled "1" will repeat for channel 2.

page 14

OMEGA FP90 Series Flow Transmitter Instructions

Page 17

FP90 Series Flow Transmitter Troubleshooting

Display Condition Suggested SolutionsPossible Causes

“- - - - -”

“Pulse Overrun Output1”

“Pulse Overrun Output2”

“Value must be more than 0”

Relay or open Collector output

is always activated

Flow rate exceeds display capability

Relay or Open Collector pulse rate

exceeds 300 pulses per minute.

Pulse width set too wide.

K-factors cannot be set to 0.

Hysteresis value too large

• Increase Flow units timebase

• Move fl ow decimal one place to the right

• Increase Output Volume setting

• Decrease pulse width setting

• Reduce system fl ow rate

• Enter K-factor between 0.0001 to 99999

• Reset the hysteresis value

OMEGA FP90 Series Flow Transmitter Instructions

page 15

Page 18

Notes:

page 16

OMEGA FP90 Series Flow Transmitter Instructions

Page 19

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13

months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal

one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive

maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written

request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at

no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for

any damages that result from the use of its products in accordance with information provided

by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it

will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component”

under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on

humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on

humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY / DISCLAIMER

language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage

whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING

ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S

CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then

be marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in

transit.

FOR WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

2. Model and serial number of the product under

3. Repair instructions and/or speci c problems relative

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This a ords our customers the

latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2000 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated,

or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA

ENGINEERING, INC.

was PURCHASED,

warranty, and

to the product.

FOR NON-WARRANTY REPAIRS,

repair charges. Have the following information available

BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the

repair,

2. Model and serial number of the product, and

3. Repair instructions and/or speci c problems relative

to the product.

consult OMEGA for current

OMEGA FP90 Series Flow Transmitter Instructions

Page 20

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

•

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

•

Wire: Thermocouple, RTD & Thermistor

•

Calibrators & Ice Point References

•

Recorders, Controllers & Process Monitors

•

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

•

Transducers & Strain Gages

•

Load Cells & Pressure Gages

•

Displacement Transducers

•

Instrumentation & Accessories

FLOW/LEVEL

•

Rotameters, Gas Mass Flowmeters & Flow Computers

•

Air Velocity Indicators

•

Turbine/Paddlewheel Systems

•

Totalizers & Batch Controllers

pH/CONDUCTIVITY

•

pH Electrodes, Testers & Accessories

•

Benchtop/Laboratory Meters

•

Controllers, Calibrators, Simulators & Pumps

•

Industrial pH & Conductivity Equipment

DATA ACQUISITION

•

Data Acquisition & Engineering Software

•

Communications-Based Acquisition Systems

•

Plug-in Cards for Apple, IBM & Compatibles

•

Datalogging Systems

•

Recorders, Printers & Plotters

HEATERS

•

Heating Cable

•

Cartridge & Strip Heaters

•

Immersion & Band Heaters

•

Flexible Heaters

•

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

•

Metering & Control Instrumentation

•

Refractometers

•

Pumps & Tubing

•

Air, Soil & Water Monitors

•

Industrial Water & Wastewater Treatment

•

pH, Conductivity & Dissolved Oxygen Instruments

6-8550.090-OM (D-10/08) M3630/1008

Loading...

Loading...