Page 1

User’s Guide

Shop online at

www.omega.com

e-mail: info@omega.com

FP-6000 Series

Flow Sensors

Page 2

OMEGAnet® Online Service Internet e-mail

www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

®

®

®

Mexico: En Español: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: Rudé armády 1868, 733 01 Karviná 8

TEL: +420 (0)69 6311899 FAX: +420 (0)69 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

TEL: +33 (0)130 621 400 FAX: +33 (0)130 699 120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7059 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: germany@omega.com

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

Chapter Page

Table of

1 Introduction 1

1.1 Description 1

1.2 Theory of Operation 1

2 Installation and Wiring 2

2.1 Location of Fitting 2

2.2 Sensor Position 2

2.3 Sensor Wiring 3

3 Installation 4

3.1 Hardware, Standard Sensor 4

3.2 Hardware, Hot-Tap Sensor 4

3.3 Standard Fitting Installation 4

3.4 Hot-Tap Fitting Installation 5

3.5 Calculating the H Dimension 6

3.6 Standard Installation 8

3.7 Hot-Tap Installation 10

4 Sensor Removal Procedures 14

4.1 Standard Sensor Removal 14

4.2 Hot-Tap Sensor Removal 14

Contents

5Maintenance and Replacement Parts 16

5.1 Maintenance 16

5.2 Replacement Parts 16

5.3 Rotor Replacement Procedure 17

"H" Dimensions for Standard Sensors 18

"H" Dimensions for Hot-Tap Sensors 19

Calibration Constants 20

Specifications 23

Warranty 25

Page 4

.

Page 5

Important Safety Information!

CAUTION:

(Standard version) Never remove the flow sensor

from a pressurized pipe. Always wear safety face

protection during sensor installation/removal.

(Hot-Tap version) Follow the recommended

installation/removal instructions in this manual.

Always wear safety face protection during sensor

installation/removal.

Pipe fittings MUST be installed by a certified

welder only. OMEGA will not assume liability of

any kind for improper fitting installations.

Serious bodily injury and/or damage to the sensor

can result if the conditions and specifications

presented in this manual are exceeded. DO NOT

exceed specifications under any circumstances.

The FP-6000 Hot-Tap system's overall specifications and limitations depend on the lowest maximum rating of the components associated with the

system. In other words, the Hot-Tap system is only

as strong as its weakest link. For example, a ball

valve, a component of the system, is rated at a

maximum 100 psi @ 185 °F, limiting the entire

system's maximum pressure/temperature rating to

100 psi @ 185 °F. All higher maximum specifications MUST yield to the component with the lowest

maximum specification.

Maximum Operating Pressure:

225 psi (15 bar)

Maximum Operating Temperature:

212 °F (100 °C)

Page 6

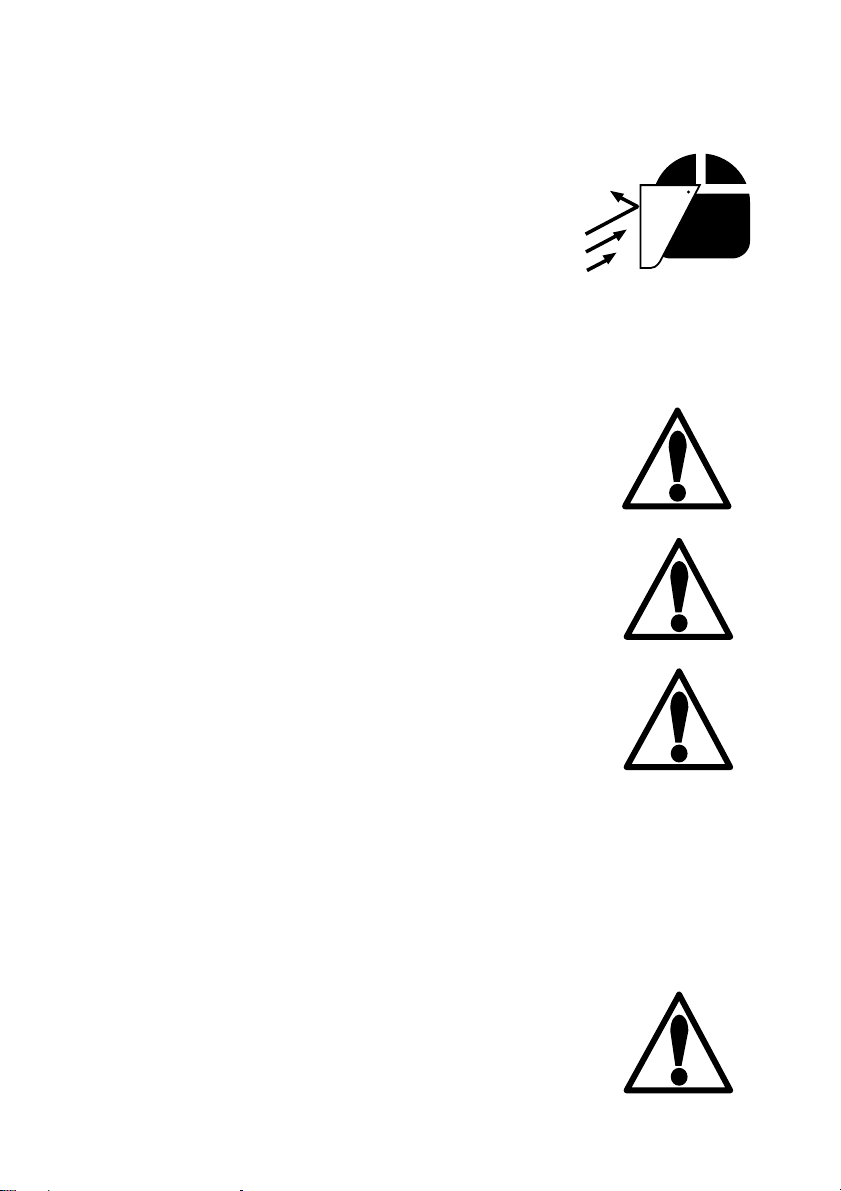

OMEGA FP-6000, -6001

Adjustable Brass Flow Sensor

Order Number:

FP-6000

1-1/2 in. NPT threads

FP-6001

7/1-R 1-

1/2

ISO threads

Unpacking and Inspection

Your flow sensor package includes the following

items:

OMEGA FP-6000 Series Adjustable Brass Flow Sensor

6 inch ruler (Standard sensor version only)

10 inch brass alignment rod

Warranty Record

For your protection, record your sensor's purchase

information for future reference. The serial number

is located on the metal tag attached to the upper

portion of the sensor body.

Type: OMEGA FP-6000 Series

Adjustable Brass Flow Sensor

OMEGA FP-6002, -6003

Adjustable Brass Flow Sensor

for Hot-Tap installations

Order Number:

FP-6002

1-1/2 in. NPT threads

FP-6003

7/1-R 1-

1/2

ISO threads

Purchase Date: __________________________

Model Number: _________________________

Serial Number: __________________________

Purchased From: _________________________

Purchase Order Number: _________________

Page 7

This manual contains description, specifications

Fluid

Flow

and instruction for the installation, removal, and

operation of the OMEGA FP-6000 Series

Adjustable Brass Flow Sensor. Please read the

manual thoroughly. If you require further

assistance, please contact your OMEGA dealer.

1.1 Description

The FP-6000 Series is an insertion flow sensor

used to measure the flow velocity of fluids through

process pipes. The sensor insertion depth is

adjustable, allowing installation into metal pipes

ranging from 11/2 to 24 inches in diameter (11/

to 36 in. for Hot-Tap). The Hot-Tap version

enables installation in active pipes, reducing

downtime to a minimum. Wetted parts include

C36000 brass, CD4MCu steel, tungsten steel,

Fluoroloy B, and Viton®.

Chapter 1

Introduction

2

The FP-6000 Series mounts on the pipe through

any standard 1

1

/2 inch female pipe fitting. The

unit comes equipped with standard NPT threads

or optional ISO 7/1-R 11/2 threads.

1.2 Theory of Operation

Liquid flowing through a process pipe rotates the

sensor paddlewheel. An AC frequency is induced

into the sensor coil which is proportional to the

fluid velocity in amplitude and frequency. The AC

signal is then input to a control instrument where

the frequency is converted to engineering units and

used to display flow rate and control external

devices.

Patented open-cell rotor

design provides a linear AC

output over a wider velocity

range.

1

Page 8

Chapter 2

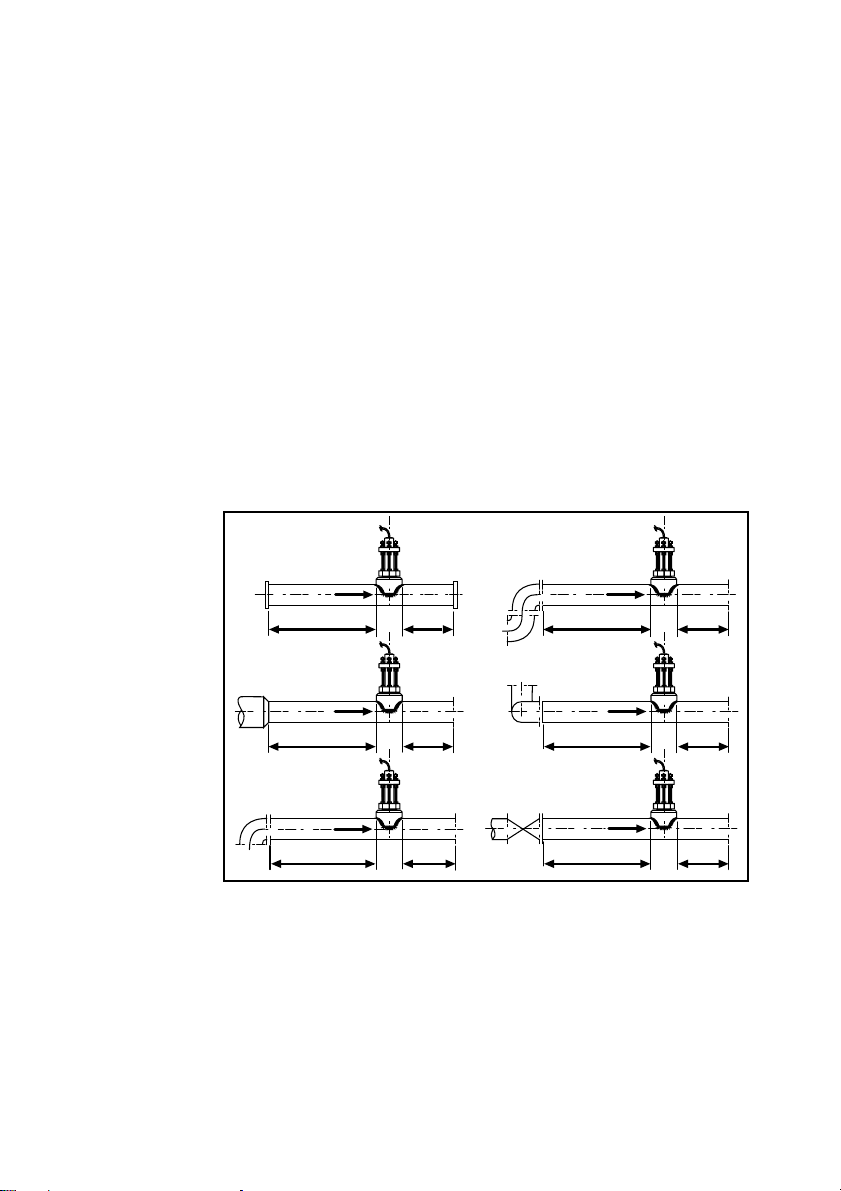

15 X I.D. 5 X I.D.

Reducer

Flange

40 X I.D. 5 X I.D.

2 x 90° Elbow

3 dimensions

20 X I.D. 5 X I.D.

90° Elbow

50 X I.D. 5 X I.D.

Valve/Gate

10 X I.D. 5 X I.D.

25 X D 5 X I.D.

2 x 90°

Elbow

Inlet OutletInlet Outlet

Installation and

Wiring

Figure 1

Sensor upstream/

downstream mounting

requirements

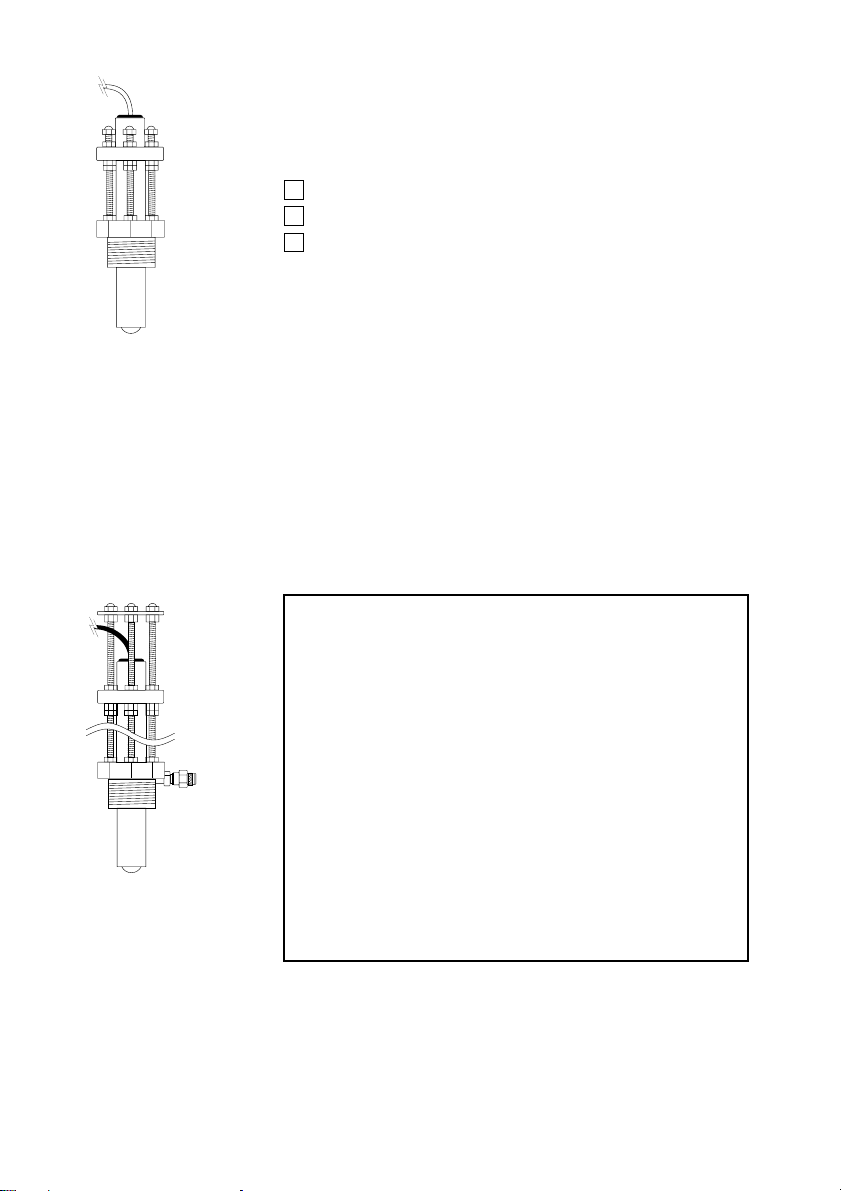

The linearity and accuracy of the FP-6000 Series

sensor depend on predictable flow conditions in

the pipe and proper location of the fitting. As

with any insertion flow sensor, the pipe must be full

and generally free of air pockets.

2.1 Location of Fitting

The sensor must be located in a free-flowing

straight run of pipe. OMEGA recommends a

minimum of 10 pipe diameters of straight pipe

upstream and a minimum of 5 diameters downstream to insure a fully developed flow profile.

Any obstructions to the flow will require considerably longer straight runs. Figure 1 illustrates

several common situations and recommended

piping distances.

2

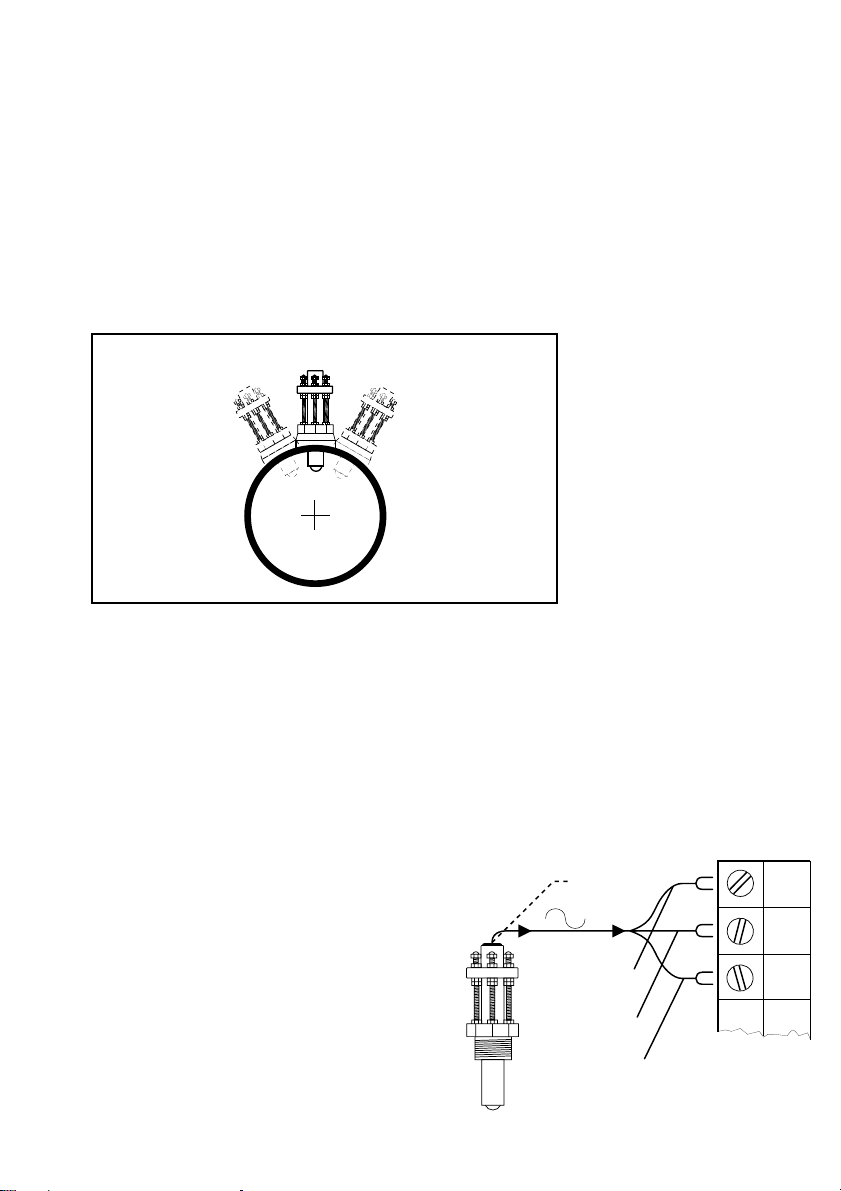

2.2 Sensor Position

When installing the sensor in a horizontal pipe run

the optimum position is at 0° or 180°, assuming

the line is always full and contains no solids.

Air pockets or sediment in the line will disturb the

rotation of the paddlewheel, causing inaccuracy in

the calibration. Installing the sensor at an angle

Page 9

(max. 30°) will help to avoid these problem areas,

blk

F-

red

F+

shld

black

(AC signal out)

red

(AC signal out)

silver

(shield)

instrument

1/2 in. conduit

port

but use caution. Excessive angles will cause

bearing drag at lower flow rates.

On a vertical pipe run locate the sensor where the

flow is upward. If downward flow is necessary

the system must be designed to prevent air/water

vapor pockets from developing in the pipe which

will affect the performance of the sensor.

0°

+30°-30°

Maximum Sensor

Installation Range

Process Pipe

Special Considerations

For Hot-Tap installations allow at least 3 feet of

vertical clearance for sensor installation plus the

distance required for the isolation valve and fittings

attached to the pipe. More clearance may be

necessary to suit the drilling machine used during

sensor installation.

2.3 Sensor Wiring

Both Standard and Hot-Tap sensor

versions include 25 feet of cable. The

cable may be extended up to 200 feet

without amplification. A 1/2 inch

conduit port is available in the sensor to

install the cable in protective conduit.

Figure 2

Sensor Installation Range

Vertical mounting is recommended to provide best

overall performance.

3

Page 10

Chapter 3

Installation

The following items are required to properly install

the OMEGA FP-6000 Series Adjustable Brass flow

sensor.

3.1 Hardware, Standard Sensor

• female pipe fitting (weld-on or saddle)

11/2 in. NPT or ISO 7/1-Rc 1-1/2

•11/4 in. (32 mm) diameter drill

• Pipe thread sealant

• Tape measure

3.2 Hardware, Hot-Tap Sensor

The Hot-Tap sensor requires all the above items

plus:

•Hot-Tap drilling machine (e.g. Mueller drilling

machine or equivalent)

• Female ball or gate valve (full port only)

11/2 in. NPT or ISO 7/1-Rc 1-1/2

Caution: Depressurize and

drain pipe before drilling .

4

• Male pipe nipple, 11/2 x 2 in./32 x 50 mm

11/2 in. NPT or ISO 7/1-R 11/

•Hot-Tap installation tool (purchased separately)

2

3.3 Standard Fitting Installation

1. Depressurize and drain pipe.

2. Wearing safety face protection, drill a 11/4 in.

(32 mm) diameter hole in the pipe.

3. Install the pipe fitting on the outside of the pipe

according to the manufacturer's instructions.

Failure to follow these instructions may result in

bodily injury and/or product failure.

Page 11

4. Remove brass sensor nut from sensor.

brass sensor nut

pipe fitting

(Teflon tape recommended)

process pipe

5. Thread brass sensor nut into pipe fitting.

3.4 Hot-Tap Fitting Installation

1. Install the pipe fitting on the outside diameter of

the pipe according to the manufacturer's instructions. Failure to follow these instructions may result

in bodily injury and/or product failure.

2. Install the pipe nipple and isolation valve (ball

or gate valve) onto the external pipe fitting using

pipe sealant on the threads.

customer supplied

ball or gate valve

customer supplied

nipple; 1.25 x 2 in.

(32 x 50 mm) long

process pipe

(side view)

3. Wearing safety face protection, install an

appropriate hole cutting tool per manufacturers

instructions (e.g. Mueller drilling machine) with a

1

/4 in. (32 mm) drill onto the top of the isolation

1

valve, ensuring a tight fit. Use the recommended

drill bit size or damage to the isolation valve

may occur.

5

Page 12

A

B

1

2

3

4

5

6

1

2

3

4

5

A

B

1

2

3

4

5

6

1

2

3

4

5

I.D.

wall

thickness

A

B

1

2

3

4

5

6

1

2

3

4

5

incorrect

correct

brass sensor nut

bleed valve

make sure

bleed valve

clears isolation

valve handle

process pipe

For Hot-Tap installations, we

assume pipe dimensions are

known

Wall

thickness:____________

4. Open the isolation valve and insert the drill

through the valve and cut the sensor clearance

hole. After the hole is cut, withdraw the drill from

the isolation valve and close the valve. Remove

the drilling machine per manufacturer's instructions.

5. Install brass sensor nut/bleed valve into the top

of the isolation valve. Make sure the bleed valve

clears the handle of the isolation valve during

operation.

3.5 Calculating the H Dimension

Before installing the sensor some critical dimensions must be established. The rotor shaft must be

located 10% inside the pipe I.D. to insure accurate

calibration capability. To accomplish this, the "H"

dimension is measured from the outside surface of

the pipe to the bottom of the sensor flange.

Nominal "H" dimensions for standard pipes are

listed on page 18-19. For irregular pipe dimensions, calculate the "H" dimension using the given

formulas (page 7). The 6 inch ruler may be used

to measure the I.D. and wall thickness of pipes up

to 5 inch (standard sensors only).

I.D.: ________________

For standard sensor installations, the ruler may be used to

measure wall thickness and

I.D. of pipes up to 5 inches in

diameter.

6

Page 13

Standard Sensor

"H"

alignment rod

sensor flange

process pipe

direction of flow

pipe side view

process pipe (side view)

direction of flow

alignment rod

"H"

protector plate

H = 5.95 - pipe wall thickness - (0.10 X I.D.)

Example:

3.0 inch schedule 80 wrought steel;

Wall thickness= 0.3 in.

Inside diameter = 2.9 in.

H = 5.95 - 0.3 - (0.10 X 2.9)

H = 5.36 in.

Hot-Tap Sensor

H = 15.00 - pipe wall thickness - (0.10 X I.D.)

Record your pipes "H"

dimension for future

reference:

H= _________________

Example:

10 inch schedule 40 wrought steel;

Wall thickness= 0.365 in.

Inside diameter = 10.02 in.

H = 15.00 - 0.365 - (0.10 X 10.02)

H = 13.633 in.

Record your pipes "H"

dimension for future

reference:

H= _________________

7

Page 14

Step 1

brass sensor nut

Step 2

hex nut

lock washer

Once the correct dimensions are calculated and

recorded, the sensor can be installed in the fitting.

The Standard and Hot-Tap versions require

substantially different procedures.

3.6 Standard Installation

1. Thread one hex nut onto each of the three

threaded rods included in package. Install

threaded rod with a lock-washer onto the brass

sensor nut. Secure rods in place by tightening

each hex nut against the brass sensor nut.

2. Thread one jam nut and lower hex nut onto

each stud so that the top surface of each nut is at

the proper "H" dimension for your pipe. Secure

each hex nut with a jam nut.

3. Insert the flow sensor into the brass sensor nut,

making sure the alignment hole on the sensor

flange is pointing downstream.

lower hex nut, 2nd

jam nut, 1'st

lower hex nuts

(3/16 x 1/4-20)

jam nuts

(5/32 x 1/4-20)

"H"

hex nut and lock washer

brass sensor nut

process pipe

8

Page 15

4. Place the alignment rod in the hole on the

sensor flange. Align the flange so rod is parallel

to the process pipe.

sensor flange

alignment rod

direction of flow

process pipe (top view)

The flow sensor alignment rod MUST be

parallel to the process pipe as shown.

5. Thread upper hex nuts with lock-washers until

they contact the sensor flange and tighten. Check

for proper "H" dimension and readjust if necessary.

cap nuts

upper hex nuts

and lock-washers

lower

hex nuts

5.95 in.

(151 mm)

sensor flange

jam nuts

brass sensor nut

FLOW

"H"

1-1/2 in. NPT or

ISO 7/1-Rc 1-

female pipe fitting

process pipe

1/2

in.

FLOW

10% of I.D.

wall

thickness

pipe I.D.

9

Page 16

Step 1

lower hex nuts

(3/16 x 1/4-20)

jam nuts

(5/32 x 1/4-20)

13.75 in.

(350 mm)

brass sensor nut

brass sensor nut

Step 2

hex nut

lock washer

3.7 Hot-Tap Installation

1. Thread one hex nut onto each of the three

threaded rods included in package. Install

threaded rod with a lock-washer onto the brass

sensor nut. Secure rods in place by tightening

each hex nut against the brass sensor nut.

2. Thread one jam nut and lower hex nut onto

each stud so the top surface of each nut is 13.75

in. (350 mm) from top surface of brass sensor nut.

Secure each hex nut with a jam nut.

This setting is critical to ensure an adequate

sensor seal and to prevent the rotor from hitting

the isolation valve orifice during installation.

lower hex nut, 2nd

jam nut, 1'st

10

Page 17

3. Wipe the FP-6000 Series sensor body with a

dry, clean cloth. Orient the alignment hole on the

sensor flange to point downstream. Place the

slotted flange over the threaded rods. Lower the

sensor into fitting until the sensor flange rests on

the lower hex and jam nuts.

4. Secure the sensor with lock-washers and upper

hex nuts on the top of the flange. Before tightening, align the sensor flange so that the alignment

rod is parallel and level with the process pipe.

5. Make sure the bleed valve is closed (full

clockwise position).

sensor flange

direction of flow

The flow sensor alignment rod MUST be

parallel to the process pipe as shown.

alignment rod

process pipe (top view)

sensor flange

lower hex nut and

jam nuts

18 inch threaded rods

Brass sensor nut

Upper hex nuts

(3/16 x 1/4-20)

1/4 in. lock washers

alignment rod

13.75 in.

Bleed valve

direction of flow

process pipe (side view)

11

Page 18

swivel mount

w/cable port

installation tool

threaded shaft

sensor flange

sensor

cable

bearing plate

cap nuts

protector plate

hex nuts

sensor body

protector plate

cap nuts

1.0 in.

(25 mm)

Using the Hot-Tap Installation Tool

The Hot-Tap installation tool helps to lower the

sensor into place against the pressure in the pipe.

1. Thread protector plate hex nuts onto each of the

three threaded rods. Adjust each hex to a height

of approximately 1 in. (25 mm) from the top of

each rod. Remove the black plastic cable grommet in top of sensor with a screwdriver. Slide the

grommet up the cable away from sensor.

2. Position the installation tool bearing plate by

rotating it so that it is approximately 2 inches away

from the swivel mount. Mount the installation tool

by placing the threaded rods through the holes in

the tool's bearing plate, resting the bearing plate

on top of the protector plate hex nuts. Make sure

the swivel mount's ears are mounted between the

threaded rods (not over the rods). Install the

bearing plate cap nuts. Tighten the bearing plate

cap nuts to secure the installation tool in place.

Protector plate

removed during

sensor installation

Protector plate hex nut

(3/16 x 1/4-20)

cable

grommit

12

Page 19

3. Align the sensor cable with the swivel mount

cable port to prevent cable pinching. Use a

3/8 inch wrench or socket to turn the installation

tool shaft clockwise until it is seated in the hole at

the top of the sensor flange.

4. Wearing safety face protection, slowly open

the isolation valve to the full open position.

Loosen the lower hex and jam nuts and move them

to the required "H" dimension. Turn the installation

tool shaft clockwise until the sensor flange contacts

the lower hex and jam nuts. Thread the upper hex

nuts down until they contact the sensor flange.

Tighten the upper hex nuts to secure the sensor.

5. Remove cap nuts and withdraw the installation

tool by turning shaft counterclockwise. Be careful

to not damage cable. Snap cable grommet into

top of sensor and replace protector plate and cap

nuts.

installation tool

shaft

upper hex nuts

cap nuts

alignment rod

lower hex nuts

jam nuts

protector plate

cap nuts

protector plate

protector plate

hex nut

"H"

direction of flow

13

Page 20

Chapter 4

Sensor Removal

Procedures

4.1 Standard Sensor Removal

To remove the Standard FP-6000 Series sensor

from a depressurized empty pipe, simply remove

the cap nuts and upper hex nuts located above the

sensor flange. Pull up on sensor flange with

twisting motion.

4.2 Hot-Tap Sensor Removal

To remove the Hot-Tap sensor safely from a

pressurized active pipe, the entire installation

process must be reversed.

14.2 in.

(361 mm)

protector plate

cap nuts

protector plate

protector plate

hex nut

1. Remove the cap nuts, protector plate, protector

plate hex nuts, and sensor cable grommet.

2. Thread installation tool in place and secure

bearing plate in place of sensor protector plate.

3. Turn shaft of installation tool clockwise to lower

tool into opening in sensor flange. Guide cable

into the port to prevent damage.

installation tool

threaded shaft

4. Wearing

upper hex nuts

and lock washers

sensor flange

lower hex and

jam nuts

safety face

protection,

loosen the upper

hex nuts and raise to 14.2 in.

(361 mm) from top of brass

sensor nut to bottom of nut. This

measurement is critical to

maintain watertight seal in

sensor while allowing clearance

to close the isolation valve.

14

process pipe (side view)

Page 21

installation tool

threaded shaft

cap nuts

protector plate

hex nuts

sensor cable

upper hex nuts

installation tool

bearing plate

swivel mount

w/cable port

sensor flange

1 lower hex nut

and jam nut

sensor body

5. Wearing safety face protection, turn the

installation tool shaft counterclockwise to withdraw

sensor until the sensor flange contacts the upper

hex nuts.

6. Raise one lower hex and jam nut to bottom of

sensor flange.

7. Close valve, remove bearing plate and tool.

To remove the sensor

8. Wearing safety face protection, cover the

bleed valve with suitable protection (rag, towel,

etc.) and open the bleed valve (ccw rotation) to

relieve internal pressure. Pull sensor up until bleed

valve purges some fluid (indicating sensor is past

1st o-ring seal inside brass sensor nut) then remove

sensor from brass sensor nut/threaded rod

assembly.

Caution: In case of a leaky isolation valve, the

sensor will be under a slight amount of pressure.

Care should be taken when removing the sensor.

Use the bleed valve to relieve this pressure taking

care not to spray fluid on yourself or others.

When reinstalling the

sensor:

hex nut in position to guide

sensor to proper height before

opening valve. Return to "H"

dimension height after valve is

opened.

leave one lower

15

Page 22

Chapter 5

Maintenance

5.1 Maintenance

All versions of the FP-6000 series sensor require

little or no maintenance, with the exception of an

occasional sensor/paddlewheel cleaning.

and

Replacement

Parts

♦Rotor Kit

retainer retainer

rotor shaft

bearing

rotor

Refer to rotor replacement

instructions, pg# 17

bearing

5.2 Replacement Parts

(Standard version)

1. Standard sensor assembly FP-6000, -6001

2. Rotor kit (bearings, shaft, retainers, and rotor

included), see table below♦

• FP52509-1 kit with stainless steel shaft

• FP52509-2 kit with Tungsten Carbide shaft

3. Instruction manual M-2973

FP52509-1 Rotor Kit

• Retainer material: 316 stainless steel

• Rotor shaft material: 316 stainless steel

• Bearing material: Fluoroloy B

• Rotor material: CD4MCu stainless steel

FP52509-2 Rotor Kit

• Retainer material: 316 stainless steel

• Rotor shaft material: Tungsten Carbide

• Bearing material: Fluoroloy B

• Rotor material: CD4MCu stainless steel

16

(Hot-Tap version)

4. Hot-Tap sensor assembly FP-6000, -6001

5. Rotor kit (bearings, shaft, retainers, and rotor

included), see table above♦

• FP52509-1 kit with stainless steel shaft

• FP52509-2 kit with Tungsten Carbide shaft

6. Instruction manual M-2973

Page 23

5.3 Rotor Replacement Procedure

Rotor Pin

Rotor Pin

Existing

Retainer

New

Bearings

Rotor

Assembly

1. With a small pair of needle-nose pliers, firmly

grip the center of the rotor pin (axle) and with a

twisting motion, bend the rotor pin into an "S"

shape. This should pull the ends of the pin out of

the shaft retainers and free the rotor assembly.

2. Remove shaft retainer from each side by gently

tapping it inwards using a punch. Install a new

shaft retainer with the rotor shaft clearance hole

inward. Only install one shaft retainer at this

time.

3. Insert the new rotor assembly and bearings into

the rotor housing of the sensor and place the new

rotor pin (axle) through the open end of the rotor

housing, through the rotor and bearings, and into

the previously installed shaft retainer.

4. Tap the second shaft retainer (rotor shaft clearance hole inwards) into the hole while lining up the

rotor pin with the center of the shaft retaining hole.

This completes the rotor replacement procedure.

Retainer

Punch

17

Page 24

H Dimensions

H Dimensions for Standard Sensors

Wrought Steel Pipe Per ANSI 36.10

NPS SCH 40 SCH 80 STD XS

1-1/2 in.

2 in.

2-1/2 in.

3 in.

3-1/2 in.

4 in.

5 in.

6 in.

8 in.

10 in.

12 in.

14 in.

16 in.

18 in.

20 in.

22 in.

24 in..

5.644 in.

5.589 in.

5.500 in.

5.427 in.

5.369 in.

5.310 in.

5.187 in.

5.064 in.

4.830 in.

4.583 in.

4.350 in.

4.200 in.

3.950 in.

3.700 in.

3.475 in.

*

3.000 in.

5.600 in.

5.538 in.

5.442 in.

5.360 in.

5.296 in.

5.230 in.

5.094 in.

4.942 in.

4.688 in.

4.400 in.

4.125 in.

3.950 in.

3.675 in.

3.400 in.

3.125 in.

2.850 in.

2.575 in.

5.644 in.

5.589 in.

5.500 in.

5.427 in.

5.369 in.

5.310 in.

5.187 in.

5.064 in.

4.830 in.

4.583 in.

4.375 in.

4.250 in.

4.050 in.

3.850 in.

3.650 in.

3.450 in.

3.250 in.

Conversion:

Stainless Steel Pipe Per ANSI B36.19

mm = inches (25.4)

5.600 in.

5.538 in.

5.442 in.

5.360 in.

5.296 in.

5.230 in.

5.094 in.

4.942 in.

4.688 in.

4.475 in.

4.275 in.

4.150 in.

3.950 in.

3.750 in.

3.550 in.

3.350 in.

3.150 in.

NPS SCH 5S SCH 10S SCH 40S SCH 80S

1-1/2 in.

2 in.

2-1/2 in.

3 in.

3-1/2 in.

4 in.

5 in.

6 in.

8 in.

10 in.

12 in.

14 in.

16 in.

18 in.

20 in.

22 in.

24 in.

(*) represents values currently unavailable

5.708 in.

5.660 in.

5.596 in.

5.534 in.

5.484 in.

5.434 in.

5.306 in.

5.200 in.

5.000 in.

4.768 in.

4.550 in.

4.425 in.

4.218 in.

4.018 in.

3.800 in.

3.600 in.

3.376 in.

5.673 in.

5.625 in.

5.567 in.

5.504 in.

5.454 in.

5.404 in.

5.287 in.

5.180 in.

4.969 in.

4.743 in.

4.531 in.

4.400 in.

4.200 in.

4.000 in.

3.776 in.

3.576 in.

3.350 in.

5.644 in.

5.589 in.

5.500 in.

5.427 in.

5.369 in.

5.310 in.

5.187 in.

5.064 in.

4.830 in.

4.583 in.

4.375 in.

*

*

*

*

*

*

18

5.600 in.

5.538 in.

5.442 in.

5.360 in.

5.296 in.

5.230 in.

5.094 in.

4.942 in.

4.688 in.

4.475 in.

4.275 in.

*

*

*

*

*

*

Page 25

H Dimensions for Hot-Tap Sensors

H Dimensions

Wrought Steel Pipe Per ANSI 36.10

NPS SCH 40 SCH 80 STD XS

1-1/2 in.

2 in.

2-1/2 in.

3 in.

3-1/2 in.

4 in.

5 in.

6 in.

8 in.

10 in.

12 in.

14 in.

16 in.

18 in.

20 in.

22 in.

24 in.

14.694 in.

14.639 in.

14.550 in.

14.477 in.

14.419 in.

14.360 in.

14.237 in.

14.144 in.

13.880 in.

13.633 in.

13.400 in.

13.250 in.

13.000 in.

12.750 in.

12.525 in.

*

12.050 in.

14.650 in.

14.588 in.

14.492 in.

14.410 in.

14.346 in.

14.280 in.

14.144 in.

13.992 in.

13.738 in.

13.450 in.

13.175 in.

13.000 in.

12.725 in.

12.450 in.

12.175 in.

11.900 in.

11.625 in.

14.694 in.

14.639 in.

14.550 in.

14.477 in.

14.419 in.

14.360 in.

14.237 in.

14.144 in.

13.880 in.

13.633 in.

13.425 in.

13.300 in.

13.100 in.

12.900 in.

12.700 in.

12.500 in.

12.300 in.

Conversion:

Stainless Steel Pipe Per ANSI B36.19

mm = inches (25.4)

14.650 in.

14.588 in.

14.492 in.

14.410 in.

14.346 in.

14.280 in.

14.144 in.

13.992 in.

13.738 in.

13.525 in.

13.325 in.

13.200 in.

13.000 in.

12.800 in.

12.600 in.

12.400 in.

12.200 in.

NPS SCH 5S SCH 10S SCH 40S SCH 80S

1-1/2 in.

2 in.

2-1/2 in.

3 in.

3-1/2 in.

4 in.

5 in.

6 in.

8 in.

10 in.

12 in.

14 in.

16 in.

18 in.

20 in.

22 in.

24 in.

(*) represents values currently unavailable

14.758 in.

14.711 in.

14.646 in.

14.584 in.

14.534 in.

14.484 in.

14.357 in.

14.250 in.

14.050 in.

13.818 in.

13.600 in.

13.475 in.

13.268 in.

13.068 in.

12.850 in.

12.650 in.

12.426 in.

14.723 in.

14.675 in.

14.617 in.

14.554 in.

14.504 in.

14.454 in.

14.337 in.

14.230 in.

14.019 in.

13.793 in.

13.581 in.

13.450 in.

13.250 in.

13.050 in.

12.826 in.

12.626 in.

12.400 in.

14.694 in.

14.639 in.

14.550 in.

14.477 in.

14.419 in.

14.360 in.

14.237 in.

14.144 in.

13.880 in.

13.633 in.

13.425 in.

*

*

*

*

*

*

14.650 in.

14.588 in.

14.492 in.

14.410 in.

14.346 in.

14.280 in.

14.144 in.

13.992 in.

13.738 in.

13.525 in.

13.325 in.

*

*

*

*

*

*

19

Page 26

K-factors

Stainless Steel

SCH 5S STAINLESS STEEL PIPE PER ANSI B36.19

K-FACTOR K-FACTOR A-FACTOR A-FACTOR

PIPE PULSES/ PULSES/ U.S.

SIZE U.S. GAL LITER GPM/HZ LPM/HZ

104.200 27.5297 0.5758 2.1795

1 1/2

2 67.160 17.7437 0.8934 3.3815

2 1/2 46.060 12.1691 1.3026 4.9305

3 29.790 7.8705 2.0141 7.6234

3 1/2 22.060 5.8283 2.7199 10.295

4 16.890 4.4624 3.5524 13.446

5 10.6500 2.8137 5.6338 21.324

67.1160 1.8801 8.4317 31.914

83.8700 1.0225 15.504 58.682

10 2.3570 0.6227 25.456 096.35

12 1.6060 0.4243 37.360 141.41

14 1.2980 0.3429 46.225 174.96

16 0.9620 0.2542 62.370 236.07

18 0.7400 0.1955 81.081 306.89

20 0.5900 0.1559 101.695 384.92

22 0.4790 0.1266 125.26 474.11

24 0.3990 0.1054 150.38 569.17

SCH 10S STAINLESS STEEL PIPE PER ANSI B36.19

K-FACTOR K-FACTOR A-FACTOR A-FACTOR

PIPE PULSES/ PULSES/ U.S.

SIZE U.S. GAL LITER GPM/HZ LPM/HZ

113.600 30.0132 0.5282 1.9991

1 1/2

2 72.560 19.1704 0.8269 3.1298

2 1/2 48.750 12.8798 1.2308 4.6585

3 31.250 8.2563 1.9200 7.2672

3 1/2 23.010 6.0793 2.6076 09.870

4 17.540 4.6341 3.4208 12.948

5 10.8700 2.8719 5.5198 20.892

67.2410 1.9131 8.2861 31.363

83.9520 1.0441 15.182 57.465

10 2.3880 0.6309 25.126 095.10

12 1.6200 0.4280 37.037 140.19

14 1.3110 0.3464 45.767 173.23

16 0.9680 0.2557 61.983 234.61

18 0.7440 0.1966 80.645 305.24

20 0.5930 0.1567 101.180 382.97

22 0.4820 0.1273 124.48 471.16

24 0.4020 0.1062 149.25 564.93

SCH 40S STAINLESS STEEL PIPE PER ANSI B36.19

K-FACTOR K-FACTOR A-FACTOR A-FACTOR

PIPE PULSES/ PULSES/ U.S.

SIZE U.S. GAL LITER GPM/HZ LPM/HZ

122.000 32.2325 0.4918 1.8615

1 1/2

2 78.690 20.7900 0.7625 2.8860

2 1/2 55.630 14.6975 1.0786 4.0823

3 35.530 9.3871 1.6887 6.3918

3 1/2 26.070 6.8877 2.3015 08.711

4 19.840 5.2417 3.0242 11.447

5 12.090 3.1942 4.9628 18.784

68.0410 2.1244 7.4618 28.243

84.3500 1.1493 13.793 52.207

10 2.6080 0.6890 23.006 87.078

12 1.7400 0.4597 34.483 130.52

14 ****

16 ****

18 ****

20 ****

22 ****

24 ****

SCH 80S STAINLESS STEEL PIPE PER ANSI B36.19

K-FACTOR K-FACTOR A-FACTOR A-FACTOR

PIPE PULSES/ PULSES/ U.S.

SIZE U.S. GAL LITER GPM/HZ LPM/HZ

136.100 35.9577 0.4409 1.6686

1 1/2

2 88.590 23.4055 0.6773 2.5635

2 1/2 62.810 16.5945 0.9553 3.6157

3 39.990 10.5654 1.5004 5.6789

3 1/2 29.220 7.7199 2.0534 7.7721

4 22.160 5.8547 2.7076 10.248

5 13.420 3.5456 4.4709 16.923

69.0160 2.3820 6.6548 25.189

84.8190 1.2732 12.451 47.126

10 2.7730 0.7326 21.637 81.897

12 1.8240 0.4819 32.895 124.51

14 ****

16 ****

18 ****

20 ****

22 ****

24 ****

Page 27

STD WROUGHT STEEL PIPE PER ANSI B36.10

SCH 40 WROUGHT STEEL PIPE PER ANSI B36.10

K-FACTOR K-FACTOR A-FACTOR A-FACTOR

PIPE PULSES/ PULSES/ U.S.

SIZE U.S. GAL LITER GPM/HZ LPM/HZ

1 1/2 122.000

32.232 0.4918 1.8615

2 78.690 20.790 0.7625 2.8860

2 1/2 55.630 14.697 1.0786 4.0823

3 35.530 9.3871 1.6887 6.3918

3 1/2 26.070 6.8877 2.3015 08.711

4 19.840 5.2417 3.0242 11.447

5 12.090 3.1942 4.9628 18.784

6 8.0410 2.1244 7.4618 28.243

8 4.3500 1.1493 13.793 52.207

10 2.6080 0.6890 23.006 87.078

12 1.7610 0.4653 34.072 128.96

14 1.4250 0.3765 42.105 159.37

16 1.0590 0.2798 56.657 214.45

18 0.8180 0.2161 73.350 277.63

20 0.6460 0.1707 92.879 351.55

22 ****

24 0.4350 0.1149 137.93 522.07

SCH 80 WROUGHT STEEL PIPE PER ANSI B36.10

K-FACTOR K-FACTOR A-FACTOR A-FACTOR

PIPE PULSES/ PULSES/ U.S.

SIZE U.S. GAL LITER GPM/HZ LPM/HZ

1 1/2

136.100 35.9577 0.4409 1.6686

2 88.590 23.4055 0.6773 2.5635

2 1/2 62.810 16.5945 0.9553 3.6157

3 39.990 10.5654 1.5004 5.6789

3 1/2 29.220 7.7199 2.0534 7.7721

4 22.160 5.8547 2.7076 10.248

5 13.420 3.5456 4.4709 16.923

6 9.0160 2.3820 6.6548 25.189

8 4.8190 1.2732 12.451 47.126

10 2.8970 0.7654 20.711 78.391

12 1.9620 0.5184 30.581 115.75

14 1.5890 0.4198 37.760 142.92

16 1.1750 0.3104 51.064 193.28

18 0.9040 0.2388 66.372 251.22

20 0.7160 0.1892 83.799 317.18

22 0.5820 0.1538 103.093 390.21

24 0.4820 0.1273 124.48 471.16

K-FACTOR K-FACTOR A-FACTOR A-FACTOR

PIPE PULSES/ PULSES/ U.S.

SIZE U.S. GAL LITER GPM/HZ LPM/HZ

122.000 32.2325 0.4918 1.8615

1 1/2

2 78.690 20.7900 0.7625 2.8860

2 1/2 55.630 14.6975 1.0786 4.0823

3 35.530 9.3871 1.6887 6.3918

3 1/2 26.070 6.8877 2.3015 08.711

4 19.840 5.2417 3.0242 11.447

5 12.090 3.1942 4.9628 18.784

6 8.0410 2.1244 7.4618 28.243

8 4.3500 1.1493 13.793 52.207

10 2.6080 0.6890 23.006 87.078

12 1.7400 0.4597 34.483 130.52

14 1.3950 0.3686 43.011 162.80

16 1.0220 0.2700 58.708 222.21

18 0.7800 0.2061 76.923 291.15

20 0.6150 0.1625 97.561 369.27

22 0.4970 0.1313 120.72 456.94

24 0.4110 0.1086 145.99 552.55

XS WROUGHT STEEL PIPE PER ANSI B36.10

K-FACTOR K-FACTOR A-FACTOR A-FACTOR

PIPE PULSES/ PULSES/ U.S.

SIZE U.S. GAL LITER GPM/HZ LPM/HZ

136.100 35.9577 0.4409 1.6686

1 1/2

2 88.590 23.4055 0.6773 2.5635

2 1/2 62.810 16.5945 0.9553 3.6157

3 39.990 10.5654 1.5004 5.6789

3 1/2 29.220 7.7199 2.0534 7.7721

4 22.160 5.8547 2.7076 10.248

5 13.420 3.5456 4.4709 16.923

6 9.0160 2.3820 6.6548 25.189

8 4.8190 1.2732 12.451 47.126

10 2.7730 0.7326 21.637 81.897

12 1.8240 0.4819 32.895 124.51

14 1.4550 0.3844 41.237 156.08

16 1.0590 0.2798 56.657 214.45

18 0.8050 0.2127 74.534 282.11

20 0.6320 0.1670 94.937 359.34

22 0.5100 0.1347 117.65 445.29

24 0.4200 0.1110 142.86 540.71

K-factors

Wrought Steel

21

Page 28

K-factors

Plastic Pipe

Schedule 40 Plastic pipe per ASTM-D-1785

K-FACTOR K-FACTOR A-FACTOR A-FACTOR

PIPE PULSES/ PULSES/ U.S.

SIZE U.S. GAL LITER GPM/HZ LPM/HZ

124.400 32.8666 0.4823 1.8256

1 1/2

2 80.140 21.1731 0.7487 2.8338

2 1/2 56.730 14.9881 1.0576 4.0032

3 36.180 9.5588 1.6584 6.2769

3 1/2 26.500 7.0013 2.2642 8.5698

4 20.140 5.3210 2.9791 11.276

5 12.250 3.2365 4.8980 18.539

6 8.1430 2.1514 7.3683 27.889

8 4.3980 1.1620 13.643 51.637

10 2.6340 0.6959 22.779 86.219

12 1.7770 0.4695 33.765 127.80

Schedule 80 Plastic pipe per ASTM-D-1785

K-FACTOR K-FACTOR A-FACTOR A-FACTOR

PIPE PULSES/ PULSES/ U.S.

SIZE U.S. GAL LITER GPM/HZ LPM/HZ

139.400 36.8296 0.4304 1.6291

1 1/2

2 90.790 23.9868 0.6609 2.5014

2 1/2 64.610 17.0700 0.9286 3.5149

3 41.050 10.8454 1.4616 5.5323

3 1/2 29.940 7.9102 2.0040 7.5852

4 22.660 5.9868 2.6478 10.022

5 13.700 3.6196 4.3796 16.577

69.1990 2.4304 6.5224 24.687

84.9060 1.2962 12.230 46.290

10 2.9450 0.7781 20.374 77.114

12 1.9930 0.5266 30.105 113.95

K-factors and A-factors are listed in

U.S. gallons and in liters. Conversion

formulas for other engineering units

are listed below.

K = 60/A

by the FP-6000 series paddlewheel per unit of

liquid in a specific pipe size.

• The A-factor is the flow rate (per minute) repre-

• The K-factor is the number of pulses generated

A = 60/K

sented by 1 Hz output from the FP-6000 series

sensor in a specific pipe size.

To convert K from to multiply K by

U.S. gallons cubic feet 7.479

U.S. gallons cubic inches 0.00433

U.S. gallons cubic meters 263.85

U.S. gallons pounds of water 0.120

U.S. gallons acre feet 325853

U.S. gallons liters 0.264

U.S. gallons Imperial gallons 1.201

To convert K from to multiply K by

liters cubic meters 1000

liters kilograms of water 1

liters gallons 3.785

22

Page 29

General Data

Flow velocity range: 1.6 to 20 ft/s

0.5 to 6 m/s

Linearity: ±1% of full range

Repeatability: ±0.5% of full range

Pipe sizes:

Standard version: 1.5 to 24 in.

(38 to 610 mm)

Hot-Tap version: 1.5 to 36 in.

(38 to 914 mm)

Cable length: 25 ft (7.6 m), can extend

up to 200 ft (61 m)

without amplification

Materials

Sensor material: C36000 free cutting

brass

Specifications

Rotor material: CD4MCu stainless steel

Rotor bearings: Fluoroloy B®

Rotor shaft: 316 stainless steel (opt.)

Tungsten Carbide (std.)

O-ring material: Viton®

Electrical Data

Power requirements: Self powered

Load impedance: 0 to 1000 Ω max.

Ambient Conditions

Maximum

23

Page 30

Specifications

operating pressure: 225 psi (15 bar)

Maximum

operating temperature: 212°F (100 °C)

Caution: The FP-6002 and FP-6003 Series HotTap system's overall specifications and limitations

depend on the lowest maximum rating of the

components associated with the system. For

example, a ball valve, a component of the system,

is rated at a maximum 100 psi @ 185°F, limiting

the entire system's maximum pressure/temperature

rating to 100 psi @ 185°F. All higher maximum

specifications MUST yield to the component with

the lowest maximum specification.

Note: Pressure/temperature specifications refer to

sensor performance in water. Certain chemical

limitations may apply. Chemical compatibility

should be verified before sensor installation.

24

Page 31

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided

by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it

will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY / DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR

WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the

product was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2000 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of

the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

consult OMEGA

Page 32

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

6-2517.090-OM/(D-8/02) M-2973/0802

Loading...

Loading...