Page 1

ARTWORK/PRODUCT ART/ TEMPERATURE/T-FP5100/5300/5800

FP-5100/5300.F-43.ill

THE FL0W SENSOR THAT MAKES SHORT

WORK OF YOUR FLOW MEASUREMENTS

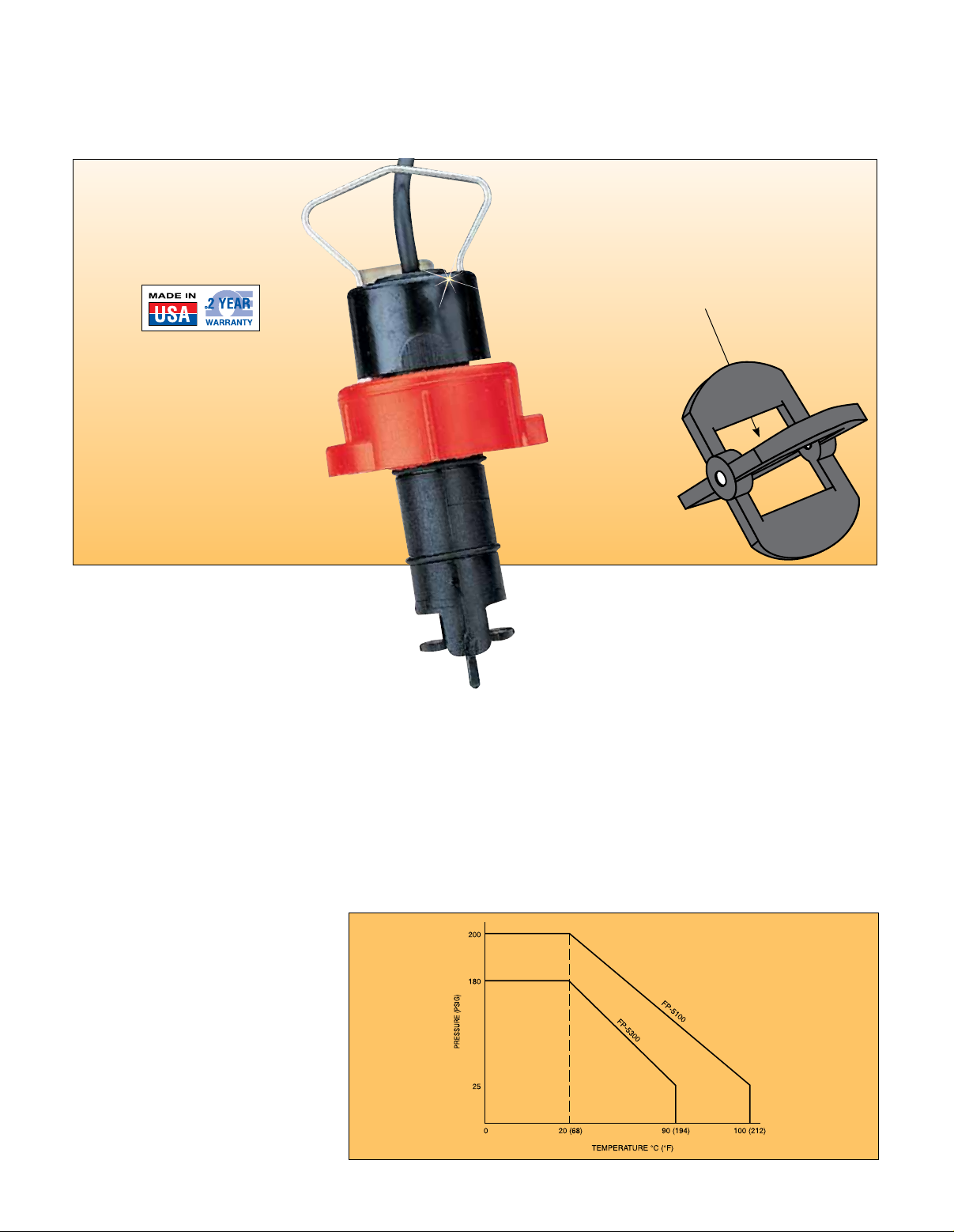

Paddlewheel Flow Sensors

FP-5300 Series

Streamline your flow measurement

operation with the FP-5300 Series

flow sensor. Using this compact

flow sensor, a matched sensor

installation fitting, an OMEGA®

flow meter or controller, and

ordinary handtools, you can

assemble a complete flow

monitoring or controlling system in

minutes. Accurate to ±0.2 fps, with

repeatability at ±0.1 fps, this

insertion sensor operates on a simple

electromechanical principle, proven in

thousands of liquid flow applications

worldwide. It all adds up to precision,

dependability, and convenience–

basic advantages that are quickly

surpassing its in-line competition.

A TIMESAVER YOU

CAN BANK ON

Convert your maintenance hours

into minutes with the FP-5300.

Should a sensor, rotor, or O-ring

need to be replaced, it takes only

seconds. Reduce your system

downtime substantially with a

stand-alone FP-5300 sensor, or

simply add a Wet Tap Assembly

and eliminate downtime completely.

Combined with the FP-5300 during

initial installation, the Wet Tap

allows sensor removal without

system shut-down. Optional local or

remote capability lets you place your

meter up to 200 feet away without

signal amplification, and you can

install the FP-5300 in pipe sizes ranging from 1⁄2 inch to 36 inches without

a lot of additional cost, because the price of the FP-5300 increases only

slightly for larger pipe sizes.

RUGGED CONSTRUCTION FOR LONG WEAR

Available in a choice of chemically resistant, non-contaminating housing

materials, the FP-5300 stands up to the harshest environments. The glassfilled polypropylene housing version is lightweight but strong, which makes

it ideal for handling a wide range of liquids, including corrosive fluids in

chemical processing. For processes involving acids and solvents, the PVDF

(polyvinylidene fluoride) housing version is a tough fluorocarbon that is highly

resistant to more severe fluids. (Visit omega.com/fp5100 for more information

on OMEGA’s all-PVDF flow monitoring systems.)

Patented “flow-through” rotor

design ensures accurate, linear

output to ±1%.

FP-5300

shown

actual size.

F-X

Page 2

Flow Measurement Simple and Accurate

The sensor works on a simple but precise

electromechanical principle based on measuring the

rate and volume of flow in your pipe. Four permanent

magnets, imbedded in the rotor blades, spin past a

coil in the sensor body. As the fluid flow causes the

rotor to move, a sine wave signal is produced, directly

proportional to the flowrate. The patented “open cell”

feature of the rotor ensures a linear, repeatable output,

up to 23 fps, with accuracy of ±0.2 fps. The result is

minimal head loss and no cavitation.

COMMON SPECIFICATIONS

Accuracy: ±1% full scale

Output Signal: 1 V p-p/fps

Output Frequency: 6 Hz/fps nominal

Flow Rate Range: 1 to 20 fps

Source Impedance: 8 KΩ

Maximum Pressure:

FP-5300 Series: 180 psig max @ 20°C (68°F)

FP-5100 Series: 200 psig max @ 20°C (68°F)

Minimum Temperature: 0°C (32°F)

Maximum Temperature: See chart on previous

page for complete temperature and pressure rating

Pressure Drop: Equal to

2.5 m (8') of straight pipe

Material: Transducer Housing: glass-filled

polypropylene; O-Rings: FKM;

Shaft: Titanium (PVDF opt.); Rotor: PVDF

Maximum % Solids: 1% of fluid volume,

non-abrasive, nonmagnetic, <100 micron

diameter and length standard

Cable Length: 7.5 m (25')

Max Viscosity: 1 centipoise (water);

up to 5 cp above 5 fps velocity

See omega.com for

compatible fittings.

F

DPF701

Visit omega.com/dpf700

Paddlewheel Flow Sensors

To Order Visit omega.com/fp5100_5300 for Pricing and Details

Weight Sensor Length Compatible

Model No. Housing Material Shaft Material Pipe Size (inch) g (oz) mm (inch) Meters

FP-5300 Polypro Titanium

1

to 4 341 (12) 89 (3.50)

⁄

2

FP-5301 Polypro Titanium 5 to 8 341 (12) 127 (5.00)

FP-5302 Polypro Titanium 10 or larger 454 (16) 197 (7.75)

FP-5100 PVDF Hastelloy C

1

to 4 341 (12) 89 (3.50)

⁄

2

FP-5101 PVDF Hastelloy C 5 to 8 341 (12) 127 (5.00)

† See omega.com for the complete selection of compatible meters available from OMEGA.

DPF701,

DPF402,

DPF70W/

FLSC-AMP,

FPM-5500,

FPM-5740

FP90

FPM-9020A

Wet Tap Assembly* (Details Available at omega.com/fp319)

Wet Tap

Valve Sensor Sensor

Assembly Housing Shaft Pipe Size Weight Length Wet Tap Max Operating

Model No. Material Material Material (inch) kg (lb) mm (inch) Temperature/Pressure

1

FP-3193 PVC Polypro Titanium

FP-3194 PVC Polypro Titanium 5 to 8 2.4 (5.25) 330 (13.00)

FP-3195 PVC Polypro Titanium 10 and up 2.4 (5.25) 406 (16.00)

Pipe installation fitting not included. See omega.com for required fittings.

*

Comes complete with operators manual.

Ordering Examples: FP-5300, paddlewheel sensor, plus FP-5310M, 1" PVC fitting (see omega.com).

FP-5301 sensor, plus FP-5350GI, 5" Galvanized Iron saddle fitting (see omega.com).

to 4 2.4 (5.25) 298 (11.75)

⁄

2

100 psig @ 20°C (68°F);

60°C (140°F) @ 25 psig

†

F-X

Page 3

PRESSURE/TEMPERATURE CHARTS

For FP-5100, FP-5200, FP-5300 and FP-8500 Series

Sensors and Associated Fittings

NOTE: All pressure/temperature ratings listed are for water under non-shock conditions with no pressure cycling.

Various chemicals and cycling pressures up and down can weaken plastics. Fittings must be installed so that the

fitting does not carry the weight of the piping and does not suffer from thermal expansion stresses. Water hammer,

fluid surges, and cavitation must always be avoided. If the end user elects to thread the plastic fittings with socket

ends, the pressure rating will be substantially decreased.

FP-5100, FP-5300 and FP-8500 Series Sensors

Pressure/Temperature Ratings

PVC and CPVC Tees and Saddles

225

200

175

150

125

(psi)

100

75

50

25

0

-18 -4 10 24 38 52 66 79 93 107

°C

0255075 100 125 150 175 200 225

°F

CPVC 0.5 TO 1.5"

PVC 2 TO 8"

0.5 TO 1.5 PVC

WARNING: THE ABOVE PRESSURE/TEMPERATURE CURVES ARE SPECIFICALLY FOR THE FP-5100.

FP-5300, AND FP-8500 SENSORS. DURING SYSTEM DESIGN, THE SPECIFICATIONS OF ALL

COMPONENTS MUST BE CONSIDERED. IN A METAL PIPING SYSTEM, A PLASTIC SENSOR WILL

REDUCE THE SYSTEM SPEC. ON THE OTHER HAND, IF USING A PVDF SENSOR IN A PVC PIPING

SYSTEM, THE FITTING WILL REDUCE THE SYSTEM SPEC.

Metal Weld-On and Saddle FittingsMetal Tees

225

200

175

BRONZE TEES

150

125

(psi)

100

75

50

25

0

0

°F

°C

25-4501075241003812552150661757920093225

-18

METAL TEES 0.5

TO 2"

107

225

200

175

150

125

(psi)

100

75

50

25

0

0

°F

°C

25-4501075241003812552150661757920093225

-18

METAL WELD-ON 2.5 T

IRON SADDLES 10"-UP

METAL WELD-ON AND

O 8"

IRON SADDLES

2 TO 8"

107

These ratings are for PVC and PVDF fittings. For all metal

fittings 10" and larger, a PVC insert is used; for 8" and below, a

PVDF insert is used. Use the appropriate curve to determine the

maximum pressure rating of these fittings.

F-X

Loading...

Loading...