Page 1

User’s Guide

Shop online at

www.omega.com

e-mail: info@omega.com

FP-5200

Flow Sensor

Page 2

OMEGAnet® Online Service Internet e-mail

www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

®

®

®

Mexico: En Español: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: Rudé armády 1868, 733 01 Karviná 8

TEL: +420 (0)69 6311899 FAX: +420 (0)69 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

TEL: +33 (0)130 621 400 FAX: +33 (0)130 699 120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7059 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: germany@omega.com

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

page 2 OMEGA FP-5200 Flow Sensor Instructions

Page 3

OMEGA FP-5200 Flow Sensor Instructions

45°

45°

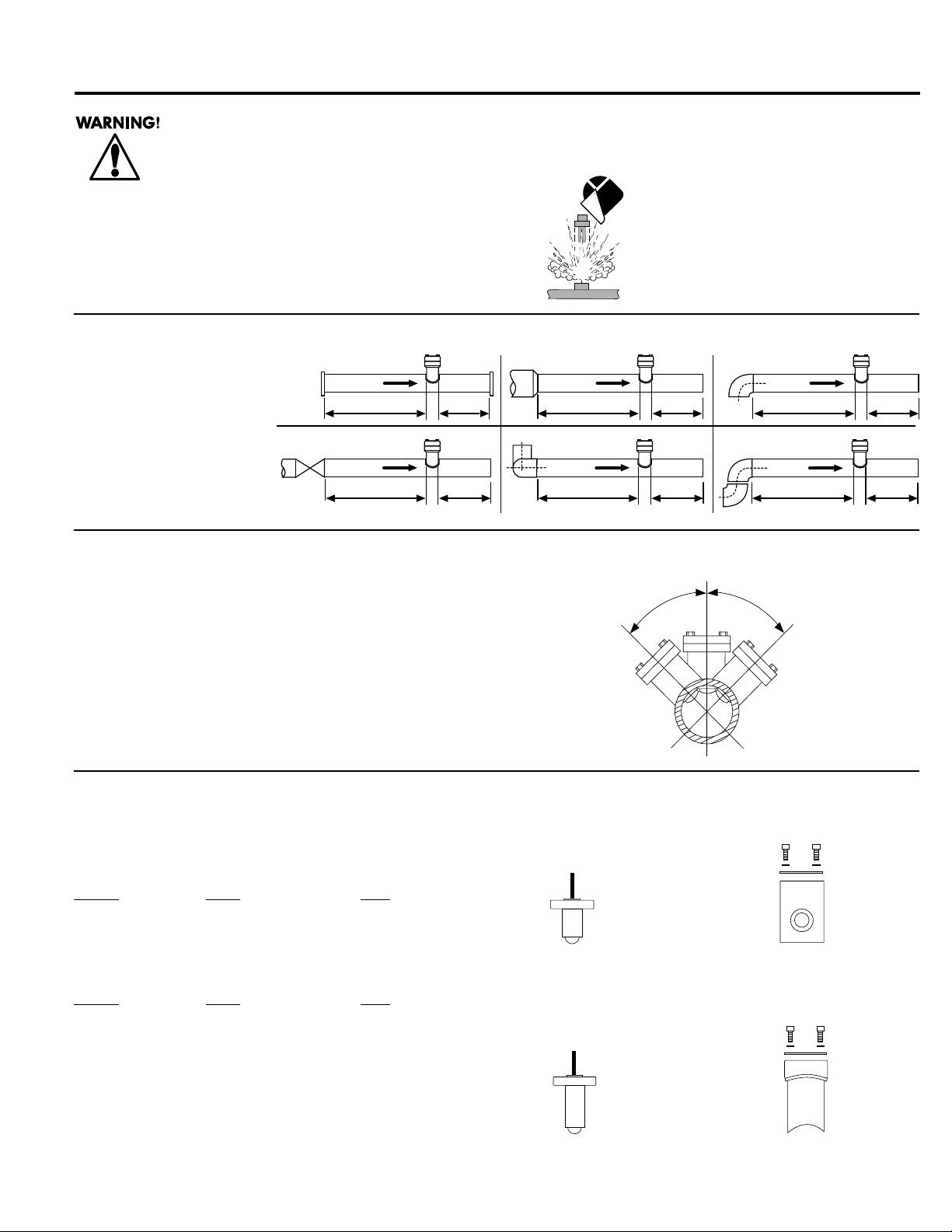

Important Safety Information!

• Never remove a sensor from a pressurized pipe. Always wear

protective clothing during sensor installation/service.

Maximum Operating Pressure/Temperature:

• Pipe fitting MUST be installed by a certified welder only. Signet

will not assume liability of any kind for improper fitting installations.

• Serious bodily injury and/or product failure can result if the

conditions in this manual are exceeded. DO NOT exceed

specifications under any circumstances.

1. Location of Fitting

Inlet Outlet

Recommended sensor

upstream/downstream

mounting requirements.

Flange

10 X I.D. 5 X I.D.

Valve/Gate

50 X I.D. 5 X I.D.

2. Sensor Mounting Position

• Horizontal pipe runs: Mount sensor in the upright (0°) position for best

overall performance. Mount at a maximum of 45° when air bubbles are

present. Do not mount on the bottom of pipe when sediments are present.

Reducer

15 X I.D. 5 X I.D.

2 x 90° Elbow

3 dimensions

40 X I.D. 5 X I.D.

FP-5200 Series Sensor with:

• FP-5200 Series Saddle Fittings:

21 bar (300 psi) @ 66 °C (150 °F)

• FP-5200 Series Tee & Mini-Tap Fittings:

103 bar (1500 psi) @ 149 °C (300 °F)

90° Elbow

20 X I.D. 5 X I.D.

2 x 90° Elbow

25 X I.D. 5 X I.D.

• Vertical pipe runs: Sensor must be mounted in lines with UPWARD flow only.

3. Sensor/Fitting Selection

The FP-5200 Sensor is designed for installation into SCH 40 stainless steel

pipes via FP-5200 Series Tee, Mini-Tap or Saddle fittings, see options below:

FP-5200 Series Tee Fittings

Pipe (in.) Sensor Fitting

0.50 FP-5200 FP-5205

0.75 FP-5200 FP-5207

1.00 FP-5200 FP-5210

FP-5200 Series Mini-Tap Fittings

Pipe (in.) Sensor Fitting

1.25 FP-5201 FP-5212

1.50 FP-5201 FP-5215

2.00 FP-5201 FP5220

2.50 FP-5201 FP-5225

3.00 FP-5201 FP-5230

4.00 FP-5201 FP-5240

5.00 FP-5201 FP-5250

6.00 FP-5201 FP-5260

8.00 FP-5201 FP-5280

10.0 FP-5201 FP-5281

12.0 FP-5201 FP-5282

Sensor

Sensor

Wetted fitting materials:

316 SS

Tee Fitting,

hardware included

Wetted fitting materials:

316 SS & 347 SS

Mini-Tap Fitting,

hardware included

page 3OMEGA FP-5200 Flow Sensor Instructions

Page 4

FP-5200 Series Saddle Fittings

Pipe (in.) Sensor Fitting

2.00 FP-5202 FP-5220S

2.50 FP-5202 FP-5225S

3.00 FP-5202 FP-5230S

4.00 FP-5202 FP-5240S

5.00 FP-5202 FP-5250S

6.00 FP-5202 FP-5260S

8.00 FP-5202 FP-5280S

10.0 FP-5202 FP-5281S

12.0 FP-5202 FP-5282S

4. Fitting Installation, Required Hardware

Tee & Mini-Tap Fittings

• 0.5 to 1 inch pipes, FP-5200 Series fitting required

• 1.25 to 12 inch pipes: FP-5200 Series fitting and 27 mm (1-1/16 in.)

diameter drill required

• Mini-Tap fittings are welded onto the pipe and are used with FP-5200

sensors.

Wetted fitting materials:

Ductile Iron, 347 SS,

Carbon steel,

Buna-N/Neoprene

Sensor

FP-5200 Series Saddle Fitting

• 27 mm (1-1/16 in.) diameter drill required

Saddle type fittings are strapped to the pipe and are used with FP-5202

sensors. Welds MUST be made by a certified welder who is licensed to weld

stainless steel and other high-carbon grade steels.

Saddle Fitting,

hardware included

4.1 Installation, Tee & Mini-Tap Fittings

1. Select an appropriate mounting location as outlined in sections 1 and 2.

2. Depressurize and drain pipe.

3. Use the following welding and installation procedures appropriate for your

fitting/pipe size:

FP-5200 Series Tee Fittings, 0.5 to 1 inch:

• Insert pipe into fitting socket

• Make sure the pipe is parallel to the bottom of the Mini-Tap fitting.

• Weld pipe into place

FP-5200 Series Mini-Tap Fittings, 1.25 to 12 inch:

• Drill a 27 mm (1-1/16 in.) diameter hole completely through the ONE

surface of the pipe. Thoroughly deburr inner and outer edges of hole.

• Tack weld the Mini-Tap fitting onto the pipe, making sure the hole in the pipe

is lined up with the Mini-Tap fitting hole.

• Weld the Mini-Tap fitting onto the pipe.

5. Sensor Installation

1. Set the gasket supplied with the fitting onto the fitting flange, making

sure the holes align.

2. Remove the red rotor protection cap and insert the sensor into the fitting,

making sure not to bump the rotor assembly. Make sure the arrow on the

side of the sensor is pointing in the direction of flow.

Fitting

flange

Flow

Flow sensor

arrow

4.2 Installation, Saddle Fittings

1. Select an appropriate mounting location as outlined in sections 1 and 2.

2. Drill a 27 mm (1-1/16 in.) diameter hole completely through the TOP

surface of the pipe. Thoroughly deburr inner and outer edges of hole.

3. Place the Buna-N/Neoprene saddle O-ring over

the pipe hole (small hole side towards pipe). Position

the saddle fitting over the O-ring, making sure the

O-ring centers on the underside fitting ridge. Center

saddle fitting and O-ring over the pipe hole, then

strap the fitting to the pipe with the two U-bolts. Snug

all four nuts in a criss-cross pattern. Using a torque

wrench (when possible) torque the U-bolts in a

criss-cross pattern to 52 foot-pounds.

14

U-bolt

torque

pattern

6. Sensor Wiring

1/2 in. NPT

conduit port

Blk

F-

Red

(AC signal out)

black

red

(AC signal out)

F+

Shld

23

silver

3. Slip two washers onto each bolt and insert the bolt/washer onto each

of the four fitting flange holes.

4. Snug all four flange bolts in a criss-cross pattern. Using a torque

wrench (when possible), torque the flange nuts in a criss-cross pattern to

52 foot-pounds.

FP-5200 Series

• Use 2-conductor shielded cable for cable splices to 60 m (200 ft).

(ground) Instruments

• Maintain cable shield through splice.

14

Flange

bolt torque

pattern

23

page 4 OMEGA FP-5200 Flow Sensor Instructions

• Shield the unjacketed silver (ground) wire using electrical tape to

prevent potential noise interference and/or shorting hazards.

• FPM-9010A, use 525 input card setting.

Page 5

7. Sensor Removal Procedure

1. Depressurize and drain pipe.

2. Remove the four sensor flange bolts and lockwashers. Pull upward

on the sensor flange with an alternating twisting motion.

WARNING!

Never remove a sensor from a pressurized pipeline. Always

wear protective clothing during sensor installation/service.

9. Accessories

Refer to section 3 for a list of available sensors and fittings.

Part no. Description

M2489 Instruction manual

FP-52648 Fitting cap kit, cap and gasket

FP-52504-1 Rotor pin, 316 SS (optional)

FP-52504-2 Rotor pin, Tungsten Carbide (standard)

FP-52509 Rotor kit, 316 SS pin

FP-52509-2 Rotor kit, Tungsten pin

10. Rotor Replacement Procedure

1. With a small pair of needle-nose

pliers, firmly grip the center of the rotor

pin (axle) and with a twisting motion,

bend the rotor pin into an "S" shape.

This should pull the ends of the pin out of

the retainers and free the rotor assembly.

Rotor Pin

8. Maintenance

The FP-5200 Series Sensor requires little or no maintenance of any kind, with

the exception of an occasional sensor/paddlewheel cleaning.

FP-52509/FP-52509-2 Rotor kit

retainer retainer

bearing

3. Insert the new rotor assembly and

bearings into the rotor housing of the

sensor and place the new rotor pin

(axle) through the open end of the rotor

housing, through the rotor and bearings,

and into the previously installed retainer.

rotor pin

rotor

Existing

Retainer

bearing

Rotor Pin

Rotor

Assembly

New

Bearings

2. Remove retainer from each side by

gently tapping it inwards using a punch.

Install a new retainer with its rotor pin

clearance hole inward. Only install one

retainer at this time.

Retainer

11. K-factors

The K-factor is the number of pulses the sensor will generate for each

engineering unit of fluid which passes. They are listed in U.S. gallons and in

liters. For example, in a 1 inch SCH 40S stainless steel pipe, the sensor

generates 266.17 pulses per gallon of fluid passing the rotor. K-factors are

listed for SCH 40S stainless steel pipes up to 12 inch.

Conversion Formulas

1 U.S. gallon = 0.003785 cubic meters

0.000003069 Acre feet

8.3454 pounds of water

Punch

4. Tap the second retainer (rotor pin

cleareance hole inwards) into the

hole while lining up the rotor pin

with the center of the retainer hole.

Thiscompletes the rotor replacement

procedure.

SCH 40S STAINLESS STEEL PIPE PER ANSI B36.19

K-FACTOR K-FACTOR A-FACTOR A-FACTOR

PIPE PULSES/ PULSES/ U.S.

SIZE U.S. GAL LITER GPM/HZ LPM/HZ

1/2 IN. 873.03 230.66 0.0687 0.2601

3/4 IN. 515.41 136.17 0.1164 0.4406

1 IN. 266.17 70.322 0.2254 0.8532

1 1/4 IN. 148.84 39.324 0.4031 1.5258

1 1/2 IN. 107.98 28.528 0.5557 2.1032

2 IN. 64.808 17.122 0.9258 3.5042

2 1/2 IN. 44.685 11.806 1.3427 5.0822

3 IN. 28.579 7.5506 2.0994 7.9464

4 IN. 16.302 4.3070 3.6805 13.931

5 IN. 10.237 2.7046 5.8611 22.184

6 IN. 7.0057 1.8509 8.5645 32.416

8 IN. 3.9641 1.0473 15.136 57.289

10 IN. 2.4690 0.6523 24.301 91.981

12 IN. 1.6894 0.4463 35.516 134.43

page 5OMEGA FP-5200 Flow Sensor Instructions

Page 6

12. Specifications

General Data

Flow velocity range: 0.5 to 6 m/s (1.6 to 20 ft/s)

Frequency output: 29 to 46 Hz per m/s (9 to 14 Hz per ft/s)

Linearity: ±1% of full range

Repeatability: ±0.5% of full range

Pipe size range: 13 to 305 mm (0.5 to 12 in.)

Cable length: 7.6 m (25 ft), can splice up to 60 m (200 ft.) with no

significant degradation of signal strength

Cable type: 150 °C 22 AWG, 2-conductor w/shield

Materials

Sensor body: ACI type CF-8M (316 cast stainless steel) per

ASTM A351

Rotor material: CD4MCu stainless steel

Rotor pin: Tungsten Carbide (316 stainless steel, optional)

Retainers (2): 316 stainless steel

Rotor bearings (2): Fluoroloy B®

Electrical Data

Voltage output: Approximate sine wave, 0.005 to 0.008 Vp-p per

Hertz

Coil resistance: 11.6 kΩ @ 25 °C

Coil inductance: 3.5 Henrys @ 25 °C

Required input module: P52577 (included)

Quality Standards

• CE

• Manufactured under ISO 9001

Ambient Conditions

Maximum Pressure/Temperature Limitations:

FP-5200 Series Sensor with:

• FP-5200 Series Saddle Fitting: 21 bar (300 psi) max. @

66 °C (150 °F)

FP-5200 Series Sensor with:

• FP-5200 Series Tee or Mini-Tap Fitting: 103 bar (1500 psi) max. @

149 °C (300 °F)

page 6 OMEGA FP-5200 Flow Sensor Instructions

Page 7

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided

by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it

will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY / DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR

WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the

product was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2000 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of

the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

page 7OMEGA FP-5200 Flow Sensor Instructions

Page 8

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

P52590-OM/(G-08/02) M-2489/0802

Loading...

Loading...