Page 1

omega.com

User’s Guide

T

Shop online at

TM

omega.com

®

www.omega.com

e-mail: info@omega.com

ISO 9001

CERTIFIED

CORPORATE QUALITY

STAMFORD, C

ISO 9002

CERTIFIED

CORPORATE QUALITY

MANCHESTER, UK

FP-2540/FP-3-1500 Series

Flow Sensors

Page 2

omega.com

TM

omega.com

®

OMEGAnet® Online Service Internet e-mail

www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certifi ed Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

®

®

®

Mexico: En Español: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Rudé arm

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certifi ed Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-48

e-mail: sales@omega.co.uk

.

dy 1868, 733 01 Karvin. 8

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is

constantly pursuing certifi cation of its products to the European New Approach Directives. OMEGA will add the CE

mark to every appropriate device upon certifi cation.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifi cations without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

Omega FP-2540/FP-3-1500 Series

SAFETY INSTRUCTIONS

1. Do not remove from pressurized lines.

2. Do not exceed maximum temperature/pressure specifi cations.

3. Wear safety goggles or faceshield during installation/service.

4. Do not alter product construction.

5. Apply sealant or PTFE tape to sensor threads, inspecting threads to ensure integrity.

Do not install a sensor with damaged threads.

Pipe fi ttings MUST be installed by a certifi ed welder only. Omega will not assume liability of any kind for improper fi tting

installations.

Omega FP-3-1500 Series Hot-Tap sensor specifi cations and limitations depend on the lowest maximum rating of the

components associated with the system. If a ball valve, a component of the system, is rated at a maximum 100 psi @ 175°F,

the entire system's maximum pressure/temperature rating is limited to 100 psi @ 175°F. All higher maximum specifi cations

MUST yield to the component with the lowest maximum specifi cation.

Maximum Operating Pressure/Temperature:

• 17 bar (250 psi) @ 82°C (180°F) with standard FPM sensor fi tting O-rings.

• 17 bar (250 psi) @ 100°C ( 212°F) with optional EPR sensor fi tting O-rings.

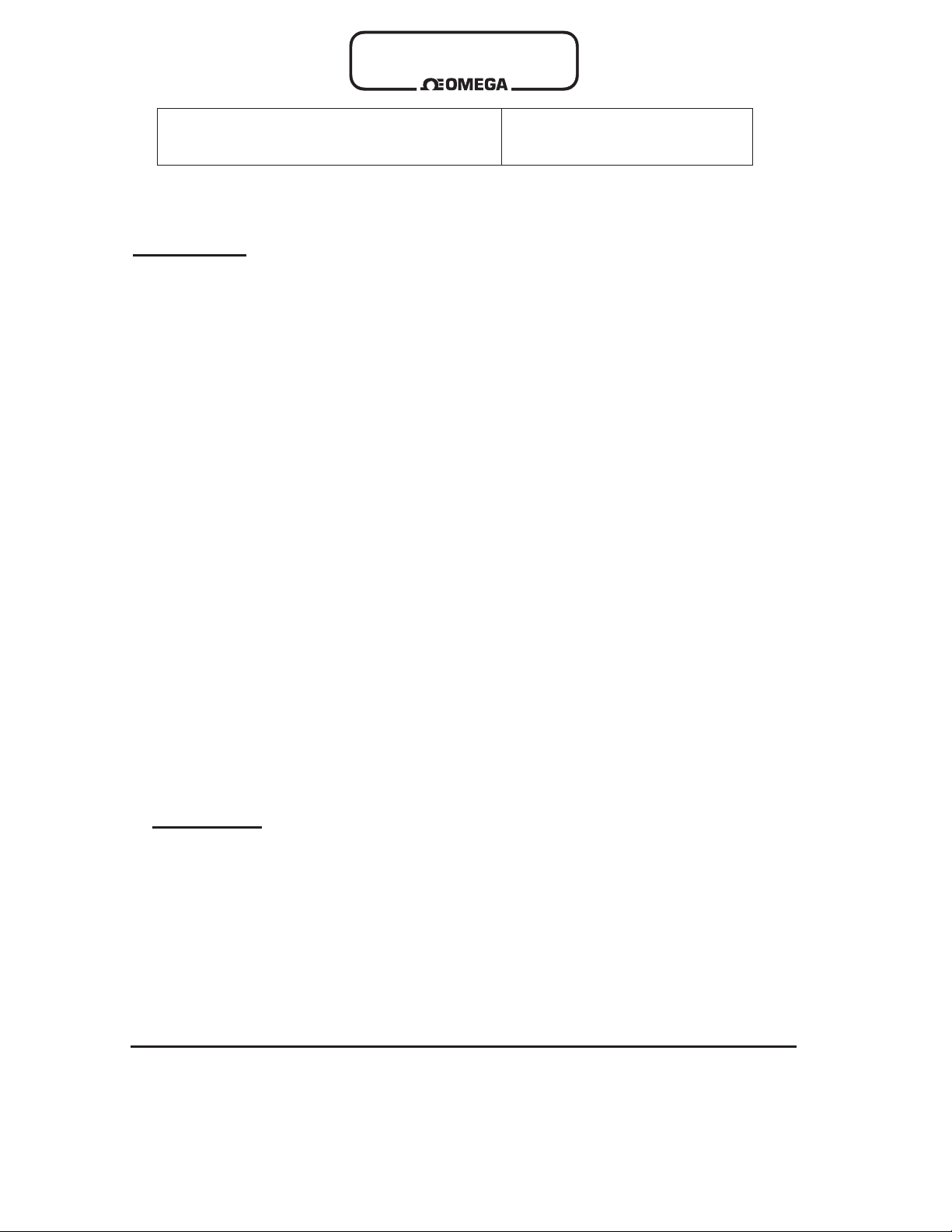

Inlet

1. Location of Fitting

Recommended sensor upstream/

downstream

mounting requirements.

Flange

10x I.D. 5x I.D.

Outlet

Reducer

15x I.D. 5x I.D.

2 x 90° Elbow

3 dimensions

Valve/Pump

50x I.D. 5x I.D.

40x I.D. 5x I.D.

2. Sensor Mounting Position

Vertical mounting is recommended for best overall performance. Mount at a maximum of 30°

when air bubbles are present. DO NOT mount on the bottom of the pipe when sediments are

present.

3. Sensor Wiring

Omega FPM Series Instruments

Other Brands

90° Elbow

20x I.D. 5x I.D.

2 x90° Elbow

25x I.D. 5x I.D.

0°

-

30°

Process Pipe

+30°

1/2 in. NPT conduit port

Black (5 to 24 VDC)

Blk, sensor

power

Red, freq.

input

Shld,

Gnd

Red (signal out)

Silver (DC return)

Use 2-conductor shielded cable for cable extensions up to 300m (1000 ft.)

Maintain cable shield through splice.

instrument

black

silver

red

pull-up resistor required (10 kΩ recommended).

Use 2-conductor shielded cable for cable extensions up to 300m (1000 ft.)

Maintain cable shield through splice.

10 kΩ

+

-

Gnd.

Input

5 to 24

VDC

Other

instrument

1

Page 4

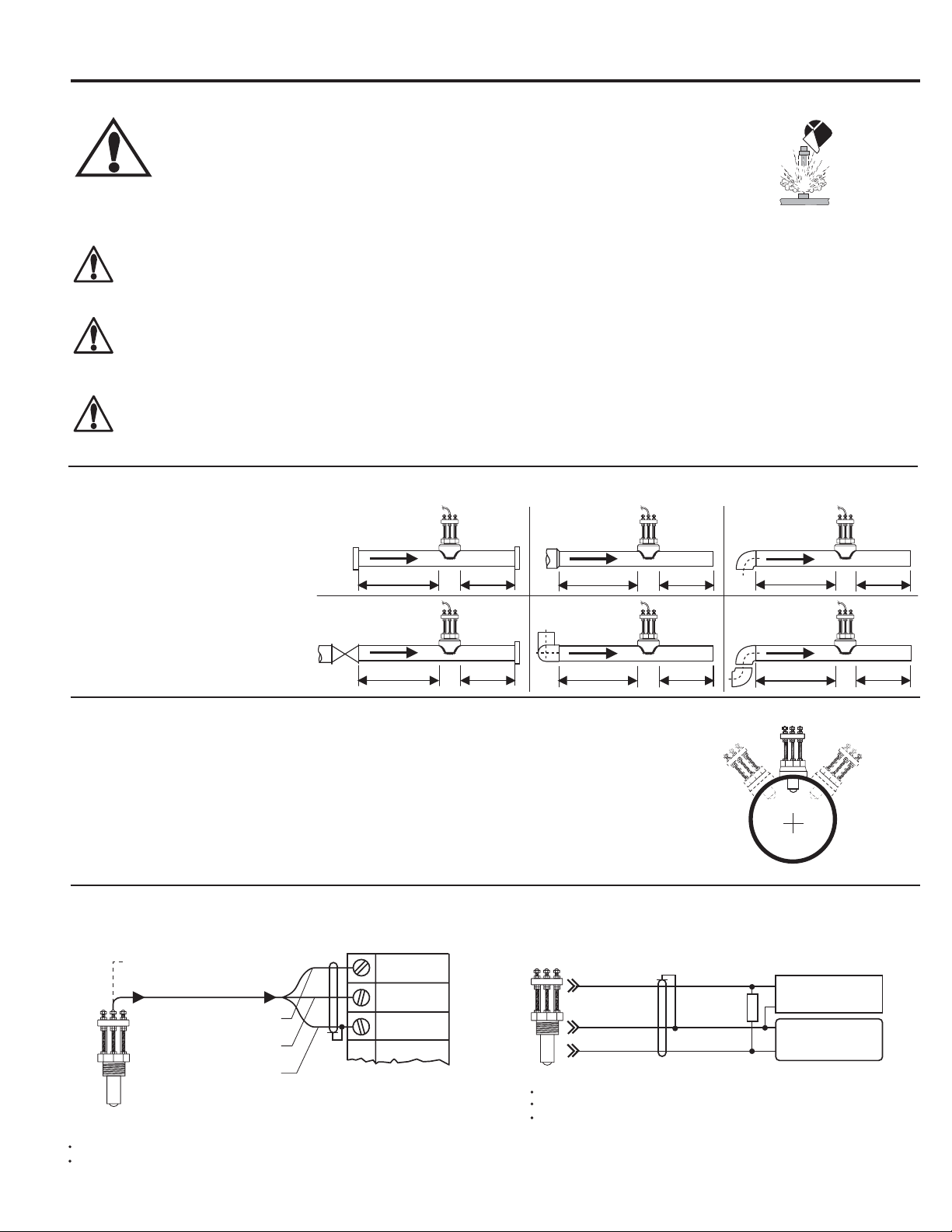

4. Electronics Module Installation and Removal

The electronics module of this sensor can be replaced without removing the steel sensor body from the line.

1. Loosen liquid tight connector cap.

2. Loosen liquid tight connector compression fi tting from sensor body.

3. Grasp the electronics at the rubber strain relief (do not pull on cable) and pull fi rmly.

To reinstall the electronics module:

• Insert module into sensor housing, making sure module is fully seated. Electronic pick-up module tip must bottom-out in the sensor

housing.

• Replace the liquid tight connector assembly.

To install the cable inside protective conduit, remove the liquid tight connector completely. Thread 1/2 in. conduit into top of sensor body.

Liquid Tight Connector-

Liquid Tight Connector-Cap

Compression Fitting

w/ 1/2 in. NPT threads

Grip the electronics

module at rubber

strain relief

1/2 in. NPT Threads

Electronics Module

FP-2540-EM (for Standard sensor)

FP-3-1500-EM (for Hot-tap sensor)

2

Page 5

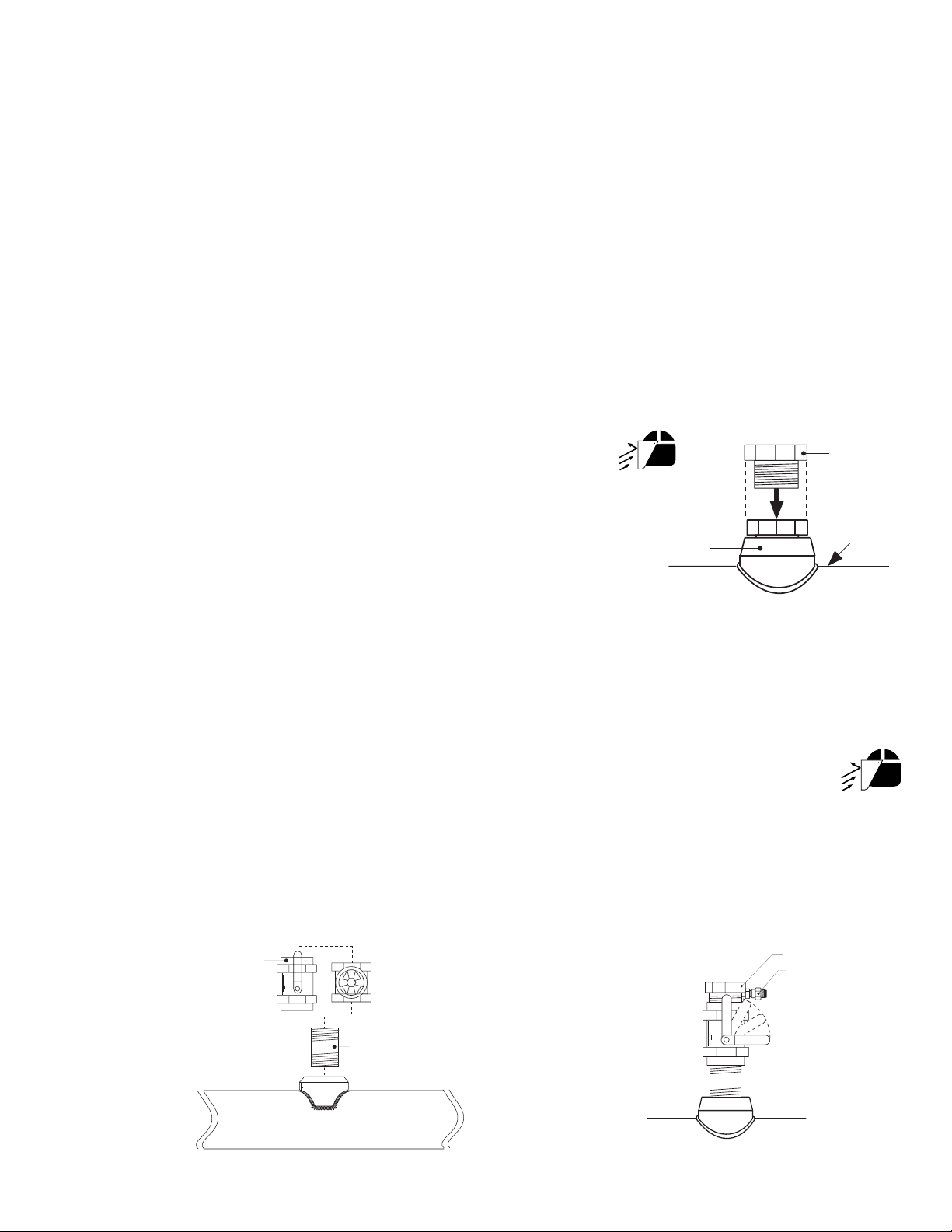

5. Installation

The following items are required to properly install Omega FP-2540/FP-3-1500 series Sensors.

5.1 Hardware, Standard Sensor

• Female pipe fi tting (weld-on or saddle) with 1.5 in. NPT or ISO 7/1-Rc 1.5 threads

• 32 mm (1.25 in.) diameter drill

• Pipe thread sealant

• Tape measure

5.2 Hardware, Hot-Tap Sensor

The Hot-Tap sensor requires all the standard sensor items plus:

• Hot-Tap drilling machine (e.g., Mueller drilling machine or equivalent)

• Female ball or gate valve (full port only) with 1.5 in. NPT or ISO 7/1-Rc 1.5 threads

• Male pipe nipple, 32 x 50 mm (1.5 x 2 in.) with 1.5 in. NPT or ISO 7/1-R 1.5 threads

• Hot-Tap installation tool (purchased separately)

5.3 Standard Fitting Installation

A. Depressurize and drain pipe.

B. Wearing safety face protection, drill a 32 mm (1.25 in.) diameter hole in the

pipe.

C. Install the pipe fi tting of the outside of the pipe according to the manufacturer's

instructions. Failure to follow these instructions may result in serious bodily

injury and/or product failure.

pipe

sensor

fitting

process

pipe

fitting

D. Remove sensor fi tting from sensor assembly.

E. Thread sensor fi tting into pipe fi tting. (Fig. 1)

5.4 Hot-Tap Fitting Installation

A. Install the pipe fi tting on the outside diameter of the pipe according to the manufacturer's instructions. Failure to follow these

instructions may result in serious bodily injury and/or product failure.

B. Install the pipe nipple and isolation valve (ball or gate valve) onto the external pipe fi tting using pipe sealant on the

threads. (Fig. 2)

C. Wearing safety face protection, install an appropriate hole cutting tool per manufacturer's instructions (e.g., Mueller

drilling machine) with a 32 mm (1.25 in.) drill onto the top of the isolation valve, ensuring a tight fi t. Use the

recommended drill bit size or damage to the isolation valve may occur.

D. Open the isolation valve and insert the drill through the valve and cut the sensor clearance hole. After the hole is cut, withdraw the

drill from the isolation valve and close the valve. Remove the drilling machine per manufacturer's instructions. (Fig. 3)

pipe sealant recommended

Fig. 1

E. Install the sensor fi tting/bleed valve into the top of the isolation valve. Make sure the bleed valve clears the handle of the isolation

valve during operation.

sensor fitting

bleed valve

make sure

bleed valve

clears isolation

valve handle

Fig. 2

customer supplied

ball or gate valve

customer supplied

nipple: 32 x 50 mm

(1.25 x 2 in.) long

process pipe (side view)

Fig. 3

process pipe

3

Page 6

5.5 Calculating the H Dimension

Before installing the sensor some critical dimensions must be

established. The rotor shaft must be located 10% inside the pipe

I.D. to ensure accurate calibration capability. To accomplish this,

the "H" dimension is measured from the outside surface of the

pipe to the bottom of the sensor fl ange.

"H" dimensions for standard pipes are listed below.

For non-standard pipe dimensions, calculate the "H" dimension

using the formula below, based on the pipe's wall thickness and

inside diameter (id).

correct

wall

thickness

5

4

3

2

1

A

6

5

4

3

2

1

B

incorrect

6

5

5

4

4

3

3

2

2

1

1

A

B

6

5

5

4

4

3

3

2

2

1

1

A

B

pipe I.D.

H dimension formula

Calculate for a: Standard sensor Hot-tap sensor

Start with: 5.23 in. 15.39 in.

Subtract: wall thickness wall thickness

now subtract 10% of id 10% of id

The fi nal result: H H

Standard Sensors (2541, 2542)

Wrought Steel Pipe Per ANSI 36.10

NPS SCH 40 SCH 80 STD XS

inches inches inches inches inches

1½ 4.924 4.880 4.924 4.880

2 4.869 4.818 4.869 4.818

2½ 4.780 4.722 4.780 4.722

3 4.707 4.640 4.707 4.640

3½ 4.649 4.576 4.649 4.576

4 4.590 4.510 4.590 4.510

5 4.467 4.374 4.467 4.374

6 4.344 4.222 4.344 4.222

8 4.110 3.968 4.110 3.968

10 3.863 3.680 3.863 3.755

12 3.630 3.405 3.655 3.555

14 3.480 3.230 3.530 3.430

16 3.230 2.955 3.330 3.230

18 2.980 2.680 3.130 3.030

20 2.755 2.405 2.930 2.830

22 ----- 2.130 2.730 2.630

24 2.280 1.855 2.530 2.430

Use the 6 inch ruler to measure the pipe id and wall thickness up

to 5 inches (standard sensors only). for Hot-Tap installations, we

assume the pipe dimensions are known)

Pipe wall thickness: __________ Pipe id: ___________

Standard Sensors (2541, 2542)

Stainless Steel Pipe Per ANSI B36.19

NPS SCH 5S SCH10S SCH40S SCH 80S

inches inches inches inches inches

1½ 4.988 4.953 4.924 4.880

2 4.940 4.905 4.869 4.818

2½ 4.876 4.847 4.780 4.722

3 4.814 4.784 4.707 4.640

3½ 4.764 4.734 4.649 4.576

4 4.714 4.684 4.590 4.510

5 4.586 4.567 4.467 4.374

6 4.480 4.460 4.344 4.222

8 4.280 4.249 4.110 3.968

10 4.048 4.023 3.863 3.755

12 3.830 3.811 3.655 3.555

14 3.705 3.680 ----- ----16 3.498 3.480 ----- ----18 3.298 3.280 ----- ----20 3.080 3.056 ----- ----22 2.880 2.856 ----- ----24 2.656 2.630 ----- -----

Hot-Tap Sensors (FP-3-1500-2B, FP-3-1500-2M)

Wrought Steel Pipe Per ANSI 36.10

NPS SCH 40 SCH 80 STD XS

inches inches inches inches inches

1½ 15.084 15.040 15.084 15.040

2 15.029 14.978 15.029 14.978

2½ 14.940 14.882 14.940 14.882

3 14.867 14.800 14.867 14.800

3½ 14.809 14.736 14.809 14.736

4 14.750 14.670 14.750 14.670

5 14.627 14.534 14.627 14.534

6 14.534 14.382 14.534 14.382

8 14.270 14.128 14.270 14.128

10 14.023 13.840 14.023 13.915

12 13.790 13.565 13.815 13.715

14 13.640 13.390 13.690 13.590

16 13.390 13.115 13.490 13.390

18 13.140 12.840 13.290 13.190

20 12.915 12.565 13.090 12.990

22 ----- 12.290 12.890 12.790

24 12.440 12.015 12.690 12.590

4

Hot-Tap Sensors (FP-3-1500-2B, FP-3-1500-2M)

Stainless Steel Pipe Per ANSI B36.19

NPS SCH 5S SCH 10S SCH 40S SCH 80S

inches inches inches inches inches

1 ½ 15.148 15.113 15.084 15.040

2 15.101 15.065 15.029 14.978

2 ½ 15.036 15.007 14.940 14.882

3 14.974 14.944 14.867 14.800

3 ½ 14.924 14.894 14.809 14.736

4 14.874 14.844 14.750 14.670

5 14.747 14.727 14.627 14.534

6 14.640 14.620 14.534 14.382

8 14.440 14.409 14.270 14.128

10 14.208 14.183 14.023 13.915

12 13.990 13.971 13.815 13.715

14 13.865 13.840 ----- ----16 13.658 13.640 ----- ----18 13.458 13.440 ----- ----20 13.240 13.216 ----- ----22 13.040 13.016 ----- ----24 12.816 12.790 ----- -----

(-----) unavailable

Page 7

5.6 Standard Sensor Installation

A. Thread one hex nut onto each of the three threaded rods

included in package. Install threaded rod with a lock washer

onto the sensor fi tting. Secure rods in place by tightening each

hex nut against the sensor fi tting. (Fig. 4)

Fig. 4

hex nut

Lock washer

B. Thread one jam nut and lower hex nut onto each threaded

rod so that the top surface of each nut is at the proper "H"

dimension for your pipe. Secure each hex nut with a jam nut.

(Fig. 5)

sensor fitting

C. Insert the fl ow sensor into the sensor fi tting, making sure the

alignment hole on the sensor fl ange is pointing downstream.

D. Place the alignment rod in the alignment hole

on the sensor fl ange. Align the fl ange so rod is

parallel to the process pipe. (Fig. 6)

E. Thread upper hex nuts with lock washers until they

contact the sensor fl ange and tighten. Check for

proper "H" dimension and readjust if necessary.

(Fig. 7)

sensor

flange

flow direction

alignment

rod

process pipe

(top view)

The flow sensor alignment rod MUST be

parallel to the process pipe as shown.

Fig. 6

5.7 Hot-Tap Sensor Installation

A. Thread one hex nut onto each of the three threaded rods included in package. Install threaded

rod with a lock washer onto the sensor fi tting. Secure rods in place by tightening each hex nut

against the sensor fi tting. (Fig. 8)

Fig. 5

"H"

"H"

sensor

flange

jam nuts

sensor

fitting

Fig. 7

FLOW

lower hex nuts

(3/16 x 1/4-20)

jam nuts

(5/32 x 1/4-20)

hex nut &

lock washer

sensor fitting

process pipe

cap nuts

upper hex nuts

& lockwashers

lower hex nuts

female pipe fitting

process

pipe wall I.D.

B. Thread one jam nut and lower hex nut onto each threaded rod so that the top surface of each

nut is 359 mm (14.14 in.) from the top surface of the sensor fi tting. Secure each hex nut with

a jam nut. (Fig. 9)

CAUTION: This setting is critical to ensure an adequate sensor seal and to

prevent the rotor from hitting the isolation valve orifi ce during installation.

C. Wipe the sensor body with a dry, clean cloth. Orient the alignment hole on the sensor fl ange

to point downstream. Place the slotted fl ange over the threaded rods. Lower the sensor into

the fi tting until the sensor fl ange rests on the lower hex and jam nuts.

D. Secure the sensor with lock washers and upper hex nuts on the top of the fl ange. Before

tightening, align the sensor fl ange so that the alignment rod is parallel and level with the

process pipe. (Fig. 10 & Fig. 11)

E. Make sure the bleed valve is closed (full clockwise position).

lower hex nuts

(3/16 x 1/4-20)

jam nuts

(5/32 x 1/4-20)

359 mm

(14.14 in.)

sensor

fitting

sensor

flange

flow direction

alignment

rod

process pipe

(top view)

The flow alignment rod MUST be

parallel to the process pipe as shown.

sensor flange

lower hex nut

and jam nuts

18 inch

threaded rods

sensor

fitting

Fig. 8

hex nut

Lock washer

sensor fitting

Upper hex nuts

(3/16 x 1/4-20)

1/4 in. lock

washers

alignment rod

359 mm (14.14 in)

bleed valve

Fig. 9

UNDER PRESSURE!

Fig. 10

Fig. 11

direction

of flow

process pipe (side view)

5

Page 8

Hot-Tap Sensor Installation - Continued

F. Thread protector plate hex nuts onto each of the three

threaded rods. Adjust each hex nut to a height of

approximately 25 mm (1 in.) from the top of each rod.

Remove the black plastic cable grommet in top of sensor

with a screwdriver. Slide the grommet up the cable away

from sensor. (Fig. 12)

protector plate

cap nuts

25mm

(1.0 in.)

protector plate

removed during

sensor installation

protector plate

hex nut (3/16 x

1/4-20)

cable

grommit

Fig. 12

G. Position the installation tool bearing plate by rotating it so that it is approximately 40 mm (1.6 in.) from the swivel mount. Mount

the installation tool by placing the threaded rods through the holes in the tool's bearing plate, resting the bearing plate on top of

the protector plate hex nuts. Make sure the swivel mount's ears are mounted between the threaded rods (not over the rods).

Install the bearing plate cap nuts. Tighten the bearing plate cap nuts to secure the installation tool in place. (Fig. 13)

H. Align the sensor cable with the swivel mount cable port to prevent cable pinching. Use a 3/8 inch wrench or socket to turn the

installation tool shaft clockwise until it is seated in the hole at the top of the sensor fl ange.

I. Wearing safety face protection, slowly open the isolation valve to the full open position. Loosen the lower hex and

jam nuts and move them to the proper "H" dimension. Turn the installation tool shaft clockwise until the sensor fl ange

contacts the lower hex and jam nuts. Thread the upper hex nuts down until they contact the sensor fl ange. Tighten the

upper hex nuts to secure the sensor. (Fig. 14)

J. Remove cap nuts and withdraw the installation tool. Be careful to not damage cable. Snap cable grommet into top of sensor

and replace protector plate and cap nuts. (Fig. 15)

Fig. 14

Fig. 13

cap nuts

protector plate

hex nuts

sensor

cable

installation tool

threaded shaft

bearing plate

swivel mount

w/cable port

sensor flange

installation

tool shaft

upper hex nuts

"H"

cap nuts

alignment rod

lower hex nuts

jam nuts

isolation valve

Fig. 15

protector plate

cap nuts

protector plate

protector plate

sensor body

hex nut

direction

of flow

6. Standard Sensor Removal

To remove the sensor from a depressurized empty pipe, simply remove the cap nuts and upper hex nuts located above the sensor

fl ange. Pull up on sensor fl ange with twisting motion.

6

Page 9

r

7. Hot-Tap Sensor Removal

To remove the Hot-Tap sensor safely from a pressurized active pipe, the entire installation

process must be reversed.

A. Remove the cap nuts, protector plate, protector plate hex nuts, and sensor cable grommet.

(Fig. 16)

372 mm

(14.6 in.)

installation tool

threaded shaft

upper hex nuts

and lock washers

sensor flange

lower hex and

jam nuts

B. Thread installation tool in place and secure bearing plate in place of sensor protector plate.

(Fig. 17)

C. Turn shaft of installation tool clockwise to lower tool into opening in sensor fl ange. Guide

cable into the port to prevent damage.

Fig. 16

protector plate

cap nuts

protector plate

protector plate

hex nut

Fig. 17

UNDER PRESSURE!

process pipe (side view)

D. Wearing safety face protection, loosen the upper hex nuts and raise to 372 mm (14.6 in.) from top of sensor fi tting to

bottom of upper hex nuts/lock washers. CAUTION! This measurement is critical to maintain watertight seal in

sensor while allowing clearance to close the isolation valve.

E. Wearing safety face protection, turn the installation tool shaft

counterclockwise to withdraw sensor until the sensor fl ange contacts

the upper hex nuts. (Fig. 18)

F. Raise one lower hex and jam nut to bottom of sensor fl ange.

cap nuts

protector plate

hex nuts

G. Close isolation valve, remove bearing plate and tool.

upper hex nuts

H. Wearing safety face protection, cover the bleed valve with suitable

protection (rag, towel, etc.) and open the bleed valve (ccw rotation)

to relieve internal pressure. Pull sensor up until bleed valve purges

some fl uid (indicating sensor is past 1st o-ring seal inside sensor

fi tting).

sensor fitting

isolation valve

installation tool

threaded shaft

installation tool

bearing plate

swivel mount

w/cable port

sensor flange

1 lower hex nut

and jam nut

sensor body

CAUTION: In case of a leaky isolation valve, the sensor will be under a slight

Fig. 18

amount of pressure. Care should be taken when removing the sensor.

Use the bleed valve to relieve this pressure taking care not to spray fl uid on yourself or others.

Sensor can now be safely removed. When reinstalling the sensor: leave one lower hex nut in position to guide sensor to proper

isolation valve clearance height before opening isolation valve. Return to "H" dimension height after valve is opened.

8. Maintenance

Your sensor requires little or no maintenance of any kind, with the exception of an occasional sensor/paddlewheel cleaning.

9. Sensor Parts

2541 Sensor Assemblies Accessories

Order no. Sensor type Fitting type Order no. Description

FP-2541 Standard 1.5 in. NPT FP-3-1500-302 Hot-Tap installation tool

FP-2542 Standard IS0 7/1-R 1.5 FP-3-2540-321 Rotor kit w/Tungsten Carbide pin Fluoroloy-B bearings, 316 SS retainers

FP-3-1500-2B Hot-Tap 1.5 in. NPT FP-3-2540-322 Rotor kit w/316 SS pin, Fluoroloy-B bearings, 316 ss retainers

FP-3-1500-2M Hot-Tap IS0 7/1-R 1.5 FPP-1220-0021* Standard FPM O-ring for sensor fi tting

FPP-1224-0021* Optional EPR O-ring for sensor fi tting

FP-2540-EM Replacement electronics module, standard

FP-3-1500-EM Replacement electronics module, hot-tap

M-2346 Instruction manual

___________

*One O-ring required for standard sensor

Two O-rings required for Hot-Tap sensor

retainer retaine

bearing

rotor pin

bearing

rotor

7

Page 10

10. K-Factors (Stainless Steel, Wrought Steel & Plastic Pipe)

SCH 5S STAINLESS STEEL PIPE

PER ANSI B36.19

K-Factor K-Factor

PIPE PULSES/ PULSES/

SIZE U.S. GAL LITER

1½ in. 115.1900 30.433

2 in. 71.3960 18.863

2 ½ in. 49.263 13.015

3 in. 32.636 8.622

3 ½ in. 24.537 6.483

4 in. 19.1350 5.055

5 in. 12.4490 3.289

6 in. 8.4602 2.235

8 in. 4.9137 1.298

10 in. 3.1228 0.825

12 in. 2.1772 0.575

14 in. 1.7977 0.475

16 in. 1.3717 0.362

18 in. 1.0855 0.287

20 in. 0.8801 0.233

22 in. 0.7293 0.193

24 in. 0.6141 0.162

SCH 10S STAINLESS STEEL PIPE

PER ANSI B36.19

K-Factor K-Factor

PIPE PULSES/ PULSES/

SIZE U.S. GAL LITER

1½ in. 127.930 33.799

2 in. 76.439 20.195

2 ½ in. 51.946 13.724

3 in. 34.174 9.029

3½ in. 25.571 6.756

4 in. 19.829 5.239

5 in. 12.730 3.363

6 in. 8.5938 2.270

8 in. 5.0062 1.323

10 in. 3.1793 0.840

12 in. 2.1914 0.579

14 in. 1.8147 0.479

16 in. 1.3798 0.365

18 in. 1.0912 0.288

20 in. 0.8855 0.234

22 in. 0.7334 0.194

24 in. 0.6175 0.163

XS WROUGHT STEEL PIPE

PER ANSI B36.10

K-Factor K-Factor

PIPE PULSES/ PULSES/

SIZE U.S. GAL LITER

1 ½ in. 161.79 42.745

2 in. 95.713 25.287

2 ½ in. 66.686 17.618

3 in. 42.986 11.357

3 ½ in. 31.983 8.450

4 in. 24.668 6.517

5 in. 15.480 4.090

6 in. 10.691 2.825

8 in. 5.9733 1.578

10 in. 3.6489 0.964

12 in. 2.4548 0.649

14 in. 1.9931 0.527

16 in. 1.4970 0.396

18 in. 1.1727 0.310

20 in. 0.9388 0.248

22 in. 0.7685 0.203

24 in. 0.6446 0.170

STD WROUGHT STEEL PIPE

PER ANSI B36.10

K-Factor K-Factor

PIPE PULSES/ PULSES/

SIZE U.S. GAL LITER

1 ½ in. 140.030 36.996

2 in. 83.240 21.992

2 ½ in. 59.034 15.597

3 in. 38.674 10.218

3 ½ in. 28.752 7.596

4 in. 22.226 5.872

5 in. 14.061 3.715

6 in. 9.5160 2.514

8 in. 5.4523 1.441

10 in. 3.4507 0.912

12 in. 2.3318 0.616

14 in. 1.9186 0.507

16 in. 1.4483 0.383

18 in. 1.1390 0.301

20 in. 0.9146 0.242

22 in. 0.7506 0.198

24 in. 0.6311 0.167

SCH 40S STAINLESS STEEL PIPE

PER ANSI B36.19

K-Factor K-Factor

PIPE PULSES/ PULSES/

SIZE U.S. GAL LITER

1 ½ in. 140.030 36.996

2 in. 83.240 21.992

2 ½ in. 59.034 15.597

3 in. 38.675 10.218

3 ½ in. 28.752 7.596

4 in. 22.226 5.872

5 in. 14.061 3.715

6 in. 9.5160 2.514

8 in. 5.4523 1.441

10 in. 3.4507 0.912

12 in. 2.3318 0.616

SCH 40 STAINLESS STEEL PIPE

14 in. 1.9556 0.517

16 in. 1.4970 0.396

18 in. 1.1900 0.314

20 in. 0.9577 0.253

24 in. 0.6662 0.176

SCH 40 WROUGHT STEEL PIPE

PER ANSI B36.10

K-Factor K-Factor

PIPE PULSES/ PULSES/

SIZE U.S. GAL LITER

1 ½ in. 140.030 36.996

2 in. 83.240 21.992

2- ½ in. 59.034 15.597

3 in. 38.674 10.218

3 ½ in. 28.752 7.596

4 in. 22.226 5.872

5 in. 14.061 3.715

6 in. 9.5160 2.514

8 in. 5.4523 1.441

10 in. 3.4507 0.912

12 in. 2.3517 0.621

14 in. 1.9556 0.517

16 in. 1.4970 0.396

18 in. 1.1900 0.314

20 in. 0.9577 0.253

24 in. 0.6662 0.176

K-factors are listed in U.S. gallons and in liters. Conversion formulas for other engineering units are

listed below.

• K = 60/A

The K-factor is the number of pulses generated by the 2540 paddlewheel per unit of liquid in a

specifi c pipe size.

To convert multiply

K from: to: K by:

U.S. gallons cubic feet 7.479

U.S. gallons cubic inches 0.00433

U.S. gallons cubic meters 263.85

U.S. gallons pounds of water 0.120

U.S. gallons acre feet 325853

U.S. gallons Imperial gallons 1.201

8

Page 11

K-Factors (Stainless Steel, Wrought Steel & Plastic Pipe) continued

SCH 80S STAINLESS STEEL PIPE

PER ANSI B36.19

K-Factor K-Factor

PIPE PULSES/ PULSES/

SIZE U.S. GAL LITER

1 ½ in. 161.790 42.745

2 in. 95.710 25.287

2 ½ in. 66.686 17.618

3 in. 42.986 11.357

3 ½ in. 31.983 8.450

4 in. 24.668 6.517

5 in. 15.480 4.090

6 in. 10.691 2.825

8 in. 5.9733 1.578

10 in. 3.6489 0.964

12 in. 2.4548 0.649

SCH 80 STAINLESS STEEL PIPE

14 in. 2.1557 0.570

16 in. 1.6444 0.434

18 in. 1.3036 0.344

20 in. 1.0533 0.278

22 in. 0.8689 0.230

24 in. 0.7335 0.194

SCH 80 WROUGHT STEEL PIPE

PER ANSI B36.10

K-Factor K-Factor

PIPE PULSES/ PULSES/

SIZE U.S. GAL LITER

1 ½ in. 161.790 42.745

2 in. 95.713 25.287

2 ½ in. 66.686 17.618

3 in. 42.986 11.357

3 ½ in. 31.983 8.450

4 in. 24.668 6.517

5 in. 15.480 4.090

6 in. 10.691 2.825

8 in. 5.9733 1.578

10 in. 3.7983 1.004

12 in. 2.6198 0.692

14 in. 2.1557 0.570

16 in. 1.6444 0.434

18 in. 1.3036 0.344

20 in. 1.0533 0.278

22 in. 0.8689 0.230

24 in. 0.7335 0.194

SCH 40 Plastic pipe per ASTM-D-1785

K-Factor K-Factor

PIPE PULSES/ PULSES/

SIZE U.S. GAL LITER

1 ½ in. 139.850 36.948

2 in. 82.968 21.920

2 ½ in. 60.194 15.903

3 in. 39.513 10.439

3 ½ in. 29.295 7.740

4 in. 22.565 5.962

5 in. 14.308 3.780

6 in. 9.8630 2.606

8 in. 5.6400 1.490

10 in. 3.4476 0.911

12 in. 2.3786 0.628

SCH 80 Plastic pipe per ASTM-D-1785

K-Factor K-Factor

PIPE PULSES/ PULSES/

SIZE U.S. GAL LITER

1 ½ in. 162.290 42.877

2 in. 97.186 25.677

2 ½ in. 68.559 18.113

3 in. 43.870 11.590

3 ½ in. 32.831 8.674

4 in. 25.250 6.671

5 in. 15.835 4.184

6 in. 11.041 2.917

8 in. 6.2877 1.661

10 in. 3.8529 1.018

12 in. 2.6407 0.698

9

Page 12

11. Specifi cations

General Data

Flow velocity range: 0.1 to 6 m/s (0.3 to 20 ft/s)

Linearity: ±1% of full range

Repeatability: ±0.5% of full range

Pipe range:

• Standard version: 38 to 610 mm (1.5 to 24 in.)

• Hot-Tap version: 38 to 914 mm (1.5 to 36 in.)

Sensor fi tting options: 316 SS with 1.5 in. NPT threads,

OR 316 SS with IS0 7/1-R 1.5 threads

Cable length: 7.6 m (25 ft.), can splice up to

300 m (1000 ft.)

Cable type: 2-conductor twisted-pair with shield

Fluid Conditions

Maximum operating pressure/temperature:

• Sensor with standard FPM sensor fi tting O-rings:

17 bar (250 psi) @ 82 °C (180 °F)

• Sensor with optional EPR sensor fi tting O-rings:

17 bar (250 psi) @ 100 °C (212 °F)

Wetted Materials

Sensor body: 316 stainless steel

Sensor fi tting: 316 stainless steel

Sensor fi tting O-rings: Standard Viton®, optional

EPR

Rotor: CD4MCu stainless steel

Rotor shaft: Tungsten carbide (standard)

316 stainless steel (option)

Shaft retainers (2): 316 stainless steel

Rotor bearings (2): Fluoroloy B®

Electrical Data

Supply voltage: 5 to 24 VDC

Supply current: 1.5 mA max.

Output type: Open collector, sinking

Output current: 10.0 mA max.

7.5 m (25 ft.)

integral cable

Adjustable

length

O-ring

seal (1)

Caution: The OMEGA FP-3-1500 Series Hot-Tap

system's overall specifi cations and limitations depend

on the lowest maximum rating of the components

associated with the system. In other words, the HotTap system is only as strong as its weakest link. For example,

a ball valve, a component of the system, is rated at a maximum

100 psi @ 175 °F, limiting the entire system's maximum pressure/

temperature rating to 100 psi @ 175 °F. All higher maximum

specifi cations MUST yield to the component with the lowest

maximum specifi cation.

Note: Pressure/temperature specifi cations refer to sensor

performance in water. Certain chemical limitations may apply.

Chemical compatibility should be verifi ed.

64 mm (2.5 in.) dia.

64 mm (2.5 in.) dia.

7.6 m

(25 ft.)

127 mm

(5.0 in.)

Sensor fitting:

1.5 in. NPT or

ISO 7/1-R 1.5

thread

cable

O-ring

seals (2)

Adjustable

length

457 mm

(18 in.)

Bleed

valve

Sensor fitting:

1.5 in. NPT or

ISO 7/1-R 1.5

thread

24 mm (0.94 in.) dia.

Standard Sensor Dimensions:

• FP-2541 = 1.5 in. NPT fi tting

• FP-2542 = ISO 7/1-R 1.5 fi tting

24 mm (0.94 in.) dia.

Hot-Tap Sensor Dimensions:

• FP-3-1500-2B = 1.5 in. NPT fi tting

• FP-3-1500-2M = ISO 7/1-R 1.5 fi tting

10

Page 13

11

Page 14

12

Page 15

SA

MAD E

IN

IN

USA

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period

of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to

the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s

customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for

any damages that result from the use of its products in accordance with information provided

by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it

will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity,

medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in

our basic WARRANTY / DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold

OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a

manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR)

NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING

DELAYS). The assigned AR number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

FOR WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specifi c problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our

customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2000 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced,

translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of

OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

consult OMEGA for

current repair charges. Have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the

repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specifi c problems

relative to the product.

Page 16

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine

Totalizers & Batch Controllers

/Paddlewheel Systems

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

/Laboratory Meters

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

14

6-2540.090-OM (H-6/06) M-2346/0606

Loading...

Loading...