Page 1

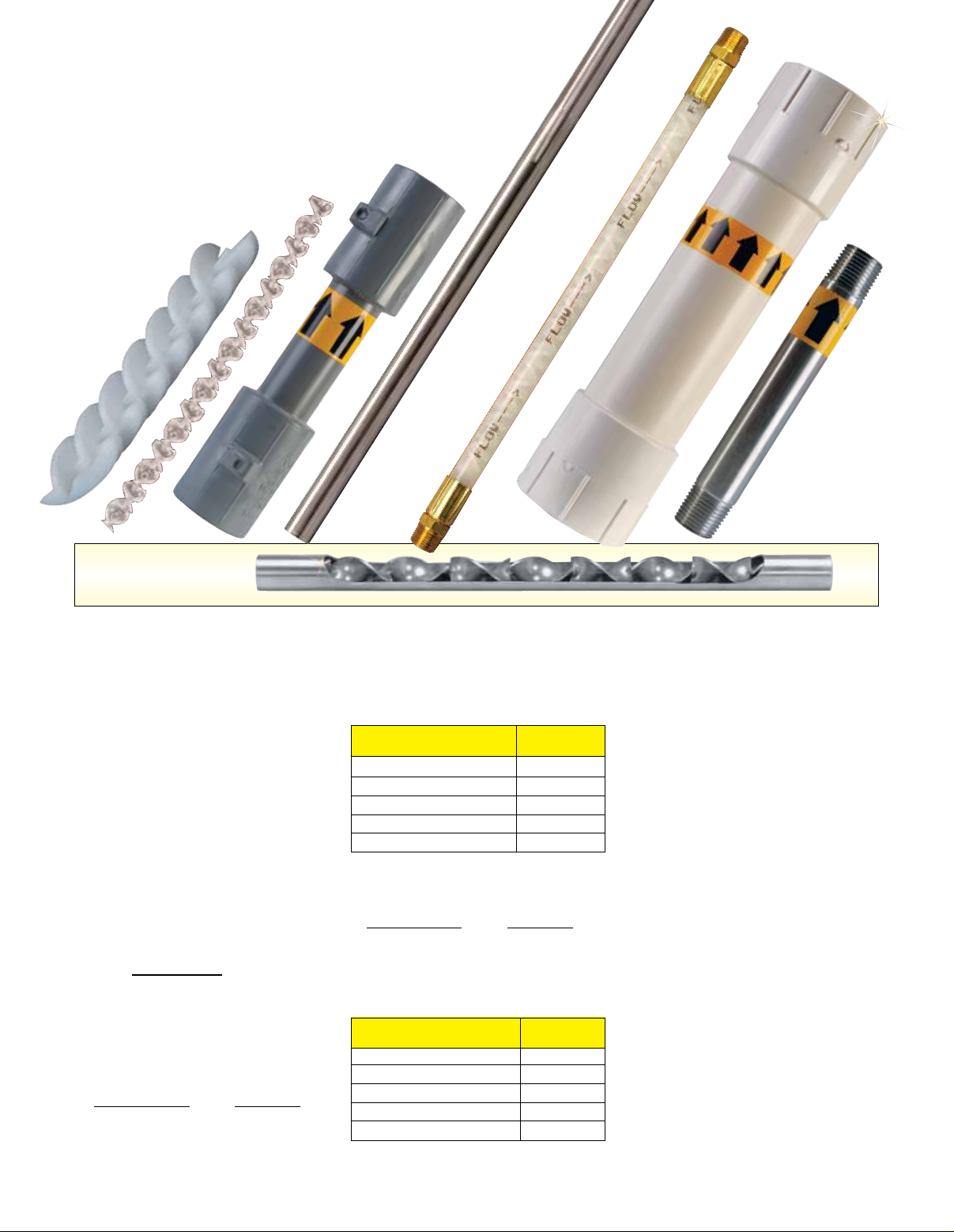

STATIC MIXERS

A Technical Introduction

FMX8125-P,

pkg of 10

FMX7109-AC,

pkg of 10

All shown

smaller

than actual

size.

FMX7221-CP

FMX9611

FMX7251

FMX8263

pkg of 10

FMX8481S

FMX9603,

interior detail.

Selection Guide

For each application, the designer

must first determine the number of

mixing sections required to achieve

a complete mix. The guidelines

below are based upon the Reynolds

Number of your system. Also

included are tables with some

general application guidelines.

Next, the designer should select a

diameter and/or a construction that

will give the desired mixing

performance without exceeding your

system’s maximum allowable

pressure drop (see item 3 below).

1. Calculate the Reynolds

Number. Use the diameter given

in the charts. If both inside and

outside diameters are supplied,

use the inside diameter

3157 x Q x S

RE =

2. Select a model based on the

FMX7000 Series Mixers:

No. of

800 to1000 14

>1000 7

D x MU

Reynolds Number.

Reynolds No. Elements

Typical No. of

Application Elements

Ozone Absorption 7

pH Control 7

Gas/Gas Blending 7

Dilution of Chemicals 7

Polyelectrolyte Dilution 14

FMX8000 Mixers:

No. of

Reynolds No. Elements

<10 24 to 32

10 to 500 16 to 24

500 to 2000 8 to 16

>2000 4 to 8

Typical No. of

Application Elements

1-1 Epoxies 24

Urethanes/Elastomers 32

Urethane Foam 16

In-line Aeration 8

Admixing of Additives 8

3. Determine the Pressure Drop

Laminar Flow:

Reynolds Number < 500

DP = Q x MU x L

Turbulent Flow:

Reynolds Number > 500

DP = Q2 x S x T

Note: If the pressure drop across the

mixer exceeds its maximum rating, a

modular mixer is required. For example,

if a 24-element FMX8300 mixer is required

and the pressure drop exceeds the 250 psi

rating, we recommend coupling two

12-element mixers in series.

Symbols

RE = Reynolds Number

Dimensionless

Q = Flow rate in Gallons/Minute

S = Specific Gravity—

Dimensionless

MU = Viscosity in Centipoise

D = Diameter in Inches

DP = Pressure Drop in psi

L = Laminar Factor—

See Mixer Tables

T = Turbulent Factor —

See Mixer Tables

L-X

Page 2

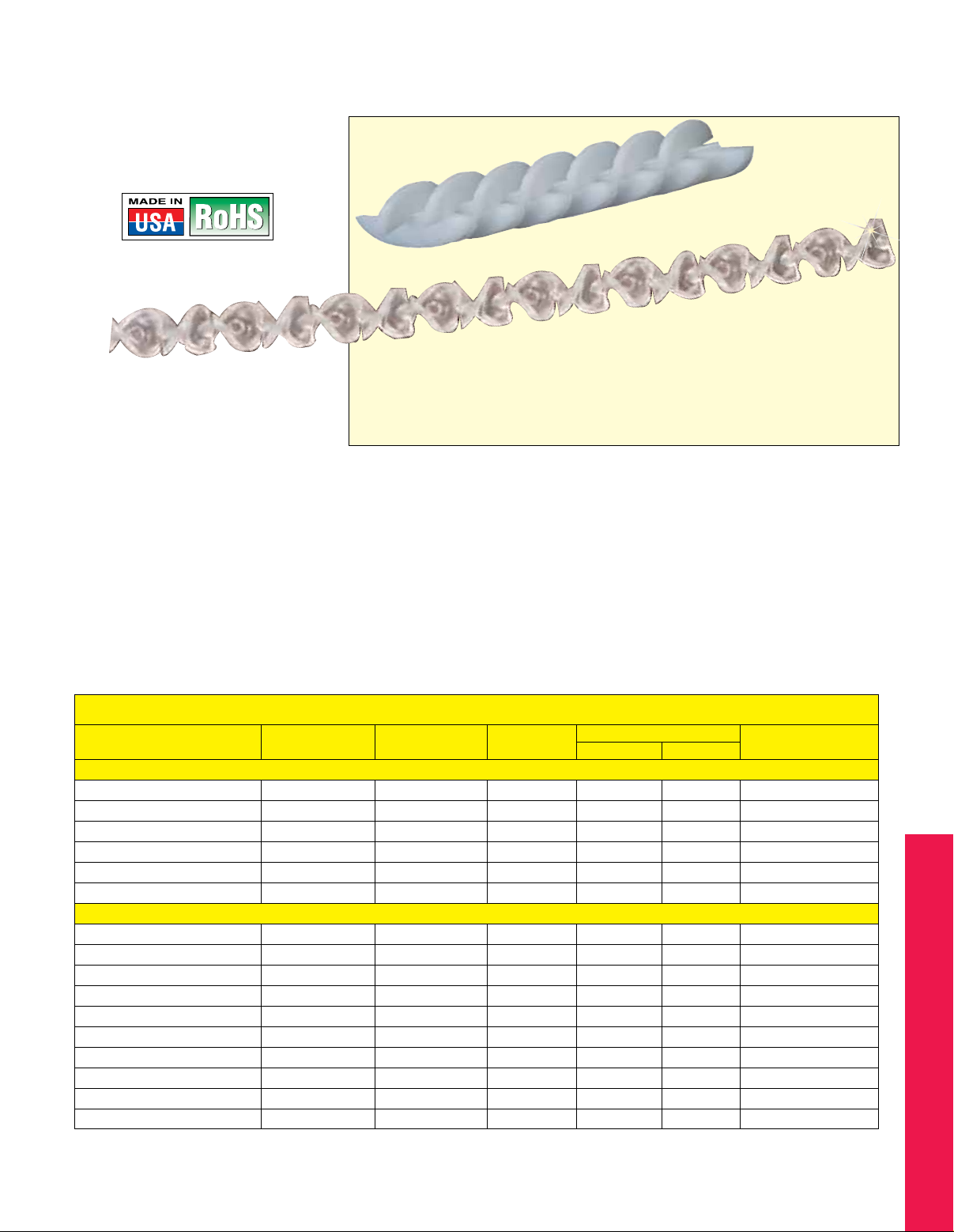

MIXING ELEMENTS

FMX7100/

8100 Series

The FMX7100 and FMX8100

series mixing elements are injection

molded in one operation to ensure

low cost with excellent quality.

The FMX7100 series are

specifically designed for low

viscosity applications. The

FMX8100 plastic spiral elements

were developed for adhesive and

sealant and other high viscosity

mixing applications. The leading

and trailing edges of the FMX8000

mixers are “knife edged” so that

the unit flushes clean with less

solvent—no flat leading edges to

accumulate material.

FMX7109-AC, low viscosity

mixing elements,

package of 10.

Both shown larger than actual size.

Polyacetal is completely inert to

most common solvents, such as

MEK acetone, and methylene

chloride for use in the Adhesive

and Insulation industries. Its

maximum service temperature is

250°F. Polyacetal is not

recommended for service with

bases or acids. Polypropylene has

FMX8125-P, high viscosity

mixing element, sold

in package of 10.

excellent chemical resistance and

a maximum service temperature

to 200°F. Metal or plastic tubing may

be used to house the mixing sections.

However, to achieve maximum

performance, the sections must fit

snugly inside the tube. Accepted

tolerance is no more than 2% greater

than the mixer diameter.

To Order Visit omega.com/fmx for Pricing and Details

Factors

Model No. Package of 10

Low Viscosity Mixing Elements

FMX7103-AC 0.300 7 1.4 0.18 8.74 Polyacetal

FMX7106-P 0.687 7 4.2 0.015 0.276 Polypropylene

FMX7109-AC 0.903 7 5.3 0.0066 0.092 Polyacetal

FMX7109-P 0.906 7 5.3 0.0066 0.092 Polypropylene

FMX7120-AC 2.040 5 9.0 0.0003 0.0018 Polyacetal

FMX7120-P 2.050 5 9.0 0.0003 0.0018 Polypropylene

High Viscosity Mixing Elements

FMX8112-AC 0.125 12 1.3 1.29 328.7 Polyacetal

FMX8112-P 0.125 12 1.3 1.29 328.7 Polypropylene

FMX8118-AC 0.187 16 2.5 0.5152 104.7 Polyacetal

FMX8118-P 0.187 16 2.5 0.5152 104.7 Polypropylene

FMX8124-AC 0.250 16 4.0 0.216 35.7 Polyacetal

FMX8125-P 0.251 16 4.0 0.216 35.7 Polypropylene

FMX8137-AC 0.370 12 3.9 0.048 4.27 Polyacetal

FMX8137-P 0.373 12 3.9 0.048 4.27 Polypropylene

FMX8149-AC 0.498 12 5.1 0.0192 1.23 Polyacetal

FMX8150-P 0.500 12 5.1 0.0192 1.23 Polypropylene

Ordering Examples: FMX7109-AC, polyacetal low viscosity mixing elements, package of 10.

FMX8125-P, polypropylene high viscosity mixing elements, package of 10.

Diameter (inch)

Elements

Length (inch)

L-X

L T

Material

L

Page 3

ALL-PLASTIC STATIC MIXER ASSEMBLIES

FMX7200 Series

Sizes:

Sizes:

3

3

⁄4 to 2"

⁄8 to 2"

diameter

diameter

FMX7200 Series

The FMX7200 Series is an effective

answer to your mixing requirements.

Operating in-line, with no moving

parts, these mixers blend and

disperse treatment chemicals into

waste water streams. Compared to

competitive mixers, its unique

baffling design ensures complete

mixing in a shorter length and lower

pressure drop.

The FMX7200 Series is easily

installed in new or existing process

lines. They are available in pipe sizes

from ³⁄₄ to 2" diameter. Construction

materials include PVC, and CPVC.

FMX7200 Series mixers are specially

designed for waste water treatment,

mixing additives, pH control, and

polyelectrolyte dilution. These

all-plastic mixers combine PVC

or CPVC pipe with polypropylene

internals. Certain sizes feature

clipped sections, which eliminate

sharp crevices where material can

accumulate and plug up the mixer.

Polypropylene has excellent chemical

resistance to most acids and bases.

The maximum service temperature

of a standard FMX7200 Series mixer

is 60°C (140°F) with PVC housing,

82°C (180°F) with CPVC housing.

SPECIFICATIONS

Section: Polypropylene non-removable

Housing: PVC or CPVC;

schedule 80 up to and including

1"; schedule 40 for 2"

OMEGA® FMX7200 Series mixers are designed for efficient

turbulent-flow mixing at low pressure drop. Ideal for admixing water/

wastewater treatment chemicals, polymer dilution, and other

low-viscosity applications. Mixing elements consist of a series of

polypropylene baffles, and are mounted in a PVC housing with

FNPT ends. CPVC and clear PVC housings available.

FMX7221-CP (above) and FMX7251 (left)

NPT threaded model, shown smaller

than actual size.

Pressure Limitations

Pipe Size psig @ 24°C (75°F)

³⁄₄" 690

1" 630

2" 200

To Order Visit omega.com/fmx for Pricing and Details

Model No. (PVC) Model No. (CPVC) Dia. (inch) Elements Ends FNPT (inch) Length mm (inch) L T

— FMX7221-CP 0.687 7 clipped

FMX7222 — 0.687 14 clipped

FMX7232 — 0.906 14 clipped 1 320 (12.6) 0.013 0.16

FMX7251 FMX7251-CP 2.05 5 2 287 (11.3) 0.0003 0.0016

Comes complete with PVC housing and PVC 150# Van Stone SlipON flanged ends, internal mixing elements are CPVC material.

Ordering Examples: FMX7221-CP,

FMX7251, 2 FNPT, 5 clipped elements.

3

FNPT, 7 clipped elements.

⁄

4

Factors

No. of

³⁄₄

178 (7.0) 0.015 0.24

³⁄₄

267 (10.5) 0.03 0.48

L-X

Page 4

ALL STAINLESS STEEL STATIC MIXERS

With Optional PFA-Coated Elements

FMX8400 Series

Sizes:

Sizes:

1

1

⁄8 to 2"

⁄8 to 2"

diameter

diameter

FMX8400 Series

FMX8400 Series pipe mixers feature

304 SS piping (schedule 40 nominal)

with 316 SS elements. For routine

maintenance, the elements can be

pushed out and cleaned.

The leading and trailing edges of the

mixers are “knife edged” to

flush clean with less solvent,

having no flat leading edges to

accumulate material.

The FMX8400 Series consists of

effective motionless mixers. When

combined with metering pumps, these

mixers replace expensive treatment

tanks and dynamic mixers. Consider

these advantages: zero maintenance,

low cost, easy installation, and low

energy consumption.

Typical applications include laminar or

turbulent blending, liquid/gas contacting,

and enhanced heat transfer. The mixing

process is modular: the more difficult the

application, the greater the number of

elements required.

FMX8400 Pressure Limitations

Pipe Size (in) psig @ 24°C (300°F)

¹⁄₈ 8750

¹⁄₄ 8500

³⁄₈ 7250

¹⁄₂ 7250

³⁄₄ 6000

1 4500

1¹⁄₂ 3000

2 2500

OMEGA FMX8400 Series mixers offer efficient mixing of low

or high viscosity fluids at low pressure drop. Also ideal for

two-phase (gas-liquid) mixing and blending of gases. Elements

consist of a series of left and right helixes fabricated from 316 SS.

304 SS housing is corrosion-resistant, designed for high pressure

and high temperature service. MNPT ends ensure easy installation.

FMX8481S (NPT threaded model),

shown actual size.

316 SS Elements

To Order

ID No. of Ends Length Factors

Model No. (inch) Elements MNPT (inch) L T

FMX8442S 0.28 12

FMX8451S 0.37 6

FMX8452S 0.37 12

FMX8462S 0.51 12

FMX8481S 0.64 6

FMX8482S 0.64 12

FMX8412S 0.80 12

FMX8413S 1.06 6 1 9.5 0.001 0.024

FMX8414S 1.06 12 1 18.5 0.002 0.048

FMX8415S 1.61 6 1

FMX8421S 2.07 6 2 17.5 0.0001 0.0013

Ordering Example: FMX8481S, 316 SS element mixer.

Visit omega.com/fmx for Pricing and Details

¹⁄₈

5.4 0.1176 12.2

¹⁄₄

3.7 0.0237 1.9

¹⁄₄

7.0 0.0474 3.8

³⁄₈

9.5 0.0184 1.1

¹⁄₂

5.7 0.0049 0.22

¹⁄₂

11.0 0.0098 0.44

³⁄₄

14.7 0.0046 0.08

¹⁄₂

14.0 0.0002 0.004

L-X

L

Page 5

STAINLESS TUBE AND SPIRAL

SANITARY MIXERS

FMX9600 Series

The FMX9600 Series spiral mixers

are designed for high-pressure

applications such as two component

adhesives and sealants. The mixers

consist of a series of left and right

hand spiral elements which have

been “edge-sealed” into a tube.

The spiral tube mixer is available

in four diameters and with 21 to 32

elements. The elements have been

nicrobrazed along their complete

length and cannot be removed from

the tube. Consider the advantages

of this all-stainless steel assembly:

the moderate price offers significant

savings over competitive mixers,

the contour of the elements ensures

that the mixer flushes clean with

less solvent, and the tube mixers

are manufactured with heavy walled

tubing, which resists warpage

during furnace cleaning and

increases the life of the mixer.

Inset to show

detail.

FMX9604, shown

actual size.

FMX9611,

shown actual size.

SPECIFICATIONS

Elements: 316 stainless steel,

non-removable

Housing: 304 stainless steel

with plain ends

To Order Visit omega.com/fmx for Pricing and Details

Element Housing

Diameter Mixing Length Outside Dia. Pressure Limitation L Factor to Calc.

Model No. mm (inch) Elements cm (inch) mm (inch) psi@300°F bar@150°C Pressure Drop

FMX9603 2.87 (0.113) 27 19.05 (7.50) 4.75 (0.187) 6900 476 3.180

FMX9604 4.75 (0.187) 21 17.78 (7.00) 6.35 (0.250) 4200 290 0.540

FMX9605 4.75 (0.187) 27 23.50 (9.25) 6.35 (0.250) 4200 290 0.700

FMX9608 7.42 (0.292) 27 35.56 (14.00) 9.53 (0.375) 3600 248 0.110

FMX9611 10.62 (0.418) 32 62.87 (24.75) 12.70 (0.500) 2800 193 0.077

Supplied with plain ends, the elements are edge sealed to the housing to handle the mixing of high pressure or highly viscous materials.

Elements are 316 SS and the housing is 304 SS.

Ordering Examples: FMX9604, spiral mixer, 4.75 mm (0.187").

FMX9611, spiral mixer, 10.62 mm (0.418") diameter.

L-X

Page 6

POLYACETAL STATIC

MIXER ASSEMBLIES

FMX8200 Series

The Series FMX8200 disposable

spiral mixers are idea for adhesives

or other high viscosity applications.

The leading and trailing edges of

the mixers are “knifed edged” to

flush clean with less solvent–no

flat leading edges to accumulate

material.

FMX8263, sold in

package of 10

FMX8234, sold in

package of 10

SPECIFICATIONS

Max Pressure Drop: 250 psi

Element: Polyacetal

Housing: Nylon plain ends

Pressure limitaion

OD PSIG @ 75ºF

0.187 580

0.250 430

0.375 600

0.500 460

0.625 350

FMX8213, sold in

package of 10

All models shown

smaller than actual size.

To Order Visit omega.com/fmx for Pricing and Details

Model No.

Polyacetal Package of 10

FMX8213 0.125 24 2.8 0.187 2.58 657.4 Polyacetal

FMX8214 0.125 30 3.5 0.187 3.23 821.7

FMX8223 0.187 24 4.1 0.250 0.7728 157.1 Polyacetal

FMX8224 0.187 32 5.4 0.250 0.9660 209.4

FMX8233 0.250 24 6.5 0.375 0.3240 53.6 Polyacetal

FMX8234 0.250 32 8.5 0.375 0.4320 71.4

FMX8251 0.370 12 7.5 0.500 0.0480 4.27 Polyacetal

FMX8253 0.370 24 11.5 0.500 0.0960 8.54

FMX8254 0.370 30 13.5 0.500 0.1200 10.7

FMX8262 0.498 18 11.1 0.625 0.0288 1.85

FMX8263 0.498 24 13.5 0.625 0.0384 2.46 Polyacetal

Ordering Examples: FMX8213, plain ends, 24 elements, package of 10.

FMX8234, plain ends, 32 elements, package of 10.

Diameter (inch)

Elements

Length (inch) O.D.

L-X

L T Material

Factors

L

Loading...

Loading...