Page 1

Model FLSC-C1-LIQ

Microprocessor Based

Loop Powered Transmitter

Page 2

Page 3

CONTENTS

1. Introduction------------------------------------------------------------ 2

2. Specifications----------------------------------------------------------- 3

3. Principle of Operation ----------------------------------------------- 4

3-1 Functional Blocks------------------------------------------------ 4

3-1-1 Preamplifier --------------------------------------------- 4

3-1-2 Microcontroller ----------------------------------------- 5

3-1-3 Loop Driver --------------------------------------------- 5

3-1-4 Communications Interface ---------------------------- 5

3-2 System Response Time------------------------------------------ 6

4. Installation-------------------------------------------------------------- 7

4-1 Typical Connections--------------------------------------------- 7

4-2 Communications Connections---------------------------------- 8

4-3 Wiring ------------------------------------------------------------- 8

Appendix A – Default Configuration----------------------------------- 9

Appendix B – Communications-----------------------------------------11

Message Format And Timeout --------------------------------------11

Messages ---------------------------------------------------------------13

- 1 -

Page 4

1. Introduction

The FLSC-C1-LIQ is a microprocessor based loop powered transmitter.

The transmitter accepts a low-level frequency signal on the input and

provides a 4-20mA analog output proportional to the flow rate. FLSCC1-LIQ is compatible with FTB100 and FTB200 Series Omega turbine

flowmeters as well as the FTB3000 series positive displacement

flowmeters.

The FLSC-C1-LIQ model provides for 20-point linearization of the

flow input signal and outputs a linearized analog current. FLSC-C1LIQ is fully configurable via an RS232 communications port located

under the top plate. FLSC-C1-LIQ configuration software is a

Windows based application that provides the interface for entering Kfactors, frequencies, the timebase for rate measurement, and calibration

of the analog output. Configuration and remote monitoring can also be

performed using any PC based communications program (e.g.,

HyperTerminal) or ASCII terminal.

The standard unit is packaged in an extruded aluminum enclosure for

wall mounting or may be mounted directly on a flowmeter using an

optional NEMA 4X or EX enclosure. An optional bracket is also

available for mounting on standard DIN rail.

- 2 -

Page 5

2. Specifications

Specifications

Input Signal Type: Magnetic pick up, Contact Closure

Input frequency range: 0.2 Hz to 4 KHz

Signal level: 10 mV rms to 30 Vdc

Power supply: Loop Power 8-30 Vdc

Reverse polarity protection

Analog Output: 4-20 mA

24 mA overflow condition

Load resistance: Max 650 Ohms at 24 Vdc

Accuracy: +/- 0.02% of full scale @ 20

Temperature drift: 40ppm/deg C

Communications RS232 port for Configuration and dia gn ost i cs

Operating temperature: -40

Humidity: 0-90% Non-condensing

o

to 85o C

Enclosure: Extruded aluminum, DIN rail mount, or

Explosion Proof

Regulatory: CE compliant

Options

20 point linearization

o

C

- 3 -

Page 6

3. Principle of Operation

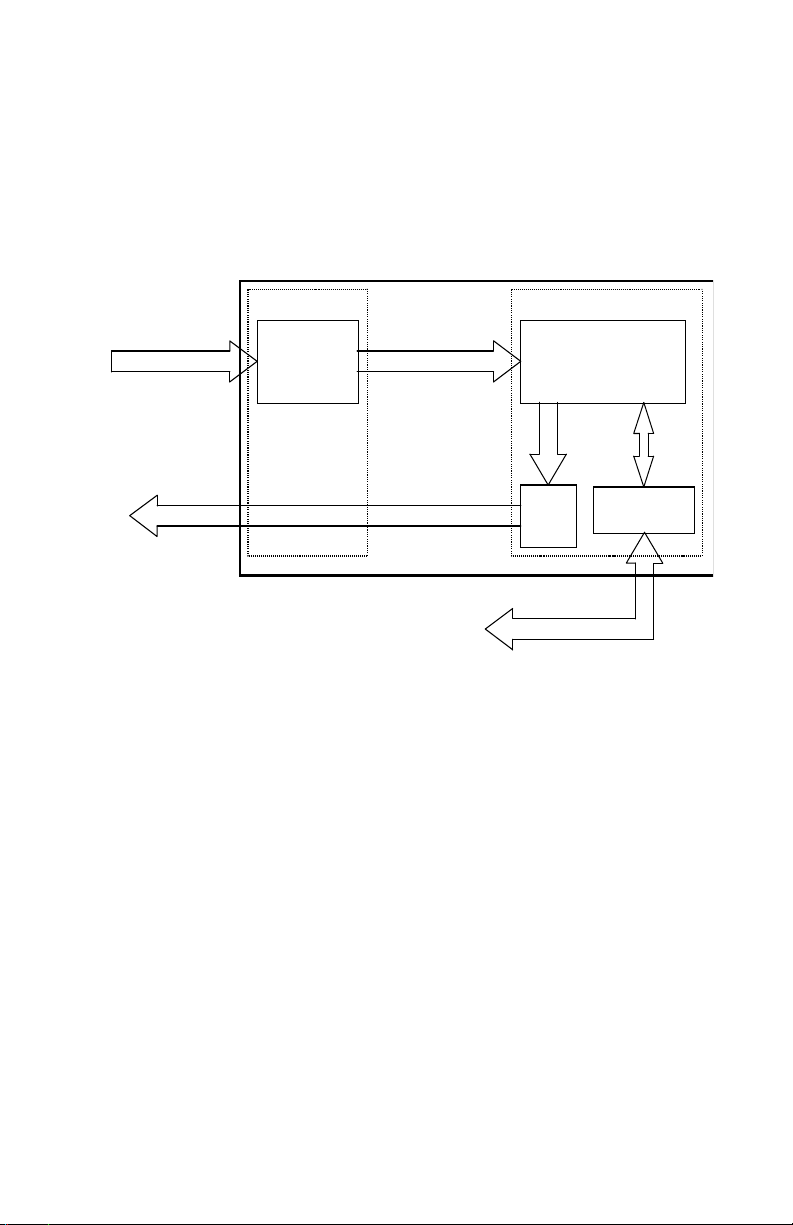

The FLSC-C1-LIQ consists of two printed circuit boards and four main

functional blocks: the Preamplifier, Microcontroller, Loop Driver, and

Communications Interface.

PCA180

FLOWMETER INPUT

4-20 mA

PREAMP

CONDITIONED SIGNAL

4-20 mA

MICROCONTROLLER

LOOP

DRIVER

RS232

3-1 Functional Blocks

3-1-1 Preamplifier

The Preamplifier, located on PCA180, accepts the input from

the flowmeter. The Preamplifier applies amplification, low-pass

filtering, and wave-shaping to the input signal. The wave

shaping function converts the signal into a square-wave before

sending it to the Microcontroller.

PCA183

COMMUNICATIONS

INTERFACE

- 4 -

Page 7

3-1-2 Microcontroller

The Microcontroller, located on PCA183, accepts the squarewave output of the preamplifier and performs all of the

calculations that are required to control the Loop Driver. After

measuring the frequency of the square-wave, the

Microcontroller uses the following equations to compute the

flow rate and current.

flowrate

Where:

Kfactor = Is dependent on the Flow Calculation Method setting and

FM = Is the Flow rate Units setting of 0, 1, or 2. Where “0” is

CF = Is the Correction Factor setting.

Where:

AF = Is the 20 mA maximum Flow rate value.

If the calculated flowrate is greater than the AF setting, the

current will be set to 24mA to indicate an “Over-range”

condition. After calculating the current, the Microcontroller

digitally sends the current information to the Loop Driver.

3-1-3 Loop Driver

The loop driver, located on PCA183, uses the digital

information sent to it by the Microcontroller to set the current

of the loop. The Loop Driver also supplies power to the

Microcontroller.

frequency

FM

xCFx

60

Kfactor

is either the Average K-Factor or the Linearized K-Factor

from the Frequency / K-Factor table.

for Seconds, “1” is for Minutes, and “2” is for Hours.

mAxmAcurrent 164

flowrate

AF

3-1-4 Communications Interface

The Communications Interface, located on PCA183, provides

an RS232C port to the Microcontroller. The connector for the

communication interface may be accessed by removing the top

plate. The external terminal device provides power for the

Communication Interface. The Communications Interface is

used to configure and trouble-shoot the transmitter.

- 5 -

Page 8

3-2 System Response Time

The analog output response time to reach steady state due to a

change in the flow rate is approximately two (2) seconds. When

flow stops, the time for the analog output to return to 4 mA will

be between 3 and 12 seconds, depending on the Maximum

Sample Time (MST) setting. MST is adjusted using the NB=

(DATA) command, where NB is a value between 1 and 80. The

default MST setting is NB= 1. Adjusting the MST is only

recommended for low flow applications where the minimum

input frequency is below 1 Hz.

- 6 -

Page 9

4. Installation

4-1 Typical Connections

Loop powered with MAG Coil Installation

-

-

DC

POWER

SUPPLY

Mag Pickup Coil

LOAD

Dip Switch Settings

SW1 SW2

1 1 1

+

BA

+

PCA180

DC+

N/C

SIG+

SIGANLG

N/C

N/C

N/C

N/C

N/C

PCA183

SW1

- 7 -

Page 10

4-2 Communications Connections

The RS232 serial port connector is located under the top plate of

FLSC-C1-LIQ and may be accessed by removing the two

screws from the top plate. FLSC-C1-LIQ unit has to be powered

from external supply in order to be able to communicate.

Additional power for FLSC-C1-LIQ communication circuitry is

supplied by the RS232 serial port of the computer/terminal.

COM port settings must be set as follows:

Baud Rate: 2400

Data Bits: 8

Parity: None

Stop bits: 1

Handshaking: None

Communications Cable P/N FLSC-C-CABLE

DB9

CD 1

Rx 2

Tx 3

DTR 4

SIG COM 5

6 DSR

7 RTS

8 CTS

9 NC

VDC1

VDC2

Pin 1

Molex

0511100660

or

Equivalent

Pin 2

4-3 Wiring

When installing the FLSC-C1-LIQ, it is good practice to use

shielded cable. The shield should be connected to earth ground

near the instrument. The other end of the shield should not be

connected.

In order to comply with the requirements for Electromagnetic

Compatibility, as per EMC-Directive 89/336/EEC of the

Council of European Community, this wiring practice is

mandatory.

- 8 -

Page 11

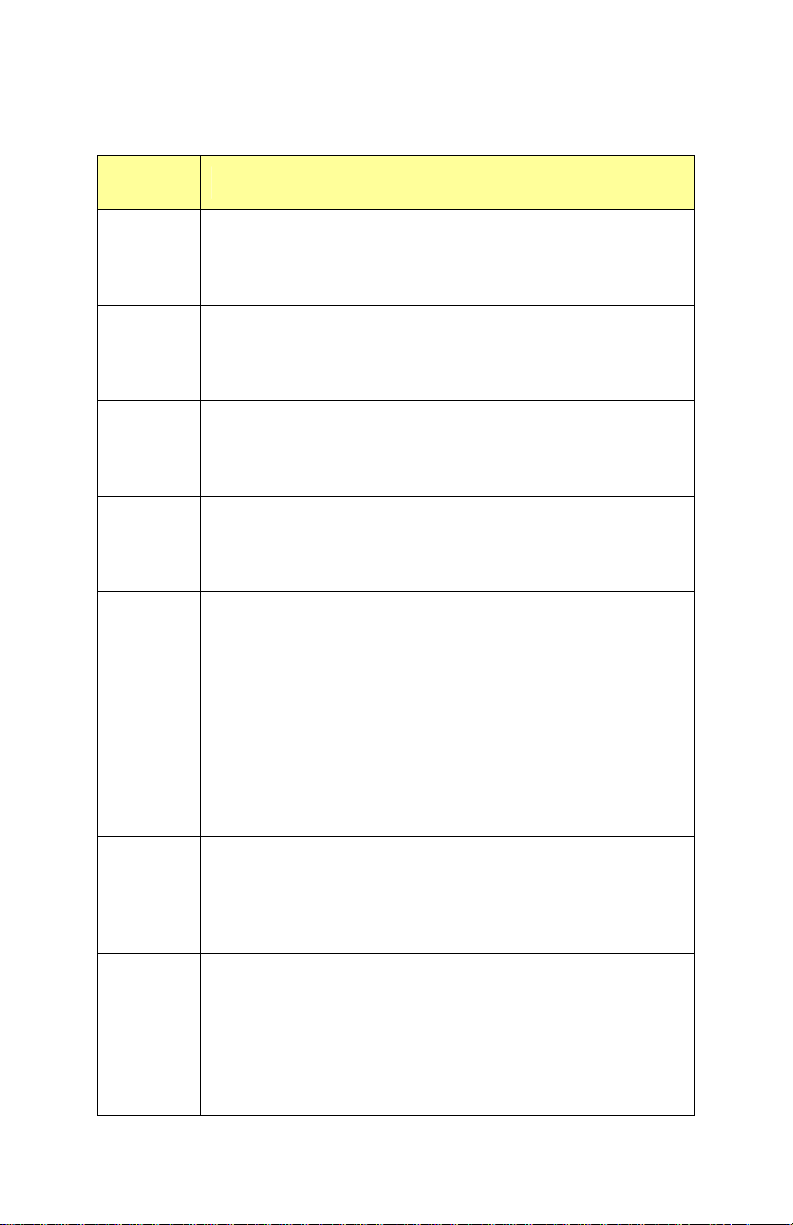

Appendix A – Default Configuration

Factory default configuration:

FIELD Value

DN 10000000

FC 0 (Average)

KD 3

AK 1.00

NP 20

F01 4999.981

F02 4999.982

F03 4999.983

F04 4999.984

F05 4999.985

F06 4999.986

F07 4999.987

F08 4999.988

F09 4999.989

F10 4999.990

F11 4999.991

F12 4999.992

F13 4999.993

F14 4999.994

F15 4999.995

F16 4999.996

F17 4999.997

F18 4999.998

F19 4999.999

F20 5000.000

K01 1.00

K02 1.00

K03 1.00

K04 1.00

K05 1.00

K06 1.00

K07 1.00

K08 1.00

K09 1.00

K10 1.00

K11 1.00

K12 1.00

K13 1.00

K14 1.00

K15 1.00

- 9 -

Page 12

FIELD Value

K16 1.00

K17 1.00

K18 1.00

K19 1.00

K20 1.00

TU 100 (GAL)

FM 1 (MIN)

NB 01

PA 1234

OC 0 (Rate)

- 10 -

Page 13

Appendix B – Communications

Message Format and Timeout

Communication messages consist of a string of ASCII characters

terminated by a carriage return character. The maximum message

length received by FLSC-C1-LIQ is 20 characters, including the

carriage return. The FLSC-C1-LIQ will transmit no more than 35

characters before transmitting a carriage return.

If a message longer than A 20 characters command is sent, the

instrument responds with

“Command Sequence is Too Long!<NL>”

If an unrecognized or invalid command is sent, the in strumen t respond s

with

“Invalid Command! <NL>”

The sending unit RS232C serial port configuration must be configured

as follows:

Baud rate: 2400

Data bits: 8

Parity: none

Stop bits: 1

Handshaking: none

The FLSC-C1-LIQ echoes all received messages and then transmits a

response string terminated with a carriage return. If the sending unit

takes longer than one minute to send a message, the FLSC-C1-LIQ

aborts the message by clearing the receive buffer.

If the sending unit (PC or other such device) wishes to change a setting

on the FLSC-C1-LIQ, the sending unit shall follow the command with

an equal sign (“=”) with the data following immediately after the equal

sign. The carriage return terminates the message.

Any FLSC-C1-LIQ response that sends data back to the sending unit

shall have an equal sign (“=”) followed by the data. Space is allowed

between the equal sign and the data on the return message, but th e total

message length is limited to 35 characters.

- 11 -

Page 14

READ Example:

If the sending unit wishes to read the number of points that the

FLSC-C1-LIQ has in the K-factor table, the sending unit shall

send

“NP<CR>”

The FLSC-C1-LIQ echoes the sent message, and responds with

“NUM PTS = 2<CR>”

WRITE Example:

If the sending unit wishes to change the number of points to 20 in

the K factor table, the sending unit shall send

“NP=20<CR>”

The FLSC-C1-LIQ echoes the sent message and responds with

“NUM PTS = 20<CR>”.

The FLSC-C1-LIQ checks the ranges for data and rejects writes that are

not within the allowed range. If the sending unit sends data that is not

within the allowed range, the FLSC-C1-LIQ echoes the sent message

and responds with the value that is currently stored in the FLSC-C1LIQ.

Example:

If the sending unit wishes to change the max sample time to 2000

from the previous setting of 10, the sending unit shall send

“NB=2000<CR>”

The FLSC-C1-LIQ echoes the sent message, and responds with

“MAX M TIME= 10<CR>”.

- 12 -

Page 15

Messages

Commands Supported By Communications Messages

Command Description/Allowed Data/Response

DN

FC

KD

AK

Tag Number

“0” to “99999999”

“TAG NUM = (DATA)”

The first three digits are the units code for total. Changing

these digits will change the TU settings.

Linearization

“0” = Average K factor

“1” = Linearization table

“F C METHOD = AVG” for Average K factor

or

“F C METHOD = LIN” for Linearization table

K Factor Decimal Point Location

“0” for 00000000.

“1” for 0000000.0 and all K Factors are less than

9999999.9, otherwise not allowed

“2” for 000000.00and all K Factors are less than 999999.99,

otherwise not allowed

“3” for 00000.000 and all K Factors are less than

99999.999, otherwise not allowed

“K-FAC DECL=(DATA)”

Average K Factor

“0.001” to

“99999.999” if KD = 3

“999999.99” if KD = 2

“9999999.9” if KD = 1

“ 99999999” if KD = 0

“AVG KFAC =(DATA)”

NP

Number Points in the Table

“2” to “20”

“NUM PTS =(DATA)”

- 13 -

Page 16

Command Description/Allowed Data/Response

F##

K##

TU

Frequency 1-20

F01 has a range of “0.000” to the value of F02 minus

0.001; F20 has a range of the value from F19 plus 0.001

to “5000.000”; Frequencies F02 to F19 must be 0.001

greater than the previous frequency and 0.001 less than the

next frequency.

“FREQ ## =(DATA)” for F01 through F20. Data to

fixed three decimal places.

K-Factor 1-20

“K-FACT # =(DATA)” for K01 through K09.

“K-FACT ## =(DATA)” for K10 through K20.

DATA to decimal places as per KD command.

Total Units

“100” for gallons

“140” for liters

“110” for cubic feet

“150” for cubic meters

“180” for barrels

All other integer values from 0 and less than 999 will map to

custom units

“TOT UNITS =(DATA)”

(DATA) shall be:

“GAL” for gallons

“LIT” for liters

“FT3” for cubic feet

“M3 ” for cubic meters

“BBL” for barrels

“CUS” for custom

These three numbers will be the same as the first three digits

of the tag number. Changes to this menu shall cause the

changes to the tag number.

- 14 -

Page 17

Command Description/Allowed Data/Response

FM

NB

LF

AF

Rate Units

“0” for seconds

“1” for minutes

“2” for hours

“3” for days

“FLOW UNITS=(DATA)”

(DATA) shall be:

“SEC” for seconds

“MIN” for minutes

“HR ” for hours

“DAY” for days

Max Sample Time

“1” to “80”

“MAX M TIME=(DATA)”

Out Low

“0.000” to a maximum value of the Out High setting

“4mA FLOW =(DATA)”

Out High

Minimum is the Out Low Setting (LF) to a maximum of the

following:

“99999.999” if RD = 3

“999999.99” if RD = 2

“9999999.9” if RD = 1

PA

OC

“ 99999999” if RD = 0

“20mA FLOW =(DATA)”

Password

“0” to “9999”

“PASS WORD =(DATA)”

Current Out

“0” - Current output follows rate.

“1” - Current output set to 4mA.

“2” - Current output set to 12mA.

“3” - Current output set to 20mA.

For “0”, response = “ Output equal to input.”

For “1”, response = “ Output is 4mA.”

For “2”, response = “ Output is 12mA.”

For “3”, response = “ Output is 20mA.”

- 15 -

Page 18

System Commands Supported by Communications Messages

System

Command

OI

MO

OM

OF

AA

DA

UI

Description/Response/Comments

Output 4mA

“ Output is 4mA.”

Current output set to 4mA.

Output 12mA

“ Output is 12mA.”

Current output set to 12mA.

Output 20mA

“ Output is 20mA.”

Current output set to 20mA.

Output = Rate (Input)

“ Output equal to input.”

Current output follows rate.

Auto Data

“F (DATA) R (DATA) T (DATA)”

The response, not the echo, is sent every two seconds until it

receives another message from the master. The (DATA)

following the F denotes the frequency of the pulses to a

precision of three places past the decimal, the (DATA)

following the R denotes the rate to a precision of three

places past the decimal, and the (DATA) following the T

denotes the total to a precision of three places past the

decimal.

Dump All

All of the responses in previous table.

The FLSC-C1-LIQ gives all responses except for the CL

command.

Unit Identification

“UNIT MODEL=HIT2A XX YY.ZZ”

Model and software number for the unit. XX is the hardware

revision number, YY.ZZ is the software revision where YY

is the major software revision and ZZ is the minor software

revision.

- 16 -

Page 19

System

Command

RR

CN

CM

Description/Response/Comments

Read Rate

“FLOW = (DATA)”

(DATA) = “0” to the following maximums:

“99999.999” if RD = 3

“999999.99” if RD = 2

“9999999.9” if RD = 1

“ 99999999” if RD = 0

Adjust 4mA output point

“CN=#(DATA)”

(DATA) is the integer value that the FLSC-C1-LIQ sends

to the 4-20mA converter to output 4mA

This parameter is passed to the FLSC-C1-LIQ to adjust the

4mA output point of the device. This value is used in

production at the test step to calibrate the 4mA output point.

“CN” will cause an Invalid Command response and absence

of the # symbol will cause the FLSC-C1-LIQ to ignore the

data.

Adjust 20mA output point

“CM=#(DATA)”

(DATA) is the integer value that the FLSC-C1-LIQ sends

to the 4-20mA converter to output 20mA

This parameter is passed to the FLSC-C1-LIQ to adjust the

20mA output point of the device. This value is used in

production at the test step to calibrate the 20mA output

point. “CM” will cause an Invalid Command response and

absence of the # symbol will cause the FLSC-C1-LIQ to

ignore the data.

- 17 -

Page 20

- 18 -

Page 21

-19-

M-5130/0412

Loading...

Loading...