Page 1

FL0W METER PROCESS CONTROL

INFORMATION SYSTEMS

FLR Series

Optional

FLR Flow Sensors

U 2% FS Accuracy

U No Straight Pipe

Run Required

U Mounts in Any Position

U 4 to 20 mA,

0 to 5 Vdc, and

0 to 10 Vdc

Standard Outputs

U Digital Flow Rate

and Total

Flow Indicator

U In-Field

Compensation for:

– Specific Gravity

of All Fluids

– Viscosity of

Petroleum-Based Fluids

– Specific Gravity,

Pressure, and

Temperature of

Pneumatic Applications

B2B2

Rugged In-Line Flow Sensors

Available in 13 mm (1⁄2"), 19 mm (3⁄4"), and 32 mm

(11⁄4") sizes with anodized aluminum or brass. Comes

with 4.5 m (15') of stripped end integral cable. In the

field, integral cable can be extended up to 300 m

(1000') with shielded copper cable. Units are securely

FLR7330D shown

smaller than actual size.

protected in a sturdy cast aluminum enclosure, and

are easy to install and mount in any position, vertical

or horizontal. Capable of monitoring fluids to 150 GPM

or pneumatic lines to 1000 SCFM.

B-67a

Page 2

SPECIFICATIONS

Temperature Range:

-29 to 116°C (-20 to 240°F)

Maximum Pressure: 3500 psig

(liquids); 1000 psig (gases)

Power Requirement:

0 to 5 Vdc Output: 10 to 30 Vdc @

0.75 W maximum

0 to 10 Vdc Output: 12 to 30 Vdc @

0.75 W maximum

4 to 20 mA Output: Loop-powered,

30 Vdc maximum

Power Consumption: 25 mA maximum

Circuit Protection:

Reverse polarity and current limit

Repeatability: ±0.5%

Non-Linearity: ±0.05%

Isolation: Inherently isolated from

the piping system

Display: Fixed or toggle modes of

operation for rate and totalizer display.

8-digit, 0.70" high numeric display

for rate and total 8-digit 0.35" high

alphanumeric display for units

and setup

Response Time: 1.0 sec

Temperature Drift:

0.05% of span per °C maximum

Analog Outputs:

4 to 20 mA into 1KΩ maximum

0 to 5 Vdc into 10KΩ minimum

0 to 10 Vdc into 10KΩ minimum

User Connections:

15' pig-tail (standard)

Transmission Distance:

4 to 20 mA limited by cable resistance

0 to 5 Vdc 300 m (1000') maximum

0 to 10 Vdc 300 m (1000') maximum

Enclosure:

Material: Anodized and epoxy

powder-coated aluminum with

polycarbonate lens

Seals: Silicone gasket between

enclosure and lens/cover FKM

O-rings between enclosure and

flow meter body

Connection: 4-pin connection

(standard)

Fasteners: T303 SS

Rating: NEMA 12 and 13 (IP52/54)

Materials:

2024 - T351 anodized aluminum

body, piston and cone C360 brass

body, piston and cone petroleum (oil)

common parts

Spider Plate: T316 SS

Spring: T302 SS

Fasteners: T303 SS

Pressure Seals: FKM

Lens: Polycarbonate

Retaining Ring: SAE 1070/1090

carbon steel

Retaining Spring: SAE 1070/1090

carbon steel

Internal Magnet: PPS/ceramic

Enclosure Seal: Silicone gasket

water-based, water, air

common parts

Spider Plate: T316 SS

Spring: T302 SS

Fasteners: T303 SS

Pressure Seals: FKM

Lens: Polycarbonate

Retaining Ring: T316 SS

Retaining Spring: ST316 SS

Internal Magnet: PPS/ceramic

Enclosure Seal: Silicone gasket

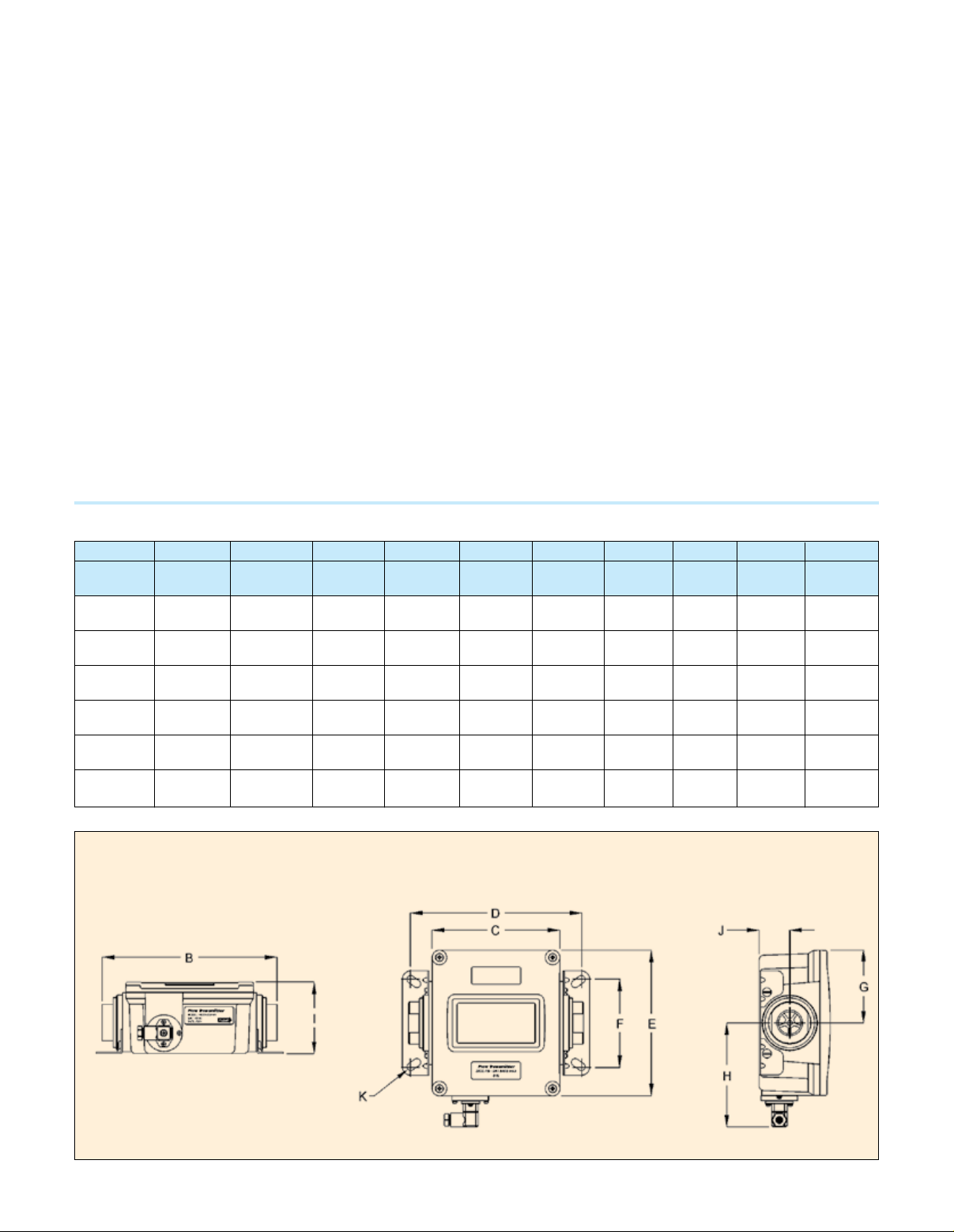

Dimensions: mm (in)

B C D E F G H I J K

Nominal

Port Size Length Length Length Width Width Width Width Depth Offset Hole Dia.

¹⁄₄ 168 134 163 152 82 76 107 75 38 8

(SAE 6) (6.60) (5.27) (6.41) (6.00) (3.23) (3.00) (4.20) (2.94) (1.51) (0.31)

¹⁄₂ 168 134 163 152 82 76 107 75 38 8

(SAE 10) (6.60) (5.27) (6.41) (6.00) (3.23) (3.00) (4.20) (2.94) (1.51) (0.31)

³⁄₄ 183 134 179 152 91 76 107 75 32 8

(SAE 12) (7.20) (5.27) (7.04) (6.00) (3.60) (3.00) (4.20) (2.94) (1.27) (0.31)

1 183 134 179 152 91 76 107 75 32 8

(SAE 16) (7.20) (5.27) (7.04) (6.00) (3.60) (3.00) (4.20) (2.94) (1.27) (0.31)

1¹⁄₄ 310 271 296 194 123 97 128 114 56 8

(SAE 20) (12.20) (10.68) (11.65) (7.63) (4.84) (3.82) (5.02) (4.50) (2.20) (0.31)

1¹⁄₂ 310 271 296 194 123 97 128 114 56 8

(SAE 24) (12.20) (10.68) (11.65) (7.63) (4.84) (3.82) (5.02) (4.50) (2.20) (0.31)

B-67b

Page 3

FLR9110D

FLR6305D

To Order

Model No. Flow Range Medium NPT Body

FLR6102D 0.2 to 2.0 GPM Oil ¹⁄₂ Aluminum

FLR6105D 0.5 to 5.0 GPM Oil ¹⁄₂ Aluminum

FLR6115D 1 to 15 GPM Oil ¹⁄₂ Aluminum

FLR7120D 0.2 to 2.0 GPM Oil ³⁄₄ Aluminum

FLR7130D 3 to 30 GPM Oil ³⁄₄ Aluminum

FLR8140D 4 to 40 GPM Oil 1 Aluminum

FLR8150D 5 to 50 GPM Oil 1 Aluminum

FLR9175D 10 to 75 GPM Oil 1¹⁄₄ Aluminum

FLR9110D 10 to 100 GPM Oil 1¹⁄₄ Aluminum

FLR9115D 10 to 150 GPM Oil 1¹⁄₄ Aluminum

FLR6302D 0.2 to 2.0 GPM Water ¹⁄₂ Brass

FLR6305D 0.5 to 5.0 GPM Water ¹⁄₂ Brass

FLR6315D 1 to 15 GPM Water ¹⁄₂ Brass

FLR7320D 2 to 20 GPM Water ³⁄₄ Brass

FLR7330D 3 to 30 GPM Water ³⁄₄ Brass

FLR8340D 4 to 40 GPM Water 1 Brass

FLR8350D 5 to 50 GPM Water 1 Brass

FLR9375D 10 to 75 GPM Water 1¹⁄₄ Brass

FLR9310D 10 to 100 GPM Water 1¹⁄₄ Brass

FLR9315D 10 to 150 GPM Water 1¹⁄₄ Brass

FLR6725D 2 to 25 SCFM Air 100 psi ¹⁄₂ Aluminum

FLR6750D 5 to 50 SCFM Air 100 psi ¹⁄₂ Aluminum

FLR7710D 10 to 100 SCFM Air 100 psi ³⁄₄ Aluminum

FLR7715D 15 to 150 SCFM Air 100 psi ³⁄₄ Aluminum

FLR8725D 25 to 250 SCFM Air 100 psi 1 Aluminum

FLR9740D 25 to 400 SCFM Air 100 psi 1¹⁄₄ Aluminum

FLR9760D 50 to 600 SCFM Air 100 psi 1¹⁄₄ Aluminum

FLR9710D 100 to 1000 SCFM Air 100 psi 1¹⁄₄ Aluminum

Comes complete with operator’s manual.

For 5-point NIST certificate add “-NIST5” to model number for additional cost.

For British standard pipe thread parallel add “-BSPP” to model number, no additional cost.

Ordering Examples: FLR6105D, flow transmitter, 0.5 to 5.0 GPM for oil, with analog output FLR5101D, flow transmitter, 0.1 to 1.0 GPM for oil

with analog output.

Visit omega.com/flr-d for Pricing and Details

All shown smaller than actual size.

FLR7130D

B2

B-67c

Loading...

Loading...