Omega Products FLR-1600A Installation Manual

FLR-1600A and FLV-4600A Series

Water Flow Meters and Controllers

08/08/2007 Rev.3 DOC-OMEGALIQMAN

Notes for Using FLR-1600A and FLV-4600A Water Flow Devices

USE ONLY PURE, CLEAN DI OR DISTILLED WATER IN THIS DEVICE. ►

DO NOT ► use tap water, water with any biological components, minerals or oils.

Any of these substances will a ect the viscosity of the water (creating ow

measurement inaccuracies). More importantly, any impurities will quickly

build up inside the small laminar fl ow channels and damage

the sensors.

If you cannot meet the requirement of pure water, then do not use the laminar

water ow device in your application. Damage caused by impurity build up is not

covered by the warranty.

Please read the operating manual that accompanied your device. Keep the manual ►

for future reference.

When rst using the laminar water meter or controller for the day, please take the ►

following precautions:

Apply your source pressure (approx. 20-30 PSIG for best results) to the device 1.

with the downstream ow blocked o .

Then slightly open both bleed ports (DO NOT completely remove the screws) 2.

and allow any trapped air to escape. Allow some ow and let water pass through

while bleeding (if the unit is a controller be sure to give it at least a 50% setpoint). See page 8 of the manual for more information regarding bleed ports

and bleeding.

Try not to get any water in-between the black electronics case and the stainless 3.

steel ow body. Wipe up any excess water around these seams.

Tighten up both bleed screws, and then block the downstream water ow again. 4.

Visually verify zero ow through.

Now you can safely tare (zero) a meter (5. page 13) using the tare button on the

device, or in the case of a water ow controller, command the zero set-point

(page 18) which will auto-tare the unit.

Smooth and consistent source pressure is highly preferable, as any pulsing or ►

uctuation in water pressure will hydraulically couple to the di erential pressure

sensor, and the resultant ow reading will jump analogously.

Please note that, depending on model and ow range, water ow meters have an ►

inherent internal pressure drop higher than that of standard gas ow meters. The

minimum water device pressure drop is 2 PSID, going all the way to 20 PSID drop in

certain models. Your source input pressure must meet or exceed this speci cation,

in addition to any back pressure you may have on the downstream end of your

process. Please see page 29 of the manual.

Please contact Omega if you have any questions.

Table of Contents Page

Flow Measurement Operating Principle 5

Flow Control Operating Principle 6

Installation 7

Plumbing 7

Mounting 7

Application 7

Bleed Ports 8

Power and Signal Connections 9

Analog Input Signal 10

RS232 Digital Input Signal 10

Optional RS485 Input Signal 10

RS232 Digital Output Signal 10

Optional RS485 Output Signal 10

Standard Voltage (0-5 Vdc) Output Signal 11

Optional 0-10 Vdc Output Signal 11

Optional Current (4-20 mA) Output Signal 11

Optional 2nd Analog Output Signal 11

FLR-1600A Series Water Flow Meter Operation 13

Main Mode 13

Tare 13

Line Pressure 14

Line Temperature 14

Volume 14

Flashing Error Message 14

Select Menu Mode 14

Communication Select Mode 15

Unit ID 15

Baud 15

Data Rate 15

Manufacturer Data 16

Miscellaneous Mode 16

LCD Contrast 17

Display Zero Deadband 17

Pressure Averaging 17

Flow Averaging 17

FLV-4600A Series Water Flow Meter Operation 18

Main Mode 18

Line Pressure 18

Line Temperature 18

Set Pt. 18

Flashing Error Message 18

Select Menu Mode 19

Control Setup Mode 19

Input 19

Loop 20

Select 20

Table of Contents Page

Communication Select 21

Manufacturer Data 21

Miscellaneous Mode 21

RS232 / RS485 Output and Input 21

Confi guring HyperT erminal® 21

Changing from Streaming to Polling Mode 21

Tareing via RS232 / RS485 22

Sending a Set-Point via RS232 / RS485 22

Adjusting P & D Terms via RS232 / RS485 23

Collecting Data 24

Data Format 24

Sending a Simple Script File to HyperTerminal® 25

Troubleshooting 26

Maintenance and Recalibration 27

Flow Conversion Table 28

Technical Specifi cations 29

Dimensional Drawings 30

Additional Information

Option: Totalizing Mode 33

Option: FLR-1600A -B Portable Meters 34

Accessory: FMA1600-MDB Multi-Drop Box 35

Accessories 35

Eight Pin Mini-DIN Pin-Out 36

DB15 Pin-Outs 37

Calibration Certifi cate Pocket 39

Warranty / Returns 41

Table of Figures

Figure 1. Bleed Ports 8

Figure 2. 8 Pin Mini-DIN Connector 9

Figure 3. Simple Method for Providing Set-Point to Controllers 10

Figure 4. Mini-DIN to DB-9 Connection for RS232 Signals 11

Figure 5. Typical Multiple Device (Addressable) Wiring Confi guration 12

Figure 6. Main Mode Display, FLR-1600A Series Flow Meter 13

Figure 7. Proper Set Up for Remote Tare on Meters 14

Figure 8. Select Menu Display 14

Figure 9. Communication Select 15

Figure 10. Manufacturer Data 16

Figure 11. Miscellaneous Mode Display 17

Figure 12. Main Mode Display, FLV-4600A Series Flow Meter 18

Figure 13. FLV-4600A Series Control Setup Display 19

Thank you for purchasing an FLR-1600A Series Water Flow Meter or FLV-4600A Series Water Flow

Controller. Please take the time to fi nd and read the information contained in this manual. This will help

to ensure that you get the best possible service from your instrument. This manual covers the following

Omega instruments:

FLR-1600A Series Water Flow Meters

FLV - 4600A Series Water Flow Controllers

FLR-1600A-B Series Portable Water Meters

(Note: All FLR-1600A-B Series Portable Water Meters operate in accordance with the instructions

found in this manual. Please see page 34 for information regarding battery replacement.)

Flow Measurement Operating Principle

All FLR-1600A or FL V -4600A Series W ater Flow Meters/Controllers accurately determine the fl ow rate by

creating a pressure drop across a unique internal restriction, known as a Laminar Flow Element (LFE),

and measuring differential pressure across it. The restriction is designed so that the water molecules are

forced to move in parallel paths along the entire length of the passage; hence laminar (streamline) fl ow

is established for the entire range of operation of the device. Unlike other fl ow measuring devices, in

laminar fl ow meters the relationship between pressure drop and fl ow is linear. The underlying principle

of operation of the fl ow meters is known as the Poiseuille Equation:

Q = (P1-P2)πr4/8ηL (Equation 1)

Where: Q = Volumetric Flow Rate

P

= Static pressure at the inlet

1

P2= Static pressure at the outlet

r = Radius of the restriction

η

= (eta) absolute viscosity of the fl uid

L = Length of the restriction

Since p, r and L are constant; Equation 1 can be rewritten as:

Q = K (ΔP/η) (Equation 2)

Where K is a constant factor determined by the geometry of the restriction. Equation 2 shows the linear

relationship between volumetric fl ow rate (Q) differential pressure (DP) and absolute viscosity (h) in a

simpler form.

In order to have an accurate reading of the fl ow rate, the absolute viscosity of the fl uid must be established.

The rate at which liquids change viscosity with changes in temperature is not linear. The relationship

between temperature and viscosity for water is well established and Omega FLR-1600A and FLV -4600A

Series units utilize a high accuracy temperature sensor and this relationship to provide an accurate

viscosity reference. For this reason, these meters and controllers are generally recommended

only for use with pure water. Any additives to water (such as antifreeze or disinfectants) that might

affect the viscosity should be avoided. As shown in Equation 2, an error in viscosity between the actual

fl uid and water will result in a 1:1 error percentage in the fl ow rate reported by the meter. For instance if

the actual fl uid passing through the meter is 5% different than that of pure water at a given temperature,

the reported fl ow rate will be 5% inaccurate.

5

Flow Control Operating Principle

For the purposes of this explanation, the term “valve” will refer to the proportional control valve mounted

on the controller. The term “controller” will refer to the fl ow meter and the measurement and control

electronics portion of the device. In actuality, the whole device is generally referred to as a controller.

The valve normally mounted downstream of the controller.

FLV-4600A Series Flow Controllers ship with a normally closed proportional control valve. No fl ow

will occur until the valve receives a voltage signal from the controller, and the controller will not send

a voltage signal to the valve until the user provides a set-point to the controller. The user can provide

a set-point either locally via the display and user interface buttons, or more commonly, by providing

an external signal that corresponds to the fl ow range of the controller. This external signal can be an

analog voltage or current signal such as a 0-5 Vdc or 4-20 mA signal, or a digital RS232 / RS485 signal

via serial communication with a computer.

The controller utilizes what is called PID (Proportional, Integral, Derivative) loop control circuitry and

software. The PID loop control works by repeatedly comparing the measured fl ow rate to the set-

point and incrementally adjusting the voltage signal to the valve in a continuous attempt to match the

measured fl ow rate to the set-point. For example, at any given time the controller looks at the measured

fl ow rate and the set-point, if the set-point is higher than the measured fl ow rate, the controller will

slightly increase the voltage signal to the valve and thus open it little more. If the set-point is lower than

the measured fl ow rate, the controller will slightly decrease the voltage signal to the valve and thus

close it off a little more. This look, compare, and adjust “loop” occurs on the order of 1000 times each

second.

FLV-4600A Series Flow Controllers ship with a general PID tuning that is usually suffi cient for most

applications. Occasionally an application will require the customer to change this tuning. The Proportional

and Derivative terms can be fi eld adjusted in all FLV-4600A Series controllers. In very general terms,

the P term can be thought of as how fast the controller responds to change and the D term can be

thought of as a damping factor.

6

Installation

Plumbing

All FLR-1600A Series Meters and FLV-4600A Series Controllers are equipped with female inlet and

outlet port connections. Because the fl ow meters set up a laminar fl ow condition within the fl ow body, no

straight runs of pipe are required upstream or downstream of the meter. The inlet and outlet ports are

equal in size and symmetric (in-line). The port sizes (process connections) and mechanical dimensions

for different fl ow ranges are shown on page 30.

Meters with M5 (10-32) ports have o-ring face seals and require no further sealant or tape. On other

meters/controllers, avoid the use of pipe dopes or sealants on the ports as these compounds can cause

permanent damage to the meter should they get into the fl ow stream. Use of thread sealing PFA tape is

recommended to prevent leakage around the threads. When applying the tape, avoid wrapping the fi rst

thread or two to minimize the possibility of getting a piece of shredded tape into the fl ow stream. When

changing fi ttings, always clean any tape or debris from the port threads.

It is also recommended that a 20 micron fi lter be installed upstream of meters/controllers with full scale

ranges of 100CCM or less and a 50 micron fi lter be installed upstream of meters/controllers with full

scale ranges above 100CCM.

Note: Avoiding long runs of small diameter tubing upstream or downstream of controllers will

reduce water hammer.

Mounting

All FLR-1600A Series Meters and FLV-4600A Series Controllers have mounting holes for convenient

mounting to fl at panels. These meters are position insensitive and can be mounted in any orientation.

The sizes and dimensions for the mounting holes are shown on pages 31-33.

Note: For applications that may continuously introduce occasional air bubbles to the fl ow stream

upstream of the device, the device may be mounted upside down to prevent the bubbles from becoming

trapped in the differential pressure sensor ports. If the device has been installed upside down, avoid

using the bleed screws as water may leak into the electronics housing causing permanent damage that

is not covered under warranty!

Application

Maximum operating line pressure is 100 PSIG (689 kPa). Caution: Exceeding the maximum specifi ed

line pressure may cause permanent damage to the solid-state differential pressure transducer.

If the line pressure is higher than the 100 PSIG (689 kPa), a pressure regulator should be used upstream

from the fl ow meter to reduce the pressure to 100 PSIG (689 kPa) or less if possible. Although the

meter’s operation is uni-directional, reversing the fl ow direction will infl ict no damage as long as the

maximum specifi ed limits are not exceeded. The differential pressure sensor utilized in this fl ow meter/

controller is a very sensitive device capable of detecting minute differences in pressure.

Avoid installations (such as snap acting solenoid valves upstream) that apply instantaneous

high pressure to the meter as permanent damage to the differential pressure sensor could

result. This damage is not covered under warranty!

7

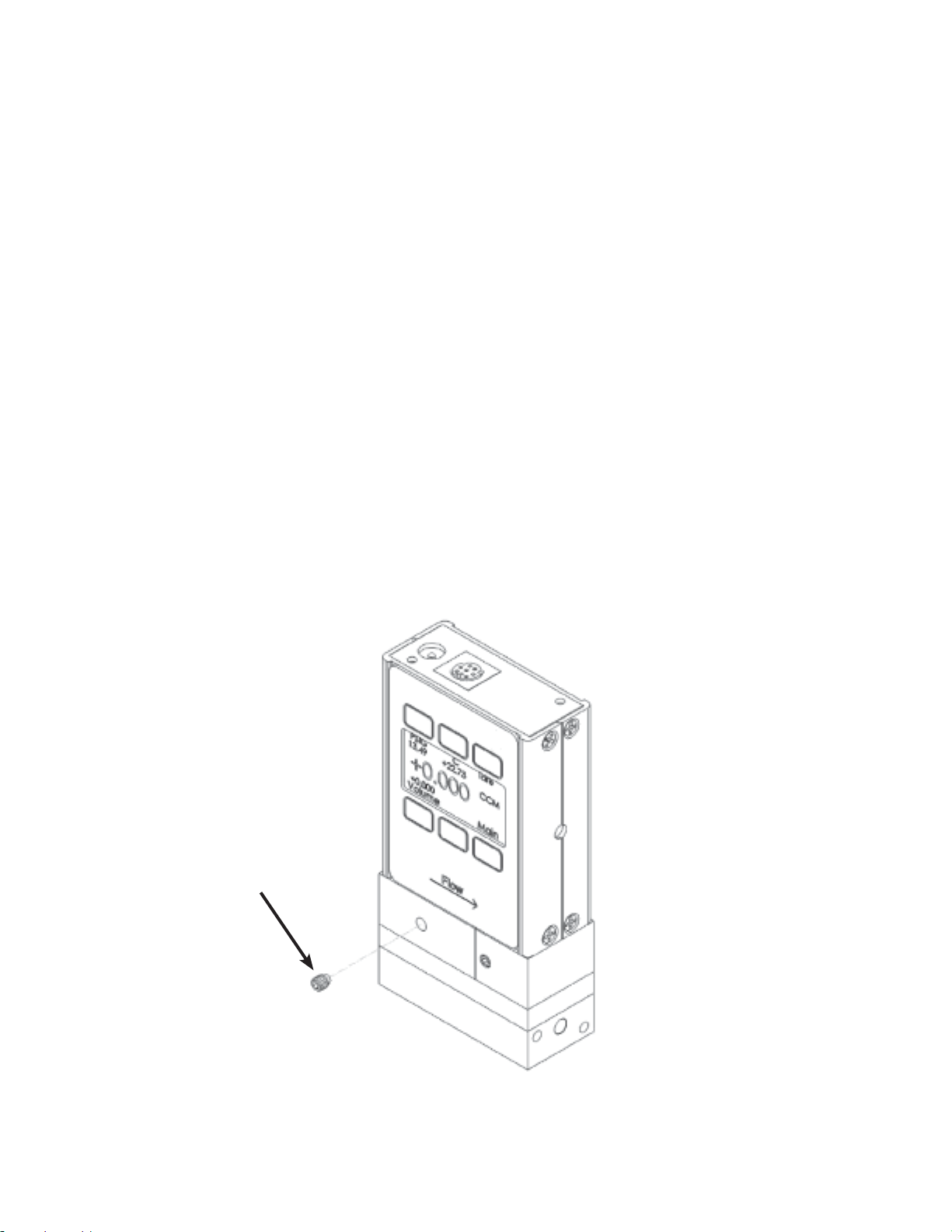

Bleed Ports

FLR-1600A and FLV-4600A Series fl ow meters and controllers are equipped with bleed ports on the

front to aid in the removal of air bubbles from the differential pressure sensor ports. The bleed ports

consist of a threaded hole with an 8-32 nylon tipped screw as shown in Figure 1. After installation or

anytime it is suspected that air may be trapped in the sensor ports, bleed the ports as follows:

CAUTION: A small amount of water will leak from the device during this procedure. Take necessary

precautions to prevent the leaking water from damaging anything around the unit, taking special care

to avoid any live electrical devices or lines.

With the meter/controller installed and line pressure applied, gently loosen the upstream bleed port

screw 1-2 turns or until water begins to leak from the threads. DO NOT REMOVE THE SCREW as the

port is subject to line pressures and injury, equipment damage, or loss of required parts may result!

Gently tap the fl ow body (a wooden or plastic screwdriver handle works well for this) to encourage air

bubbles to exit the port.

Any air in the port will generally be removed as the water leaks out even though you may not see or

hear it.

Gently tighten the screw until the leakage stops, taking care not to crush the nylon tip.

Repeat steps 1-4 with the second bleed port.

8-32 Nylon Tipped Bleed Screw

5/64 Hex Loosen to Bleed

DO NOT REMOVE!

Figure 1. Bleed Ports

8

Power and Signal Connections

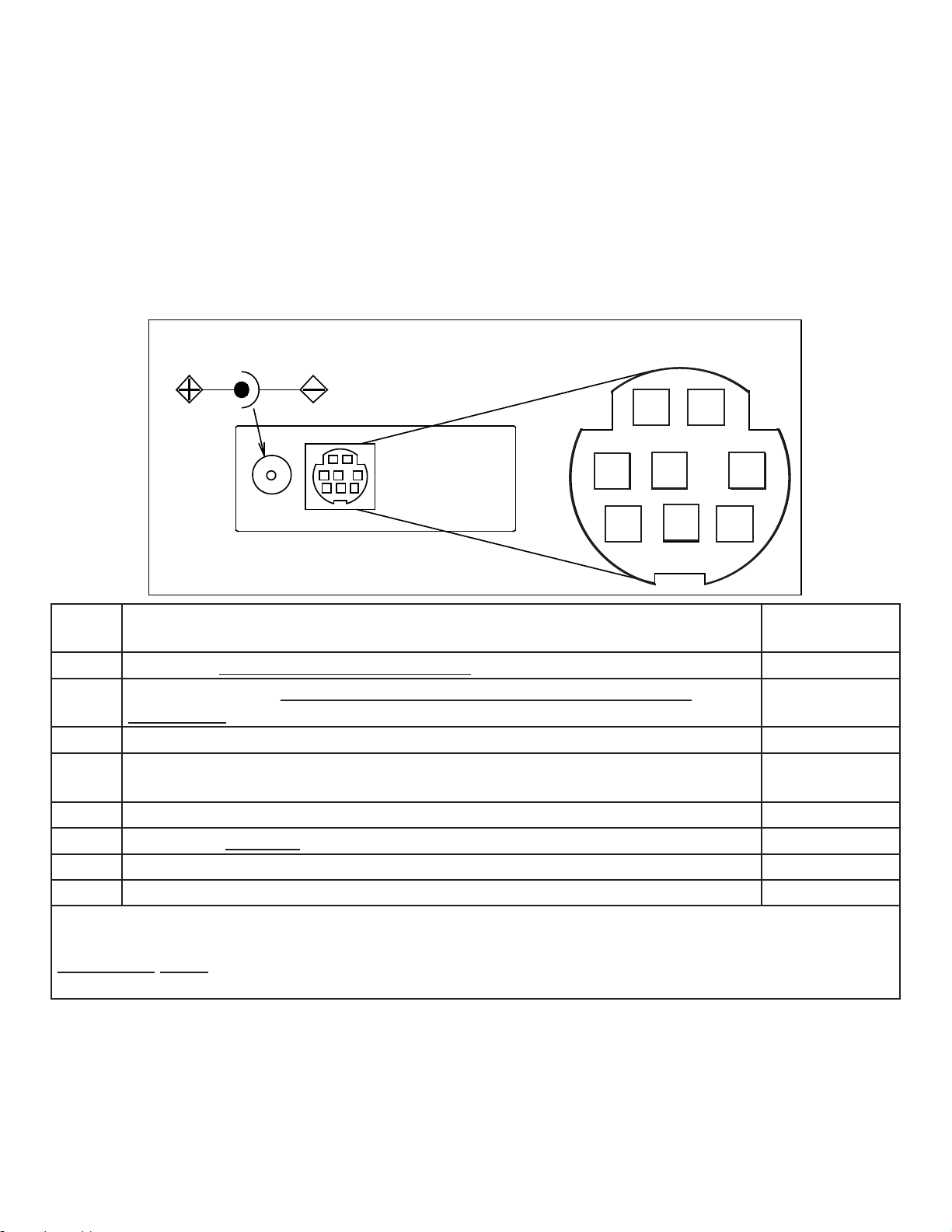

7 8

1 2

3 4 5

AC/DC Adap ter Jack

6

Power can be supplied to your meter or controller through either the AC/DC adapter jack or through the

8 pin Mini-DIN connector as shown in Figure 2.

A 2.1mm, positive center, 7-30 Vdc AC/DC adapter rated for at least 100 mA is required to use the

adapter jack in a FLR-1600A Series meter.

A 2.1mm, positive center, 12-30 Vdc AC/DC adapter rated for at least 250 mA is required to use the

adapter jack in a Small Valve FLV -4600A Series controller. Note: 4-20mA output requires at least 15 Vdc.

A 2.1mm, positive center, 24-30 Vdc AC/DC adapter rated for at least 500 mA is required to use the

adapter jack in a Large Valve FLV-4600A Series controller.

Cables can be purchased from Omega (see Accessories on page 40) or they are available from

electronics suppliers. Alternatively, power can be supplied through the Mini-DIN connector as shown

below:

1

3

6

Pin Function

1

2

3 RS232 Input Signal Red

4

5 RS232 Output Signal Yellow

6

7 Power In (as descibed above) Blue

8 Ground (common for power, communications and signals) Purple

Note: The above pin-out is applicable to all the fl ow meters and controllers available with the Mini-

DIN connector. The availability of different output signals depends on the fl ow meter options ordered.

Underlined Items in the above table are optional confi gurations that are noted on the unit’s

calibration sheet.

Inactive or 4-20mA Primary Output Signal Black

Static 5.12 Vdc or Secondary Analog Output (4-20mA, 5Vdc, 10Vdc) or

Basic Alarm

Analog Input Signal = Remote Tare (Meters - see Figure 8)

= Set-Point In (Controllers - see Figure 3)

0-5 Vdc (or 0-10 Vdc) Output Signal Green

2

4 5

7

8

Mini-DIN

cable color

Brown

Orange

Figure 2. 8 Pin Mini-DIN Connector

CAUTION:Do not connect power to pins 1 through 6 as permanent damage can occur!

Note: Upon initial review of the pin out diagram in Figure 2, it is common to mistake Pin 2 (labeled

5.12 Vdc Output) as the standard 0-5 Vdc analog output signal! In fact Pin 2 is normally a constant

5.12 Vdc that refl ects the system bus voltage and can be used as a source for the input signal. This

allows the user in the fi eld to run this output through a 50K ohm potentiometer and back into the analog

set-point pin to create a 0-5 Vdc set-point source (see Figure 3).

9

Analog Input Signal

Apply analog input to Pin 4 as shown in Figure 2.

Unless ordered otherwise, 0-5 Vdc is the standard analog input signal. Apply the 0-5 Vdc input signal

to pin 4, with common ground on pin 8. The 5.12 Vdc output on pin 2 can be wired through a 50K ohm

potentiometer and back to the analog input on pin 4 to create an adjustable 0-5 Vdc input signal source

as in Figure 3 below.

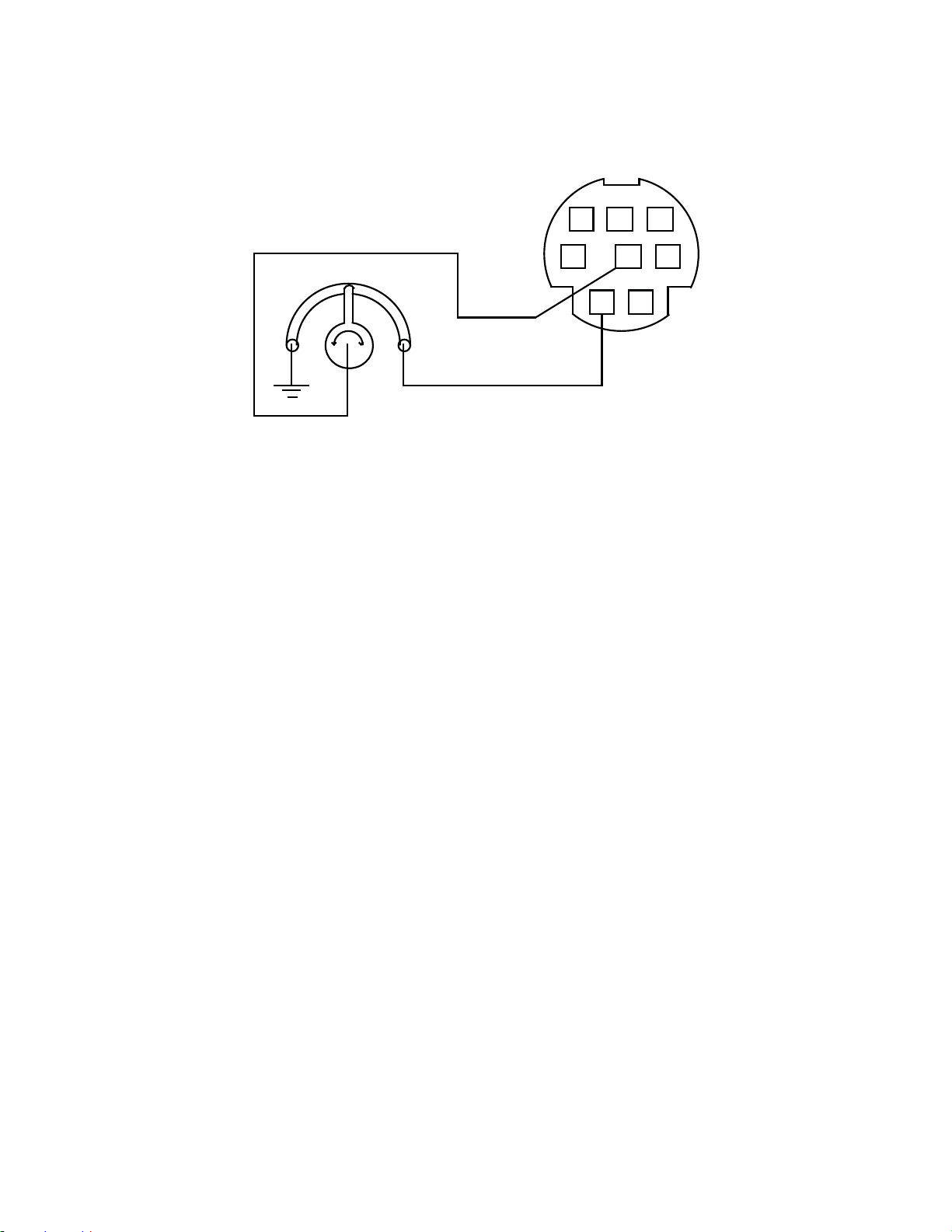

6

7

8

0-5 Vd c

3

5

4

1

2

5.12 Vdc

50 KOhm

P o te n ti o meter

Figure 3. Simple Method for Providing Set-Point to Controllers

Optional 0-10 Vdc: If specifi ed at time of order, a 0-10 Vdc input signal can be applied to pin 4, with

common ground on pin 8.

Optional 4-20 mA: If specifi ed at time of order, a 4-20 mA input signal can be applied to pin 4, with

common ground on pin 8.

RS232 Digital Input Signal

If you will be using the RS232 output signal, it is necessary to connect the RS232 Output Signal (Pin 5),

the RS232 Input Signal (Pin 3), and Ground (Pin 8) to your computer serial port as shown in Figure 4.

Adapter cables are available from Omega (see Accessories page 40) or they can be constructed in the

fi eld with parts from a local electronic supply house. In Figure 4, note that the diagrams represent the

“port” side of the connections, i.e. the connector on top of the meter and the physical DB-9 serial port

on the back of the computer. The cable ends will be mirror images of the diagram shown in Figure 4.

(See page 22 for details on accessing RS232 output and input.)

Optional RS485 Digital Input Signal

If you will be using the RS485 output signal, it is necessary to connect the RS485 Input Signal with the

appropriate DB15 pin out as shown on pages 43 and 44. (See page 22 for details on accessing RS485

output.)

RS232 Digital Output Signal

If you will be using the RS232 output signal, it is necessary to connect the RS232 Output Signal (Pin 5),

the RS232 Input Signal (Pin 3), and Ground (Pin 8) to your computer serial port as shown in Figure 4.

Adapter cables are available from the manufacturer or they can be constructed in the fi eld with parts

from an electronics supply house. In Figure 4, note that the diagrams represent the “port” side of the

connections, i.e. the connector on top of the meter and the physical DB-9 serial port on the back of the

computer. The cable ends will be mirror images of the diagram shown in Figure 4. (See page 22 for

details on accessing RS232 output.)

Optional RS485 Digital Output Signal

If you will be using the RS485 output signal, it is necessary to connect the RS485 Output Signal with

the appropriate DB15 pin out as shown on pages 43 and 44. (See page 22 for details on accessing

RS485 output.)

10

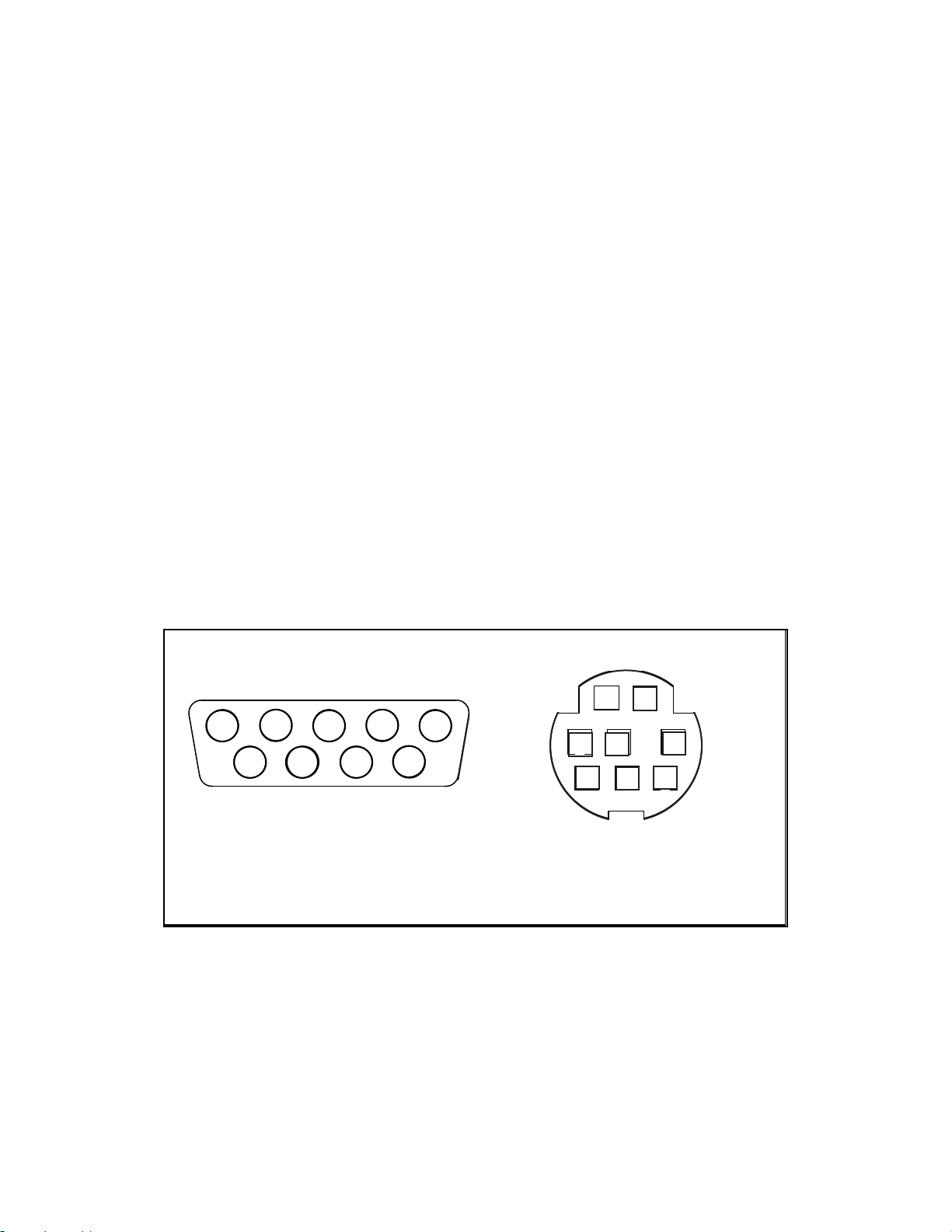

Standard Voltage (0-5 Vdc) Output Signal

7

4

6

21

DB-9 Serial Port

5

5----------Ground--------------------------------------Ground----------8

3----------Transmit------------------------------------Receive---------3

2----------Receive-------------------------------------Transmit--------5

8 Pin Min i-DIN Port

8

1 2 3 4 5

6 7

8 9

3

All FLR-1600A and FLV -4600A Series fl ow meters/controllers have a 0-5 Vdc (optional 0-10 Vdc) output

signal available on Pin 6. This is generally available in addition to other optionally ordered outputs. This

voltage is usually in the range of 0.010 Vdc for zero fl ow and 5.0 Vdc for full-scale fl ow. The output

voltage is linear over the entire range. Ground for this signal is common on Pin 8.

Optional 0-10 Vdc Output Signal

If your meter/controller was ordered with a 0-10 Vdc output signal, it will be available on Pin 6. (See the

Calibration Data Sheet that shipped with your device to determine which output signals were ordered.)

This voltage is usually in the range of 0.010 Vdc for zero fl ow and 10.0 Vdc for full-scale fl ow. The

output voltage is linear over the entire range. Ground for this signal is common on Pin 8.

Optional Current (4-20 mA) Output Signal

If your meter/controller was ordered with a 4-20 mA current output signal, it will be available on Pin 1.

(See the Calibration Data Sheet that shipped with your device to determine which output signals were

ordered.) The current signal is 4 mA at 0 fl ow and 20 mA at the meter’s full scale fl ow . The output

current is linear over the entire range. Ground for this signal is common on Pin 8. (Current output units

require 15-30Vdc power.)

Note: This is a current sourcing device. Do not attempt to connect it to “loop powered “ systems.

Optional 2nd Analog Output Signal

You may specify an optional 2nd analog output on Pin 2 at time of order. (See the Calibration Data

Sheet that shipped with your device to determine which output signals were ordered.) This output may

be a 0-5 Vdc, 0-10 Vdc, or 4-20 mA analog signal that can represent any measured parameter.

Note: This is a current sourcing device. Do not attempt to connect it to “loop powered “ systems.

2

4

6

Figure 4. Mini-DIN to DB-9 Connection for RS232 Signals

5

8

7

11

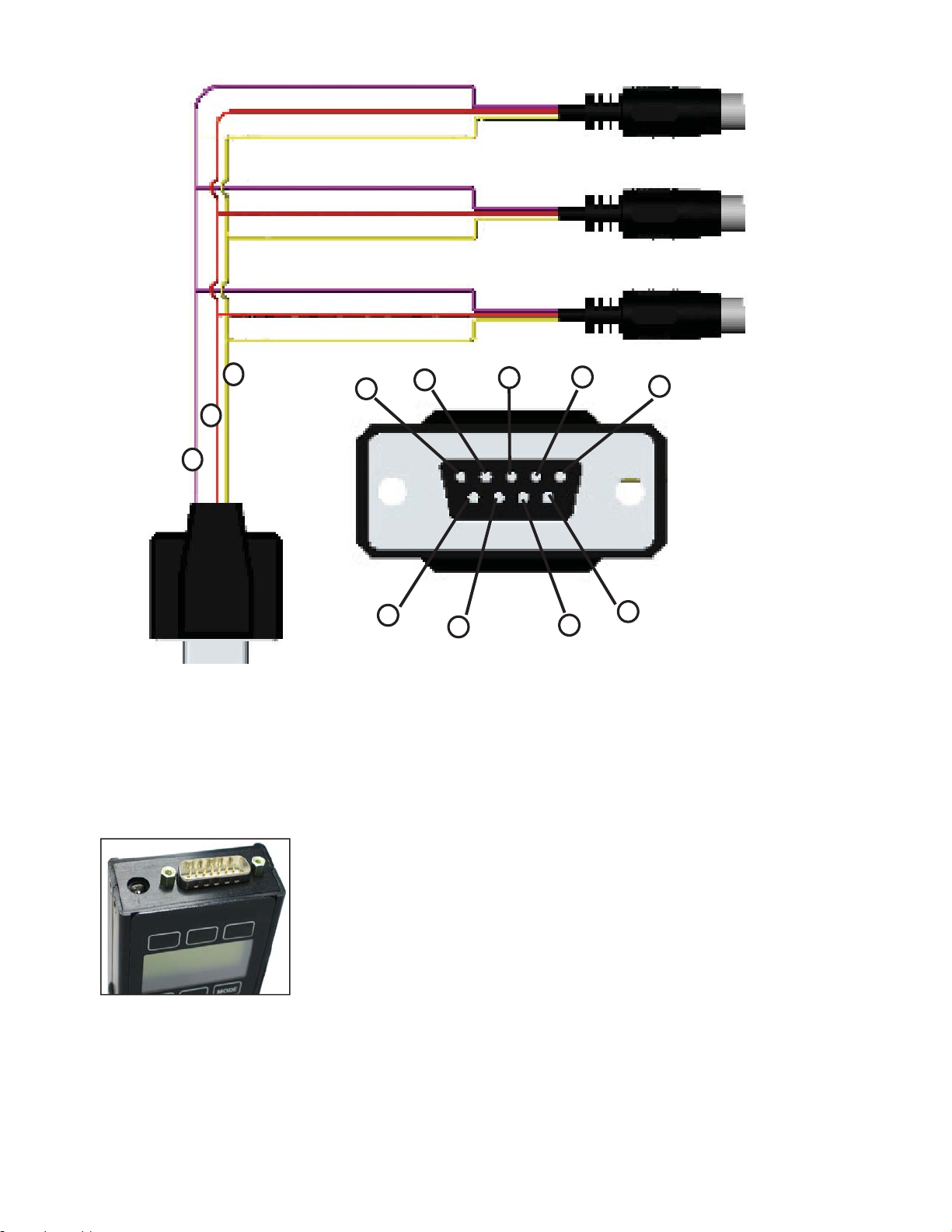

Purple (Ground)

Red

Yellow

Unit A

Purple

Red

Yellow

Unit B

Purple

Red

Yellow

Unit C

2

5

3

5

4

3

2

1

9

8

7

6

Female Serial Cable Front

Figure 5. Typical Multiple Device (Addressable) Wiring Confi guration

Note: The easiest way to connect multiple devices is with a FMA1600-MDB Multi-Drop Box (page 35).

(Note: FMA1600-MDB Multi-Drop Box is not compatible with RS485.)

DB15 Pin-out Diagrams:

Pin-out diagrams for devices ordered with a DB15

connector can be found on pages 37 and 38 .

All devices ordered with RS485 communications require a

DB15 connector.

12

Loading...

Loading...