Page 1

INSTALLATION, OPERATION

& MAINTENANCE INSTRUCTIONS

AIR COOLED CONDENSERS

FLUID COOLERS

HEAT RECLAIM UNITS

Page 2

CONTENT

SAFETY CONSIDERATIONS .........................2

INTRODUCTION..............................................2

HANDLING.......................................................3

INSTALLATION ...............................................3

STEPS #1 INSPECTION/LOCATION:..3

STEP #3 WIRING:.........................................3

STEPS #4 PIPING/LEAK TESTING ....3

OPERATION .....................................................4

FAN MOTORS/FAN CYCLING...................4

MAINTENANCE - CLEANING .......................4

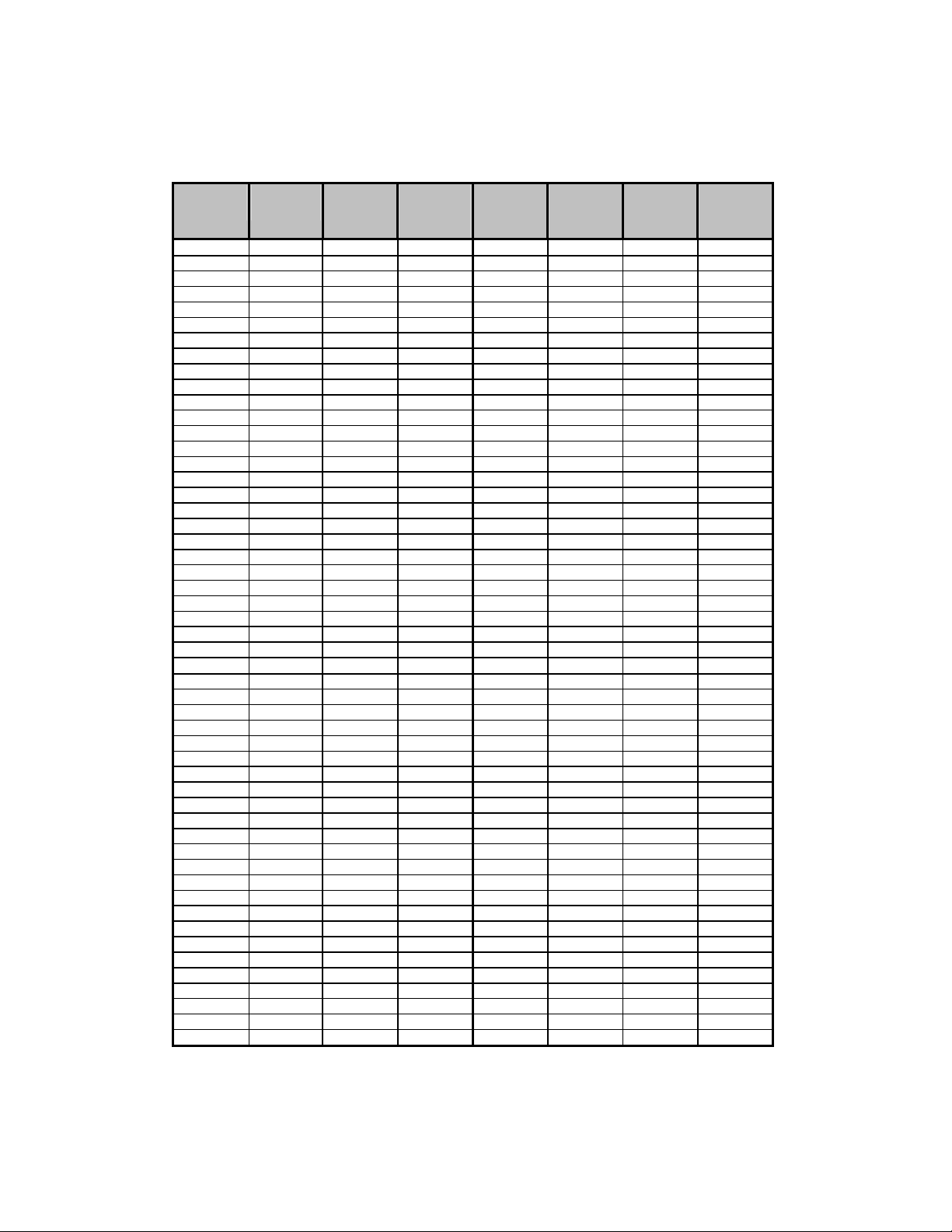

TABLE 1: FLUID COOLERS: ..........................5

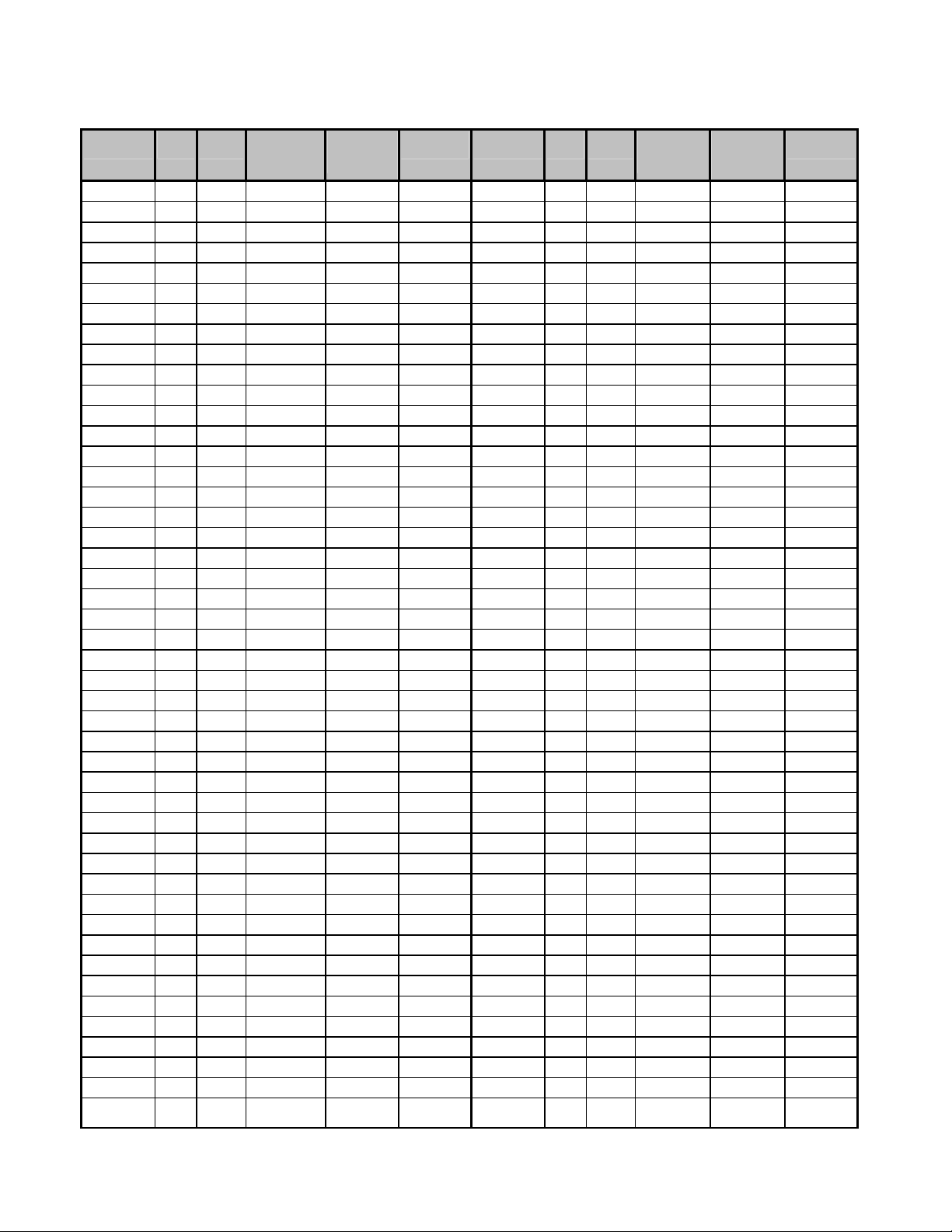

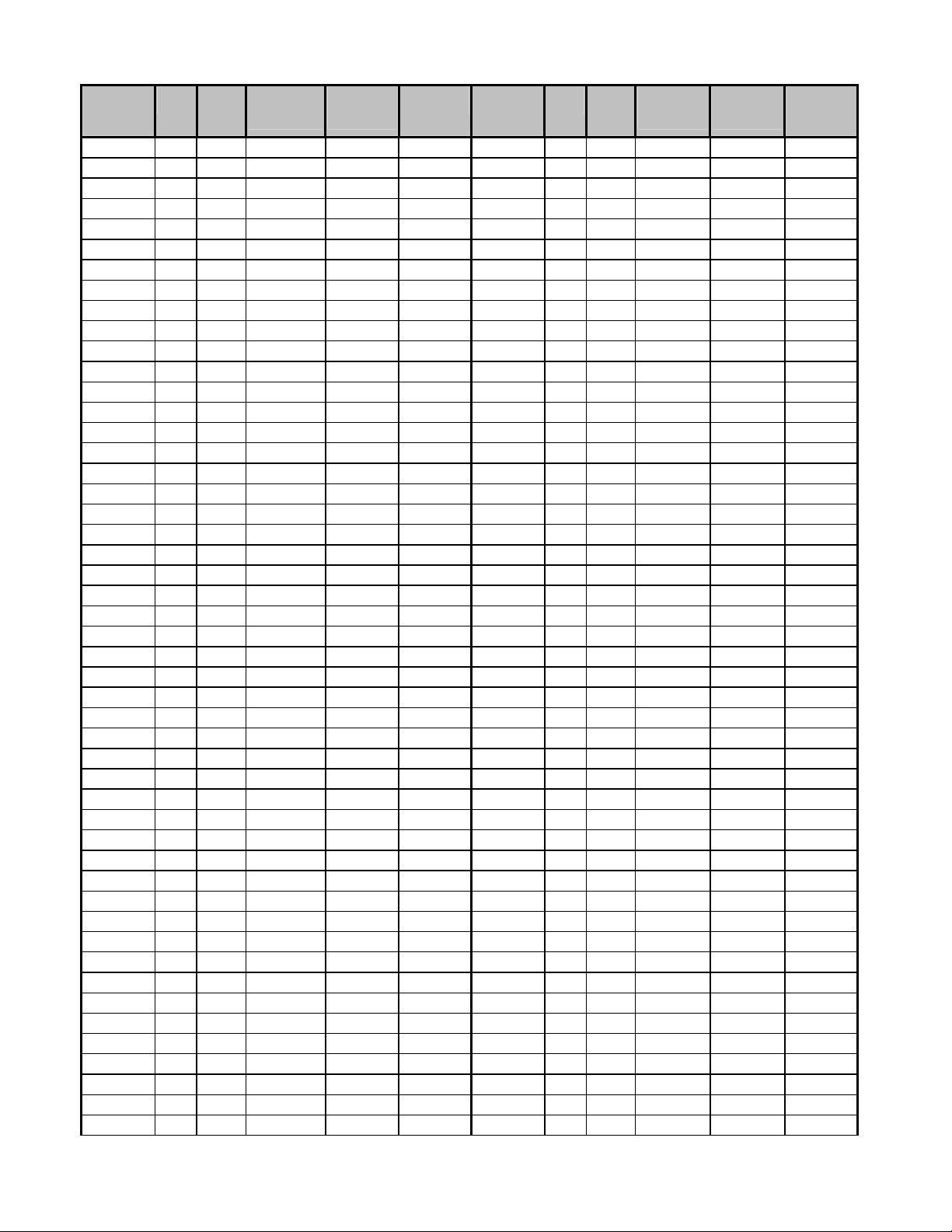

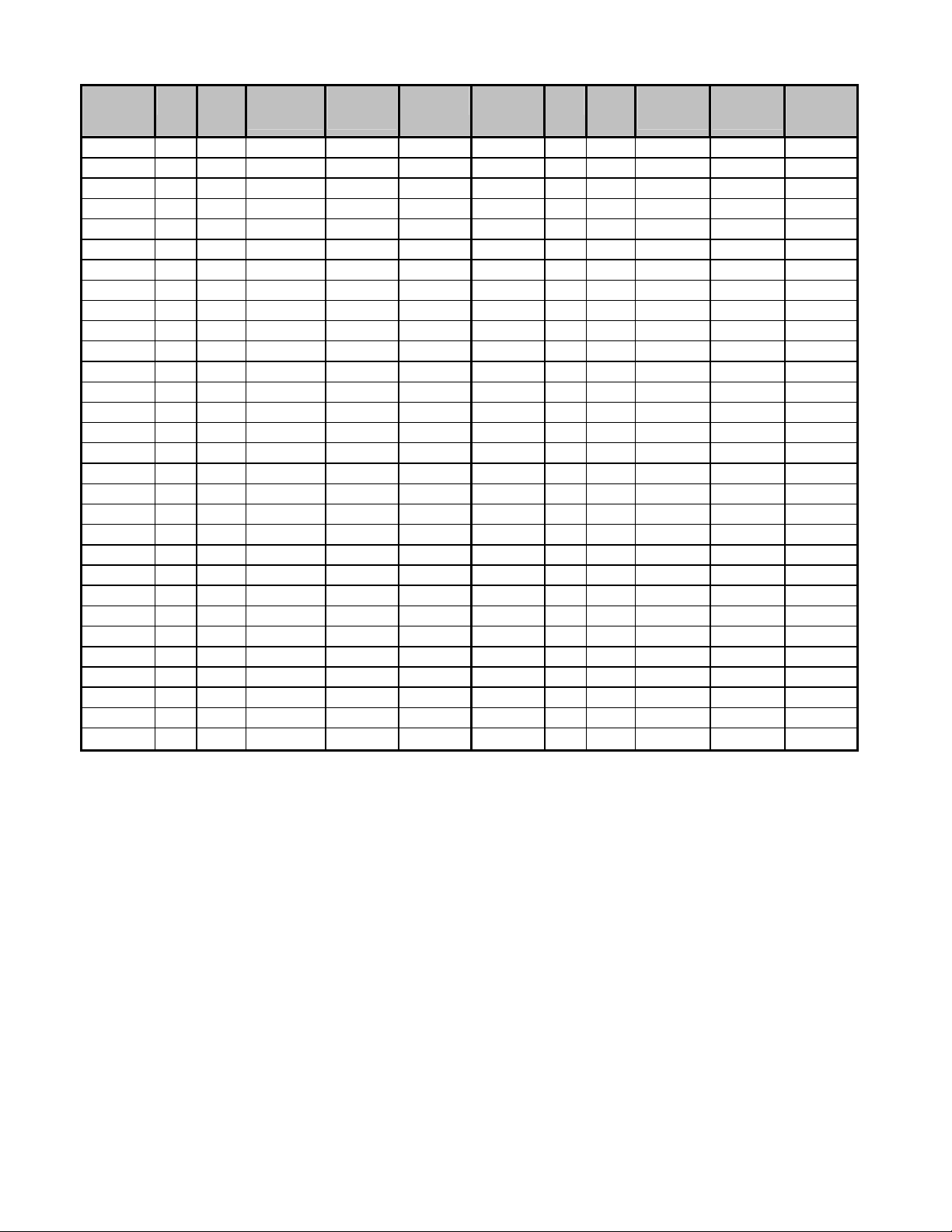

TABLE 2: CONDENSER & HEAT

RECLAIM ............................................6 to 16

Fig # 1: Standard legs .......................................17

Condenser/Fluid Cooler Dimensions........18& 19

Fig. #2 : Extended Legs....................................20

Fig #3 : 2 fans ...................................................21

Fig # 4: 1 fan ....................................................22

Table #3............................................................23

Table #4............................................................24

Table #5............................................................25

Table #6............................................................26

Table #7............................................................27

Replacement part list…………………... 28 & 29

WARRANTIES................................................30

SAFETY CONSIDERATIONS

Installing, starting up, and servicing

equipment can be hazardous due to system

pressures, electrical components and equipment

location (roofs, elevated structures, etc.). Only

trained, qualified installers and service

mechanics should install, start up, and service

this equipment.

When working on the equipment, observe

precautions in the literature and on the tags,

stickers, and labels attached to the equipment.

Follow all safety codes. Wear safety glasses

and work gloves. Keep quenching cloths and fire

extinguisher nearby when brazing. Use care in

handling, rigging, and setting bulky equipment.

WARNING

Before installation, always check to be sure

main power to systems is OFF. Electrical

shock can cause personal injury or death.

INTRODUCTION

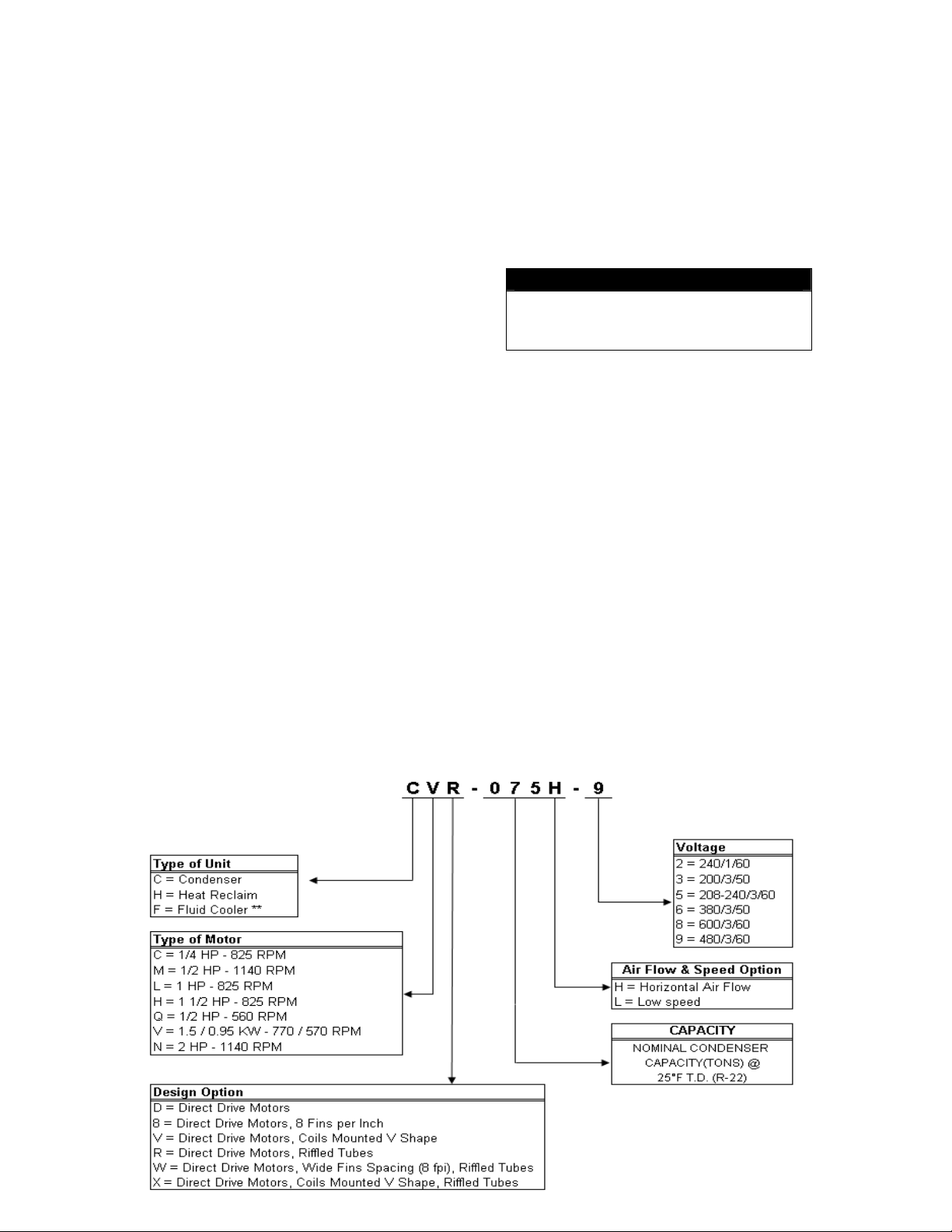

Air Cooled condensers series CCR, CMR, CLR,

CLW, CLX, CNR, CNW, CNX, CVR, CVW,

CVX, CCD, CQD, CLD, CMD, CH8, CL8,

CHD and CID are designed for refrigerant

condensing of refrigeration and air conditioning

systems. They can be manufactured for single or

multiple circuits, for single or multiple

compressors.

Fluid coolers series FCD, FLD, FID, FMD,

FNV, FVD, FVV and FND are designed to cool

glycol, oil or any other fluid that is not corrosive

to copper and will not let the leaving air

temperature exceed 140°F (60°C).

Heat recovery units HCD and HMD are designed

to recover heat from refrigeration system in

warehouse or shipping area.

2

Page 3

HANDLING

CAUTION : Do not use forklift truck to

handle units. Use only chains with hooks and

spread bars to lift units.

When a unit is shipped on its side, two or three

hangers are installed. Use them to unload the

unit from truck.

A lift truck can be used with the wood base in

that position only to lower the unit on the

ground.

Two others hangers, four, six or eight legs

(depending on the unit) and the required

hardware are supplied attached to the cabinet.

Lifting method 1 :

• Install all the legs on the same side as

hangers.

• Gently lower the unit on those legs.

• Install hangers on opposite side.

• Raise the other side and install other legs.

• Install chains and spread bars to raise the

unit to its final position.

Lifting method 2 :

• Gently lower the unit on a flat surface.

• Install hangers on opposite side.

• Install chains and spread bars to raise the

unit.

• Lift the unit and install all the legs.

• Lift the unit to it’s final position.

See fig # 1 for more details. If the unit as been

ordered with extended legs, see fig. #2 for field

assembly. Also refer to table #1, #2 for unit

weight.

INSTALLATION

STEP #1 INSPECTION:

If the unit is suspected of having been damaged

in transit, immediately notify the carrier and file

a claim with that carrier. The refrigeration coil

section(s) of the unit should display a pressurised

nitrogen gas holding charge. Unit should then be

pressurised to 350 psi with dry nitrogen gas and

leak-checked prior to rigging; this to insure no

coil damage has occurred after the unit left the

factory. Bolts & nuts may have become loose in

transit, as well as electrical components. Please

make sure that everything is tight prior to startup.

STEP #2 LOCATION:

Condensers and fluid coolers are installed on the

roof or ground level. If a unit is installed on the

ground it must be fenced to prevent possible

damage. Heat recovery units are installed inside

at the ceiling level. Check loading capacity of the

roof, the ceiling or the floor before installation.

The unit is intended to be installed in an

atmosphere containing only neutral water

vapour, natural precipitation and air. Use in any

other atmosphere must be checked for

compatibility with metals, materials and coating

used in manufacturing of this equipment.

Unit positioning as well as firmness and perfect

levelness of mounting base supports are

important: Good installation practices are well

known and are to be followed. Air flow paths on

all sides as well as coil inlet and fan discharge

areas are not to be restricted. Unit positioning

that may result in air recirculation as well as

prevailing wind impedance is to be avoided.

If a unit is to be placed close to a wall the

minimum distance should be 24 inches for single

row of fans and 48 inches for double row of fans.

If units are to be placed side by side, the

minimum distances should be 48 inches for

single row of fans and 96 inches for a double

row of fans. The chosen location must be

convenient and allow safe accessibility for

maintenance.

STEP #3 WIRING:

NOTE: A wiring diagram is provided with the

unit, it is located on the inner face of the

electrical box access door.

All wiring must be done in accordance with

national and local codes. Check the nameplate

with the current characteristics to be used for

wiring unit. Internal wiring connections of the

fan motors, optional controls and contactors have

been completed at the factory. Once wired, make

sure the unit has been grounded. Disconnect

switch at the unit must be provided by others.

On air cooled condensers with flooding valve,

one fan (single width unit) or one pair of fans

(double width unit) must operate when

compressor is operating to avoid internal damage

to the condenser coil.

3

Page 4

STEP #4 PIPING:

probably occur.

CAUTION: The unit has not been designed to

carry the weight of any extended piping or

valves. The piping must be well supported

otherwise tube breaking at the coil will most

All refrigerant or fluid system components must

be installed in accordance with applicable local

and national codes and in accordance with good

engineering practice required for proper

operation.

Use top quality refrigeration tubing that is

internally free of dirt, humidity or other

contaminants. Unsealed tubing should not be

used. Long radius elbows are recommended.

Dry nitrogen must be swept through the lines

while joints are brazed to avoid oxidation and

carbon deposits.

IMPORTANT: The use of a calibrated

pressure gage and regulator must always be

used with nitrogen gas cylinders.

To minimise hydraulic shock line breakage

possibilities, valving and controls must be

designed to eliminate any rapid introduction of

hot gas into cold piping. Most especially if the

piping contains liquid refrigerant or is at a much

lower pressure than the hot discharge gas, which

can be the case of double-wide condensers that

feature one-half operation during winter. Plans

should be for utilising either a slow-shifting

three-way/four-way valve, or not completely

lowering to suction pressure the condenser coil

side that deactivates during winter. Most often, a

combination of both of these options works well

in geographic areas that encounter lower than

freezing seasonal outdoor temperatures.

Air-cooled condensers must be provided with

inverted “P” trap with a purge connection. A

separate sub cooling circuit may be necessary if

liquid line must rise to level higher than the unit.

Vibration in the discharge or liquid line must be

corrected immediately to avoid piping and/or

header breakage and refrigerant loss.

Generally, horizontal-piping runs should grade

slightly downwards in the direction of the flow.

Liquid line piping must be arranged so that it is

free draining from the condenser to the receiver.

It is best to pipe liquid lines so that there is an

immediate drop, at least 2 or 3 feet, at the

condenser outlet, before headering or running

horizontally.

STEP #5 LEAK TESTING:

Leak testing and evacuation must be done in

accordance with local and national codes.

Once all refrigerant connections are made, leak

test all joints before charging the system with

refrigerant. After leak testing, all moisture and

non-condensable gas must be evacuated from the

system. Attach high vacuum line pump and gage

on both high and low pressure sides of the

system. A minimum vacuum level of 100

microns is required to effectively remove

moisture.

Be sure all valves such as compressor, hot gas,

receiver, and liquid solenoid valves are open.

Break the vacuum in the system with the

refrigerant to be used. Always charge the

refrigerant into the system through a new 16 cu.

in drier (field supplied) in the charging manifold

line.

OPERATION

The notice below depicts the label that is affixed

to the control box cover.

WARNING

ONE FAN (SINGLE WIDTH UNIT) OR ONE

PAIR OF FANS (DOUBLE WIDTH UNIT)

OPERATE SIMULTANEOUSLY TO AVOID

Not complying to this condition can cause

uneven rapid expansion and contraction of the

condenser core tubing contributing to condenser

tubes failures. Violation of this condition will

void the warranty of the misused unit.

For a refrigeration system to function properly,

the condensing pressure and temperature must be

maintained within certain limits.

To prevent excessively low head pressure during

winter operation, two basic control methods are

used, refrigerant side control and air side control.

Warranty Condition

AND THE COMPRESSOR MUST

DAMAGE TO THE CONDENSER COIL.

4

Page 5

1) A) Refrigerant-side control is accomplished

by modulating the amount of active

condensing surface available for condensing

by flooding the coil with liquid refrigerant.

This method requires a receiver and a larger

charge of refrigerant. See fig. #3.

B) Refrigerant-side control by doing the

one-half condenser operation. The

condenser is initially resigned with two

equal sections, each accommodating 50% of

the load during normal operation.

During winter an ambient controlled flow

divider valve blocks off one section of the

condenser and pumps down the inactive

section in the suction. This saves the

flooding overcharge and sometimes allows

the shutdown of the fans on the inactive

condenser side. Fig. #4

2) Airside control is accomplished by cycling

fans in response to condensing pressure or

outdoors-ambient temperature. To reduce

stress on the condenser coil, one fan or one

pair of fans must operate when a condenser

is operating. Speed control on the constant

operating fan may be used to reduce motor

cycling and stabilise the operating pressure.

See table 3 to 6 for more information.

For low ambient operation this method must be

combined with refrigerant side control.

FAN MOTORS:

Check the fan blade clearances within the

venturies, as well as check for proper rotation.

Fan motors operating at higher elevations will

draw lower than rated amp as well as draw less

effective air volume across the coil surface. This

is due to the reduced density of the higher

altitude air, which results in higher compressor,

and higher discharge pressure along with

reduced unit capacity. Please consult factory if

you suspect this situation.

The fan motors are permanently lubricated for

service free operation. The motor may restart on

automatic thermal protection. Motors are readily

serviced by removing fan guards and fans. If a

motor is inoperative or it cycles on thermal

protection, check supply voltage at the motor

leads. Fan motors may cycle on thermal

protection if the coil is blocked.

Units equipped with axial fans, CVR, CVW,

CVX: The entire fan assembly, motor, blade and

ventury need to be replaced if there is a failure of

any kind. With the two speed version, 3

contactors are used per motor. Do not attempt to

manually close one of these contactors; this may

result in motor winding damage.

FAN CYCLING:

Optional temperature or pressure controls are

located in the control box. Air temperature

sensors are located in the air flow and pressure

controls are directly connected to the circuit in a

return bend.

Optional line duty controls are connected

directly to the fan motors. Controls are double

pole single throw, one line remain live on the

motors. Units must be completely disconnected

before servicing.

Optional pilot duty controls are connected to 3

pole motor contactors. If controls or contactors

are defective, they must be replaced.

MAINTENANCE

CLEANING:

After one day of operation, check for any

vibration that might have developed in the unit.

It is recommended that the unit be inspected

occasionally for dirt accumulation. Grease and

dust should be removed from the fans and fan

guards.

Periodical cleaning of finned surfaces can be

done by washing down dust with warm water

spray and a mild detergent. Do not use alkaline

or acidic solution as it will attack the coil

material.

The inner face of the coil may be cleaned by the

access panel on the side of the units or by

removing the fan guards.

Always pressure -clean in reverse of the air flow.

5

Page 6

TABLE 1: FLUID COOLERS

Fluid

CoolerID

FCD02 1 1 190 FLD015 1 1 654

FCD03 1 1 201 FLD018 1 2 985

FCD04 1 1 210 FLD021 1 2 1005

FID010 1 1 515 FLD023 1 2 1063

FID011 1 1 525 FLD026 1 2 1091

FID013 1 1 592 FLD028 1 2 1117

FID014 1 1 602 FLD030 1 2 1159

FID016 1 1 641 FLD035 1 3 1460

FID017 1 1 654 FLD040 1 3 1490

FID020 1 2 985 FLD042 2 2 1625

FID023 1 2 1005 FLD043 1 3 1570

FID025 1 2 1063 FLD045 1 3 1609

FID029 1 2 1091 FLD049 2 2 1792

FID031 1 2 1117 FLD050 1 4 1875

FID034 1 2 1159 FLD053 2 2 1781

FID039 1 3 1460 FLD054 1 4 1915

FID044 1 3 1490 FLD056 2 2 1882

FID046 2 2 1625 FLD057 1 4 2019

FID049 1 3 1570 FLD060 2 2 1934

FID051 1 3 1609 FLD061 1 4 2071

FID054 2 2 1792 FLD063 2 3 2323

FID055 1 4 1875 FLD066 1 5 2403

FID058 2 2 1781 FLD070 1 5 2475

FID059 1 4 1915 FLD075 1 5 2540

FID064 2 2 1882 FLD080 2 3 2508

FID065 1 4 2019 FLD085 2 3 2664

FID068 2 2 1934 FLD090 2 3 2742

FID069 1 4 2071 FLD099 2 4 3029

FID070 2 3 2323 FLD106 2 4 3129

FID073 1 5 2403 FLD113 2 4 3338

FID079 1 5 2475 FLD120 2 4 3442

FID085 1 5 2540 FLD124 2 5 4198

FID088 2 3 2508 FLD132 2 5 4298

FID095 2 3 2664 FLD142 2 5 4560

FID101 2 3 2742 FLD150 2 5 4690

FID112 2 4 3029 FLD159 2 6 5292

FID119 2 4 3129 FLD170 2 6 5642

FID129 2 4 3338 FLD180 2 6 5798

FID137 2 4 3442 FLD190 2 6 6535

FID141 2 5 4198 FMD05 1 1 308

FID149 2 5 4298 FMD07 1 1 335

FID162 2 5 4560 FMD08 1 1 350

FID171 2 5 4690 FMD09 1 2 489

FID178 2 6 5292 FMD11 1 2 518

FID194 2 6 5642 FMD12 1 2 532

FID205 2 6 5798 FMD13 1 2 544

FID214 2 6 6535 FMD14 1 2 566

FLD009 1 1 515 FMD18 1 3 727

FLD010 1 1 525 FMD20 1 3 741

FLD012 1 1 592 FMD21 1 3 767

FLD013 1 1 602 FMD23 1 3 789

FLD014 1 1 641

Width

(fan)

Length

(fan)

Shipping

Weight

(lb)

Fluid

Cooler ID

Width

(fan)

Length

(fan)

Shipping

Weight

(lb)

6

Page 7

TABLE 2: CONDENSER AND HEAT RECLAIM

Condenser

ID

CCD02 1 1 1.8 5.8 190 CL8053 2 2 47 153 1882

CCD03 1 1 2.7 8.7 201 CL8054 1 4 46 150 2019

CCD04 1 1 3.5 12 210 CL8055 2 3 34 112 2323

CH8010 1 1 5.8 19 515 CL8059 1 5 43 140 2403

CH8013 1 1 8.8 29 592 CL8068 1 5 57 187 2475

CH8015 1 1 12 38 641 CL8071 2 3 52 169 2508

CH8020 1 2 12 38 985 CL8081 2 3 69 225 2664

CH8026 1 2 17 57 1063 CL8094 2 4 68 224 3029

CH8029 1 2 23 76 1117 CL8108 2 4 91 299 3338

CH8038 1 3 26 85 1460 CL8118 2 5 85 280 4198

CH8040 2 2 23 75 1625 CL8135 2 5 114 373 4560

CH8044 1 3 34 112 1570 CL8141 2 6 164 553 5292

CH8051 2 2 35 115 1792 CL8162 2 6 218 717 5642

CH8052 1 4 34 112 1875 CLD009 1 1 5.8 19 515

CH8058 2 2 47 153 1882 CLD010 1 1 5.8 19 525

CH8059 1 4 46 150 2019 CLD012 1 1 8.8 29 592

CH8060 2 3 34 112 2323 CLD013 1 1 8.8 29 602

CH8065 1 5 43 140 2403 CLD014 1 1 12 38 641

CH8074 1 5 57 187 2475 CLD015 1 1 12 38 654

CH8078 2 3 52 169 2508 CLD018 1 2 12 38 985

CH8088 2 3 69 225 2664 CLD021 1 2 12 38 1005

CH8104 2 4 68 224 3029 CLD023 1 2 17 57 1063

CH8118 2 4 91 299 3338 CLD026 1 2 17 57 1091

CH8130 2 5 85 280 4198 CLD028 1 2 23 76 1117

CH8147 2 5 114 373 4560 CLD030 1 2 23 76 1159

CH8156 2 6 197 664 5292 CLD035 1 3 26 85 1460

CH8177 2 6 262 860 5642 CLD040 1 3 26 85 1490

CHD010 1 1 5.8 19 515 CLD042 2 2 23 75 1625

CHD012 1 1 5.8 19 525 CLD043 1 3 34 112 1570

CHD013 1 1 8.8 29 592 CLD045 1 3 34 112 1609

CHD014 1 1 8.8 29 602 CLD049 2 2 35 115 1792

CHD015 1 1 12 38 641 CLD050 1 4 34 112 1875

CHD016 1 1 12 38 654 CLD053 2 2 35 115 1781

CHD020 1 2 12 38 985 CLD054 1 4 34 112 1915

CHD024 1 2 12 38 1005 CLD056 2 2 47 153 1882

CHD026 1 2 17 57 1063 CLD057 1 4 46 150 2019

CHD029 1 2 17 57 1091 CLD060 2 2 47 153 1934

CHD030 1 2 23 76 1117 CLD061 1 4 46 150 2071

CHD032 1 2 23 76 1159 CLD063 2 3 34 112 2323

CHD040 1 3 26 85 1460 CLD066 1 5 43 140 2403

CHD044 1 3 26 85 1490 CLD070 1 5 57 187 2475

CHD045 1 3 23 75 1625 CLD075 1 5 57 187 2540

CHD048 1 3 34 112 1570 CLD080 2 3 52 169 2508

CHD049 2 2 34 112 1609 CLD085 2 3 69 225 2664

CHD055 2 2 35 115 1792 CLD090 2 3 69 225 2742

Width

Length

(fan)

(fan)

Refrigerant

Charge

Summer (lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight (lb)

Condenser

ID

Width

(fan)

Length

(fan)

Refrigerant

Charge

Summer (lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight (lb)

7

Page 8

Condenser

ID

CHD056 1 4 34 112 1875 CLD099 2 4 68 224 3029

CHD059 2 2 35 115 1781 CLD106 2 4 68 224 3129

CHD060 1 4 34 112 1915 CLD113 2 4 91 299 3338

CHD061 2 2 47 153 1882 CLD120 2 4 91 229 3442

CHD062 1 4 46 150 2019 CLD124 2 5 85 280 4198

CHD063 2 2 47 153 1934 CLD132 2 5 85 280 4298

CHD064 1 4 46 150 2071 CLD142 2 5 114 373 4560

CHD073 2 3 34 112 2323 CLD150 2 5 114 373 4690

CHD074 1 5 43 140 2403 CLD159 2 6 164 553 5292

CHD077 1 5 57 187 2475 CLD170 2 6 218 717 5642

CHD079 1 5 57 187 2540 CLD180 2 6 218 717 5798

CHD089 2 3 52 169 2508 CMD05 1 1 3.3 11 308

CHD092 2 3 69 225 2664 CMD07 1 1 4.9 16 335

CHD096 2 3 69 225 2742 CMD08 1 1 6.5 22 350

CHD110 2 4 68 224 3029 CMD09 1 2 6.3 21 489

CHD118 2 4 68 224 3129 CMD11 1 2 9.5 31 518

CHD123 2 4 91 299 3338 CMD12 1 2 9.5 31 532

CHD127 2 4 91 229 3442 CMD13 1 2 13 42 544

CHD138 2 5 85 280 4198 CMD14 1 2 13 42 566

CHD148 2 5 85 280 4298 CMD18 1 3 14 47 727

CHD153 2 5 114 373 4560 CMD20 1 3 14 47 741

CHD159 2 5 114 373 4690 CMD21 1 3 19 62 767

CHD177 2 6 164 553 5292 CMD23 1 3 19 62 789

CHD184 2 6 218 717 5642 CQD008 1 1 5.8 19 525

CHD191 2 6 218 717 5798 CQD009 1 1 5.8 19 535

CID010 1 1 5.8 19 515 CQD010 1 1 8.8 29 602

CID011 1 1 5.8 19 525 CQD011 1 1 8.8 29 612

CID013 1 1 8.8 29 592 CQD012 1 1 12 38 651

CID014 1 1 8.8 29 602 CQD013 1 1 12 38 664

CID016 1 1 12 38 641 CQD016 1 2 12 38 1085

CID017 1 1 12 38 654 CQD019 1 2 12 38 1025

CID020 1 2 12 38 985 CQD021 1 2 17 57 1083

CID023 1 2 12 38 1005 CQD022 1 2 17 57 1111

CID025 1 2 17 57 1063 CQD023 1 2 23 76 1137

CID029 1 2 17 57 1091 CQD024 1 2 23 76 1179

CID031 1 2 23 76 1117 CQD031 1 3 26 85 1490

CID034 1 2 23 76 1159 CQD034 1 3 26 85 1520

CID039 1 3 26 85 1460 CQD035 1 3 34 112 1600

CID044 1 3 26 85 1490 CQD036 1 3 34 112 1639

CID046 2 2 23 75 1625 CQD041 2 2 35 115 1832

CID049 1 3 34 112 1570 CQD042 1 4 34 112 1915

CID051 1 3 34 112 1609 CQD044 2 2 35 115 1821

CID054 2 2 35 115 1792 CQD045 1 4 34 112 1955

CID055 1 4 34 112 1875 CQD046 2 2 47 153 1922

CID058 2 2 35 115 1781 CQD047 1 4 46 150 2059

CID059 1 4 34 112 1915 CQD048 2 2 47 153 1974

CID064 2 2 47 153 1882 CQD049 1 4 46 150 2111

CID065 1 4 46 150 2019 CQD057 1 5 43 140 2453

CID068 2 2 47 153 1934 CQD058 1 5 57 187 2525

Width

(fan)

Length

(fan)

Refrigerant

Charge

Summer (lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight (lb)

Condenser

ID

Width

(fan)

Length

(fan)

Refrigerant

Charge

Summer (lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight (lb)

8

Page 9

Condenser

ID

CID069 1 4 46 150 2071 CQD061 1 5 57 187 2590

CID070 2 3 34 112 2323 CQD069 2 3 52 169 2568

CID073 1 5 43 140 2403 CQD070 2 3 69 225 2724

CID079 1 5 57 187 2475 CQD072 2 3 69 225 2800

CID085 2 5 57 187 2540 CQD083 2 4 68 224 3109

CID088 2 3 52 169 2508 CQD091 2 4 68 224 3209

CID095 2 3 69 225 2664 CQD093 2 4 91 299 3418

CID101 2 3 69 225 2742 CQD096 2 4 91 299 3522

CID112 2 4 68 224 3029 CQD104 2 5 85 280 4298

CID119 2 4 68 224 3129 CQD114 2 5 85 280 4398

CID129 2 4 91 299 3338 CQD116 2 5 114 373 4660

CID137 2 4 91 229 3442 CQD121 2 5 114 373 4790

CID141 2 5 85 280 4198 CQD137 2 6 164 553 5412

CID149 2 5 85 280 4298 CQD140 2 6 218 717 5762

CID162 2 5 114 373 4560 CQD145 2 6 218 717 5918

CID171 2 5 114 373 4690 HCD02 1 1 0.6 0.6 190

CID178 2 6 164 553 5292 HCD03 1 1 0.9 0.9 201

CID194 2 6 218 717 5642 HCD04 1 1 1.2 1.2 210

CID205 2 6 218 717 5798 HMD05 1 1 1.1 1.1 308

CL8009 1 1 5.8 19 515 HMD07 1 1 1.6 1.6 335

CL8012 1 1 8.8 29 592 HMD08 1 1 2.1 2.1 350

CL8014 1 1 12 38 641 HMD09 1 2 2.1 2.1 489

CL8018 1 2 12 38 985 HMD11 1 2 3.1 3.1 518

CL8024 1 2 17 57 1063 HMD12 1 2 3.1 3.1 532

CL8027 1 2 23 76 1117 HMD13 1 2 4.3 4.3 544

CL8035 1 3 26 85 1460 HMD14 1 2 4.3 4.3 566

CL8036 2 2 23 75 1625 HMD18 1 3 4.6 4.6 727

CL8041 1 3 34 112 1570 HMD20 1 3 4.6 4.6 741

CL8047 2 2 35 115 1792 HMD21 1 3 6.3 6.3 767

CL8048 1 4 34 112 1875 HMD23 1 3 6.3 6.3 789

Width

(fan)

Length

(fan)

Refrigerant

Charge

Summer (lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight (lb)

Condenser

ID

Width

(fan)

Length

(fan)

Refrigerant

Charge

Summer (lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight (lb)

9

Page 10

Refrigerant

Charge

Condenser

ID

CCR02 1 1 2 6 190 CMR16 1 2 13 42 566

CCR03 1 1 3 9 201 CMR18 1 3 10 33 727

CCR04 1 1 4 12 210 CMR22 1 3 15 48 741

CNW011 1 1 6 19 520 CMR25 1 3 20 66 789

CNW014 1 1 9 29 597 CMR30 2 4 19 62 1064

CNW017 1 1 12 38 648 CMR33 2 4 26 84 1132

CNW021 1 2 12 38 612 CMR36 2 6 20 66 1454

CNW028 1 2 23 76 995 CMR45 2 6 29 96 1482

CNW033 1 2 23 76 1138 CMR49 2 6 39 132 1578

CNW042 1 3 26 85 1475 CVR012L 1 1 6 19 565

CNW050 1 3 34 112 1590 CVR014L 1 1 6 19 575

CNW056 1 4 34 112 1796 CVR016L 1 1 9 29 642

CNW057 2 4 35 115 1900 CVR017L 1 1 9 29 652

CNW066 1 4 46 150 1908 CVR018L 1 1 12 38 691

CNW067 2 4 47 153 2045 CVR019L 1 1 12 38 704

CNW077 1 5 68 230 2361 CVR025L 1 2 12 38 1085

CNW089 1 5 90 298 2507 CVR028L 1 2 12 38 1105

CNW085 2 6 52 170 2468 CVR031L 1 2 17 57 1163

CNW092 1 6 82 276 2768 CVR034L 1 2 17 57 1191

CNW100 2 6 68 224 2703 CVR035L 1 2 23 76 1217

CNW107 1 6 109 359 3003 CVR037L 1 2 23 76 1259

CNW113 2 4 68 224 3079 CVR047L 1 3 26 85 1610

CNW133 2 4 92 300 3390 CVR051L 1 3 26 85 1640

CNW154 2 5 136 460 4248 CVR053L 1 3 34 112 1720

CNW179 2 5 180 596 4625 CVR056L 1 3 34 112 1759

CNW185 2 6 164 552 5242 CVR061L 1 4 34 112 2075

CNW215 2 6 218 718 5716 CVR062L 2 4 35 115 1910

CNR012 1 1 6 19 515 CVR067L 1 4 34 112 2115

CNR014 1 1 6 19 525 CVR068L 2 4 35 115 1992

CNR016 1 1 9 29 592 CVR070L 1 4 46 150 2219

CNR017 1 1 9 29 602 CVR071L 2 4 47 153 2082

CNR018 1 1 12 38 641 CVR074L 1 4 46 150 2271

CNR019 1 1 12 38 654 CVR075L 2 4 47 153 2134

CNR024 1 2 12 38 985 CVR083L 2 6 36 114 2623

CNR027 1 2 12 38 1005 CVR084L 1 5 68 230 2653

CNR032 1 2 17 57 1063 CVR089L 1 5 68 230 2653

CNR035 1 2 17 57 1091 CVR092L 1 5 90 298 2725

CNR036 1 2 23 76 1117 CVR096L 1 5 90 298 2790

CNR039 1 2 23 76 1159 CVR094L 2 6 52 170 2730

CNR048 1 3 26 85 1460 CVR099L 1 6 82 276 3000

CNR052 1 3 26 85 1490 CVR101L 2 6 52 170 2808

CNR054 1 3 34 112 1570 CVR105L 1 6 82 276 3108

CNR058 1 3 34 112 1609 CVR106L 2 6 68 224 2964

Width

(fan)

Length

(fan)

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

Condenser

ID

Width

(fan)

Length

(fan)

Refrigerant

Charge

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

10

Page 11

Refrigerant

Charge

Condenser

ID

CNR063 1 4 34 112 1875 CVR111L 1 6 109 359 3264

CNR064 2 4 35 115 1792 CVR112L 2 6 68 224 3042

CNR069 1 4 34 112 1915 CVR116L 1 6 109 359 3342

CNR070 2 4 35 115 1781 CVR125L 2 4 68 224 3429

CNR072 1 4 46 150 2019 CVR135L 2 4 68 224 3529

CNR073 2 4 47 153 1934 CVR141L 2 4 92 300 3738

CNR077 1 4 46 150 2071 CVR149L 2 4 92 300 3842

CNR078 2 4 47 153 2071 CVR165L 2 5 136 460 4698

CNR082 2 6 36 114 2323 CVR177L 2 5 136 460 4798

CNR085 1 5 68 230 2338 CVR184L 2 5 180 596 5060

CNR092 1 5 68 230 2403 CVR192L 2 5 180 596 5190

CNR096 1 5 90 298 2475 CVR200L 2 6 164 552 5736

CNR101 1 5 90 298 2540 CVR212L 2 6 164 552 5892

CNR095 2 6 52 170 2430 CVR221L 2 6 218 718 6242

CNR102 1 6 82 276 2730 CVR231L 2 6 218 718 6398

CNR104 2 6 52 170 2508 CVR012 1 1 6 19 565

CNR111 1 6 82 276 2808 CVR014 1 1 6 19 575

CNR109 2 6 68 224 2664 CVR016 1 1 9 29 642

CNR116 1 6 109 359 2964 CVR017 1 1 9 29 652

CNR115 2 6 68 224 2742 CVR018 1 1 12 38 691

CNR121 1 6 109 359 3000 CVR019 1 1 12 38 704

CNR127 2 4 68 224 3029 CVR025 1 2 12 38 1085

CNR139 2 4 68 224 3129 CVR028 1 2 12 38 1105

CNR145 2 4 92 300 3338 CVR031 1 2 17 57 1163

CNR154 2 4 92 300 3442 CVR034 1 2 17 57 1191

CNR171 2 5 136 460 4198 CVR035 1 2 23 76 1217

CNR185 2 5 136 460 4298 CVR037 1 2 23 76 1259

CNR193 2 5 180 596 4560 CVR047 1 3 26 85 1610

CNR202 2 5 180 596 4690 CVR051 1 3 26 85 1640

CNR205 2 6 164 552 5136 CVR053 1 3 34 112 1720

CNR222 2 6 164 552 5292 CVR056 1 3 34 112 1759

CNR231 2 6 218 718 5642 CVR061 1 4 34 112 2075

CNR243 2 6 218 718 5798 CVR062 2 4 35 115 1910

CNX015 1 1 7 24 550 CVR067 1 4 34 112 2115

CNX019 1 1 11 35 600 CVR068 2 4 35 115 1992

CNX021 1 1 15 47 650 CVR070 1 4 46 150 2219

CNX030 1 2 14 46 850 CVR071 2 4 47 153 2082

CNX038 1 2 22 69 900 CVR074 1 4 46 150 2271

CNX043 1 2 29 92 950 CVR075 2 4 47 153 2134

CNX057 1 3 32 103 1300 CVR083 2 6 36 114 2623

CNX064 1 3 43 137 1425 CVR084 1 5 68 230 2653

CNX076 1 4 43 136 1725 CVR089 1 5 68 230 2653

CNX086 1 4 57 182 1900 CVR092 1 5 90 298 2725

Width

(fan)

Length

(fan)

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

Condenser

ID

Width

(fan)

Length

(fan)

Refrigerant

Charge

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

11

Page 12

Refrigerant

Charge

Condenser

ID

CNX096 1 5 53 170 2150 CVR096 1 5 90 298 2790

CNX108 1 5 71 227 2375 CVR094 2 6 52 170 2730

CNX123 1 6 101 323 2575 CVR099 1 6 82 276 3000

CNX135 1 6 134 430 2850 CVR101 2 6 52 170 2808

CNX144 1 7 117 376 3012 CVR105 1 6 82 276 3108

CNX158 1 7 157 501 3362 CVR106 2 6 68 224 2964

CNX164 1 4 134 429 3450 CVR111 1 6 109 359 3264

CNX181 1 4 179 572 3800 CVR112 2 6 68 224 3042

CNX061 2 4 29 92 1000 CVR116 1 6 109 359 3342

CNX077 2 4 43 138 1600 CVR125 2 4 68 224 3429

CNX087 2 4 58 184 2000 CVR135 2 4 68 224 3529

CNX115 2 6 64 205 2600 CVR141 2 4 92 300 3738

CNX129 2 6 86 274 3000 CVR149 2 4 92 300 3842

CNX154 2 4 85 273 3600 CVR165 2 5 136 460 4698

CNX172 2 4 114 363 4000 CVR177 2 5 136 460 4798

CNX192 2 5 106 340 4500 CVR184 2 5 180 596 5060

CNX215 2 5 142 453 5000 CVR192 2 5 180 596 5190

CNX247 2 6 202 645 5400 CVR200 2 6 164 552 5736

CNX271 2 6 269 860 6000 CVR212 2 6 164 552 5892

CNX288 2 7 235 752 6400 CVR221 2 6 218 718 6242

CNX316 2 7 313 1002 7000 CVR231 2 6 218 718 6398

CNX329 2 8 268 858 7400 CVW011 1 1 6 19 570

CNX362 2 8 358 1145 8000 CVW014 1 1 9 29 647

CLW009 1 1 6 19 515 CVW016 1 1 12 38 698

CLW012 1 1 9 29 592 CVW021 1 2 12 38 1012

CLW014 1 1 12 38 641 CVW028 1 2 23 76 1095

CLW019 1 2 12 38 985 CVW033 1 2 23 76 1238

CLW024 1 2 23 76 1063 CVW042 1 3 26 85 1625

CLW028 1 2 23 76 1117 CVW049 1 3 34 112 1740

CLW036 1 3 26 85 1460 CVW055 1 4 34 112 2100

CLW042 1 3 34 112 1570 CVW056 2 4 35 115 1996

CLW048 1 4 34 112 1875 CVW064 1 4 46 150 2245

CLW049 2 4 35 115 1792 CVW065 2 4 47 153 2108

CLW056 1 4 46 150 2019 CVW070 1 5 68 230 2611

CLW057 2 4 47 153 1882 CVW081 1 5 90 298 2757

CLW066 1 5 68 230 2403 CVW084 2 6 52 170 2768

CLW075 1 5 90 298 2475 CVW090 1 6 82 276 3068

CLW073 2 6 52 170 2508 CVW098 2 6 68 224 3003

CLW079 1 6 82 276 2808 CVW104 1 6 109 359 3303

CLW085 2 6 68 224 2664 CVW112 2 4 68 224 3479

CLW090 1 6 109 359 2964 CVW130 2 4 92 300 3790

CLW097 2 4 68 224 3029 CVW140 2 5 136 460 4748

CLW113 2 4 92 300 3338 CVW163 2 5 180 596 5125

Width

(fan)

Length

(fan)

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

Condenser

ID

Width

(fan)

Length

(fan)

Refrigerant

Charge

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

12

Page 13

Refrigerant

Charge

Condenser

ID

CLW131 2 5 136 460 4198 CVW167 2 6 164 552 5842

CLW151 2 5 180 596 4560 CVW195 2 6 218 718 6316

CLW158 2 6 164 552 5292 CVW011L 1 1 6 19 570

CLW181 2 6 218 718 5642 CVW014L 1 1 9 29 647

CLR010 1 1 6 19 515 CVW016L 1 1 12 38 698

CLR011 1 1 6 19 525 CVW021L 1 2 12 38 1012

CLR013 1 1 9 29 592 CVW028L 1 2 23 76 1095

CLR014 1 1 9 29 602 CVW033L 1 2 23 76 1238

CLR015 1 1 12 38 641 CVW042L 1 3 26 85 1625

CLR016 1 1 12 38 654 CVW049L 1 3 34 112 1740

CLR021 1 2 12 38 985 CVW055L 1 4 34 112 2100

CLR023 1 2 12 38 1005 CVW056L 2 4 35 115 1996

CLR027 1 2 17 57 1063 CVW064L 1 4 46 150 2245

CLR029 1 2 17 57 1091 CVW065L 2 4 47 153 2108

CLR031 1 2 23 76 1117 CVW070L 1 5 68 230 2611

CLR032 1 2 23 76 1159 CVW081L 1 5 90 298 2757

CLR040 1 3 26 85 1460 CVW084L 2 6 52 170 2768

CLR044 1 3 26 85 1490 CVW090L 1 6 82 276 3068

CLR046 1 3 34 112 1570 CVW098L 2 6 68 224 3003

CLR049 1 3 34 112 1609 CVW104L 1 6 109 359 3303

CLR053 1 4 34 112 1875 CVW112L 2 4 68 224 3479

CLR054 2 4 35 115 1792 CVW130L 2 4 92 300 3790

CLR057 1 4 34 112 1915 CVW140L 2 5 136 460 4748

CLR058 2 4 35 115 1781 CVW163L 2 5 180 596 5125

CLR060 1 4 46 150 2019 CVW167L 2 6 164 552 5842

CLR062 2 4 47 153 1882 CVW195L 2 6 218 718 6316

CLR064 1 4 46 150 2071 CVX015 1 1 7 24 600

CLR065 2 4 47 153 1934 CVX019 1 1 11 35 650

CLR069 2 6 36 114 2323 CVX021 1 1 15 47 700

CLR072 1 5 68 230 2338 CVX031 1 2 14 46 950

CLR077 1 5 68 230 2403 CVX038 1 2 22 69 1000

CLR081 1 5 90 298 2475 CVX042 1 2 29 92 1050

CLR084 1 5 90 298 2540 CVX057 1 3 32 103 1450

CLR080 2 6 52 170 2430 CVX063 1 3 43 137 1575

CLR086 1 6 82 276 2730 CVX076 1 4 43 136 1925

CLR087 2 6 52 170 2508 CVX084 1 4 57 182 2100

CLR093 1 6 82 276 2808 CVX096 1 5 53 170 2400

CLR092 2 6 68 224 2664 CVX106 1 5 71 227 2625

CLR096 1 6 109 359 2964 CVX122 1 6 101 323 2875

CLR097 2 6 68 224 2742 CVX131 1 6 134 430 3150

CLR101 1 6 109 359 3042 CVX142 1 7 117 376 3362

CLR107 2 4 68 224 3029 CVX153 1 7 157 501 3712

CLR117 2 4 68 224 3129 CVX163 1 4 134 429 3850

Width

(fan)

Length

(fan)

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

Condenser

ID

Width

(fan)

Length

(fan)

Refrigerant

Charge

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

13

Page 14

Refrigerant

Charge

Condenser

ID

CLW131 2 5 136 460 4198 CVW167 2 6 164 552 5842

CLW151 2 5 180 596 4560 CVW195 2 6 218 718 6316

CLW158 2 6 164 552 5292 CVW011L 1 1 6 19 570

CLW181 2 6 218 718 5642 CVW014L 1 1 9 29 647

CLR010 1 1 6 19 515 CVW016L 1 1 12 38 698

CLR011 1 1 6 19 525 CVW021L 1 2 12 38 1012

CLR013 1 1 9 29 592 CVW028L 1 2 23 76 1095

CLR014 1 1 9 29 602 CVW033L 1 2 23 76 1238

CLR015 1 1 12 38 641 CVW042L 1 3 26 85 1625

CLR016 1 1 12 38 654 CVW049L 1 3 34 112 1740

CLR021 1 2 12 38 985 CVW055L 1 4 34 112 2100

CLR023 1 2 12 38 1005 CVW056L 2 4 35 115 1996

CLR027 1 2 17 57 1063 CVW064L 1 4 46 150 2245

CLR029 1 2 17 57 1091 CVW065L 2 4 47 153 2108

CLR031 1 2 23 76 1117 CVW070L 1 5 68 230 2611

CLR032 1 2 23 76 1159 CVW081L 1 5 90 298 2757

CLR040 1 3 26 85 1460 CVW084L 2 6 52 170 2768

CLR044 1 3 26 85 1490 CVW090L 1 6 82 276 3068

CLR046 1 3 34 112 1570 CVW098L 2 6 68 224 3003

CLR049 1 3 34 112 1609 CVW104L 1 6 109 359 3303

CLR053 1 4 34 112 1875 CVW112L 2 4 68 224 3479

CLR054 2 4 35 115 1792 CVW130L 2 4 92 300 3790

CLR057 1 4 34 112 1915 CVW140L 2 5 136 460 4748

CLR058 2 4 35 115 1781 CVW163L 2 5 180 596 5125

CLR060 1 4 46 150 2019 CVW167L 2 6 164 552 5842

CLR062 2 4 47 153 1882 CVW195L 2 6 218 718 6316

CLR064 1 4 46 150 2071 CVX015 1 1 7 24 600

CLR065 2 4 47 153 1934 CVX019 1 1 11 35 650

CLR069 2 6 36 114 2323 CVX021 1 1 15 47 700

CLR072 1 5 68 230 2338 CVX031 1 2 14 46 950

CLR077 1 5 68 230 2403 CVX038 1 2 22 69 1000

CLR081 1 5 90 298 2475 CVX042 1 2 29 92 1050

CLR084 1 5 90 298 2540 CVX057 1 3 32 103 1450

CLR080 2 6 52 170 2430 CVX063 1 3 43 137 1575

CLR086 1 6 82 276 2730 CVX076 1 4 43 136 1925

CLR087 2 6 52 170 2508 CVX084 1 4 57 182 2100

CLR093 1 6 82 276 2808 CVX096 1 5 53 170 2400

CLR092 2 6 68 224 2664 CVX106 1 5 71 227 2625

CLR096 1 6 109 359 2964 CVX122 1 6 101 323 2875

CLR097 2 6 68 224 2742 CVX131 1 6 134 430 3150

CLR101 1 6 109 359 3042 CVX142 1 7 117 376 3362

CLR107 2 4 68 224 3029 CVX153 1 7 157 501 3712

CLR117 2 4 68 224 3129 CVX163 1 4 134 429 3850

Width

(fan)

Length

(fan)

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

Condenser

ID

Width

(fan)

Length

(fan)

Refrigerant

Charge

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

14

Page 15

Refrigerant

Charge

Condenser

ID

CLR122 2 4 92 300 3338 CVX175 1 4 179 572 4200

CLR130 2 4 92 300 3442 CVX062 2 4 29 92 1100

CLR144 2 5 136 460 4198 CVX077 2 4 43 138 1700

CLR155 2 5 136 460 4298 CVX085 2 4 58 184 2100

CLR161 2 5 180 596 4560 CVX115 2 6 64 205 2750

CLR167 2 5 180 596 4690 CVX127 2 6 86 274 3150

CLR173 2 6 164 552 5292 CVX154 2 4 85 273 3800

CLR186 2 6 164 552 5642 CVX170 2 4 114 363 4200

CLR193 2 6 218 718 5798 CVX192 2 5 106 340 4750

CLR202 2 6 218 718 5798 CVX212 2 5 142 453 5250

CLX013 1 1 7 24 550 CVX245 2 6 202 645 5700

CLX016 1 1 11 35 600 CVX262 2 6 269 860 6300

CLX018 1 1 15 47 650 CVX285 2 7 235 752 6750

CLX026 1 2 14 46 850 CVX306 2 7 313 1002 7350

CLX032 1 2 22 69 900 CVX326 2 8 268 858 7800

CLX036 1 2 29 92 950 CVX350 2 8 358 1145 8400

CLX049 1 3 32 103 1300 CVX015L 1 1 7 24 600

CLX054 1 3 43 137 1425 CVX019L 1 1 11 35 650

CLX064 1 4 43 136 1725 CVX021L 1 1 15 47 700

CLX071 1 4 57 182 1900 CVX031L 1 2 14 46 950

CLX081 1 5 53 170 2150 CVX038L 1 2 22 69 1000

CLX089 1 5 71 227 2375 CVX042L 1 2 29 92 1050

CLX103 1 6 101 323 2575 CVX057L 1 3 32 103 1450

CLX111 1 6 134 430 2850 CVX063L 1 3 43 137 1575

CLX120 1 7 117 376 3012 CVX076L 1 4 43 136 1925

CLX129 1 7 157 501 3362 CVX084L 1 4 57 182 2100

CLX138 1 4 134 429 3450 CVX096L 1 5 53 170 2400

CLX148 1 4 179 572 3800 CVX106L 1 5 71 227 2625

CLX053 2 4 29 92 1000 CVX122L 1 6 101 323 2875

CLX065 2 4 43 138 1600 CVX131L 1 6 134 430 3150

CLX072 2 4 58 184 2000 CVX142L 1 7 117 376 3362

CLX097 2 6 64 205 2600 CVX153L 1 7 157 501 3712

CLX107 2 6 86 274 3000 CVX163L 1 4 134 429 3850

CLX130 2 4 85 273 3600 CVX175L 1 4 179 572 4200

CLX143 2 4 114 363 4000 CVX062L 2 4 29 92 1100

CLX162 2 5 106 340 4500 CVX077L 2 4 43 138 1700

CLX178 2 5 142 453 5000 CVX085L 2 4 58 184 2100

CLX207 2 6 202 645 5400 CVX115L 2 6 64 205 2750

CLX222 2 6 269 860 6000 CVX127L 2 6 86 274 3150

CLX241 2 7 235 752 6400 CVX154L 2 4 85 273 3800

CLX259 2 7 313 1002 7000 CVX170L 2 4 114 363 4200

CLX275 2 8 268 858 7400 CVX192L 2 5 106 340 4750

CLX296 2 8 358 1145 8000 CVX212L 2 5 142 453 5250

Width

(fan)

Length

(fan)

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

Condenser

ID

Width

(fan)

Length

(fan)

Refrigerant

Charge

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

15

Page 16

Refrigerant

Charge

Condenser

ID

CMR06 1 1 3 11 308 CVX245L 2 6 202 645 5700

CMR07 1 1 5 16 335 CVX262L 2 6 269 860 6300

CMR08 1 1 7 22 350 CVX285L 2 7 235 752 6750

CMR12 1 2 6 21 489 CVX306L 2 7 313 1002 7350

CMR15 1 2 10 31 532 CVX326L 2 8 268 858 7800

CVX350L 2 8 358 1145 8400

Width

(fan)

Length

(fan)

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

Condenser

ID

Width

(fan)

Length

(fan)

Refrigerant

Charge

Summer

(lb)

Refrigerant

Charge

Winter (lb)

Shipping

Weight

(lb)

16

Page 17

Fig. #1: Standard Legs

17

Page 18

18

Page 19

19

Page 20

Fig. #2 : Extended Legs

20

Page 21

Fig #3: 2 fans

21

Page 22

Fig # 4: 1 fan

22

Page 23

Table #3

Fan Motor

WITH ANY

Condenser Fan Alignment Ambient Control Temperature Setting (°F)

Temperature Control ------ T1 T2 T3 T4 T5 T6 T7

Single Wide Units M1 M2 M3 M4 M5 M6

Number

Difference

Fan On 60

Fan Off 40

Difference

Fan On 55 65

Fan Off 45 50

Difference

Fan On 55 60 70

Fan Off 45 55 65

Difference

Fan On 55 60 70 75

Fan Off 45 55 65 70

Difference

Fan On 55 60 65 70 80

Fan Off 45 55 60 75 75

Difference

Fan On 55 60 65 70 75 80

Fan Off 45 55 60 65 70 75

Difference

Fan On 50 55 60 65 70 75 80

Fan Off

Double Wide Units

M1

M2

20

10 15

10 5 5

10 5 5 5

10 5 5 5 5

10 5 5 5 5 5

5 5 5 5 5 5 5

FAN (S)

RUNS

COM-

PRESSOR

M3

M4

45 50 55 60 65 70 75

M5

M6

M7

M8

M9

M10

M11

M12

M13

M14

M15

M16

23

Page 24

Table #4

Fan Motor

WITH ANY

Condenser Fan Alignment Pressure Control

Pressure Settings (PSIG) (R-22)

Pressure Control ------ P1 P2 P3 P4 P5 P6 P7

Single Wide Units M1 M2 M3 M4 M5 M6

Number

Difference

Fan On 200

Fan Off 160

Difference

Fan On 200 210

Fan Off 160 170

Difference

Fan On 200 205 215

Fan Off 160 165 175

Difference

Fan On 200 205 210 220

Fan Off 160 165 170 180

Difference

Fan On 200 205 210 215 225

Fan Off 160 165 170 175 185

Difference

Fan On 200 205 210 215 220 225

Fan Off 160 165 170 175 180 185

Difference

Fan On 200 205 210 215 220 225 230

Fan Off

Double Wide Units

M1

M2

40

40 40

40 40 40

40 40 40 40

40 40 40 40 40

40 40 40 40 40 40

40 40 40 40 40 40 40

FAN (S)

RUNS

COM-

PRESSOR

M3

M4

160 165 170 175 180 185 190

M5

M6

M7

M8

M9

M10

M11

M12

M13

M14

M15

M16

24

Page 25

Fan Motor

WITH ANY

Table #5

Condenser Fan Alignment Pressure Control

Pressure Settings (PSIG) (R-404A, R-507)

Pressure Control ------ P1 P2 P3 P4 P5 P6 P7

Single Wide Units M1 M2 M3 M4 M5 M6

Number

Difference

Fan On 240

Fan Off 200

Difference

Fan On 240 250

Fan Off 200 210

Difference

Fan On 240 250 255

Fan Off 200 210 215

Difference

Fan On 240 245 255 260

Fan Off 200 205 215 220

Difference

Fan On 240 245 255 255 265

Fan Off 200 205 215 215 225

Difference

Fan On 240 245 250 255 260 265

Fan Off 200 205 210 215 220 225

Difference

Fan On 240 245 250 255 260 265 270

Fan Off

Double Wide Units

40

40 40

40 40 40

40 40 40 40

40 40 40 40 40

40 40 40 40 40 40

40 40 40 40 40 40 40

M1

M2

FAN (S)

RUNS

COM-

PRESSOR

M3

M4

200 205 210 215 220 225 230

M5

M6

M7

M8

M9

M10

M11

M12

M13

M14

M15

M16

25

Page 26

Table #6

Fan Motor

WITH ANY

Condenser Fan Alignment Pressure Control

Pressure Settings (PSIG) (R-134)

Pressure Control ------ P1 P2 P3 P4 P5 P6 P7

Single Wide Units M1 M2 M3 M4 M5 M6

Number

Difference

Fan On 125

Fan Off 95

Difference

Fan On 125 135

Fan Off 95 105

Difference

Fan On 125 130 130

Fan Off 95 100 110

Difference

Fan On 125 130 135 145

Fan Off 95 100 105 115

Difference

Fan On 125 130 135 140 150

Fan Off 95 100 105 110 120

Difference

Fan On 125 130 135 140 145 150

Fan Off 95 100 105 110 115 120

Difference

Fan On 125 130 135 140 145 150 155

Fan Off

Double Wide Units

M1

M2

30

30 30

30 30 30

30 30 30 30

30 30 30 30 30

30 30 30 30 30 30

30 30 30 30 30 30 30

FAN (S)

RUNS

COM-

PRESSOR

M3

M4

95 100 105 110 115 120 125

M5

M6

M7

M8

M9

M10

M11

M12

M13

M14

M15

M16

26

Page 27

Table #7

Fan Motor

WITH ANY

Condenser Fan Alignment Pressure Control

Pressure Settings (PSIG) (R-407)

Pressure Control ------ P1 P2 P3 P4 P5 P6 P7

Single Wide Units M1 M2 M3 M4 M5 M6

Number

Difference

Fan On 220

Fan Off 180

Difference

Fan On 220 230

Fan Off 180 190

Difference

Fan On 220 225 235

Fan Off 180 185 195

Difference

Fan On 220 225 230 240

Fan Off 180 185 190 200

Difference

Fan On 220 225 230 235 245

Fan Off 180 185 190 195 205

Difference

Fan On 220 225 230 235 240 250

Fan Off 180 185 190 195 200 210

Difference

Fan On 220 225 230 235 240 245 250

Fan Off

Double Wide Units

40

40 40

40 40 40

40 40 40 40

40 40 40 40 40

40 40 40 40 40 40

40 40 40 40 40 40 40

M1

M2

FAN (S)

RUNS

COM-

PRESSOR

M3

M4

180 185 190 195 200 205 210

M5

M6

M7

M8

M9

M10

M11

M12

M13

M14

M15

M16

27

Page 28

28

Page 29

29

Page 30

WARRANTIES

RefPlus warrants the labeled (serial No.), new Refplus equipment and all parts thereof, to be free from defects in

workmanship and material at the time of purchase. Apply to original purchaser only (Not transferable).

Under this warranty RefPlus shall be limited to repairing or exchanging any parts, without charge FOB factory or nearest

authorized parts wholesalers, which may prove defective to the satisfaction of RefPlus within one year from date of start up,

not to exceed eighteen (1 8) months from date of shipment from the factory.

The warranties to repair or replace above recited, are the only warranties, express, implied, or statutory, made by RefPlus.

No express or implied warranties as to merchantability or fitness for a particular purpose or use. RefPlus neither assumes,

nor authorizes any person to assume for it, any other obligation or liability in connection with the sale of said equipment or

any part thereof.

EXCLUSIONS

THIS WARRANTY SHALL NOT APPLY TO LOSS OF PRODUCT OR REFRIGERANT DUE

TO FAILURE FOR ANY REASON.

RefPlus SHALL NOT BE LIABLE:

1 - For any repairs or replacement by buyer without the written consent of RefPlus, or when the equipment is installed or

operated in a manner contrary to the instructions covering installation and service which accompanied such equipment.

2- For any damages, delays, or losses, direct or consequential, caused by defects, nor for damages caused by short or

reduced supply of materials, fire, flood, strikes, acts of God, or circumstances beyond its control.

3- When the failure or defect of any part or parts is incidental to ordinary wear, accident, abuse or misuse; or when the serial

number of the equipment has been removed, defaced, altered, or tampered with.

4- When this equipment is operated on low or improper voltages.

6- When this equipment is moved to different location other than the original installation.

5- For payment of any removal or installation charges of parts or units.

Specifications subject to change without notice.

30

Loading...

Loading...