Page 1

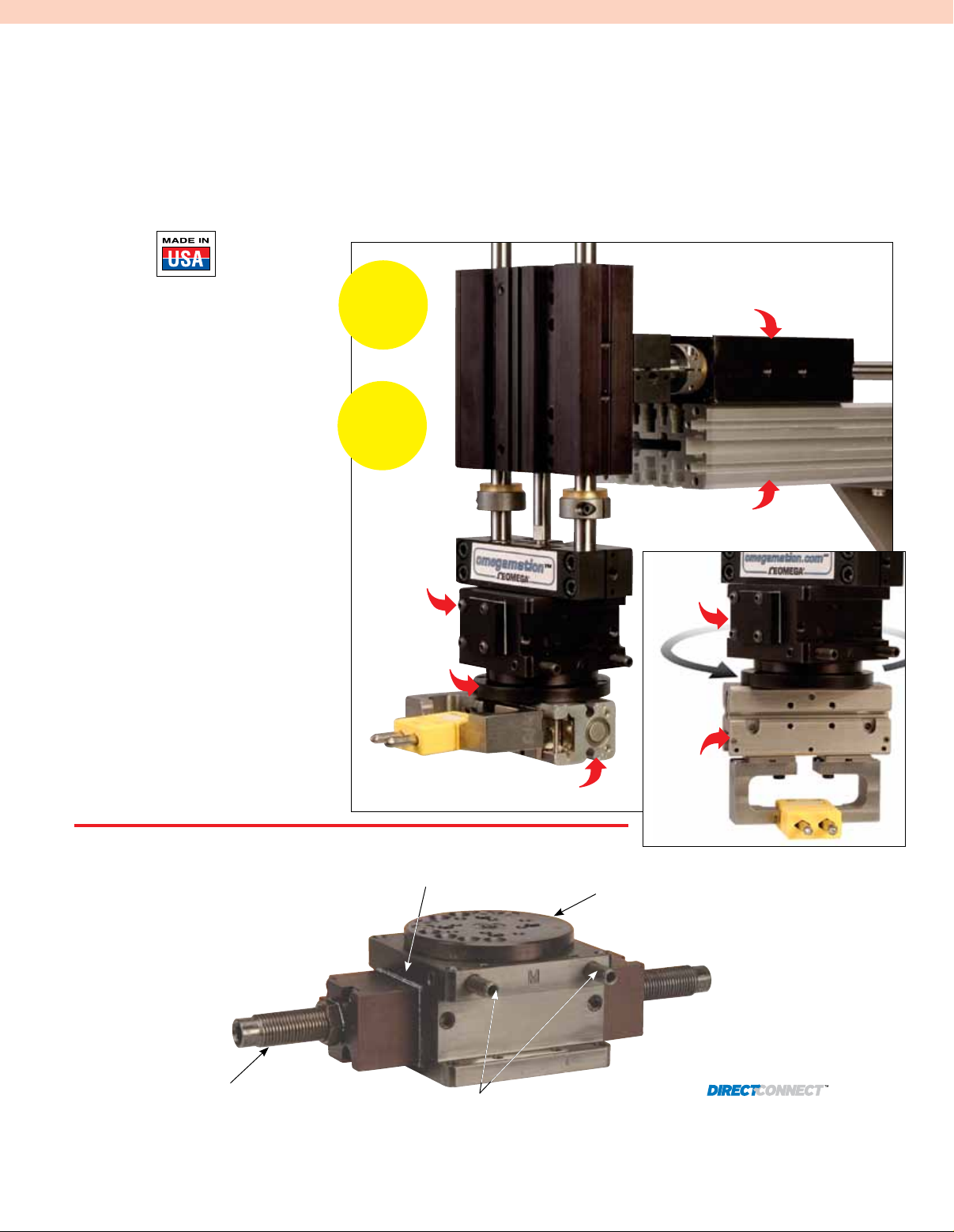

rotary actuators—pneumatic,

flange mountable Drf

Directconnecttm series

DRF Series

l Rotary Motion Actuator—

Precision End Stop Position

and Zero Backlash

l Adjustable Rotation with a

Maximum of 180° Full Rotation

l Repeatability ±0.02° of Rotation

l Highly Configurable Modular

Automation, Exclusive

DirectConnect Technology

l Multiple Mounting Locations—

Tapped and Through the Flange

on Top and Bottom Surfaces

l Up to 5 Million Cycles in Typical

Application, Up to 10 Million with

Maintenance

l Temperature Operating Range

-35 to 80°C (-30 to 180°F)

l Double Acting Air Cylinder

l System Requires 3 to 7 bar

(40 to 100 psi) Dry Filtered

(40 Micron or Better) Air Supply

l Accessory Equipment Required—

4-Way, 2 Position Pneumatic

Direction Control Valve

No Adaptor

Plates

Required!

Rotary

Positioning

Rotation

up to 180°

ODRF-004

turntable

module

to attach

grippers

DPP-10M-12 parallel gripper,

with OSTW-K-M thermocouple

connector visit omega.com

DLT-10M-E-C-50 linear slide

visit omega.com

DMEX mounting

stanchions,

visit omega.com

DRF-075M-180

Gripper

(sold

separately)

proDuct features

Sensor Mounting Slots

Standard mounting slots for Magneto Resistive

Sensors magnet mounted in piston standard

(sensors sold separately).

Extremely

Rugged Design

Pinion is supported with

upper and lower sealed

ball bearings.

End Stop Deceleration

(-A Option)

Shock absorbers decelerates

load at end of stroke.

Case Hardened

Rack and pinion are

case hardened for wear

and long life.

Black Anodize Body

The body and End Plates are

Black anodized, steel parts are

black oxide.

Rotational Adjustments

All rotational adjustments made

from front face. Adjustments are

locked with set screw on side.

C-15

Flange Mounting

Turntable has

DIRECTCONNECT

mounting pattern

DRF-075M-90-A

shown close

to actual size.

Tapped and Dowel mounting surface

on bottom of body and on turntable.

One Piece Body

One piece lightweight aircraft

quality aluminum body.

Dowel Holes

Slip fit dowel pin holes

in bottom body, and on

turntable.

Piston

Made of Delrin® for

extended life.

Mounting Patterns

Page 2

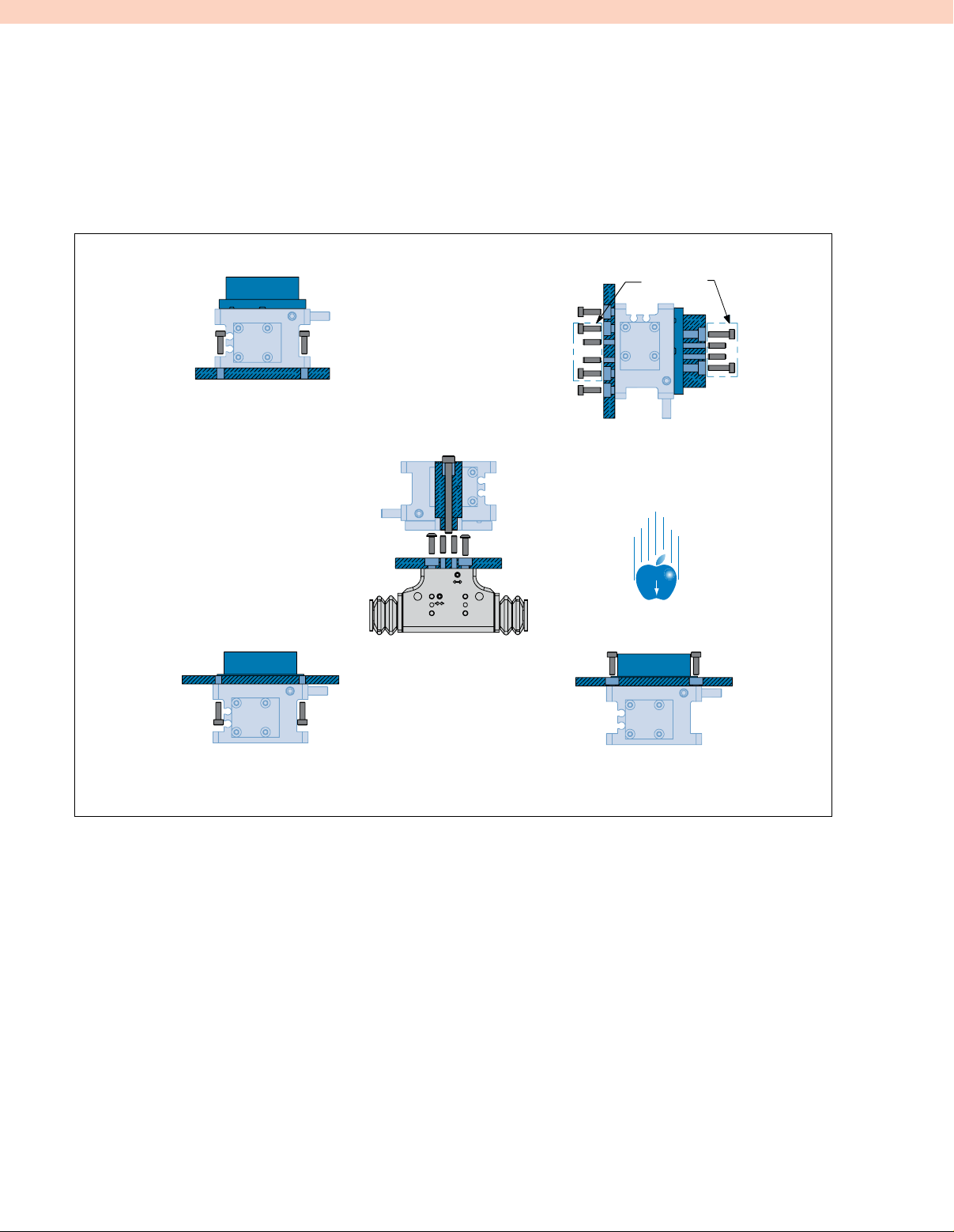

Directconnect

Mounting

mounting information

Directconnect

Mounting

Directconnect

Mounting

Directconnect

Mounting

Rotaries can be mounted and operated in any orientation.

Mounting through bottom flange

clearance holes into tapped holes

in customer application.

DIRECTCONNECT

Mounting: Gripper is

mounted from the under

side of Turntable with

Button Head screws and

slip fit dowels. Turntable

is then mounted to rotary

with one screw through the

center of the pinion and

two slip fit dowel pins.

Directconnect

Mounting

Body mounts with screws

and slip fit dowels from

bottom. Payload is attached

with screw and slip fit dowels.

G

Mounting through top flange

clearance holes into tapped holes

in customer application.

SPECIFICATIONS

PNEUMATIC SPECIFICATIONS

Pressure Operating Range: 3 to 7 bar

(40 to 100 psi)

Cylinder Type: Double acting

Dynamic Seals: Internally lubricated buna-N

Valve Required to Operate: 4-way, 2-position

AIR QUALITY REQUIREMENTS

Air Filtration: 40 micron or better

Air Lubrication: Not necessary*

Air Humidity: Low moisture content (dry)

Top mounting from underside of table

using tapped holes in body top flange.

Temperature Operating Range:

Buna-N Seals (Standard): -35 to 80°C

(-30 to 180°F)

With Shocks: 0 to 66°C (32 to 150°F)

MAINTENANCE SPECIFICATIONS

Expected Life:

Normal Application: 5 million cycles

With Preventative Maintenance:

10+ million cycles*

Field Repairable: Yes

Seal Repair Kits Available: Yes

* Addition of lubrication will greatly increase service life.

C-16

Page 3

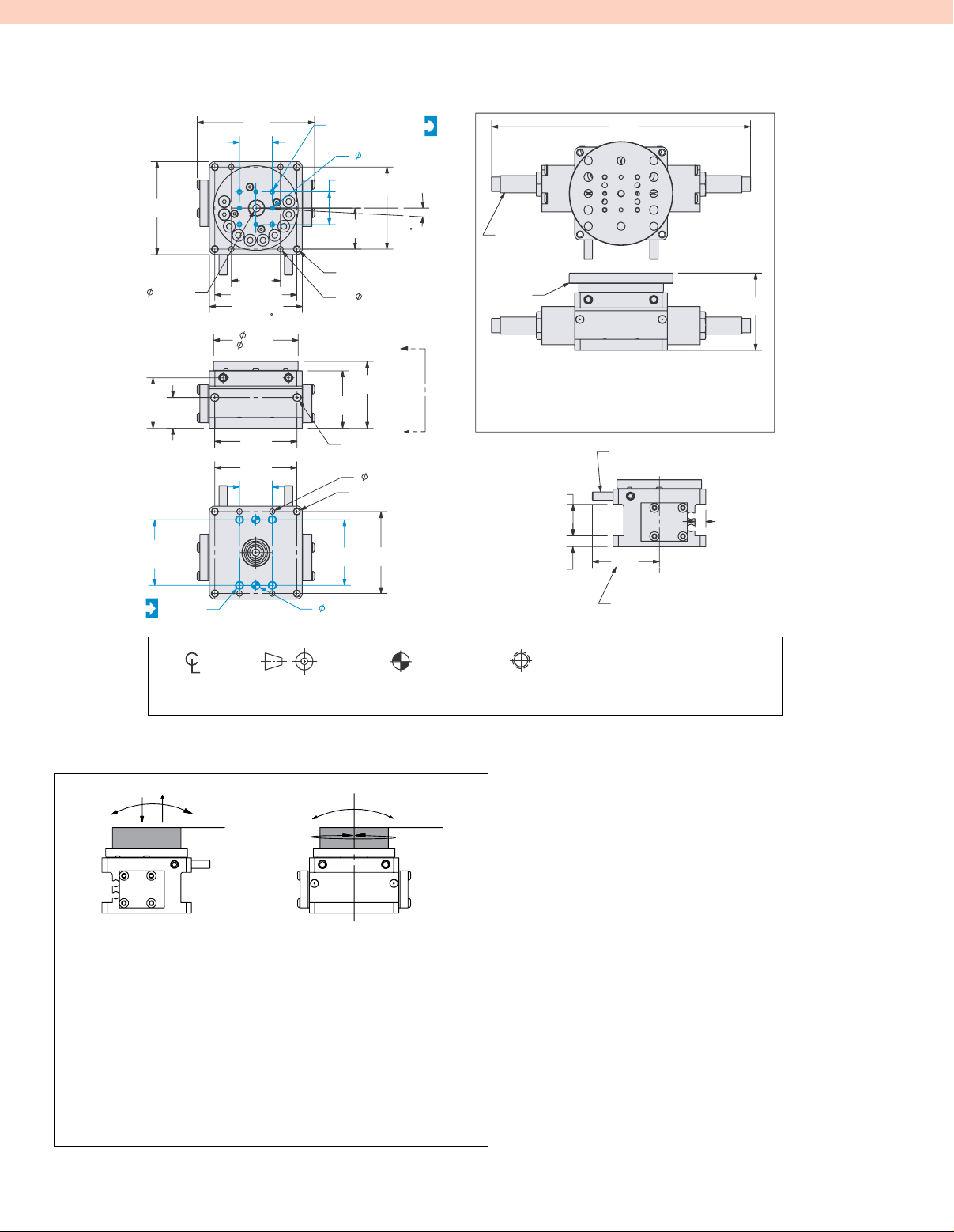

"Z"

Drf-075m

54 ±0.5

(2.13 ±0.02)

[4.4] THRU

29.4

(1.156)

17.9

(0.705)

1.5000

[38.10]

DOWELS

[M5

(2.69)

19.05

(0.7500)

(1.125)

47.6 (1.875)

54.0 (2.125)

UN IT SHOWN IN 0 POSITIO N

ROTATED FU LLY C W

(1.938)

(1.886)

(1.875)

(0.750)

X 5 DP]

68

28.5

49.2

47.9

47.6

19.1

[M3 X 5 DP]

DO NOT EXCEED DEPT

[3

H7 X 4 DP]

19.05

47.6

(0.7500)

(1.875)

23.8

(0.938)

[M4] THRU TOP FLANGE

[3.3] THRU TOP FLANGE

4X

38.8

(1.529)

33.4

(1.313)

2X

[M5 X 5 DP]

AIR PORTS

[3.3] THRU BOTTOM FLANGE

[M4] THRU BOTTOM FLANGE

47.6

38.1

(1.875)

(1.500)

[M

5 H7 X 5 DP]

H

1 TO 3°

OVERTRAVEL

BOTH ENDS

"A "

"A "

151

(5.93)

M 10 X 1. 0

O DRF-003

SH OW N

44

(1.76)

-A SHOCK ABSO RBER OPTIO N

SHOWN ABOVE

SHOCKS FULLY ACTIVATED ONLY AT

45°, 90°, 135°, AND 180° ROTATIONS

INTERMEDIATE ROTAT ION WILL REDUCE

SHOCK ABSORBER ABILITY AND PAYLOAD

MUST BE REDUCED

HA RD STOP

AD JUST IN G SCREWS

2X 18

(0.7 2)

2X 6

(0.2 5)

C

37

PINIO N

2X 6

(0.2 5)

M AX FOR STANDA RD ROTATION S

(1.53)

VI EW "A-A"

L

UNLESS OTHERWISE NOTED ALL TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

centerline

Third Angle

Projection

Dimensions: mm (inch)

DIRECTCONNECTTM dimensions shown in blue

"T"

"C"

W,J

"M",x

"X"

Loading Capacity Static Dynamic

Maximum Tensile T 44 N (10 lb) 9 N (2 lb)

Maximum Compressive C 89 N (20 lb) 18 N (4 lb)

Maximum Moment Mx 2.3 Nm (20 in-lb) 0.5 Nm (4 in-lb)

Maximum Moment My 2.3 Nm (20 in-lb) 0.5 Nm (4 in-lb)

Maximum Payload W

(with Shocks)

Maximum Inertia J

(with Shocks)

Note: Higher payloads and inertia possible with external shocks and stops.

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±0.0005" or [±0.013 mm]

"M",y

"Y"

"Z"

0.45 kg (1.0 lb)

1.8 x 10-4 N-m-sec

(

0.0016 in-lb-sec2)

Metric Threads

Course Pitch

Imperial inch

0.00 = ±0.01 0. = ±0.25

0.000 = ±0.005 0.0 = ±0.13

0.0000 = ±0.000 0.00 = ±0.013

Metric mm

SPECIFICATIONS

Maximum Payload with Shocks (-A): 0.45 kg (1 lb)

Maximum Payload without Shocks: 0.23 kg (0.5 lb)

Maximum Payload Inertia with Shocks (-A):

1.8 x 10

Maximum Payload Inertia without Shocks:

9.0 x 10-5 N-m-sec2 (0.0008 in-lb-sec2)

Maximum Torque @ 7 bar (100 psi): 0.9 N-m (8.3 lb-in)

Maximum Rotation: 180°

Pitch Diameter of Pinion: 9.5 mm (0.375")

Weight with Shocks (-A Option): 0.34 kg (0.72 lb)

Weight without Shocks: 0.24 kg (0.54 lb)

Pressure Range: 3 to 7 bar (40 to 100 psi)

Bore: 19.1 mm (0.750")

Displacement (180°): 5.1 cm

Actuation Time [180° @ 7 bar (100 psi)]: 0.38 sec (0.38 sec)

Actuation Time [90° @ 7 bar (100 psi)]: 0.29 sec (0.29 sec)

Over Travel (Each End): 1 to 3°

Temperature Range without Shocks: -35 to 82°C (-30 to 180°F)

2

Temperature Range with Shocks (-A): 0 to 66°C (32 to 150°F)

End Stop Adjustability (Each End): 23°

Repeatability: ±0.02°

Valve Required to Actuate: 4-way, 2-position

-4

N-m-sec2 (0.0016 in-lb-sec2)

3

(0.31 in3)

C-17

Page 4

71 ±0.5

"Z"

(2.78 ±0.02)

(0.7500)

[ 5.3] THRU

33.3

(1.313)

38.10

(1.5000)

DOWELS

[M

19.05

21.4

(0.844)

M5 X 8DP

5 H7 X 7 DP]

86

(3.38)

19.05

(0.7500)

34.9

(1.375)

60.3 (2.375)

70.6 (2.781)

UN IT SHOWN IN 0 POSITIO N

ROTATED FU LLY C W

60.3

(2.375)

62.7

(2.468)

60.3

(2.375)

38.1

(1.500)

19.1

(0.750)

Drf-094m

[M3 X 6 DP]

DO NOT EXCEED DEPT

[3 H7 X 5 DP

30.6

(1.203)

[M5] THRU TOP FLANGE

[5.1] THRU TOP FLANGE

4X

38.9

(1.531)

(1.500)

]

61.1

(2.406)

1 TO 3°

OVERTRAVEL

BOTH ENDS

"A "

44.8

(1.764)

"A "

[M5 X 11 DP]

2X

AIR PORT S

[5.1] THRU BOTTOM FLANGE

[M5] THRU BOTTOM FLANGE

19.1

61.1

(2.406)

H

M 12 X 1. 0

O DRF-009

SH OW N

-A SHOCK ABSO RBER OPTIO N

SHOWN ABOVE

SHOCKS FULLY ACTIVATED ONLY AT

45°, 90°, 135°, AND 180° ROTATIONS

INTERMEDIATE ROTAT ION WILL REDUCE

SHOCK ABSORBER ABILITY AND PAYLOAD

MUST BE REDUCED

21

(0.81)

7

(0.28)

189

(7.45)

HA RD STOP

AD JUST IN G SCREWS

C

PINIO N

L

49

(1.85)

VI EW "A-A"

M AX FOR STANDA RD ROTATION S

2X 10

(0.4 1)

52

(2.04)

UNLESS OTHERWISE NOTED ALL TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

centerline

Third Angle

Projection

Dimensions: mm (inch)

DIRECTCONNECTTM dimensions shown in blue

"T"

"C"

W,J

"M",x

"X"

Loading Capacity Static Dynamic

Maximum Tensile T 67 N (15 lb) 13 N (3 lb)

Maximum Compressive C 133 N (30 lb) 27 N (6 lb)

Maximum Moment Mx 5.6 Nm (50 in-lb) 1.1 Nm (10 in-lb)

Maximum Moment My 5.6 Nm (50 in-lb) 1.1 Nm (10 in-lb)

Maximum Payload W

(with Shocks)

Maximum Inertia J

(with Shocks)

Note: Higher payloads and inertia possible with external shocks and stops.

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±0.0005" or [±0.013 mm]

"M",y

"Y"

"Z"

1.4 kg (3 lb)

1.3 x 10-3 N-m-sec

(

0.0111 in-lb-sec2)

Metric Threads

Course Pitch

Imperial inch

0.00 = ±0.01 0. = ±0.25

0.000 = ±0.005 0.0 = ±0.13

0.0000 = ±0.000 0.00 = ±0.013

Metric mm

SPECIFICATIONS

Maximum Payload with Shocks (-A): 1.4 kg (3 lb)

Maximum Payload without Shocks: 0.68 kg (1.5 lb)

Maximum Payload Inertia with Shocks (-A):

1.3 x 10

Maximum Payload Inertia without Shocks:

6.3 x 10-4 N-m-sec2 (0.0056 in-lb-sec2)

Maximum Torque @ 7 bar (100 psi): 1.9 N-m (17.3 lb-in)

Maximum Rotation: 180°

Pitch Diameter of Pinion: 12.7 mm (0.500")

Weight with Shocks (-A Option): 0.64 kg (1.4 lb)

Weight without Shocks: 0.50 kg (1.1 lb)

Pressure Range: 3 to 7 bar (40 to 100 psi)

Bore: 23.8 mm (0.938")

Displacement (180°): 9.0 cm3 (0.55 in3)

Actuation Time [180° @ 7 bar (100 psi)]: 0.38 sec (0.38 sec)

Actuation Time [90° @ 7 bar (100 psi)]: 0.29 sec (0.29 sec)

Over Travel (Each End): 1 to 3°

Temperature Range without Shocks: -35 to 82°C (-30 to 180°F)

2

Temperature Range with Shocks (-A): 0 to 66°C (32 to 150°F)

End Stop Adjustability (Each End): 23°

Repeatability: ±0.02°

Valve Required to Actuate: 4-way, 2-position

-3

N-m-sec2 (0.0111 in-lb-sec2)

C-18

Page 5

"Z"

Drf-106m

100 ±0.5

(3.94 ±0.02)

42.9

(1.688)

76.20

(3.0000)

DOWELS

5 H7 X 5 DP]

[M

38.10

(1.5000)

26.2

(1.031)

38.10

(1.5000)

DOWELS

X 7 DP

M5

115

(4.54)

38.10

(1.5000)

50.8

(2.000)

82.6 (3.250)

100.0 (3.938)

UN IT SHOWN IN 0 POSITIO N

ROTATED FU LLY C W

86.5

(3.406)

93.7

(3.690)

63.5

(2.500)

38.1

(1.500)

19.1

(0.750)

[M5 X 8 DP]

DO NOT EXCEED DEPT

[5 H7 X 5 DP]

82.6

(3.250)

41.3

(1.625)

THRU TOP FLANGE

THRU TOP FLANGE

57.9

(2.279)

49.2

(1.938)

[M5 X 13 DP]

2X

AIR PORTS

[M8 H7 THRU BOTTOM FLANGE

[M10] THRU BOTTOM FLANGE

[5.5] THRU BOTTOM FLANGE

38.1

(1.500)

1 TO 3°

OVERTRAVEL

BOTH ENDS

[M6]

4X [6.0]

"A "

"A "

76.2

(3.000)

H

]

M 14 X 1. 5

O DRF-015

SH OW N

250

(9.84)

-A SHOCK ABSO RBER OPTIO N

SHOWN ABOVE

SHOCKS FULLY ACTIVATED ONLY AT

45°, 90°, 135°, AND 180° ROTATIONS

INTERMEDIATE ROTAT ION WILL REDUCE

SHOCK ABSORBER ABILITY AND PAYLOAD

MUST BE REDUCED

HA RD STOP

AD JUST IN G SCRE W

29

(1.13)

C

8

(0.31)

74

(3.03)

M AX FOR STANDA RD ROTATION S

L

VI EW "A-A"

PINIO N

2X 19

(0.7 5)

66

(2.59)

UNLESS OTHERWISE NOTED ALL TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

centerline

Third Angle

Projection

Dimensions: mm (inch)

DIRECTCONNECTTM dimensions shown in blue

"T"

"C"

W,J

"M",x

"X"

Loading Capacity Static Dynamic

Maximum Tensile T 111 N (25 lb) 22 N (5 lb)

Maximum Compressive C 89 N (50 lb) 44 N (10 lb)

Maximum Moment Mx 8.5 Nm (75 in-lb) 1.7 Nm (15 in-lb)

Maximum Moment My 8.5 Nm (75 in-lb) 1.7 Nm (15 in-lb)

Maximum Payload W

(with Shocks)

Maximum Inertia J

(with Shocks)

Note: Higher payloads and inertia possible with external shocks and stops.

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±0.0005" or [±0.013 mm]

"M",y

"Y"

"Z"

3.6 kg (8 lb)

4.7 x 10-3 N-m-sec

(

0.0414 in-lb-sec2)

Metric Threads

Course Pitch

Imperial inch

0.00 = ±0.01 0. = ±0.25

0.000 = ±0.005 0.0 = ±0.13

0.0000 = ±0.000 0.00 = ±0.013

Metric mm

SPECIFICATIONS

Maximum Payload with Shocks (-A): 3.6 kg (8 lb)

Maximum Payload without Shocks: 1.8 kg (4 lb)

Maximum Payload Inertia with Shocks (-A):

4.7 x 10

Maximum Payload Inertia without Shocks:

2.3 x 10-5 N-m-sec2 (0.0207 in-lb-sec2)

Maximum Torque @ 7 bar (100 psi): 3.8 N-m (33.2 lb-in)

Maximum Rotation: 180°

Pitch Diameter of Pinion: 19.1 mm (0.750")

Weight with Shocks (-A Option): 1.4 kg (3.1 lb)

Weight without Shocks: 1.1 kg (2.5 lb)

Pressure Range: 3 to 7 bar (40 to 100 psi)

Bore: 27.0 mm (1.063")

Displacement (180°): 19.0 cm

Actuation Time [180° @ 7 bar (100 psi)]: 0.60 sec (0.60 sec)

Actuation Time [90° @ 7 bar (100 psi)]: 0.45 sec (0.45 sec)

Over Travel (Each End): 1 to 3°

Temperature Range without Shocks: -35 to 82°C (-30 to 180°F)

2

Temperature Range with Shocks (-A): 0 to 66°C (32 to 150°F)

End Stop Adjustability (Each End): 23°

Repeatability: ±0.02°

Valve Required to Actuate: 4-way, 2-position

-3

N-m-sec2 (0.0414 in-lb-sec2)

3

(1.16 in3)

C-19

Page 6

"Z"

Drf-131m

133 ±0.5

(5.25 ±0.02)

[M10 X 16 DP

76.20

(3.0000)

DOWELS

(1.5000)

53.7

(2.115)

38.10

(1.5000)

DOWELS

38.10

UN IT SHOWN IN 0 POSITIO N

ROTATED FU LLY C W

33.7

(1.325)

]

153

(6.02)

38.10

(1.5000)

57.2

(2.250)

114.3 (4.500)

133.4 (5.250)

104.8 (4.125)

120.7 (4.750)

114.3 (4.500)

76.2 (3.000)

[M5 X 9 DP]

DO NOT EXCEED DEPT

[5 H7 X 6 DP

114.3

(4.500)

57.2

(2.250)

OVERTRAVEL

BOTH ENDS

THRU TOP FLANGE

4X [9.9]

THRU TOP FLANGE

71.7

(2.821)

62.2

(2.450)

[M8 H7 X 10 DP

38.1

(1.500)

[G1/8 X 8 DP]

2X

AIR PORTS

"A "

"A "

[9.9]

THRU BOTTOM FLANGE

[M10]

THRU BOTTOM FLANGE

76.2

(3.000)

H

1 TO 3°

]

114.3

(4.500)

301

(11.85)

]

M 20 X 1. 5

O DRF-021

SH OW N

-A SHOCK ABSO RBER OPTIO N

SHOWN ABOVE

SHOCKS FULLY ACTIVATED ONLY AT

45°, 90°, 135°, AND 180° ROTATIONS

INTERMEDIATE ROTAT ION WILL REDUCE

SHOCK ABSORBER ABILITY AND PAYLOAD

MUST BE REDUCED

HA RD STOP

AD JUST IN G SCREWS

37

(1.44)

2X 19

(0.8 1)

81

(3.20)

X 7 DP]

[M5

38.1

(1.500)

19.1

(0.750)

5 H7 X 5 DP]

[M

UNLESS OTHERWISE NOTED ALL TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

centerline

Third Angle

Projection

Dimensions: mm (inch)

DIRECTCONNECTTM dimensions shown in blue

"T"

"C"

W,J

"M",x

"X"

Loading Capacity Static Dynamic

Maximum Tensile T 222 N (50 lb) 44 N (10 lb)

Maximum Compressive C 445 N (100 lb) 89 N (20 lb)

Maximum Moment Mx 11.3 Nm (100 in-lb) 2.3 Nm (20 in-lb)

Maximum Moment My 11.3 Nm (100 in-lb) 2.3 Nm (20 in-lb)

Maximum Payload W

(with Shocks)

Maximum Inertia J

(with Shocks)

Note: Higher payloads and inertia possible with external shocks and stops.

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±0.0005" or [±0.013 mm]

1.1 x 10-2 N-m-sec

(

0.0970 in-lb-sec2)

"M",y

"Y"

"Z"

6.8 kg (15 lb)

10

(0.38)

Metric Threads

Course Pitch

86

C

(3.62)

M AX FOR STANDA RD ROTATION S

Imperial inch

0.00 = ±0.01 0. = ±0.25

0.000 = ±0.005 0.0 = ±0.13

0.0000 = ±0.000 0.00 = ±0.013

PINION

L

VI EW "A-A"

Metric mm

SPECIFICATIONS

Maximum Payload with Shocks (-A): 6.8 kg (15 lb)

Maximum Payload without Shocks: 3.4 kg (7.5 lb)

Maximum Payload Inertia with Shocks (-A):

1.1 x 10

Maximum Payload Inertia without Shocks:

5.5 x 10-3 N-m-sec2 (0.0485 in-lb-sec2)

Maximum Torque @ 7 bar (100 psi): 7.6 N-m (67.6 lb-in)

Maximum Rotation: 180°

Pitch Diameter of Pinion: 25.4 mm (1.000")

Weight with Shocks (-A Option): 3.1 kg (6.8 lb)

Weight without Shocks: 2.9 kg (6.3 lb)

Pressure Range: 3 to 7 bar (40 to 100 psi)

Bore: 33.4 mm (1.313")

Displacement (180°): 34.6 cm3 (2.11 in3)

Actuation Time [180° @ 7 bar (100 psi)]: 0.87 sec (0.87 sec)

Actuation Time [90° @ 7 bar (100 psi)]: 0.68 sec (0.68 sec)

Over Travel (Each End): 1 to 3°

Temperature Range without Shocks: -35 to 82°C (-30 to 180°F)

2

Temperature Range with Shocks (-A): 0 to 66°C (32 to 150°F)

End Stop Adjustability (Each End): 23°

Repeatability: ±0.02°

Valve Required to Actuate: 4-way, 2-position

-2

N-m-sec2 (0.0970 in-lb-sec2)

C-20

Page 7

Turntable

ODRF-04

ø 60 (2.38)

Drf-075m,

094m, 106m

DF

DQ*

DD

SURFACE

“A”

DB*

DC

B

* DIMENSIONS ALSO APPLY TO BLANK

TURNTABLE

C'BORE FOR BUTTON HEAD SCREWS

Drf-131m

DF

DH

DD

DC*

DJ

SURFACE

“A”

B

* DIMENSIONS ALSO APPLY TO BLANK

TURNTABLE

C'BORE"S FOR BUTTON HEAD SCREWS

DB

DC*

DB*

DC

DH

DD

DK

Dimensions:

l DIRECTCONNECT Turntable,

Easily Removed, Pin Located

DD

DQ*

DS

DU

l High Quality Aircraft Aluminum, Black Anodized Finish

l Mounts Through Pinion with One Screw and Two Dowels

l No Machining Required, DIRECTCONNECT Grippers Mount Directly

l 90° and 180° Orientations in Stock

Sensor and

Flow Controls

l PNP and NPN Magneto Resistive Available

l Sensors Are Slot Mounted, No Mounting Kits Required

l Precision Rotary Adjustments Made from Face and Locked with Set Screws

l Tubing, Fittings and Additional Pneumatic Controls and Accessories

Available, visit omega.com or Consult Sales

DM

DP

Dimensions: mm (inch)

DIRECTCONNECTTM

dimensions shown in blue

mm (inch)

Dimensions:

mm (inch)

SURFACE "A"

DIRECTCONNECT

Turntable

18.1

(0.715)

OHSN-017

OHSP-017

25.4

(1.00)

DIRECTCONNECT DIMENSIONS

STANDARD MOUNTING PATTERN

FOR ALL SIZES

DA 9.5 mm

DB 19.1 mm

DC 38.1 mm

DD 5 mm THRU

DF C’BORE FOR M5 BUTTON

HEAD SCREW

DH M5 THRU

DJ 76.2 mm

DK 10 mm THRU

DM C’BORE FOR 10 mm

BUTTON HEAD SCREW

DP M10 THRU

DQ 3 H7 THRU

DS C’BORE FOR M3 BUTTON

HEAD SCREW

DU M3 THRU

OHSN-011

OHSP-011

TURNTABLE PLATE DIAMETER AND THICKNESS “B”

THICKNESS DIAMETER

MODEL NO. TURNTABLE NO. mm (inch) mm (inch)

DRF-075M ODRF-002/004 5.9 (0.23) 60 ±0.8 (2.38 ±0.03)

DRF-094M ODRF-008/010 7.1 (0.281) 76 ±0.8 (3.00 ±0.03)

DRF-106M ODRF-014/016 7.9 (0.313) 102 ±0.8 (4.00 ±0.03)

DRF-131M ODRF-020/022 9.5 (0.375) 133 ±0.8 (5.25 ±0.03)

C-21

Page 8

To Order Visit omega.com/drf_075m_094m for Pricing and Details

DEPTH WIDTH HEIGHT MAX PAYLOAD MAX WEIGHT

MODEL NO. mm (inch) mm (inch) mm (inch) Kg (lbs) ROTATION Kg (lbs)

DRF-075M-90 54 (2.13) 69 (2.69) 37 (1.52) 0.23 (0.5) 90° 0.24 (0.54)

DRF-075M-180 54 (2.13) 69 (2.69) 37 (1.52) 0.23 (0.5) 180° 0.24 (0.54)

DRF-075M-90-A 54 (2.13) 151 (5.93) 37 (1.52) 0.45 (1) 90° 0.34 (0.72)

DRF-075M-180-A 54 (2.13) 151 (5.93) 37 (1.52) 0.45 (1) 180° 0.34 (0.72)

DRF-094M-90 71 (2.78) 86 (3.36) 49 (1.76) 0.68 (1.50) 90° 0.50 (1.10)

DRF-094M-180 71 (2.78) 86 (3.36) 49 (1.76) 0.68 (1.50) 180° 0.50 (1.10)

DRF-094M-90-A 71 (2.78) 189 (7.45) 49 (1.76) 1.4 (3.00) 90° 0.64 (1.40)

DRF-094M-180-A 71 (2.78) 189 (7.45) 49 (1.76) 1.4 (3.00) 180° 0.64 (1.40)

DRF-106M-90 100 (3.94) 115 (4.54) 58 (2.28) 1.8 (4.00) 90° 1.1 (2.50)

DRF-106M-180 100 (3.94) 115 (4.54) 58 (2.28) 1.8 (4.00) 180° 1.1 (2.50)

DRF-106M-90-A 100 (3.94) 250 (9.84) 58 (2.28) 3.6 (8.00) 90° 1.4 (3.10)

DRF-106M-180-A 100 (3.94) 250 (9.84) 58 (2.28) 3.6 (8.00) 180° 1.4 (3.10)

DRF-131M-90 133 (5.25) 153 (6.02) 72 (2.82) 3.4 (7.50) 90° 2.9 (6.30)

DRF-131M-180 133 (5.25) 153 (6.02) 72 (2.82) 3.4 (7.50) 180° 2.9 (6.30)

DRF-131M-90-A 133 (5.25) 301 (11.85) 72 (2.82) 6.8 (15.00) 90° 3.1 (6.80)

DRF-131M-180-A 133 (5.25) 301 (11.85) 72 (2.82) 6.8 (15.00) 180° 3.1 (6.80)

Ordering Example: DRF-075M-90-A, precision rotary actuator with 90° of rotation and built in shock absorber. Recommend accessories

include 2 sensors and 2 pneumatic flow controls for each slide, along with a 4-way 2 position valve. DRF-075M models: actuation time

[180° @ 7 bar (100 psi) 0.38 seconds], actuation time [90° @ 7 bar (100 psi) 0.29 seconds]. DRF-094M models: actuation time [180° @ 7 bar

(100 psi) 0.38 seconds], actuation time [90° @ 7 bar (100 psi) 0.29 seconds]. DRF-106M models: actuation time [180° @ 7 bar (100 psi)

0.38 seconds], actuation time [90° @ 7 bar (100 psi) 0.29 seconds]. DRF-131M models: actuation time [180° @ 7 bar (100 psi) 0.38 seconds],

actuation time [90° @ 7 Bar (100 psi) 0.29 seconds]. All models end stop adjustability 23°, over travel (each end) 1 to 3°.

Detailed specification and CAD drawings available at omega.com.

Accessories

MODEL NO. DESCRIPTION

SENSOR ACCESSORIES

OHSP-011 PNP magneto resistive sensor 90° barrell with quick disconnect fitting

OHSN- 011 NPN magneto resistive sensor 90° barrell with quick disconnect fitting

OHSP-017 PNP magneto resistive sensor short barrell with quick disconnect fitting

OHSN- 017 NPN magneto resistive sensor short barrell with quick disconnect fitting

CABL-010 Quick disconnect cable 2 m (6.6') long

CABL-013 Quick disconnect cable 5 m (16') long

PNEUMATIC ACCESSORIES

Pneumatic Tubing Polyurethane tubing in multiple diameters and colors available, visit omega.com

Pneumatic Fittings Rotary sizes 075M to 106M use M5 threads, 131M use 1/8G threads

Pneumatic Flow Controls Adjustable flow control fittings and directional control valves, visit omega.com

MECHANICAL ACCESSORIES

ODRF-002 Rotary size 075M blank turn table, machining required

ODRF-004 Rotary size 075, DirectConnect turntable metric, direct mounting for gripper,

ODRF-008 Rotary size 094M blank turn table, machining required

ODRF-010 Rotary size 094, DirectConnect turntable metric, direct mounting for gripper,

ODRF-014 Rotary size 106M blank turn table, machining required

ODRF-016 Rotary size 106M, DirectConnect turn table, direct mounting for grippers,

ODRF-020 Rotary size 131M blank turn table, machining required

ODRF-022 Rotary size 131M, DirectConnect turn table, direct mounting for grippers,

DMM Series Aluminum extruded mounting stanchions for slides and thrusters, visit¡ omega.com

no machining necessary

no machining necessary

no machining necessary

no machining necessary

C-22

Loading...

Loading...