Page 1

CONTENTS

Chapter 1…………………..Description

Chapter 2…………………..Installation

Chapter 3…………………..Operation

Chapter 4…………………..Omega Viewer

Chapter 5…………..………Specifications

Page 2

Chapter 1

Description

The DP470V is designed as a fully programmable

digital process indicator and miniature datalogger. The unit

will accept either 0-10 Vdc or 4-20 mA input and is fully

scalable from –999 to +9999 display counts. Scaling and

decimal point placement is selectable through the front panel

keys. PROGRAM (P) and PROCESS (L) status are indicated

by a green, .4" seven segment LED located to the right of the

main display.

The displays are 0.56" in-line red LED type. The

menu driven display prompts and 14-segment alphanumeric

characters make programming simple. A single dash (-)

displayed at the left of the readout indicates a negative

reading. Positive readings are inferred (no dash displayed).

Overload is indicated by an 'OL' on the display. Plus OL

(+OL) indicates a positive over range condition. Negative (OL) indicates a negative over range condition. The DP470V

Series is powered by a 100-240Volt, 50-400Hz AC source and

uses a switching power supply for maximum input power

flexibility.

Serial communications is standard, either RS232 or

RS485. This bi-directional serial port allows the user

complete program set-up, programming and operational

capability. All controls and features are selectable through the

front panel. The front panel lens may be removed to install or

remove the program lockout jumper or fine tune the analog

output if necessary. Power and serial connections to the meter

are made to the rear of the instrument via a removable Euro-

1

Page 3

style terminal block. Sensor connections are made by screw

terminals also on the rear of the instrument.

Minimum and Maximum values are always available

for viewing. On the Basic model (no options), the information

is accessible through the front panel menu system.

Configuration settings are stored in on-board memory and are

not affected by power loss.

RS-232 Models RS-485 Models Description

DP470-V-C2 DP470-V-C4 Base Meter

DP471-V-C2 DP471-V-C4 Meter with Dual Alarms

DP472-V-C2 DP472-V-C4 Multi-channel Input Meter

DP473-V-C2 DP473-V-C4 Meter with Analog Out Voltage

DP474-V-C2 DP474-V-C4 Meter with Analog Out Current

Power Options Description

-12VDC 8 to 15 Vdc

-24VDC 20 to 28 Vdc

-24VAC 20 to 28 Vac

Multiple Input and Output Boards for Base Units

DP470-206 Six channel voltage or current inputs

DP470-AOV Analog voltage output board

DP470-AOC Analog current output board

DP470-AL2 Dual alarm output board

DP470-C2-SOFT RS-232 configuration and datalogging

software

DP470-C2-CABLE Configuration cables includes: RS-232 cable

and power cable pre-wired to a

DP470 connector

DP470-PROTOCOL Protocol manual for RS-485

2

Page 4

Chapter 2

Installation

Panel Installation

1. Prepare a mounting panel cutout by cutting a rectangular

hole (3.62” +0.02/-0.0” X 1.77” + 0.02/-0.0”) in the

desired location (see Figure following page). The

maximum panel thickness is 3/8 inches.

2. Remove the mounting bracket from the instrument

housing by removing the two screws on the rear of the

indicator.

3. Remove the pluggable terminal block located at the rear of

the unit and wire the input power and RS232 or RS485

wires. If an option board is installed in the indicator,

remove

the connector and make the appropriate connections (refer

to

diagram on page 6).

WARNING!

Dangerous voltages are exposed at the screw

terminals. Always remove power before working in

this area for rewiring, disassembly, and all other

activities that involve proximity to electrical

circuitry. Allow at least 10 minutes prior to

working on the unit.

3

Page 5

PANEL CUTOUT

1.77 in.

+0.02/-0.0

3.62 in.

+0.02/-0.0

4. Install the indicator in the panel cutout from the

front side of the panel. Be sure the instrument is

right-side-up. See figure on following page.

5. Reinstall the mounting bracket on the indicator.

Tighten the bracket screws to achieve a snug fit

against the panel. Avoid distorting or cracking the

housing by not over- tightening the bracket screws.

4

Page 6

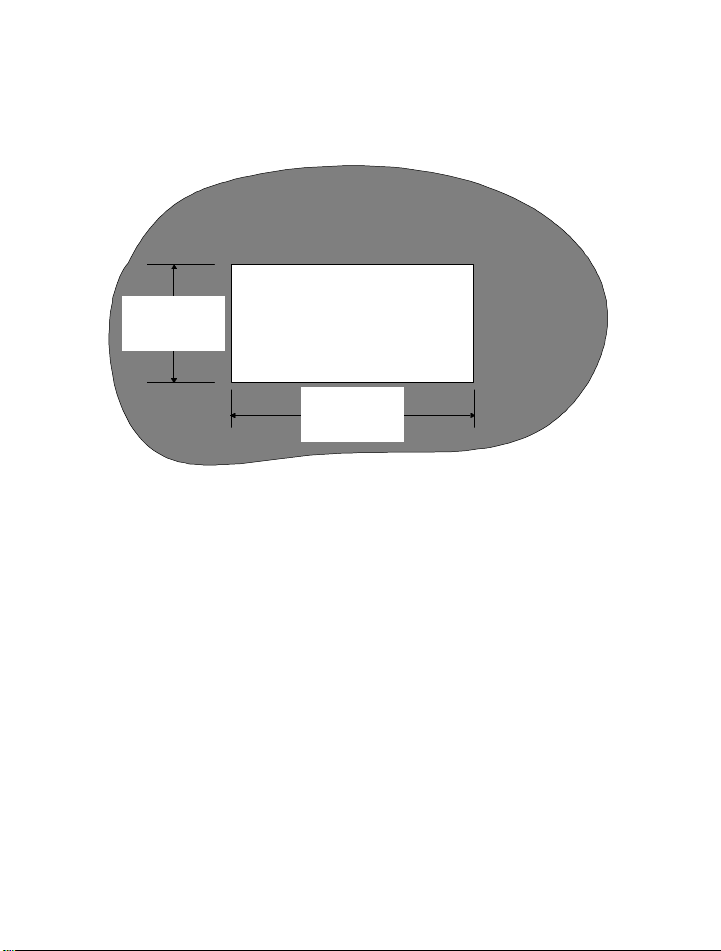

INSIDE

BRACKET

SCREWS

.27"

(7mm)

4.92"

(142mm)

5.80"

(148mm)

CASE

3.78"

(96mm)

5

Page 7

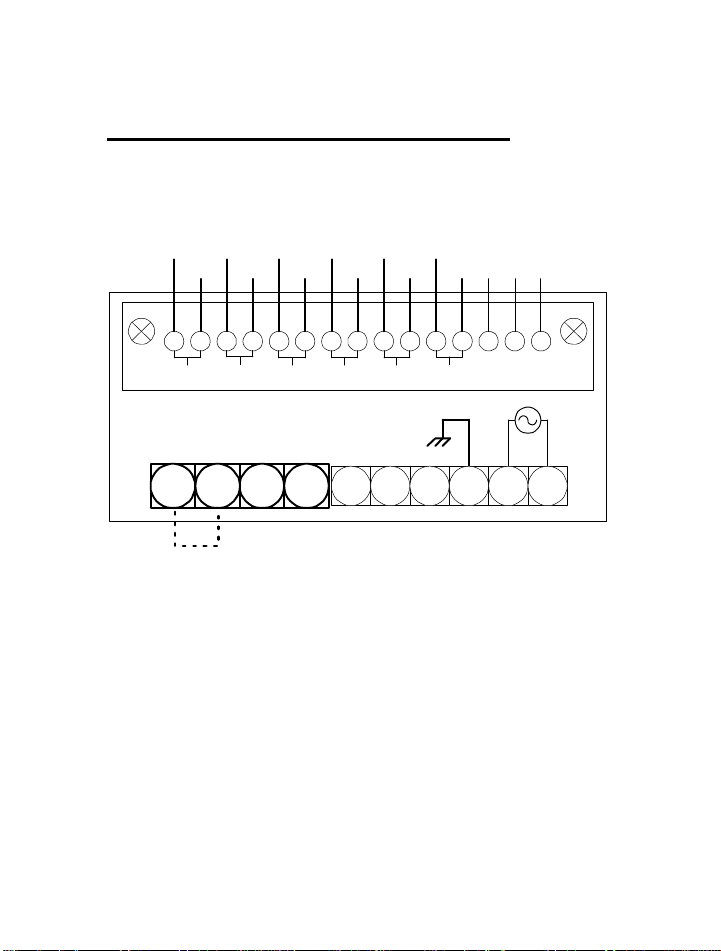

Single Channel Wiring (DP470)

100/240VAC HOT

For easy installation, remove the pluggable terminal block

located at the rear of the unit. Connect the input power and

RS232 or RS485 wires to the wire entry locations beneath and

perpendicular to the plug-in direction according to figure

below.

-I

1

2 3 4

-V

NOTE: FOR 4 TO 20 mA CURRENT INPUT ADD

JUMPER (NOT INCLUDED) BETWEEN TERMINALS 1

AND 2

+V

+I

SERIAL RXD

SERIAL TXD

SERIAL COM

GND

5 6 7 8 9 10

NEUTRAL

WARNING!

Dangerous voltages are exposed at the screw

terminals. Always remove power before working in

this area for rewiring, disassembly, and all other

activities that involve proximity to electrical

circuitry.

6

Page 8

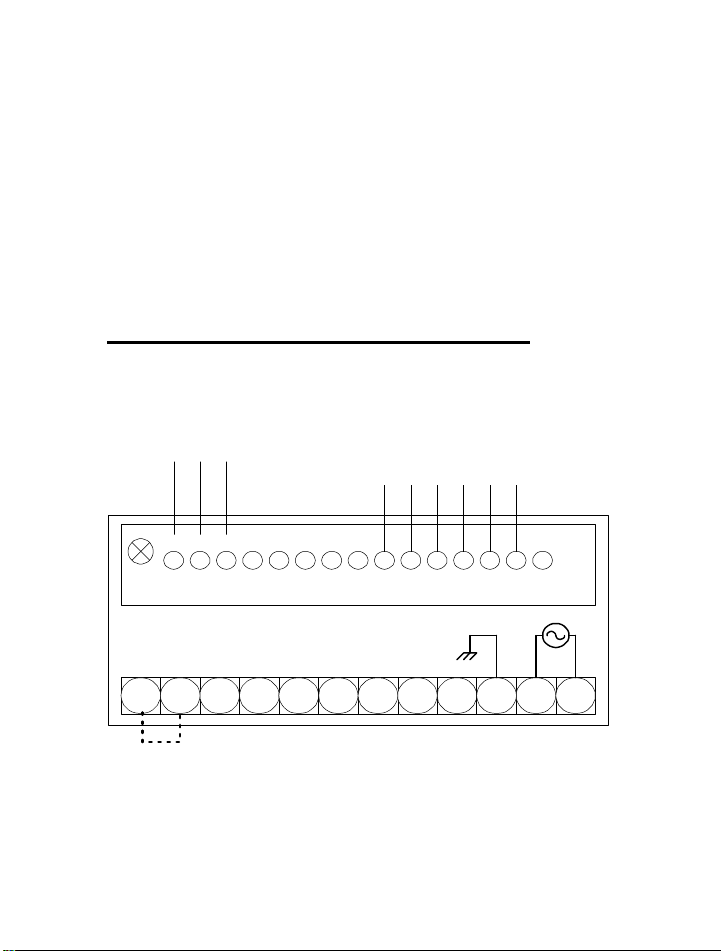

Multiple Channel Wiring (DP472)

6-CHANNEL MULTIPLE INPUT WIRING DIAGRAM

+

+-+-+ +

-

1 2 4 5 6 7 83

CH1 CH2 CH3 CH4 CH5 CH6

- -

+

-

10 11 12 13 14 15

9

RELAY NO

COMMON

RELAY NC

1 2 3 4

NOTE: FOR 4 TO 20 mA CURRENT INPUT ADD

JUMPER (NOT INCLUDED) BETWEEN TERMINALS

1 AND 2

5 6 7 8 9 10

Multiple input current configuration:

Remove power and snap off the front panel lens. Leave the

keypad attached to the display board, as it will be required to

enter the calibration menu. Remove the rear pluggable

connectors from the rear of the indicator and slide the main

board electronics out of the case from the front. (Gently lift

the display board above the catch located on the bottom of the

inside of the plastic housing while pushing on the rear male

7

Page 9

connector on the rear of the main board assembly.) Locate the

three-pin header near the rear of the unit. Move the jumper

from position A to position B. Carefully re-install the

electronics back into the housing and wire the inputs

according to the diagram on page 7.

Note: If the multiple input option is used to switch 4

to 20 mA inputs, note that loop continuity will not

be maintained when changing channels.

Analog Output/Dual Alarm Wiring

ALOG +V/-I

ALOG +I

ALOG -V

COM2

RELAY2 NC

9 10 11 12 13 14 151 2 4 5 6 7 83

COM1

RELAY1 NC

RELAY2 NO

RELAY1 NO

1 2 3 4 5 6 7 8 9 10 11 12

NOTE: FOR 4 TO 20 mA CURRENT INPUT ADD JUMPER (NOT

INCLUDED) BETWEEN TERMINALS 1 AND 2

8

Page 10

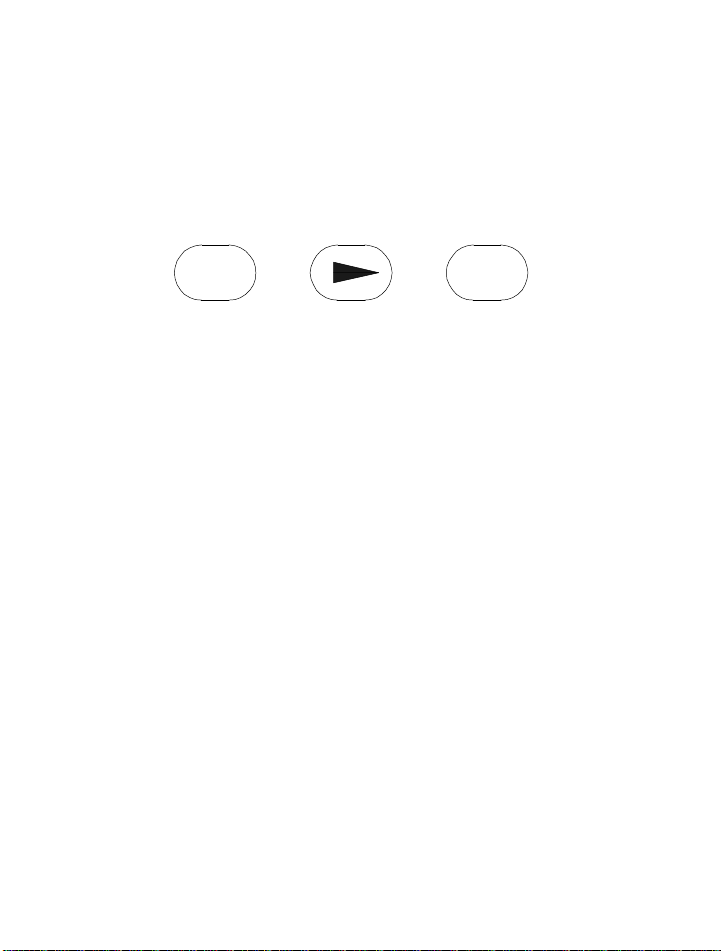

Chapter 3

PGM

Operation

Your indicator is programmed by a series of menu driven

displays that are operated by three front panel pushbuttons;

Program-PGM, Arrow-∆, and Enter-ENT.

ENT

PROGRAM ARROW ENTER

Addressing the main menu items configures the indicator.

The indicator has a program lockout jumper located behind

the front panel lens. Removing the jumper will prevent any

front panel changes of the indicator programming. The

indicator may still be programmed via the computer interface.

Note: When using the DP470 Viewer Software, the front

panel keyboard is automatically disabled.

The basic unit has three main menu items-

1. SCAL: Sets up desired display counts

including decimal points.

2. MATH: Selection enables viewing of either

minimum or maximum value.

3. CAL: Used for calibrating the voltage or

current limits.

9

Page 11

The following menu items are displayed only when the

appropriate option is installed-

4. ALM1/ALM2: Sets relay trip points to

programmed values, hysteresis and delay.

5. AOUT: Programs the indicator to translate the

display to a proportional analog voltage or

current output.

6. MULT: Configures indicator for multiple

voltage or current inputs

Pressing the PGM key allows you to access any of the menus

listed above by placing the indicator in program mode,

indicated by a ‘P’ lit to the right of the display. Placing the

indicator in PGM mode will prevent the indicator from

performing measurements. Any alarm monitoring will be

disabled.

If the PGM key is pressed anywhere within a menu,

the menu reverts to the previous menu level. Repeatedly

pressing the PGM key will return the indicator to the display

mode. Choices within a menu are viewed by pressing the

ARROW key. A menu item is selected by pressing the ENT

key for selection, or edited by pressing the ARROW key.

Generally, the ARROW key allows you to scroll horizontally

through a selection of choices while the ENT key enables you

to make selections and move down vertically to the next menu

item.

10

Page 12

Unlatching the Relays

The keypad may be used to unlatch the relays in MAN

(manual) mode. If the DP470 Viewer Software is being used

the front panel keypad becomes disabled and the relays can be

unlatched only through the software control panel.

-Relay #1 may be unlatched by pressing and holding

the ARROW key while pressing the PGM key.

-Relay #2 may be unlatched by pressing and holding

the ARROW key while pressing the ENT key.

Scaling and Calibration

For the indicator to display in your desired engineering units,

the indicator must be scaled and then calibrated. Scaling and

calibration are performed in the SCAL and CAL menus

respectively. The SCAL menu allows you to set the desired

engineering units within a range of –999 to +9999 counts.

The CAL menu requires the actual simulation of two

different inputs (typically 0 to 10 Vdc or 4 to 20 mA).

Calibration can be performed through the front panel keypad

or PC interface.

Note: It is not necessary to recalibrate when the

indicator is rescaled.

11

Page 13

Scaling Procedure

Example: Program the indicator to display 0-5000

lbs. With a 4 to 20mA input signal.

STEP 1. Press the PGM button. PGM will appear on the

display. The indicator status LED will change from L (linear)

to P (for ‘Program Mode’) and the SCAL menu will appear.

Press ENT.

STEP 2. A LOW or HIGH will appear. Pressing the

ARROW key repeatedly will cause LOW and HIGH to

alternate on the display. With LOW on the display, select

LOW by pressing the ENT key. The digits 0000 will appear

with the left most digit flashing. With the ARROW key

select the number 0. Press ENT. The second digit will flash.

Enter 0 again with the ARROW key. Continue on until 0000

is on the display. Press ENT.

STEP 3. A HIGH will appear on the display. Press the

ARROW key. A number with the left most digit flashing will

appear on the display. Using the ARROW key, set the left

most digit until the number 5 appears. Press ENT. The next

digit will flash. Use the ARROW key to set the remaining

digits to 000. With the right most 0 flashing, press ENT.

dCPT will appear.

12

Page 14

STEP 4. With dCPT on the display, press the ARROW

until the decimal point disappears. Press ENT. The CAL

menu appears on the display. The scaling portion is now

complete.

Calibration Procedure

4 to 20mA Input

STEP 1. Hook up the current input to terminals 1 (-I) and 4

(+I) according the wiring diagram on page 6. In addition, for

4-20mA current inputs install jumper wire between terminals

1 and 2.

STEP 2. With the CAL menu on the display, press ENT.

INLO will appear on the display. Input 4.00 mA and press

ENT. INHI will appear on the display.

STEP 3. With INHI on the display, input 20.0mA into the

meter. Press ENT. Calibration is complete.

0 to 10 Vdc Input

STEP 1. Hook up the current input to terminals 2 (-V) and

3 (+V) according the wiring diagram on page 6.

STEP 2. With the CAL menu on the display, press ENT.

INLO will appear on the display. Input 0.0 Vdc and press

ENT. INHI will appear on the display.

STEP 3. With INHI on the display, input 10.0 Vdc into the

meter. Press ENT. Calibration is complete.

13

Page 15

Math Function Setup

*For DP472 multi-channel models, MATH

functions can only be viewed through the Omega

DP470 Software.

Example: View the maximum display value recorded.

Note: A running record is kept of the minimum and

maximum display values. Nothing is required to

initiate this recording. These values are there

whenever you need them. You can display the

Minimum or Maximum value by following the steps

below.

STEP 1. With the MATH menu on the display, open this

menu item by pressing the ENT key. MIN will appear on the

display.

STEP 2. Press the Arrow key to toggle between MIN and

MAX. When the display shows MAX, press the ENT key and

the display will now indicate the maximum value. The

MIN/MAX memory may be reset at this point by pressing the

ARROW key. With CLR (CLEAR) on the display, press

ENT. This will restart the recording process. To go back to

the current temperature display, press the PGM button and

the display will indicate the current temperature reading.

14

Page 16

Multiple Input (DP472)

Note: For multiple-channel 4 to 20 mA current inputs,

see the instructions in Chapter 2 page 7.

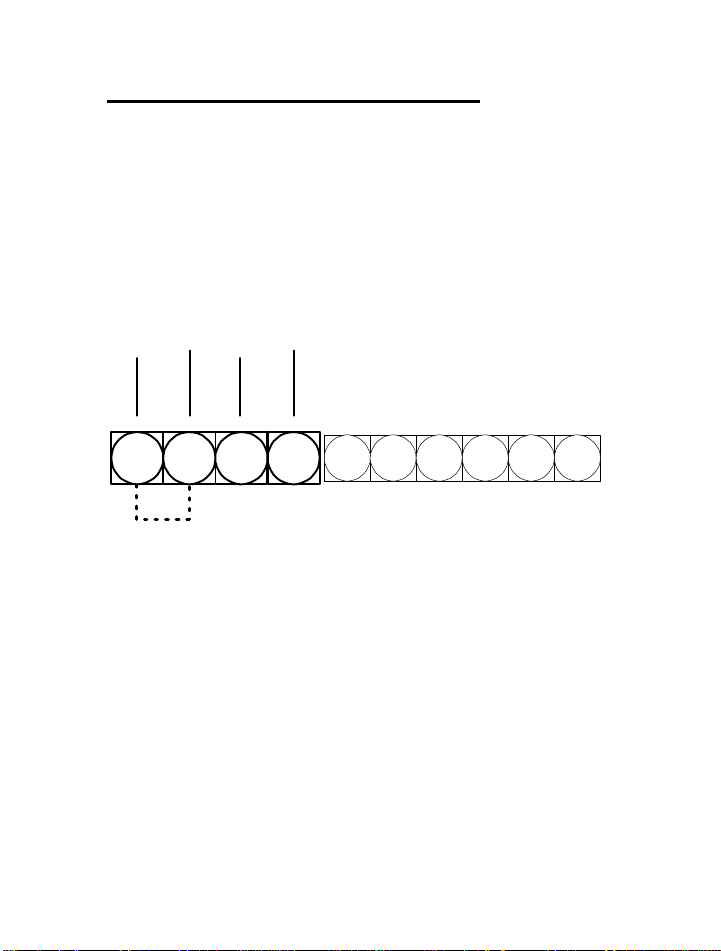

The multiple input option will enable the user to

monitor up to 6 same type inputs, either voltage or current.

Any number of channels can be selected manually or scanned

automatically. Alarm limits may be assigned to individual

channels. One NO/NC 5 amp 115VAC relay contact is

available for high or low alarm limit programming.

Two scanning modes are selectable for the multiple

input option- manual (MAN), and automatic (AUTO). MAN

mode allows the user to view a selected channel. Pressing the

arrow key advances the display to the next active channel.

The channel number is indicated by a .4” green LED located

in the upper left-hand corner of the display. To begin

automatic scanning, enter the MULT menu, and select

AUTO. The scan rate is selectable in one-second increments

between 5 and 20 seconds. The display readout will then

sequentially show the display values of the active channels.

Any number of channels may be selected for scanning.

If an alarm limit is exceeded on any displayed

channel, the display will flash, and the relay contact will

latch. The relay will remain latched until the alarm condition

clears. In scanning mode the display will flash on the alarm

channel as it scans.

By using the Omega DP470 Viewer, the DP470 can

log and send multiple channel data through the serial port

making it a miniature datalogger (see Chapter 5).

15

Page 17

Dual Alarm (DP471,DP473,DP474)

The alarm card has two 5 amp/115VAC relays for high, low

or deviation set points. The alarm card is available by itself or

with analog output (either voltage or current). Relay set

points are programmed through the front panel menu or via

the serial port. An alarm limit may be disabled within the

alarm menu by selecting OFF at the first menu prompt. If

OFF is selected the display will return to the next main menu

item for further programming. If ON is selected the menu

proceeds down through the alarm menu for further set point

programming.

The relays can be operated in MAN or AUTO mode.

In AUTO mode, the relay unlatches by itself once the alarm

limit is no longer exceeded.

In MAN mode the relay is reset manually. However,

the display continues to flash until the alarm limit is no

longer exceeded.

- Pressing and holding the ARROW key and pressing

the PGM key resets Relay 1 (ALM1).

- Pressing and holding the ARROW key and pressing

the ENT key resets Relay 2 (ALM2)

Note: When using Viewer Software, the front panel keys

are disabled. Relays must therefore be reset using the

Unlatch buttons on the Viewer control panel.

When HIGH is selected, a displayed value greater

than the limit value will cause an alarm. When LOW is

selected, a displayed value less than the limit value will cause

an alarm.

16

Page 18

Note: When setting alarm limits enter only the raw

counts. Ignore any decimal points. For example, an

alarm limit of 100.0 would be entered as 1000.

Using Deviation

Deviation allows the user to assign alarm limits above and

below the normal operating points of a process. If the

displayed value remains within the high and low deviation set

points no alarm occurs. If the displayed value equals or

exceeds either the high or low deviation limits an alarm

occurs. Hysteresis and delay are also programmable for

deviation set points (see following explanations). Deviation

allows the user to assign two set points per alarm relay for a

total of four alarm set points per alarm option (See drawing

below). This could be useful for indicating a warning

condition with one relay and an emergency condition for the

other relay.

upper

deviation

limit

normal

operating

point

lower

deviation

limit

TIME

17

Page 19

Hysteresis

Hysteresis or deadband is used to prevent the latching and

unlatching of an alarm relay around the set point. Hysteresis

is selectable from 0-500 counts in 1-count increments.

Hysteresis assumes negative values for HIGH limits and

positive values for LOW limits.

For example:

- Alarm limit set to High

- The alarm set point is 5000

- Hysteresis is set at 50 counts

If the display value exceeds 5000, the alarm relay closes and

the display flashes. The relay will not open until the display

value drops below 4950.

Delay

Programming the meter for alarm delay prevents an alarm

trip for a specified period of time (0-99 seconds). An alarm

delay would be used whenever an unstable or noisy input

signal is present. By filtering out short duration alarm

conditions, alarm delay prevents unnecessary alarms from

occurring.

Analog Output (DP473, DP474)

The analog output option translates the indicators’ display

reading to a proportional analog output signal. There are two

versions of the analog output option, either 0-10VDC

(DP473) or 4 to 20ma (DP474). Both voltage and current

outputs are scalable within their ranges and are similarly

programmed. Note that the analog output is active only in the

display mode. When in Program mode, the output goes to its

18

Page 20

zero output value. The display reading can be scaled from 999 to +9999, which enables the user to use only a portion of

the full scale if necessary.

Analog Output Setup

Example 1: Program the indicator to output 4.0 ma at 0

lbs. and 20.0 ma at 8000lbs.

STEP 1. Press the PGM button. PGM will appear on the

display. The P/L LED will change from L to P (for ‘Program

Mode’).

STEP 2. Press the Arrow key until ALOG appears on the

display. Open the ALOG Menu for programming by pressing

the ENT key.

STEP 3. A LOW or HIGH will appear. Pressing the Arrow

key repeatedly will cause LOW and HIGH to alternate on the

display. With LOW on the display, select LOW by pressing

the ENT key. The digits 0000 will appear with the left most

digit flashing. With the ARROW key select the number 0.

Press ENT. The second digit will flash. Enter 0 again with

the ARROW key. Continue on until 0000 is on the display

with the right most digit flashing. Press ENT.

STEP 4. HIGH will appear on the display. Press ENT. Set

the first digit to 8 by using the ARROW button. Set the

second digit to 0 and so on until 8000 is on the display. With

the farthest digit to the right flashing, press ENT. The next

menu item appears.

19

Page 21

Example 2: Program the indicator to output 0.0 Vdc at

0 gallons and 5.0 Vdc at 4000 gallons.

Note: The analog output may be scaled to output

various voltages such as 0 to 2VDC, 1 to 5VDC etc.

STEP 1. Press the PGM button. PGM will appear on the

display. The P/L LED will change to P (for ‘Program Mode’).

STEP 2. Press the Arrow key until ALOG appears on the

display. Open the ALOG Menu for programming by pressing

the ENT key.

STEP 3. A LOW or HIGH will appear. Pressing the Arrow

key repeatedly will cause LOW and HIGH to alternate on the

display. With LOW on the display, select LOW by pressing

the ENT key. The digits 0000 will appear with the left most

digit flashing. With the ARROW key select the number 0.

Press ENT. The second digit will flash. Enter 0 again with

the ARROW key. Continue on until 0000 is on the display

with the 0 flashing. Press ENT.

STEP 4. HIGH will appear on the display. Press ENT. Set

the first digit to 8 by using the ARROW button. Set the

second digit to 0 and so on until 8000 is on the display. With

the farthest digit to the right flashing, press ENT. The next

menu item appears.

20

Page 22

Analog Output Calibration

Current: 4 to 20mA (DP474)

NOTE: The Analog Output Current option is

calibrated from the factory to output 20.00 ma with

100.0 on the display and 4.00 ma with 0.0 on the

display. The output may be trimmed to meet your

specific application.

Equipment Required:

1. Precision current meter with 0.1% accuracy and 10uA

resolution.

2. Interconnecting copper wire from the DC current meter

to the indicator, +I to terminal 3 and –I to terminal 1 of

the 15 position terminal block located at the rear of the

unit.

3. Trimmer adjusting tool.

4. Precision voltage (accuracy ± .01% ±2uV) or current

source (accuracy ±0.1% ±2uA).

STEP 1. Remove power and snap off the front panel lens.

Leave the keypad attached to the display board, as it will be

required to enter the programming menu.

21

Page 23

STEP 2. Apply power to the unit and allow at least a 10-

minute warm-up. Program the unit for the appropriate sensor

type.

STEP 3. With the input set to correspond with the LOW

input, adjust the zero pot to read 4.00ma on the DC Ammeter.

STEP 4. With the input set to correspond with the HIGH or

full scale input, adjust the full-scale potentiometer to read

20.00ma on the DC Ammeter.

FULL SCALE

ZERO

Voltage: 0 to 10 Vdc (DP473)

NOTE: The Analog Output Voltage option is

calibrated from the factory to output 10.00 VDC

with 100.0 on the display and 0.00 VDC with 0.0 on

the display. The output may be trimmed to meet

your specific application.

22

Page 24

Equipment Required:

1. Precision voltage meter with 0.1% accuracy and

10mVdc resolution.

2. Interconnecting copper wire from the DC voltmeter to

the indicator, -V to terminal 3 and +V to terminal 1 of

the 15 position terminal block located at the rear of the

unit.

3. Trimmer adjusting tool.

4. Precision voltage (accuracy ± .01% ±2uV) or current

source (accuracy ±0.1% ±2uA).

STEP 1. Remove power and snap off the front panel lens.

Leave the keypad attached to the display board, as it will be

required to enter the programming menu.

STEP 2. Apply power to the unit and allow at least a 10-

minute warm-up. Program the unit for the appropriate sensor

type.

STEP 3. With the input set to correspond with the LOW

input, adjust the zero pot to read 0.00Vdc on the DC

voltmeter.

STEP 4. With the input set to correspond with the HIGH or

full scale input, adjust the full-scale potentiometer to read

10.00Vdc on the DC Voltmeter.

23

Page 25

Chapter 4

Omega DP470 Viewer Overview

DP470 Series indicators interface to PC compatible

computers through the RS232 port. Remote monitoring as

well as scaling and calibration can be accomplished without

the use of the front panel keys. Configuration of RS232 is

accomplished simply by selection of an active COM port.

Baud rate and communications parameters are automatically

configured. All DP470 series features (Alarm Status, Input

Identification, Min/Max Indication, Time Tagged Readings)

are presented with a simulated LED display in an on-screen

control panel format. A bar graph located below the simulated

display indicates the percentage of full scale.

The internal clock is automatically set to your computer’s

time and date each time you launch the DP470 Viewer

Software. The Omega DP470 Viewer enhances the DP470

series indicators by adding large volume data logging

capability. Data is logged to formatted ASCII text files that

are compatible with most modern spreadsheet applications.

Data can be logged in increments from 1 minute to 24 hours.

Minimum PC requirements

486 Processor minimum (Pentium recommended)

Windows 95/NT

16 Mb ram (32 recommended)

Mouse

3.5 inch disk drive

9 or 25 pin serial port-max length 50 feet

24

Page 26

File Formats

Space delimited ASCII text

DATE TIME AM/PM CHAN READING ALM STATUS (optional)

Alarm relay status not present on the model DP470.

Units with alarm relays installed also indicate alarm status within

the file text. Alarm SET (S) or Alarm CLEAR (C) are located in the

far right column.

Installation

1. Connect a communications cable between your PC and

the meter according to the diagram next page.

2. Start Windows 95.

3. Insert disk into drive A or (B).

4. In Windows 95 choose RUN from the Start menu.

5. Type A:\setup (or B:\setup) and click OK.

The Installation Wizard will guide you through the remainder

of the installation procedure.

COM port 1 is the default port. After installation the indicator

will attempt to establish communications with COM port 1. If

the unit is not communicating ensure the serial

communications cable is wired correctly and the proper COM

port is selected. Another COM port may be selected through

25

Page 27

the Preferences menu. After selecting another COM port, the

application must be closed and then reopened again.

Note: Once communications is established, the PC

has control of the instrument and the front panel

keys become non-functional. In order to regain

control of the front panel the software program

must be closed. Configuration data is

automatically saved each time you exit the

program.

REAR VIEW

5 6 7 8 9 101 2 3 4

PC 9-PIN OR 25 PIN

RS232 CONNECTOR

72 3

26

Page 28

General Operation

The simulated display on the control panel represents the

current reading. The following parameters may be selected

through the preferences menu.

- Display scaling

- Datalogging

- Software alarms

- Engineering units

The control panel can be minimized at any time while

maintaining communications and control of the indicator.

Alarms

A small box located to the left of the alarm box indicates

alarm status. An L inside the box indicates a low alarm limit

and an H indicates a high alarm limit. A gray box with no

letter indicates an inactive alarm.

- A green box indicates an active alarm not

in an alarm condition

- A flashing red box indicates that the channel is

in an alarm condition

If an alarm condition occurs while the Viewer window is

minimized, the window will reopen automatically to alert the

user that an alarm limit has been exceeded. The window

cannot be minimized when alarming.

27

Page 29

Multiple Input

Active channels, Minimum and Maximum values and alarm

status of each channel can be viewed simultaneously. The

following parameters may be selected through the preferences

menu:

- Channel ID

- Auto/Manual scan

- Scan rate (5 to 20 seconds)

- Alarm limits

When in MANUAL mode, the instrument can only monitor

the selected channel. The selected channel and its ID is

displayed under the simulated display

- The next active channel may be viewed by

pressing the NEXT button located beneath and

to the left of the simulated display

- If a selected channel alarms and the next

channel is selected, the flashing red indicator

turns yellow. This indicates that this channel

was in an alarm condition when last viewed.

The time a Minimum or Maximum occurred can be viewed

by clicking the TIME button located near the MIN/MAX

section of the control panel.

28

Page 30

Logging data

To create a file of logged data, open the preference menu by

clicking the Preferences button located in the upper right

hand corner of the Viewer window. Open the LOG menu by

clicking the LOG button. You may name your file any

acceptable Windows 95 name. The default file extension is

.dat. The path for your log file will be shown on the main

control panel window. Select the interval (between 0-24

hours at 1-minute increment.) at which logs will be taken.

Close the log preference window. To begin logging, click the

button on the main control panel labeled OFF. The button

will change to ON and the unit will now begin logging. The

log data can be reviewed by clicking the ON/OFF button and

opening the log file.

29

Page 31

Chapter 5

General Electrical Specifications

Input Range:

mA: 0 to 20 mADC

Voltage: 0 to 10VDC

Sensitivity:

Maximum: 200uV/count; 0.4 uA/count

Minimum: 1 count

Accuracy Specification (at ROC):

0.02%± 1 digit

Reference Operating Conditions: (ROC)

23±2°C ambient temperature

<80% RH non-condensing

Repeatability +/- 1 Count (single channel only)

Stability with temperature

Zero: 1uV/° C

Span: .01%/rdg/°C

Noise Rejection

NMRR: 60dB @ 50/60 Hz

CMRR: 120dB @ 50/60 Hz (+/-0.1Hz with 250Ω

unbalance)

30

Page 32

Overload Protection

Power leads to ground: (1500Vdc or Vac RMS)

Across inputs, for one minute:

Voltage: up to 250Vdc or Vac, V+ to VCurrent: up to 75mA dc or mA Ac

Input Impedance

Voltage: 1 MΩ

Current: 10Ω

Point Update Rate

2 per second nominal

Display

4 Digit, 14-segment red or green .56 in. height

LED plus 1.4 inch green L/P LED

Environmental Ranges

Operating: 0°C to 50°C

Storage: -40°C to +65°C

Humidity: ≤80%RH non-condensing

Alarm Relay Contact Rating

5A@ 120Vac(non-inductive load) Form C

Power 100-240Vac (±10%), 50-400Hz, switching power

supply

31

Page 33

RS-232 Serial Communications (-C2)

Type: Full-duplex voltage, isolated from ground to 500Vac.

Complete configuration set-up and message display

capability, programmable to transmit current display. 9600

bps 8 bits no parity 1 stop bit. Isolation: Isolated between

input and internal circuit to 500VAC

RS-485 Serial Communications (-C4)

Type: Two-wire connection. Half-duplex, bi-directional

voltage isolated from ground to 500Vac. Communications

uses MODBUS-RTU protocol with selectable baud rate from

1200-19.2K baud. Addressable up to 99. Transmit of RS-485

interface is connected to terminal 6 of the DP470. Receive is

connected to terminal 5 of DP470.

Analog Output (Option)

0-10Vdc (load current 2ma maximum)

4-20mA dc (load resistance 300Ω maximum)

Accuracy: ±0.25% full scale of display value

Resolution: Approximately .0125 full scale

Isolation: Isolated between input and internal circuit

to 500Vac.

32

Page 34

Notes:

33

Loading...

Loading...