Page 1

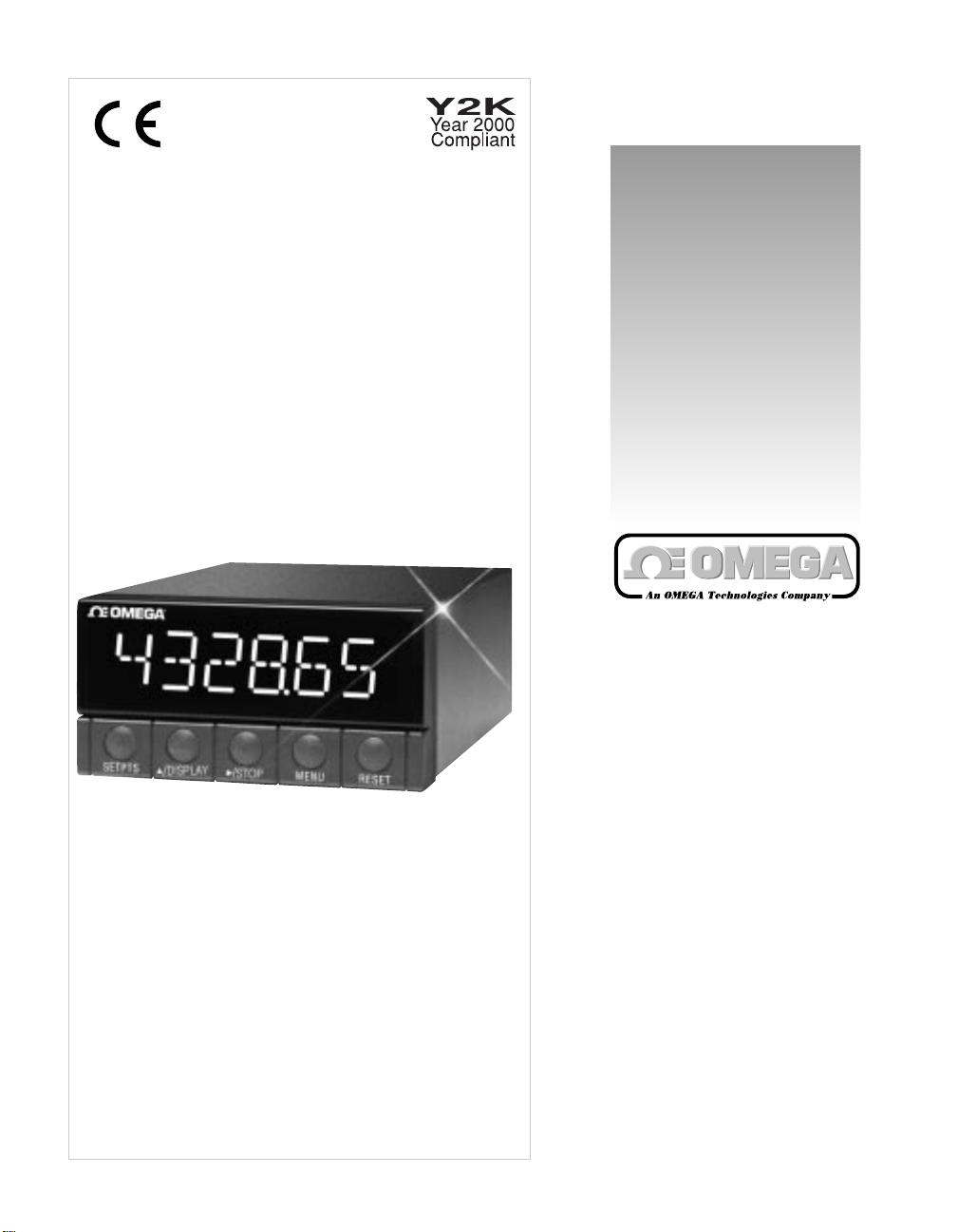

®

Made in the USA

User ’s Guide

http://www.omega.com

e-mail: info@omega.com

DPF400 Series

High Accuracy Frequency or

Analog Input Flow Indicator

Page 2

®

®

OMEGAnet® On-Line Service Internet e-mail

http://www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

Mexico and

Latin America:

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Tel: (95) 800-TC-OMEGA

SM

En Espan˜ol: (203) 359-7803 e-mail: espanol@omega.com

SM

SM

SM

FAX: (95) 203-359-7807

Servicing Europe:

Benelux: Postbus 8034, 1180 LAAmstelveen, The Netherlands

Czech Republic: ul.Rude armady 1868, 733 01 Karvina - Hranice

France: 9, rue Denis Papin, 78190 Trappes

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

United Kingdom: One Omega Drive,

ISO 9002 Certified River Bend Technology Centre

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certification of its products to the European New Approach Directives.

OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts no liability for

any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

This device is marked with the international caution symbol. It is important to read the Setup Guide before

installing or commissioning this device as it contains important information relating to safety and EMC.

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

e-mail: czech@omega.com

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

Northbank, Irlam,

Manchester, M44 5EX, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

e-mail: info@omega.co.uk

Page 3

Table of Contents -

HOW TO USE THIS MANUAL

This manual is organized to follow a sequence of setting up the

meter, configuring it, and operating it. The table of contents

reflects this sequence. The contents also show that the manual

contains a lot of information; we have taken care to answer likely

questions and provide all the information you may need. We have

purposely included all sections in the contents, to allow you to use

it as an index–to easily pinpoint specific information and go

directly to it.

Page

SAFETY CONSIDERATIONS.......................................................................vi

SECTION 1 INTRODUCTION

1.1 Description ...................................................................................1

1.2 Features.........................................................................................1

1.3 Meter Modes.................................................................................2

1.3.1 Rate Meter/Totalizer.....................................................................2

1.3.2 Rate Meter/Totalizer/Square Root Extractor ...............................2

1.3.3 Batch Controller...........................................................................2

1.3.4 Clock.............................................................................................2

1.4 Optional Boards Overview...........................................................3

1.4.1 Isolated Pulse Input Board............................................................3

1.4.2 Isolated Analog Input Board........................................................3

1.4.3 Isolated Analog Output Board.....................................................4

1.4.4 Isolated Parallel BCD Output Board............................................4

1.4.5 Dual Relay Output and 4 Relay Output Board............................4

1.4.6 Isolated RS-232 Serial Communications Board ..........................4

1.4.7 Isolated RS-485 Serial Communications Board .........................5

1.5 Available Models and Options.....................................................5

Table of

Contents

SECTION 2 SETUP

2.1 Unpacking ....................................................................................8

2.2 Safety Precautions ........................................................................10

2.2.1 Power Voltage...............................................................................10

2.2.2 Power Wiring................................................................................11

2.3 Assembly/Disassembly ..................................................................11

i

Page 4

Table of

Contents

Page

2.3.1 Opening the Meter.......................................................................11

2.3.2 Checking and Installing Jumpers.................................................15

2.3.2.1 Main Board Jumpers .....................................................................16

2.3.2.2 Optional Input and Output Board Jumper Information .............18

2.3.3 Installing Optional Boards ...........................................................19

2.3.3.1 Isolated Pulse Input Board............................................................21

2.3.3.2 Isolated Analog Input Board........................................................22

2.3.3.3 Isolated Analog Output Board .....................................................23

2.3.3.4 Isolated Parallel BCD (Binary-Coded Decimal) Output Board ..24

2.3.3.5 Dual Relay and 4 Relay Output Board ........................................25

2.3.3.6 Isolated RS-232 Serial Communications Board ..........................25

2.3.3.7 Isolated RS-485 Serial Communications Board ..........................26

2.3.4 Reinserting the Main Board Assembly into the Case .................26

2.3.5 Wiring...........................................................................................26

2.3.5.1 P1 - AC Power Wiring.................................................................27

2.3.5.2 Battery Backup Connections........................................................27

2.3.5.3 P2 - Control Input/Output Wiring ..............................................28

2.3.5.4 Basic Meter Input Wiring.............................................................29

2.3.5.5 Isolated Pulse Input Board Wiring...............................................29

2.3.5.6 Isolated Analog Input Board Wiring ...........................................29

2.3.5.7 Isolated Analog Output Board Wiring.........................................29

2.3.5.8 Isolated Parallel BCD Output Board Wiring...............................29

2.3.5.9 Dual Relay and 4 Relay Output Board Wiring............................30

2.3.5.10 Isolated RS-232 or RS-485 Serial Comm. Board Wiring............30

2.4 Panel-Mount Assembly ................................................................30

SECTION 3 FRONT AND REAR FEATURES

3.1 Front-Panel Displays and Buttons................................................33

3.2 Rear Connectors...........................................................................35

SECTION 4 BASIC CONCEPTS AND APPROACHES

TO SETUP AND CONFIGURATION

4.1 Choosing an Operating Mode......................................................39

4.2 Mode-Associated Measurements..................................................39

4.3 Using Scale Factors ......................................................................40

4.4 Using Offsets.................................................................................40

4.5 Automatic Scale and Offset.........................................................40

4.6 Overflow Values and Exponential Format...................................41

4.7 Negative-True Logic.....................................................................41

4.8 Different Meter Modes.................................................................41

4.9 Setpoints.......................................................................................42

4.9.1 Setpoint Assignments...................................................................42

4.9.2 Configuring Setpoints ..................................................................44

ii

Page 5

Page

4.10 Resets and Stops...........................................................................44

4.10.1 Power-On (Hard) Reset ...............................................................44

4.10.2 Configuration (Cold) Reset .........................................................44

4.10.3 Setpoint-Only Reset.....................................................................45

4.10.4 Rate and Sq Rt Mode Resets........................................................45

4.10.4.1 RESET-A ......................................................................................45

4.10.4.2 RESET-B.......................................................................................46

4.10.4.3 RESET-C.......................................................................................46

4.10.4.4 Front-Panel RESET......................................................................46

4.10.5 Batch Mode Resets.......................................................................47

4.10.5.1 RESET-A ......................................................................................47

4.10.5.2 RESET-B.......................................................................................47

4.10.5.3 RESET-C.......................................................................................47

4.10.5.4 Front-Panel RESET......................................................................48

4.10.5.5 Autoreset ......................................................................................48

4.10.6 STOP ............................................................................................48

4.11 Counting Up or Down .................................................................48

4.11.1 Counting Up.................................................................................49

4.11.2 Counting Down............................................................................50

4.12 An Example Showing Setpoint and Reset Control ....................52

Table of

Contents

SECTION 5 CONFIGURING THE METER

5.1 Parameters, Choices, and Settings ...............................................54

5.2 The Basics of Configuration.........................................................55

5.3 Lockouts........................................................................................56

5.3.1 Lockouts and Corresponding Actions..........................................57

5.3.2 Setting Lockouts...........................................................................60

5.3.3 Removing the S1-A Jumper for Added Security.........................61

5.4 Other Meter Parameters...............................................................61

5.4.1 MODE (Operating Mode) ...........................................................61

5.4.2 CNFG 1 through CNFG 4 (Configuration Parameters)

Rate, Sq Rt, Batch........................................................................61

5.4.3 AVG.CNF (Running Average Configuration) Rate, Sq Rt........69

5.4.4 IN.SC.OF (Input Scale and Offset) Rate, Sq Rt, Batch .............70

5.4.5 OT.SC.OF (Output Scale and Offset) Rate, Sq Rt, Batch .........71

5.4.6 RTE DP (Rate Decimal Point) Rate, Sq Rt ................................73

5.4.7 RTE OF (Rate Offset) Rate, Sq Rt..............................................73

5.4.8 RTE SC (Rate Scale) Rate, Sq Rt...............................................74

5.4.9 TOT DP (Total Decimal Point) Rate, Sq Rt, Batch...................74

5.4.10 TOT OF (Total Offset) Rate, Sq Rt, Batch ................................75

5.4.11 TOT SC (Total Scale) Rate, Sq Rt, Batch..................................75

5.4.12 AL TI (Alarm Time) Rate, Sq Rt, Batch ....................................76

5.4.13 GATE T (Gate Time) Rate..........................................................76

iii

Page 6

Table of

Contents

Page

5.4.14 BAUD, SER.CNF, DAT FT, BUS FT, ADDRES, SER TI

(Baud Rate, Serial Configuration, Data Format, Bus Format,

Device Address, Serial Time) Rate, Sq Rt, Batch ......................77

5.4.15 SET TI (Set Time) Rate, Sq Rt, Batch ......................................80

5.4.16 BAT DP (Batch Decimal Point) Batch .......................................81

5.4.17 B LOAD (Batch Load) Batch......................................................81

5.4.18 BAT SC (Batch Scale) Batch ......................................................82

5.4.19 CAL VZ, CAL VS, CALmAZ, and CALmAS

(Calibrate Voltage Zero, Calibrate Voltage Span,

Calibrate milliAmp Zero, Calibrate milliAmp Span).................82

5.5 Step-by-Step Programming Example 1:

Rate Mode; Shaft RPM from a Gear-Tooth Detector .................82

5.5.1 Determining the Rate Scale (RTE SC).......................................83

5.5.2 Configuring the Meter..................................................................83

5.6 Step-by-Step Programming Example 2:

Linear Flow; Adding TOTAL to RATE

with Excitation from the Basic Meter..........................................85

5.6.1 Determining the Rate Decimal Point (RTE DP) and

Rate Scale (RTE SC)...................................................................85

5.6.2 Determining the Total Decimal Point (TOT DP) and

Total Scale (TOT SC) .................................................................86

5.6.3 Configuring the Meter..................................................................86

SECTION 6 OPERATING THE METER

6.1 Rate Mode ....................................................................................88

6.2 Sq Rt Mode...................................................................................89

6.3 Batch Mode ..................................................................................89

APPENDICES

A Basic Meter: General Information, Specifications,

Jumper Configuration, and Input Connections ..........................91

B Isolated Pulse Input Board: General Information,

Specifications, Jumper Configuration, and Wiring .....................97

C Isolated Analog Input Board: General Information,

Specifications, Jumper Configuration,

Wiring, and Calibration...............................................................107

D Isolated Analog Output Board: General Information,

Specifications, Wiring, and Calibration ......................................118

E Isolated Parallel BCD Output Board: General Information,

Specifications, Jumper Configuration, And Wiring....................122

F Dual Relay and 4 Relay Output Board: General Information,

Specifications, Jumper Configuration, and Wiring .....................128

iv

Page 7

Page

G Isolated RS-232 and RS-485 Serial Communications Boards:

General Information and Specifications......................................131

H Error Messages ..............................................................................132

J Factory Preset Configuration Settings/ User Settings .................134

K Ramp Specifications.....................................................................147

L Specifications................................................................................149

Table of

Contents

vv

Page 8

Safety

Considerations

SAFETY CONSIDERATIONS

This device is marked with the international Caution symbol. It is important to read this

manual before installing or commissioning this device as it contains important information

relating to Safety and EMC (Electromagnetic Compatibility).

Unpacking & Inspection

Unpack the instrument and inspect for obvious shipping damage. Do not attempt to operate the

Note

This instrument has no power-on switch. An external switch or circuit-breaker shall be included in the

building installation as a disconnecting device. It shall be marked to indicate this function, and it shall be

in close proximity to the equipment within easy reach of the operator. The switch or circuit-breaker shall

not interrupt the Protective Conductor (Earth wire), and it shall meet the relevant requirements of

IEC 947–1 and IEC 947-3 (International Electrotechnical Commission). The switch shall not be

incorporated in the mains supply cord.

Furthermore, to provide protection against excessive energy being drawn from the mains supply in case

of a fault in the equipment, an overcurrent protection device shall be installed.

unit if damage is found.

☞

This instrument is a panel mount device protected in accordance with Class I of EN 61010

(115/230 AC power connections). Installation of this instrument should be done by Qualified

personnel. In order to ensure safe operation, the following instructions should be followed.

Note

•The Protective Conductor must be connected for safety reasons. Check that the power cable

has the proper Earth wire, and it is properly connected. It is not safe to operate this unit

without the Protective Conductor Terminal connected.

• Do not exceed voltage rating on the label located on the top of the instrument housing.

☞

• Always disconnect power before changing signal and power connections.

• Do not use this instrument on a work bench without its case for safety reasons.

• Do not operate this instrument in flammable or explosive atmospheres.

• Do not expose this instrument to rain or moisture.

• Unit mounting should allow for adequate ventilation to ensure instrument does not exceed

operating temperature rating.

• Use electrical wires with adequate size to handle mechanical strain and power

requirements. Install without exposing bare wire outside the connector to minimize

electrical shock hazards.

EMC Considerations

•Whenever EMC is an issue, always use shielded cables.

•Never run signal and power wires in the same conduit.

•Use signal wire connections with twisted-pair cables.

•Install Ferrite Bead(s) on signal wires close to the instrument if EMC problems persist.

vivi

Page 9

l. Introduction

1.1 DESCRIPTION

The Counter Timer is a multifunctional panel meter that can

measure counts, rates, flows, times, totals and batches from pulse

and analog input sources over the range of 0.2 to 20,000 Hz.

The meter can function in four different modes and be applied to a

wide range of applications, serving functions as simple as displaying

incoming pulses–or as complex as detecting out-of-limits

conditions, triggering alarms, and channeling communications for

a process control system.

The front panel displays values and messages with six, 14-segment

LEDs, indicates which mode-associated measurement is being

displayed through three Measurement LEDs, and indicates alarm

status through four Setpoint LEDs. Five buttons below the LED

display allow easy front-panel configuration and access to the

meter’s many features. These features can also be accessed through

digital communications.

1

Introduction

The meter can be mounted in a panel or simply placed on a bench top.

1.2 FEATURES

The following list outlines the meter’s features.

• Six-digit display

• Microprocessor-based, with nonvolatile memory-no battery

backup required

• Configurable via front-panel push buttons and/or through

RS-232 or RS-485 ports

• High accuracy

• Large digital offset enabling easy scaling in engineering units

• Five open-collector outputs for RATE, TOTAL, BATCH count,

BAT NO (Number of Batches), and TIME

• Programmable decimal point selection

• Read/Display/Output rates up to 25 per second

• Plug-in input and output optional boards

1

Page 10

1

1.3 METER MODES

Introduction

The meter can be configured to operate in four different modes.

These are Rate Meter/Totalizer (Rate), Rate Meter/Totalizer/

Square Root Extractor (Sq Rt), Batch Controller (Batch), and

Clock (C).

1.3.1 RATE METER/TOTALIZER

As a rate meter/totalizer, the meter measures the rate, totalizes and

displays pulses in any engineering units required, and provides

unregulated sensor excitation. The meter can also provide running

averages and process time in HH:MM:SS format in this mode.

With the addition of the Isolated Analog Input Board, analog signals

can be received and displayed in the required engineering units.

1.3.2 RATE METER/TOTALIZER/SQUARE ROOT EXTRACTOR

As a rate meter/totalizer/Square Root Extractor, the meter can

accept dc signals from any typical differential flow transmitter and

extract the square root to provide highly accurate flow values.

Digital calculation ensures accurate readings–which can be displayed in any engineering units desired.

This mode requires the Isolated Analog Input Board.

1.3.3 BATCH CONTROLLER

As a batch controller, the meter can count the batch, number of

batches completed, and the grand total of pulses received. In

addition, it has an internal timer for process time displayed in

HH:MM:SS format. Any of the above functions can be displayed

during the process without interrupting or stopping the process.

1.3.4 CLOCK

As a clock, the meter can function in real, 24-hour time mode

using the HH:MM:SS display format. It can also function as a

99-hour process timer. Time is derived from the power line

frequency, 50 or 60 Hz, which ensures accuracy. If power fails and

the meter is equipped with a backup battery, the clock function

continues working (although the display will not be lit). Refer to

Section 2.3.5.2 for information on battery backup.

2

Page 11

1.4 OPTIONAL BOARDS OVERVIEW

1

The meter is designed to accommodate numerous optional boards.

These boards transform the meter into a single instrument that

“can do it all.” On the input end, they allow the meter to accept

signals from a wider variety of sources, and on the output end, to

communicate with, or control a wide variety of other devices.

1.4.1 ISOLATED PULSE INPUT BOARD

The Isolated Pulse Input Board is a signal conditioning board that

allows the meter to accept low- and high-level input signals from

sources whose pulses may be too weak for the Main Board of the

meter to handle, or that need selectable hysteresis and/or regulated

excitation. This board is used mainly for weak magnetic pick-ups,

high-level line voltage sources, and NAMUR sources.

If this board is used, the Isolated Analog Input Board cannot be used.

(See Appendix B for specifications, jumper configuration, wiring,

and applications for the Isolated Pulse Input Board.)

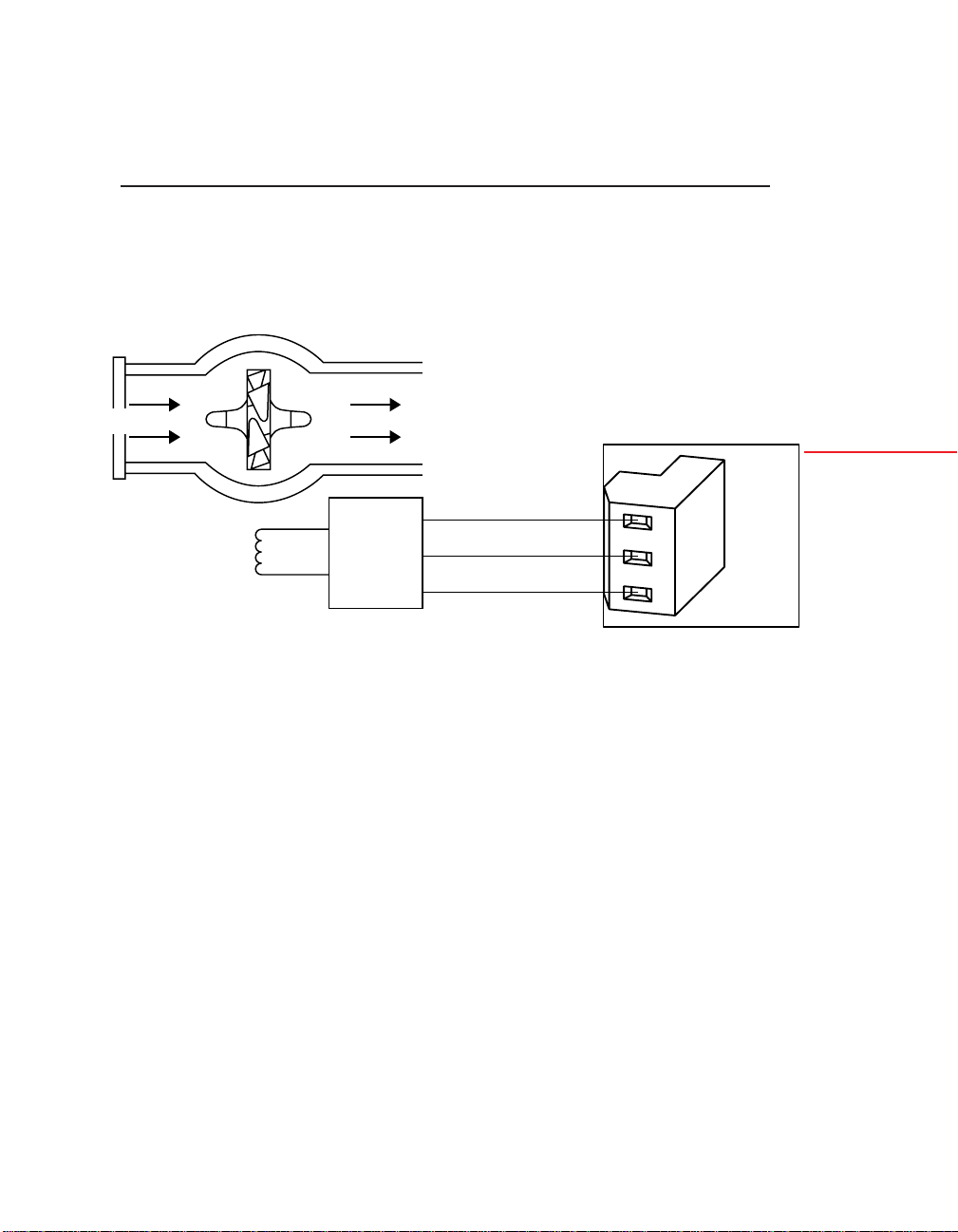

1.4.2 ISOLATED ANALOG INPUT BOARD

Introduction

The Isolated Analog Input Board is a signal conditioning board

that converts analog signals to frequency and allows the meter to

accept input signals from non-pulsed or direct current sources. This

board is often used with differential pressure flow transmitters to

provide linear flow values. (First-time installation requires calibration using calibration data on the back of the board.)

If this board is used, the Isolated Pulse Input Board cannot be used.

(See Appendix C for specifications, jumper configuration, wiring,

and applications for the Isolated Analog Input Board.)

3

Page 12

1

Introduction

1.4.3 ISOLATED ANALOG OUTPUT BOARD

The Isolated Analog Output Board converts display readings into

voltage or current output. This board is often used as a control

board in process applications. (First-time installation requires

calibration using calibration data on the back-the solder or outboard side of the board.)

(See Appendix D for specifications, jumper configuration, wiring,

calibration, and applications for the Isolated Analog Output Board.)

1.4.4 ISOLATED PARALLEL BCD (BINARY-CODED DECIMAL) OUTPUT BOARD

The Isolated Parallel BCD Output Board produces binary-coded

decimal output for direct communication with a printer or with an

intelligent device such as a PLC (Programmable Logic Controller).

If this board is used, the Dual Relay Output Board cannot be used.

(See Appendix E for specifications, jumper configuration, wiring,

and applications for the Isolated Parallel BCD Output Board.)

1.4.5 DUAL RELAY OUTPUT AND 4 RELAY OUTPUT BOARD

The Dual Relay Output and 4 Relay Output Board enables

setpoint-triggered switching to an external device.

If either option board is used, the Isolated Parallel BCD Output

Board cannot be used.

(See Appendix F for specifications, jumper configuration, wiring,

and applications for the Relay Output Board.)

1.4.6 ISOLATED RS-232 SERIAL COMMUNICATIONS BOARD

The Isolated RS-232 Serial Communications Board provides an

isolated digital communications channel between a single meter

and a computer, serial printer, or other device.

If this board is used, the RS-485 Serial Communications Board

cannot be used.

(See Appendix G for specifications, jumper configuration, wiring,

and applications for the Isolated RS-232 Serial Communications

Board.)

4

Page 13

1.4.7 ISOLATED RS-485 SERIAL COMMUNICATIONS BOARD

The Isolated RS-485 Serial Communications Board provides an

isolated digital communications channel where multiple meters

(addressed from 0 to 199) can communicate with a single computer.

If this board is used, the RS-232 Serial Communications Board

cannot be used.

(See Appendix G for specifications, jumper configuration, wiring, and

applications for the Isolated RS-485 Serial Communications Board.)

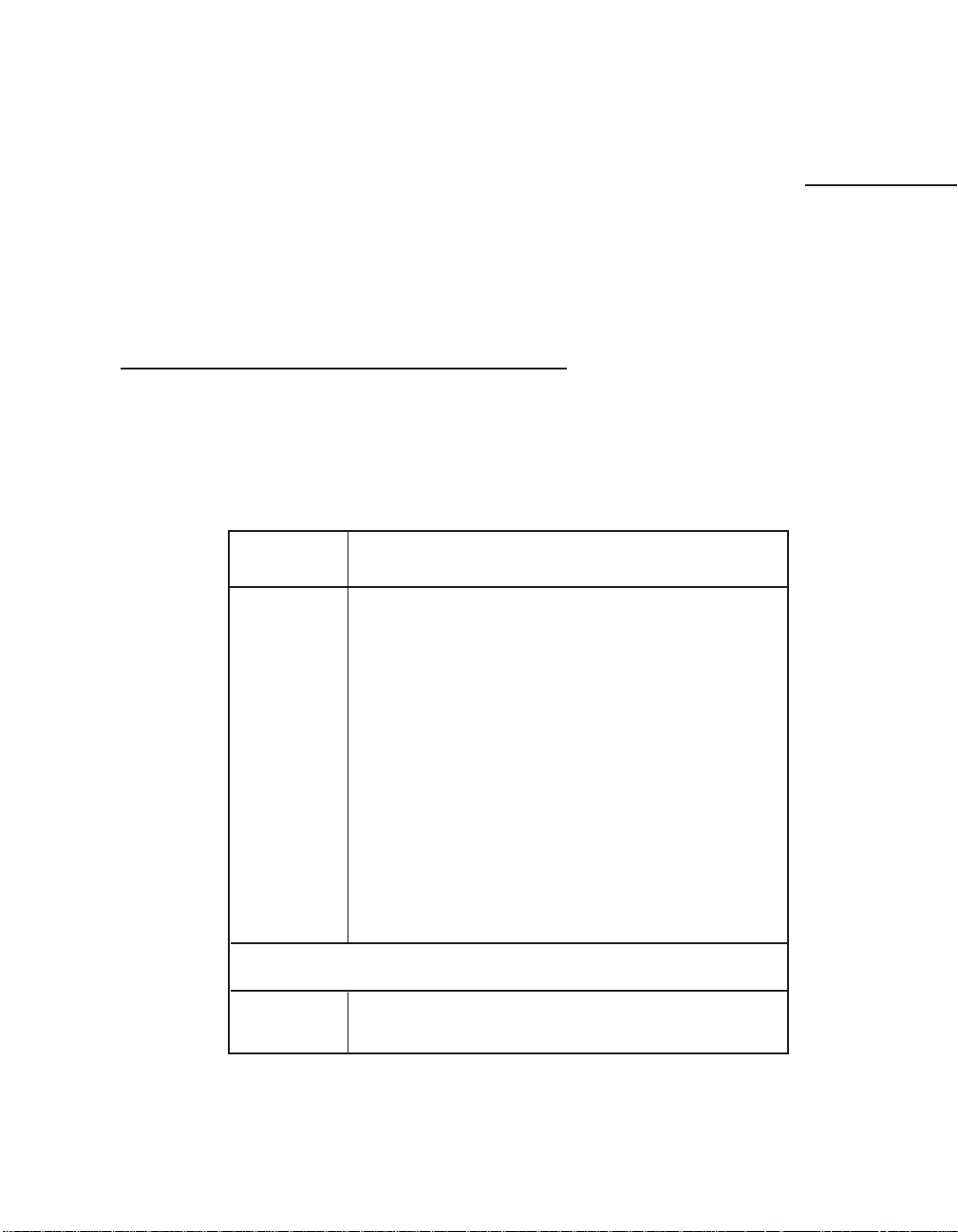

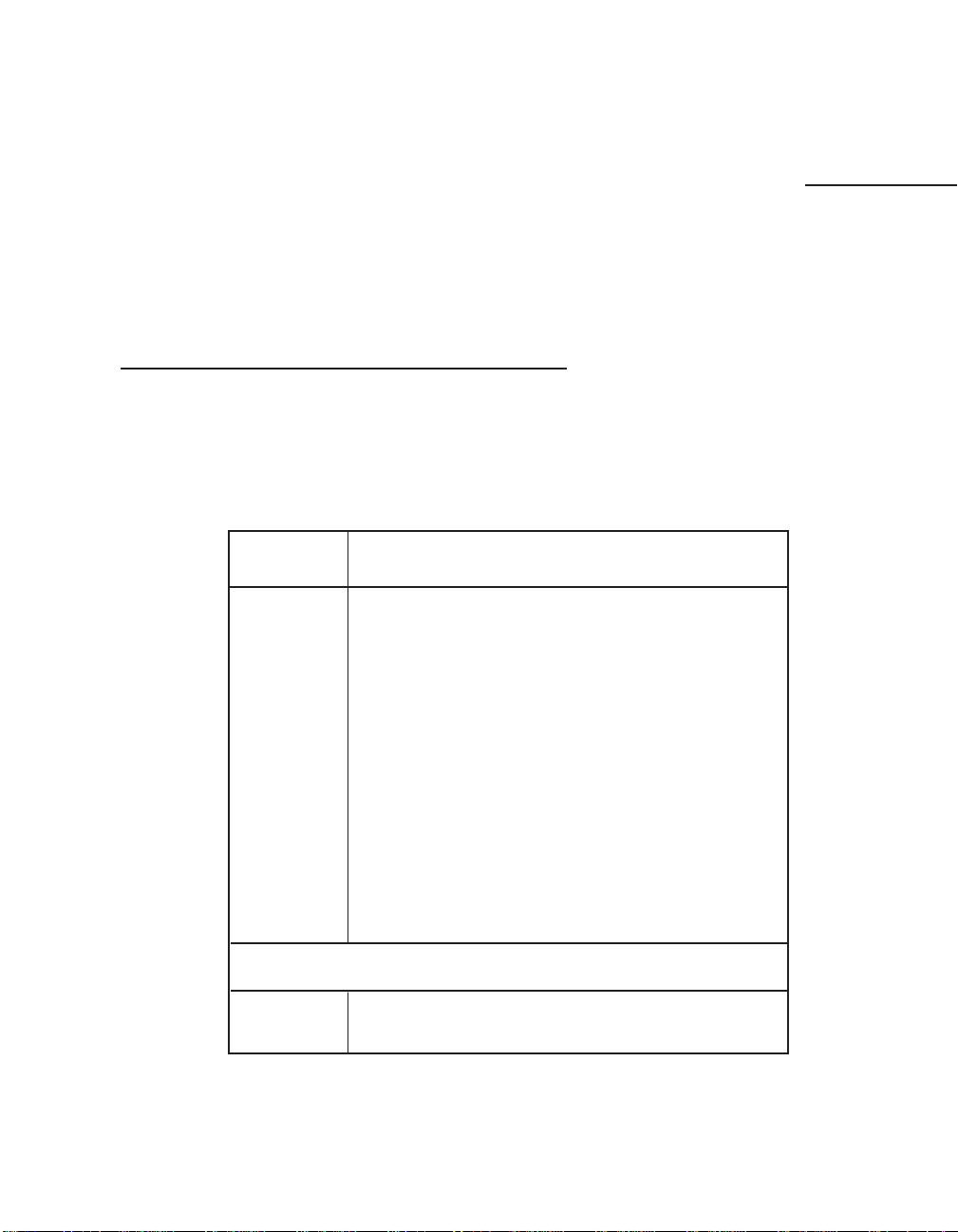

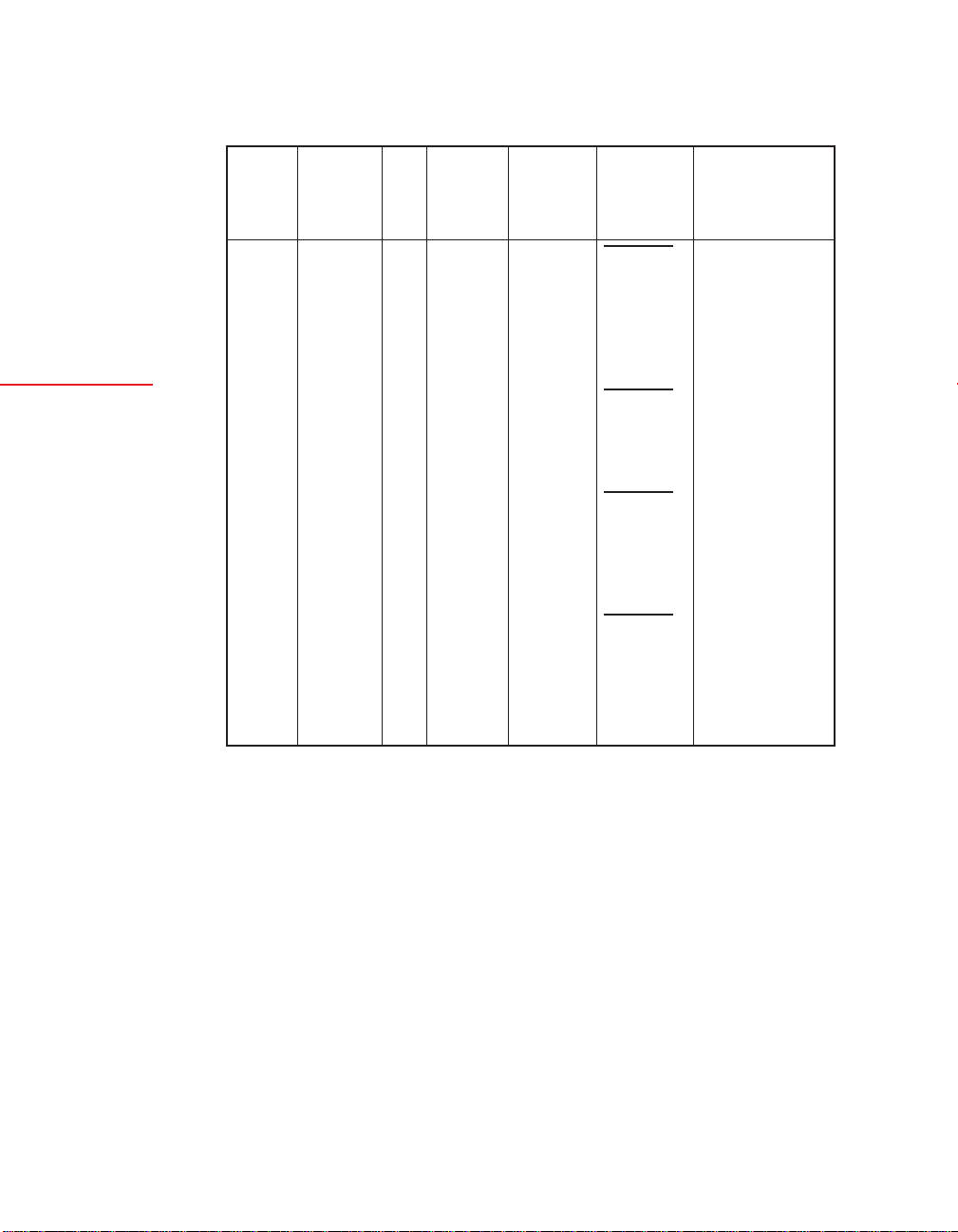

1.5 AVAILABLE MODELS AND OPTIONS

The following models and options are available. Optional boards

are either installed at the time of purchase, or available as separate

items and installed by the user after purchase.

BASIC MODELS AND INPUT OPTIONS

MODEL

NUMBER DESCRIPTION

DPF401 No optional input board; Basic Meter accepts low

level and high level pulses from TTL/CMOS

sources, open collector outputs and contact closures;

provides 14-20 V unregulated sensor excitation

1

Introduction

DPF402 Isolated Pulse Input Board. Single-input for magnetic

pick-ups with low- and high-level signals; direct

connection to NPN, PNP, or NAMUR sensors.

Includes electrically floating, regulated sensor excitation rated 12.6 V @ 70 mA or 8.2 V or 5 V

DPF403 Isolated Analog Input Board. Input ranges of

0-1 mA, 4-20 mA, 0-5 V, 1-5 V, and 0-10 V are

jumper selectable. Standard factory default

calibration: 4-20 mA dc = 0-10000

FOR OPTIONS ADD SUFFIX TO MODEL NUMBER

-GR Green LED display

-230V 230 V ac, power

5

Page 14

1

Introduction

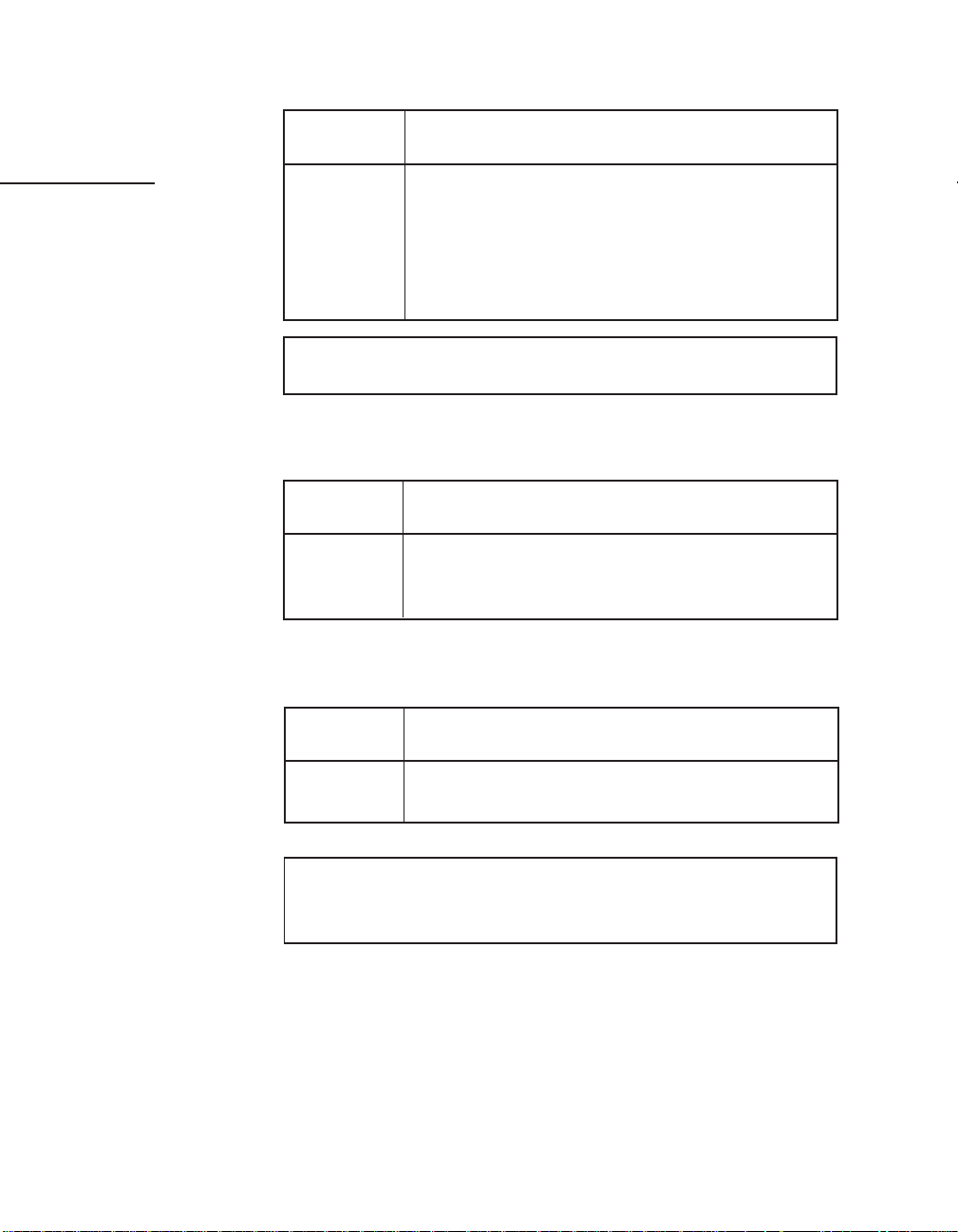

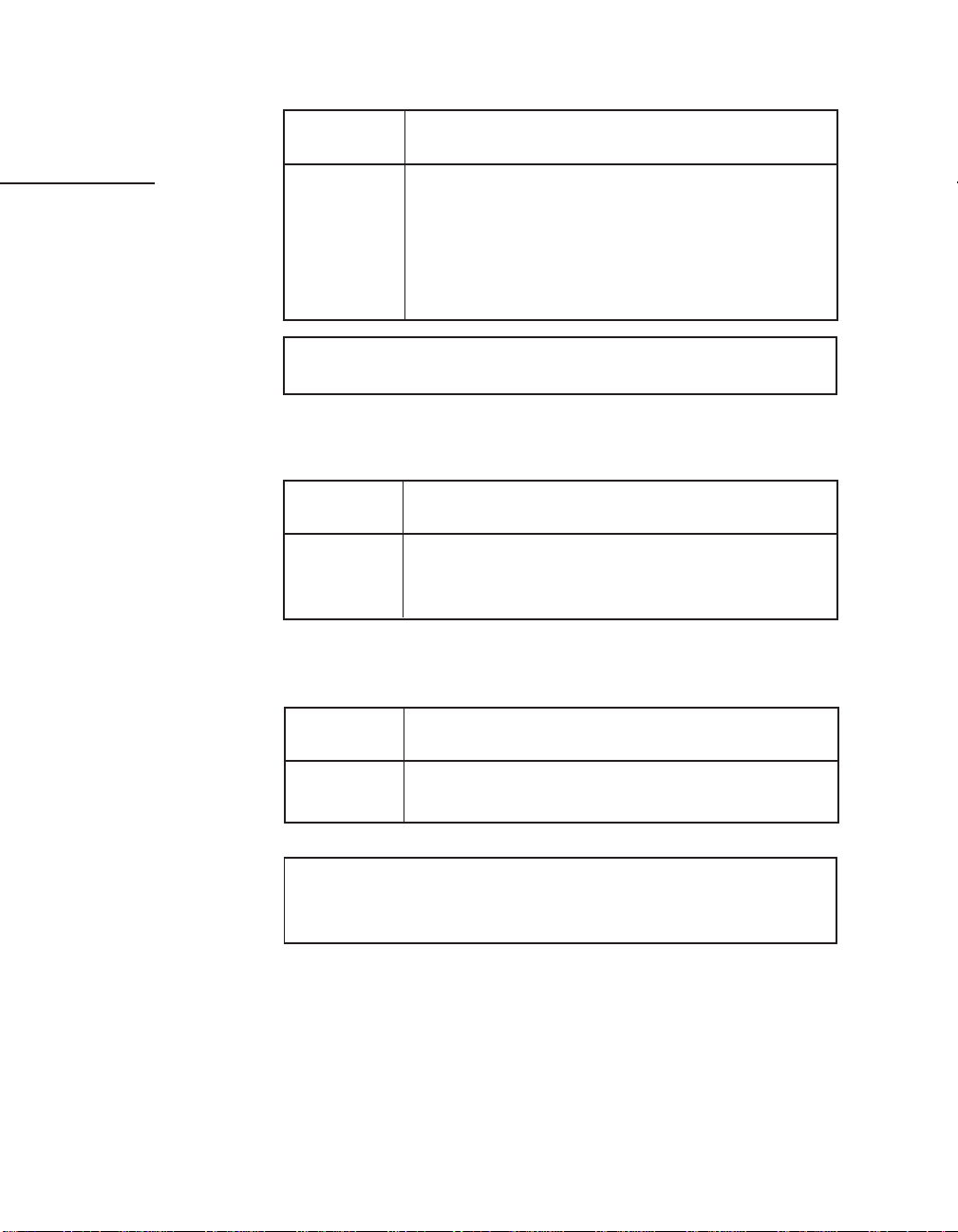

CONTROL/BCD OUTPUT OPTIONS

MODEL

NUMBER DESCRIPTION

DP40-B Isolated Parallel BCD (Binary-Coded Decimal)

Output Board

DP40-R Dual Relay Output Board; Two 7-amp,

Form-C Relays

DP40-R4 4 Relay Output Board; Two 7-amp & two 1 amp

Form-C Relays.

NOTE: Choose only one Control/BCD output option per meter.

A 40-socket plug is included with the BCD option.

ANALOG OUTPUT OPTIONS

MODEL

NUMBER DESCRIPTION

DP40-A Isolated Analog Output Board: Configurable output;

0-20 mA, 4-20 mA, 0-5 V, 0-10 V. Standard factory

default calibration: 0-10000 = 4-20 mA dc

DATA COMMUNICATIONS OPTIONS

MODEL

NUMBER DESCRIPTION

DPF400-S2 Isolated RS-232 Serial Communications Board*

DPF400-S4 Isolated RS-485 Serial Communications Board**

NOTE: Choose only one option per meter. Both computer

communications come with a 6-foot communications cable with

phone plug termination.

* We recommend purchase of 9SC2 or 25SC2 (see OPTIONS

below)

** We recommend purchase of 9SC4 or 25SC4 (see OPTIONS

below)

6

Page 15

OPTIONS

MODEL

NUMBER DESCRIPTION

DP40-9SC2 9-pin Serial Connector for RS-232 port

DP40-9SC4 9-pin Serial Connector for RS-485 port

DP40-25SC2 25-pin Serial Connector for RS-232 port

DP40-25SC4 25-pin Serial Connector for RS-485 port

1

Introduction

7

Page 16

2

Setup

2. Setup

2.1 UNPACKING

Unpack all items and make sure that every item on the packing list

is present. The items you should receive are listed below. If

something is missing, use the phone number for the Customer

Service Department nearest you.

Also, inspect the shipping container and enclosed equipment for any

signs of damage. Take particular note of any evidence of rough

handling in transit. Immediately report any damage to the shipping

agent.

NOTE: The shipping agent will not honor any claims unless all

shipping material is saved for their examination. After examining

and removing contents, save all packing material and containers in

the event that reshipment is required.

You should receive the following items :

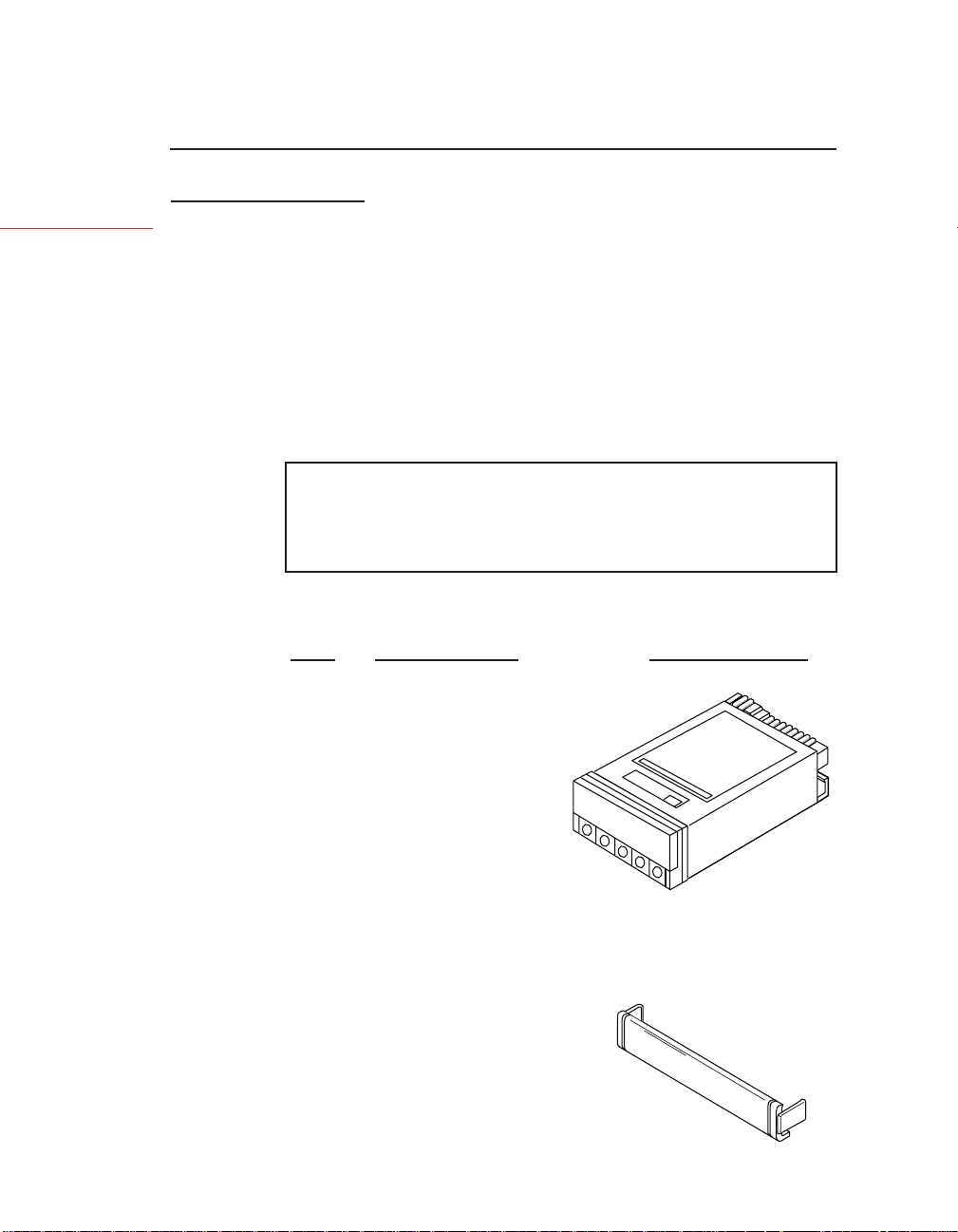

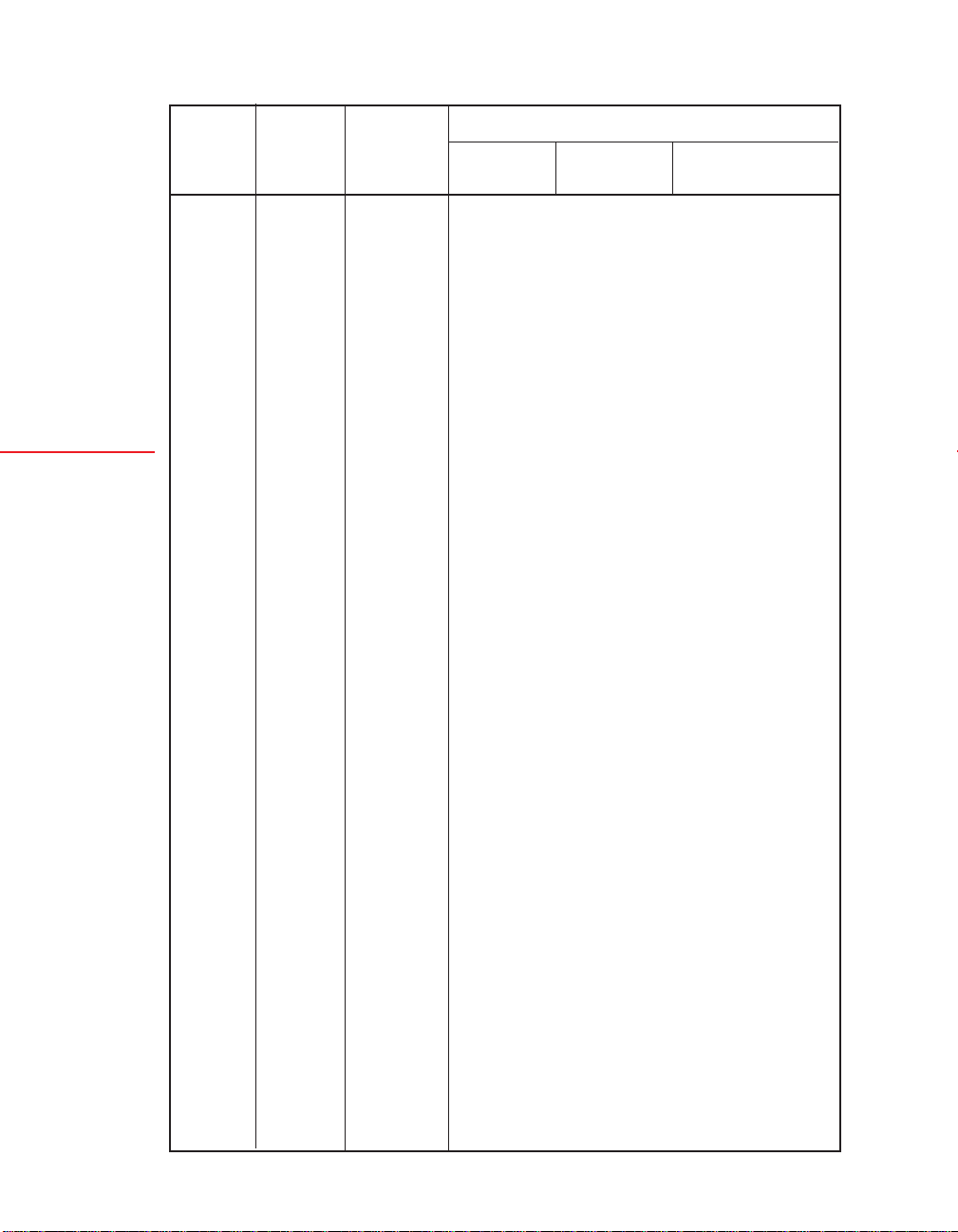

QTY DESCRIPTION ILLUSTRATION

1 Basic meter with

main board (and

optional boards if

ordered by number);

in plastic case with

sleeve, panel

gasket, two

thumbnuts

1 Front-panel

button cover available

with return of the

postcard (see meter box)

8

Page 17

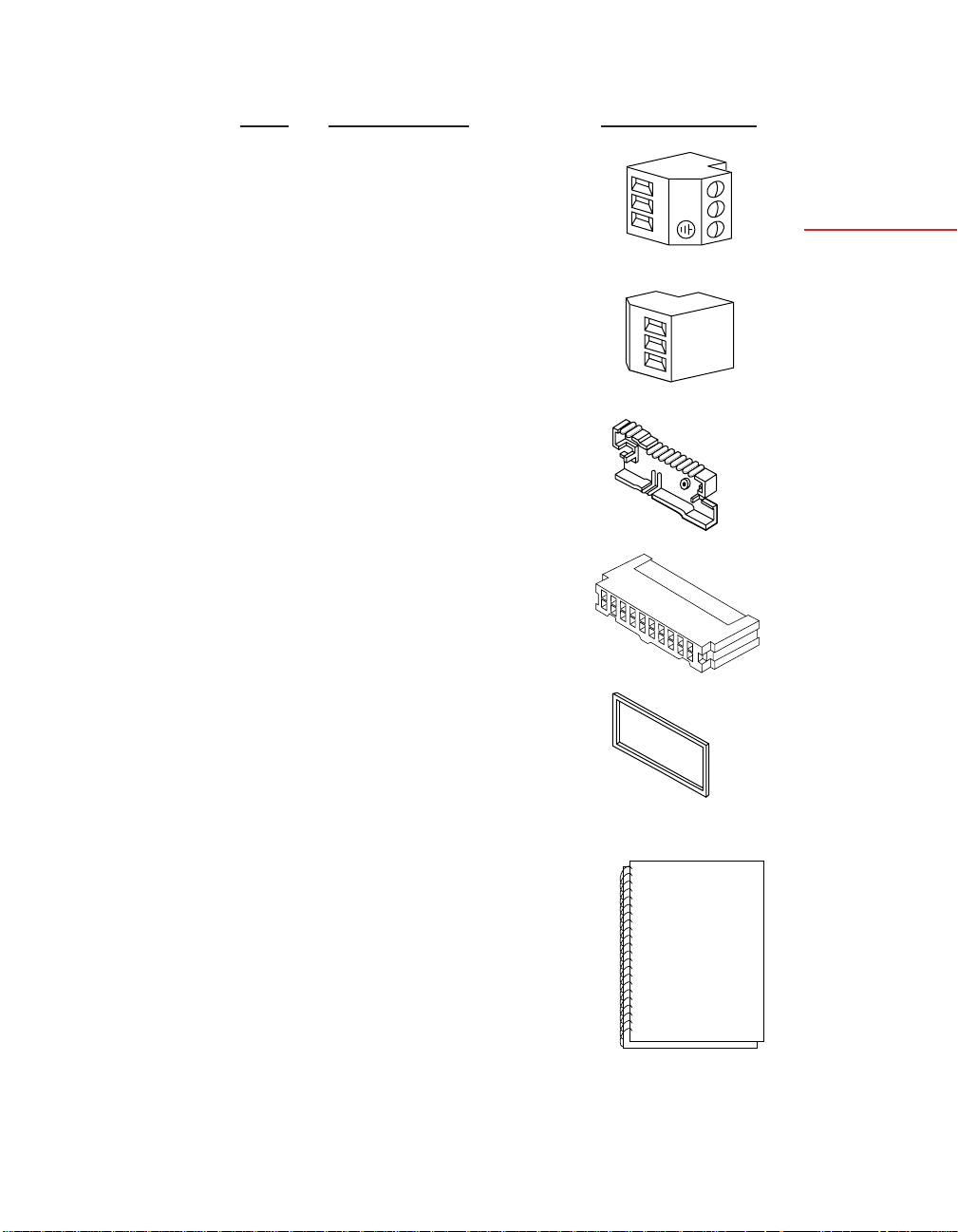

QTY DESCRIPTION ILLUSTRATION

1 Orange, 3-socket

power connector (P1);

for AC input

1 Gray, 3-socket

input connector (P3);

for signal input

1 Rear cover with

holddown screw

1 20-Socket Ribbon

Connector (P2)

L

2

1

2

N

3

1

2

3

Setup

2 Panel-mount gasket

(1 spare)

1 Operator’s manual

9

Page 18

2.2 SAFETY PRECAUTIONS

2

Setup

The meter is protected in accordance with Class I of EN61010.

Refer to Safety Considerations page.

WARNING: If your meter is to be wired to sensors or to control

!

2.2.1 POWER VOLTAGE

inputs that could have hazardous potentials, these potentials will be

carried to the 20-pin output connector (P2) at the rear. They will

also be present on the meter’s circuit boards. Follow all instructions

carefully, inserting the electronics into the case and installing connectors BEFORE connecting the meter to any source of power.

DO NOT contact any exposed metal parts, install optional board(s),

change jumpers, or in any way disassemble or assemble the meter

while it is connected to AC voltage.

Note the following information and guidelines for safe operation of

your meter:

Your power source voltage rating should agree with the voltage

under which the meter has been configured to operate. The first

thing you should do is verify this.

The meter’s operating voltage is shown in the VOLTS: entry of

the ID and Serial Number Label. Figure 2-1 shows a copy of this

label. It is located on the meter packing box and is clearly visible.

(Another label is also affixed to the meter case.)

MODEL:

SERIAL NO.:

PART NO.:

VOLTS: WATTS:

Figure 2-1. ID and Serial Number Label showing the Meter's

operating voltage.

10

Page 19

2.2.2 POWER WIRING

CAUTION: The meter has no power-on switch; it will be ON

!

when power is applied.

Section 2.3.5 shows you how to wire not only the AC power

connector, but all other connectors as well.

2.3 ASSEMBLY/DISASSEMBLY

2.3.1 OPENING THE METER

Your meter is fully assembled, but not wired. In most cases, if you

have ordered optional boards with the meter, these boards will

already be installed.

You will need to remove only the rear cover to complete wiring,

but you will have to open the meter to do one or more of the

following:

WARNING: You must disconnect and turn-off the power and

!

connector signals before accessing the unit and installing optional

boards. Failure to do so may result in injury!

2

Setup

a. Check or reconfigure the Transformer Jumpers on the Main

Board so that they correspond to your line voltage (W1 and W2

for 115 V ac, or W3 for 230 V ac). See Section 2.3.2.1.

b. Access jumpers on the Main and optional boards.

See Section 2.3.2.

c. Install optional boards. See Section 2.3.3.

11

Page 20

2

Setup

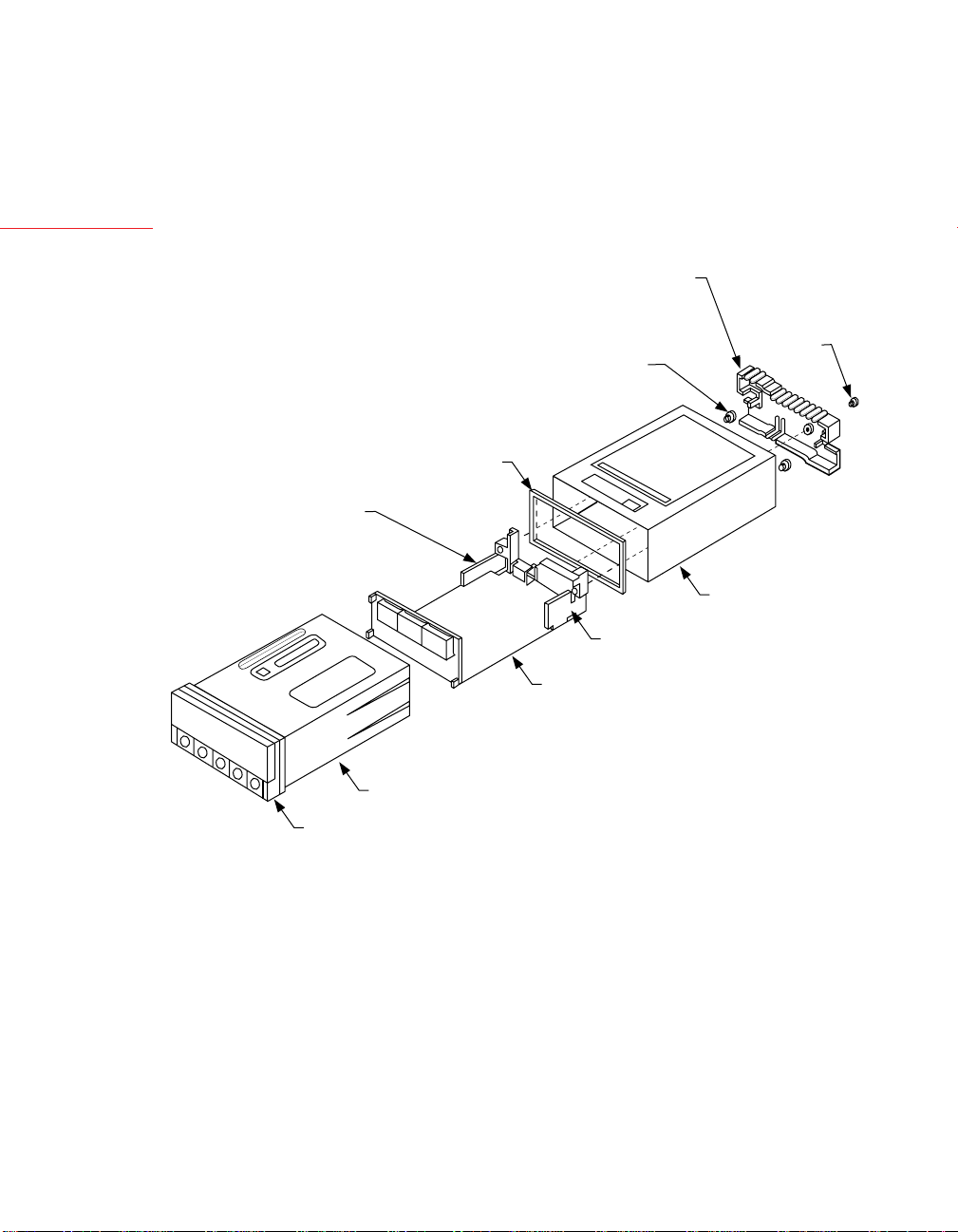

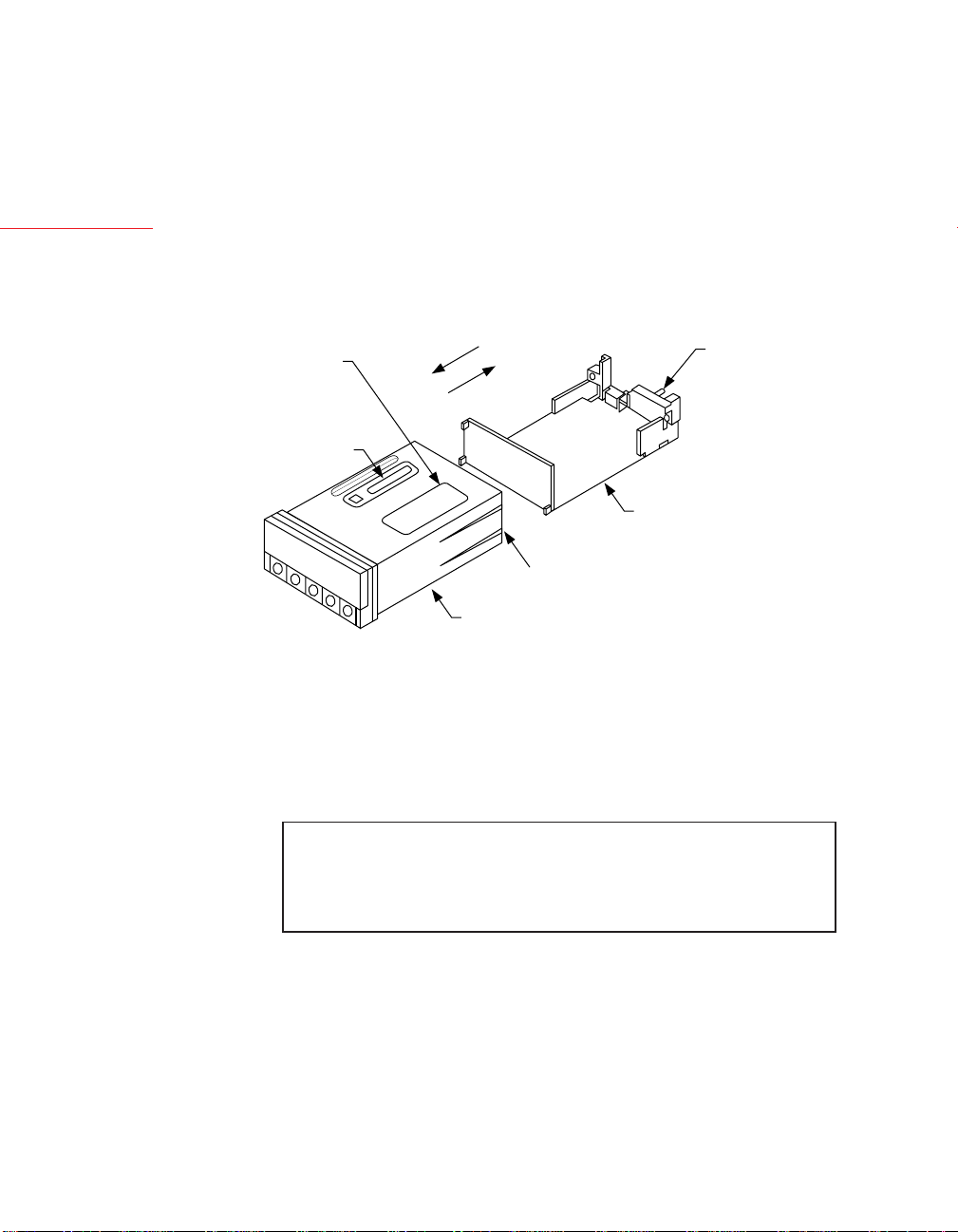

REAR

PROTECTIVE

COVER

COVER

MOUNTING

SCREW

THUMBNUTS

GASKET

SIGNAL

CONNECTOR

BOARD

SLEEVE

AC POWER BOARD

MAIN BOARD ASSY

CASE

BEZEL

Figure 2-2. Exploded View of the Meter

12

Page 21

Using Figures 2-2 as a guide, follow these simple instructions to

open the meter:

2

!

IMPORTANT: Turn-off the power and input signals from the

unit before proceeding. Failure to do so may result in injury!

1. Remove the cover mounting screw that secures the rear protective

cover to the meter, and remove the Rear Protective Cover.

If you are simply wiring the meter–but not checking jumpers or

installing or removing boards–this is as far as the meter needs to

be disassembled. Go to Section 2.3.5.

2. Remove all wiring connectors from the rear of the meter.

3. Remove the two thumbnuts that secure the case to the sleeve.

4. Remove the sleeve completely by sliding it back from the front

bezel.

Setup

13

Page 22

l. Introduction

1.1 DESCRIPTION

The Counter Timer is a multifunctional panel meter that can

measure counts, rates, flows, times, totals and batches from pulse

and analog input sources over the range of 0.2 to 20,000 Hz.

The meter can function in four different modes and be applied to a

wide range of applications, serving functions as simple as displaying

incoming pulses–or as complex as detecting out-of-limits

conditions, triggering alarms, and channeling communications for

a process control system.

The front panel displays values and messages with six, 14-segment

LEDs, indicates which mode-associated measurement is being

displayed through three Measurement LEDs, and indicates alarm

status through four Setpoint LEDs. Five buttons below the LED

display allow easy front-panel configuration and access to the

meter’s many features. These features can also be accessed through

digital communications.

1

Introduction

The meter can be mounted in a panel or simply placed on a bench top.

1.2 FEATURES

The following list outlines the meter’s features.

• Six-digit display

• Microprocessor-based, with nonvolatile memory-no battery

backup required

• Configurable via front-panel push buttons and/or through

RS-232 or RS-485 ports

• High accuracy

• Large digital offset enabling easy scaling in engineering units

• Five open-collector outputs for RATE, TOTAL, BATCH count,

BAT NO (Number of Batches), and TIME

• Programmable decimal point selection

• Read/Display/Output rates up to 25 per second

• Plug-in input and output optional boards

1

Page 23

1

1.3 METER MODES

Introduction

The meter can be configured to operate in four different modes.

These are Rate Meter/Totalizer (Rate), Rate Meter/Totalizer/

Square Root Extractor (Sq Rt), Batch Controller (Batch), and

Clock (C).

1.3.1 RATE METER/TOTALIZER

As a rate meter/totalizer, the meter measures the rate, totalizes and

displays pulses in any engineering units required, and provides

unregulated sensor excitation. The meter can also provide running

averages and process time in HH:MM:SS format in this mode.

With the addition of the Isolated Analog Input Board, analog signals

can be received and displayed in the required engineering units.

1.3.2 RATE METER/TOTALIZER/SQUARE ROOT EXTRACTOR

As a rate meter/totalizer/Square Root Extractor, the meter can

accept dc signals from any typical differential flow transmitter and

extract the square root to provide highly accurate flow values.

Digital calculation ensures accurate readings–which can be displayed in any engineering units desired.

This mode requires the Isolated Analog Input Board.

1.3.3 BATCH CONTROLLER

As a batch controller, the meter can count the batch, number of

batches completed, and the grand total of pulses received. In

addition, it has an internal timer for process time displayed in

HH:MM:SS format. Any of the above functions can be displayed

during the process without interrupting or stopping the process.

1.3.4 CLOCK

As a clock, the meter can function in real, 24-hour time mode

using the HH:MM:SS display format. It can also function as a

99-hour process timer. Time is derived from the power line

frequency, 50 or 60 Hz, which ensures accuracy. If power fails and

the meter is equipped with a backup battery, the clock function

continues working (although the display will not be lit). Refer to

Section 2.3.5.2 for information on battery backup.

2

Page 24

1.4 OPTIONAL BOARDS OVERVIEW

1

The meter is designed to accommodate numerous optional boards.

These boards transform the meter into a single instrument that

“can do it all.” On the input end, they allow the meter to accept

signals from a wider variety of sources, and on the output end, to

communicate with, or control a wide variety of other devices.

1.4.1 ISOLATED PULSE INPUT BOARD

The Isolated Pulse Input Board is a signal conditioning board that

allows the meter to accept low- and high-level input signals from

sources whose pulses may be too weak for the Main Board of the

meter to handle, or that need selectable hysteresis and/or regulated

excitation. This board is used mainly for weak magnetic pick-ups,

high-level line voltage sources, and NAMUR sources.

If this board is used, the Isolated Analog Input Board cannot be used.

(See Appendix B for specifications, jumper configuration, wiring,

and applications for the Isolated Pulse Input Board.)

1.4.2 ISOLATED ANALOG INPUT BOARD

Introduction

The Isolated Analog Input Board is a signal conditioning board

that converts analog signals to frequency and allows the meter to

accept input signals from non-pulsed or direct current sources. This

board is often used with differential pressure flow transmitters to

provide linear flow values. (First-time installation requires calibration using calibration data on the back of the board.)

If this board is used, the Isolated Pulse Input Board cannot be used.

(See Appendix C for specifications, jumper configuration, wiring,

and applications for the Isolated Analog Input Board.)

3

Page 25

1

Introduction

1.4.3 ISOLATED ANALOG OUTPUT BOARD

The Isolated Analog Output Board converts display readings into

voltage or current output. This board is often used as a control

board in process applications. (First-time installation requires

calibration using calibration data on the back-the solder or outboard side of the board.)

(See Appendix D for specifications, jumper configuration, wiring,

calibration, and applications for the Isolated Analog Output Board.)

1.4.4 ISOLATED PARALLEL BCD (BINARY-CODED DECIMAL) OUTPUT BOARD

The Isolated Parallel BCD Output Board produces binary-coded

decimal output for direct communication with a printer or with an

intelligent device such as a PLC (Programmable Logic Controller).

If this board is used, the Dual Relay Output Board cannot be used.

(See Appendix E for specifications, jumper configuration, wiring,

and applications for the Isolated Parallel BCD Output Board.)

1.4.5 DUAL RELAY OUTPUT AND 4 RELAY OUTPUT BOARD

The Dual Relay Output and 4 Relay Output Board enables

setpoint-triggered switching to an external device.

If either option board is used, the Isolated Parallel BCD Output

Board cannot be used.

(See Appendix F for specifications, jumper configuration, wiring,

and applications for the Relay Output Board.)

1.4.6 ISOLATED RS-232 SERIAL COMMUNICATIONS BOARD

The Isolated RS-232 Serial Communications Board provides an

isolated digital communications channel between a single meter

and a computer, serial printer, or other device.

If this board is used, the RS-485 Serial Communications Board

cannot be used.

(See Appendix G for specifications, jumper configuration, wiring,

and applications for the Isolated RS-232 Serial Communications

Board.)

4

Page 26

1.4.7 ISOLATED RS-485 SERIAL COMMUNICATIONS BOARD

The Isolated RS-485 Serial Communications Board provides an

isolated digital communications channel where multiple meters

(addressed from 0 to 199) can communicate with a single computer.

If this board is used, the RS-232 Serial Communications Board

cannot be used.

(See Appendix G for specifications, jumper configuration, wiring, and

applications for the Isolated RS-485 Serial Communications Board.)

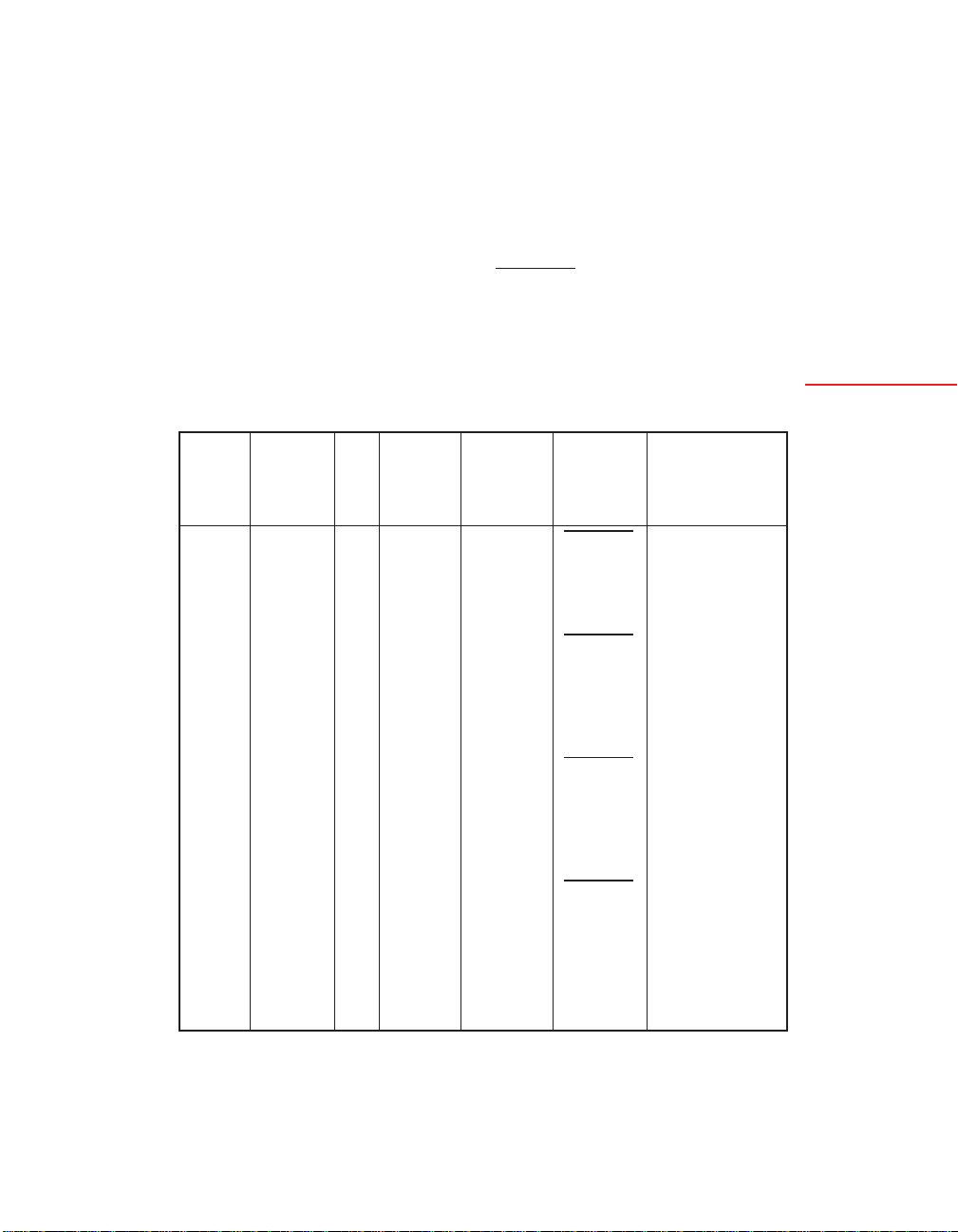

1.5 AVAILABLE MODELS AND OPTIONS

The following models and options are available. Optional boards

are either installed at the time of purchase, or available as separate

items and installed by the user after purchase.

BASIC MODELS AND INPUT OPTIONS

MODEL

NUMBER DESCRIPTION

DPF401 No optional input board; Basic Meter accepts low

level and high level pulses from TTL/CMOS

sources, open collector outputs and contact closures;

provides 14-20 V unregulated sensor excitation

1

Introduction

DPF402 Isolated Pulse Input Board. Single-input for magnetic

pick-ups with low- and high-level signals; direct

connection to NPN, PNP, or NAMUR sensors.

Includes electrically floating, regulated sensor excitation rated 12.6 V @ 70 mA or 8.2 V or 5 V

DPF403 Isolated Analog Input Board. Input ranges of

0-1 mA, 4-20 mA, 0-5 V, 1-5 V, and 0-10 V are

jumper selectable. Standard factory default

calibration: 4-20 mA dc = 0-10000

FOR OPTIONS ADD SUFFIX TO MODEL NUMBER

-GR Green LED display

-230V 230 V ac, power

5

Page 27

1

Introduction

CONTROL/BCD OUTPUT OPTIONS

MODEL

NUMBER DESCRIPTION

DP40-B Isolated Parallel BCD (Binary-Coded Decimal)

Output Board

DP40-R Dual Relay Output Board; Two 7-amp,

Form-C Relays

DP40-R4 4 Relay Output Board; Two 7-amp & two 1 amp

Form-C Relays.

NOTE: Choose only one Control/BCD output option per meter.

A 40-socket plug is included with the BCD option.

ANALOG OUTPUT OPTIONS

MODEL

NUMBER DESCRIPTION

DP40-A Isolated Analog Output Board: Configurable output;

0-20 mA, 4-20 mA, 0-5 V, 0-10 V. Standard factory

default calibration: 0-10000 = 4-20 mA dc

DATA COMMUNICATIONS OPTIONS

MODEL

NUMBER DESCRIPTION

DPF400-S2 Isolated RS-232 Serial Communications Board*

DPF400-S4 Isolated RS-485 Serial Communications Board**

NOTE: Choose only one option per meter. Both computer

communications come with a 6-foot communications cable with

phone plug termination.

* We recommend purchase of 9SC2 or 25SC2 (see OPTIONS

below)

** We recommend purchase of 9SC4 or 25SC4 (see OPTIONS

below)

6

Page 28

OPTIONS

MODEL

NUMBER DESCRIPTION

DP40-9SC2 9-pin Serial Connector for RS-232 port

DP40-9SC4 9-pin Serial Connector for RS-485 port

DP40-25SC2 25-pin Serial Connector for RS-232 port

DP40-25SC4 25-pin Serial Connector for RS-485 port

1

Introduction

7

Page 29

2

6. Using Figure 2-4 as a guide, bend the side-panel detents on the

case outward and pull the board assembly out of the case by the

mounting screw stem.

Setup

These six steps are known as “accessing the Main Board assembly.”

ID AND SERIAL

NUMBER LABEL

SIGNAL INPUT

JUMPER LABEL

Figure 2-4. Removing the Main Board Assembly from the Case

TO INSTALL

TO REMOVE

BEND DETENTS OUTWARD

TO INSTALL MAIN BOARD

CASE

MOUNTING

SCREW

STEM

MAIN BOARD ASSY

The meter is now disassembled to the point where you can check

and configure jumpers and install boards.

NOTE: When the sleeve is removed from the case in Step 5

above, the Connector Label on the case will be exposed.

See Figure 2-5. Use this label for reference when wiring or connecting plugs.

14

Page 30

P2/CABLE CONNECTOR

ALARM 1 OUTPUT

ALARM 3 OUTPUT

ALARM, BATTERY RETURN

P4/RS-232

6

5

4

3

2

1

P1/AC PWR

1

2

3

TWICE LINE FREQ

1 1

N/C

COMM RTN

RX

TX

RTS

N/C

{

LINE

NEUTRAL

AC GND

RESET-A

RESET-B

TEST TX

PULSE OUTPUT

RESET-C

STOP

P4/RS-485

6

5

4

3

2

1

P6/RELAY

1

2

3

1

3

5

7

9

10

11

12

13

14

15

16

17

18

19

20

N/C

B RX

A RX

COMM RTN

B TX/RX

A TX/RX

NO1

CM1

NC1

ALARM V + INPUT

2

ALARM 2 OUTPUT

4

ALARM 4 OUTPUT

6

ALARM 5 OUTPUT

8

DEBOUNCE

TEST RX

DIGITAL RETURN

HOLD / PRINT REQ

GATE INPUT

BACKUP BATTERY +

P5 ANALOG OUT

P7/RELAY

1

2

3

1

2

3

1

2

Setup

1

RETURN

4-20 mA

0-10 V

NO2

CM2

NC2

BCD

P5

1

.

.

.

P18 for 4 RELAY

1

P8

...

...

1

P6

P2

1

.

..........

.

..........

P1

.

1

1

CONNECT TO LOW VOLTAGE LIMITED ENERGY CIRCUITRY ONLY.

P8

1

P7

P4

.

.

.

.

1

.

19

Figure 2-5. Connector Label

2.3.2 CHECKING AND INSTALLING JUMPERS

This section contains figures and instructions for checking and

installing jumpers, but it gives full information on the Main Board

only. If you have any optional boards, refer to the appropriate

appendix for specific jumper information.

NOTE: When referring to jumpers and the corresponding boards,

the view is from the REAR of the meter.

P9

P3

.

1

.

.

.

1

.

.

PULSE INPUT

P9 & P3

FILTER

SIG IN HI LEVEL

PULL UP/DOWN

EXCITATION

SIG IN LO LEVEL

SIG RETURN

ANALOG INPUT

+24 V EXC

SIGNAL IN

RETURN

TEST

TEST

TEST

1

15

Page 31

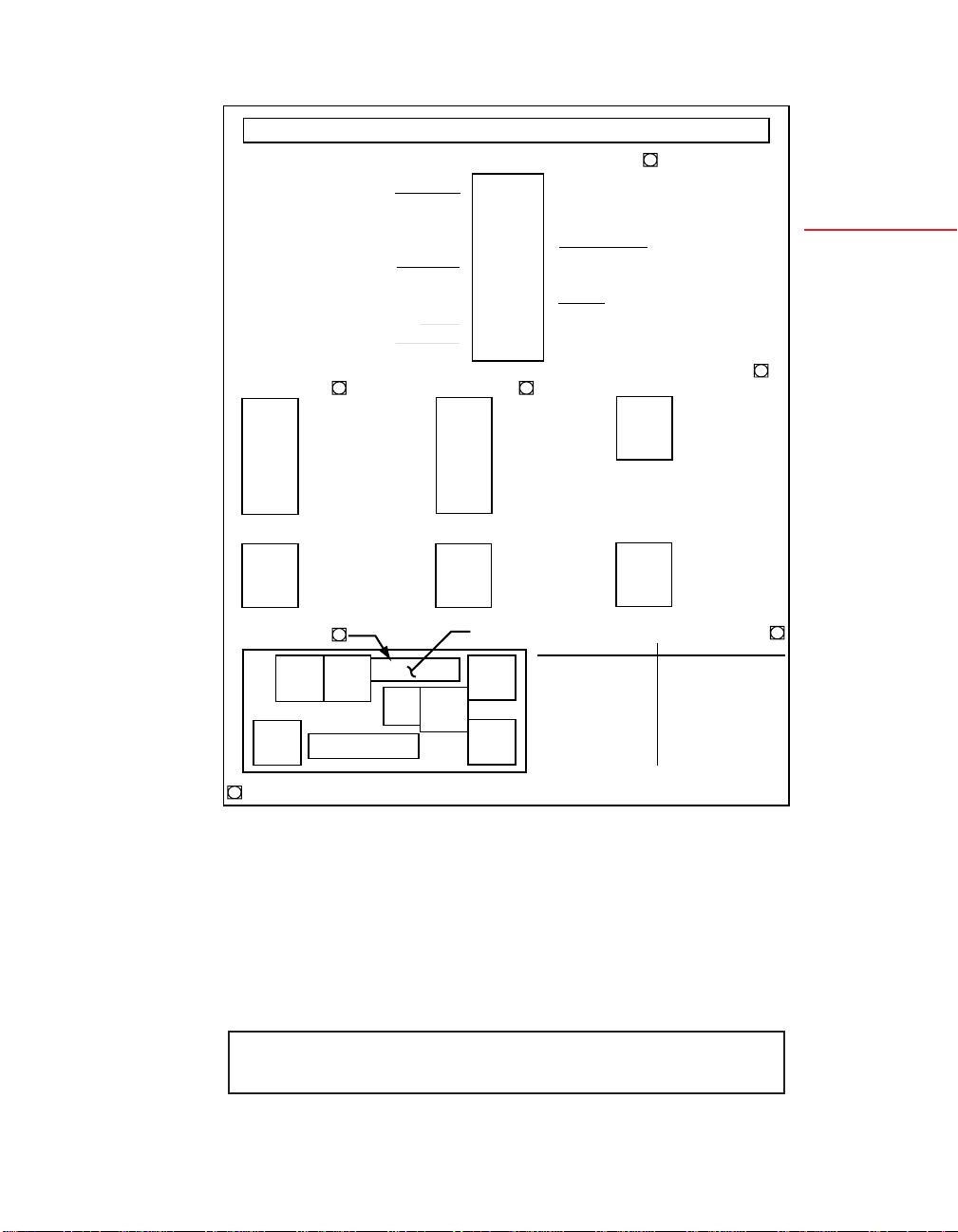

2.3.2.1 MAIN BOARD JUMPERS

2

Setup

DISPLAY

BOARD

MAIN

BOARD

!

Using Figure 2-6 and Table 2-1, configure or check Main Board

jumpers.

CAUTION: The meter has no power-on switch; it will be in

operation as soon as you apply power. To change the factory preset

jumpers, disconnect the power from the unit. Failure to do so may

result in injury! The jumpers must be changed by specially trained

personnel.

W6

(BEHIND

J13 PINS)

W7

S2

A

SIGNAL

CONNECTOR

BOARD

J3

J2

J14

T1

S1

J12

A

J13

J11

J10

W2

W3

W1

AC POWER BD

Figure 2-6. Main Board Jumpers

16

J1

W2 W1

W3

115 V ac

230 V ac

Page 32

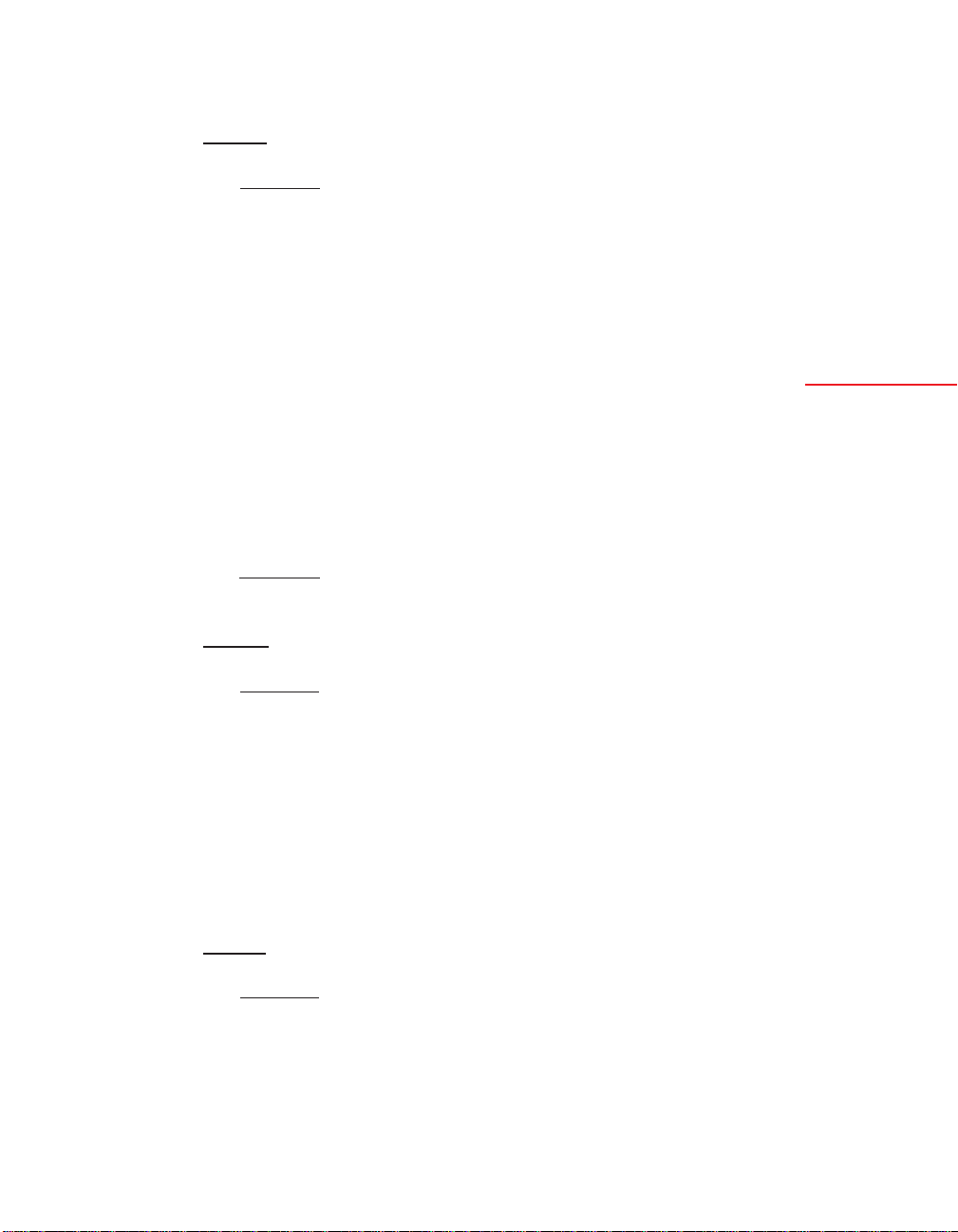

TABLE 2-1. MAIN BOARD JUMPERS

LOCATION, VIEWING

THE BOARD FROM THE

JUMPER REAR OF THE METER FUNCTION

S1-A On the right, immediately Enables push buttons to

behind the Display board control lockout

programming

S2-A First two pins of J13 on Channels non-isolated

the right side of the Main excitation out to P3-1;

Board remove if input board used

W1 and

W2 Left side Enables 115 V operation

W3 Left side Enables 230 V operation

W6 and

W7 Right side of Main Board Bypasses isolation circuitry

next to J13 used for option boards;

remove if input board used

If your line voltage is 115 V ac, jumpers W1 and W2 (but NOT

W3) should be installed.

2

Setup

If your line voltage is 230 V ac, jumper W3 (but NOT W1 or W2)

should be installed.

NOTE: When referring to jumpers, the letter S means “switch”

and the letter W means “wire.” Switch jumpers are caps that bridge

two pins; they can easily be moved from one position to another.

Wire jumpers are soldered in; they must be cut when “removed”

and resoldered if reinstalled.

If no optional input board is used, jumper S2-A should be installed

on the first two pins of J13. This jumper brings non-isolated

excitation out to the P3-1 connection. Wire jumpers W6 and W7

should also be in place. These jumpers bypass the isolation circuitry

used for optional boards. See Figure 2-6.

17

Page 33

2

If one of the optional input boards is used, S2-A should be removed

(or be installed on only one pin), and W6 and W7 should be

removed.

Setup

S1-A allows front-panel control of the three lockouts so that you

can lock and unlock meter features. You may want to remove this

jumper later to lock in certain settings that you don’t want to be

changed. (See Section 5.3.) It should be installed when the meter

is first configured.

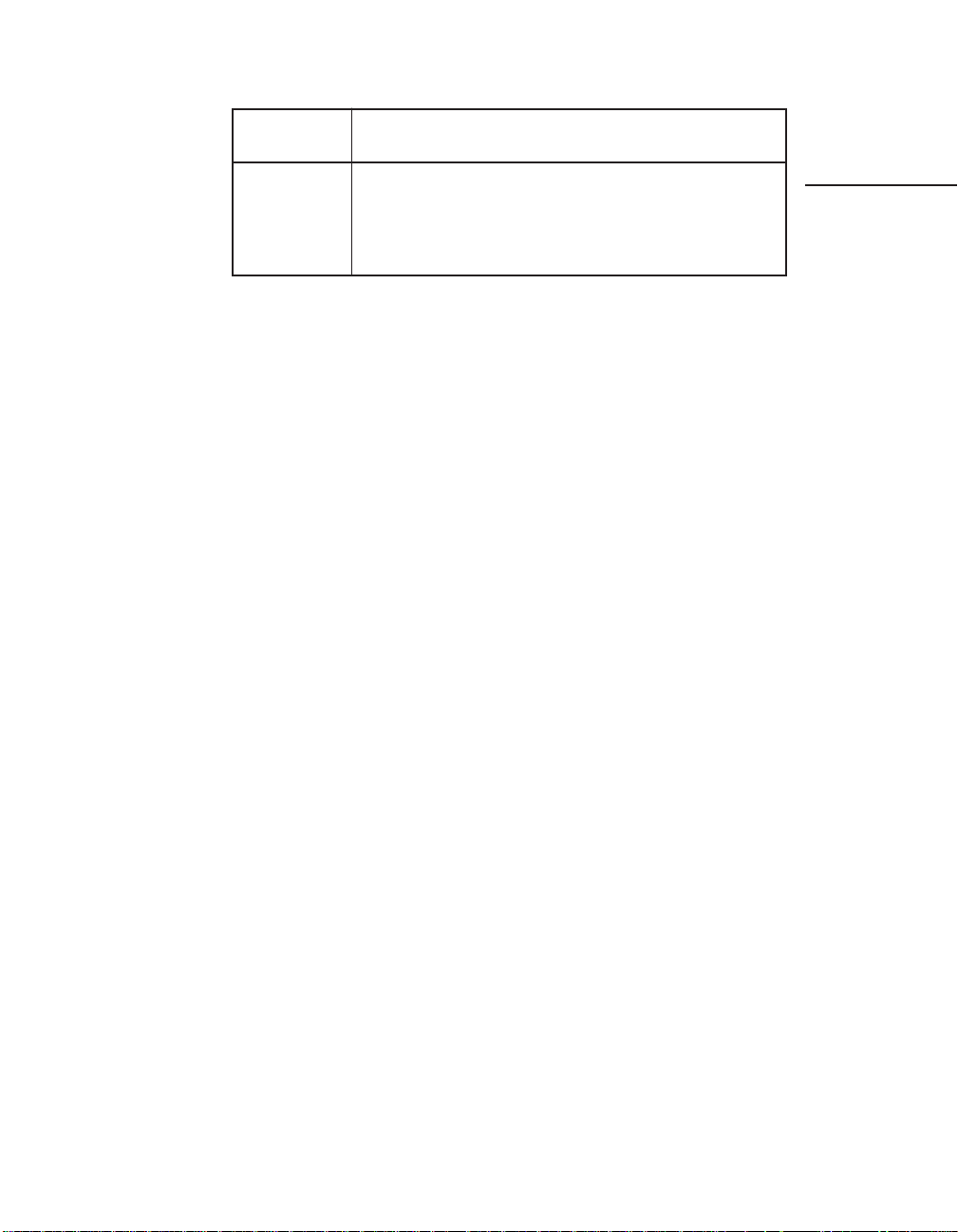

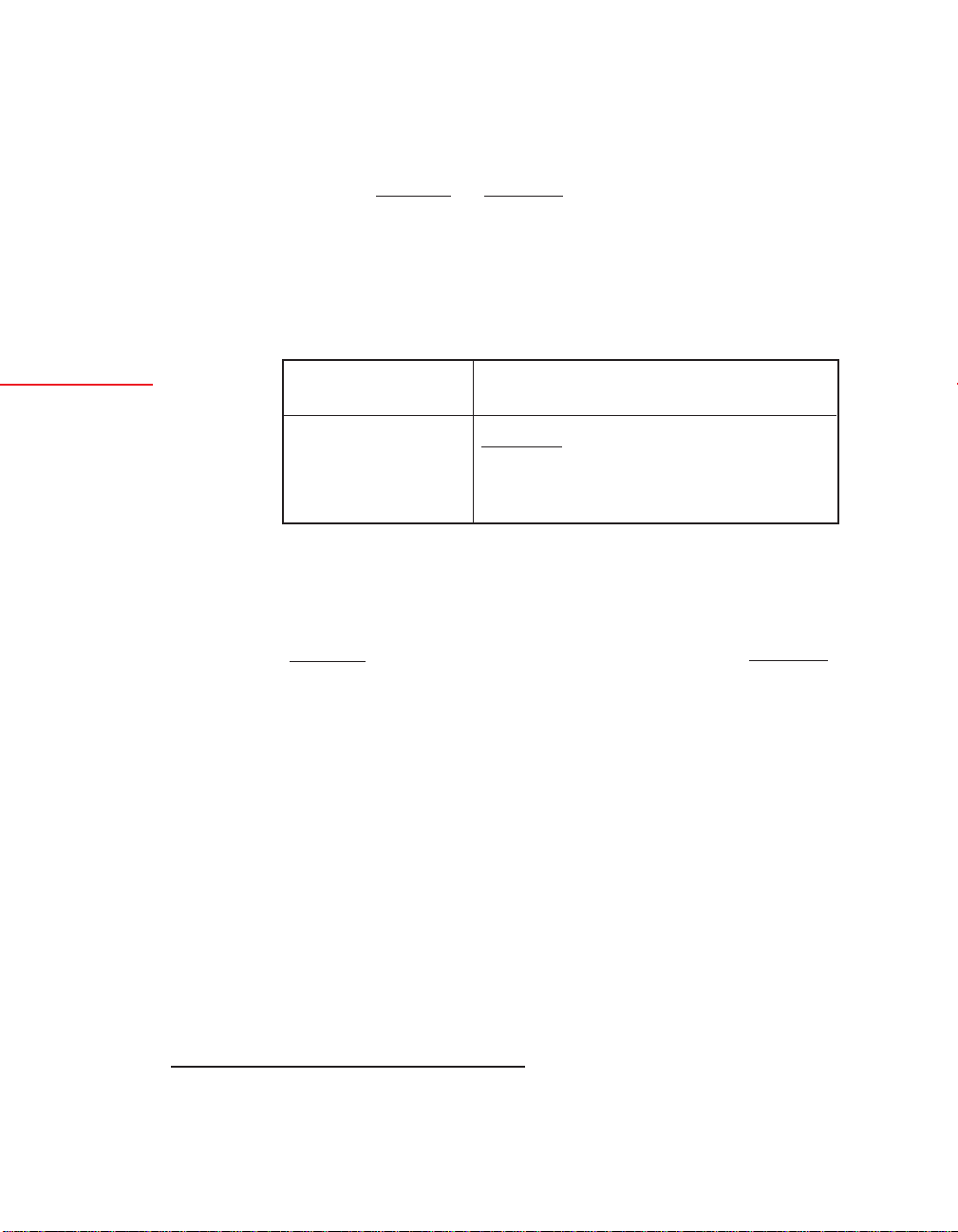

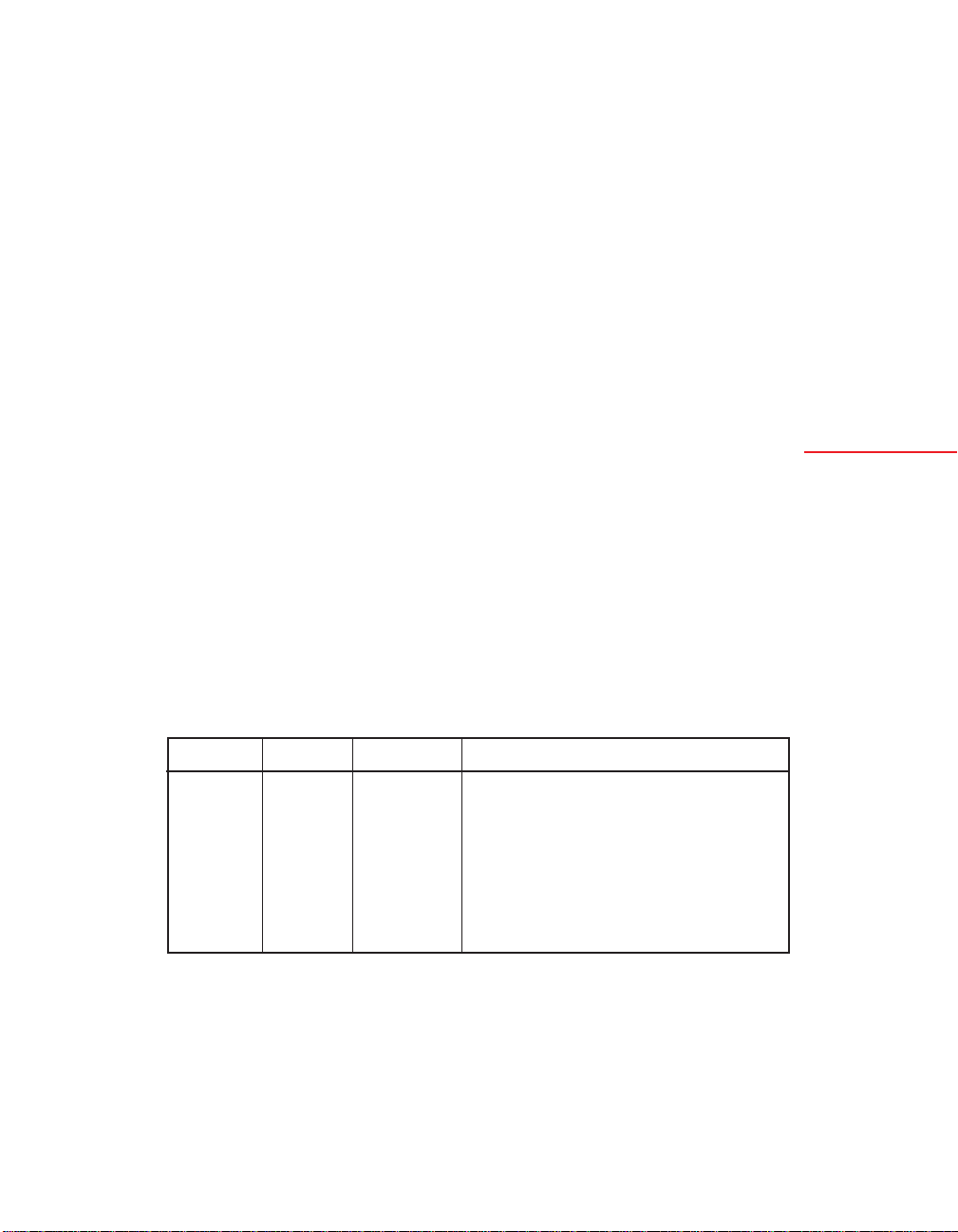

2.3.2.2 OPTIONAL INPUT AND OUTPUT BOARD JUMPER INFORMATION

JUMPER(S) CONFIGURING

BOARD TYPE PRESENT INFORMATION NOTES

Isolated pulse input Yes Appendix B –

Isolated analog input Yes Appendix C A one-time

calibration is

needed when

installed the

first time.

Isolated analog output No Appendix D A one-time

calibration is

needed when

installed the

first time.

Isolated Parallel

BCD output Yes Appendix E –

Dual relay output Yes Appendix F –

and 4 Relay output

Isolated RS-232 Serial

Communications

Output No Appendix G –

Isolated RS-485 Serial

Communications

Output Yes Appendix G –

18

Page 34

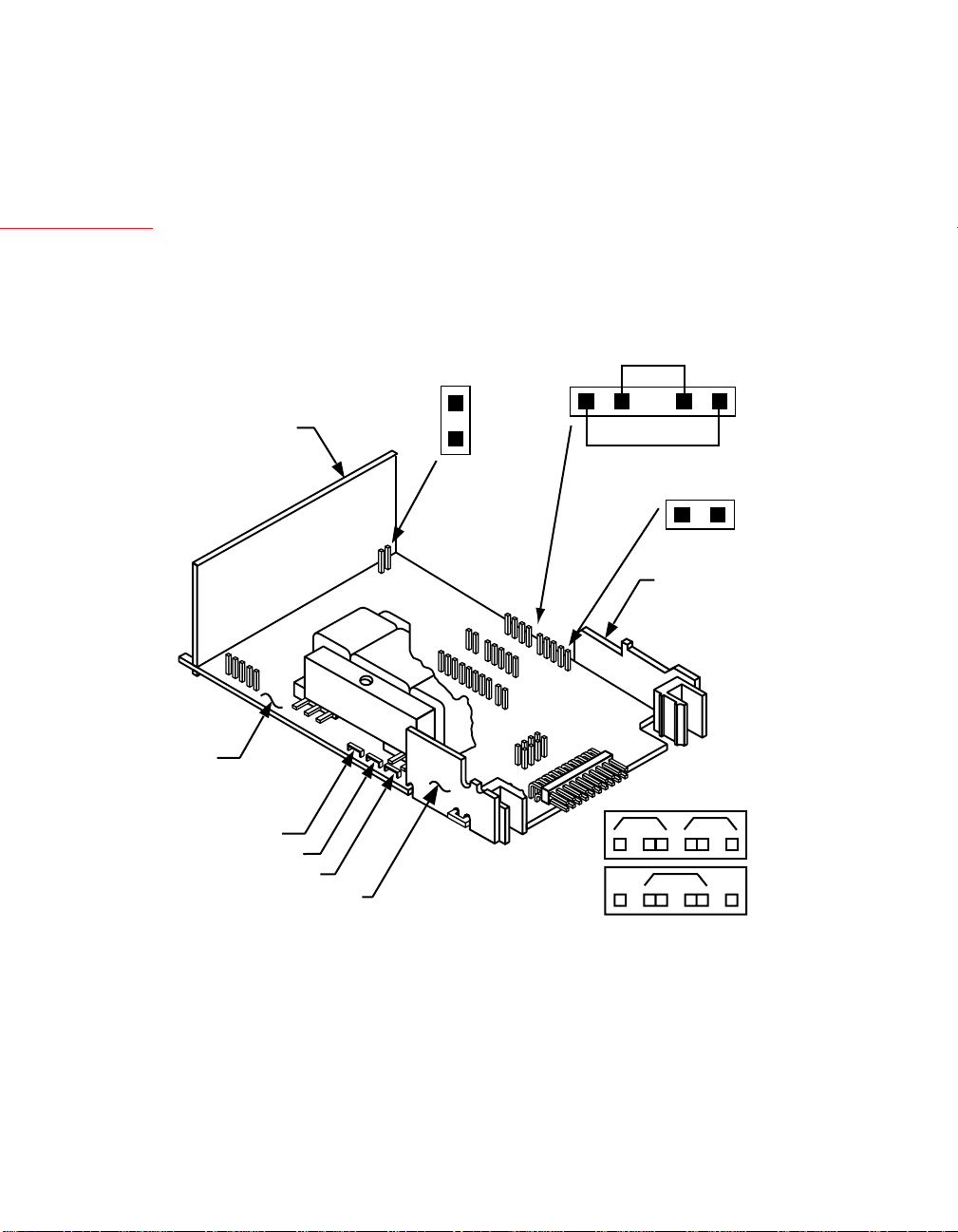

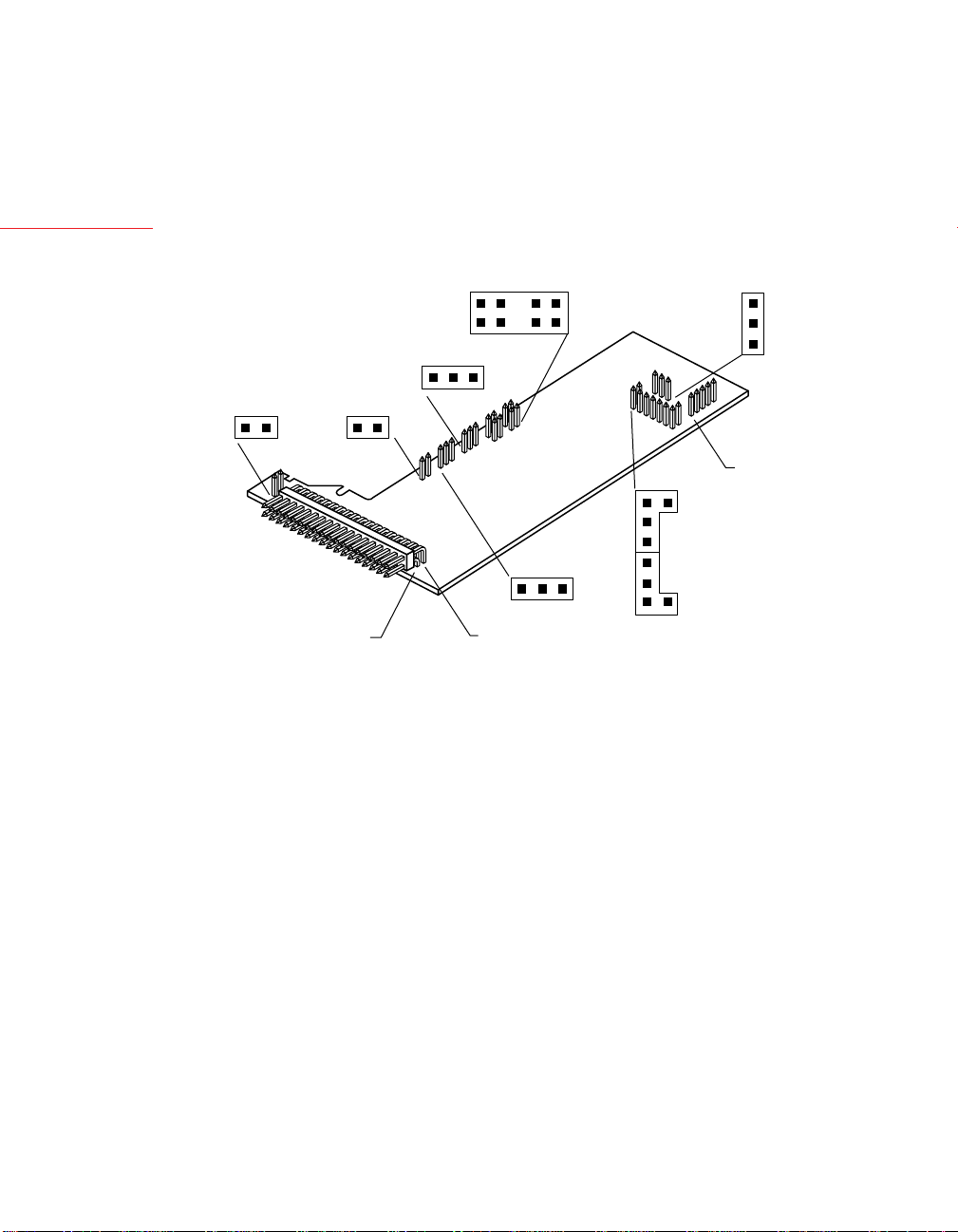

2.3.3 INSTALLING OPTIONAL BOARDS

FRONT

MAIN

BOARD

NOTE: When referring to installing optional boards, the view is

from the REAR of the meter.

Figure 2-7 shows the Main Board and Figure 2-8 shows an exploded

view of the meter with the optional board locations. In Figure 2-7,

the “front” of the board refers to the side with the Display Board;

the back is the side with J1 and J2 connections. Refer to Figures 2-7

and 2-8 as you insert optional boards. All boards must be jumpered

before insertion. See Section 2.3.2.

DISPLAY

BOARD

SIGNAL

CONNECTOR

BOARD

J2

J14

T1

J12

J11

J13

J10

2

Setup

J3

AC POWER BD

Figure 2-7. Main Board

REAR

J1

19

Page 35

2

Setup

PULSE

INPUT BOARD

OR ANALOG

INPUT BOARD

ISOLATED ANALOG

OUTPUT BOARD

RS-232/RS-485 BOARD

SIGNAL CONNECTOR

BOARD

P13

P20

P14

P12

P11

J13

J12 J11

J14

P10 (4 RELAY BOARD ONLY)

J20

BCD or 4 RELAY BOARD

INTERCONNECT BOARD

(PART OF BCD ASSY)

RETAINER (ALWAYS USED

EXCEPT FOR BCD OR

4 RELAY OPTION)

REAR

PROTECTIVE

COVER

DUAL

RELAY BOARD

P10

J10

AC POWER BOARD

MAIN BOARD ASSY

GASKET

COVER

MOUNTING

SCREW

THUMBNUTS

SLEEVE

BEND DETENTS OUTWARD

TO INSTALL MAIN BOARD

CASE

Figure 2-8. Exploded View of Main and Optional Boards

20

Page 36

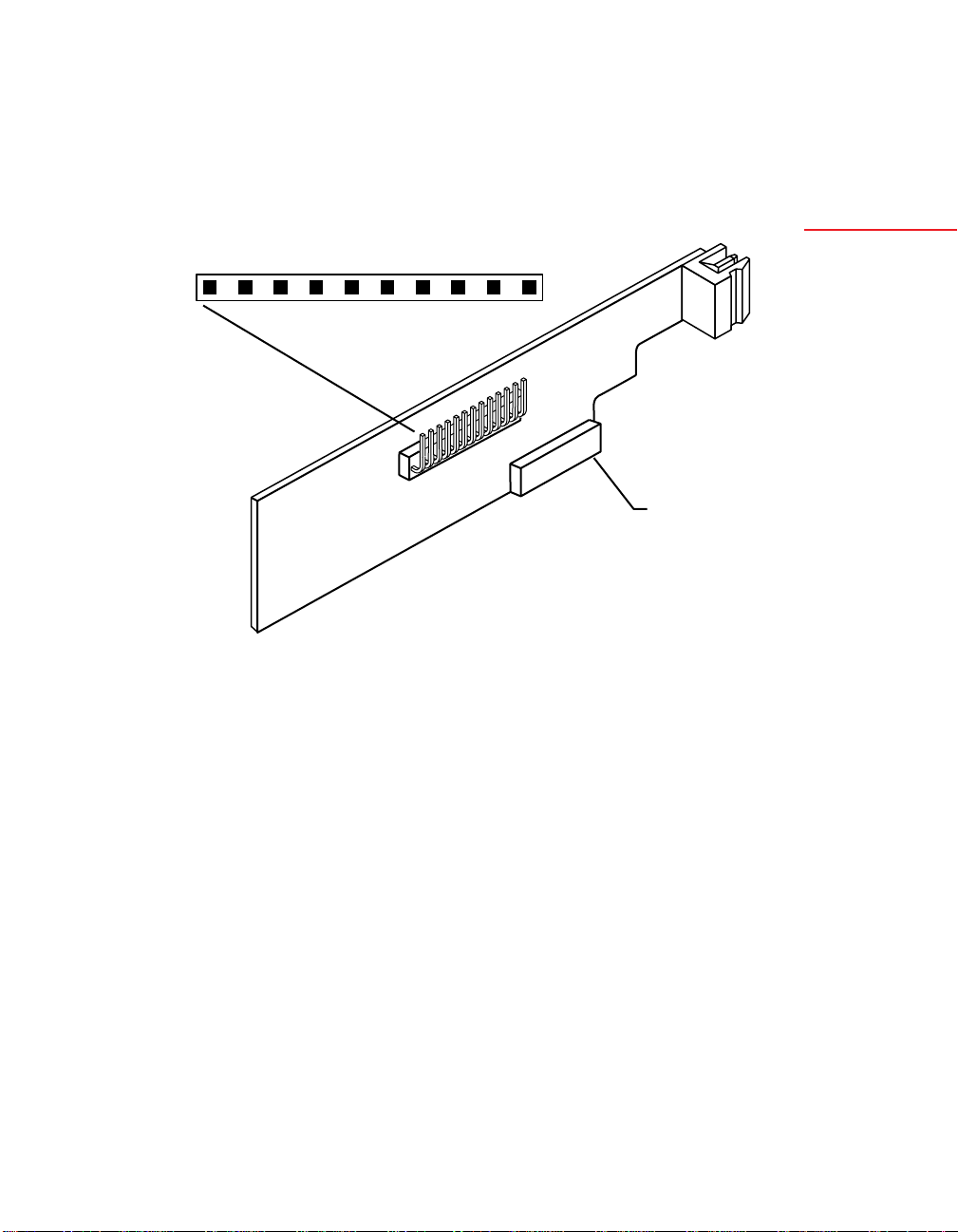

2.3.3.1 ISOLATED PULSE INPUT BOARD

The Isolated Pulse Input Board plugs into J13 on the right side of

the Main Board. J13 consists 10-pins with a gap at pin 5.

S1

E

A

B

C

Figure 2-9. Isolated Pulse Input Board

D

F

J9

S1

P13

PIN 1

2

Setup

Follow these steps before installing the board:

1. Remove (or connect to a single pin) jumper S2-A, the black

jumper clip on the first two pins of J13 on the Main Board.

2. Remove wire jumpers W6 and W7, the two soldered-in connections to the immediate right of J13.

3. Plug the input board onto the J13 jack.

The Pulse Input Board and Analog Input Board can be installed

at J13. However, only one can be installed at a time.

Refer to Appendix B to configure this board.

21

Page 37

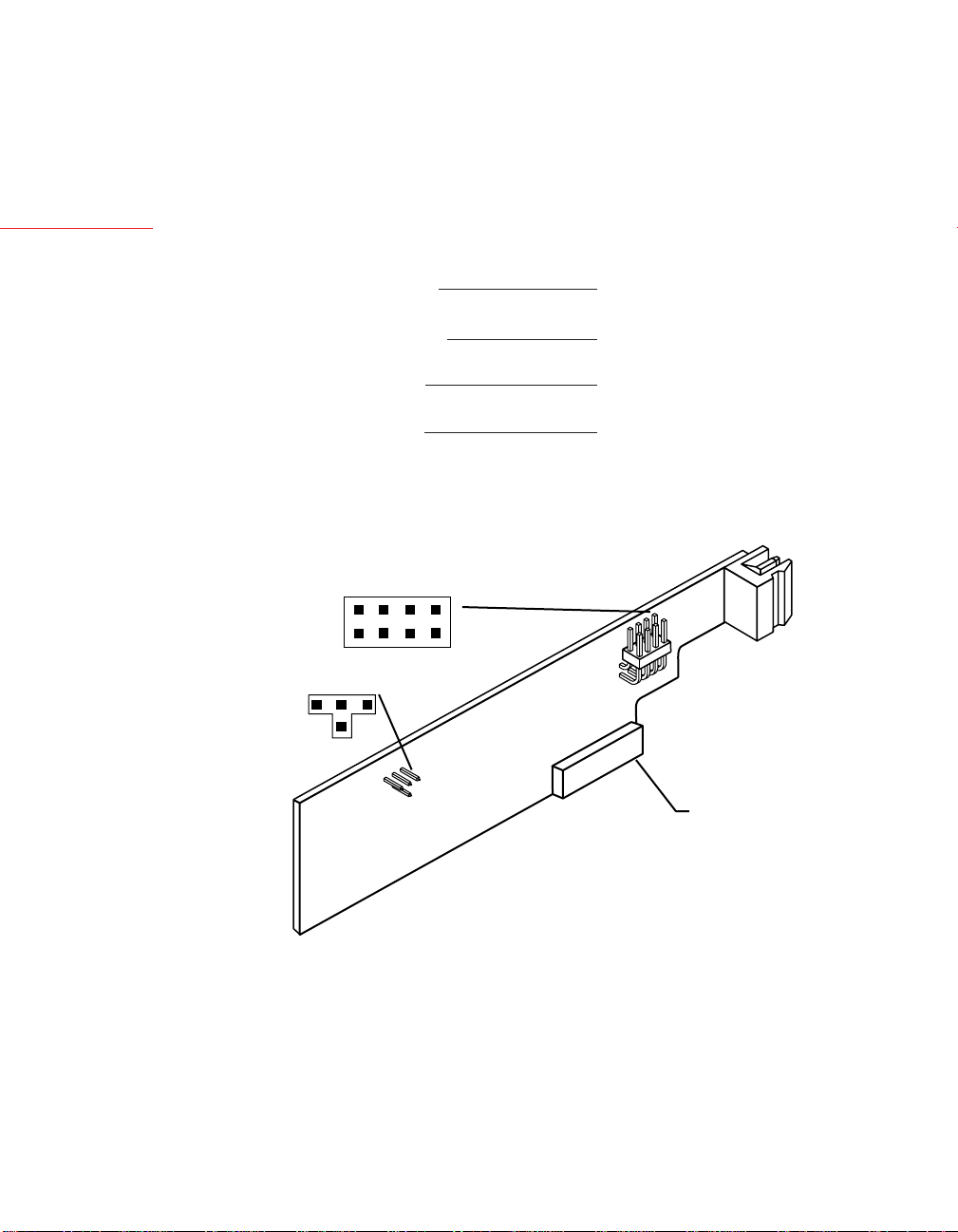

2.3.3.2 ISOLATED ANALOG INPUT BOARD

2

Setup

The solder side of the Isolated Analog Input Board contains

calibration data for precisely calibrating the board. Make sure you

copy the data before you install the board.

Record them here:

Input 1 @ 4 mA =

Input 2 @ 20 mA =

Input 1 @ 0 V =

Input 2 @ 5 V =

The Isolated Analog Input Board plugs into J13 also. See section

2.3.3.1, Steps 1 through 3.

A

AB

C

C

B

E

D

S1

J9

S2

S2

Figure 2-10. Isolated Analog Input Board

The Analog Input Board and Pulse Input Board can be installed

at J13. However, only one can be installed at a time.

Refer to Appendix C to configure this board.

P13

PIN 1

22

Page 38

2.3.3.3 ISOLATED ANALOG OUTPUT BOARD

The solder side of the Analog Output Board contains calibration

data for precisely calibrating the board. Make sure you copy the

data readings–CAL VZ (Calibrate Voltage Zero), CAL VS (Calibrate Voltage Span), CALmAZ (Calibrate milliAmp Zero), and

CALmAS (Calibrate milliAmp Span)–before you install the board.

Record them here:

CAL VZ =

CAL VS =

CALmAZ =

CALmAS =

The Analog Output Board plugs into J12, between J13 (on the

right edge of the Main Board) and the transformer. J12 consists of

8 pins with a gap at pin 6.

NOTE: Future analog output boards will be supplied with a 10-pin

connector for use with a DC powered version of this instrument.

CALmAS

2

Setup

CALmAZ

CAL VS

CAL VZ

130 m

S=

PIN 1

Figure 2-11. Isolated Analog Output Board

Refer to Appendix D to configure this board.

723

V Z=

P5

23

mA

Z=

715

12125

S=

P12

PIN 1

Page 39

2.3.3.4 ISOLATED PARALLEL BCD (BINARY-CODED DECIMAL) OUTPUT BOARD

2

Setup

The Isolated Parallel BCD Output Board mounts above (and

parallel to) the Main Board using the small vertical Interconnector

Board as a support. Note that this board is inserted component-

side down.

S5

A

E

C

G

S4

A B

S1

A A

J8

U1

S2

L1

S3

A B

S6

B

A

A

S7

B

A

B

S8

J20

PIN 1

Figure 2-12. Isolated Parallel BCD Output Board

1. Insert the P14 plug of the Interconnect Board onto the J14 pins

on the Main Board. J14 consists of 5 vertical pins on the left side

of the Main Board, immediately behind the Display Board.

2. Insert the P20 connector of the Interconnect Board onto the J20

pins on the BCD Board. (See Figure 2-8.)

The Dual Relay or 4 Relay Output Option may not be installed

at the same time as the Parallel BCD Output Option.

Refer to Appendix E to configure this board.

24

Page 40

2.3.3.5 DUAL RELAY AND 4 RELAY OUTPUT BOARDS

4 RELAY BOARD

PIN 1 OF CABLE

PIN 1

MAIN BOARD

J10

P10

The Dual Relay Board is a vertical board and the 4 Relay board is a

horizontal board which plugs into J10, the double row of 4 pins

each at the rear of the Main Board.

P7

P6

Figure 2-13. The Dual Relay Output Board and the 4 Relay

Output Board.

Both the Dual Relay Output Board and the 4 Relay Output

Board can be installed at J10. However, only one option board can

be installed at a time.

Refer to Appendix F to configure this board.

2

Setup

2.3.3.6 ISOLATED RS-232 SERIAL COMMUNICATIONS BOARD

The Isolated RS-232 Serial Communications Board plugs into J11,

to the right of the transformer.

P 11

Figure 2-14. Isolated RS-232 Serial Communications Board

J11 consists 11 pins with a gap at pin 9. (Note that the mating

socket of the communications board does not mate with pin 11

of J11; this pin is reserved for future use.)

The RS485 Board can be installed at J11. However, only one

option board can be installed at the same time.

25

J4

PIN 1

Page 41

2.3.3.7 ISOLATED RS-485 SERIAL COMMUNICATIONS BOARD

2

Setup

The Isolated RS-485 Serial Communications Board mounts in a

manner identical to that of the RS-232 board in the previous

section.

S1

A

B

Figure 2-15. Isolated RS-485 Serial Communications Board

The RS232 Board can be installed at J11. However, only one

option board can be installed at the same time.

Refer to Appendix G to configure this board.

2.3.4 REINSERTING THE MAIN BOARD ASSEMBLY INTO THE CASE

S3

A

P11

J4

PIN 1

A

S2

2.3.5 WIRING

Reinsert the Main Board into the case once Main Board jumpers

have been configured (Section 2.3.2.1) and optional boards have

been configured and installed (Sections 2.3.2.2 through 2.3.3).

Spread the side-panel detents of the case, and carefully slide the

Main Board all the way in.

You are now ready to wire your meter.

The way you connect your input wiring to your meter depends on

your pulse or input source, and the types of optional boards you

have installed. Therefore, this section contains complete instructions for wiring only the AC Power connector (P1), and guidelines

for wiring the input/output control connector (P2). You will be

referred to the appropriate appendix for specific wiring instructions

based on your optional board configuration.

26

Page 42

2.3.5.1 P1 - AC POWER WIRING

!

!

CAUTION: As mentioned in Section 2.2.2, the meter has no

power ON/OFF switch. The meter will be ON when power is

applied.

WARNING: Do not connect ac power to your meter until you

have completed all input and output connections. Failure to do

so may result in injury! This device must only be installed

electrically by specially trained electrician with corresponding

qualifications. The meter is factory set to the power specified by

the customer at the time of ordering. The voltage is printed on

the Label under Input power.

Wire your power (from a wall socket or other source) to P1, the

orange, 3-socket connector that plugs into the 3 pins on the left

side as you view the meter from the rear. Refer to Figure 2-16 and

Table 2-2 below.

LN

ORANGE

CONNECTOR

EARTH

NEUTRAL

LINE

FUSE

SWITCH

Check for proper Earth grounding in the

power distribution system (single phase).

GREEN WIRE

L

N

[

P1

1

2

3

2

Setup

Figure 2-16. P1, ~AC Power Connector Wiring

TABLE 2-2. P1, AC POWER CONNECTOR WIRING

P1 AC POWER EUROPE USA

1 {ac Line Brown Black

2 {ac Neutral Blue White

3 {ac Protective Earth GND Green/Yellow Green

2.3.5.2 BATTERY BACKUP CONNECTIONS

The purpose of the battery backup is to allow the internal clock to

continue to run when a loss of the AC power is experienced. All

other functions will cease to operate until AC power is resumed. The

minimum requirements of the battery needed is 7-12 Vdc at 50 mA.

Connect the negative lead of your battery to P2-9 (ALARM,

BATTERY RETURN) and the positive lead of your battery to

P2-20 (BACKUP BATTERY).

WIRE COLOR

27

Page 43

2.3.5.3 P2 - CONTROL INPUT/OUTPUT WIRING

2

Setup

P2, the 20-socket ribbon connector plugs into the center rear of the

Main Board, sends out the setpoint transistor collectors and permits

remote control of significant meter features. Table 2-3 describes

the function of each pin.

TABLE 2-3. P2, INPUT/OUTPUT CONNECTIONS

P2

SOCKET/

PIN NO. DESCRIPTION/FUNCTION

P2-1 Setpoint 1 transistor open-collector output

P2-2 Input of external V+ used for setpoint transistors so that

internal diodes can clamp inductive-load spikes

P2-3 RESET-A: When grounded in Rate or Sq Rt Modes,

resets TOTAL to 0, resets TOTAL setpoint latches; in

Batch Mode, starts a new BATCH count, increments

BAT NO (Number of Batches), resets BATCH-count

setpoint latches, and clears any STOP (See Section 4.10)

P2-4 Setpoint 2 transistor open-collector output

P2-5 Setpoint 3 transistor open-collector output

P2-6 Setpoint 4 transistor open-collector output

P2-7 Twice-line-frequency, 5-V pulse output (also used by

microcontroller to detect line failure)

P2-8 Setpoint 5 transistor open-collector output

P2-9 Return ground connection: SP-transistor external supply

and/or backup battery ground

P2-10 Debounce capacitor for P3-2 signal input (tie to ground

for contact input)

P2-11 RESET-B: When grounded in Rate or Sq Rt Modes,

starts a new AVG RTE (Average Rate) period, resets

RATE setpoint latches; in Batch Mode, resets BAT NO

(Number of Batches) to 0 (if count is up) or to

Setpoint 4 value (if count is down), and resets

BAT NO setpoint latches (if SP4 has been assigned)

(See Section 4.10)

P2-12 TTL-level Test RX

P2-13 TTL-level Test TX

P2-14 Meter digital ground (internally connected to P2-9)

P2-15 Programmable Pulse Output (see AL TI, Section 5.4.12)

28

continued next page

Page 44

continued from previous page

P2

SOCKET/

PIN NO. DESCRIPTION/FUNCTION

2

P2-16 HOLD/PRINT REQUEST: When grounded, if enabled

by CF4.3 and CF4.4, freezes displayed value/initiates

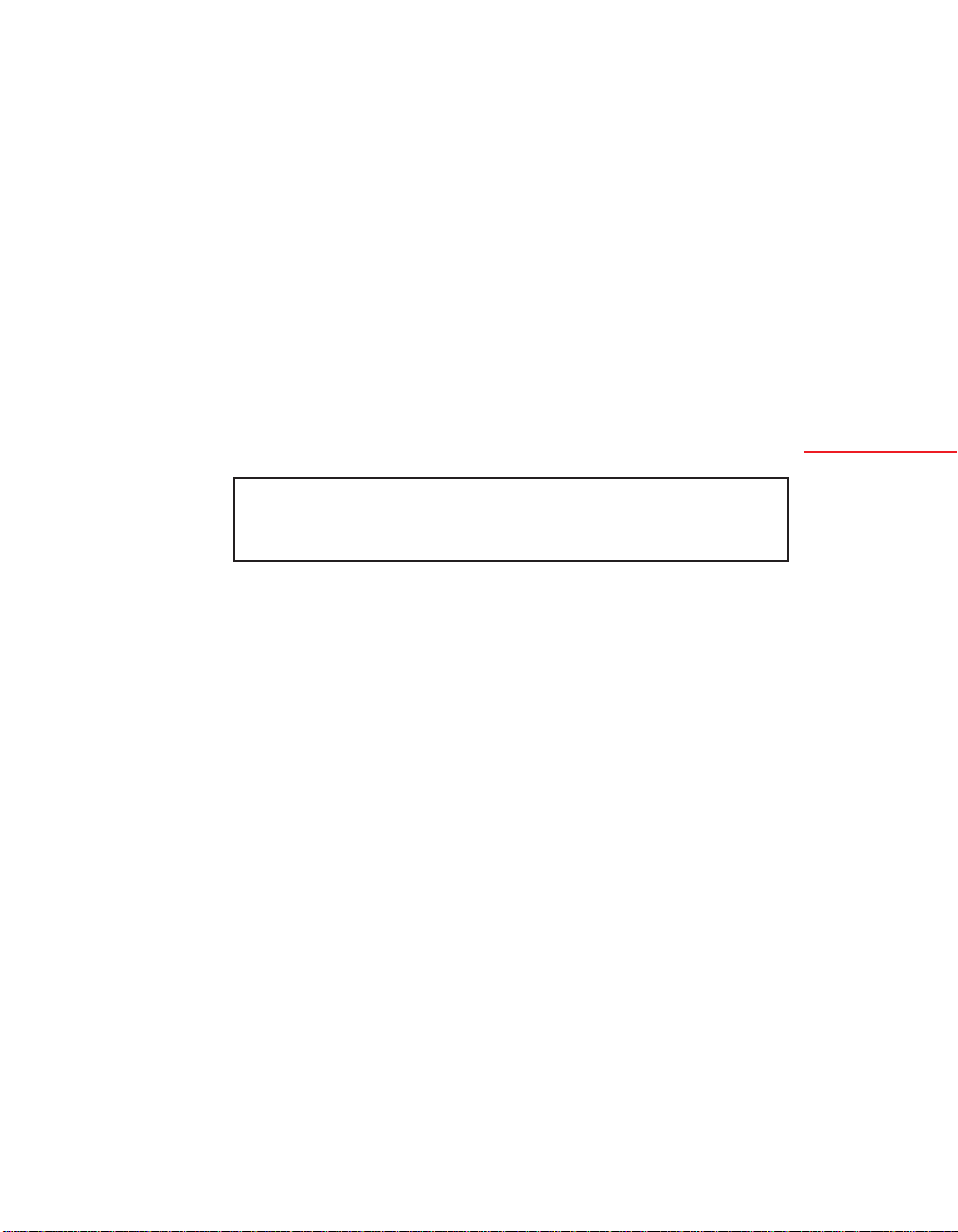

print out (V01 Command)

P2-17 STOP: When grounded in rate or sq rt modes, stops

the clock until released; in batch mode, sets all setpoint

outputs to their active states

P2-18 GATE: Nonisolated input: Can be used as the input

signal or to gate P3/P9 inputs

P2-19 RESET-C: when grounded in rate or sq rt modes,

resets the clock to SET TI (Set Time, see Section

5.4.15), and resets TIME setpoint latches; in Batch,

resets the clock to SET TI, resets the grand TOTAL to

0, resets a TOTAL setpoint latch (See Section 4.10)

P2-20 Backup battery +V input

2.3.5.4 BASIC METER INPUT WIRING

If you are going to be operating the meter as a basic meter–with no

optional boards–see Appendix A for further wiring instructions.

2.3.5.5 ISOLATED PULSE INPUT BOARD WIRING

If your meter has the isolated pulse input board, see Appendix B for

wiring.

Setup

2.3.5.6 ISOLATED ANALOG INPUT BOARD WIRING

If your meter has the isolated analog input board, see Appendix C

for wiring.

2.3.5.7 ISOLATED ANALOG OUTPUT BOARD WIRING

If your meter has the isolated analog output board, see Appendix D

for wiring.

2.3.5.8 ISOLATED PARALLEL BCD OUTPUT BOARD WIRING

If your meter has the isolated parallel BCD output board, see

Appendix E for wiring.

29

Page 45

2.3.5.9 DUAL RELAY OUTPUT AND 4 RELAY OUTPUT BOARD WIRING

2

Setup

If your meter has the Dual Relay Output Board or the 4 Relay

Output Board, see Appendix F for wiring.

2.3.5.10 ISOLATED RS-232 OR RS-485 SERIAL COMMUNICATIONS BOARD WIRING

If your meter has either the Isolated RS-232 or RS-485 Serial

Communications Board, see Appendix G for wiring or connections.

2.4 PANEL-MOUNT ASSEMBLY

The meter can be mounted in a panel so that the front of the meter

is flush with the vertical panel surface. Panel mounting can be

seen as simply “sandwiching” the panel between the inner case and

the outer sleeve in the last phases of assembly. Figure 2-17 shows

the panel cutout dimensions, and the dimensions for the panel

thickness. It requires that the following already be done:

1. Your line voltage rating has been checked against the meter

rating on the ID and serial number label on the meter case. See

Section 2.2.1.

2. You have configured all jumpers–those on the main board as well

as those on any optional boards. See Section 2.3.2.1 for main

board jumper configuration and Appendices B through G for

optional board jumper configuration.

!

3. You have installed all optional boards and inserted the main

board assembly back into the case. See Sections 2.3.3 and 2.3.4.

4. You have wired P1, the AC power connector, and P2 the input/

output control connector; connectors are not installed in the

meter, but are ready to be. See Sections 2.3.5.1 and 2.3.5.2.

5. You have wired all connectors for optional boards; connectors

are not connected to the meter, but are ready to be. See Appendices B through G.

CAUTION: Connectors with the wiring connections will be

installed after mounting the unit.

If all of these steps are done, continue here using Figure 2-17 as a

guide:

30

Page 46

2

PANEL CUTOUT

0.06

R

[1.5]

4PLCS

3.622 +0.032/-.000

[92.00 +0.81/-0.00]

PANEL

Setup

PANEL THICKNESS

0.25 [6.4] MAX

0.03 [0.8] MIN

1.772 +0.024/-.000

[45.00 +0.61/-0.00]

REAR

PROTECTIVE

COVER

COVER

MOUNTING

SCREW

THUMBNUTS

METER

SLEEVE

CASE

GASKET

BEZEL

Figure 2-17. Panel-Mount Assembly

31

Page 47

2

6. Punch or cut a hole in the panel using the panel cutout

dimensions in Figure 2-17. Remove burrs and paint the panel

as required.

Setup

!

7. Insert the panel-mount gasket around the rear of the case and

slide it forward to the bezel (if it’s not already in place).

8. Working from the front of the panel, insert the case assembly,

rear end first, all the way into the panel cutout such that the

gasket firmly backs the panel surface.

9. Working from the rear of the panel, slide the sleeve forward

over the case and up to the panel surface.

The panel should now be sandwiched between the bezel-backed

gasket in front and the sleeve in back.

10. Replace the thumbnuts that secure the sleeve tabs to the case.

WARNING: Do not "turn-on" the ac power and input signals

until all connections are connected to the meter.

11. Set P1, the AC power connector, aside and connect or reconnect all other connectors to the back of the meter using Figures

3-2 and 3-3 in Section 3.2 as guides.

NOTE: The P1 connector is “keyed”; it is shaped in such a way

that it fits only the J1 male pins.

Connect P1 last.

12. Replace the rear protective cover and secure it with the cover

mounting screw.

Your meter is now ready for operation and you can turn-on the

power.

32

Page 48

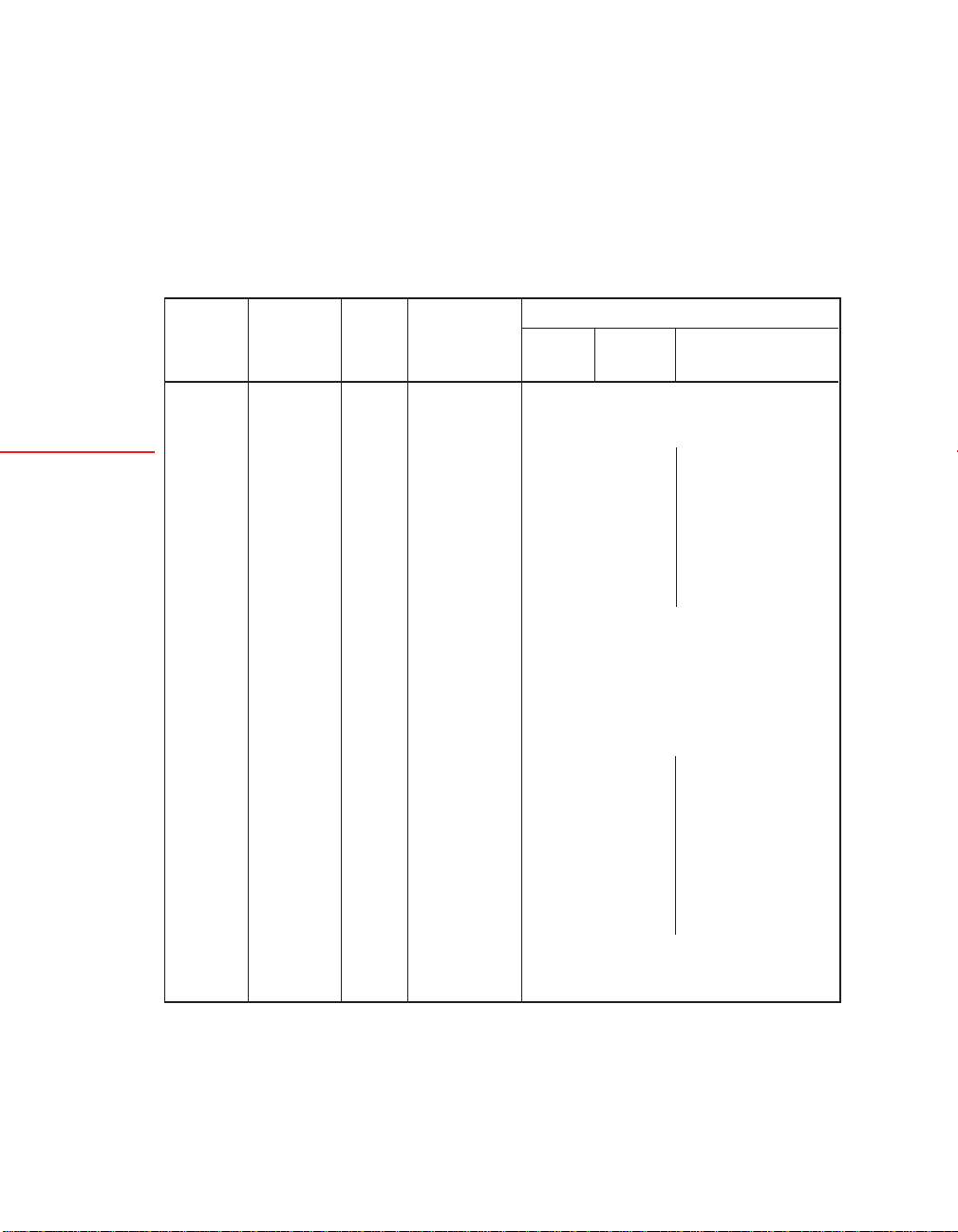

3. Front and Rear Features

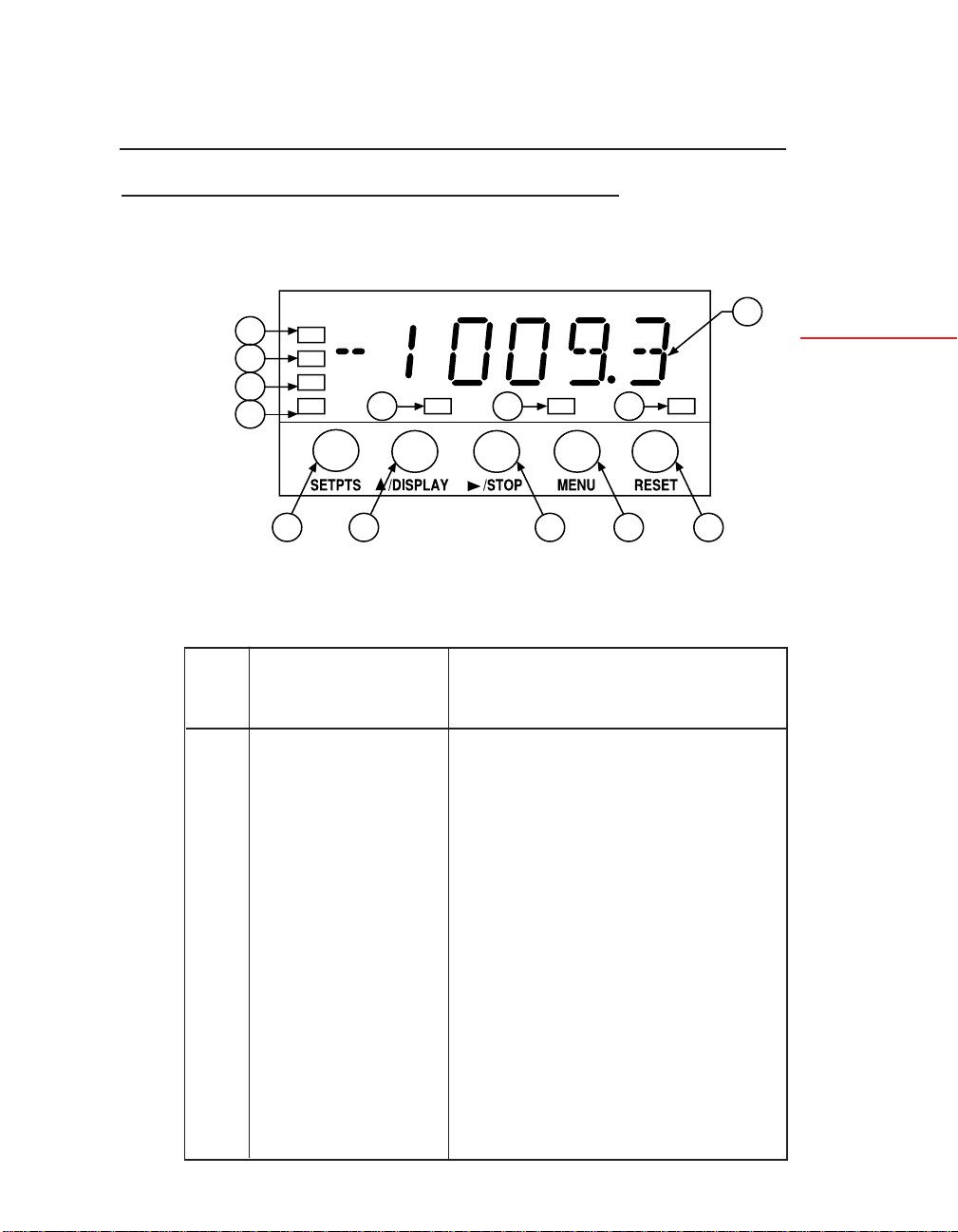

3.1 FRONT-PANEL DISPLAYS AND BUTTONS

Refer to Figure 3-1 as you read about front panel displays and

buttons.

2

2

2

3

4 5

Figure 3-1. Front Panel

TABLE 3-1. FRONT-PANEL DISPLAYS AND BUTTONS

FRONT-PANEL

BUTTON OR

ITEM FEATURE DESCRIPTION/FUNCTION

1 6-Digit Display 6-Digit, 14-segment, 0.54-inch LED

3

3 3

6

display produces alphanumeric readout;

programmable decimal point; red with

green option

7

8

3

Front

1

and Rear

Features

2 Measurement Green LEDs; designate which

measurement is being

displayed (See DISPLAY, below)

3 Setpoint LEDs Red LEDs; designate which setpoints are

active; when flashing, designate which

setpoint is being viewed and/or set

4 SETPTS Button In Run mode changes to Setpoint Mode

and allows setting of five setpoints; allows

value change by pressing the ▲/DISPLAY

button and the /STOP button

33

▲

continued next page

Page 49

3

Front

and Rear

Features

continued from previous page

FRONT-PANEL

BUTTON OR

ITEM FEATURE DESCRIPTION/FUNCTION

5 ▲ /DISPLAY Two-Function button: In Run Mode,

Button sequences the display through mode-

▲

6 /STOP Button Two-Function button: In run mode,

(STOP enabled imposes STOP condition; in configuraby CF4.8=1) tion and setpoint modes, accesses the

associated measurements; in Configuration and Setpoint Modes, sequences

through possible digit and numerical

settings

• In Rate-Run Mode, sequences the

display through unlocked values of

RATE, AVG RT, TOTAL, and TIME

• In Sq Rt-Run Mode, sequences the

display through unlocked values of

SQ RT, AVG RT, TOTAL and TIME

• In Batch-Run Mode, sequences the

display through unlocked values of

BATCH, BAT NO, TOTAL and TIME

• In Setpoint and Configuration Modes,

sequences through possible

alphanumeric settings: For

numbers,increments the flashing digit

by 1; for alphabetical settings,

sequences to the next possible setting

next digit or choice

• In batch-run mode, if CF4.8=1, puts

all setpoints in their ACTIVE states

and displays STOP. (After 3 seconds,

▲

the /STOP button can be pressed

again to reset alarms and return to run

mode)

• Inactive in rate-run or sq rt-run modes

• In setpoint mode advances the

flashing digit one place to the right,

making the new digit accessible for

resetting by the ▲/DISPLAY button

34

continued next page

Page 50

continued from previous page

FRONT-PANEL

BUTTON OR

ITEM FEATURE DESCRIPTION/FUNCTION

7 MENU Button • In run mode, terminates measure-

(Enabled by ments and switches to Configuration

L3C.8=0; Mode

disabled by • In configuration mode, stores new

L3C.8=1 and values in EEPROM (nonvolatile

removal of S1) memory) and advances the display to

8 RESET Button • In Run Mode, RESETs the value of

(Enabled by the measurement on display to zero

CF4.7=0) (or to the reset value designated by

• In configuration mode, advances the

flashing digit one place to the right,

making the new digit accessible for

resetting by the ▲/DISPLAY button;

advances the displayed choice to the

next choice in sequence

the next parameter to be programmed

configuration) Also RESETs any

latched alarms assigned to the dis

played measurement

• In setpoint mode, switches back to run

mode; any new setpoint values entered

with the /STOP button and the

▲/DISPLAY button that have not

been stored are discarded

• In configuration mode, the first press

backs up one parameter (Menu item);

the second one RESETs the meter and

returns to run mode

▲

3

Front

and Rear

Features

3.2 REAR CONNECTORS

Figure 3-2 shows the rear of the meter with the Dual Relay Board,

and a serial communications board. Figure 3-3 shows it with the

Isolated Parallel BCD Output Board, a serial communications

board, Isolated Analog Output Board, and Analog or Pulse Input

Board. Figure 3-4 shows the connector label with pin assignments.

35

Page 51

3

Front

and Rear

Features

P6

1

2

P1

L

1

2

N

3

P7

3

1

2

3

J4

1

P2

1

20

P18

2

3

4

5

6

1

2

3

1

2

3

P9

P3

Figure 3-2. Rear View of the Meter with the 4-Relay and

Serial Communications Boards

U1

L1

P1

L

1

2

N

3

1

P8

U20

L20

P5

1

2

3

1

2

3

P9

P3

J4

1

2

20

P2

3

Figure 3-3. Rear View with the BCD, Serial Communications, and

Analog Output Boards

36

Page 52

P2/CABLE CONNECTOR

ALARM 1 OUTPUT

ALARM 3 OUTPUT

1

2

3

{

1

P1

...

1

N/C

COMM RTN

RX

TX

RTS

N/C

LINE

NEUTRAL

AC GND

P8

P6

P2

..........

..........

1

TWICE LINE FREQ

...

1

ALARM, BATTERY RETURN

P4/RS-232

6

5

4

3

2

1

P1/AC PWR

.

.

.

1

CONNECT TO LOW VOLTAGE LIMITED ENERGY CIRCUITRY ONLY.

RESET-A

RESET-B

TEST TX

PULSE OUTPUT

RESET-C

1 1

1

P8

P4

.

.

.

.

1

.

19

P7

STOP

P4/RS-485

6

5

4

3

2

1

P6/RELAY

1

2

3

BCD

1

.

.

.

P5

1

3

5

7

9

11

13

15

17

19

P18 for 4 RELAY

.

1

.

.

P9

.

1

.

.

P3

ALARM V + INPUT

2

ALARM 2 OUTPUT

4

ALARM 4 OUTPUT

6

ALARM 5 OUTPUT

8

DEBOUNCE

10

TEST RX

12

DIGITAL RETURN

14

HOLD / PRINT REQ

16

GATE INPUT

18

BACKUP BATTERY +

20

N/C

B RX

A RX

COMM RTN

B TX/RX

A TX/RX

NO1

CM1

NC1

PULSE INPUT

FILTER

SIG IN HI LEVEL

PULL UP/DOWN

EXCITATION

SIG IN LO LEVEL

SIG RETURN

1

P5 ANALOG OUT

1

2

3

P7/RELAY

1

2

3

P9 & P3

ANALOG INPUT

+24 V EXC