Page 1

am

a-

Q

m

@

A

y

DP409

DP434

DP409A

/

DP434A

I

and

Analog Melt Pressure Indicator

&

Digital Melt Pressure Indicator

459 ’

3

2

1

7

a

9

DP409/DP409A

0

ee@

--am”-.

@

00@00

._I,

t3

10

_I. .

Page 2

OMEGA? .. Your Source for

Process Measurement and Control

TEMPERATURE

&

&

M

0’

Wire: Thermocouple, RTD

&

M

Calibrators

M

Recorders, Controllers

0’

infrared Pyrometers

Ice Point References

Thermistor Probes, Connectors, Panels Themocoupie, RTD

&

Thermistor

&

Process Monitors

PRESSURE/STRAIN FORCE

0’

Transducers & Strain Gauges

&

I2

Load Cells

I2

Displacement Transducers

I2

instrumentation

Pressure Gauges

&

Accessories

FLOW/LEVEL

II?

Rotameters, Gas Mass Flowmeters

IZ?

Air Velocity indicators

Ca

TurbinelPaddiewheei

&

M

Totaiizers

Batch Controllers

Systems

pH/CONDUCTIVITY

&

pH

Electrodes, Testers

Gf

[a

BenchtoplLaboratory

0’

Controllers, Calibrators, Simulators

I2

industrial

&

Conductivity Equipment

pH

Accessories

Meters

&

Flow Computers

8 Pumps

Assemblies

DATA ACQU ISITION

II@

Data Acquisition and Engineering Software

IET

Communications-Based Acquisition Systems

&

I2

Plug-in Cards for Apple, IBM

[a

Datalogging Systems

&

I33

Recorders, Printers

Plotters

Compatibles

HEATERS

0’

Heating Cable

&

I@

Cartridge

0’

immersion & Band Heaters

I% Flexible Heaters

0’

Laboratory Heaters

Strip Heaters

Page 3

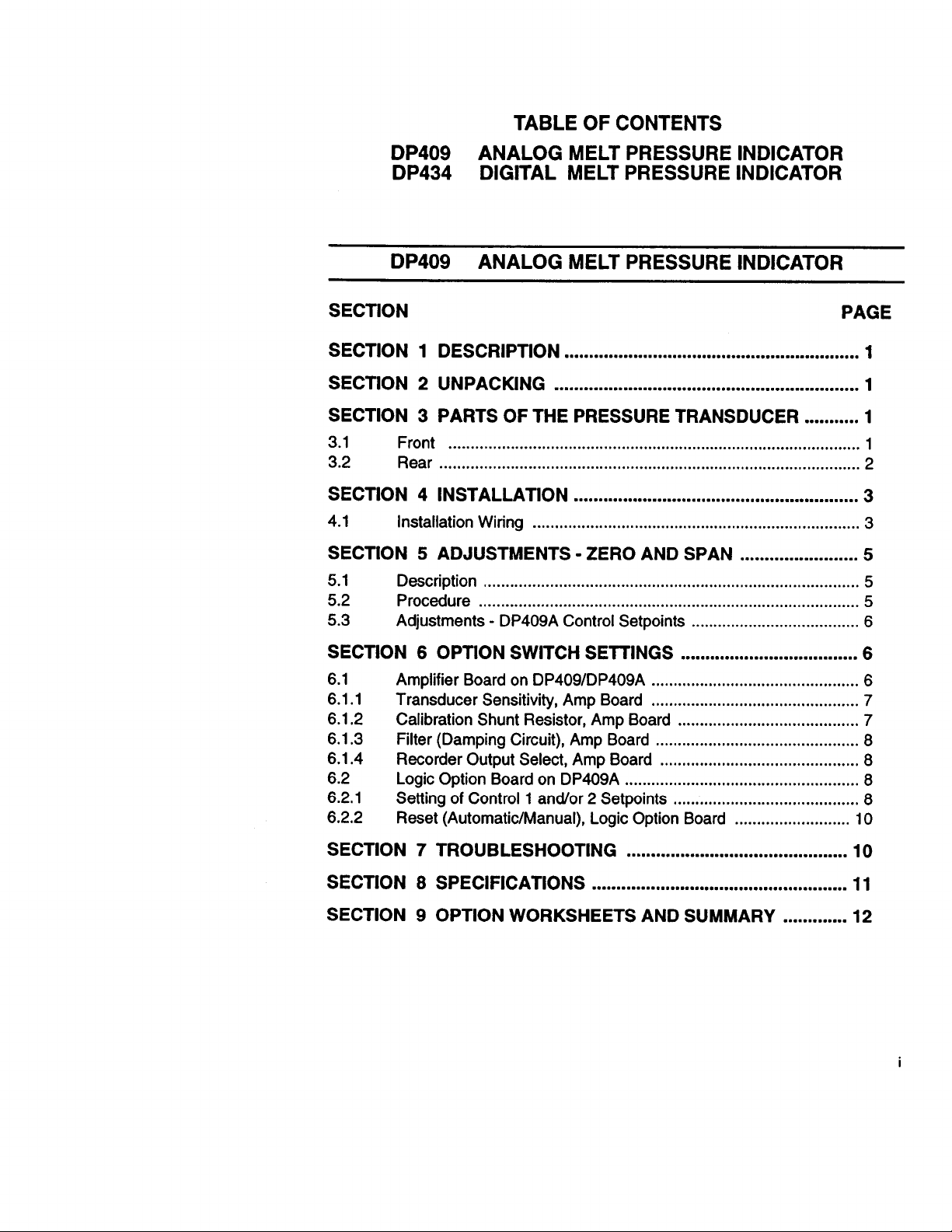

TABLE OF CONTENTS

DP409

DP434

DP409

ANALOG MELT PRESSURE INDICATOR

DIGITAL MELT PRESSURE INDICATOR

ANALOG MELT PRESSURE INDICATOR

SECTION

SECTION 1 DESCRIPTION

SECTION 2 UNPACKING

3

SECTION

3.1

3.2

PARTS OF THE PRESSURE TRANSDUCER . . . . . . . . . . . 1

Front

Rear

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 INSTALLATION

4.1

SECTION

5.1

5.2

5.3

installation Wiring

5

ADJUSTMENTS

Description .....................................................................................

Procedure

Adjustments

......................................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DP409A

-

PAGE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

ZERO AND SPAN

Control

Setpoints

......................................

. . . . . . . . . . . . . . . . . . . . . . . .

1

1

1

2

3

3

5

5

5

6

SECTION 6 OPTION SWITCH

6.1

6.1.1

6.1.2 Calibration Shunt

6.1.3 Filter (Damping Circuit), Amp Board ..............................................

6.1.4

6.2

6.2.1

6.2.2

Amplifier Board on

Transducer

Recorder Output Select, Amp Board

Logic Option Board on

Setting of Control 1 and/or 2 Setpoints

Reset (Automatic/Manual), Logic Option Board

Sensitivity,

DP409/DP409A

Resistor,

SECTION 7 TROUBLESHOOTING

SECTION 6 SPECIFICATIONS

9

SECTION

OPTION WORKSHEETS AND SUMMARY

SElTlNGS

Board

Amp

Amp Board .........................................

DP409A

.....................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

....................................

...............................................

...............................................

.............................................

..........................................

.......................... 10

. . . . . . . . . . . . . 12

6

6

7

7

8

8

8

8

10

11

Page 4

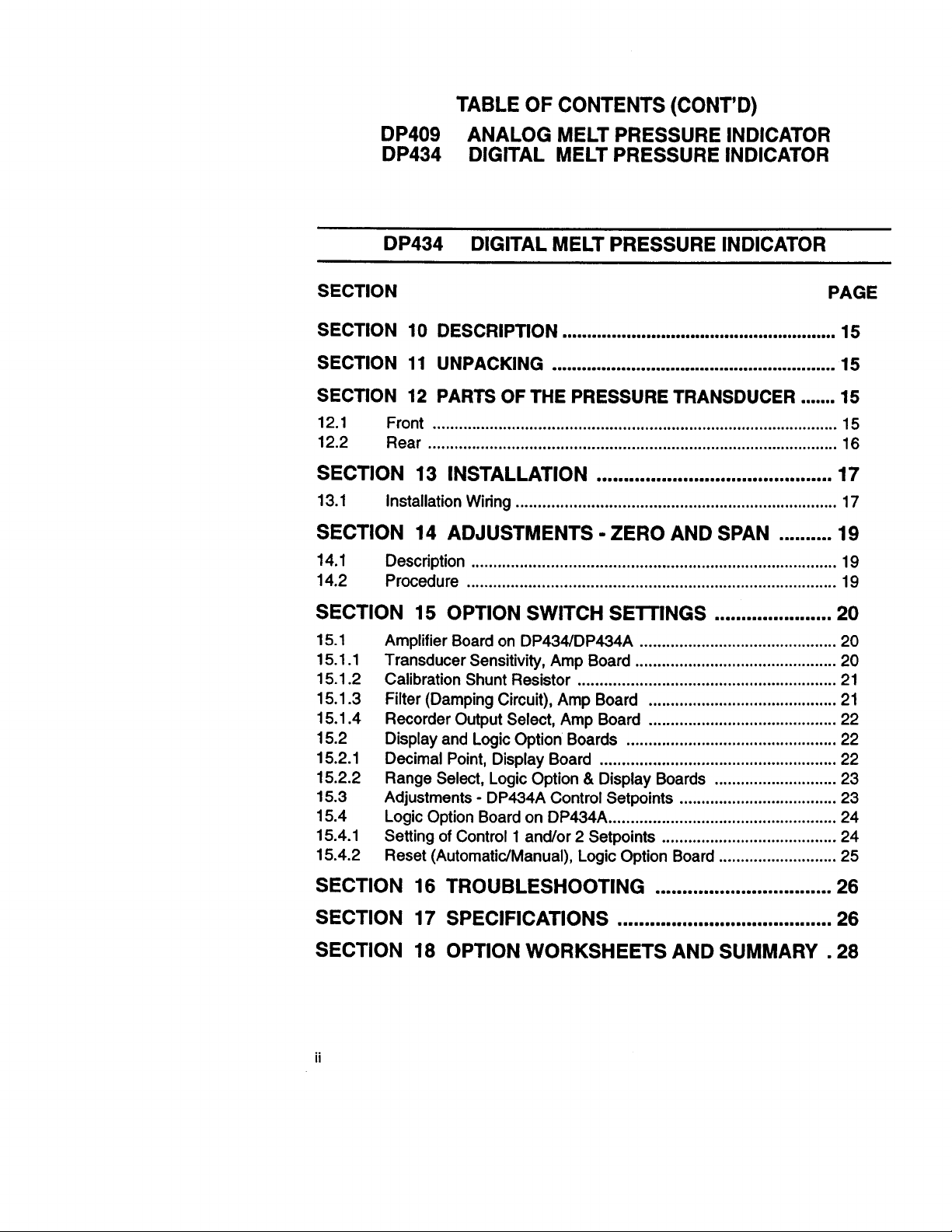

TABLE OF CONTENTS (CONT ’D)

DP409

DP434

DP434

ANALOG MELT PRESSURE INDICATOR

DIGITAL MELT PRESSURE INDICATOR

DIGITAL MELT PRESSURE INDICATOR

SECTION

SECTION 10 DESCRIPTION

SECTION 11 UNPACKING

12

SECTION

12.1

12.2

Front

Rear

PARTS OF THE PRESSURE TRANSDUCER..

............................................................................................

.............................................................................................

........................................................

..........................................................

SECTION 13 INSTALLATION

13.1

SECTION

14.1

14.2

installation Wiring .........................................................................

14

ADJUSTMENTS

Description

Procedure

...................................................................................

....................................................................................

PAGE

.15

....

............................................

-

ZERO AND SPAN

.........

.I9

15

15

15

16

17

17

19

19

SECTION

15.1

15.1.1

15.1.2

151.3

15.1.4

15.2

15.2.1

15.2.2

15.3

15.4

15.4.1

15.4.2

Amplifier Board

Transducer Sensitivity, Amp Board

Calibration Shunt Resistor

Filter (Damping Circuit), Amp Board

Recorder Output Select, Amp

Display and Logic Option Boards

Decimal Point, Display Board

Range Select, Logic Option

Adjust men ts

Logic Option Board on

Setting of Control 1 and/or 2 Setpoints

Reset (Automatic/Manual), Logic Option Board

15

OPTION SWITCH

DP434/DP434A

on

DP434A Control Setpoints

-

DP434A

SElTlNGS

...........................................................

Board

................................................

......................................................

&

Display Boards

....................................................

SECTION 16 TROUBLESHOOTING

SECTION

17 SPECIFICATIONS

........................................

.............................................

..............................................

...........................................

...........................................

........................................

.................................

......................

............................

....................................

...........................

SECTION 18 OPTION WORKSHEETS AND SUMMARY

ii

20

20

20

21

21

22

22

22

23

23

24

24

25

26

26

.28

Page 5

SECTION 1 DESCRIPTION

DP409

The OMEGA

transducer power supply, indicator and signal conditioner. The

%

DIN standard size case of extruded aluminum protects against

RFI noise, heat dispersion and physical damage. The

is styled for ease of reading and incorporates an intematronal face.

Analog Melt Pressure Transducer is a combination

6”:

240 degree meter

DP409

DP409

EMI

and

The DP409 is designed for use with an OMEGA pressure transducer or any

4-169,

350 ohm wheatstone bridge strain

push-button allows for span adjustment w ile you adjust zero at zero

pressure. The complete electronic assembly can be removed and/or

replaced from the front panel for convenient service and option selection.

Options include dual setpoints and auxiliary outputs for recorders, remote

indicators or a computer interface. The dual

the letter “A”

shutdown sequence is initiated, thereb

prevent accidental shutdown, the act o

will not actuate the alarm relays.

(DP409A),

can be used to give a warning before an actual

age transducer. A calibration

%

setpoint

reducing or avoiding downtime. To

Y

setting of the

option, designated by

setpoint

or calibration

SECTION 2 UNPACKING

Remove the Packing List and verify that all equipment has been received.

there are any questions about the shipment, please call the OMEGA

Customer Service Department at l-800-622-2378 or (203) 359-l 660.

U

on receipt of shipment, inspect the container and equipment for any signs

P

damage. Take particular note of any evidence of rough handling in

o

transit. Immediately report any damage to the shipping agent.

NOTE

claims

The canter will not honor any

their examination. After examining and removing contents, save packing

material and carton in the event reshipment is necessary.

unless all shipping material is saved for

SECTION 3 PARTS OF THE MELT PRESSURE TRANSDUCER

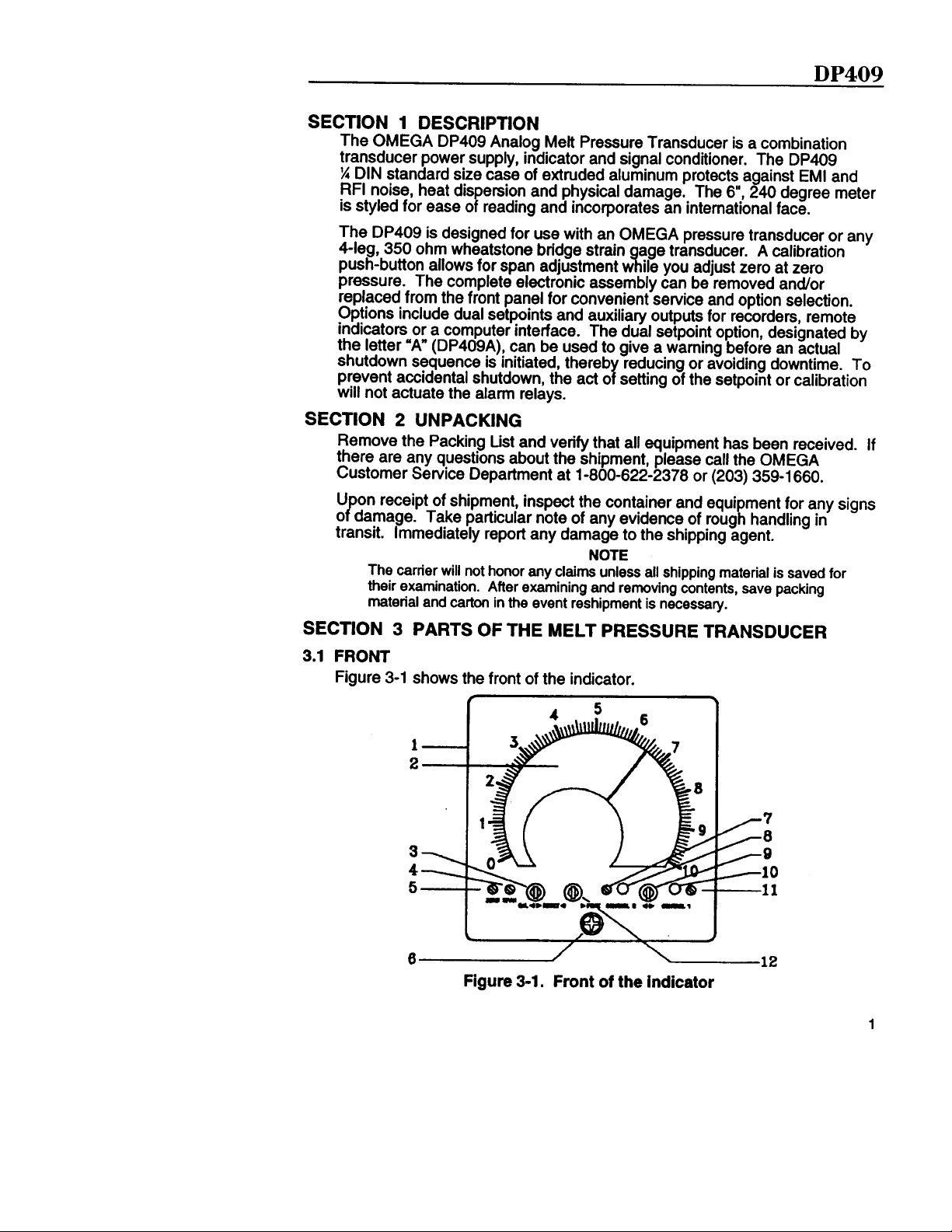

3.1 FRONT

Figure 3-1 shows the front of the indicator.

If

Figure 3-1. Front

of the indicator

1

Page 6

DP409

KEY

1

2

3

4

5

6

7

8

9

10

DESCRIPTION

l/ 4

D IN

Enclosure.

Large Analog Display with

p ressu re and con tr o l

p ressu re to fu ll- sca le r ange .

Ca lib ra ti on

ad jus t span fo r ca li b ra ti on p ressu re o f tr ansduce r and to rese t con tr o l

a la rm s when con fi gu red fo r m anua l r ese t.

Selector/Reset Toggle Switch.

Span Potentiometer.

con junc ti on w it h ca li b ra ti on /r ese t s w it ch .

Ze ro Po ten ti o m e te r. U sed to ra ise /t owe r ze ro ca li b r a ti on po in t on

d isp lay .

Access

access to in te r na l D IP sw it ches .

Screw.

Control 2 Potentiometer.

se tpo in t.

Fa ; F ti

Con tr o l l/ Con tr o l 2 Se lec to r Togg le Sw it ch . Used to d isp lay and

ad jus t Con tr o l 1 and Con tr o l 2 se tpo in ts .

Ea ;n t;

2 A la rm Ind ica ti on LED . L igh ts when Con tr o l 2

1 A la rm Ind ica ti on LED . L igh ts when Con tr o l 1

O u te r case d im ens ions

240”

dial indication.

a la rm

se tpo in ts . Shows re la ti on o f ope r a ti ng

U sed to ra ise /l owe r ca li b ra ti on p r essu r e in

Unsc r ew to re m ove ind ica to r fr o m enc losu re to ga in

U sed to r a ise /lowe r Con tr o l 2 a la rm

Ind ica tes ope r a ting

U sed to d isp lay and

se tpo in t

se tpo in t

i s

i s

11

Con tr o l Po ten ti o m e te r. U sed to ra ise /t owe r Con tr o l 1 a la rm se tpo in t.

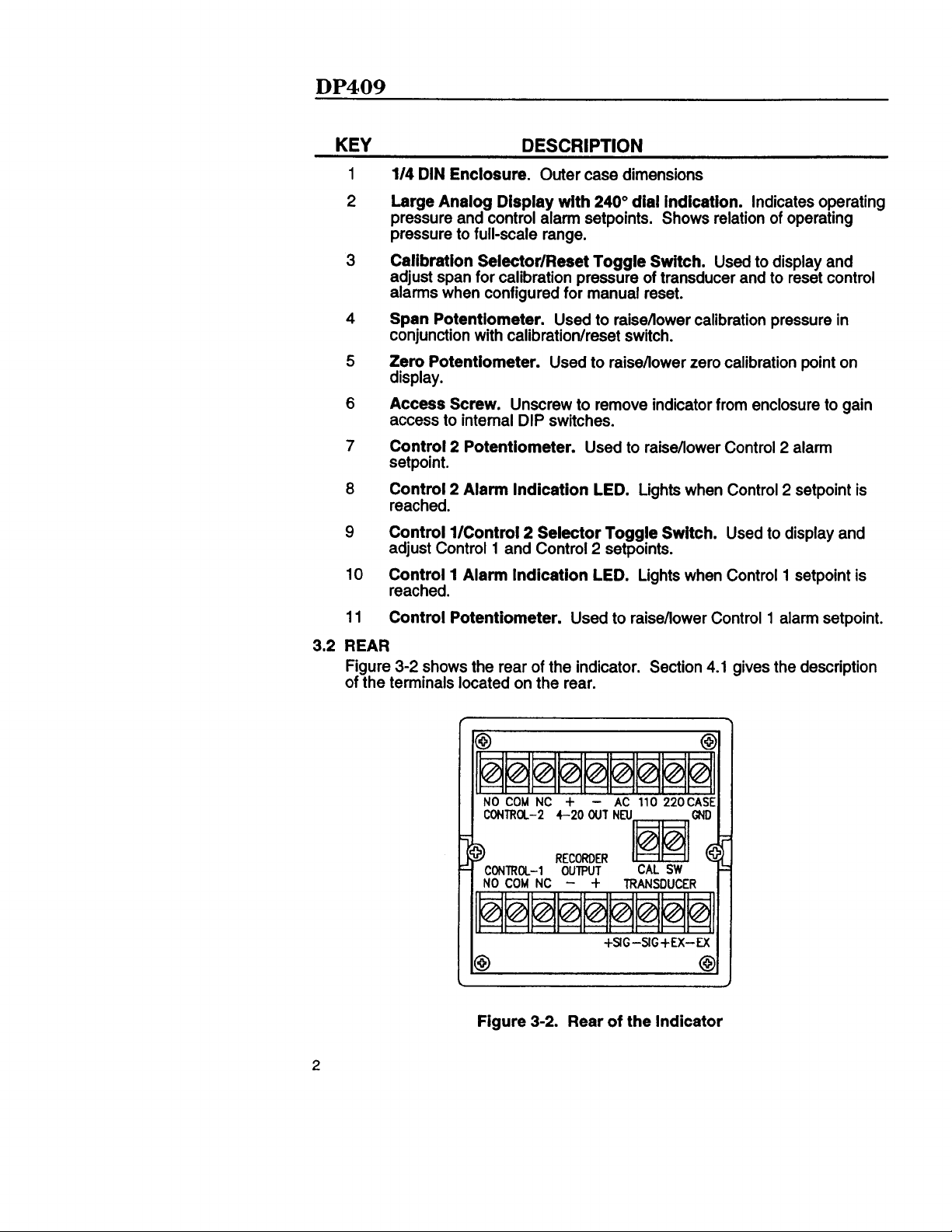

3 .2 REAR

F igu re 3 -2 shows the rea r o f t he ind ica to r. Sec ti on 4 .1 g ives the desc ri p ti on

o f t he te rm ina ls loca ted on the rea r.

-

COM

NO

oNma-

Figure

NC

+

3 -2 .

AC 110 220CASE

4-20 OUT NEU

+SlG-SlG+EX-

Rear of the Indicator

Page 7

DP409

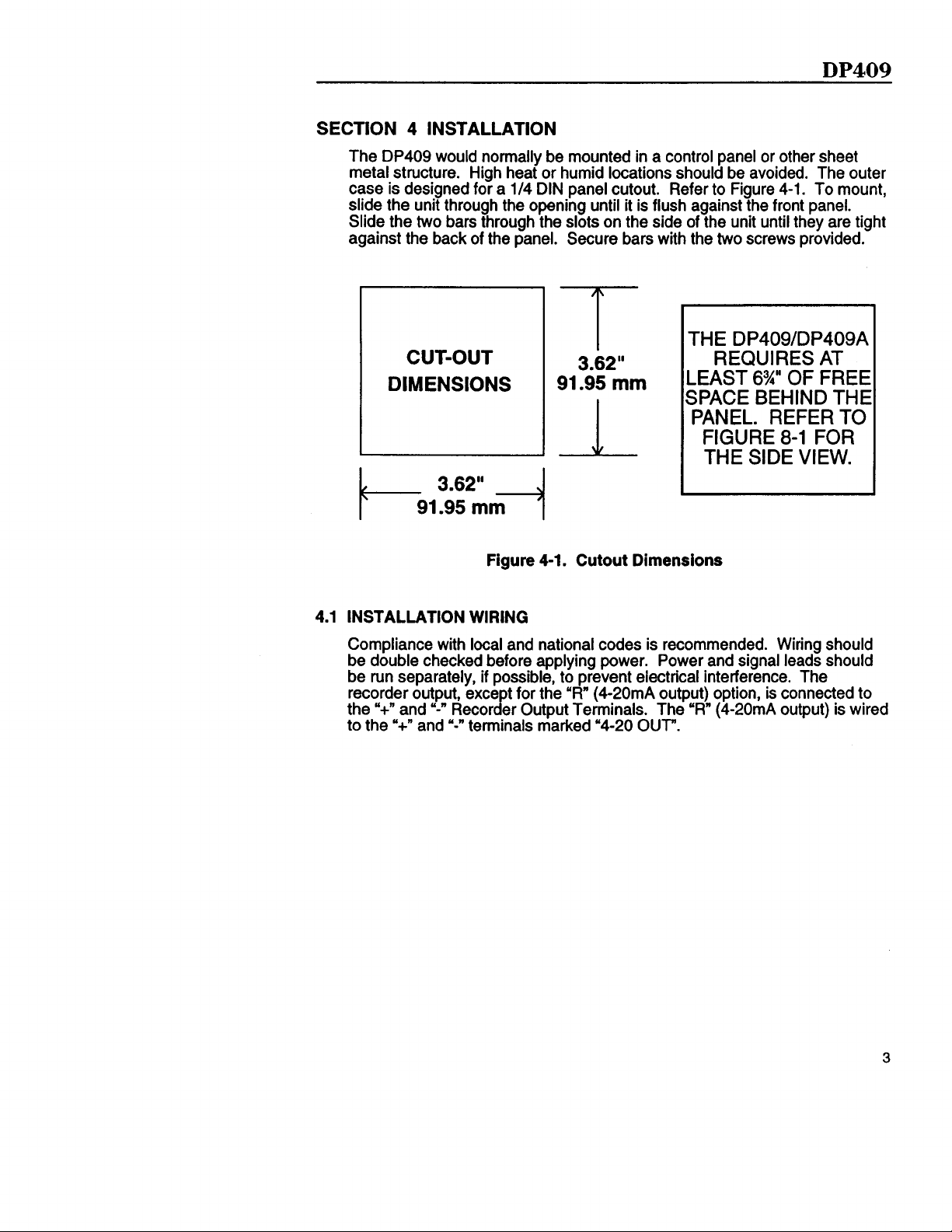

SECTION 4 INSTALLATION

DP409

The

metal structure. High heat or humid locations should be avoided. The outer

case is designed for a

slide the unit through the opening until it is flush against the front panel.

Slide the two bars through the slots on the side of the unit until they are tight

against the back of the panel. Secure bars with the two screws provided.

would normally be mounted in a control panel or other sheet

l/4

DIN panel cutout. Refer to Figure 4-1. To mount,

THE

DP409/DP409A

REQUIRES AT

-EAST

SPACE

6%” OF FREE

BEHIND THE

CUT-OUT

DIMENSIONS

T

3.62”

91.95

mm

PANEL. REFER TO

FIGURE

8-l FOR

THE SIDE VIEW.

Figure 4-1. Cutout Dimensions

4.1 INSTALLATION

Compliance with local and national codes is recommended. Wiring should

be double checked before applying power. Power and signal leads should

be run separately, if possible, to prevent electrical interference. The

recorder output, except for the

‘+”

and

the

‘+” and

to the

WIRING

“R”

(4-20mA output) option, is connected to

y-n

Recorder Output Terminals. The

“-”

terminals

marked

“4-20

OUT ”.

(4-20mA

“R”

output) is wired

3

Page 8

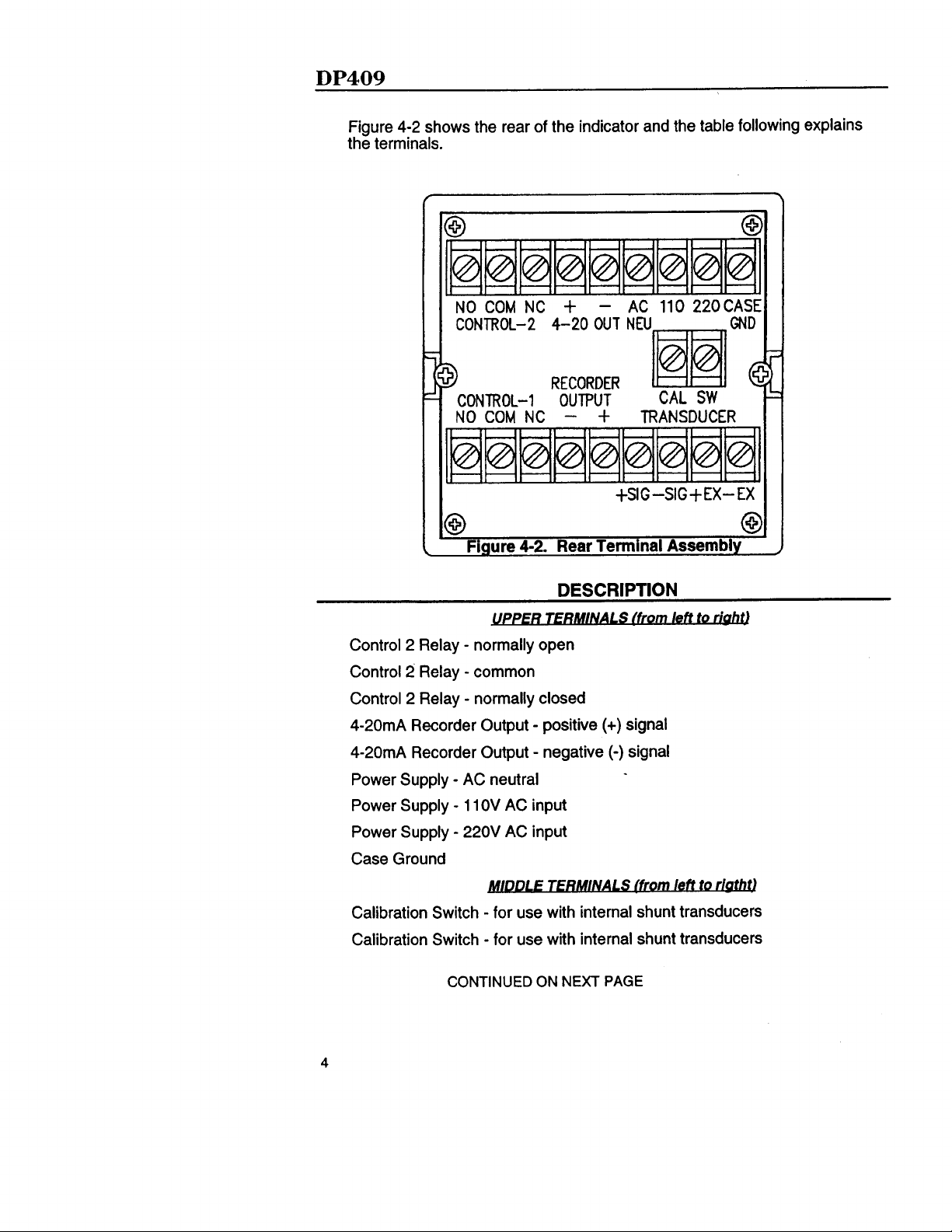

Figure 4-2 shows the rear of the indicator and the table following explains

the terminals.

-

i

NO COM NC +

4-20 OUT

AC 110 220CASE

GND

1

NO COM NC

@

Control 2 Relay

Control 2 Relay

Control 2 Relay

4-20mA

4-20mA

Power Supply

Power Supply

Power Supply

Recorder Output

Recorder Output

-

AC neutral

-

11 OV AC input

-

220V AC input

RECORDER

@

OUTPUT

-

+ TRANSDUCER

‘1

u

‘1

11

‘1

+SIG-SIG+EX-EX

0

0.

Figure 4-2. Rear Terminal Assembly

DESCRIPTION

-

normally open

-

common

-

normally closed

-

positive (+) signal

(-)

-

negative

signal

Case Ground

Calibration Switch

Calibration Switch

4

-

for use with internal shunt transducers

-

for use with internal shunt transducers

CONTINUED ON NEXT PAGE

Page 9

Control 1 Relay

TS

-

normally open

DESCRIPTION

lDWFR

left

to

nbhtl

DP409

Control 1 Relay

Control 1 Relay

Voltage Recorder Output

Voltage Recorder Output

Transducer

Transducer

Transducer

Transducer

SECTION 5 ADJUSTMENTS

5.1

DESCRIPTION

All Wheatstone bridge type strain gages have some zero imbalance. This

small error can be

potentiometer on the front panel. The zero should only be reset when zero

pressure is being applied to the transducer. The zero adjustment changes

the offset or starting point for the indicator to correspond to zero pressure on

the transducer. The span adjustment changes the gain or slope of the

amplifier to match the output curve of the transducer. A

or dead-weight tester can be used to check calibration.

then be adjusted to give the desired output at a particular pressure. Most

transducers are calibrated against an external shunt resistor. This shunt

resistor simulates an actual pressure input value. The value is normally

marked on the transducer itself. It would look like this: 30.1 k ohms, 8123

PSIG. This means that if an external resistor of 30.1 k ohms resistance

were placed between the excitation positive (+) wire and signal positive (+)

wire an input si nal equivalent to 8123

signal positive +) and the signal negative

PROCEDURE

5.2

-

common

-

normally closed

(-)

-

negative

-

positive (+) signal

-

positive (+) signal connection (green)

(-)

-

negative

-

positive (+) excitation (red)

-

negative

?

signal connection (white)

(-)

excitation (black)

-

ZERO AND SPAN

vrrtually

eliminated by using the zero adjustment

signal

PSIG

will be simulated between the

(-)

wires.

ressure standard

P

he

span would

The following is a typical adjustment procedure:

ALL CALIBRATION ADJUSTMENTS

TRANSDUCERS UNDER NO LOAD AND AT OPERATING TEMPERATURE.

1.

Power the instrument.

2.

With zero pressure on the transducer, adjust the zero potentiometer to

obtain a zero reading.

3.

Push and hold the calibration selector switch to the left while adjusting

the span potentiometer until the correct calibration pressure is

obtained.

4.

Release the calibration switch and recheck the zero reading. If

incorrect, repeat Steps 2 through 4.

SHOULD BE PERFORMED WITH THE

Page 10

DP409

5.

The electrical zero may be checked any time the transducer is at zero

pressure. This may be necessary after heat-up to correct any thermal

zero shift of the transducer.

NOTE

DO NOT CHANGE THE SPAN CALIBRATION WHEN THERE IS

PRESSURE ON THE TRANSDUCER. IF THIS IS DONE, THE

PRESSURE READING MAY

BE IN ERROR.

DP409A

-

5.3 ADJUSTMENTS

DP409A

The

one relay to trigger an auxiliary alarm, corrective action can be taken before

mandatory shut-down is reached. The second relay circuit can then be used

for mandatory shut-down.

CONTROL 1

1.

Push and hold the control selector switch to the right.

2.

Adjust the Control 1 potentiometer until the desired control pressure is

displayed on the indicator.

3.

Release the selector toggle switch.

CONTROL 2

1.

Push and hold the control selector switch to the right.

2.

Adjust the Control 2 potentiometer until the desired control pressure is

displayed on the indicator.

3.

Release the selector toggle switch.

SECTION 6 OPTION SWITCH SETTINGS

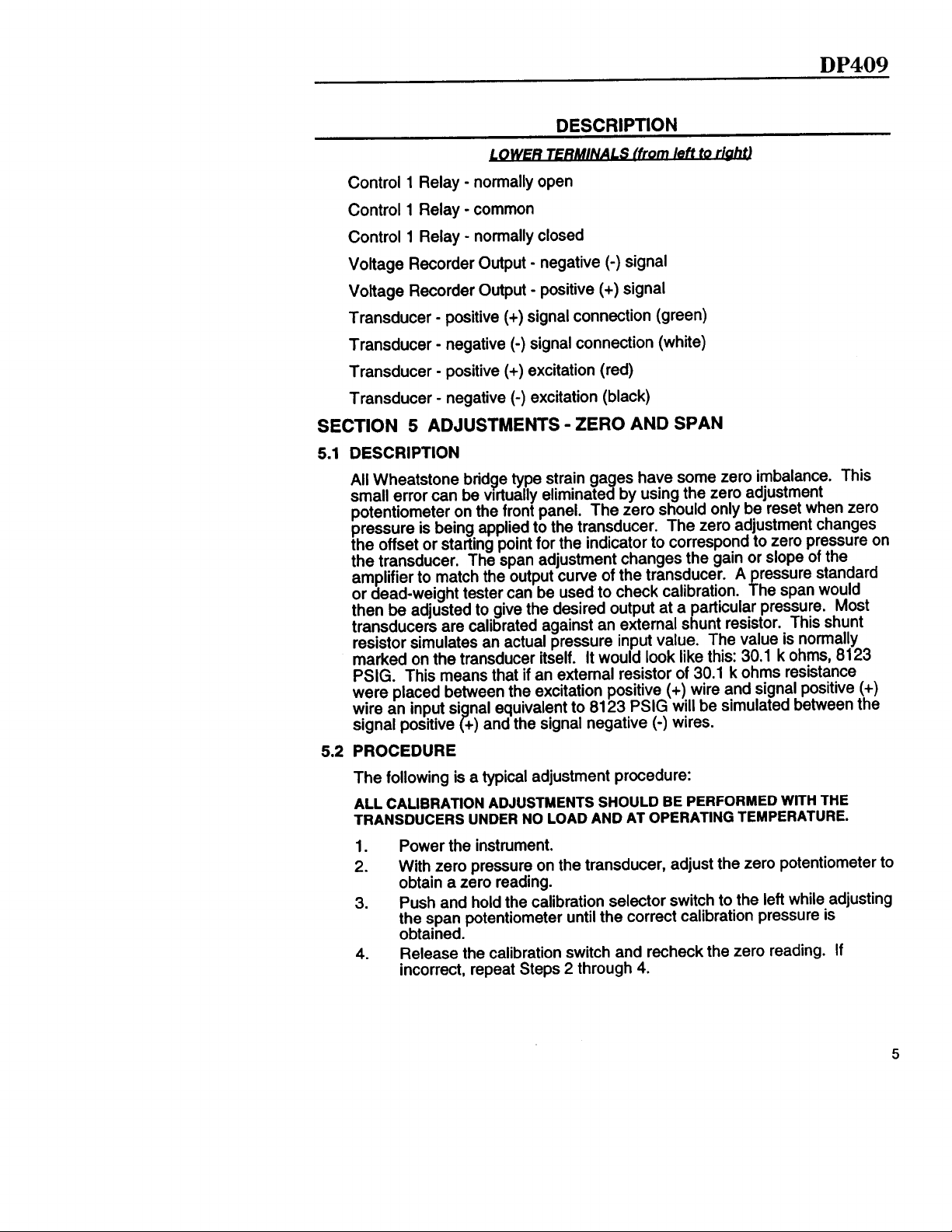

6.1 AMPLIFIER BOARD ON

Figure 6-1 shows the location of DS4 and DS5 on the Amplifier Board.

provides two separate setpoints circuits and relays. By using

CONTROL SETPOINTS

DP409/DP409A

El

pmm l

DS5

I

m l

DS4

I

III

b

I

f-

Figure 6-1. Amplifier Board

6

Page 11

DP409

.l

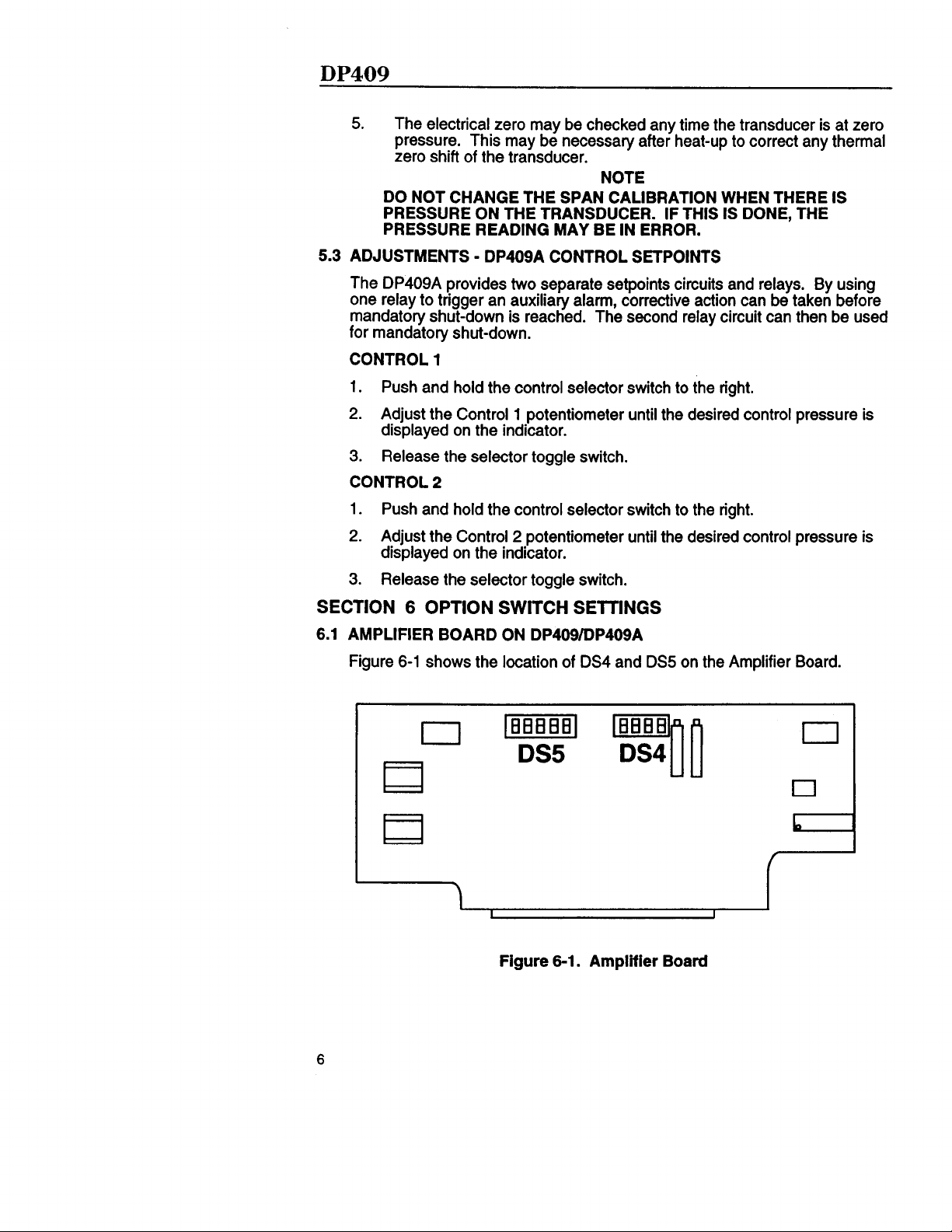

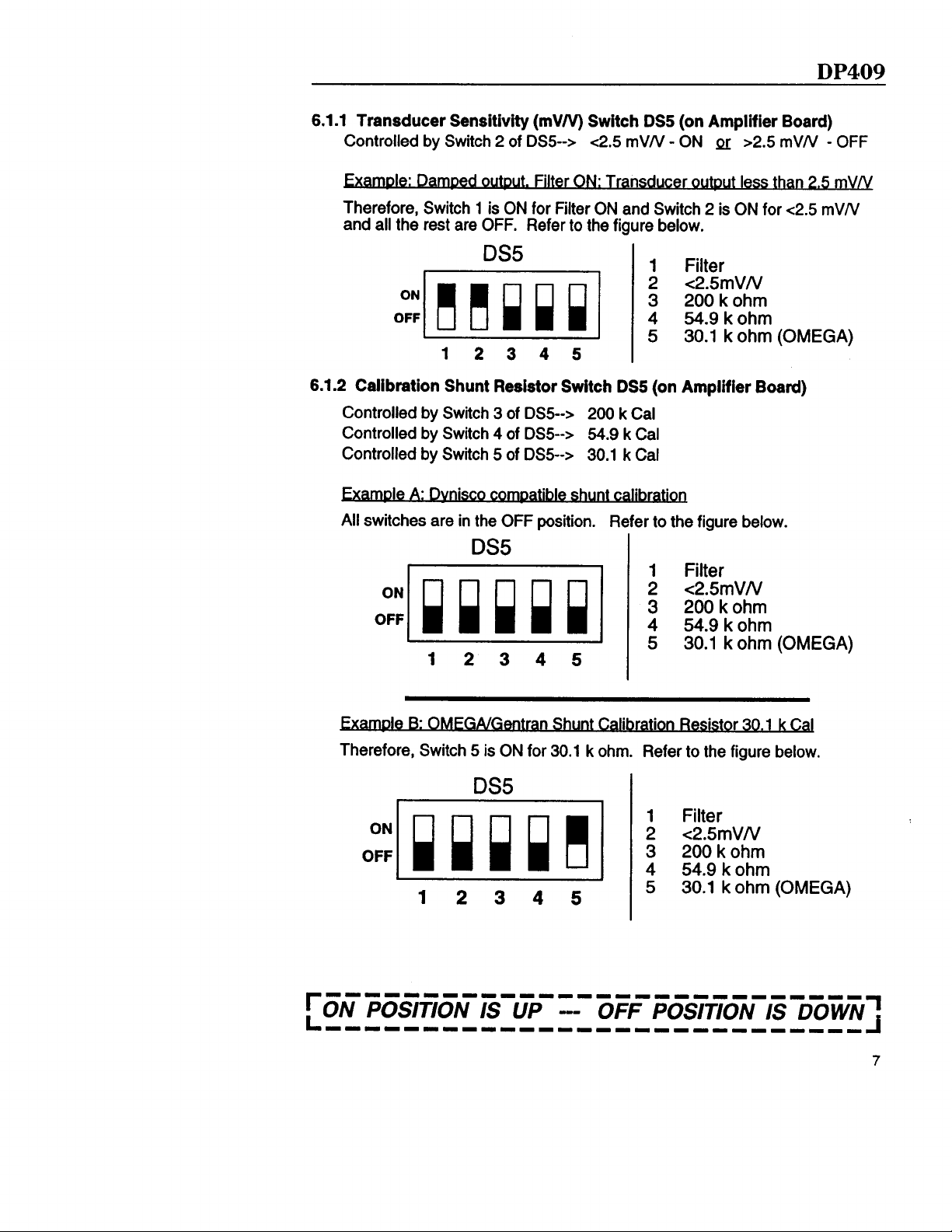

Transducer Sensitivity

6.1

Controlled by Switch 2 of

Dued

ble:

Therefore, Switch 1 is ON for Filter ON and Switch 2 is ON for

and all the rest are OFF. Refer to the figure below.

or&~,&

(mV/V)

Filter

DS5

6.1.2 Calibration Shunt Resistor Switch

com&le

DS5-->

DS5-->

DS5-->

Controlled by Switch 3 of

Controlled by Switch 4 of

Controlled by Switch 5 of

*

.

Dvnrsco

ale

A.

All switches are in the OFF position.

Switch DS5 (on Amplifier Board)

PI

-

mV/V

~2.5

DS5-->

ON: Transducer

shunt

DS5

200 k Cal

54.9 k Cal

30.1 k Cal

ca

Refer to the figure below.

ON

oum

less than

1

Filter

<2.5rnVN

2

3 200 k ohm

54.9kohm

4

5 30.1 k ohm

(on Amplifier Board)

..

DS5

~2.5

-

OFFmVN

3

5

mVN

~2.5

(OMEGA)

mVN.

i%~

;

o;pgq

3011

5

k ohm (OMEGA)

1 2 3 4 5

n Shunt Calibration Resistor 30.1 k

Therefore, Switch 5 is ON for 30.1 k ohm. Refer to the figure below.

DS5

111~1~1111~~11111111~~~~~~~~

I

Caj

DOWN:

IS CON POSITION IS UP -- OFF POSITION

111~11111~1111111111llllllll

7

Page 12

DP409

6.1.3 Filter (Damping Circuit) Switch DS5 (on Amplifier Board)

Controlled by Switch 1 of

DS5-->

Filter ON, slower response, 5 seconds

Fifter

OFF, fast response,

113

DS5

~~e5’rnVlV

i

oj.mkq

1

2 3 4 5

6.1.4 Recorder Output Select Switch DS4 (on Amplifier Board)

3 20b koh m

4 54.9 k ohm

5

30.1 k ohm (OMEGA)

second

Controlled by Switch 1 of

Controlled by Switch 2 of

Controlled by Switch 3 of

Controlled by Switch 4 of

)

Volt DC required

Therefore, Switch 2 is ON for 5

the figure below.

DS4-->

O-10 Volts DC

DS4-->

DS4-->

DS4-->

Volts

O-5 Volts DC

O-2 Volts DC

O-l Volt DC

DC and all the rest are OFF.

DS4

o:mi

1

2 3 4

6.2 LOGIC OPTION BOARD ON

6.2.1 Setting of Control 1 and/or 2 Setpoints

Figure 6-2 shows the location of

DP409A

ONLY

DSl

and DS2 on the Logic Option Board.

;

Switch

!gicJ

_

DSl (on Logic Bd)

ml

~lieesleaeaass~

DSl

DS2

Refer to

Figure 6-2. Logic Option Board

1111111111111~1111~1~~~~~~~~

1-1

[ON

POSITION IS UP

OFF POSITION IS

1111111111111~111111~~~~~~~~

DOWN:

Page 13

DP409

Controlled by Switches 1 and 4 of

Controlled by Switches 2 and 3 of

Controlled by Switches 5 and 8 of

Controlled by Switches 6 and 7 of

”

A: Controls 1 and

Therefore, Switches

1,4,5,

above

7

ON

and 8 are ON and the rest are OFF. Refer to

the figure below.

DSl

1234567 0

ale

B:

Control 1 ON “below”

Therefore, Switches

the figure below.

1,4,6,

setgotnt

and 7 are ON and the rest are OFF. Refer to

DSl

DSl-->

-->

DSl

-->

DSl

-->

DSl

(1

setDot&

Control 2 for above

Control 2 for below

Control 1 for above

Control 1 for below

setooints,

ContrQL2

and

ON

Y

above

setpoint

setpoint

setpoint

setpoint

n

1234567 8

le C:

Controls 1 and 7 ON below ”

Therefore, Switches

the figure below.

1234567 8

setpoir&

2,3,6,

and 7 are ON and the rest are OFF. Refer to

Page 14

DP409

D: Control 1 ON

Therefore, Switches

Y

2,3,5,

n

seto

aboveExamDIe

oint and

mtrol7

ON “below”

and 8 are ON and the rest are OFF. Refer to

the figure below.

DSl

ON

OFF

I

1234567 8

6.2.2

Reset (Auto/Manual Reset) Switch DS2 (on Logic Option Board)

Controlled by Switch 1 of

Controlled by Switch 2 of

Controlled by Switch 3 of

Controlled by Switch 4 of

JZxample:

Manual Reset on Control

DS2-->

DS2-->

DS2-->

DS2-->

Control 1 Auto Reset

Control 2 Auto Reset

Control 2 Manual Reset

Control 1 Manual Reset

Control

on

1

and

Reset

Therefore, Switches 2 and 4 are ON for and all the rest are OFF. Refer to

the figure below.

DS2

se-

Z

1 2 3 4

NOTE: CONTROL LOGIC CANNOT OCCUPY TWO STATES AT ONCE. WHEN

DESIRED RESET MODE IS

MODE SHOULD BE SWITCHED OFF. (I.E.;

SWITCHED ON, CONTROL

SWlTCHED

1

MANUAL RESET SHOULD BE SWITCHED OFF.)

ON, ALTERNATE CORRESPONDING

IF

CONTROL

1

AUTO

RESET/S

SECTION 7 TROUBLESHOOTING

PROBLE M

Indicator pegs full scale.

Cannot adjust zero low Transducer over-pressured. Check

enough.

i

ON POSITION IS UP -- OFF POSITION IS DOWN

i0

Opening in

transducer.

cable is removed from transducer.)

transducer.

SOLUTION

wiring between indicator

(NOTE: will occur when transducer

and

;

Page 15

DP409

SECTION 8

POWER:

OPERATING TEMP. RANGE:

DISPLAY:

ACCURACY:

TRANSDUCER POWER SUPPLY:

TRANSDUCER BRIDGE

SHUNT CALIBRATION RESISTOR:

INPUT SENSITIVITIES:

ZERO BALANCE:

RESPONSE TIME:

RECORDER OUTPUTS:

RECORDER OUTPUT ACCURACY:

RECORDER OUTPUT

RECORDER OUTPUT

RECORDER OUTPUT STABILITY:

DIMENSIONS:

WEIGHT:

SPEClFlCATlONS

CIRCUlT:

REPEATABIUTY:

LINEARlTY:

50160

106-l 25VAC or

110

A max.

0”

to 140°F (-17.8 ” to 60°C)

6’ long scale, 240 degree angle

*2.0% full scale

Within

f

8.2VDC

4 leg, 350 ohm nominal resistance

Selectable 30.1 k ohm,

ohm

O-l to O-O.25

DIP-switch selectable

f35%

potentiometer

1M

O-l VDC,

DIP-switch selectable, min. load 5000

ohms

‘R”

set, min. load 15 ohms, max load 600

ohms

fO.l%

within

within

within

Refer to Figure

2.5 pounds (1.134 kg)

5%

adjustable with the front panel

second or 5 seconds selectable

option -- O-20mA or

full scale

fO.l%

fO.l%

fO.l%

200-250VAC,

mVN

0-2VDC,

full

full scale

full scale

8-l

54.9k

and O-2.5 to O-5

OJVDC, O-l OVDC

4-2OmA

scaie

Hz,

ohm, 200k

mV/V

factory

RELAYS:

RELAY RATING:

SETPOINT

ACCURACY:

HYSTERESIS:

INDICATION:

MODE:

RESET:

RANGE:

FRONT VIEW

r

IFlCATlONS

--I--

3.93-

D9.82

mm

1

Figure

2 SPDT (single pole double throw)

8 amps at

30VDC

l-1 00% of full scale

within

within

Front panel

Above or below setpoint, switch selectable

Automatic or manual, switch selectable

8-l.

Dimensions

1251250VAC

*0.3% of full scale

*0.5% of full scale

LEDs

or 5 amps at

11

Page 16

DP409

SECTION 9 OPTION WORKSHEETS AND SUMMARY OF DIP

SWITCH POSITIONS

INSTRUCTIONS: Fill in this page, if desired, with the indicator positions of

the switches (either ON or OFF) within

Refer to this sheet when calling OMEGA for technical

assistance.

DSl and DS2.

LOGIC OPTION BOARD --

DS2

j-mq

1

Reset

Control

Logic

Loaic

2 3 4

--

--

Da

1234567 8

Control 1, Auto Reset

Control 2, Auto Reset

Control 2, Manual Reset

Control 1, Manual Reset

Control 2, Above DSl

Control 2, Below

Control 2, Below

Control 2, Above

Control

Control

Control

Control

1,

1,

1,

1,

DP409A

DSl

Above

Below

Below

Above

Setpoint

Setpoint

ONLY

Setpoint

Setpoint

Setpoint

Setpoint

Setpoint

Setpoint

12

NOTES

Page 17

.

INSTRUCTIONS: Fill in this page, if desired, with the indicator positions of

the switches (either ON or OFF) within DS4 and DS5.

Refer to this sheet when calling OMEGA for technical

assistance.

DP409A

&

AMP BOARD -- DP409

DP409

o$ imq

1

Filter.

Transducer

t Calibration

Recorder Output

Sensitivitv,

DS5

2 3 4

DSs

_

_

DS4

:p m iq

5

1

Filter (Damping)

mVN Transducer Output

~2.5

2

3

4

5

1

2 O-5 Volts DC

3

4

200 k Cal

54.9 k Cal

k Cal

30.1

O-l 0 Volts DC

O-2 Volts DC

O-l Volt DC

NOTES

1

DS4

2 3

4

13

Page 18

DP409

NOTES

14

Page 19

DP434

SECTION 10 DESCRIPTION

The OMEGA DP434 Digital Melt Pressure Transducer is a combination

.

transducer power supply, indicator and signal conditioner. The DP434

EMI

%

DIN standard size case of extruded aluminum protects against

RFI noise, heat dispersion and physical damage. The 0.3 ” LED display

gives a clear indication, readable even from a distance.

The DP434 is designed for use with an OMEGA pressure transducer or any

4-leg,

350 ohm wheatstone bridge strain gage transducer. A calibration

push-button allows for span adjustment while you adjust zero at zero

pressure. The complete electronic assembly can be removed and/or

replaced from the front panel for convenient service and option selection.

Options include dual setpoints and auxiliary outputs for recorders, remote

indicators or a computer interface. The dual

the letter “A”

shutdown sequence is initiated, thereb

prevent accidental shutdown, the act o

will not actuate the alarm relays.

(DP434A),

can be used to give a warning before an actual

reducing or avoiding downtime. To

Y

setting of the

setpoint

option, designated by

setpoint

or calibration

SECTION 11 UNPACKING

Remove the Packing List and verify that all equipment has been received.

there are any questions about the shipment, please call the OMEGA

Customer Service Department at l-800-622-2378 or (203) 359-l 660.

Upon receipt of shipment, inspect the container and equipment for any signs

of damage. Take particular note of any evidence of rough handling in

transit. Immediately report any damage to the shipping agent.

NOTE

The carrier will not honor any claims unless ail shipping material is saved for

their examination. After examining and removing contents, save packing

material and carton in the event reshipment is necessary.

and

If

SECTION 12 PARTS OF THE MELT PRESSURE TRANSDUCER

12.1 FRONT

Figure 12-1 shows the front of the indicator.

Figure

12-1. Front of the indicator

15

Page 20

DP434

KEY

1

2

3

4

5

6

7

8

9

10

DESCRIPTION

l/4

DIN Enclosure Outer case dimensions.

LEDs.

Large Digital Display with

ope ra ti ng p ressu re and con tr o l ala rm

Calibration Selector/Reset Toggle Switch.

ad jus t span fo r ca li bra tion p ressure o f tr ansducer and to rese t con tr o l

a la rm s when con fi gu red fo r m anua l r ese t.

Span Potentiometer.

con junc tion w it h ca lib ra tion /r ese t s w it ch .

Zero

Po ten ti om e te r. Used to ra ise /l owe r ze ro ca li bra tion po in t on

d isp lay .

Access Sc rew . Unsc rew to re m ove ind ica to r fr o m enc losu re to ga in

access to in te rna l D IP sw it ches .

Con tr o l 2 Po ten ti om e te r. Used to ra ise /l owe r Con tr o l 2 a la rm

se tpo in t.

Con tr o l 2 A la rm Ind ica ti on LED . L igh ts when Con tr ol 2

reached .

high efficiency

setpolnts.

U sed to ra ise /t owe r ca li bra ti on p ressure in

Control l/Control 2 Selector Toggle Switch.

ad jus t Con tr o l 1 and Con tr o l 2 se tpo in ts .

Con tr o l 1 A la rm Ind ica ti on LED . L igh ts when Con tr ol 1

reached .

I nd ica tes

Used to d isp lay and

se tpo in t

U sed to d isp lay and

se tpo in t

i s

i s

Con tr o l Po ten ti o m e te r. Used to ra ise /l owe r Con tr o l 1 a la rm se tpo in t.

11

Peak Hold/Peak Reset Toggle Switch.

12

ho ld m ode and to rese t t he peak pressure .

12.2 REAR

F igu re 12 -2 shows the rea r o f t he ind ica to r. Sec ti on 13 .1 g ives the

descr ip tion o f t he te rm ina ls loca ted on the rea r.

Figure 12-2. Rear of the Indicator

Used to sw itch un it i n to peak

16

Page 21

DP434

SECTION 13

The DP434 would

metal structure. High heat or humid locations should be avoided. The outer

case is designed for a

mount, first remove the screws holding in the slide retainer on the side of the

case. Remove the slide retainers by

Install the indicator into the panel cutout.

their slots. Install the screws and tighten enough to hold the indicator in

INSTALLAnON

normally

be mounted in a control panel or other sheet

l/4

DIN panel cutout. Refer to Figure 13-l. To

slidin

them toward the rear of the unit.

lide the slide retainers back into

8

THE DP434

CUT-OUT

DIMkNSIONS

7-

3.62”

91.95

mm

REQUIRES AT

LEAST 6%” OF

FREE SPACE

BEHIND THE

‘ANEL. REFER TO

FIGURE 17-1 FOR

THE SIDE VIEW.

Figure 13-l. Cutout Dimensions

13.1 INSTALLATION WIRING

Compliance with local and national codes is recommended. Wiring should

be double checked before applying power. Power and signal leads should

be run separately, if possible, to

recorder o

‘+”

and

the

u+n

to the

and

lr!F

ut,

Recor

-”

“-”

t

for the

exce

g

er Output Terminals. The

terminals marked

revent electrical interference. The

#f$

(4-20mA

V-20

output) option, is connected to

OUT”.

(4-20mA

‘R”

output) is wired

17

Page 22

DP434

Figure 13-2 shows the rear of the indicator and the table following explains

the terminals.

3

CONTROL-

NO COM

-1

NC

U

ii

9

3

F iaure 13-2. Rear Ter m ina l

-

Control 2 Relay

Control 2 Relay

Control 2 Relay

4-20mA

4-20mA

Power Supply

Power Supply

Power Supply

Case Ground

Calibration Switch

Recorder Output

Recorder Output

normally open

-

common

-

normally closed

-

AC neutral

-

11

-

220V AC input

I I I I II II II

+SiG-SIG+EX-EX

II II

Asse mb ly

DESCR IPT ION

-

positive (+) signal

(-)

-

negative

OV AC input

-

for use with internal shunt transducers

signal

01

lJ

1

Q

Calibration Switch

CONTINUED ON NEXT PAGE

18

-

for use with internal shunt transducers

Page 23

DP434

DESCRIPTION

r@btI

to

lQWFR

-

Control 1 Relay

Control 1 Relay

Control 1 Relay

normally open

-

common

-

normally closed

Voltage Recorder Output

Voltage Recorder Output

-

Transducer

Transducer

Transducer

Transducer

positive (+) signal connection (green)

-

negative

-

positive (+) excitation (red)

-

negative

SECTION 14 ADJUSTMENTS

TFRs

(-)

-

negative

-

positive (+) signal

(-)

signal connection (white)

(-)

excitation (black)

-

signal

ZERO AND SPAN

14.1 DESCRIPTION

All Wheatstone bridge type strain ga

small error can be virtually eliminate

potentiometer on the front panel. The zero should only be reset when zero

pressure is being applied to the transducer. The zero adjustment changes

the offset or starting point for the indicator to correspond to zero pressure on

the transducer. The span adjustment changes the gain or slope of the

amplifier to match the output curve of the transducer. A

or dead-weight tester

can

be used to check calibration.

then be adjusted to give the desired output at a

transducers are calibrated against an external s

resistor simulates an actual pressure input value. The value is normally

marked on the transducer itself. It would look like this: 30.1 k ohms, 8123

PSIG. This means that if an external resistor of 30.1 k ohms resistance

were placed between the excitation positive (+) wire and signal positive (+)

wire an input si

signal positive +) and the signal negative

14.2

PROCEDURE

nal equivalent to 8123

a

es have some zero imbalance. This

by using the zero adjustment

i

PSIG

will be simulated between the

(-)

wires.

ressure standard

he span would

P

articular

unt resistor. This shunt

1

pressure. Most

The following is a typical adjustment procedure:

WtTH

ALL CALIBRATION ADJUSTMENTS SHOULD BE PERFORMED

TRANSDUCERS UNDER NO LOAD AND AT OPERATING TEMPERATURE.

1.

Power the instrument.

2.

With zero pressure on the transducer, adjust the zero potentiometer to

obtain a zero reading.

3.

Push and hold the calibration selector switch to the left while adjusting

the span potentiometer until the correct calibration pressure is

obtained.

THE

19

Page 24

DP434

4.

Release the calibration switch and recheck the zero reading. If

incorrect, repeat Steps 2 through 4.

5.

The electrical zero may be checked any time the transducer is at zero

pressure. This may be necessary after heat-up to correct any thermal

zero shift of the transducer.

NOTE

DO NOT CHANGE THE SPAN CALIBRATION WHEN THERE IS

PRESSURE ON THE TRANSDUCER. IF THIS IS DONE, THE

PRESSURE READING MAY BE IN ERROR.

SECTION 15 OPTION SWITCH SETTINGS

15.1 AMPLIFIER BOARD ON

Figure 15-l shows the location of DS4 and DS5 on the Amplifier Board.

E l

I

I

Figure 15-l. Amplifier Board

.l Transducer Sensitivity

15.1

Controlled by Switch 2 of

o@ut.

Ded

Therefore, Switch 1 is ON for Filter ON and Switch 2 is ON for

and all the rest are OFF.

DP434/DP434A

I

(mV/V)

DS5-->

Refer to the figure below.

Switch DS5 (on Amplifier Board)

~2.5

-

ON mVN

outout

I

cl

b

pi

less than 2.5 Filter ON: Transducer

I

>2.5

~2.5

I

-

OFFmVN

mVN

mVN

DS5

i

-ml

4

1

2 3 4 5

111111111111~11111~1 llllllll

C-ON

20

POSITION IS UP-- OFF POSITION IS DOWN:

5

ijk&

3011

ohm (OMEGA)

Page 25

DP434

15.1.2 Calibration Shunt Resistor Switch DS5 (on Amplifier Board)

Controlled by Switch 3 of

Controlled by Switch 4 of

Controlled by Switch 5 of

DS5-->

DS5-->

DS5-->

200 k Cal

54.9 k Cal

30.1 k Cal

NOTE: Turn Switches

Dynisco).

Use CAL SW terminals on the back of the indicator for shunting

3,4, and 5 OFF for internal shunt transducers

wiring.

Die

A.

Dylllsco

comoattb!a

shunt

All switches are in the OFF position.

calibration

Refer to the figure below.

’

.

DS5

I

ON

OFF

1

2 3

OMEmentran

8:

ExamDIe

Therefore, Switch 5 is ON for 30.1 k ohm. Refer to the figure below.

5

4

S-ration Resistor 30.1 k Cal

I

1

Filter

<2.5mVtV

2

3 200koh m

4 54.9 kohm

5

30.1 k ohm

(OMEGA)

DS5

1

Filter

ON

OFF

<2.5mViV

2

3 200 k ohm

4 54.9 kohm

5

30.1 k ohm (OMEGA)

(i._e.

15.1.3 Filter (Damping Circuit)

Controlled by Switch 1 of

DS5-->

PI

Switch

DS5 (on Amplifier Board)

Filter ON, slower response,

Filter OFF, fast response,

DS5

$

3 20b k ohm

4 54.9 k ohm

5

IIIIIII__II_II_IIIIIIIII___II

[ON

POSITION IS UP --- OFF POSITION IS

ON

OFF

11111111~~1111111111llllllll

5 seconds

I3

second

1,

Z%rmVDJ

30.1 k ohm (OMEGA)

DOWNi

1

21

Page 26

DP434

15.1.4 Recorder Output Select Switch DS4 (on Amplifier Board)

Controlled by Switch 5 of

Controlled by Switch 6 of

Controlled by Switch 7 of

Controlled by Switch 8 of

ExamDIe.

Therefore, Switch 6 is ON for 5 Volts DC and all the rest are OFF. Refer to

the figure below.

*.

Five

(5)

Volt DC

DS4-->

DS4

O-l 0 Volts DC

DS4--> O-5 Volts DC

DS4--> O-2 Volts DC

DS4-->

reauired

O-l Volt DC

1

3,000 counts

,

i

o:mj

1234567 8

DISPLAY AND LOGIC OPTION BOARDS

15.2

(NOTE:

15.2.1 Decimal Point (Display Board)

Figure 15-2 shows the location of DS3 on the Display Board.

The

Logic Option

Board

can be found only in the

-

Switch DS3

8 O-l 0 Volts DC

Figure 15-2. Display Board

Controlled by Switch 1 of

Controlled by Switch 2 of

DS3-->

DS3-->

Divide Range by 100

Divide Range by 10

fifig!iii

DP434A.)

Refer to Section 15.2.2 for examples of how to set DS3.

DS3

2

1

ON

1111111111111111~111llllllll

r

;oN

IIIIIIIII _I_IIIIIIIIIIIIIIII

22

ON POSITION IS UP

POSITION IS TO THE LEFT

OFF

-

OFF POSITION IS DOWN

-

OFF POSITION IS TO THE

Divide Range by 100

Divide Range by 10

1

RIGHI;

Page 27

15.2.2 Range Select Switches DS3

Controlled by Switch 1 of

Controlled by Switch 2 of

Controlled by Switch 3 of

Controlled by Switch 4 of

Examole

A: 3.000

PSIG

DS4-->

DS4-->

DS4-->

DS4-->

raw

&

&

DS4 (Logic Option

O-3,000,

O-5,000,

O-l 0,000, O-l ,000 or O-l 00 readout

O-l 5,000, 01,500 or O-l 50 readout

O-300 or O-30 readout

O-500 or O-50 readout

Display Boards)

DP434

DS4

o:_]

1234567 8

Examole

B: 1 .OOO

PSIG

ranw

,ajEl;

DS4

1234567 6

DP434A

-

15.3 ADJUSTMENTS

DP434A

The

one relay to trigger an auxiliary alarm, corrective action can be taken before

mandatory shut-down is reached. The second relay circuit can then be used

for mandatory shut-down.

CONTROL 1

1.

Push and hold the control selector switch to the right.

provides two separate

CONTROL SETPOINTS

setpoint

circuits and relays. By using

DS3

ON OFF

DS3

ON

OFF

2.

Adjust the Control 1 potentiometer until the desired control pressure is

displayed on the indicator.

3.

Release the selector toggle switch.

CONTROL 2

1.

Push and hold the control selector switch to the right.

2.

Adjust the Control 2 potentiometer until the desired control pressure is

displayed on the indicator.

3.

Release the selector toggle switch.

IIIIIIIIII_IIIIII_IIII OIIIII

r

;oN

IIIIIIIIIII_II11111111111_111

ON POSITION IS UP

POSITION IS TO THE LEFT

-

OFF POSITION IS DOWN

-

OFF POSITION IS TO THE

1

RIGHa

23

Page 28

DP434

15.4 LOGIC OPTION BOARD ON

15.4.1 Setting of Control 1 and/or 2 Setpoints Switch

Figure 15-3 shows the location of

DP434A

DSl and DS2 on the Logic Option Board.

ml

pMlElElEBElE~E1~

DS2

I,,

Figure 15-3. Logic Option Board

Controlled by Switches 1 and 4 of

Controlled by Switches 2 and 3 of

Controlled by Switches 5 and 8 of

Controlled by Switches 6 and 7 of

Example A: Controls 1 and 2 ON

1,4,

Therefore, Switches

the figure below.

5, and 8 are ON and the rest are OFF. Refer to

Y

abo

->Control2

->Control2

-->Control

-->Control

ve”

setpoink

for above DSl

for below DSl

1 for above DSl

1 for below DSl

DSl (on Logic Bd)

DSl

setpoint

setpoint

setpoint

setpoint

1234567 6

Example B: Control 1 ON below ” setooint and Control 2 ON

Therefore, Switches

the figure below.

1,4, 6, and 7 are ON and the rest are OFF. Refer to

DSI

111111111~111~111111llllllll

[ON

24

POSITION IS UP --- OFF POSITION IS DOWN;

111~11111~111~1111~1llllllll

”

above

n

setpo

int,

Page 29

DP434

Examole C: Controls 1 and 2 ON “below”

2,3,6,

Therefore, Switches

the figure below.

1234567 8

&rmble

D:

Con&o1

1 ON “above”

Therefore, Switches 2,

and 7 are ON and the rest are OFF. Refer to

3,5, and 8 are ON and the rest are OFF. Refer to

the figure below.

1234567 8

15.4.2 Reset

(Auto/Manual Reset) Switch DS2

setw

DSI

setpa

2

ON

and Control

“below”

(on Logic Option Board)

SetDOint.

Controlled by Switch 1 of

Controlled by Switch 2 of

Controlled by Switch 3 of

Controlled by Switch 4 of

DS2-->

DS2-->

DS2->

DS2-->

Control 1 Auto Reset

Control 2 Auto Reset

Control 2 Manual Reset

Control 1 Manual Reset

Examole: Manual Reset on Control 1 and Auto Reset on Control 2

Therefore, Switches 2 and 4 are ON for and all the rest are OFF. Refer to

the figure below.

DS2

NOTE: CONTROL LOGIC CANNOT OCCUPY TWO STATES AT ONCE. WHEN

DESIRED RESET MODE IS

MODE SHOULD BE SWITCHED OFF. (LE.;

SWJTCHED ON, CONTROL 1 MANUAL RESET SHOULD BE SWITCHED OFF.)

1111~111111111~~1111~~~~~~~-

[ON

POSITION IS UP -- OFF POSITION IS

111111-1111111111111~~~~~~~-

SMTCHED ON, ALTERNATE CORRESPONDING

7

IF

CONTROL

AUTO RESET IS

DOWN2

25

Page 30

DP434

SECTION 16 TROUBLESHOOTING

PROBLEM

SOLUTION

0”

if

“I

“-I

0”

if

Indicator shows

overscale or

the display goes negative.

Cannot adjust zero low

enough

Opening in wiring between indicator and

transducer

cable is removed from transducer)

wiring

Transducer over-pressured. Check

transducer.

SECTION 17 SPECIFICATIONS

POWER:

OPERATING TEMP. RANGE:

DISPLAY:

ACCURACY:

TRANSDUCER POWER SUPPLY:

TRANSDUCER BRIDGE

SHUNT CALIBRATION RESISTOR:

INPUT SENSITIVITIES:

ZERO BALANCE:

RESPONSE TIME:

RECORDER OUTPUTS:

RECORDER OUTPUT ACCURACY:

RECORDER OUTPUT REPEATABILITY:

RECORDER OUTPUT LINEARITY:

RECORDER OUTPUT STABILITY:

DIMENSIONS:

WEIGHT:

CIRCUlT:

(NOTE: will occur when transducer

or improper

-

Check wiring (refer to Section 13.1).

50160

106-l 25VAC or

110

A max.

140°F

O”

to

4!4

digit high efficiency LED display, 0.3

in height with last digit fixed at zero,

selectable decimal point

fO.l%

Within

f

8.2VDC

4 leg, 350 ohm nominal resistance

Selectable 30.1 k ohm,

ohm

O-l to O-O.25

DIP-switch selectable and adjustable from

the front panel

f35%

potentiometer

113 second or 5 seconds selectable

DIP-switch selectable, min. load 5000

ohms

‘R” option --

15 ohms, max load 600 ohms

within

within

within

within

Refer to Figure 17-l

2.5 pounds (1.134 kg)

adjustable with the front panel

fO.1

fO.l%

fO.l%

fO.l%

200-250VAC,

(-17.8” to

full scale,

5%

mVN

4-20mA

scaie

% full

full scale

full scale

full scale

SO’C)

fl

digit

54.9k

and O-2.5 to O-5

0-SVDC,

factory set, min. load

f

1 digit

f

1 digit

f

1 digit

f

1 digit

0-lVDC, OQVDC,

Hz,

ohm, 200k

mVN

O-1OVDC

DP434A

RELAYS:

RELAY RATING:

SETPOINT

ACCURACY:

HYSTERESIS:

INDICATION:

MODE:

RESET:

26

CONTROL SPECIFICATIONS

RANGE:

2 SPDT (single pole double throw)

8 amps at

30VDC

l-1 00% of full scale

within

within

Front panel

Above or below setpoint, switch selectable

Automatic or manual, switch selectable

1251250VAC

*0.3% of full scale

of full scale

f0.5%

LEDs

or 5 amps at

Page 31

DP434

3.93"

99.82 mm

I

FRONT VIEW

SIDE VIEW

3.93 ”

39.82

mm

3.58”

90.93

mm

L

22.86

0.90"

mm

Figure 17-l. Dimensions

27

Page 32

DP434

SECTION 18 OPTION WORKSHEETS AND SUMMARY OF DIP

SWITCH POSITIONS

INSTRUCTIONS: Fill in this page, if desired, with the indicator positions of

OPTION BOARD --

q-mq

1

Reset

Control

Logic-

Logic

the switches (either ON or OFF) within

Refer to this sheet when calling OMEGA for technical

assistance.

DP434A

DS2

q-ii mmq

2 3 4 1234567 8

OS2

--

DSl

1

Control

2

Control

3

Control

4 Control

1

Control 2, Above

2

Control 2, Below

3

Control 2, Below

4

Control 2, Above

5

Control

6

Control 1, Below

7

Control 1, Below

8

Control

DS1

1,

Auto Reset

2,

Auto Reset

2,

Manual Reset

1,

Manual Reset

1,

Above

1,

Above

DSl

ONLY

Setpoint

Setpoint

Setpoint

Setpoint

Setpoint

Setpoint

Setpoint

Setpoint

and DS2.

28

NOTES

Page 33

INSTRUCTIONS:

Fill in this page, if desired, with the indicator positions of

the switches (either ON or OFF) within DS3

DS5.

Refer to this sheet when calling OMEGA for

technical assistance.

DISPLAY BOARD -- DP434

DS 3

10’6

180’S

ON

DSa

_

Lmic Decimal Point

1

2

AMP BOARD -- DP434

DP434A

&

OFF

Divide

Divide Range by 10

Range By 100

DP434A

&

,

DS4 and

Filter.

Transducer

Shunt Calibration

Recorder

Senw

w~ut

DS5

. .

OS5

-

_

DS

DS4

1234567 8

1

.

4

1

Filter (Damping)

~2.5

2

200 k Cal

3

54.9 k Cal

4

30.1 k Cal

5

O-3,000

2

O-5,000

3

O-l 0,000 counts

4

O-l 5,000 counts

NOTES

mVN

Transducer Output

counts

counts

O-10 Volts DC

5

O-5 Volts DC

6

O-2 Volts DC

7

O-l Volt DC

8

29

Page 34

DP434

NOTES

30

Page 35

WARRANTY

We are glad to offer suggestions on the use of our various

only wamnts that the parts

OMEGAMAKEBNoOTHERWARRAMEsDRREPREBENTATlDNBOFANYKMWHATBOEVER,

EXPREBBEDOFtk4PLlED,EXCEPTlliATDFllTLEANDALLR4PLlEDW

ANY WARRANTY OF

HEREBY-.

LIMITATION OF LIABILITY: The remedies of buyer set

total

llablllty

negligence, lndemnifkatlon, strict

price of the component upon which

for consequential, Incidental or special

Every

of OMEGA

precaution

for accuracy

ENGINEERING, INC.

nor assumes

informatton

Direct all warranty and repair

Department. Call toll free in the USA and Canada:

Internaticnal:

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, YOU

R-w

AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the out-

side of the return package and on any correspondence. Please have the following information

available BEFORE contacting OMEGA:

ltabitky

contained in the manuat.

for any damages that result

203-359-l

1. P.O. number under whii the product was PURCHASED,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems you are having

menufactured

respect to

with

lisbllity

Ilability

has

neither assumes

660,

been taken in the preparation of this manual, however,

requeslslmquiries

203-359-7807.

FAX:

FROM OUR CUSTOMER SERVICE DEPARTMENT (IN ORDER TO

will

by it

this

dsmages.

msponstbilky

be as specified and free of defects.

FITNEBS

order, whether based on contract, warranty,

or otherwise, shall not exceed the purchase

based.

is

for any

from

the use of the

to ths OMEGA ENGINEERING Customer Service

producta.

FOR A MERCHANlABllllY AND

forth

In no event shall OMEGA be liable

cnntssii

/

INQUIRIES RETURN REQUESTS

Nevertheless OMEGA

ARRANllEBlNauDlNG

PARTKXJLAR

herein are exclusive and the

PURPOSE

ARE

OMEGA

or errors that may appear

products

in accordance

wtth

m

FAX:

203-359-7611;1-600-622-2376,

OBTA~RlxFR

f&ST

wtth

the product.

the

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is

possible. That way our customers get the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

61

Copyright 1993 OMEGA ENGINEERING, INC.

thtt

manual may be reproduced

without

written

permtssbn

in

any

frcm

OMEGA ENGINEERING. INC.

tnannsr,

either

rights

reserved

Att

wholly or

illustrattons.

indudtng

h part for any purpose whatsoever

Nothing in

Printed

in U.S.A.

Loading...

Loading...