Page 1

CONTROLS

Re-Order from

omegamation.com

Omegamation

TM

1-888-55-OMEGA

1-888-55-66342

1-888-55-66342

Instruction Manual

DIGITAL SPEED POTENTIOMETER WITH DISPLAY

FOR AC AND DC DRIVES

LT24 (0807)

DP4 CONTROL SERIES

P.O. Box 10

5000 W. 106th Street

Zionsville, Indiana 46077

Phone (317) 873-5211

Fax (317) 873-1105

www.dartcontrols.com

A-5-3128F

Page 2

Quick Jump

What models and options are available?

See page 3.

Looking for detailed specifications?

See page 3.

W ant to get started fast?

See basic electrical hook-up details on page 5.

See mechanical installation details on page 4.

See some sample applications starting on page 17.

Need Help?

See troubleshooting on page 22.

Warranty

Dart Controls, Inc. (DCI) warrants its products to be free from defects in material and workmanship. The exclusive remedy

for this warranty is DCI factory replacement of any part or parts of such product which shall within 12 months after delivery

to the purchaser be returned to DCI factory with all transportation charges prepaid and which DCI determines to its satisfaction

to be defective. This warranty shall not extend to defects in assembly by other than DCI or to any article which has been

repaired or altered by other than DCI or to any article which DCI determines has been subjected to improper use. DCI assumes

no responsibility for the design characteristics of any unit or its operation in any circuit or assembly. This warranty is in lieu

of all other warranties, express or implied; all other liabilities or obligations on the part of DCI, including consequential

damages, are hereby expressly excluded.

NOTE: Carefully check the control for shipping damage. Report any damage to the carrier immediately. Do not attempt to

operate the drive if visible damage is evident to either the circuit or to the electronic components.

All information contained in this manual is intended to be correct, however information and data in this manual are subject

to change without notice. DCI makes no warranty of any kind with regard to this information or data. Further, DCI is not

responsible for any omissions or errors or consequential damage caused by the user of the product. DCI reserves the right

to make manufacturing changes which may not be included in this manual.

WARNING

Improper installation or operation of this control may cause injury to personnel or control failure. The control must

be installed in accordance with local, state, and national safety codes. Make certain that the power supply is

disconnected before attempting to service or remove any components!!! If the power disconnect point is out of sight,

lock it in disconnected position and tag to prevent unexpected application of power. Only a qualified electrician or

service personnel should perform any electrical troubleshooting or maintenance. At no time should circuit continuity

be checked by shorting terminals with a screwdriver or other metal device.

Page 3

Table of Contents

Introduction .......................................................................................................................................2

General Features ...............................................................................................................................2

Models & Options ............................................................................................................................. 3

Model Options ............................................................................................................................... 3

Available Options ..........................................................................................................................3

Specifications ....................................................................................................................................3

Electrical........................................................................................................................................3

Mechanical ....................................................................................................................................3

Environmental ............................................................................................................................... 3

Cut-out and Mounting Dimensions ................................................................................................ 4

Mechanical Installation .....................................................................................................................4

Exploded Panel View .....................................................................................................................4

Installation & Diagrams ....................................................................................................................5

P1 Terminal Block Hook-Up Diagram............................................................................................ 5

P1 Terminal Block Descriptions ..................................................................................................... 5

-1 Option Wiring .............................................................................................................................6

Basic Operating Information ........................................................................................................... 6

Visual Reference ........................................................................................................................... 6

How to Change a Parameter's Value (The Short Story) ................................................................ 7

Operating the User Interface (The Long Story) ............................................................................. 7

Detailed Configuration Instructions ................................................................................................8

Default Configuration .....................................................................................................................8

Resetting the Unit to Factory Defaults........................................................................................... 8

JP1 (Program Enable Jumper)...................................................................................................... 8

Software Parameters..................................................................................................................... 9

Parameter Descriptions............................................................................................................... 11

Application Examples ..................................................................................................................... 17

User Interface for Industrial Conveyor Oven with AC Drive .......................................................17

Digital Front Panel for Regenerative Industrial Treadmill ..............................................................18

Programmable Digital Voltage Source with Enable Switch ..........................................................20

Troubleshooting ..............................................................................................................................22

Technical Support Options ..........................................................................................................22

What's Special About www.dartcontrols.com? ...........................................................................22

1

Page 4

Introduction

The DP4 digital potentiometer is a compact, microprocessor-based unit capable of being either field or

factory configured for a number of industry's user-interface needs. The DP4 allows the user to adjust

the displayed value via the front-panel push buttons. As the displayed value is raised or lowered, the

output signal from the DP4 follows proportionally according to the unit's configuration. These units

supports both unipolar and bipolar output and are capable of automatically inverting, scaling, and

offsetting the output as needed. Utilizing Dart's new modular bus design techniques, the DP4 series

is ideal for volume OEM applications requiring specialized inputs and outputs. Contact Dart Controls'

Sales Department for details. This flexibility makes the DP4 series ideal for applications such as:

Water and Waste Treatment Systems

Conveyor Oven Controllers

Synchronized Conveyor Lines

Its durable 1/8 DIN aluminum housings can be easily mounted in a panel or control cabinet. New optional

pluggable terminal block allows the installer to quickly install or replace units without the hassle of

physically removing and reattaching wires. The units can be ordered with either standard Europeanstyle terminal block or optional “pluggable” connector.

General Features

- Microprocessor-based design combines the ultimate in responsiveness and accuracy in one package

- Digital front-end ensures long-term accuracy of output signal over time and temperature

- Non-volatile memory stores adjustable parameters even when power has been removed

- Factory or field programmable via front-panel keypad

- Adjustable parameters include display range, output range, output polarity, alarm options, etc.

- Internal program-enable jumper selectively prevents tampering with unit’s configuration

- Universal power supply accepts line voltages inputs from 85-265VAC @ 50-60Hz without switches

or jumpers. The unit automatically adjusts as needed.

- Transient voltage protection prolongs unit's life in harsh industrial environments

- Self-contained power supply for external sensor, limited to 5V @ 50mA

- Programmable alarm output with Form C contacts rated to 250VAC @ 5A

- 1/8 DIN durable aluminum housing for panel mounting.

- Large 4 digit, 1/2” LED display

- G.E. Lexan membrane and gasket (which are included) meet NEMA 4X standards when used with

NEMA 4X enclosures

- European terminal block or pluggable terminal block available

- Wide operating ambient temperature range of -10C to 45C (14F to 113F)

- Multiple operating modes including:

• Rate Mode – Displays in rate and non-rate units such as RPM, Gallons per Second, & percent

• Time Mode – Displays in time units such as HH:MM, MM:SS, SS:TT, or other unit

2

Page 5

Model Options

Models & Options

Input Voltage

Model

DP4 85-265VAC 0-2 VDC

@ 50 - 60Hz Output Voltage

THROUGH

0-24 VDC

Pickup or

Encoder

Required?

No

Available Options

Option Suffix Description Example

-1 Expansion board which adds support for remote push button wiring via a European-style

-P Optional pluggable European-style terminal block DP4-P

-9 Blank Lexan DP4-9

terminal block.

DP4-1

Specifications

Electrical

Line Input Voltage ...............................................................................................................................................Any Voltage from 85-265 VAC

Line Input Frequency ............................................................................................................................................. Any Freq. from 48-62 Hertz

Display Range ..............................................................................................................................................................................

Units of Operation ..............................................................................................................................................User Programmable, any Unit

Onboard Power Supply (Externally Accessible) ............................................................................................................................

Isolated Alarm Relay Output Ratings ..........................................................................................................................................250VAC @ 5A

Pot Lo/Hi supply VDC range .................................................................................................................................. 0-2 VDC through 0-24 VDC

Pot wiper VDC range ...............................................................................................................................Pot Lo +50mV through Pot Hi -50mV

0.001 – 9999

5V @ 50mA

Mechanical

Display Type LED, Red, 4 Digit, ½” Height

Housing Type (with supplied gasket in NEMA 4X panel) ......................................................................................................

Connector Style (pluggable connector optional) ...........................................................................................

Terminal Block Torque Setting ........................................................................................................................................ 4.4 in. lb. Max or .5Nm

Faceplate Material ................................................................................................................................ Polycarbonate with GE Lexan Overlay

Housing Material ................................................................................................................................................................................Aluminum

Length (Required Panel Depth) ...........................................................................................................................................

Faceplate Width ..................................................................................................................................................................

Weight ASP10 ......................................................................................................................................................... 0.900 lb, 14.4 oz, 408.22g

12-position 5mm European Style

1/8 DIN NEMA 4X

4.625”, 117.48mm

4.539”, 115.29mm

Environmental

Operating Temperature Range ................................................................................................................................ -10C to 45C (14F to 113F)

Operating Humidity Range ............................................................................................................................................

3

95%, non-condensing

Page 6

Mechanical Installation

Exploded Panel View

CUSTOMER

MOUNTING PANEL

(HOLE CUT-OUT FOR CONTROL

HOUSING APPROXIMATELY

3.622" WIDE BY 1.770" HIGH)

PANEL MOUNTING GASKET

(WITH THE ADHESIVE SIDE OF

GASKET FACING THE CUSTOMER

MOUNTING PANEL)

DP4

CONTROL

1) GASKET

2) (2) 6-32 X 3/4 PANHEAD BLACK OXIDE STAINLESS SCREWS

3) (2) #6 NUT WITH LOCKWASHER

Cut-out and Mounting Dimensions

4.000"

SUPPLIED WITH EACH CONTROL:

CONTROLS

Ite

Item

Rev

m

MICRO-DRIV

DIGITAL POT

Tac h

ValuPage

Tac

ValPage

Alarm

FwdNeg

ENTER

.140" x 2

5.000"

4.000"

3.622"

DP4

HOUSING DEPTH

4.625"

PA NEL CUT-OUT

0.885"

1.770"

2.289"

1.656"

4.625"

4

Page 7

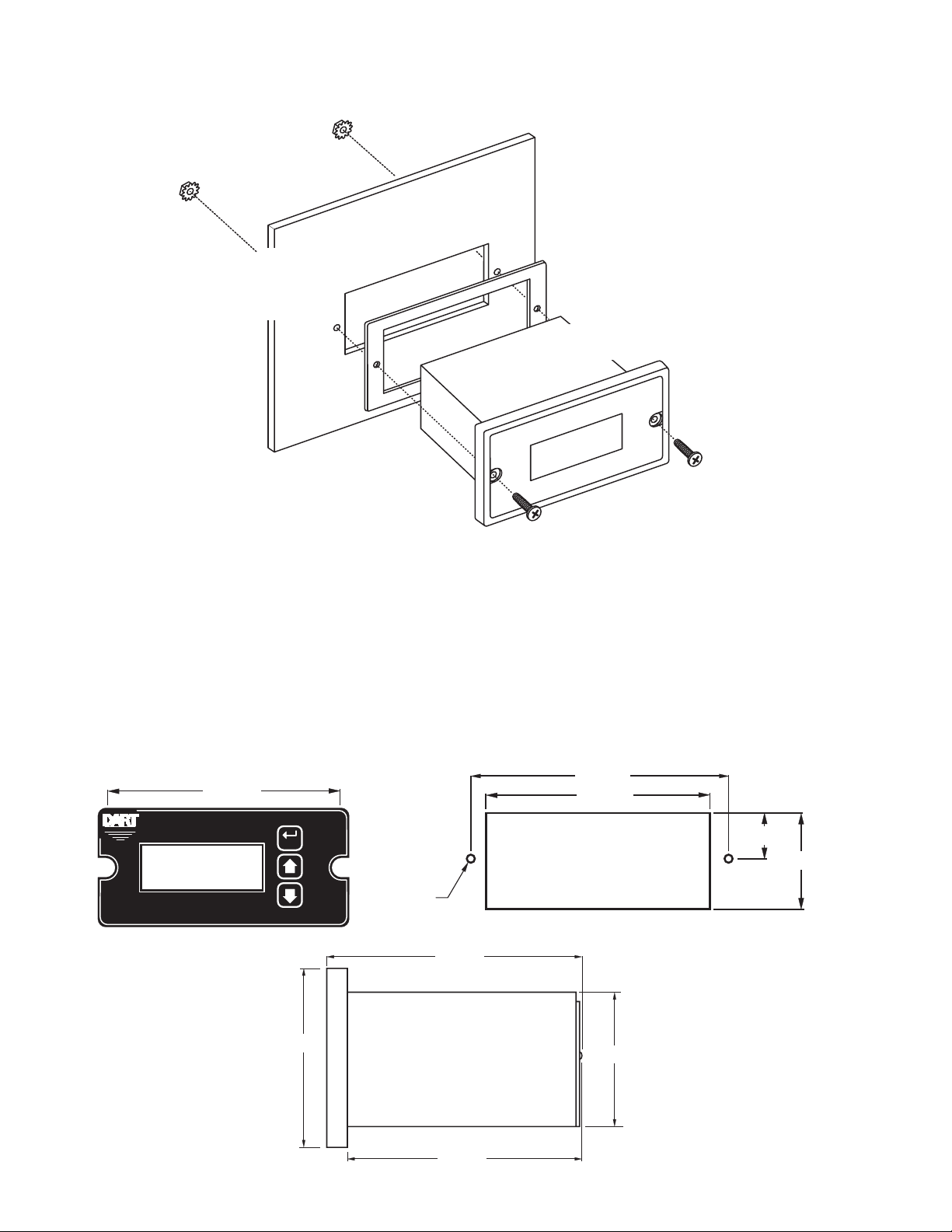

Installation & Diagrams

P1 Terminal Block Hook-Up Diagram

P1-1

P1-2

P1-3

P1-4

DP4

* P1-8 & P1-9 signal inputs may be programmed for a number of functions.

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

N

L

HI

W

LO

COM

+5V

S1

S2

NO

C

NC

2 AMP

AC INPUT

AC INPUT

HIGH OUTPUT

WIPER OUTPUT

LOW OUTPUT

COMMON

+5VDC

SIGNAL 1

SIGNAL 2

Alarm Output - Normally Open

Alarm Output - Common

Alarm Output - Normally Closed

*

*

}

85-265VAC

}

Connect to the speedpot

of the control being driven.

High must be positive

}

voltage with respect to low.

External Supply (+5V@50mA)

}

Form C

Relay output

(Programmable)

P1 Terminal Block Descriptions

P1-1 (AC / N) – For single phase AC lines connect the Neutral side of your AC line to this terminal.

For systems with two hot AC lines, connect either of the Hot AC lines to this terminal.

P1-2 (AC / L) – For single phase AC lines connect the Hot side of your AC line to this terminal. For

systems with two hot AC lines, connect either of the Hot AC lines to this terminal.

P1-3 (HI) - This is the POT HI reference terminal. This terminal must be connected to the most positive

speed pot input terminal of the partner control. This terminal will generally be referred to as Pot

HI or +V for positive supplies and Com for negative supplies.

P1-4 (WP) - This is the Wiper output terminal. This terminal will output an analog voltage signal

proportional to the referenced voltage signals connected to P1-3 (HI) and P1-5 (LO). This

terminal should be connected to the wiper or signal input of the partner control.

P1-5 (LO) - This is the POT LO reference terminal. This terminal must be connected to the most

negative speed pot input terminal of the partner control. This terminal will generally be referred

to as Pot LO or Com for positive supplies and –V for negative supplies.

P1-6 (COM) – This is the common point for the control logic. Any other equipment or source needing

to reference the control common will be connected to this terminal.

P1-7 (+5V) – This is a self-contained +5VDC power supply capable of up to 50mA. Various low-

voltage sensors can be driven from this supply if desired.

P1-8 (S1) – This is the programmable signal 1 input. It can be configured to perform a number of

special features including inhibit and jog.

P1-9 (S2) – This is the programmable signal 2 input. It can be configured to perform a number of

special features including inhibit and jog.

P1-10 (1NO) – This is the normally-open contact of the user assignable relay output.

P1-11 (1C) – This is the common contact of the user assignable relay.

P1-12 (1NC) – This is the normally-closed contact of the user assignable relay output.

5

Page 8

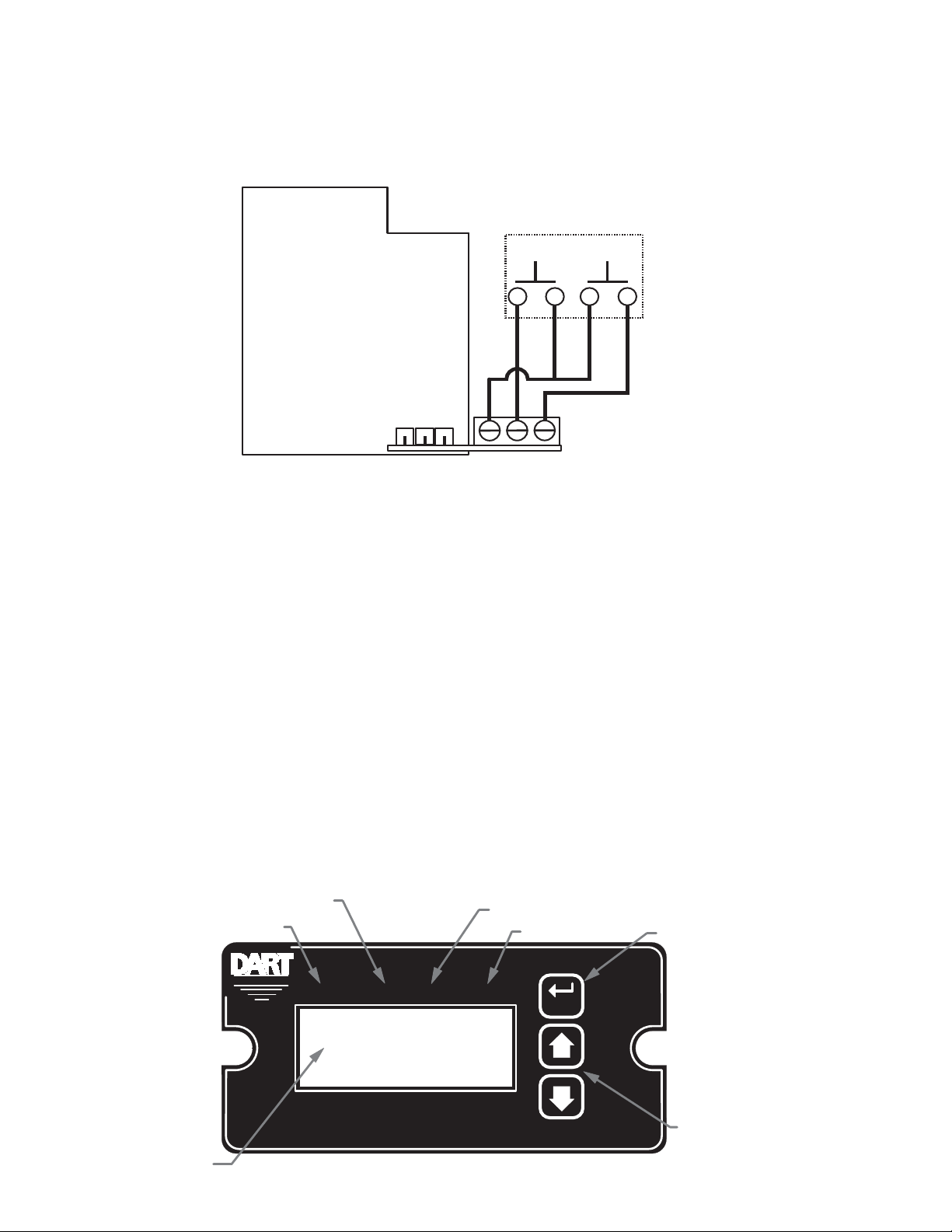

-1 Option Wiring

The -1 option board is a module which allows external up and down push buttons to be wired to the unit.

These buttons operate exactly like the Up and Down buttons on the user interface. This module is

commonly used to allow PLCs or hand-held pendants to operate the front-panel remotely. Wires for the

external buttons are attached via a 3mm European terminal block on the -1 option board. The buttons

are activated by shorting the terminal labeled Com to either the Up or Down terminal.

REMOTE SWITCHING

MICROPROCESSOR

DOWN UP

SERIES PC BOARD

-1 OPTION

BOARD

-3

COMMON

-2

DOWN

-1

UP

Basic Operating Information

The DP4 digital potentiometer is a panel-mount digital-to-analog user interface. Put simply, it allows the

user to adjust the displayed value via push buttons on the front panel; and, outputs a proportional signal

according to its configuration. It can be configured to work with both single and bidirectional partner

drives. It also supports both unipolar and bipolar output supplies.

The DP4 can display values in rate and time formats. In Rate mode, output units such as Gallons-perMinutes, RPM, and Percent are possible with just a few minor adjustments. In Time mode, output units

such as Hours:Minutes (HH:MM), Minutes:Seconds (MM:SS), and Seconds:Ticks (SS:TT) are

supported. In Time modes, the output will be inversely proportional to the displayed value in order to

represent a programmable process time.

See the application examples in this manual for additional information on how the DP4 can be

configured.

Visual Reference

Negative Indicator

Display Window

Reverse Indicator

CONTROLS

Neg

MICRO-DRIV

Ite

Item

Rev

m

Val uPage

ValPage

Fwd

DIGITAL POT

Forward Indicator

Alarm Indicator

Tach

Tac

Alarm

6

ENTER (Select) Button

ENTER

Up & Down Buttons

Page 9

How to Change a Parameter's Value (The Short Story)

1. Hold down the Enter button until Parameter-Selection Mode is entered

2. Using the Up and Down buttons, select the desired parameter number to view or edit

3. Press the Enter button to change the value of the parameter

4. Using the Up and Down buttons, change the parameter's value as desired

5. Press the Enter button to permanently save the changes (Return to Parameter-Selection Mode)

6. Select parameter zero and press the Enter button to return to Running Mode

Operating the User Interface (The Long Story)

Although the DP4 user interface is very versatile, it is also simple to setup and operate. With just a few

button presses, it allows the user to configure a number of adjustable parameters. The LED display has

three basic operating modes: Running Mode, Parameter-Selection Mode, and Value Mode. Each of the

three modes have specific visual indicators that allow the user to immediately determine the current

state or mode of the user interface. Parameter-Selection Mode and Value Mode can only be

entered if the Program Enable jumper is in the “On” position.

Running Mode is the default display of the unit when power is applied. The DP4 will spend the majority

of its time in this mode. In Running Mode, the display shows the target value in the appropriate userdefined format of rate, time, or percentage. The control will continuously attempt to drive the motor at

the requested target rate. In this display mode, the Up and Down buttons increase or decrease the

displayed target value until either the display minimum or display maximum limit is reached. Depending

on the alarm configuration, these buttons may also serve as an alarm-silence or alarm-reset button.

Example displays for rate, time, and follower operating modes are 13.60, 45:30, and 9301.

Parameter-Selection Mode can be entered by simply pressing and holding the Enter button down for

three seconds. Once in Parameter-Selection Mode, the far left of the display will be a ‘P’. The right side

of the display will indicate the currently selected parameter number for editing purposes. Pressing the

Up or Down button will increase or decrease the selected parameter number on the display. Although

the parameter numbers are in numerical order, some numbers are skipped. These numbers represent

reserved parameters that are not yet implemented and are not displayed. Once the desired parameter

number is displayed, a press of the Enter button will change the display to the Value Mode. When in

Parameter-Selection Mode, pressing the Enter button with parameter 0 selected will cause the

unit to return to Running Mode. Example displays for Parameter-Selection Mode are P 1, P 12, and

P 54. See the Software Parameters for a list of available parameters.

Value Mode is used to modify the value of the selected parameter. When in Value Mode, the two dots

which form the colon, between digits two and three, will alternately flash (one, then the other) to inform

the user that a parameter’s value is being edited. Pressing the Up or Down button increases or

decreases the selected parameter’s value. See the Software Parameters for a list of allowable values

and ranges. Value changes take effect immediately. For example, when scrolling through the alarm

output conditions, the relay will activate as the always-active selection is passed. Once the desired

value is showing in the display window, pressing the Enter button again will return to ParameterSelection Mode. The new value is not saved in permanent memory until the Enter button is pressed.

Removing power from the unit while in Value Mode may result in the specified new value being lost.

7

Page 10

Detailed Configuration Instructions

Default Configuration

When shipped from the factory, the following basic settings are in place:

Rate Mode Operation in % Units

Unipolar Output without Deadband

Decimal Point Display: XXX.X

Display Range: 0 - 100.0

Output Range: 0 - 100% of Applied Pot High Voltage

Signal Input 1 (S1) Mode: Force Output to 0% when Low

Signal Input 2 (S2) Mode: Force Output to 0% when Low

Alarm Output: Disabled

Resetting the Unit to Factory Defaults

The factory-default settings can be easily restored using either of two methods. Both methods require

the Program Enable jumper to be in the “On” position. The first is to apply power to the unit with both

the Enter and Down buttons pressed for 3 seconds. The second is to change the value of parameter

95 to 5.

JP1 (Program Enable Jumper)

The JP1 jumper is located under the dust cover on the back end of the upper board. When the jumper

is set to the "Off" position, all programming features are locked out to the front panel user. When the

jumper is in the "On" position, the programming parameters are open to change. JP1 is shipped from

the factory set in the "On" position.

8

Page 11

Software Parameters

Parameter

0 Selecting this item exits to Running Mode n/a n/a

Read-Only Parameters

1 Model Number 40 – DP4 Unit 40

2 Software Build 1 – 9999 n/a

3 Hardware Version 1 – 9999 n/a

4 Serial Number – Major (reserved) n/a n/a

5 Serial Number – Minor (reserved) n/a n/a

10 Operating Mode Rate Mo d es:

11 Display Intensity 0 – 31 (Dim – Bright) 26

12 Display Zero Blank ing 1 – ___X Show at least 1 Di git

13 Decimal Point Position 0 – DP Disabled (XXXX)

15 Keypad M ode 1 – Linear, Constant R ate

16 Keypad Scroll Delay 0 – 30 (Fast – Slow) 10

18 Power -up Mode 1 – Default to Zero Display

19 Power-up Value 0 – 9999 (Display Units) 0

20 Dis play Valu e at Mi nimum Output -9999 – 99 99 (Display Units) 0

21 Display Val u e at Ma ximum Output -9999 – 9999 (Dis play Units) 1000

22 Dis play Valu e at Center Out pu t (B ipolar Onl y ) -9999 – 9999 (Dis play Units ) 0

25 Output % - Minimum 0 – 10 00 (1/10th Percent Units) 0

26 Output % - Maximum 0 – 1000 (1/1 0th Percent Units) 1000

27 Out p ut % - Center (B ipolar Modes Only) 0 – 1000 (1/10th Pe rc e nt Units) 500

28 Output Deadband Width 0 – 1000 (1/10th Percent Units) 0

General Setup

Display & Output Setup

Description

Value Range

(units)

1 – Unipolar Output

2 – Unipolar Output with Deadband

3 – Bipolar O utput

4 – Bipolar Output with Deadband

Time Modes:

5 – Unipolar Output

6 – Unipolar Output with Deadband

7 – Bipolar O utput

8 – Bipolar Output with Deadband

Other Modes:

9 – Absolute Value Output with Relay

Direc tion Cont r ol

10 – Abso lute Valu e Ou t p ut wi th

Relay D ir ect. Control an d De adband

2 – __XX Show at least 2 Digits

3 – _XXX Show at least 3 Digits

4 – XXXX Show all 4 Digits

1 – X.XXX

2 – XX.XX

3 – XXX.X

4 – XXXX.

2 – Non-linear, Accelerating R ate

2 – Default to Power-up Value

3 – Default to Previous Running Val.

Factory

Default

1

2

3

2

3

User

Settings

9

Page 12

Software Parameters, cont'd

Parameter

Signal Input #1 (S1) Setup

30 S1 Input Configuration 1 – Output 0% When S1 Low

31 S1 Setpoin t -9999 – 9999 (Dis play Units ) 0

Signal Input #2 (S2) Setup

35 S2 Input Configuration 1 – Output 0% When S2 Low

36 S2 Setpoin t -9999 – 9999 (Dis play Units ) 0

40 Activation Conditi ons 0 – Alway s Off

41 Output Style & Reset Mode 1 – Constant & Auto Reset

42 Reset Configuration 1 – No Sil., Reset on Key

43 Display Flash On Active Alarm 0 – Alarm Flash Disabled

44 Pulse on Time 1 – 3600 (seconds) 1

45 Pulse off Time 1 – 3600 (seconds) 1

46 Pulse Count 0 – 9999 (pulses) 0

47 Lower Limit 0 – 9999 (display units) 0

48 Upper Limit 0 – 9999 (display units) 9999

95 Restore Settings to Factory Default 0 – Do Nothing & Exit

98 Save to User Default Area 0 – Do Nothing & Exit

99 Restore from User Default Area 0 – Do Nothing & Exit

Alarm Output Configuration

Parameter Memory Commands

Description

Value Range

(units)

2 – Output 0% When S1 High

3 – Output Setpoint When S1 Low

4 – Output Setpoint When S1 High

5 – Output 100% When S1 Low

6 – Output 100% When S1 High

2 – Output 0% When S2 High

3 – Output Setpoint When S2 Low

4 – Output Setpoint When S2 High

5 – Output 100% When S2 Low

6 – Output 100% When S2 High

1 – Always On

2 – Active when Above upper limit

3 – Active when Below lower limit

4 – Active in side Rang e

5 – Active outside Range

6 – Active Zero or Equivalent Output

7 – Relay Di r ection Control Mode

2 – Constant & Manual Reset

3 – Pulsed & Auto Reset

4 – Pulsed & Manual Reset

2 – No Sil., Reset on S2 High

3 – No Sil., Reset on S2 Low

4 – Sil., Reset on Key

5 – Sil., Reset on S2 High

6 – Sil., Reset on S2 Low

1 – Alarm Flash Enabled

5 – Restore Factory Defaults

5 – Save Setting

1 – Restore Settings

Factory

Default

1

1

0

1

1

0

0

0

0

User

Settings

10

Page 13

Parameter Descriptions

Parameter 0 – Exit to Running Mode

When parameter 0 is selected in Parameter-Selection Mode, the unit will return to Running Mode

and display the running value. This should be selected once the changes to the parameters are

completed.

Parameter 1 – Model Number (Read Only)

This is a number which represents the base model number for the product. The model code for

the DP4 is 40.

Parameter 2 – Software Build (Read Only)

The software build is a code which identifies the software version of the unit.

Parameter 3 – Hardware Version (Read Only)

The hardware version is a code which identifies which hardware was used to build the unit.

Parameter 4 & 5 – Serial Number, Major & Minor (Read Only)

These parameters are reserved for future use as an electronic serial number and are unique

to each manufactured unit.

Parameter 10 – Operating Mode

This parameter defines the operating mode for the entire unit. There are two basic modes of

operation, Rate and Time. In Rate modes, the unit displays in rate and non-time-based units

such as RPM, Gallons per Hour, and Percent of Maximum Output. In Time modes, the unit

displays in time-based units using the format AA:BB. The AA:BB format can be adjusted to

represent Hours:Minutes or Minutes:Seconds.

Mode 1 – Rate Mode, Unipolar Output

Mode 2 – Rate Mode, Unipolar Output with Deadband

Mode 3 – Rate Mode, Bipolar Output

Mode 4 – Rate Mode, Bipolar Output with Deadband

Mode 5 – Time Mode, Unipolar Output

Mode 6 – Time Mode, Unipolar Output with Deadband

Mode 7 – Time Mode, Bipolar Output

Mode 8 – Time Mode, Bipolar Output with Deadband

Mode 9 – Other Mode, Absolute Value Output with Relay Direction Control

This mode allows the DP4 to interface with bi-directional Controls that have FWD and REV

command inputs and use the absolute value of the pot to determine speed only. In this

mode, the user must configure the following parameter:

Display Min, Max, and Center

Output Min and Max

Output Deadband (Mode 10 Only!)

Mode 10 – Other Mode, Absolute Value Output with Relay Direction Control and with

Deadband Funcion

Same as Mode 9, except deadband is supported. Must set Deadband value at Item 28.

Parameter 11 – Display Intensity

This parameter adjusts the intensity of the LED display digits in the front panel of the unit. The

values of 0 – 31 correspond to a gradual change from very dim to very bright. This is often useful

when the DP4 is used in the same panel as other pieces of equipment with LED display and a

uniform display brightness is desired. Simply adjust the DP4 to match its surroundings.

Parameter 12 – Display Zero Blanking

This selects the number of display digits that are required to be displayed regardless of the

display value. For example, with a Display Zero Blanking setting of 3 and a displayed value of

6, the display would show "_006".

Mode 1: ___X Always show at least 1 digit

Mode 2: __XXAlways show at least 2 digits

Mode 3: _XXX Always show at least 3 digits

Mode 4: XXXX Always show all 4 digits

11

Page 14

Parameter 13 – Decimal Point (DP) Position

This selects the format of the display with respect to the decimal point’s position. This parameter does

not affect the value entry for other parameters. The decimal point is only displayed in Rate modes.

For example, if the user desires to display numbers such as 12.34 or 1.05, then parameter 13 should

be set to 2.

Mode 0: Fixed XXXX (DP disabled)

Mode 1: Fixed X.XXX

Mode 2: Fixed XX.XX

Mode 3: Fixed XXX.X

Mode 4: Fixed XXXX.

Parameter 15 – Keypad Mode

This parameter selects the operating mode of the front-panel push buttons. In some applications,

increasing or decreasing the scroll rate provides the user more controllability when entering settings.

Parameters 14 and 15 affect only the Up and Down buttons when the user interface is in Running

Mode. These settings also apply to remote Up / Down buttons which are attached via the -1 option

board.

Mode 1: Linear, Constant Rate

In linear mode, pressing and holding the Up or Down buttons will cause the display to

continuously change value in the requested direction until either the Display Minimum or Display

Maximum is reached. The displayed value will scroll at a constant rate which is specified using

parameter 15.

Mode 2: Non-linear, Accelerating Rate

In non-linear mode, pressing and holding the Up or Down buttons will cause the display to

continuously change value in the requested direction until either the Display Minimum or Display

Maximum is reached. The displayed value will initially scroll at a slow rate and increase in speed

until the maximum scroll rate is achieved. The initial scroll rate is specified using parameter 15.

Parameter 16 – Keypad Scroll Mode

This parameter sets the scroll speed for the front-panel push buttons. The function of this parameter

varies slightly depending on the Keypad Mode. See parameter 14 for more details.

Parameter 18 – Power-Up Mode

This parameter defines the mode which determines the default Running Value when power is initially

applied to the DP4.

Mode 1: Default to Zero

When in this mode, the unit will default to zero (display units).

Mode 2: Default to Power-Up Value

When in this mode, the unit will default to the Power-up Value, parameter 19.

Mode 3: Default to Previously Running Value

When in this mode, the unit will default to the previous running value before power was removed.

A previous running value must have been active for at least 3 seconds to be recalled after power

has been disconnected and reapplied.

Parameter 19 – Power-Up Value

When Power-up Mode is set to 2, this parameter will designate the default display value at power-up

in display units.

Parameter 20 – Display Value at Minimum Output

This parameter defines the lower end of the display range. This is the value which limits how low the

user is able to scroll the displayed value in Running Mode. In Rate and Time modes, this value is set

in display units. This parameter is set without consideration for the decimal point's position. For

example, setting this parameter to 125 would set the lower display limit at 12.5, 0.125, or 125 seconds

according to the other configuration parameters.

Parameter 21 – Display Value at Maximum Output

This parameter defines the upper end of the display range. This is the value which limits how high the

user is able to scroll the displayed value in Running Mode. In Rate and Time modes, this value is set

in display units. This parameter is set without consideration for the decimal point's position. For

example, setting this parameter to 1000 would set the upper display limit at 100.0, 1.000, or 1000

seconds according to the other configuration parameters.

12

Page 15

Parameter 22 – Display Value at Center Output

This defines the center value for the display in bipolar (or bidirectional) modes of operation. In

bipolar applications, this value should be set to the display value that corresponds to a null or

zero output. When in Running Mode, display values above this will produce an output toward

the programmed Maximum Output %; whereas, display values below this will produce an output

toward the programmed Minimum Output %. As the display value approaches the number

programmed in this parameter, the DP4 will produce an output that approaches the percentage

programmed in parameter 28. See parameters 25 - 27 and the application examples for

additional information.

Parameter 25 – Minimum Output % (in 1/10 percent units)

This parameter sets the output percentage which corresponds to the minimum display value,

parameter 20. This parameter has a range of 0 to 1000 which represents 0.0 to +100.0 percent

of output. When the user is adjusting the display value towards the programmed minimum

display, the output will linearly approach the value of this parameter. For example, setting this

parameter to 25 will configure the DP4 to output 2.5% when the user adjusts the display value

to equal the display minimum, parameter 20. Setting this minimum percentage higher than the

maximum (parameter 26) will cause the polarity of the output to be inverted. See parameters

20 - 22 and the application examples for additional information.

Parameter 26 – Maximum Output % (in 1/10 percent units)

This parameter sets the output percentage which corresponds to the maximum display value,

parameter 21. This parameter has a range of 0 to 1000 which represents 0.0 to +100.0 percent

of output. When the user is adjusting the display value towards the programmed maximum

display, the output will linearly approach the value of this parameter. For example, setting this

parameter to 850 will configure the DP4 to output 85.0% when the user adjusts the display value

to equal the display maximum, parameter 21. Setting this maximum percentage higher than the

minimum (parameter 25) will cause the polarity of the output to be inverted. See parameters 20

- 22 and the application examples for additional information.

Parameter 27 – Center Output % (in 1/10 percent units)

This defines the center percentage for the output in bipolar (or bidirectional) modes of operation.

In bipolar applications, this value should be set to the percentage of output that corresponds to

a null or zero output of the partner drive. When in Running Mode, display values above the

display center (parameter 22) will produce an output toward the programmed Maximum Output

%; whereas, display values below the display center (parameter 22) will produce an output

toward the programmed Minimum Output %. As the display value approaches the programmed

display center value (parameter 22), the DP4 will produce an output that approaches the

percentage programmed in this parameter. See parameters 20 - 22 and the application

examples for additional information.

Parameter 28 – Output Deadband % (in 1/10 percent units)

This defines the width of the output's deadband. This is the range of output percentage values

which will produce a zero or center output percentage in unipolar and bipolar modes respectively.

This value is the width of the range in percentage units. For example: If the DP4 were configured

for bipolar operation and this parameter were set to 50, then any output which was within 5% of

the center output percentage would be forced to the center output value. See parameters 20 22 and the application examples for additional information.

Parameter 30 – Signal Input 1 (S1) Configuration

This parameter determines the operating mode of signal input 1 (S1).

Mode 1: Output 0% When S1 Low

When the S1 input is at an electrically low state or wired to the unit's common, the DP4 will

force its output to 0%. Once the S1 input returns to an electrically high (+5V) state or

allowed to float disconnected, the output will once again correspond to the display value.

Mode 2: Output 0% When S1 High

When the S1 input is at an electrically high (+5V) state or allowed to float disconnected,

the DP4 will force its output to 0%. Once the S1 input returns to an electrically low state

or wired to the unit's common, the output will once again correspond to the display value.

13

Page 16

Mode 3: Ouput Setpoint When S1 Low

When the S1 input is at an electrically low state or wired to the unit's common, the DP4 will

force its output to a percentage which corresponds to the programmed jog setpoint,

parameter 31. Once the S1 input returns to an electrically high (+5V) state or allowed to

float disconnected, the output will once again correspond to the display value.

Mode 4: Output Setpoint When S1 High

When the S1 input is at an electrically high (+5V) state or allowed to float disconnected,

the DP4 will force its output to a percentage which corresponds to the programmed jog

setpoint, parameter 31. Once the S1 input returns to an electrically low state or wired to

the unit's common, the output will once again correspond to the display value.

Mode 5: Output 100% When S1 Low

When the S1 input is at an electrically low state or wired to the unit's common, the DP4 will

force its output to 100%. Once the S1 input returns to an electrically high (+5V) state or

allowed to float disconnected, the output will once again correspond to the display value.

Mode 6: Output 100% When S1 High

When the S1 input is at an electrically high (+5V) state or allowed to float disconnected,

the DP4 will force its output to 100%. Once the S1 input returns to an electrically low state

or wired to the unit's common, the output will once again correspond to the display value.

Parameter 31 – Signal Input 1 (S1) Setpoint

When the S1 configuration, parameter 30, is set to one of the setpoint (jog) modes(modes 3 or

4), this parameter defines the jog setpoint in display units. This parameter is always set in

display units.

Parameter 35 – Signal Input 2 (S2) Configuration

This parameter determines the operating mode of signal input 2 (S2).

Mode 1: Output 0% When S2 Low

When the S2 input is at an electrically low state or wired to the unit's common, the DP4 will

force its output to 0%. Once the S2 input returns to an electrically high (+5V) state or

allowed to float disconnected, the output will once again correspond to the display value.

Mode 2: Output 0% When S2 High

When the S2 input is at an electrically high (+5V) state or allowed to float disconnected,

the DP4 will force its output to 0%. Once the S2 input returns to an electrically low state

or wired to the unit's common, the output will once again correspond to the display value.

Mode 3: Ouput Setpoint When S2 Low

When the S2 input is at an electrically low state or wired to the unit's common, the DP4 will

force its output to a percentage which corresponds to the programmed jog setpoint,

parameter 36. Once the S2 input returns to an electrically high (+5V) state or allowed to

float disconnected, the output will once again correspond to the display value.

Mode 4: Output Setpoint When S2 High

When the S2 input is at an electrically high (+5V) state or allowed to float disconnected,

the DP4 will force its output to a percentage which corresponds to the programmed jog

setpoint, parameter 36. Once the S2 input returns to an electrically low state or wired to

the unit's common, the output will once again correspond to the display value.

Mode 5: Output 100% When S2 Low

When the S2 input is at an electrically low state or wired to the unit's common, the DP4 will

force its output to 100%. Once the S2 input returns to an electrically high (+5V) state or

allowed to float disconnected, the output will once again correspond to the display value.

Mode 6: Output 100% When S2 High

When the S2 input is at an electrically high (+5V) state or allowed to float disconnected,

the DP4 will force its output to 100%. Once the S2 input returns to an electrically low state

or wired to the unit's common, the output will once again correspond to the display value.

Parameter 36 – Signal Input 2 (S2) Setpoint

When the S2 configuration, parameter 35, is set to one of the setpoint (jog) modes(modes 3 or

4), this parameter defines the jog setpoint in display units. This parameter is always set in

display units.

14

Page 17

Parameter 40 – Alarm 1 Conditions

This defines which conditions will result in the alarm 1 output being activated.

Mode 0: Always Inactive

The alarm output will remain in an inactive state. In this state, the NC and C contacts will

be internally electrically connected.

Mode 1: Always Active (When Power Is Applied)

The alarm output will become active when the power is applied to the unit. In this state,

the NO and C contacts will be internally electrically connected.

Mode 2: Active When Display Value Above Limit

The alarm output will activate when the displayed value is above the upper limit setting,

parameter 48.

Mode 3: Active When Display Value Below Limit

The alarm output will activate when the displayed value is below the lower limit setting,

parameter 47.

Mode 4: Active When Display Value Inside Range

The alarm output will activate when the displayed value is greater than or equal to lower

limit settings and less than or equal to the upper limit setting.

Mode 5: Active When Display Value Outside Range

The alarm output will activate when the displayed value is less than the lower limit setting

or greater than upper limit setting.

Mode 6: Active When Display Value Results in a Zero or Equivalent Output

If the display is set to a value that produces a zero output or is within the programmed

deadband, then the alarm is activated.

Mode 7: Relay Direction Control Mode

In this mode, the relay output will determine which direction is being requested. This will

typically be used with Item 10 modes 9 & 10.

Forward = relay not energized; Reverse = relay energized

Parameter 41 – Alarm 1 Output Style & Reset Configuration

This setting configures the output mode and reset method for the alarm output.

Mode 1: Constant & Auto Reset

In this mode, the alarm output will remain active until the alarm condition ceases to exist.

The alarm will automatically reset when the conditions return to normal.

Mode 2: Constant & Manual Reset

In this mode, the alarm output will remain active until the alarm is reset manually. See

parameter 42 for details.

Mode 3: Pulse & Auto Reset

In this mode, the alarm output will pulse on and off until the alarm condition ceases to exist.

The pulsed modes are commonly used for audible alarms where a constant output would

be considered distracting or awkward. The alarm will automatically reset when the

conditions return to normal.

Mode 4: Pulse & Manual Reset

In this mode, the alarm output will pulse on and off until the alarm is reset manually. See

parameter 42 for reset details. The pulsed modes are commonly used for audible alarms

where a constant output would be considered distracting or awkward.

Parameter 42 – Alarm 1 Reset Configuration

This setting determines which actions will cause an active alarm to be silenced or reset.

Mode 1: No Silencing, Reset On Any Button Press

In this mode, an active alarm cannot be silenced. Once the alarm condition ceases to

exist, however, any user-interface button may be pressed to cause a manual reset.

Mode 2: No Silencing, Reset On S2 Input High (Not Wired To Common)

Similar to Mode 1. Once the alarm condition ceases to exist, setting the S2 input to a high

(+5V) state or allowing it to float disconnected will cause a manual reset.

15

Page 18

Mode 3: No Silencing, Reset On S2 Input Low (Wired To Common)

Similar to Mode 1. Once the alarm condition ceases to exist, setting the S2 input to a low

(COM) state or wiring it to common will cause a manual reset.

Mode 4: Silencing Enabled, Reset On Any Button Press

When the conditions for an active alarm persist, pressing any user-interface button will

result in the alarm being silenced or deactivated, but not reset. A second attempt to reset

the alarm must be made after the condition cease to exist to clear the alarm.

Mode 5: Silencing Enabled, Reset On S2 Input High (Not Wired To Common)

Similar to Mode 4. Setting the S2 input to a high (+5V) state or allowing it to float

disconnected will cause the alarm to be silenced or reset depending on the current state

of the alarm conditions.

Mode 6: Silencing Enabled, Reset On S2 Input Low (Wired To Common)

Similar to Mode 4. Setting the S2 input to a low (COM) state or wiring it to common will

cause the alarm to be silenced or reset depending on the current state of the alarm

conditions.

Parameter 43 – Alarm 1 Display Flash On Alarm

This will cause the display to flash when an alarm condition is active.

Parameter 44 – Alarm 1 Pulse on Time

This parameter defines the number of seconds the output should be enabled during the ‘on’

phase of an active pulsing alarm’s output.

Parameter 45 – Alarm 1 Pulse off Time

This parameter defines the number of seconds the output should be disabled during the ‘off’

phase of an active pulsing alarm’s output.

Parameter 46 – Alarm 1 Pulse Count

This setting determines how many pulses are output when the alarm is activated and is

configured in pulse output style.

When 0 is entered, the unit will be set for continuous pulses

while the alarm is active.

Parameter 47 – Alarm 1 Lower Limit

This setting defines either the lower limit or lower end of a range for the alarm region. Alarm limits

are set in display units without regard to decimal point or colon position. In Rate Modes, a limit

of 123 could represent a display value of 123, 12.3, 1.23, or 0.123. When in Time Mode, a limit

of 123 would represent 1:23 on the display.

Parameter 48 – Alarm 1 Upper Limit

This setting defines either the upper limit or upper end of a range for the alarm region. Alarm limits

are set in display units without regard to decimal point or colon position. In Rate Mode, a limit

of 123 could represent a display value of 123, 12.3, 1.23, or 0.123. When in Time Mode, a limit

of 123 would represent 1:23 on the display.

Parameter 95 – Factory Default Command

When set to a value of 5, the unit will be reset to factory default settings. This can also be

achieved by applying power to the unit with both the Enter and Down buttons depressed.

programming jumper must be in the "On" position for this method to function.

Parameter 98 – Save to User Default Area Command

When set to a value of 5, the unit will store all adjustable parameters to the user default area. The

user default area is intended to be a location where an OEM or integrator can store settings

specific to their application. Using this, an OEM can easily refresh their custom settings in the

field if an end-user accidentally reconfigures the unit unsuccessfully. Another common use for

this area is testing and initial setup. The user can store known-good settings here and easily

experiment without the fear of losing the optimal configuration.

Parameter 99 – Restore from User Default Area Command

When set to a value of 1, the unit will restore all adjustable parameters from the user default area.

See parameter 98 for additional information.

The

16

Page 19

User Interface for Industrial Conveyor Oven with AC Drive

Description:

An industrial tunnel oven currently uses an AC invertor drive with an attached speedpot to

control the motor which drives its train. Because the process time for the oven is known, it is

preferred that the user be able to set the process time in minutes and seconds on a digital display.

Using a DP4, this is quite simple and requires a minimum amount of installation and training effort

to complete. In this example, a DP4 has been connected to the existing AC invertor drive and

a remote speed select switch which allows the user to select from one of two preprogrammed

time settings (2 or 4 minutes) or to enter a manual mode where the display of the unit can be

directly adjusted using the front panel’s up and down arrow buttons. The desired display range

is from 90 seconds (1:30) to 600 seconds (10:00). Calibration and measurement from the

previously installed speed potentiometer has shown that a voltage output of 30% - 76% of the

applied reference voltage from the AC invertor will produce the desired time range.

Application Diagram:

Application Examples

Oven Speed Select Switch

SPEED 1 SPEED 2

MANUAL

AB

Heat Source

Tunnel Oven

CONTROLS

Tach

Ite

ValuPage

Alarm

FwdNeg

Rev

m

ENTER

6:30

DIGITAL POT

Dart DP4

Contol

Connect to

Coupling

Partner

Motor

Controller

Variable-Frequency

AC Control

Coupling to

Chain Drive

AC Gear Motor

Drive Train Specs:

1380 RPM at non-reduced

motor shaft equates to

6 minutes and 40 seconds

of tunnel time

17

Page 20

Wiring Diagram:

N

L

HI

W

LO

COM

+5V

S1

S2

NO

C

NC

*FUSE

+10V Ref.

Input

-10V Ref.

NOT USED

NOT USED

}

DP4

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

* Size fuse according to unit and application. See

electrical specifications for maximums.

Parameter Configuration:

Parameter Value Notes

10 5

20 90

21 600

25 30

26 76

30 3

31 120

35 3

36 240

Output mode set to time unipolar to support single-direction application

Display minimum set to 90 seconds (1 minut e 30 secon ds )

Display maximum set to 600 seconds (10 minutes)

Set output minimu m to 3 0 %

Set output maximu m to 7 6 %

Input S1 set to force jog w h en low

Input S1 jog setpoint set to 120 seconds (2:00 on the display)

Input S2 set to force jog w h en low

Input S2 jog setpoint set to 240 seconds (4:00 on the display)

VariableFrequency

AC

Control

Speed 1

Speed 2

AC Line 85-265VAC, 50-60 Hz

}

Partner

Motor

Control

Manual

Speed Selector Switch

(3-Position)

Digital Front Panel for Regenerative Industrial Treadmill

Description:

A bidirectional industrial treadmill with a speed range of +/- 12 mph is currently powered by an

analog regenerative control using an external speedpot to adjust the speed. Unfortunately, the

speed pot does not offer enough accuracy and repeatability to allow for proper operation of the

treadmill. A DP4 has been added to the system to give it a quick and easy to use digital front

panel. The DP4 has also been wired to support an external jog switch for rapidly (and

temporarily) setting the belt speed to a predetermined value of 5 mph. An enable switch allows

the user to immediately force the regen to a stopped conditional should it be necessary. For

safety reasons, the unit will default to zero output when power is initially applied.

18

Page 21

Application Diagram:

Treadmill

Belt

Analog

Regenerative

Control

DC

Motor

Wiring Diagram:

DP4

Enable Switch

Enable

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

Disable

N

L

HI

W

LO

COM

+5V

S1

S2

NO

C

NC

CONTROLS

+10V Ref.

-10V Ref.

NOT USED

}

Tach

Ite

ValuPage

Alarm

Rev

FwdNeg

m

12.4

DIGITAL POT

Dart DP4

Control

*FUSE

Analog

Input

Enable Switch

NOT USED

Regenerative

Drive

Jog Switch

Jog

ENTER

AC Line 85-265VAC, 50-60 Hz

}

Partner

Control

Jog Switch

Run

* Size fuse according to unit and application. See

electrical specifications for maximums.

19

Page 22

Parameter Configuration:

Parameter Value Notes

10 3

12 2

13 3

18 1

20 120

21 120

22 0

25 0

26 1000

27 500

35 3

36 50

Output mode set to rate bipolar to support +/-10V regenerative drive

Zero-blanking set to 2 digits

Decimal point position set to XXX.X on display

Power- up display value set to d efault at 0.0

Display minimu m se t to -1 2 .0

Display maxi mu m set to 12.0

Display center set to 0.0

Set output minimum to 0% (-10V)

Set output maximum to 100% (+10V)

Set output center to 50% (0V)

Input S2 set to force j og when low

Input S2 jog setpoint set to 5.0

Programmable Digital Voltage Source with Enable Switch

Description:

A test stand needs an easily adjustable and accurate 0 - 5VDC signal to test the response of

a device under test. The digital display of the voltage source (DP4) should read in 1/100ths of

a volt (V.VV). When the unit initially has power applied, it should always default to an output

voltage of zero volts. When the output is greater than 0 volts, an illuminated alarm should light

and flash to indicate that the device under test is being actuated.

Application Diagram:

Enable Switch

Enable

Disable

D.U.T.

0-5V

Programmable

Output

CONTROLS

ItemValuPage

Rev

3.25

DIGITAL POT

Dart DP4

Device

Under

Test

Tach

Alarm

FwdNeg

ENTER

Pylon-Style

Illuminated

Alarm

20

Page 23

Wiring Diagram:

N

L

HI

W

LO

COM

+5V

S1

S2

NO

C

NC

*FUSE

Enable Switch

NOT USED

NOT USED

DP4

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

* Size fuse according to unit and application. See

electrical specifications for maximums.

Parameter Configuration:

Parameter Value Notes

12 3

13 2

18 1

20 0

21 500

25 0

26 1000

40 2

41 3

48 0

Zero-blanking set to 3 digits

Decimal point position set to XX.XX on display

Power-up dis play value set to default at 0.00

Display minimum se t to 0 . 0 0

Display maximu m set to 5. 0 0

Set output minimum to 0% (0V)

Set output maximum to 100% (5V)

Alarm output ac tive when above upper limit

Alarm output s et to puls e and au to-reset

Alarm upper limit set to activate above valu e of 0

AC Line Input 85-265VAC, 50-60 Hz

}

0-5V Output Voltage

to Device Under Test

120VAC

Illuminated

Pylon-Style

Alarm

21

Page 24

Troubleshooting

Problem Possible Case Solution

Display is blank Power not applied

Using a volt meter, verify that a voltage between 85 and 265VAC is measured between

the L and N terminal block positions.

Defective unit

Display is dim Display intensity

When power is

applied, “LF-L” is

displayed

When power is

applied, “LF-H” is

displayed

The alarm output

does not seem to

function

parameter is too low

AC line supplying

power to unit has too

much noise

AC line supplying

power to unit has an

abnormally low

frequency

AC line supplying

power to unit has too

much noise

AC line supplying

power to unit has an

abnormally high

frequency

Alarm output

parameters not

configured properly

Contact technical support for additional help and instructions.

Editing and increasing the display intensity parameter should cause the display digits to

become brighter.

Review routing of power wires in machine to minimize electrical noise. Look for other

devices which share the same circuit which may be producing unacceptable levels of

line noise. In some applications, such as welding equipment, a careful regiment of

applying an AC line filter, re-routine wires, dividing circuits, using shielded cable, and

properly grounding devices will usually solve the problem.

The unit is designed to operate with AC lines from 48-62 Hertz (cycles per second).

This is typically not a problem because the international standards are 50 and 60 Hertz.

Review routing of power wires in machine to minimize electrical noise. Look for other

devices which share the same circuit which may be producing unacceptable levels of

line noise. In some applications, such as welding equipment, a careful regiment of

applying an AC line filter, re-routine wires, dividing circuits, using shielded cable, and

properly grounding devices will usually solve the problem.

The unit is designed to operate with AC lines from 48-62 Hertz (cycles per second).

This is typically not a problem because the international standards are 50 and 60 Hertz.

Alarm output parameters not configured properly

Review alarm output parameters. The alarm relay output can be tested by selecting

the “Always On” value for the Activation Condition parameters for the alarm output.

When doing this, the relay click should be audible and the NC (Normally Closed) and C

(Common) terminals should become internally shorted at the terminal block.

Technical Support Options

• Visit the Dart Controls Web Site at:

• Email technical support at:

techsupport@dartcontrols.com

• Telephone technical support at 317-733-2133 ext. 4

www.dartcontrols.com

What's Special About www.dartcontrols.com?

• Changes to printed material and product offerings first appear online

• Product manuals and other literature are easily accessible

• All information can be easily displayed or printed as needed

22

Page 25

- Notes -

23

Page 26

- Notes -

24

Page 27

- Notes -

25

Page 28

REPAIR PROCEDURE

Re-Order from

omegamation.com

Omegamation

TM

1-888-55-OMEGA

1-888-55-66342

1-888-55-66342

In the event that a Product manufactured by Dart Controls Incorporated (DCI) is in need of

repair service, it should be shipped, freight paid, to: Dart Controls, Inc., 5000 W. 106th Street,

Zionsville, IN. 46077, ATTN: Repair Department.

Those orders received from anyone without and existing account with DCI will need to specify

if they will be paying COD or Credit Card (Master Card or Visa). This information is required

before work can begin. If you have an account with Dart your order will be processed according

to the terms listed on your account.

Completed repairs are returned with a Repair Report that states the problem with the control

and the possible cause. Repair orders are returned via UPS Ground unless other arrangements

are made. If you have further questions regarding repair procedures, contact your Dart Controls,

Inc. at 317-733-2133 Ext.460.

YOUR MOTOR SPEED CONTROL SOLUTIONS PROVIDER

125D SERIES

AC INPUT - VARIABLE DC OUTPUT

1/50 HP through 1.0 HP

700/COMMUTROL SERIES

DC BRUSHLESS

5 & 20 Amp for

12,24,& 36VDC Inputs

Dart Controls, Inc. is a designer, manufacturer, and

marketer of analog and digital electronic variable speed

drives, controls, and accessories for AC, DC, and DC

brushless motor applica-

tions.

Shown above is just a sampling of the expanded line of

Dart controls that feature the

latest in electronic technology

and engineering. Products are

manufactured in the U.S.A. at

our Zionsville (Indianapolis,

250G SERIES

AC INPUT - VARIABLE DC OUTPUT

1/50 HP through 2.0 HP

MDP SERIES

PROGRAMMABLE

CLOSED LOOP DC

SPEED CONTROL

Indiana) production and headquarters facility - with over

2,000,000 variable speed units

in the field.

In addition to the standard offthe-shelf products, you can select from a wide variety of options to customize controls for

your specific application. For

further information and application assistance, contact your

local Dart sales representative, stocking distributor, or

Dart Controls, Inc.

www.dartcontrols.com

ISO9001:2000 REGISTERED

DC INPUT - VARIABLE DC OUTPUT

CURRENT RATINGS OF 20, 40, AND

60 AMPS

DM SERIES

65 SERIES

FIELD PROGRAMMABLE

DIGITAL TACHOMETER

Dart Controls, Inc.

Manufacturer of high quality DC and AC motor speed

controls and accessories

since 1963.

P.O. Box 10

5000 W. 106th Street

Zionsville, Indiana 46077

Phone: (317) 733-2133

Fax: (317) 873-1105

Loading...

Loading...