Page 1

User’s Guide

http://www.omega.com

e-mail: info@omega.com

DP3410 & DP3411 SERIES

W all Mount

Universal T emperature & Pr ocess

Indicators

Page 2

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship

for a period of 37 months from date of purchase. OMEGA Warranty adds an additional one (1)

month grace period to the normal three (3) year product warranty to cover handling and

shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written

request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or

replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of

the purchaser, including but not limited to mishandling, improper interfacing, operation outside of

design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit

shows evidence of having been tampered with or shows evidence of having been damaged as a

result of excessive corrosion; or current, heat, moisture or vibration; improper specification;

misapplication; misuse or other operating conditions outside of OMEGA’s control. Components

which wear are not warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability

for any damages that result from the use of its products in accordance with information

provided by OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER

WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR

IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth

herein are exclusive, and the total liability of OMEGA with respect to this order, whether

based on contract, warranty, negligence, indemnification, strict liability or otherwise,

shall not exceed the purchase price of the component upon which liability is based. In

no event shall OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a

“Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or

(2) in medical applications or used on humans. Should any Product(s) be used in or with any

nuclear installation or activity, medical application, used on humans, or misused in any way,

OMEGA assumes no responsibility as set forth in our basic WARRANTY / DISCLAIMER language,

and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability

or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN

ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the

outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR WARRANTY

RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the

product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific problems

relative to product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1998 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied,

photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in

whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the COST of

the repair,

2. Model and serial number of the products, and

3. Repair instructions and/or specific problems

relative to the product.

consult

Page 3

GETTING STARTED

This manual is divided into 5 sections which contain all the information needed to

install, configure, set up and operate the instrument. Each section is identified

clearly by a symbol as shown below.

Displays and Controls

• Displays and function keys

• LED Indication

• Error Messages

Operator Mode (Level 1)

• Operator menus for:

– Standard Indicator

– Totalizer/Batch Controller

– Maximum/Minimum/Average Indicator

8

Set Up Mode (Level 2)

• Alarm trip points

• Totalizer functions

Configuration Mode (Levels 3 and 4)

• Accessing the configuration levels

• Level 3

– Hardware assignment and input type

– Alarm types and hysteresis

– Operator functions and totalizer setup

– Digital input and serial communications

• Level 4

–

Ranges and passwords

Installation

• Siting

• Mounting

• Electrical connections

Symbol Identification and Section Contents

1

Page 4

CONTENTS

1 DISPLAYS AND FUNCTION KEYS ................................................................ 3

1.1 Introduction .............................................................................................. 3

1.2 Use of Function Keys .............................................................................. 4

1.3 LED Alarms and Indicators ..................................................................... 5

1.4 Error Messages ....................................................................................... 6

2 OPERATOR MODE ......................................................................................... 7

2.1 Introduction .............................................................................................. 7

2.2 Operating Page – Standard .................................................................... 8

2.3 Operating Page – Totalizer ..................................................................... 9

2.4 Operating Page – Math Functions ........................................................ 11

3 SET UP MODE ............................................................................................... 13

3.1 Introduction ............................................................................................ 13

3.2 Set Up Level .......................................................................................... 14

4 CONFIGURATION MODE ............................................................................. 18

4.1 Introduction ............................................................................................ 18

4.2 Accessing the Configuration Mode ....................................................... 18

4.3 Basic Configuration (Level 3)................................................................ 20

4.3.1 Hardware Assignment and Input Type ...................................... 20

4.3.2 Alarms ........................................................................................ 22

4.3.3 Operator Functions and Totalizer Set Up ................................. 26

4.3.4 Digital Input and Serial Communications .................................. 28

4.4 Ranges and Passwords (Level 4) ......................................................... 30

5 INSTALLATION ............................................................................................. 33

5.1 Siting .................................................................................................... 33

5.2 Mounting ................................................................................................ 35

5.3 Cable Glands and Conduit Fixings ....................................................... 37

5.3.1 Cable Glands (IEC – 20mm) ..................................................... 37

5.3.2 Conduit Adapters (N. American – 0.5 in.) ................................. 37

5.3.3 Cable Glands (N. American – 0.5 in.) ....................................... 38

5.4 Electrical Connections........................................................................... 39

5.4.1 Relay Contact Ratings ............................................................... 39

5.4.2 Arc Suppression......................................................................... 39

5.4.3 Logic Output ...............................................................................39

5.4.4 Control or Retransmission Analog Output ................................ 39

2

Page 5

1 DISPLAYS AND FUNCTION KEYS

Information.

The fold-out page inside on the back cover of this

manual shows all the frames in the programming

levels. Space is provided on the page for writing the

programmed setting or selection for each frame.

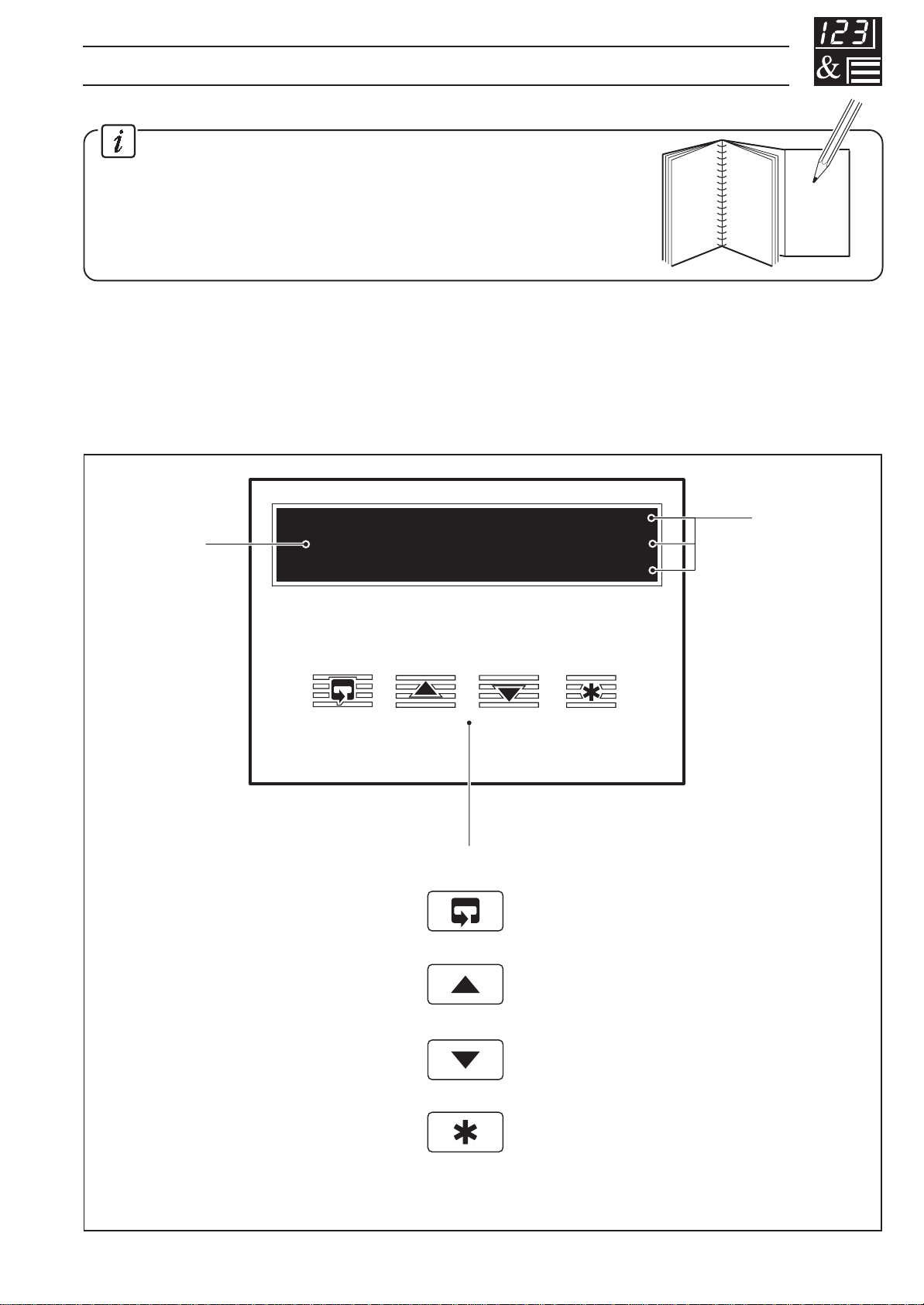

1.1 Introduction – Fig. 1.1

The instrument front panel display, function keys and LED indicators are shown in

Fig. 1.1.

Display

888888

Function Keys

Parameter Advance

A1

A2

A3

Alarm LEDs

(invisible

when off)

Raise

Lower

Multi-function Key

Fig. 1.1 Front Panel Display, Function Keys and Indicators

3

Page 6

…1 DISPLAYS AND FUNCTION KEYS

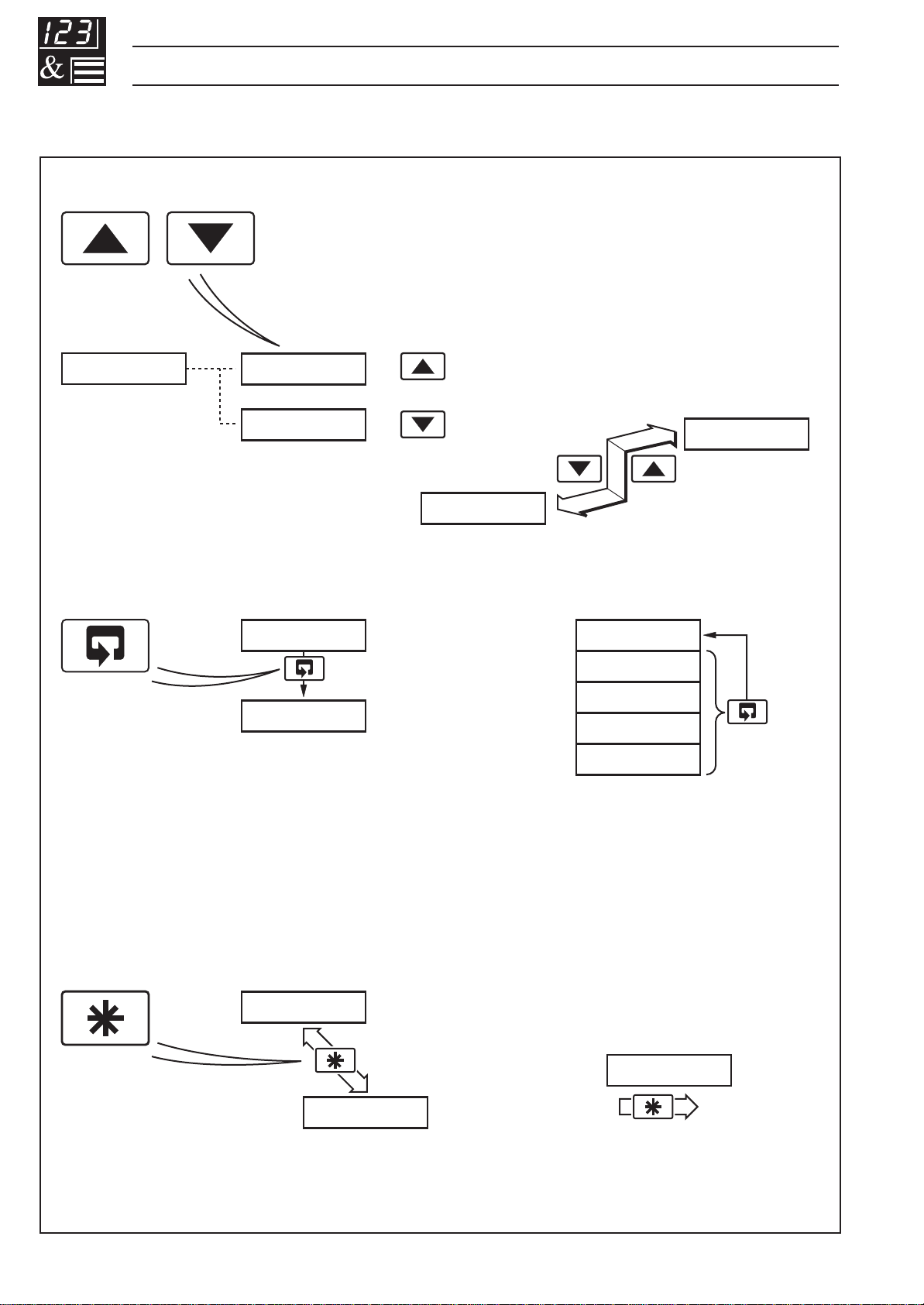

1.2 Use of Function Keys – Fig. 1.2

A – Raise and Lower Keys

100.0 100.1

99.9

Use to change/set a parameter value…

B – Parameter Advance Key

+

–

LEVEL1

100.1

Use to advance to the next

frame within a level…

or…

LEVEL1

Frame 1

(top of level)

Frame 2

…move between levels

LEVELx

100.1

or…

200.2

300.3

400.4

…select the top (LEVEL) frame

from within a level

LEVEL2

Press and

hold

Note. This key also stores any changes made in the previous frame

C – Multi-function Key

CodE

0

Use to view a parameter setting or selection…

Fig. 1.2 Use of Function Keys

4

or…

…select individual characters in a frame

123456

Page 7

1 DISPLAYS AND FUNCTION KEYS…

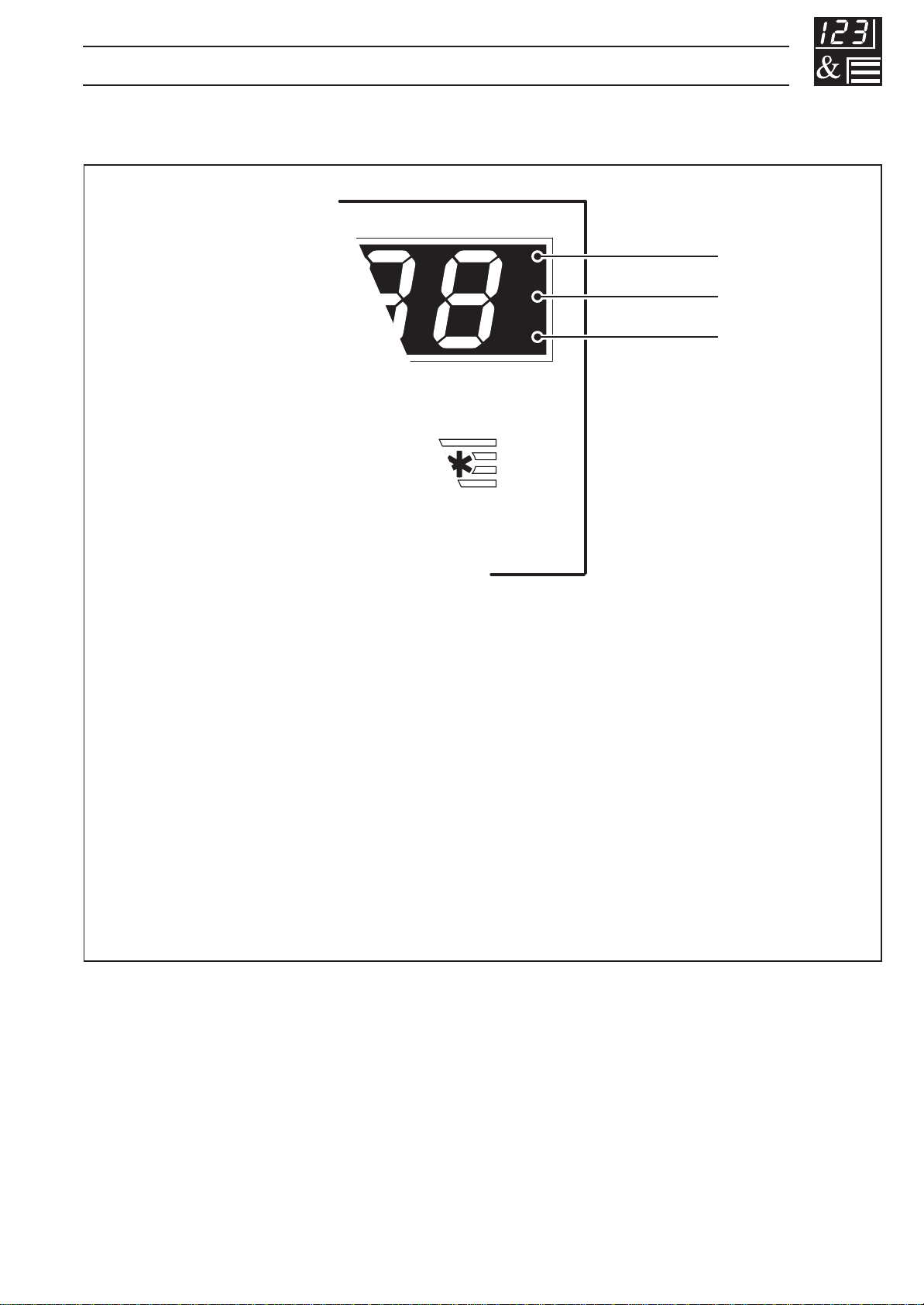

1.3 LED Alarms and Indicators

Alarm LEDs

LED Status

All Flashing

• Indicator is in the Configuration Mode – see Section 4.2.

A1

A2

A3

Alarm 1

Alarm 2

Alarm 3

A1, A2 and A3

• Flash when Alarm is active (off when inactive).

• Lit constantly when Alarm 1 is an active latched alarm which has

been acknowledged

Fig. 1.3 LED Alarms and Indicators

5

Page 8

…1 DISPLAYS AND FUNCTION KEYS

1.4 Error Messages

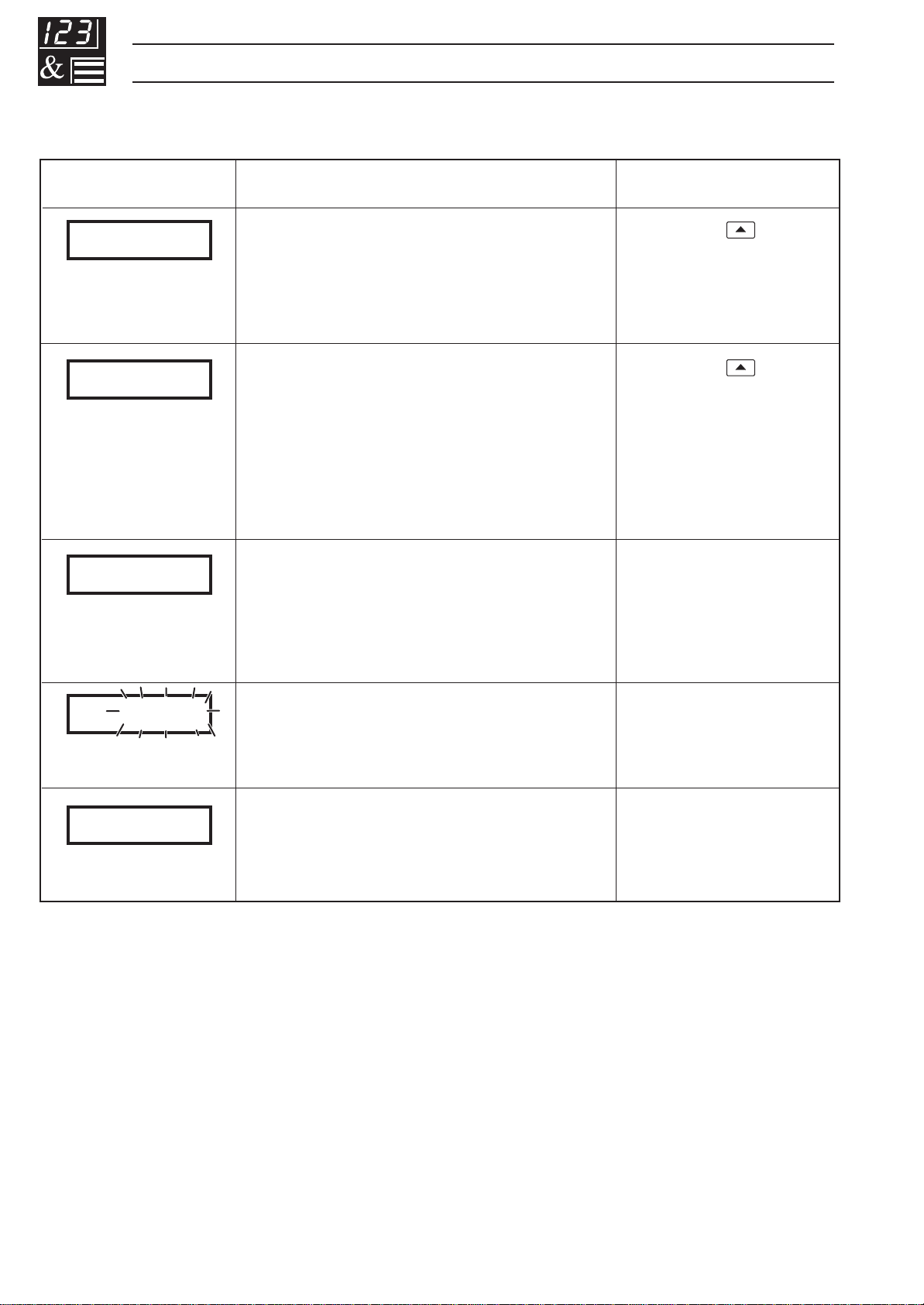

Display Error/Action

Calibration error

CALErr

Turn power off and on again (if the

error persists contact the Service

Organization).

Configuration error

CFGErr

The configuration and/or set up

data for the instrument is

corrupted. Turn power off and on

again (if error persists, check

configuration/set up settings).

A to D Converter fault

Ad Err

The analog to digital converter is

not communicating correctly.

To Clear Display

Press the

Press the key

Turn mains power

off and on again. If

the error persists,

contact the Supplier.

key

9999

DPtErr

Process variable over/under

range

Option board error

Communications to the option

board have failed.

Restore valid

input

Contact the Supplier

6

Page 9

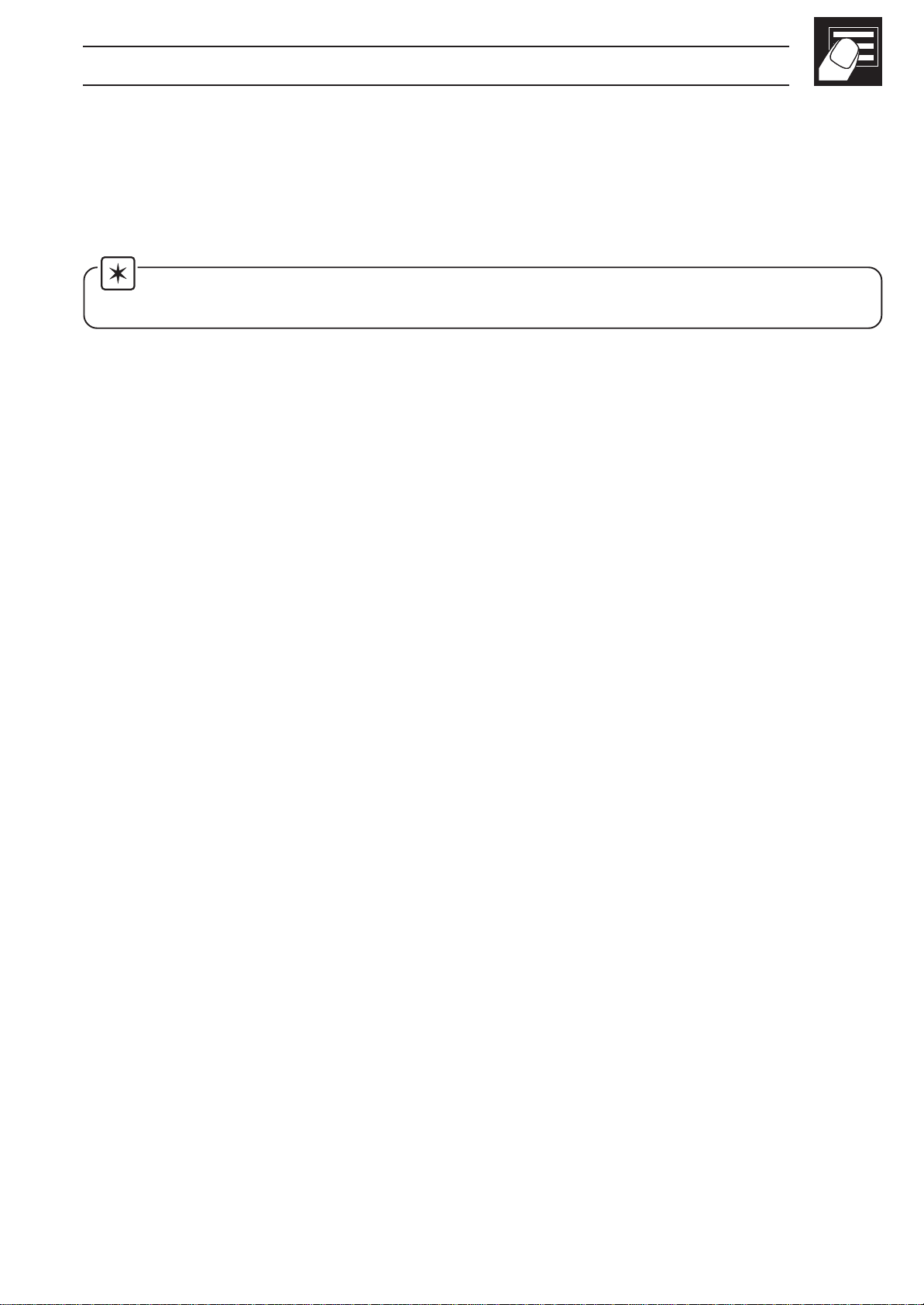

2 OPERATOR MODE

2.1 Introduction

Operator Mode (Level 1) is the normal day-to-day mode of the instrument.

Frames displayed in Level 1 are determined by the indicator functions which are

selected during configuration of the instrument – see Section 4.

Note. Only the operating frames relevant to the configured functions are

displayed in Operator Mode.

The three indicator functions are:

• Standard Indicator – page 8

• Indicator with Totalization – page 9

• Indicator with Max./Min./Average – page 11

7

Page 10

…2 OPERATOR MODE

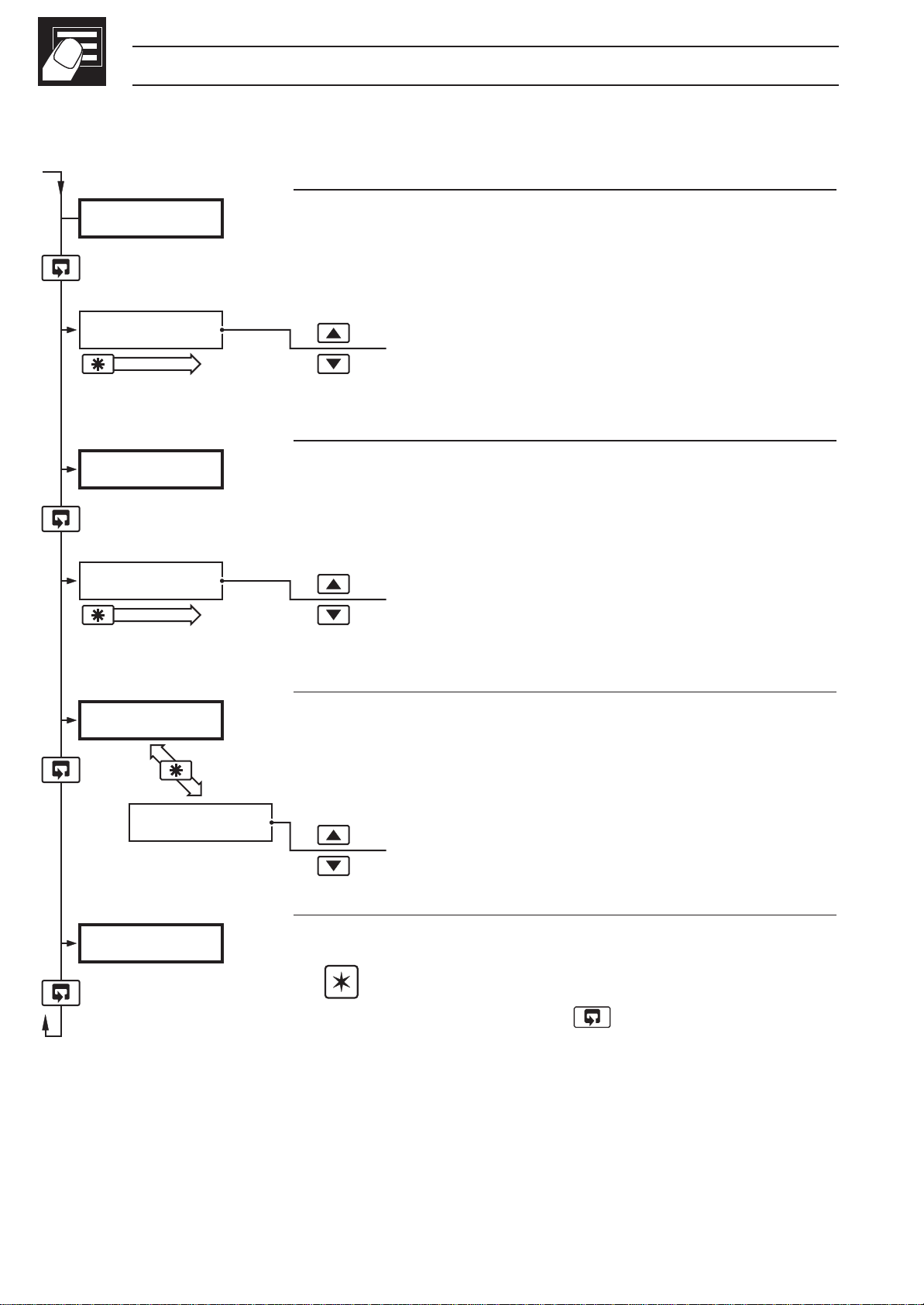

2.2 Operating Page – Standard (Level 1)

2145.3

UN-ACK

CodE

Process Variable

Normally displayed in engineering

2145.3

units.

To view the process variable in

27.6

•1

Global Alarm Acknowledge (latch alarms only)

UN-ACK. – alarm unacknowledged

ACK. – acknowledged

Security Password

Enter the correct password to access the set up level

electrical units, press the

key.

(Level 2) or the configuration level (Levels 3 and 4).

The default code is 0.

------

[0 to 9999]

Level 1

LEVEL1

Note. To select this frame from anywhere in this

level, press and hold the

•1 Only displayed if there is an active latch alarm.

key.

8

Page 11

2 OPERATOR MODE…

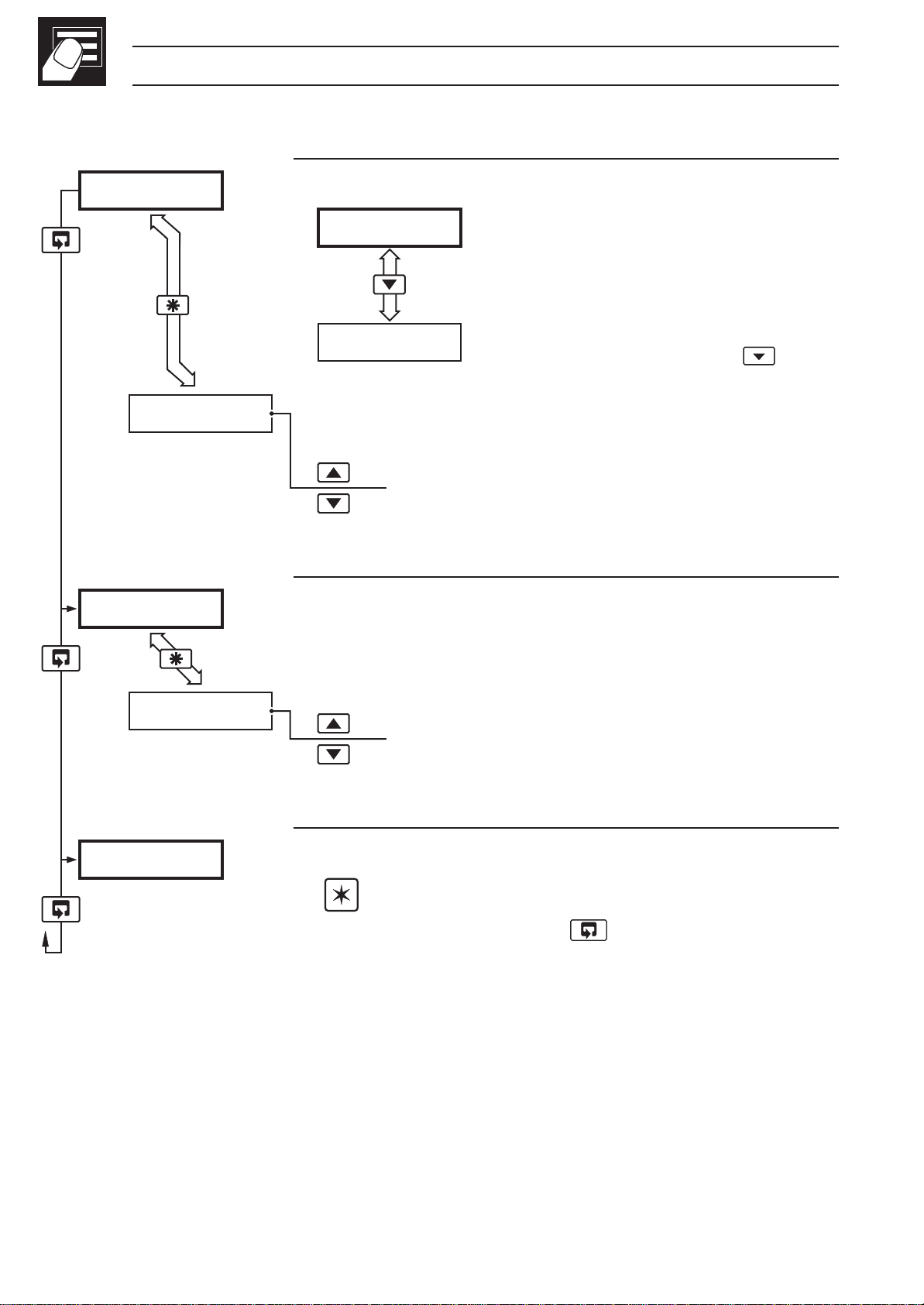

2.3 Operating Page – Totalizer (Level 1)

These frames are only displayed if the totalizer function is enabled in the

configuration level – see Section 4.3.3

2145.3

ACK-n

123456

rSt-n

•1

•1

Process Variable

To view the input value (in electrical units), press the

key.

Global Alarm Acknowledge (latch alarms only)

UN-ACK. – alarm unacknowledged

ACK. – acknowledged

Totalizer Value

When this frame is selected, the current counter

status is displayed (

Stop/Start

t–GO or t-StOP).

t–GO – start totalizer

t-StOP – stop totalizer

Reset

rSt-Y – reset totalizer

rSt-n – do not reset totalizer

To reset the totalizer, select

key.

Continued on next page.

•1 Totalizer stop/go and reset from these frames can be disabled – see

Section 4.3.3.

A digital input can also be used to start/stop or reset the totalizer – see

rSt-Y, then press the

Section 4.3.4

9

Page 12

…2 OPERATOR MODE

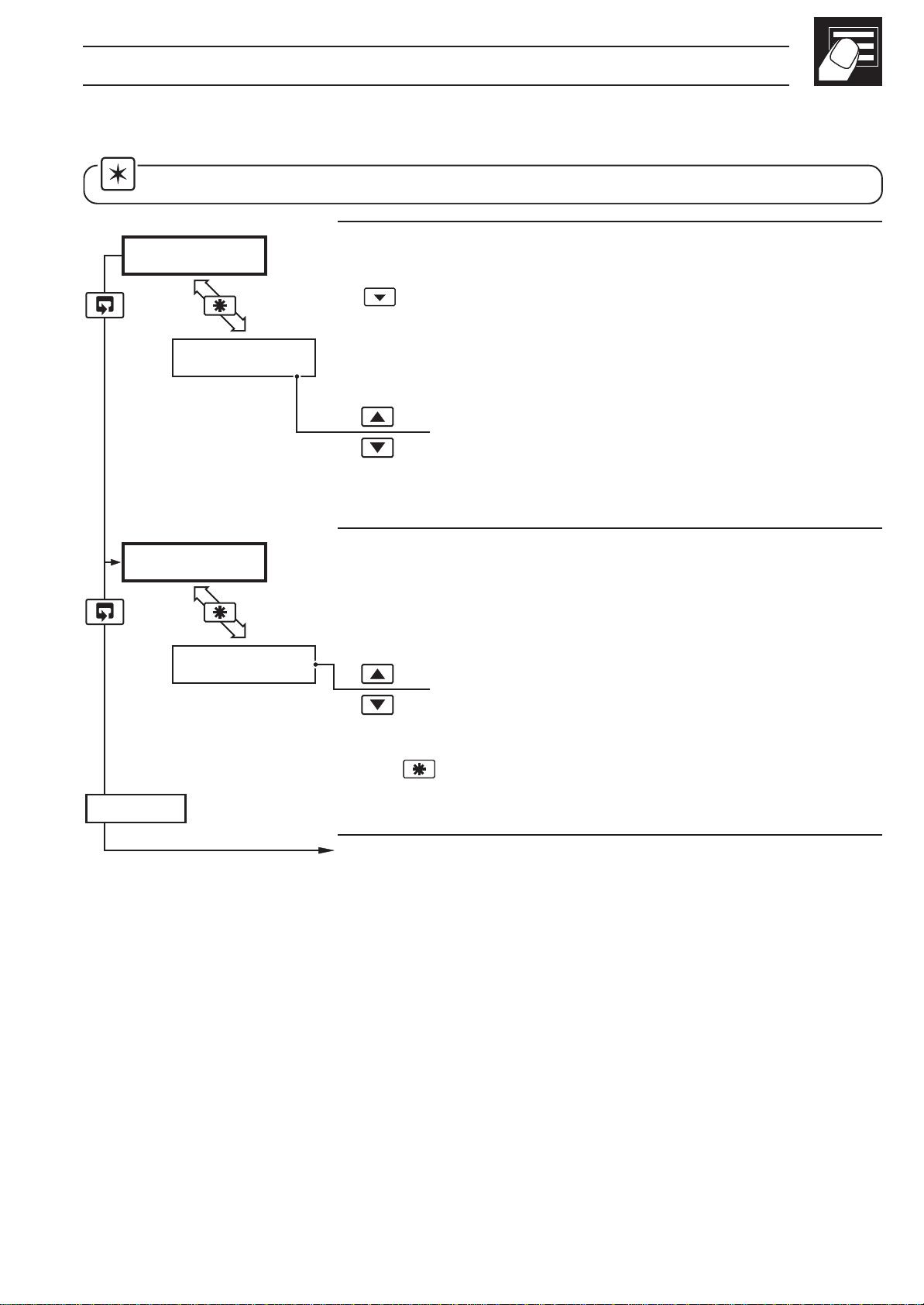

…2.3 Operating Page – Totalizer (Level 1)

PrESEt

000000

Select Digit

PrEdEt

999999

Select Digit

•2

Preset Total

This is the value the batch total is set to when it is reset

•1

[000000 to 999999 flow units]

Predetermined Total

When the predetermined total is reached, the batch

total is reset (with wrap on) or stops (wrap off),

depending on the wrap setting – see Section 4.3.3.

•1

[000000 to 999999 flow units]

CodE

Security Password

Enter the correct password to access the set up level

or the configuration level.

------

[0 to 9999]

LEVEL

•1 The predetermined value should be greater than the preset value when the

totalizer is counting up and lower than the preset value when the totalizer is

Level 1

Note. To select this frame from anywhere in this

page, press and hold the

key.

counting down.

•2 Only displayed if enabled in the configuration level – see Section 4.3.3.

10

Page 13

2 OPERATOR MODE…

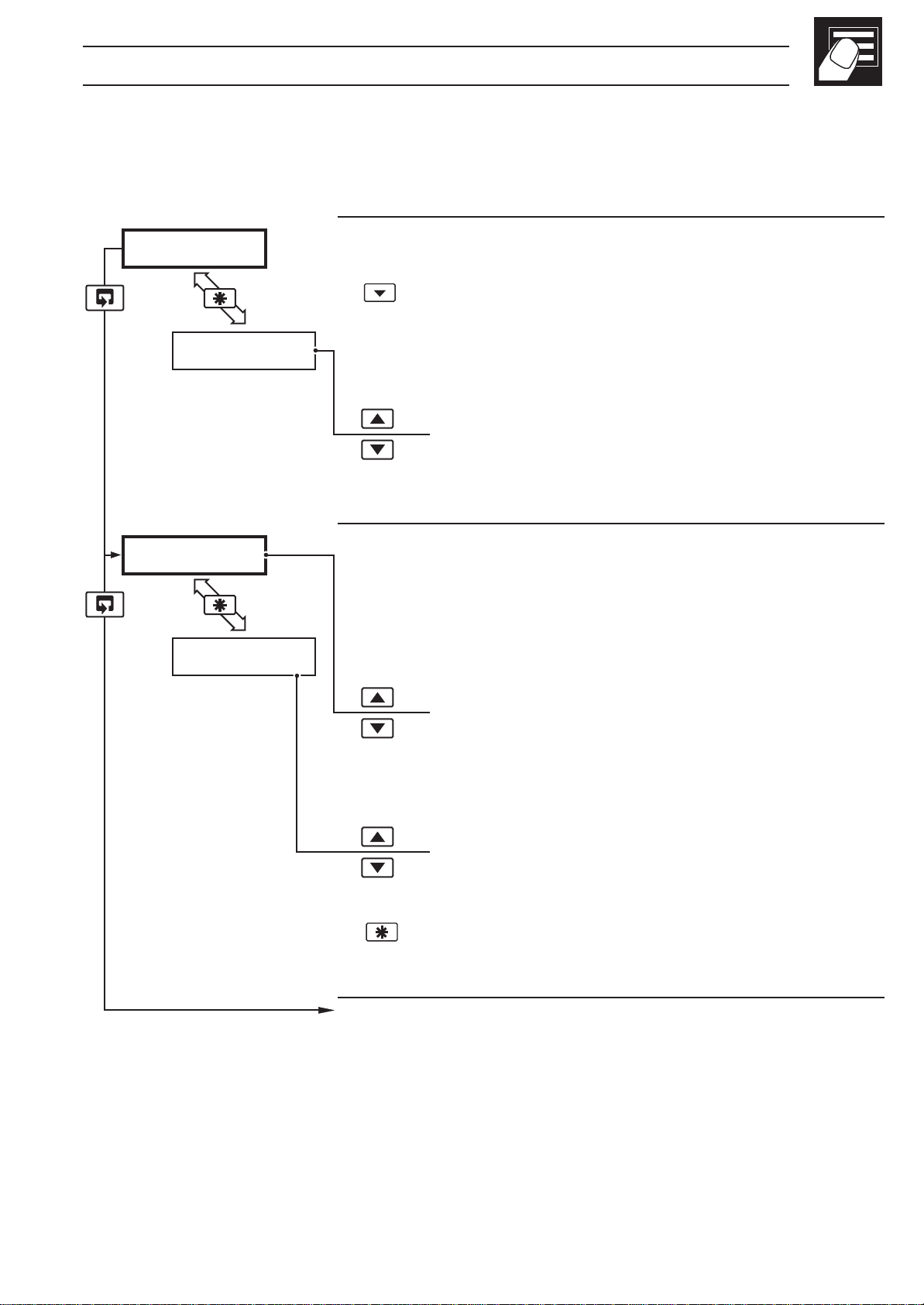

2.4 Operating Page – Max./Min./Average Functions (Level 1)

Note. It is possible to display totalizer and math functions together.

Process Variable

2145.3

To view the input value (in electrical units), press the

key.

UN-ACK

Global Alarm Acknowledge (latch alarms only)

UN-ACK. – alarm unacknowledged

ACK. – acknowledged

A 140.5

•1

rSt-n

Average Value

This is the mean average value of the process

variable input, since the average was last reset.

rSt-Y – reset

rSt-n – do not reset

To reset the average value, select

the

key.

H150.2

Continued on next page.

•1 This frame can be disabled – see Section 4.3.3.

The reset function in this frame can be disabled – see Section 4.3.3.

rSt-Y then press

The average value is reset automatically on power-up, and can also be reset

from a digital input – see Section 4.3.4.

11

Page 14

…2 OPERATOR MODE

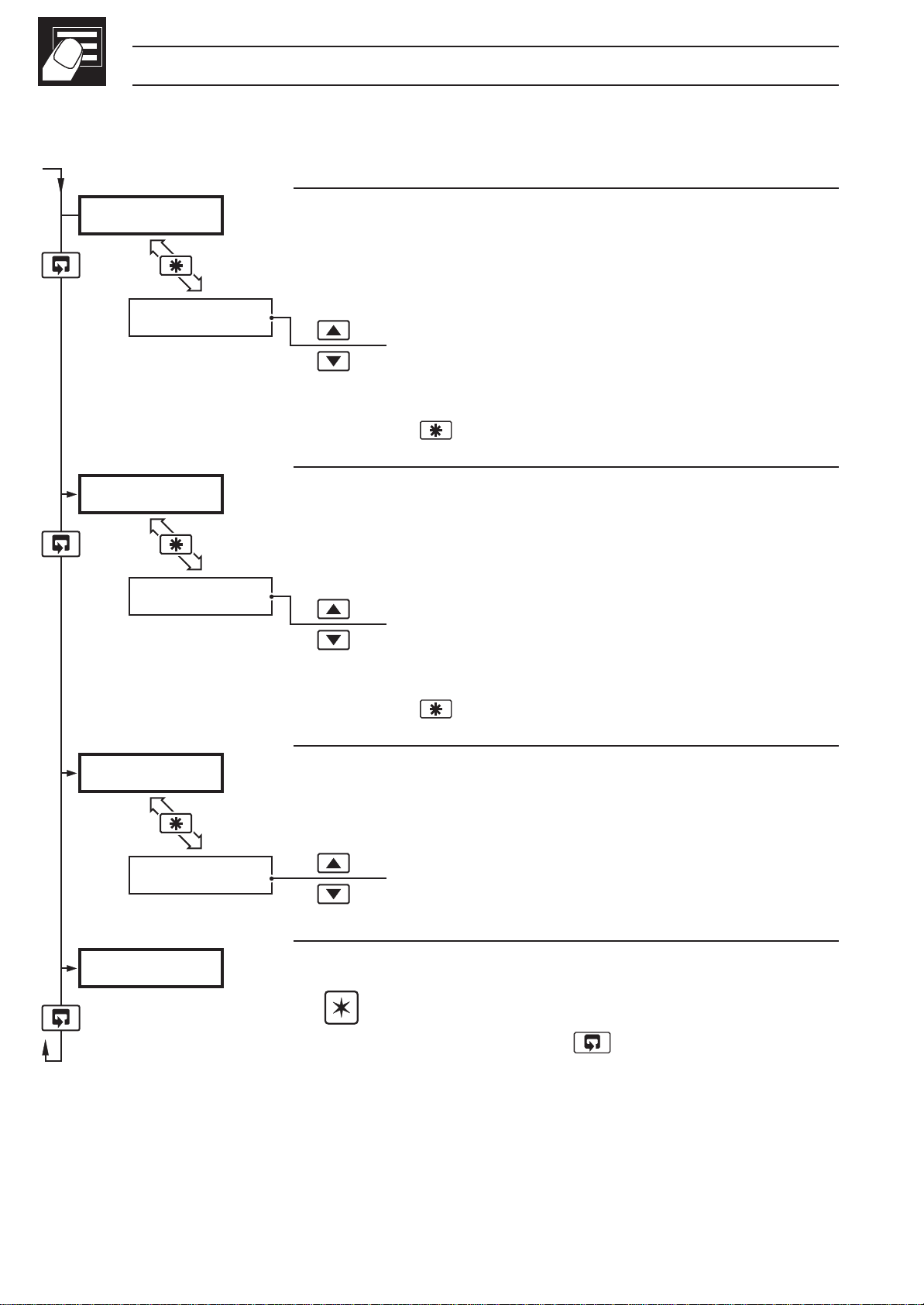

…2.4 Operating Page – Math Functions (Level 1)

H150.2

rSt-n

L130.8

rSt-n

•1

•1

Maximum Value

This is the maximum value of the process variable

since the maximum was reset.

rSt-Y – reset

rSt-n – do not reset

To reset the maximum value, select

press the

Minimum Value

This is the minimum value of the process variable

since the minimum was reset.

rSt-Y – reset

rSt-n – do not reset

key.

rSt-Y then

To reset the minimum value, select

press the

CodE

------

LEVEL1

•1 This frame can be disabled – see Section 4.3.3.

Security Code

Enter the correct code to access the set up level or the

configuration level.

[0 to 9999]

Level 1

Note. To select this frame from anywhere in this

page, press and hold the

key.

rSt-Y then

key.

12

The reset function in this frame can be disabled – see Section 4.3.3.

The average value is reset automatically on power-up, and can also be reset

from a digital input – see Section 4.3.4.

Page 15

3 SET UP MODE

8

3.1 Introduction

To access the Set Up Level (Level 2) the correct set up or configuration level

password must be entered in the security password frame (

– see Sections 2.2 to 2.4.

LEVEL2

A1xx

Level 1 –

Operating Level

LEVEL1

Correct

Password

A2xx

A3xx

Security

Password

CodE x

123456

t-GO

SEC.tot

CodE) in Level 1

Level 2 – Set Up

Alarm 1 Trip Point

Alarm 2 Trip Point

Alarm 3 Trip Point

Batch Total

Totalizer Stop/Go

Secure Total/Reset

PrESEt

PrEdEt

A xxxx

H xxxx

L xxxx

0AdJ

Fig. 3.1 Accessing the Set Up Level (Level 2)

Preset Batch Total

Predetermined

Batch Total

Average Value

Maximum Value

Minimum Value

Offset Adjustment

13

Page 16

8

3.2 Set Up Level (Level 2)

…3 SET UP MODE

LEVEL2

A1hP

100.1

A1 HYS

•1

•2

Level 2

Note. To select this frame from anywhere in this

level, press and hold the

Alarm 1 Trip Point

Alarm type:

Process and Latched Alarms in Eng. units.

Rate Alarms ±0.5 to 500% of Eng. Span/hr.

Alarm 1 Hysteresis Value

A1.hP = High process

A1.LP = Low process

A1.HL = Latched high process

A1.LL = Latched low process

A1.Fr = Fast Rate

A1Sr = Slow Rate

key.

A2LP

A2 HYS

A3hP

12.5

200.2

27.9

•1

•2

[In engineering units]

Alarm 2 Trip Point

Alarm type

[In engineering units]

Alarm 2 Hysteresis Value

[In engineering units]

Continued on next page.

•1 Not displayed if the alarm is disabled ('NONE' selected) – see Section 4.3.2.

•2 Only displayed if custom alarm hysteresis is selected – see Section 4.3.2

Not displayed if 'Rate' Alarm type is selected.

14

Page 17

…3.2 Set Up Level (Level 2)

3 SET UP MODE…

8

A3hP

300.3

A3 HYS

34.6

123456

•1

•2

•3

•4

Alarm 3 Trip Point

Alarm type

[In engineering units]

Alarm 3 Hysteresis Value

[In engineering units]

Totalizer Value

rSt-Y – reset

rSt-n – do not reset

rSt-n

rSt-Y, then

t-GO

•3

To reset the maximum value, select

press the

Totalizer Stop/Go

t–GO – start totalizer

t-StOP – stop totalizer

key.

t-StOP

Setting to

the predetermined value. Setting to

the totalizer at its present value.

SEC.tOt

Continued on next page

•1 Not displayed if the alarm is disabled ('NONE' selected) – see Section 4.3.2

t-GO starts the totalizer counting towards

t-StOP holds

•2 Only displayed if custom alarm hysteresis is selected – see Section 4.3.2

Not displayed if 'Rate' Alarm type is selected.

•3 Only displayed if enabled in the Configuration Level – see Section 4.3.3

•4 A digital input can also be used to reset the batch total.

15

Page 18

8

…3.2 Set Up Level (Level 2)

…3 SET UP MODE

SECtOt

456789

rSt-n

PrESEt

•1

•2

Secure Total

The secure total is independent of the batch total value.

When 999999 or 000000 is reached, the total is reset

and then continues counting.

Total

Reset

rSt-Y – reset totalizer

rSt-n – do not reset totalizer

To reset, select

Preset Batch Total

This is the value the batch total is set to when it is reset.

rSt-Y then press the key.

[000000 to 999999]

000000

•2

Predetermined Batch Total

PrEdEt

When this value is reached the batch total either resets

(with wrap on) or stops (wrap off) – see Section 4.3.3.

999999

A140.5

Continued on next page.

•1 Only displayed if enabled in the Configuration Level – see Section 4.3.3.

[000000 to 999999]

•2 The preset value must be lower than the predetermined value when

counting up, and greater than the predetermined value when counting down.

16

Page 19

…3.2 Set Up Level (Level 2)

3 SET UP MODE…

8

A140.5

rSt-n

H150.2

rSt-n

•1

•2

Average Value

This is the mean average value of the process variable

input since the average was reset.

rSt-Y – reset

rSt-n – do not reset

To reset, select

Maximum Value

This is the maximum value of the process variable

since the maximum was reset.

rSt-Y – reset

rSt-n – do not reset

To reset, select

rSt-Y then press the key.

rSt-Y then press the key.

L130.8

rSt-n

OAdJ

1.0

•2

Minimum Value

This is the minimum value of the process variable since

the minimum was reset.

rSt-Y – reset

rSt-n – do not reset

To reset, select

Offset Adjustment

An offset can be applied to the process variable input to

enable spot calibration or the removal of system errors.

[±10% of engineering range]

rSt-Y then press the key.

•1 The average value i s reset automatically on power-up and can also be reset

from a digital input – see Section 4.3.4.

•2 The maximum and minimum values are reset automatically on power-up and

can also be reset from a digital input – see Section 4.3.4.

17

Page 20

4 CONFIGURATION MODE

4.1 Introduction

The Configuration Mode comprises two levels (3 and 4) as shown in Fig. 4.2.

Configuration Level 3 is divided into four frames. For most simple applications it is

only necessary to set up the parameters in the first frame.

Note.

When in the configuration level:

• All the LED indicators flash.

• All relays and logic outputs are turned off.

• The analog output reverts to 0% (4mA) output level.

4.2 Accessing the Configuration Mode – Fig. 4.1

The Configuration Mode is accessed by entering the correct password in Level 1

(see Sections 2.2 to 2.4). The configuration password is set up in Level 4.

LEVEL4

Level 1 –

Operating Level

LEVEL3

LEVEL2

LEVEL1

Correct

CodE x

Security

Password

Fig. 4.1 Accessing the Configuration Level (Levels 3 and 4)

Password

18

Page 21

4 CONFIGURATION MODE…

Level 3

Hardware

Configuration

Alarms and

Set Points

Custom Operator

Settings

LEVEL3

A 1KC0

b 1KC0

C 1KC0

d 1KC0

E 0000

F 0000

G 0000

H 0000

J 0000

K 0000

L 0000

N 0000

LEVEL4

ENG HI

ENG LO

rEt HI

rEt LO

CNt HI

CUtOFF

S-PASS

Level 4

Engineering

Range High

Engineering

Range Low

Retransmission

Range High

Retransmission

Range Low

Totalizer Count

High

Totalizer Count

Cut-Off

Set Up Level

Password

Digital Input and

Serial Comms.

P 0000

r 0000

S 0000

t 0000

Fig. 4.2 Configuration Levels

C-PASS

Addr.

Configuration

Level Password

MODBUS Address

19

Page 22

…4 CONFIGURATION MODE

4.3 Basic Configuration (Level 3) – Fig. 4.3

4.3.1 Hardware Assignment and Input Type

LEVEL3

A 1KC0

B 1KC0

C 1KC0

d 1KC0

Level 3

Note. To select this frame from anywhere in this

level, press and hold the

'ABCD' Settings

The first character (A, B, C or D) identifies the

parameter to be changed. The current setting is

indicated by a flashing letter. Parameter options are

shown in Fig. 4.3.

key for a few seconds.

A = Hardware configuration

b = Input type and range

C = Temperature units

d = No. of decimal points

E 1203

Continued on page 22.

Information.

Count High Calculation

Convert flow rate into units/sec =

Count High = resultant must be >0.001 and <99.999pps.

Counter factor is the engineering value of the least significant digit shown on

the totalizer display – see Section 4.3.3.

Totalizer Count Pulse

The totalizer count pulse is on for a preset time of 250ms and off for a minimum

of 250ms.

units/sec

counter factor

actual engineering flow rate

flow range time units (in seconds)

20

Page 23

4 CONFIGURATION MODE…

A 1KC0

A – Hardware Configuration

Supply Hz Relay 1 Relay 2 Relay 3* Logic O/P Analog O/P

50 60

1AAlarm 1 Alarm 2 Alarm 3 TCP** PV

2bAlarm 1 Alarm 2 Alarm 3 TWP** PV

3CTCP** Alarm 1 Alarm 2 TWP** PV

4DTWP** Alarm 1 Alarm 2 TCP** PV

5EAlarm 1 Alarm 2 Alarm 3 TCP** PV Average

U Custom Custom Custom Custom Custom

TCP = Totalizer Count Pulse TWP = Totalizer Wrap Pulse PV = Process Variable

* Not available if MODBUS option fitted.

** Pulse energizes assigned relay

Source Source Source Source Source

B – Input Type and Range Configuration

b 1KC0

Display

b T/C Type B

E T/C Type E

J T/C Type J

K T/C Type K

n T/C Type N

r T/C Type R

S T/C Type S

t T/C Type T

P PT100 RTD

C – Temperature Units

C 1KC0

Display Temperature Units

C Degrees C*

F Degrees F*

0 No temperature units

* Temperature inputs only

Display

1 0 to 20 mA

2 4 to 20 mA

3 0 to 5 V

4 1 to 5 V

6 0 to 50 mV

7 4 to 20 mA (square root linearizer)

U Custom Configuration

d 1KC0

Display

0 xxxx

1 xxx . x

2 xx . xx

3 x . xxx

4 x . xxxx

D – Process Variable

Display Decimal Places

Fig. 4.3 Hardware Configuration and Input/Output Ranges

21

Page 24

…4 CONFIGURATION MODE

4.3.2 Alarms – Figs. 4.4, 4.5 and 4.6

Note. All relays are de-energized in the alarm state.

'EFGH' Settings

E 0000

F 0000

G 0000

The first character (E, F, G or H) identifies the

parameter to be changed. The current setting is

indicated by a flashing letter. Parameter options are

shown in Fig. 4.4.

E = Alarm 1 type

J 0000

H 0000

F = Alarm 2 type

G = Alarm 3 type

H = Alarm hysteresis

Continued on page 26.

22

Page 25

4 CONFIGURATION MODE…

E 0000

E – Alarm 1 Type

Display

0 None

1 High Process

2 Low Process

3 High Latch

4 Low Latch

5 Fast Rate

6 Slow Rate

F – Alarm 2 Type

F 0000 G 0000

Display

0 None

1 High Process

2 Low Process

3 High Latch

4 Low Latch

5 Fast Rate

6 Slow Rate

Display

0 None

1 High Process

2 Low Process

3 High Latch

4 Low Latch

5 Fast Rate

6 Slow Rate

G – Alarm 3 Type

h 0000

Display

0 None

1 0.1%

2 0.2%

3 0.5%

4 1.0%

5 2.0%

6 5.0%

U Custom

H – Alarm Hysteresis

Value in % of

engineering range

Value in engineering units

Fig. 4.4 Alarm Set Up

Note. When custom

alarm hysteresis is selected,

the alarm hysteresis values are

set individually in the

Level – see Section 3.2.

Set Up

23

Page 26

…4 CONFIGURATION MODE

…4.3.2 Alarms – Figs. 4.4, 4.5 and 4.6

Hysteresis

Hysteresis

Process

Variable

Alarm on

(Relay

de-energized)

Alarm off

(Relay

energized)

High Process

Low Process

Trip point

Alarm on

(Relay

de-energized)

Alarm off

(Relay energized)

Information.

For latch alarms, the relay remains de-energized until acknowledged in

Level 1 (or by a digital input).

Fig. 4.5 Process Alarm Action

24

Page 27

% Engineering Range

100

50

4 CONFIGURATION MODE…

10

Hours

12 3 4

t (191 secs)

Alarm On

(Relay de-energized)

Alarm Off

(Relay energized)

Information. The example above shows a fast rate alarm with a trip

value of 10% of the engineering span per hour on an engineering range of

0.0 to 100.0. The time taken to detect whether an alarm condition is

present or has cleared is calculated as follows:

t (191 secs)

5

t = 10.81 +

trip value (10% eng. span per hour)

t = 191 seconds

Fig. 4.6 Rate Alarm Action

1800

25

Page 28

…4 CONFIGURATION MODE

4.3.3 Operator Functions and Totalizer Set Up – Fig. 4.7

'JKLN' Settings

J 0000

K 0000

L 0000

The first character (J, K, L or N) identifies the

parameter to be changed. The current setting is

indicated by a flashing letter. Parameter options are

shown in Fig. 4.7.

J = Totalizer set-up

P 0000

n 0000

K = No. of decimal places for totalizer

L = Operator level frame enable

n = Operator level functions enable/disable

Continued on page 28.

26

Page 29

4 CONFIGURATION MODE…

J 0000

Display

0 Off

1 Count Up, Wrap Off

2 Count Up, Wrap On

3 Count Down, Wrap Off

4 Count Down, Wrap On

J – Totalizer Set Up

L – Operator Level Frame Enable

K 0000

Display

0 xxxxxx

1 xxxxx.x

2 xxxx.xx

3 xxx.xxx

4 xx.xxxx

5 x.xxxxx

K – Totalizer Display

Decimal Places

L 0000

Display Max/Min Values Average Value Preset/Predetermined

Displayed Displayed Values Displayed

0 No No No

1 Yes No No

2 Yes Yes No

3 No Yes Yes

4 No No Yes

5 Yes No Yes

6 Yes Yes Yes

This frame determines which frames appear in the operating page (Level 1)

N – Operator Level Math Function & T otalizer Control Enable

n 0000

Display Totalizer Stop/Go Totalizer Reset Max./Min./Average

0 No No No

1 Yes No No

2 No Yes No

3 Yes No Yes

4 No Yes Yes

5 Yes Yes Yes

This frame determines which functions the operator can control

Fig. 4.7 Totalizer Set Up and Operator Functions

27

Page 30

…4 CONFIGURATION MODE

4.3.4 Digital Input and Serial Communications – Figs. 4.8 and 4.9

'PRST' Settings

P 0000

r 0000

The first character (P, R, S or T) identifies the

parameter to be changed and the current setting is

indicated by a flashing letter. Parameter options are

shown in Fig. 4.9.

S 0000

P = Digital input function

LEVEL4

t 0000

1 Totalizer Reset

r = Analog input filter

S = Serial communications configuration

t = Serial communications parity

Continued on page 30.

Reset

Stop

Lock

Unlock

4 Front Panel Lock out

Acknowledge

28

Go

2 Totalizer Stop/Go

Max

Min

3 Average Max/Min Reset

Information.

Digital input options 1, 2, 3 and 5 are edge-triggered to enable the front

panel keys to change the function when the digital input is operational.

Fig. 4.8 Digital Function Configuration

5 Alarm Acknowledge

Page 31

4 CONFIGURATION MODE…

P 0000 r 0000

P – Digital Input Function

Display

0 None

1 Totalizer Reset

2 Totalizer Stop/Go

3 Average, Max/Min Reset

4 Front Panel Lockout

5 Alarm Acknowledge

S 0000 t 0000

Display Baud Rate, 2/4 Wire

0 Off

1 2400, 2-Wire

2 2400, 4-Wire

3 9600, 2-Wire

4 9600, 4-Wire

S – Serial Communication

Configuration

Display

0 0 seconds

1 1 second

2 2 seconds

5 5 seconds

A 10 seconds

b 20 seconds

C 40 seconds

D 60 seconds

Display

0 None

1 Odd

2 Even

R – Analog Input Filter

T – Serial Communication

Parity

Note. Settings for options P, S and T are only available if the

appropriate option board is fitted.

Fig. 4.9 Digital Function and Serial Communications Configuration

29

Page 32

…4 CONFIGURATION MODE

4.4 Ranges and Passwords (Level 4)

LEVEL4

ENG HI

100.0

ENG LO

Level 4

Note. To select this frame from anywhere in this

level, press and hold the

Engineering (Display) Range

High Value

•1

[–9999 to 99999]

Low Value

key.

•1

0.0

rEt HI

Continued on next page…

•1 The engineering range high and low values are automatically set to the

maximum allowed value when thermocouple or RTD is selected in the

Configuration Level – see Section 4.3.1. This value can be modified if

required.

[–9999 to 99999]

30

Page 33

4 CONFIGURATION MODE…

…4.4 Ranges and Passwords (Level 4)

Retransmission Range

The retransmission range defines the engineering

range to be retransmitted.

rEt HI

rEt LO

CNt HI

100.0

100.0

High (20mA output)

•1

[–9999 to 99999 (in engineering units)]

Low (4mA output)

•1

[–9999 to 99999 (in engineering units)]

Continued on next page…

•1 The retransmission range high and low values are automatically set to the

maximum allowed value when thermocouple or RTD is selected in the

configuration level – see Section 4.3.1. This value can be modified if

required.

31

Page 34

…4 CONFIGURATION MODE

…4.4 Ranges and Passwords (Level 4)

CNt HI

1.00

cut.oFF

100.0

S-PASS

•1

•1

Totalizer Count High

This frame determines the count corresponding to the

full-scale input.

[0.000 and 99.999 pulses/second]

Cut-off

This frame sets the lowest flow value at which the

totalizer is to stop counting.

[In engineering units]

Set Up Password

This password enables access to the set-up level

0

C-PASS

0

Addr.

1

•2

(Level 2).

[0 to 9999]

Configuration Password

This password enables access to the configuration

levels. (Levels 3 and 4).

[0 to 9999]

MODBUS Address

This frame sets the MODBUS address.

[1 to 99]

•1 Only displayed if enabled in the configuration level – see Section 4.3.3.

•2 Only available if the appropriate option board is fitted.

32

Page 35

5 INSTALLATION

EC Directive 89/336/EEC

In order to meet the requirements of the EC Directive 89/336/EEC for EMC

regulations, this product must not be used in a non-industrial environment.

5.1 Siting – Figs 5.1 and 5.2

Close to Sensor

At Eye Level

Minimum

Sensor

Avoid Vibration

Fig 5.1 Siting – General Requirements

33

Page 36

…5 INSTALLATION

…5.1 Siting – Figs 5.1 and 5.2

Temperature Limits

–10°C

Min.

Humidity Limits

Environmental Limits

60°C

Max.

IP66/

NEMA-4X

Use Screened Cable

0 to 90% RH

+

Note. If it is not possible to avoid strong electrical and magnetic

fields, screened cables within earthed/grounded metal conduit must be

used.

34

Fig 5.2 Environmental Requirements

Page 37

5 INSTALLATION…

5.2 Mounting – Figs. 5.3 and 5.4

The instrument is designed for wall-mounting or pipe-mounting (see Fig. 5.4). The

pipe-mounting kit is suitable for both vertical and horizontal pipes. Overall

dimensions are shown in Fig. 5.3.

Dimensions in mm (in.)

161.5 (6.3)

250

(9.84)

Fixing Holes

(x3) 6.5 (0.25) Dia

68 (2.68)

214

(8.43)

69 (2.72)

Fixing Centers

42 (1.65)

200

(7.9)

Allowance for

Cable Bends

3

61(2

232

(9.13)

/

8

Fixing Centers

) O.D. Pipe

Fig. 5.3 Overall Dimensions

Vertical Pipe shown

for example only

35

Page 38

…5 INSTALLATION

…5.2 Mounting – Figs. 5.3 and 5.4

2

Drill suitable holes

1

Wall-mounting

Mark fixing centers (see Fig. 5.3)

3

Fix instrument to wall using suitable fixings

Position plates over ‘U’ bolts

Pipe-mounting

Position ‘U’ bolts on pipe

2

1

3

Secure plates

36

4

Secure transmitter to mounting plate

Fig. 5.4 Mounting Details

Page 39

5 INSTALLATION…

Ferrule

Outer Nut

Seal

Alternative

Face Seal

Face

Seal

Hub

5.3 Cable Glands

and Conduit Fixings

5.3.1 Cable Glands

(IEC – 20mm) – Fig. 5.5

'O'-Ring

5.3.2 Conduit Adaptors

(N. American – 0.5 in.) – Fig. 5.6

Warning.

• Rigid conduit must NOT be

fitted to the Indicator.

• Indicator adapters must

incorporate a face seal.

• Torque settings for the hubs

and outer nuts on the specified

adaptors is 20ft.lbs minimum,

25ft.lbs. maximum.

Fig. 5.5 Cable Gland

(Supplied as Standard)

Note. Fittings may

vary for different makes.

Fig. 5.6 Conduit Adaptors

(Not Supplied)

37

Page 40

…5 INSTALLATION

5.3.3 Cable Glands (N. American – 0.5 in.) – Fig. 5.7

Warning.

• Indicator glands must be fitted with a face seal.

• Torque settings (hubs only) – 20ft. lbs minimum, 25ft. lbs. maximum.

• Outer nuts – hand tight plus a half turn only.

Information.

When fitting cable glands to the Indicator, start with an outer gland and also

temporarily fit a gland at the opposite end, to aid location of the transmitter

gland plate. Fit and tighten glands consecutively from initial gland.

Alternative

Face Seal

Face

Seal

Fittings vary

slightly for

different

makes

Outer Nut

Hub

38

Fig. 5.7 Cable Glands (Not Supplied)

Page 41

5 INSTALLATION…

5.4 Electrical Connections –

Figs. 5.8 and 5.9

Warning. Before making

any connections, ensure that the

instrument power supply, any

powered control circuits and high

common mode voltages are

switched off.

Note. The analog output and

the logic output share a common

positive and can be used at the

same time.

5.4.1 Relay Contact Ratings

Relay contacts are rated at:

5.4.4 Retransmission

Analog Output

Max. load 15V (750Ω at 20mA)

Isolation 500V from input (not

isolated from logic output)

Terminal Block

11 7

10 9 8

NC

Load Load

C

Suppression

component

NO

(B9303)

115/230V a.c. at 5A (noninductive)

250V d.c. 25W max.

5.4.2 Arc Suppression – Fig. 5.8

Arc suppression components are fitted

to relays 2 and 3 only. If relay 1 is

required to switch inductive loads, the arc

suppression component supplied must

be fitted across the contacts used.

5.4.3 Logic Output

18V d.c. at 20mA

Min. load 900Ω

Switched

Supply

Fig. 5.8 Fitting Arc Suppression

Components

Isolation 500V from input (not

isolated from retransmission

output)

39

Page 42

…5 INSTALLATION

1 2 14 15

N

L

85 to 265V AC

Mains Supply

+ –

24V DC Supply

See below

– +

3 4 5 6 7 8 9 10 11 12 13

RTD

TxPSU

T/C

–

3

Relay 1**

N/C

CN/O

16 17 18 19 20 21 22 23 24

N/O

Relay 2

mA

–

*

100Ω

N/C

C

2-wire Tx

Logic output

Analog output

*

100Ω

TX– TX+ RX– RX+C

+

–

+

2-lead RTD

RS485

–

3-lead RTD

lead

–

rd

3

+

input

Digital

4

14

15

+

+

–

2-wire

Transmitter

+

* Fit 100Ω resistor supplied

** Fit arc suppression components

Fig. 5.9 Electrical Connections

40

Page 43

CUSTOMER CONFIGURATION LOG

✍

LEVEL4

LEVEL3

A 1KC0

A B C D

E 0000

E F

J 0000

J K

P 0000

G H

L N

ENG HI

ENG LO

rEt HI

rEt LO

CNt HI

CUtOFF

S-PASS

P R

S T

C-PASS

Addr.

Page 44

CUSTOMER SET UP LOG

LEVEL1

CodE

8

✍

LEVEL2

A1xx

A2xx

A3xx

xxxxxx

t-GO

SEC.tot

PrESEt

PrEdEt

A xxxx

H xxxx

L xxxx

0AdJ

Instrument Serial Number:

Page 45

omega.com

OMEGAnet®On-Line Service Internet e-mail

http://www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

®

®

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

SM

Mexico and

Latin America:

Tel: (95) 800-826-6342 FAX: (95) 203-359-7807

En Espan˜ol: (95) 203-359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

SM

SM

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX, United Kingdom

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in the United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certification of its products to the European New Approach Directives.

OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability

for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 46

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

MU

Thermocouple, RTD & Thermistor Probes,

Connectors, Panels & Assemblies

MU

Wire: Thermocouple, RTD & Thermistor

MU

Calibrators & Ice Point References

MU

Recorders, Controllers & Process Monitors

MU

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

MU

Transducers & Strain Gauges

MU

Load Cells & Pressure Gauges

MU

Displacement Transducers

MU

Instrumentation & Accessories

FLOW/LEVEL

MU

Rotameters, Gas Mass Flowmeters & Flow Computers

MU

Air Velocity Indicators

MU

Turbine/Paddlewheel Systems

MU

Totalizers & Batch Controllers

pH/CONDUCTIVITY

MU

pH Electrodes, Testers & Accessories

MU

Benchtop/Laboratory Meters

MU

Controllers, Calibrators, Simulators & Pumps

MU

Industrial pH & Conductivity Equipment

DATA ACQUISITION

MU

Data Acquisition & Engineering Software

MU

Communications-Based Acquisition Systems

MU

Plug-in Cards for Apple, IBM & Compatibles

MU

Datalogging Systems

MU

Recorders, Printers & Plotters

HEATERS

MU

Heating Cable

MU

Cartridge & Strip Heaters

MU

Immersion & Band Heaters

MU

Flexible Heaters

MU

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

MU

Metering & Control Instrumentation

MU

Refractometers

MU

Pumps & Tubing

MU

Air, Soil & Water Monitors

MU

Industrial Water & Wastewater Treatment

MU

pH, Conductivity & Dissolved Oxygen Instruments

M2936/0998

Loading...

Loading...