Shm

on line at

(Wj

bvww.omega.com

e-mai/;

DMD-22

lo-

CHANNEL STRAIN METER

info@umega.

corn

OMEGAnet@

USA:

IS0

9001 Certified

Canada:

USA

and Canada:

On-Line Service

www .omega.com

Internet e-mail

info@omega.com

Servicing North America:

One

Omega Drive, P.O. Box 4047

Stamford CT 06907-0047

TEL: (203) 359-1660

e-mail: info@omega.com

976 Bergar

5Al

Lavai

(Quebec)

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail:

info@omega.ca

H7L

FAX: (203) 359-7700

For immediate technical or application assistance:

l-800-TC-OMEGAa

/

Sales Service:

Customer Service: l-800-622-2378

Engineering Service: l-800-872-9436

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

l-800-826-6342

/

l-800-622-BEST

l-800-USA-WHEN@

/

f

Mexico:

Benelux:

Czech Republic:

France:

Germany/Austria:

United Kingdom:

IS0

9002

Certified

Espaiiol: (001)

En

FAX: (001) 203-359-7807

203-359-7803

e-mail:

Servicing Europe:

Postbus

TEL:

Toil Free in Benelux: 0800 0993344

e-mail:

Rude

TEL:

Toll Free: 0800-l-66342

9, rue

TEL:

Toll Free in France: 0800-4-06342

e-mail:

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL:

Toll Free in Germany: 0800 639 7678

e-mail:

One Omega Drive, River Bend Technology Centre

Northbank, Irlam, Manchester

M44

TEL:

Toll Free in United Kingdom:

e-mail:

8034,118O

(0)20

+31

nl@omega.com

armady

(0)69

+420

Denis

(0)130

+33

france@omega.com

(0)7059

+49

germany@omega.com

SEX

United Kingdom

(0)161777

+44

sales@omega.co.uk

LA Amstelveen, The Netherlands

6418405

1868,733 01

6311899

Papin, 78190 Trappes

621400

9398-O

6611

Karvina

8

0800-488-488

FAX:

+31(0)20

FAX:

+420

e-mail: czech@omega.com

FAX:

+33

FAX:

+49

FAX:

+44

espanol@omega.com

info@omega.com.mx

6434643

(0)69

6311114

(0)130

699 120

(0)7056

9398-29

(0)161777

6622

It is the policy of OMEGA to comply with all worldwide safety and

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

EMC/EMI

regulations that

TABLE OF CONTENTS

SECTION

SECTION 1

SECTION 2

SECTION 3

3.1

3.2

SECTION 4

4.1

4.2

4.3

General Description

Unpacking

Parts

Front

Rear

Wiring

Full Bridge Configuration

Half Bridge Configuration

Quarter Bridge Configuration

PAGE

1

2

2

2

4

5

5

5

4.4

4.5

SECTION

5.1

5.2

SECTION 6

SECTION 7

5

Other Configurations

Internal Circuit

Operation

Introduction to operation

Procedure to use

Rechargeable Batteries Replacement

Specifications

a

a

12

12

13

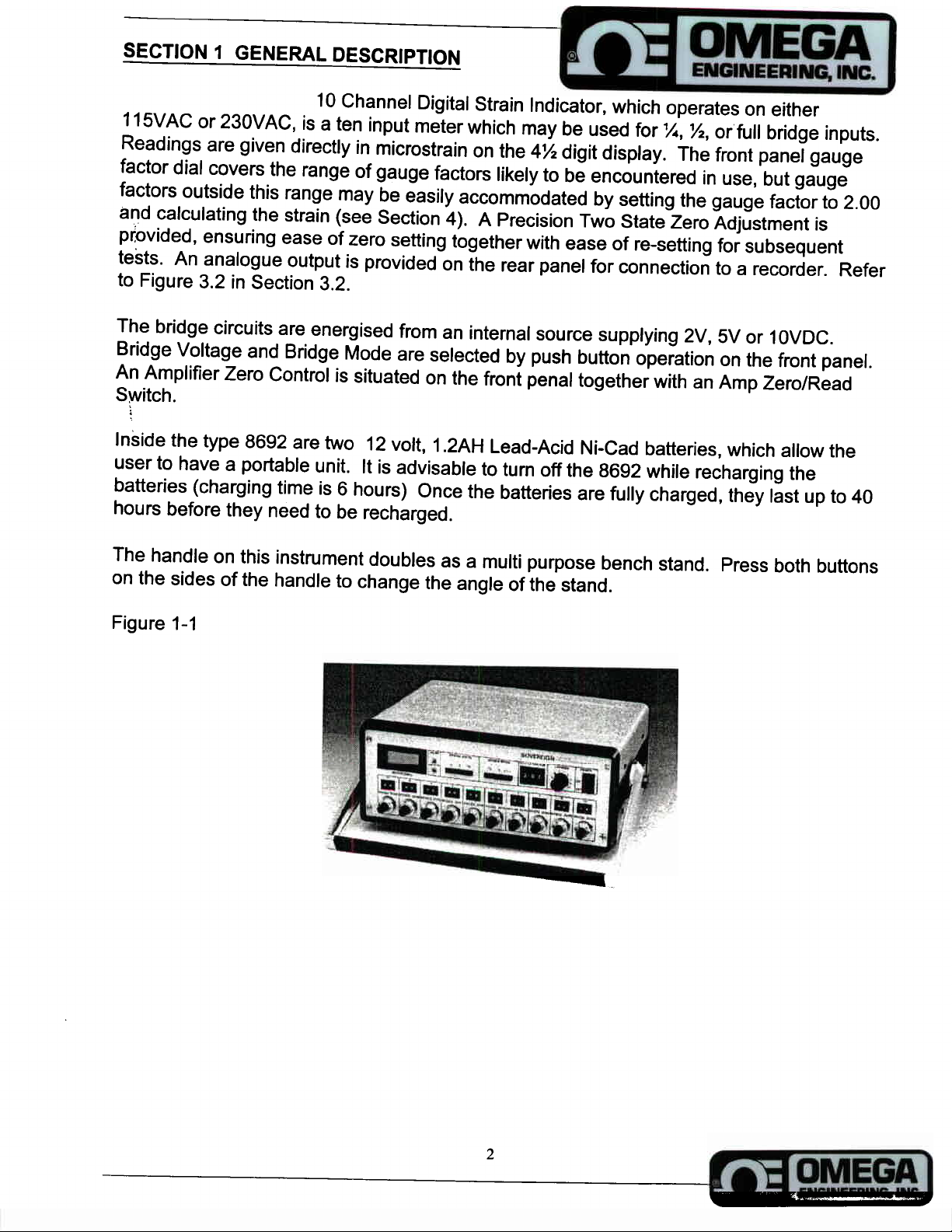

10 Channel Digital Strain Indicator, which operates on either

1/2,

or’full bridge inputs.

‘A,

SVAC

11

230VAC,

or

is a ten input meter which may be used for

Readings are given directly in microstrain on the 4% digit display. The front panel gauge

factor dial covers the range of gauge factors likely to be encountered in use, but gauge

factors outside this range may be easily accommodated by setting the gauge factor to 2.00

and calculating the strain (see Section 4). A Precision Two State Zero Adjustment is

provided, ensuring ease of zero setting together with ease of re-setting for subsequent

tests. An analogue output is provided on the rear panel for connection to a recorder. Refer

to Figure 3.2 in Section 3.2.

5V

2V,

The bridge circuits are energised from an internal source supplying

1OVDC.

or

Bridge Voltage and Bridge Mode are selected by push button operation on the front panel.

An Amplifier Zero Control is situated on the front penal together with an Amp Zero/Read

Switch.

Inside

user to have a portable unit.

the type 6692 are two 12 volt,

It is advisable to turn off the 6692 while recharging the

1.2AH

Lead-Acid Ni-Cad batteries, which allow the

batteries (charging time is 6 hours) Once the batteries are fully charged, they last up to 40

hours before they need to be recharged.

The handle on this instrument doubles as a multi purpose bench stand. Press both buttons

on the sides of the handle to change the angle of the stand.

Figure l-l

2

Operating Instructions

SECTION 2 UNPACKING

Remove the packing list and verify that all equipment has been received.

Upon receipt of shipment, inspect the container and equipment for any signs of damage.

Take particular note of any evidence of rough handling in transit.

immediately to the shipping agent/Courier.

i’

Report any damage

Note: The carrier will not honour any claims unless all shipping material is saved for their

examination. After removing and examining contents, save packing material and carton in

the event of a query.

Make sure the following items are in the shipping box:

DESCRIPTION

I

1

1

1

Digital Strain Indicator with integral battery pack and

charger.

Power Cord

Operators Manual

3

SECTION 3 PARTS

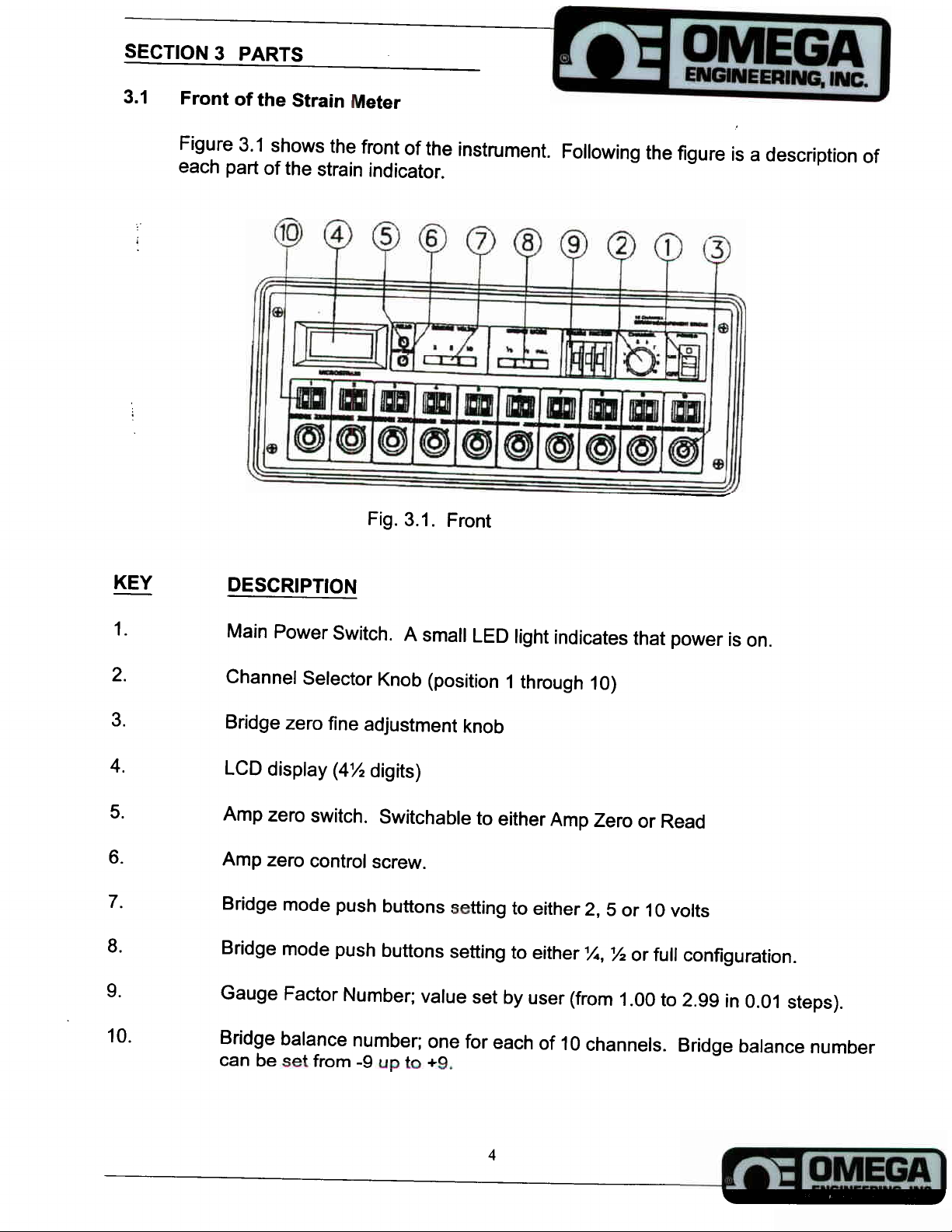

3.1

Front of the Strain Meter

Figure 3.1 shows the front of the instrument. Following the figure is a description of

each part of the strain indicator.

Fig. 3.1. Front

KEY

1.

2.

3.

4.

5.

6.

7.

a.

9.

Main Power Switch. A small LED light indicates that power is on.

Channel Selector Knob (position 1 through 10)

Bridge zero fine adjustment knob

LCD display (4% digits)

Amp zero switch. Switchable to either Amp Zero or Read

Amp zero control screw.

Bridge mode push buttons setting to either 2, 5 or 10 volts

Bridge mode push buttons setting to either

%

or full configuration.

%,

Gauge Factor Number; value set by user (from 1 .OO to 2.99 in 0.01 steps).

IO.

IO

Bridge balance number; one for each of

can be set from -9 up to

+9.

4

channels. Bridge balance number

3.2

REAR OF INSTRUMENT

Figure 3.2 shows the rear

Following the figure is a description of each

part of the strain indicator.

Fig. 3.2. Rear

KEY

DESCRIPTION

1.

2.

3.

4.

5.

Power Cord Socket

Fuse (500mA anti surge type)

Voltage Selector Switch

(115V/23OV)

Analogue output connector (BNC Connection)

Interface Connector capable of hooking up 10 Strain Gauges (one circuit per

channel).

5

SECTION 4. WIRING

1.

Make sure the voltage Selector Switch (fig. 3.2,

for your country.

2.

Connect the strain gauges to be measured to the terminals at the rear of the

instrument as shown in figures 4.1 through 4.5 and as described below.

4.3

FULL BRIDGE CONFIGURATION

Positive supply to PI

Negative supply to P2

Negative signal to

,

Positive signal to S2

No connections to P3 and P4

Minimum gauge resistance is 120

ohms.

Sl

#3)

-SIGNAL

c

FULL

is set to the appropriate voltage

I

4

BRIDGE

---_.

St

Dr

FfCCIRs

OR

S

mV/V

_.

Pa

J’r

4-1

TRANSDUCER

4

Sa

4.2

HALF BRIDGE CONFIGURATION

Positive supply to PI

Negative supply to P2

Strain Gauge junction to

Jumper PI to P3 and P2 to P4

Minimum gauge resistance is

Sl

80

D.

ohms

-EXCfTATION

&

S

S,

+EXCITATtON

r.

S

S

Sr

6

4.3

QUARTER BRIDGE CONFIGURATION

(Single gauge, three wire connection)

Strain gauge terminal 1 to PI

Strain gauge terminal 2 to

i’

,

Strain gauge terminal 2 to

Jumper PI to P3

Jumper P2 to P4

Dl

Use

1

‘I

D2 for 350 ohm gauges

4.4

For two wire quarter bridge configuration using 120 or 350 ohm gauges, connect the active

gauge between PI and

or D2 to

Refer to figure 4.4.

OTHER CONFIGURATIONS

for 120 ohm gauges or

Sl.

Jumper PI to P3, P2 to P4 and

Sl

fro 350 ohm gauges. Select

Sl

Dl or

02

‘A

bridge mode for direct reading in microstrain.

TYiREE

FICURG

WIRE

Dl

to

QUARTER BRIDGE

Sl

/

4-3

for 120 ohm gauges

For other resistance values, use the half bridge arrangement with an external resistor (RI).

Sl

In this case, connect the active gauge between terminals

resistor between

bridge mode for direct reading in microstrain. Refer to figure 4.5

Sl

and P2. Jumper

Da

0

Pl to P3 and P2 to P4 on the rear panel. Select

%

DI

J3

St

P,

Pl and

8

SZ

0

and the external

I!

?p

4

120

-

_.

%I’

Fig. 4.4. Two-wire quarter bridge

7

0 0

0

/

4.5

INTERNAL CIRCUIT

PI = + Excitation

P2 =

Sl

S2 = + Signal

P3 =

P4 =

Dl = 120 ohm,

D

w

IU

Fig. 4.5. Quarter bridge other than 120 ohms or 350 ohms

Excitation

-

-

Signal

=

%

bridge completion resistor

%

bridge completion resistor

Fig. 4.6. Internal Circuit

%

bridge completion resistor

D2 = 350 ohm,

%

bridge completion resistor

8

SECTION 5 OPERATION

5.1

1.

INTRODUCTION TO OPERATION

An output of approximately 2 volts full scale is available at the rear BNC socket of

the instrument, suitable for the connection of an oscilloscope or other high

impedance recording of display device. The available dynamic response of this

output extends beyond 20 KHz. This output may also be used to supply a Recorder

i’

provided the recorder is fitted with a suitable amplifier containing a gain control

i

enabling the signal to be set to a specific value of strain for a given trace width.

2.

For optimum accuracy, the indicator should be left on for approximately ten minutes

before final adjustment of zero is made.

of time, without being able to restore the original zero conditions of the specimen or

structure, then the reading on the zero dials should be noted, so that the indicator

may be set to the same zero condition when re connecting. Record reading

I

i

here.

3.

The gauge factor control should be set to the value appropriate to the gauges in

use.

the dial to 2.00 and correct the strain readings by simple arithmetic proportion.

If tests are being conducted over a period

If gauges are used whose gauge factor is outside the provided range, then

set

4.

Hook up a load cell or pressure transducer to display in engineering units of your

choice.

Set the gauge factor on the Type 6692 per the following formula:

GF

(mv/“)

=

1000

DX B

GF = Gauge factor setting on the instrument.

mVN = Rated output of the Transducer/Sensitivity.

If the sensor does not state the rated output in the

mV

output by the excitation voltage to get the

D=

Desired display at full scale output. Note the display does not have a decimal

mVN format, divide the full scale

mVN output.

point.

B = Bridge selection

Full Bridge = 1

Half Bridge =

Quarter Bridge =

%

‘%

9

5.

#2).

Se lect the channel desired using the channel selector knob (fig. 3.1

Make sure

the strain gauge is connected at the rear of the instru ment, to the corresponding

panel.

#5

Set front panel switch fig. 3.1

screw (fig. 3.1

#6)

until you see 0000 on the digital display, then set switch to the

to Amp Zero then set and adjust adjacent zero

“Read ” position and adjust for zero on the display by using the appropriate Coarse

Zero control (fig. 3.1

#IO)

and the Bridge Zero Knob (fig. 3.1

#3)

on the front panel.

When you have zeroed the instrument, lock the control in place using the black out

knob.

If further readings are to be taken at a later date, record the setting of the

Bridge Balance Number and the Bridge Zero Dial.

Record value here:

(Bridge Balance Number)

(

Bridge Zero)

6.

7.

a.

b.

C.

e.

f.

For dynam ic measurements, the signal available at the BNC socket on the rear

pane l (fig. 3.2

socket is

#4)

may be connected to an amplifier or a recorder. The output at this

f

2 volts which is equivalent to

&20,000

m icrostrain. The frequency

response is DC to 20 KHz.

To use the Type 6692 to monitor Strain Gauge Transducers, whose calibration is

known in ter ms of millivolts per volt.

Set volts to 10 volts

Set bridge mode to

Set the gage factor dial (fig. 3.1

Set front panel switch to READ (fig. 3.1

%

bridge

#5)

and ad just ZERO screw (fig. 3.1

#6).

#5)

and ad just zero control until zero is

shown on the Digital Volt Me ter.

App ly load to Transducer and note reading on the display (fig. 3.1

#4)

2,000

microstrain on the display indicates a signal of 1 .O millivolt per volt.

h.

Note that once the amplifier zero screw has been adjusted in step 5, it will only need

occasional re adjusting.

The following diagra ms give details of Bridge mode and gauge factor setting.

10

.._-____

.--.

..--

._

:c

---

W#

04-

-2.

ACTIVX

STMINS

‘OIlAt

coypI)22SiON.

2 IN

eRlDCX

W.L

.-. _-.

-.-.

-

-.-

,-..-

..

Bridge Mode

YONmNNC

4

+

2

CCNcICURATlON

-.-

-------St

-_-_

--.

.-

T’N.OION

__..__..

WU

.

-..

_.

&

Gague Factor

--.

“-e

- -

Se tting

. .

---_____.__.-_-._

.__

%

11

W I-

W#

.__..

-

m-

---

W#

WI-

W#(lM)

8

5.2

PROCEDURE

TO USE

1.

2.

3.

4..

5.

Connect strain gauges in accordance with section 4.

#8)

Select the correct bridge mode (fig. 3.1

Select the bridge excitation voltage (fig. 3.1

&3).

Set the bridge zero (fig. 3.1

#2

Refer to step 5 in section 5.1.

on the front panel.

#7)

required on the front panel.

Set the gauge factor dial to the gauge factor for the gauges in use, apply strain and

note reading on the LCD (fig. 3.1,

instrument is

*I9999

microstrain and therefore no range switch is required.

##4)

on the front panel.

Note that the range of the

SECTION 6 RECHARGEABLE BATTERIES REPLACEMENT

To replace batteries:

1.

2.

Turn off the type 6692, and unplug.

Unscrew the 4 screws from the top cover and remove top cover.

3.

4.

5.

6.

Unplug the 4 leads to the batteries.

Unscrew the 4 screws holding the battery clamp and remove clamp.

1.2AH

12V,

Remove old batteries and replace with fresh

lead acid rechargeable

batteries.

Follow steps 1 through 4 in reverse order.

12

SECTION 7. SPECIFICATIONS

Channels

Range

Linearity

;

Gauge resistance

10

f

19999 Microstrain

0.02% full scale

x

bridge: 120 or 350 ohms

x

bridge: at least 80 ohms

Full bridge: at least 120 ohms

gauge factor range

Bridge voltage

Bridge modes

Bridge zero

1 .OO to 2.99 in 0.01 steps

2VDC,

x,

SVDC

‘/z

or full bridge

IOVDC

or

Coarse adjustment is in 9 overlapping steps up to 10,000

microstrains,

f

2% resistance imbalance is covered. Fine

adjustment is by a locking 10 turn front panel control with

a range of 1 to 700 microstrain.

Zero drift

Gain drift

Input impedance

Gauge connections

Less than 0.5

Less than

1000

megohm

Screw terminals are at the rear and provide for

microstrain/ “C

O.O05%/ “C

full bridge connections.

Analogue output

Frequency response

Power

f

2VDC. Equivalent to

DC to 20k Hz

115/23OVAC,

(2)

12V,

50/60Hz.

1.2AH

Lead-Acid rechargeable batteries built

f

20000 microstrain

Slide switch at rear. Battery: two

in. Full charge of 40 hours approximately.

Weight

Dimensions

(less handle)

15.4 pounds (7 Kg)

14.5” L x 6.00 ” H x 11

.a”

D

(370 x 150 x 300mm) refer to fig. 7.1

W

x,

or

13

1

(I4.-0’,

Fig. 7.1

Dimensions

f

OMEGA ENGINEERING, INC.

period of 13

months

from date of purchase.

grace period to the normal

ensures that

OMEGA ’s

customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation.

warrants this unit

to be free of defects

OMEGA ’s WARRANTY

one (1) year product warranty

in

materials and workmanship for a

(1)

adds an additional one

month

to cover handling and shipping time. This

OMEGA ’s

Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification.

having

been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

This WARRANTY is VOID if the unit shows evidence of

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA ’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and

triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

pa-

OMEGA, either verbal or written. OMEGA warrants only that the

as specified and free of defects.

REPRESENTATIONS OF ANY

AND AU

IMPUED

WARRANTlES

KlND

WHATSOEVER, EXPRESS OR

INCLUDING ANY WARRANTY OF

OMEGA MAKES NO OTHER WARRANTIES OR

manufactured by it will be

IMWED,

EXCEPT THAT OF

MERCHANTABlLlTY

TlTLE,

AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LlABlLlTYz

The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

(I)

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used:

as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA ’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

WARRANTY

FOR

following information available

contacting OMEGA:

1.

Purchase Order number under which the product

was PURCHASED,

2.

Model and serial number of the product under

warranty, and

Repair instructions and/or specific problems

3.

relative to the product.

OMEGA’s

our customers the latest

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

0

Copyright 2000 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form,

prior written consent of OMEGA ENGINEERING, INC.

policy is to make running changes, not model changes, whenever an improvement is possible. This affords

RETURNS, please have the

BEFORE

in technology and engineering.

NON-WARRANTY

FOR

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

REPAIRS, consult OMEGA

Purchase Order number to cover the COST

of the repair,

Model and serial number of the product, and

Repair instructions and/or specific problems

relative to the product.

in

whole or in part, without the

I

Where Do

Find Everything I Need for

Process Measurement and Control?

OMEGA ...Of Course!

f

Shop on line af

www.omega.com

TEMPERATURE

&

IZ

Thermocouple, RTD

0 Wire: Thermocouple, RTD

0 Calibrators

0 Recorders, Controllers

0 Infrared Pyrometers

&

Ice Point References

Thermistor Probes, Connectors, Panels

&

Thermistor

&

Process Monitors

PRESSURE, STRAIN AND FORCE

&

0

Transducers

0 Load Cells

0 Displacement Transducers

0 Instrumentation

Strain Gages

&

Pressure Gages

&

Accessories

FLOW/LEVEL

&

0

Rotameters, Gas Mass Flowmeters

0 Air Velocity Indicators

Turbine/Paddlewheel Systems

0

&

Totalizers

0

Batch Controllers

Flow Computers

pH/CONDUCTIVITY

&

pH Electrodes, Testers

0

Benchtop/L.aboratory

0

0 Controllers, Calibrators, Simulators

&

Conductivity Equipment

pH

0

Industrial

Accessories

Meters

&

Pumps

DATA ACQUISITION

&

0

Data

Acquisition

0

Communications-Based Acquisition Systems

0

Plug-in Cards for Apple, IBM

0

Datalogging Systems

0

Recorders, Printers

Engineering Software

&

Compatibles

&

Plotters

&

Assemblies

HEATERS

0

Heating Cable

&

0

Cartridge

0

Immersion

0

Flexible Heaters

@’

Laboratory Heaters

Ship Heaters

&

Band Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

&

Metering

Refractometers

Pumps

Air, Soil &Water Monitors

Industrial Water

pH,

Control

&

Tubing

Conductivity

Instrumentation

&

Wastewater Treatment

&

Dissolved Oxygen Instruments

M-1247/d/00

Loading...

Loading...