Page 1

!DMD-21

Single Cha

nnel Digital Strain Indicator

I

I

Operator’s Manual

M1244/0991

Page 2

TABLE OF CONTENTS

DMD-21

SINGLE CHANNEL DIGITAL STRAIN INDICATOR

SECTION

SECTION 1

SECTION 2

SECTION 3

3.1 Front of the DMD-21

3.2 Rear of the DMD-21

SECTION 4

4.1 Full bridge configuration

4.2 Half bridge configuration

4.3 Quarter bridge configuration

4.4 Other configurations

GENERAL DESCRIPTION

UNPACKING

PARTS OF THE DMD-21

WIRING

PAGE

1

2

4.5 Internal circuit

SECTION 5

5.1 Introduction to operation

5.2 Procedure to use the DMD-21

SECTION 6

SECTION 7

SECTION 8

SECTION 9

OPERATION

RECHARGEABLE BATTERIES REPLACEMENT

ACCESSORIES

SPECIFICATIONS

&

BRIDGE MODE

GAGE FACTOR SETTING

8

8

11

11

11

12

13

i

Page 3

satisfactory

)

m onth

(I

13

for a period

period to tho normal one (1) year product warranty to cover handling and shipping time. This ensures that

customers

to the factory for evaluation.

immediately

it

w ill be

of having boen

current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

outside of OMEGA ’s control. Components which wear or which are damaged by misuse are not

These include contact points, fuses, and

repaired

months from date of purchase. OMEGA Warranty adds an additional one

of

rt?ceive

upon phone or

maximum coverage on each product. If the unit should malfunction, it must be returr

or

replaced at

ta m pered

Our Customer

written request.

no charge. However, this WARRANTY is VOID if the unit shows

with or shows evidence of being damaged as a result of excessive corrosion;

Service Department will issue an Authorized Return (AR)

Upon examination by OMEGA, if the unit is found to be defect

triacs.

serv

OMEGA warrants this unit to be free of defects in materials and workmanship and to give

grE

numt

evider

con&tic

warrants

(

There

are no warranties except as stated herein. There are no other warranties, expressed or implied,

but not limited to the implied warranties of merchantability and of fitness for a particular purpose,

INC.’

is

ENGINEERING,

not responsible for any damages or losses caused to other equipment, whether

indirect, incidental, special or consequential, which the purchaser may experience as a result of the

includi

OME<

dire,

installati

or use of the product. The buyer ’s sole remedy for any breach of this agreement by OMEGA ENGINEERIN

INC. or any

breach

of any Warranty by OMEGA ENGINEERING, INC. shall not exceed the purchase pri

paid by the purchaser to OMEGA ENGINEERING, INC. for the unit or units or equipment directly affect

by such

Every

ENGINEERING, INC.

liabilii

in the

Direct all warranty and repair requests/inquiries to the OMEGA ENGINEERING Customer Service

Call

FAX:

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, YOU MUST OBTAIN AN AUTHORIZED RETURN

NUMBER PROM OUR CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING

The

correspondonce.

brench.

precaution for accuracy has been taken in the preparation of this manual, however,

neither assumes responsibility for any omissions or errors that may appear nor

any

for

damages that result from the use of the products in accordance with the information contain

manuill.

Departme

toll

fret?

203-359-7607,

assignrId

in

AR number should then be marked on the outside of the return package and on a

the

USA:

1-800-622-2378,

FAX:

203-359-7811;

International: 203-359-166

OMEC

assun-

(1

DELAY

FOR

WAR R

following information available BEFORE contacting

OMEGA:

1.

P-0. number under which the product

was PURCHASED,

2.

Model

under

3.

Repair instructions and/or specific

problems

product.

OMEGA’s

get

OMEGA

@

any

Polk

the

latest

is

Copyright

manner,

in

ANTY

RETURNS, please have the

and serial number of the product

wirrranty, and

you

are having with the

running

is to make

111

technology and engineering.

retjistered

a

1991

cjither

trademark of OMEGA ENGINEERING, INC.

OMEGA ENGINEERING, INC. All rights reserved including illustrations.

wholly or

changes, not model changes, whenever an improvement is possible. That

any

purpose whatsoever without written permission from

for

pan

in

t

Printed in England

FOR

NON-WARRANTY

consult OMEGA for current repair/calibration

Have the following information available BEFO

1

contacting OMEGA-

Your

1.

the repair/calibration,

Model and serial number of product,

Repair instructions and/or specific

3’:

problems you are having with the

product.

P.O. number to cover the COST of

REPAIRS OR

way

Nothing in this

OMEGA

CALIBRATIC

our

manual

custom

maY

ENGINEERING,

be

charg

mploduc

Ir

Page 4

SECTION 1 GENERAL DESCRIPTION

OMEGA

The

either

DMD-21

115VAS

used for

directly in

panel gage

to be encountered in

maybe

easily

calculating the strain (see Section 4).

Zero Adjustment

together

output

with

is provided on the rear panci for connection to a

recorder.

The bridge circuits are

supplying

2V,

selected by

Amplifier Zero

mg

with an

Zero/Read Switch.

Inside the DMD-21 are two (2) 8.4 Volt,

Digital

or

i,

3,

microscrains

factor

dial covers

accommodat,ld

Strain Indicator, which

23OVAC,

fulL

or

is a single input meter which may be

bridge inputs.

44

on the

digit display.

the rsnge of gage factors likely

use,

but gage factors outside this range

by setting the

A Precision

is provided ensuring

ease of zero setting

ease of re-setting for subsequent tests. An analog

Refer to Figure 3-2 in Section 3.2.

5V

or

10MC.

push-bcxton

Control

energizec?

Bridge

operation on

is situated on the front panel together

from an intemai source

Vtiltage

the front panel.

1.2AH

which allow the user to have a portable unit.

batteries

the

to turn off

t.;e

DMD-21

while

recharging

ocerates

Readings

are

The front

gage factor to 2.00 and

.z_d

Bridge Mode are

Ni-Cad batteries

It is advisable

(charging

on

given

Two-State

in

time is 6 hours). Once the batteries are fully charged, they

last for up to 40 hours before they need to be recharged again.

The handle on the

DYD-21

doubles as a multi-position bench stand.

Press both buttons on the sides of the handle to change the angle

of the stand.

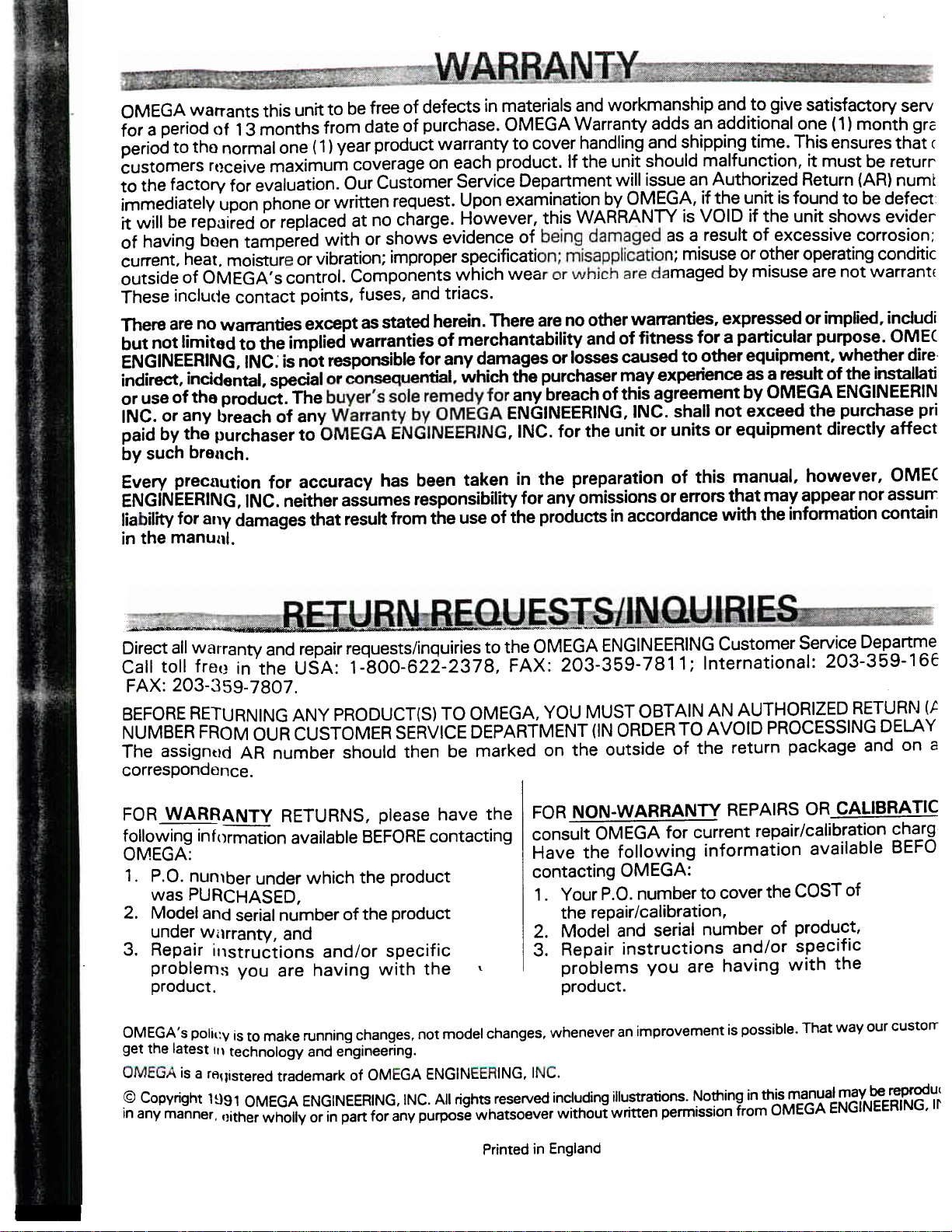

Figure

l-1

shows the DMD-21

Dioital

Strain

Indicator.

Page 5

SECTION 2

UNPACKING

Remove the Packing List and verify that all equipment has been

received.

If there are any questions about the shipment, please

call the OMEGA Customer Service Department at l-800-622-2378 or

(203) 359-1660.

Upon receipt of shipment, inspect

any signs of damage.

rough handling in transit.

Take particular note of any evidence of

Immediately report any damage to the

the container and equipment for

shipping agent.

NOTE

The carrier

will not honor

any claims

material is saved for their examination.

save

removing contents,

packing material and carton in the event

unless

After examining and

all shipping

reshipment is necessary.

Make sure the following items are in the shipping box.

Q~Y

1

DMD-21 Digital Strain Indicator

Description

(including integral battery pack and

recharger)

1

1

SECTION 3

PARTS OF THE DMD-21

Power Cord

Operator's Manual

3.1 FRONT OF THE DMD-21

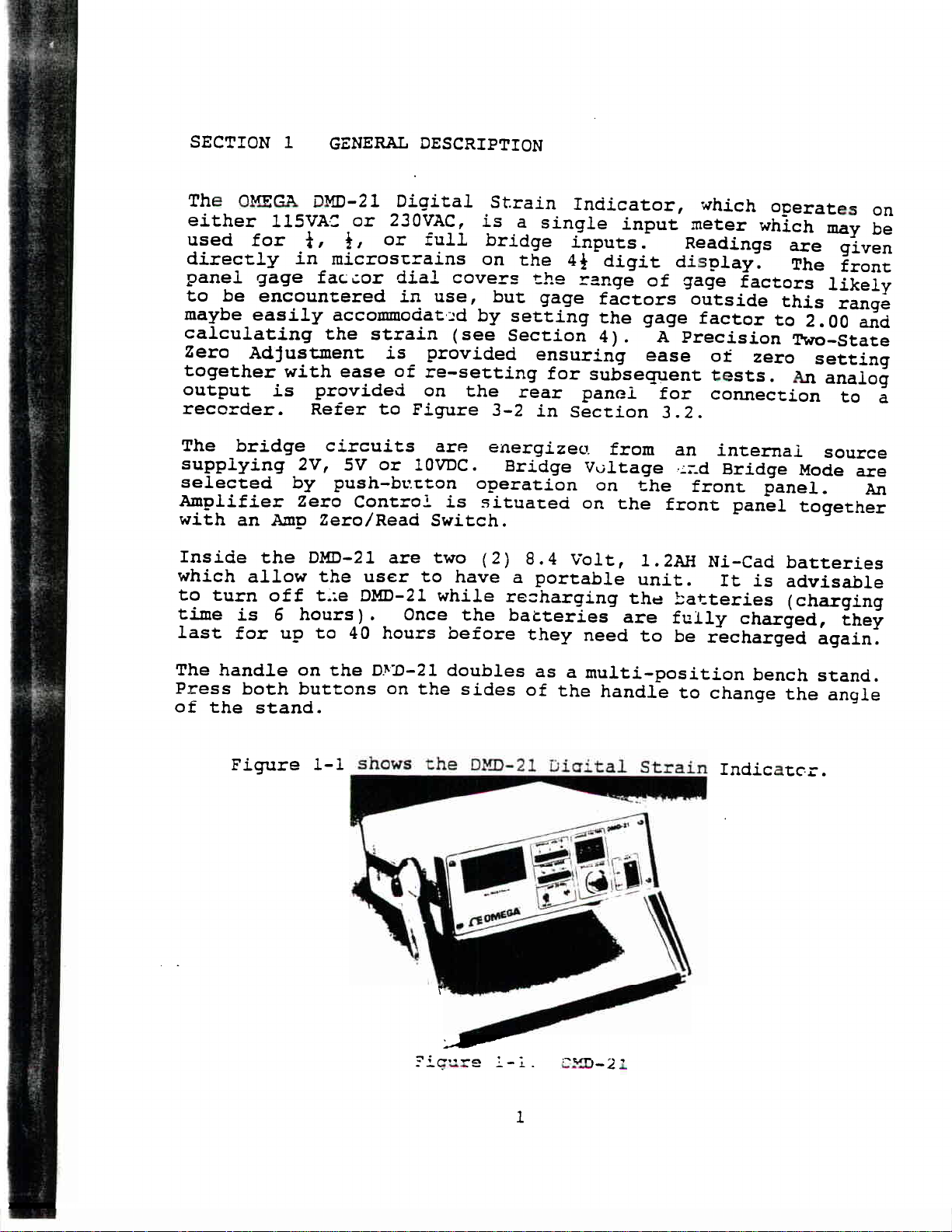

Figure 3-l shows the front of

is a description of each part

the

DIMD-21.

Following the

of the strain indicator.

2

figure

Page 6

:.

MICROSTRAIN

(

GAlJGp

FACTOR

ON

il

=i=

11EO MEC IA”

0

KEY

1

2

3

4

5

Figure 3-l.

Main Power Switch.

indicates that power is on.

Bridge Zero fine adjusting knob.

outer ring knob locks setting.

Amp Zero Control Screw.

Amp Zero Switch switchable to either

Amp Zero or Read.

Bridge Mode pushbuttons setting to either

4,

i,

READ

Front of the DMD-21

DESCRIPTION

A smail LED lit

The

or full configuration.

Bridge Volts pushbuttons setting to either

2, 5 or 10 volts.

.Gage

Factor Number;

Value set by user (from

1.00 to 2.99 in 0.01 steps).

8

LCD Display

(44

digits).

3

Page 7

3.2

REAR

OF TH E

DMD-21

Figure 3-2 shows

is a description

the rear of the DMD-21.

Following the figure

of each part of the strain indicator.

:f

,

7‘;

ed

,

Figure 3-2.

‘ 4

!

I

Rear of the DMD-21

-

I

KEY

1

2

3

4

5

6

DESCRIPTION

Fuse

(5OOmA

Voltage Selector Switch

anti-surge type)

(115V/23OV)

Analog Output Connector (BNC Connection)

Bridge Balance

interface Connector for strain gages

power

Cord Socket

4

Page 8

SECTION 4 WIRING

1.

Make sure the Voltage Selector Switch (Figure 3-2,

set to the appropriate voltage for your country.

%2)

is

2.

4.1

4.2

Connect the strain gages to be measured to the terminals at

the rear of the instrument as shown in Figures 4-l through

4-5

and as described below.

S,

pr

P,

FULL BRIDGE CONFIGURATION

‘.

Positive Supply to

Pl

0

Dr

Pz

P,

S,

D,

,a

PP

0 0

PP

Negative Supply to P2

Negative Signal to

Sl

Positive Signal to S2

No connections to P3 and P4

4-

Minimum gage resistance is

120 ohms

HALF BRIDGE CONFIGURATION

Positive Supply to

Pl

FULL BRIDGE OR

D,

Dz

FIGURE

S,

4

1

mV/V TRANSDUCER

P,

4

4

Negative Supply to P2

Strain Gage junction to

Pl

Jumper

to P3 and P2 to P4

Sl

Minimum gage resistance is 80 ohms

-EXCITATION

FIGURE 4-2

HALF BRIDGE

Page 9

4. 3

QUARTER

BRIDGE

CONFIGURATION

(Single

gage,

Strain Gage terminal 1 to

Strain

Gage

Strain Gage terminal 2 to

Pl

Juinper

to P3

three-wire connection)

Pl

terminal 2 to

Sl

Dl

Jumper P2 to P4

Dl

Use

D2

for 120 ohm

for 350 ohm gages

gages

or

4.4 OTHER CONFIGURATIONS

For other resistance values,

(Rl).

an external resistor

between terminals

and

Sl

to

P2.

Jumper

Dl

for 120 ohm gages.

Pl

and

Pl

to P3 and P2 to P4 on the rear panel.

In this case, connect the active gage

Sl

and the external resistor between

Refer to Figures 4-4 and 4-5.

I

or D2

FIGURE

THREE WIRE QUARTER BRIDGE

d-3

use the half bridge arrangement with

Sl

Jumper

Sl

Jumper

to D2 for 350 ohm gages.

Tigure

4-4.

D,

350

5,D,

I

I

P,pz

;:

s

D,

120

D2

Two-Wire Quarter Bridge

6

Sr

Page 10

Figure 4-5.

120 ohms or 350 ohms

Quarter Bridge other than

4.5

Pl

=

P2 =

Sl

=

s2 =

P3 =

P4 =

Dl

=

D2 =

INTERNAL CIRCUIT

+

Excitation

-

Excitation

-

Signal

+ Signal

f

Bridge Completion Resistor

i

Bridge Completion Resistor

120 ohm,

350 ohm,

f

Bridge Completion Resistor

$

Bridge Completion Resistor

Figure 4-6.

Internal Circuit

7

Page 11

1

I_

1

1

1

1

1.

I

I

I

I

SECTION 5

5.1 INTRODUCTION TO OPERATION

An output of approximately 2 volts full scale is available

at the rear BNC Socket of the DMD-21, suitable for the

connection of an oscilloscope or other high impedance

recording or display device.

of this output extends beyond

be used to supply a Recorder provided the recorder is fitted

with a suitable amplifier containing a gaincontrolenabling

the signal to be set to a specific value of strain for a

given trace width.

For optimum accuracy,

approximately ten minutes before final adjustment of zero

is made.

time,

conditions of the specimen or structure, then the reading

on the zero dials should be noted, so that the indicator may

be set to the same zero condition when re-connecting.

Record reading here:

The Gage Factor control should be set to the value

appropriate to the gages in use.

gage factor is outside the provided range, then set the dial

to 2.00 and correct the strain readings by simple arithmetic

proportion.

OPEEiATION

the indicator should be left on for

If tests are being conducted over a period of

without being able to restore the original zero

The available dynamic response

2OkHz.

.

This output may also

If gages are used whose

I

I

I

r

r

r

l-

8

Page 12

4 .

Hook up a load cell or pressure transducer to display in

engineering units of your choice.

Set the gage factor on the DMD-21per the following formula:

GF =

(mV/V)

1000

DX B

GF

MV/v

=.Gage

factor setting on the instrument

Rated output of the Transducer/Sensitivity

=

If the sensor does not state the rated output in the

mV/V

format, divide the full scale

excitation voltage to get the

Desired display at full scale output.

D =

does not have a decimal point.

B =

Bridge Selection

The following steps

should be taken to properly scale the

instrument with a sensor.

a.

Compute the GF setting.

If GF is less than 1.0,

bridge mode, B =

f.

mV output by the

mV/V

output.

Note the display

Full Bridge = 1

Half Bridge =

Quarter Bridge =

i

4

Assume a full bridge mode, B = 1.

then recompute GF assuming a half

b.

Wire up the sensor according to Figure 4-l regardless of

bridge mode assumed in step 1. With the sensor in a no load

condition

zero

the

display using

the

various

zero

adjustments.

9

Page 13

I

I

.)

I

5.

#4

Set front panel switch Figure 3-1,

adjacent zero screw (Figure 3-1,

the digital display then set switch to the "READ" position

and adjust for zero on the display by using the Coarse Zero

#4)

control (Figure 3-2,

the Bridge Zero knob (Figure 3-1,

When. you have

place using the black outer knob.

to be taken at a later date,

Bridge Balance Number and the Bridge Zero Dial.

Values here:

zeroed the instrument lock the control in

at the rear of the instrument and

record the setting of the

(front);

to Amp Zero and adjust

#3)

until you see 0.00 on

112)

on the front panel.

If further readings are

Record

(rear).

i

rp

1

p

I

rm

6 .

7.

For dynamic measurements,

socket (Figure 3-1,

to an amplifier or a Recorder.

f

2

is 0 to

microstrain.

To

use the DMD-21 to

whose calibration is

volt.

a .

b .

C .

d.

e.

f.

Se t

Se t

Se t

Se t

#4)

Se t

adjust

(respectively Figure 3-1,

zero is shown on the Digital Volt

Apply load

display (Figure 3-1,

display indicates a signal of 1.0 millivolt per volt.

volts which is equivalent to

The frequency response is DC to 20

volts to 1 0

bridge mode

the gage factor dial (Figure 3-1,

front panel switch to amplifier ZERO (Figure

and adjust ZERO Screw (Figure 3-1,

front panel switch to READ (Figure 3-1,

rear panel

#3)

monitor Strain

knowninterms

volts.

to

to Transducer and note reading on the

the signal available at the BNC

on the

f

bridge.

and

#8).

rear

#2

2,000 microstrain on the

panel may be connected

The output at this socket

+

20,000

Mz.

Gage Transducers,

of millivolts per

#7)

to 2.00.

#3).

#4)

front

and Figure

panel

Meter .

zero knobs

#4)

3-2,

3-1,

and

until

8 .

Not e

in step 5,

that once the Amplifier Zero

Screw

it will only need occasional re-adjusting.

10

has been adjusted

Page 14

5.2

PROCEDURE TO USE THE DMD-21

1.

2.

Connect Strain Gages in accordance

Select

the correct bridge mode (Figure 3-1,

panel.

3.

Select bridge excitation voltage (Figure 3-1,

front panel.

*.

4.

Set the bridge zero (Figures 3-1,

Refer to Step 5 in Section 5.1.

5.

Set the gage factor dial to the gage factor for the gages

in use,

apply strain and note reading on the liquid crystal

display (Figure 3-1,

the range of the instrument is

therefore no range switch is required.

SECTION 6

RECHARGEABLE

To replace batteries:

1.

Turn off the DMD-21, and unplug.

with Section 4.

#5)

on the front

#4)

&

3-2,

#2

#8)

on the front panel. Note that

+

19999 microstrain and

accurately.

BATTERIES REPLACEMENT

#6)

on the

2.

Unscrew the 4 screws from the top cover and remove top

cover.

3.

4.

Disconnect the 4 leads to the batteries.

Unscrew the 2 screws holding the battery clamp and remove

clamp.

5.

Remove old batteries and replace with fresh 8.4 Volt, 1.2

AH Ni-Cad rechargeable batteries.

6.

SECTION 7

Follow steps 1 through 4 in reverse order.

ACCESSORIES

The DMD-21 may be used in' conjunction with

Channel Switch and Balance Unit.

10

range of the instrument

adjustment.

Refer to the operator's manual for the DMD-21SB

to

Use of the DMD-21SB extends the

inputs each with its own zero

more details.

the DMD-21SB

lo-

for

11

Page 15

SECTION 8 SPECIFICATIONS

CHANNELS:

RANGE:

LINEARITY:

GAGE RESISTANCE:

GAGE FACTOR RANGE:

BRIDGE VOLTAGE:

BRIDGE MODES:

BRIDGE ZERO:

ZERO DRIFT:

1

+

19999

0.02%

+

bridge:

4

bridge: at least 80 ohms

Full bridge:

1.00 to 2.99 in 0.01 step s

2VDC,

f,

microstrain

full scale

SVDC

f

or Full

120 or 350 ohm

at least 120 ohms

or 10 VD C

Bridg e

Coarse adjustment is in 9 overlapping

steps up to 10,000 microstrains,

resistance

imbalanced

is covered.

2.2%

Frne

adjustment is by a locking 10 turn front

panel control with a range of 1 to 700

microstrains.

Less than 0.5

microstrain/"C

GAIN DRIFT:

INPUT IMPEDANCE:

GAGE CONNECTIONS:

ANALOG

OUTPUT:

FREQUENCY RESPONSE:

POWER:

WEIGHT:

DIMENSIONS:

Less than

1000 Megohms

O.OOS%/"C

Screw terminals are at the rear and

4

or full bridge

f,

provide

for

connections

20,000+

+ 2vDc.

microstrain

DC

to 20k H z

Equivalent to

115/23OVAC,

rear.

Cad

Battery: two (2)

recharaeable

SO/60

Hz.

batteries built-in.

Slide switch at

8.4V,

1.2AHNi-

Full charge-of up to 40 hours use.

11 pounds (5 kg)

11.81"L

x

4.33"W

x

17.72"D

(300 x

x 450 mm)

110

12

Page 16

Servicing USA and Canada: Call OMEGA Toll

OMEGA Engineering, Inc.

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Headquarters: (203) 359-1660

U.S.A.

Free

Sales: l-800-826-6342

Customer Service: l-800-622-2378

Engineering:

FAX: (203) 359-7700

Servicing Europe: United Kingdom Sales and Distribution Center

P.O. Box 1,

Telephone: (0455) 285520 FAX: (0455) 283912

The OMEGA Complete Measurement and

Control Handbooks

Temperature

Pressure, Strain

Flow and Level

l-800-TC-OMEGA

/

l-800-622-BEST

/

l-800-USA-WHEN

/

l-800-872-9436

TELEX:

996404

EASYLINK:

OMEGA Technologies Ltd.

Broughton Astley, Leicestershire

6XR,

England

EncyclopediasT”

&

ti

V

L/

LE9

& Force

(USA

pH

Data Acquisition Systems

Electric Heaters

and Canada)

(USA

(USA

and Conductivity

and Canada)

CABLE: OMEGA

only)

I-

m-

i!

Call

for Your FREE Handbook Set Today:

(203)

3599RUSH

Loading...

Loading...