Page 1

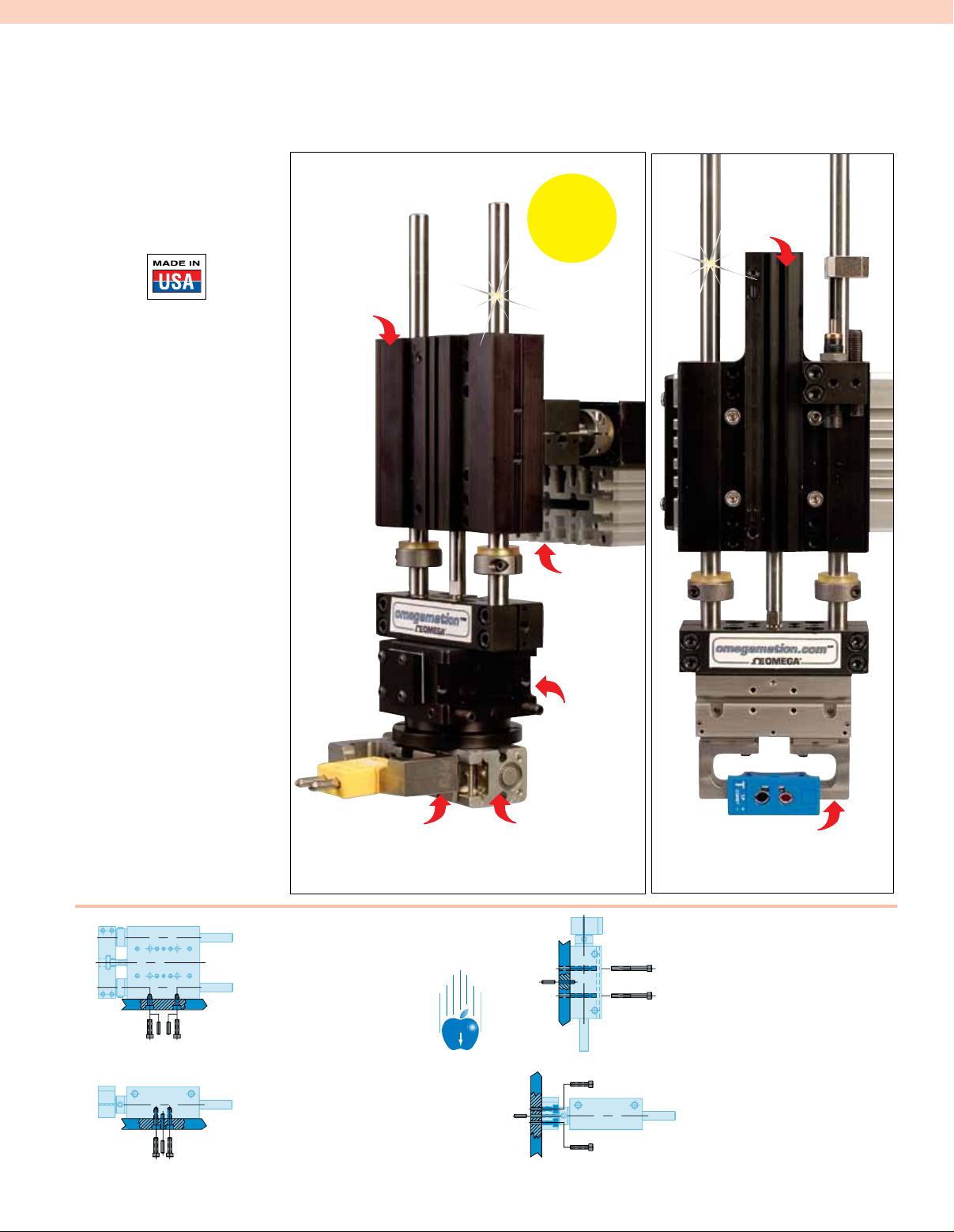

Linear thruster sLides

Pneumatic internaLLy Powered

directconnecttm moduLar series

Shown smaller

DLT Series

l Highly Configurable

Modular Automation—

Exclusive DirectConnect™

Technology

l Precision Linear Motion—

5 to 150 mm (0.20 to 6")

of Travel

l Thruster Force 89 to 275 N

(20 to 62 lb) at 5.5 bar

(80 psi)

l Repeatability 0.03 mm

(0.001") with Precision

Stop Option

l Up to 5 Million Cycles in

Typical Application—

Up to 10 Million with

Maintenance

l Temperature Operating

Range -35 to 80°C

(-30 to 180°F)

l Double Acting Pneumatic

Cylinder Requiring

3 to 7 bar (40 to 100 psi)

Dry Filtered (40 micron

or Better) Air Supply

Along with a 4-Way,

2 Position Valve

than actual size.

DLT-10M-E-C-50

E-Series short

body linear

thruster slide.

Note: Gripper fingers

are shown for reference

purposes, tooling is the

customers responsibility.

DPP-10M-12 parallel

gripper with OSTW-K-M

thermocouple connector.

Visit omega.com

Two Axis

Motion

Control

DMEX-16-12

mounting

stanchions. Visit

omega.com

DRF-075M-180

rotary actuator.

Visit omega.com

DPP-10M-12 parallel gripper

with SMP-T-F snap-in panel jack

thermocouple connector.

DLT-10M-L-C-100

L-Series long

body thruster.

Visit omega.com

Body mounts with screws

and loacte with slip fit

dowel pin holes on side

using DIRECTCONNECT

mounting patterns.

Body can be mounted from the

back using the DIRECTCONNECT

pattern of threaded mounting and

dowel pin holes.

Body back mounts with screws

from the front using the

clearance and counterbored

DIRECTCONNECT pattern and

located with dowel holes.

G

Payload attaches to tooling

plate DIRECTCONNECT

mounting pattern with screws

and locates using slip fit

dowel pin holes.

C-5

Page 2

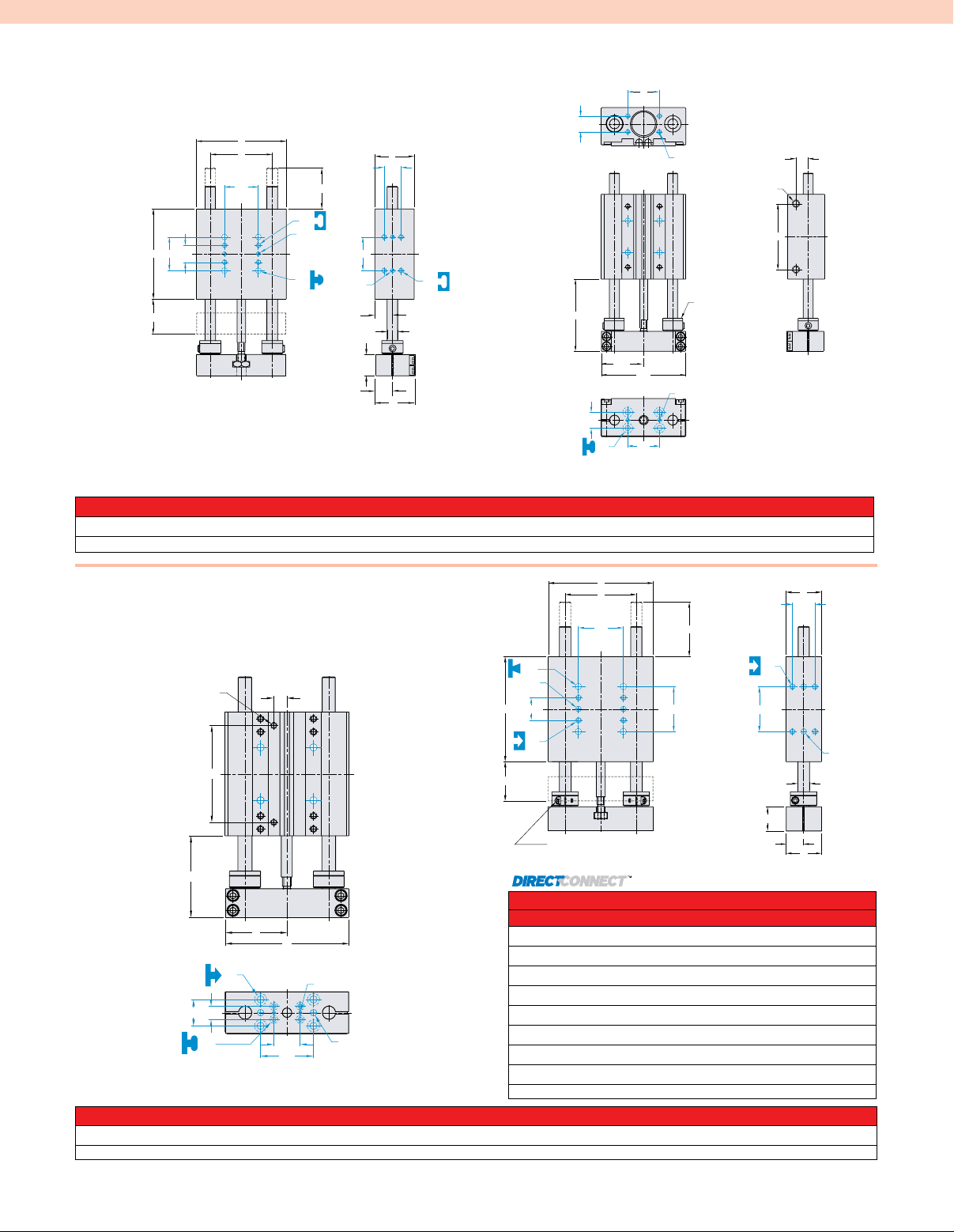

Product Features

Sensor Magnet

Standard in piston

Mounting Patterns

Main bodies have tapped and

counterbored through holes

including slip fit dowel holes on

DIRECTCONNECT mounting surface

Inductive Proximity Sensors

4 or 8 mm diameter, threaded body

with quick disconnect

Shock Absorbers

With built-in hard stop;

dual stop capable

Misalignment

Coupling

Increases service life

Universal Mounting Kit

Contains mounting bracket,

hardened steel target,

and hardware; allows the

mounting of shocks and

ajustable hard stops

Urethane Bumpers

& Clamp Collars

Magneto Resistive Sensors

Slot mounted sensor with threaded

quick disconnect

Sensors Grooves

For mounting Magneto

Resistive Sensors

Oil Wick

Supplies constant

bearing lubrication

Aircraft Quality

Aluminum

TECHNICAL SPECIFICATIONS

Pneumatic Specifications

Pressure Operating Range*:

3 to 7 bar (40 to 100 psi)

Cylinder Type: Double acting

Dynamic Seals:

Internally lubricated Buna-N

Valve Required to Operate:

4-way, 2-position

Air Quality Requirements

Air Filtration: 40 micron or better

Air Lubrication: Not necessary

Air Humidity: Low moisture

content (dry)

Preloaded Linear

Ball Bushings

Precision Ground Shafting

Case hardened to RC60-65; corrosion

resistant optional

Temperature Operating Range

Buna-N Seals (Standard):

-35 to 80°C (-30 to 180°F)

FKM Seals (Optional):

-30 to 150°C (-20 to 300°F)

Maintenance Specifications

Expected Life:

Normal Application: 5 million cycles

With Preventative Maintenance:

10+ million cycles**

Field Repairable: No

Seal Repair Kits Available: No

Adjustable Hard Stops

For precision (±0.001") hard stop

end point positioning; allows for stop

adjustment independent of shock

absorber hard stop; dual stop capable

DLT-10M-L-C-100

shown smaller than

actual size.

Application Restrictions:

Flow controls, shock absorbers and

urethane bumpers recommended for

nearly all applications. Use composite

bushing in dirty or gritty environments.

Never use silicone based lubricants with

composite bushings.

* Higher pressure possible. Consult Sales

with application details.

** Addition of lubrication will greatly increase

service life.

C-6

Page 3

L

C

L

C

P

N

M5

AIR PORTS

(A DIA. BORE)

E + STROKE

H

J

short body thruster

L

C

L

C

L

C

L

C

L

C

L

C

L

C

DQ

DA

DA

DB

DR

E + STROKE

N

P

M5

AIR PORTS

(A DIA. BORE)

STANDARD

H

J

RETRACT

ADJUSTMENT

COLLARS AND BUMPERS

dLt-06m, 08m-e buiLt-in

rePairabLe cyLinder

B

S

DB

C

L

B

DA

DB

E

G + STROKE

DR

DQ

C

L

DT

F

DA

C

L

C

DB

DQ

L

DR

R

C DIA.

DA

E + STROKE

DB

C

L

C

L

C

L

P

C

N

L

C

L

DR

AIR PORTS

(A DIA. BORE)

RETRACT

ADJUSTMENT

COLLARS AND BUMPERS

STANDARD

M5

M

L

K

J

H

C

L

DQ

DA

DB

DS

C

L

Basic Unit Dimensions (mm)

MODEL NO. A B C E F G H J K L M N P R S

DLT-06M-E 14 50.8 6 19.9 22.4 16.8 50.3 25.1 22.2 9.3 11.9 39.4 7.4 9.9 34.93

DLT-08M-E 14 63.5 8 19.9 22.4 10.4 62.7 31 22.2 9.3 11.9 52.1 7.4 9.9 44.95

B

short body thruster

dLt-10m, 12m buiLt-in

rePairabLe cyLinder

M5

AIR PORTS

(A DIA. BORE)

N

E + STROKE

DF

DB

DA

DS

Basic Unit Dimensions (mm)

C

L

P

C

L

J

H

C

L

DQ

C

L

DB

DC

DD

DG

DD

B

DB

DE

E

STANDARD MOUNTING PATTERN FOR ALL SIZES

MILLIMETERS

DA 9.5

DB 19.1

DC 38.1

DD 5 mm H7 x 6 DP

DE M5 x 8.5 DP

DF Clearance for M5

DG Clearance for M5

DQ 3H7 x 2 DP

DS Clr & C’bore for M3

RETRACT ADJUSTMENT

S

DC

C

L

BUMPERS & COLLARS

STANDARD

G + STROKE

C

DC

L

Dimensions

DC

MODEL NO. A B C E F G H J K L M N P R S

DLT-10M-E 19 88.9 9.5 33.4 30.2 20.8 88.6 44.2 29.9 14.8 20.7 69.7 9.4 60.33

DLT-12M-E 25 101.6 12 33.4 41.4 20.8 101.2 50.4 41 20.4 20.7 83.3 9.4 69.85

C-7

F

DB

C

L

DE

C

L

DD

C DIA.

M

L

K

Page 4

Long body thruster

L

C

L

C

L

C

L

C

L

C

DC

DD

DQ

DF

DB

DA

DS

DB

DD

DB

DE

M

C DIA.

F

P

N

Q

E + STROKE

M5

AIR PORTS

(A DIA. BORE)

H

J

K

L

L

C

L

C

L

C

DD

DQ

DF

DB

DA

DS

DB

P

N

Q

E + STROKE

M5

AIR PORTS

(A DIA. BORE)

H

J

dLt-06m, 08m-L buiLt-in rePairabLe cyLinder

F

DA

C

L

C

DB

DQ

M

L

DR

R

L

K

E + STROKE

C DIA.

DA

DS

D

DB

B

E

Basic Unit Dimensions (mm)

B

S

DB

C

L

G + STROKE

DR

DQ

C

DA

L

DT

MODEL NO. A B C D E F G H J K L M N P Q R S

DLT-06M-L 14 50.8 6 44.4 19.9 22.4 16.8 50.3 25.1 22.2 9.3 11.9 39.4 5.4 9.9 34.93

DLT-08M-L 14 63.5 8 44.4 19.9 22.4 10.4 62.7 31 22.2 9.3 11.9 52.1 5.4 9.9 44.95

Long body thruster

dLt-10m, 12m, 16m-L

buiLt-in rePairabLe cyLinder

C

L

C

L

P

M5

AIR PORTS

(A DIA. BORE)

C

N

RETRACT

ADJUSTMENT

COLLARS AND

BUMPERS

STANDARD

J

H

C

L

DQ

C

L

DB

C

M5

AIR PORTS

(A DIA. BORE)

L

P

L

B

S

DC

C

L

D

DG

DD

B

DB

DE

E

RETRACT ADJUSTMENT

BUMPERS & COLLARS

STANDARD

G + STROKE

C

DC

L

F

DB

C

L

DC

DE

DC

C

L

STANDARD MOUNTING PATTERN FOR ALL SIZES

MILLIMETERS

DD

C DIA.

DA 9.5

DB 19.1

DC 38.1

N

Q

E + STROKE

DB

J

DF

DA

DS

Dimensions

H

C

L

DQ

C

L

DD

DB

DC

DD 5 mm H7 x 6 DP

DE M5 x 8.5 DP

M

Basic Unit Dimensions (mm)

L

K

MODEL NO. A B C D E F G H J K L M N P Q R S

DLT-10M-L 19 88.9 9.5 50.8 33.4 30.2 20.8 88.6 44.2 29.9 14.8 20.7 12.7 9.4 9.6 60.33

DLT-12M-L 25 101.6 12 63.5 33.4 41.4 20.8 101.2 50.4 41 20.4 20.7 146.8 9.4 9.1 69.85

DLT-16M-L 25 120.7 16 69.9 34.9 41.4 19.3 120.3 59.9 41 20.4 20.7 172.2 9.4 9.1 82.55

C-8

DF Clearance for M5

DG Clearance for M5

DQ 3H7 x 2 DP

DS Clr & C’bore for M3

Page 5

W

XAM

Loading Curves

12

10

8

6

4

2

0

53

45

35

27

18

9

0

lbs.N

0 0.256.5

13

1

25

1.5

38

.75

19

1.25

32

1.75 in.

44mm

STROKE

)W+F( DAOLYAP+ECROF

"500. )31.(

"200. )50.(

W

XAM

Loading Curves

10

8

6

4

2

0

45

35

27

18

9

0

lbs.N

0

0

.25

6

.5

13

1

25

.75

19

1.25 in.

32mm

STROKE

)W+F( DAOLYAP+ECROF

"500. )31.(

"200.

)50.(

W

XAM

Loading Curves

12

10

8

6

4

2

0

53

45

35

27

18

9

0

lbs.N

0 0.256.5

13

1

25

.75

19

1.25

32

STROKE

)W+F( DAOLYAP+ECROF

"200. )50.(

0

0

.5

13

1

25

1.5

38

2 in.

50mm

Loading Curves

W

XAM

40

35

30

25

20

15

10

5

0

178

156

133

111

89

67

44

22

0

lbs.N

STROKE

)W+F( DAOLYAP+ECROF

00. "2 0.( )5

"500. )31.(

70

60

50

40

30

20

10

0

311

267

222

178

133

89

44

0

lbs.N

0

0

1

25

)W+F( DAOLYAP+ECROF

.5

13

0. 20 " 0.( )

5

1.25 in.

32mm

W

XAM

Loading Curves

12

10

8

6

4

2

0

53

45

35

27

18

9

0

lbs.N

0 0.256.5

13

1

25

1.5

38

.75

19

1.25

32

1.75 in.

44mm

STROKE

)W+F( DAOLYAP+ECROF

"500. )31.(

"200. )50.(

Loading Curves

W

MAX

70

60

50

40

30

20

10

0

311

267

222

178

133

89

44

0

lbs.N

0

0

1

25

3 in.

76mm

STROKE

)W+F( DAOLYAP+ECROF

2

50

2.5

64

1.5

38

.5

13

0. 20 " 0.( )

5

"500. )31.(

"010. )52.(

W

XAM

Loading Curves

.256.5

13

1

25

1.5

38

.75

19

1.25

32

1.75 in.

44mm

STROKE

"500. )31.(

"200. )50.(

W

XAM

Loading Curves

10

8

6

4

2

0

45

35

27

18

9

0

lbs.N

0 0.25

6

.5

13

1

25

.75

19

1.25 in.

32mm

STROKE

)W+F( DAOLYAP+ECROF

"500. )31.(

"200.

)50.(

W

XAM

Loading Curves

12

10

8

6

4

2

0

53

45

35

27

18

9

0

lbs.N

0 0.256.5

13

1

25

1.5

38

.75

19

1.25

32

1.75 in.

44mm

STROKE

)W+F( DAOLYAP+ECROF

"500. )31.(

"200. )50.(

25

20

15

10

5

0

111

89

67

44

22

0

lbs.N

Loading Curves

0

0

.5

13

1

25

1.5

38

2 in.

50mm

STROKE

)W+F( DAOLYAP+ECROF

W

XAM

00. "2 50.( )

"500. )31.(

"010. )52.(

0

0

.5

13

1

25

1.5

38

2 in.

50mm

Loading Curves

W

XAM

40

35

30

25

20

15

10

5

0

178

156

133

111

89

67

44

22

0

lbs.N

STROKE

)W+F( DAOLYAP+ECROF

00. "2 0.( )5

"500. )31.(

Loading Curves

W

MAX

70

60

50

40

30

20

10

0

311

267

222

178

133

89

44

0

lbs.N

0

0

1

25

3 in.

76mm

STROKE

)W+F( DAOLYAP+ECROF

2 502.5

64

1.5

38

.5

13

0. 20 " 0.( )

5

"500. )31.(

"010. )52.(

M

DLT-06M-E & L

DLT-08M-E & L

lbs.N

10

45

)W+F( DAOLYAP+ECROF

8

35

6

27

4

18

2

9

0

0

0

0

.25

6

DLT-10M-E & L

lbs.N

25

111

0

0

00. "2 50.( )

.5

13

)W+F( DAOLYAP+ECROF

20

89

15

67

10

44

5

22

0

0

F=Externally applied force (lbs. or N)

W=Weight of payload (lbs. or N)

F+W=Total force (lbs. or N)

Loading Curves

"200.

)50.(

.5

13

STROKE

Loading Curves

W

STROKE

.75

19

"500. )31.(

XAM

1

25

DLT-16M-L

311

267

)W+F( DAOLYAP+ECROF

222

178

133

89

44

"500. )31.(

W

XAM

1

25

"010. )52.(

1.5

38

lbs.N

70

60

50

40

30

20

10

0

0

0

0

F

W

1.25 in.

32mm

2 in.

50mm

0. 20 " 0.( )

5

.5

13

lbs.N

12

53

10

45

)W+F( DAOLYAP+ECROF

35

27

18

9

0

8

6

4

2

0

0 0.256.5

Loading Curves

"200. )50.(

.75

13

19

W

XAM

1

1.25

25

32

STROKE

DLT-12M-E & L

.5

13

Loading Curves

00. "2 0.( )5

W

1

25

STROKE

W in this range use Urethane Bumpers

"500. )31.(

XAM

1.5

38

lbs.N

40

178

35

156

)W+F( DAOLYAP+ECROF

30

133

25

111

20

89

1

25

Loading Curves

"500. )31.(

1.5

38

STROKE

Shock Absorbers and Flow Controls are recommended for nearly all applications

(W)in this range use Single Shock in both directions

Shaded shock absorption ranges of horizontal payload (W) @ 80psi, flow controls fully open. For vertical

applications do not exceed 1/2 of the recommended payload due to the additional acceleration effect of gravity.

C-9

67

44

22

W

MAX

2

50

15

10

5

0

0

0

0

2.5

64

"010. )52.(

3 in.

76mm

"500. )31.(

1.5

38

50mm

1.75 in.

44mm

2 in.

Page 6

accessories For dLt thrusters

C

D

C

D

E

A

B

C

D

E

C

D

E

Urethane Bumpers

& Clamp Collars

A

B

E

D

C

l Urethane Bumpers for Shock Absorption and Noise Dampening

l Adjustable Clamp Collars for End of Stroke Position Adjustment

l Kit Contains 2 Collars and 2 Shock Pads for Adjustment of Travel

in One Direction

l Kit Required for Extend (Kit for Retract Comes Standard)

Adjustable

Hard Stops

l For Precision (±0.001") End Point Positioning of Retract Position

l Allows for End Stop Position Adjustment Independent of Shock

Absorber Hard Stop

l Allen Wrench Adjustable

Shock Absorbers

l Full Stroking Piston Rod

l Built-In Hard Stop

l Position Adjustable

Universal Mounting Kit

l Kit Mounts One Shock Absorber or One Adjustable Hard Stop

l Kit Includes One Mounting Bracket, One Hardened Tool Steel Target

and Hardware

l Target Allows for Unlimited Retract Stroke Adjustment (No Extend

Position Adjustment); Fine Adjustment is Achieved Using Adjustable

Hard Stop or Shock Absorber

l Mounting Bracket Keys Into Body for Secure Positioning and

Excellent Rigidity

l Four Possible Mounting Positions

Inductive Proximity Sensors

l 4 or 8 mm (0.16 or 0.32") Diameter

l Threaded Quick Disconnect with Built-In LED Output

l PNP and NPN Available

Quick Disconnect Cable

l Threaded Coupling with Knurled Head for Secure Electrical Connections

l 2 m (6.6') Cable Length

l 5 m (16') Cable Length

Magneto Resistive Sensors

l No Mounting Kit Required (Slot Mounted)

l Threaded Quick Disconnect with Built-In LED Output

l PNP and NPN Available

l Low Profile

Quick Disconnect Cable

l Threaded Coupling with Knurled Head for Secure Electrical Connections

l 2 m (6.6') Cable Length

l 5 m (16') Cable Length

Basic Unit Dimensions (mm)

MODEL NO. A B C D E F G

DLT-06M 6.0 12 6.4 7.9 6.9 — —

DLT-08M 6.0 16 6.4 7.9 6.9 — —

DLT-10M 8.7 22.1 9.5 12.2 8.1 14.7 91.4

DLT-12M 9.5 23.9 9.5 11.4 5.8 14.7 91.4

DLT-16M 11.1 33.3 11.1 11.4 8.6 14.7 91.4

C-10

Page 7

To Order Visit omega.com/dlt_series for Pricing and Details

BORE BODY SIZE SHAFT MAX THRUSTER

DIAMETER (Width) DIAMETER LENGTH HEIGHT STROKE WEIGHT FORCE @

MODEL NO. mm (inch) mm (inch) mm (inch) mm (inch) mm (inch) mm (inch) kg (lbs) 5.5 bar (80 psi)

DLT-06M-E-C-25

DLT-08M-E-C-44

DLT-10M-E-C-50

DLT-12M-E-C-50

DLT-06M-L-C-50

DLT-08M-L-C-75

DLT-10M-L-C-100

DLT-12M-L-C-125

DLT-16M-L-C-150

Ordering Example: DLT-06M-E-C-25, pneumatic presision thruster with maximum stroke of 25 mm (0.984").

Recommended accessories include 2 inductive sensors OISP-014, with an inductive sensor mounting kit, OSMK-076. Additional urethane bumper/

stop collar kit, OSAK-067 or 2 precision adjustable hard stops, DLT-0623, with 2 universal mounting kits,

OSAK-069. DLT requires a 4-way, 2-position valve to operate recommended 2 pneumatic flow controls.

CAD drawings available at omega.com

4 (0.55) 50.8 (2) 6 (0.236) 106.1 (4.177) 22.4 (0.882) 25 (0.984) 0.15 (.34) 89 (20)

14 (0.55) 63.5 (2.5) 8 (0.315) 137.8 (5.425) 22.4 (0.882) 44 (1.732) 0.30 (.65) 89 (20)

19 (0.75) 88.9 (3.5) 9.5 (0.374) 193.1 (7.602) 30.2 (1.189) 50 (1.969) 0.84 (1.18) 155 (35)

25 (0.98) 101.6 (4) 12 (0.473) 205.8 (8.102) 41.4 (1.630) 50 (1.969) 1.35 (2.98) 275 (62)

14 (0.55) 50.8 (2) 6 (0.236) 137.5 (5.413) 22.4 (0.882) 50 (1.969) 0.28 (0.61) 89 (20)

14 (0.55) 63.5 (2.5) 8 (0.315) 168.8 (6.646) 22.4 (0.882) 75 (2.953) 0.44 (1.96) 89 (20)

19 (0.75) 88.9 (3.5) 9.5 (0.374) 243.1 (9.571) 30.2 (1.189) 100 (3.937) 0.88 (1.95) 155 (35)

25 (0.98) 101.6 (4) 12 (0.473) 280.8 (11.055) 41.4 (1.630) 125 (4.921) 1.46 (3.21) 275 (62)

25 (0.98) 120.7 (4.75) 16 (0.630) 324.9 (12.791) 41.4 (1.630) 150 (5.906) 2.03 (4.81) 275 (62)

SHOCK/STOP ACCESSORIES

MODEL NO. QUANTITY DESCRIPTION

OSAK-069 1, 2, 3, or 4 Universal mounting kit (shock or stop) for -06M

OSAK-070 1, 2, 3, or 4 Universal mounting kit (shock or stop) for -08M

OSAK-055 1, 2, 3, or 4 Universal mounting kit (shock, stop or sensor) for -10M

OSAK-057 1, 2, 3, or 4 Universal mounting kit (shock, stop or sensor) for -12M

OSAK-059 1, 2, 3, or 4 Universal mounting kit (shock, stop or sensor) for -16M

SHOK-030 1, 2, 3, or 4 Shock absorber for -06M and -08M (2 max on -06)*

SHOK-028 1, 2, 3, or 4 Shock absorber for -10M*

SHOK-010 1, 2, 3, or 4 Shock absorber for -12M and -16M*

DLT-0623 1, 2, 3, or 4 Adjustable hard stop for -06M and -08M*

DLT-1023 1, 2, 3, or 4 Adjustable hard stop for -10M ,-12M and -16M*

OSAK-067 1 Urethane bumper/stop collar kit for -06M

OSAK-068 1 Urethane bumper/stop collar kit for -08M

OSAK-065 1 Urethane bumper/stop collar kit for -10M

OSAK-066 1 Urethane bumper/stop collar kit for -12M

OSAK-060 1 Urethane bumper/stop collar kit for -16M

SENSOR ACCESSORIES

OSMK-076 1 or 2 Inductive sensor mounting kit for -06M

OSMK-077 1 or 2 Inductive sensor mounting kit for -08M

OISP-011 1 or 2 Inductive PNP with quick disconnect

† for -10M, -12M and -16M*

OISN-011 1 or 2 Inductive NPN with quick disconnect† for -10M, -12M and -16M*

OISP-014 1 or 2 Inductive PNP with quick disconnect† for -06M and -08M*

OISN-014 1 or 2 Inductive NPN with quick disconnect† for -06M and -08M*

OHSP-017 1 or 2 Magneto resistive sensor PNP quick disconnect all models

†

OHSN-017 1 or 2 Magneto resistive sensor NPN quick disconnect all models†

CABL-010 1 or 2 Quick disconnect 2 m (6.6') cable length all models†

CABL-013 1 or 2 Quick disconnect 5 m (16') cable length all models†

PNEUMATION ACCESSORIES

SLKT-108 1 Cylinder repair kit for -06M, -08M

SLKT-100 1 Cylinder repair kit for -10M

SLKT-102 1 Cylinder repair kit for -12M, -16M

* Requires universal mounting kit. † Sensor and cable sold separately.

Ordering Example: For DLT-06M thruster slide order two DLT-0623, adjustable hard stops with two OISP-014, inductive PNP sensors,

and two OSMK-076, mounting kits, [sensors require two CABL-013, quick disconnect cables, 5 m (16')].

C-11

Loading...

Loading...