Page 1

C-3

LINEAR SLIDES—PNEUMATIC

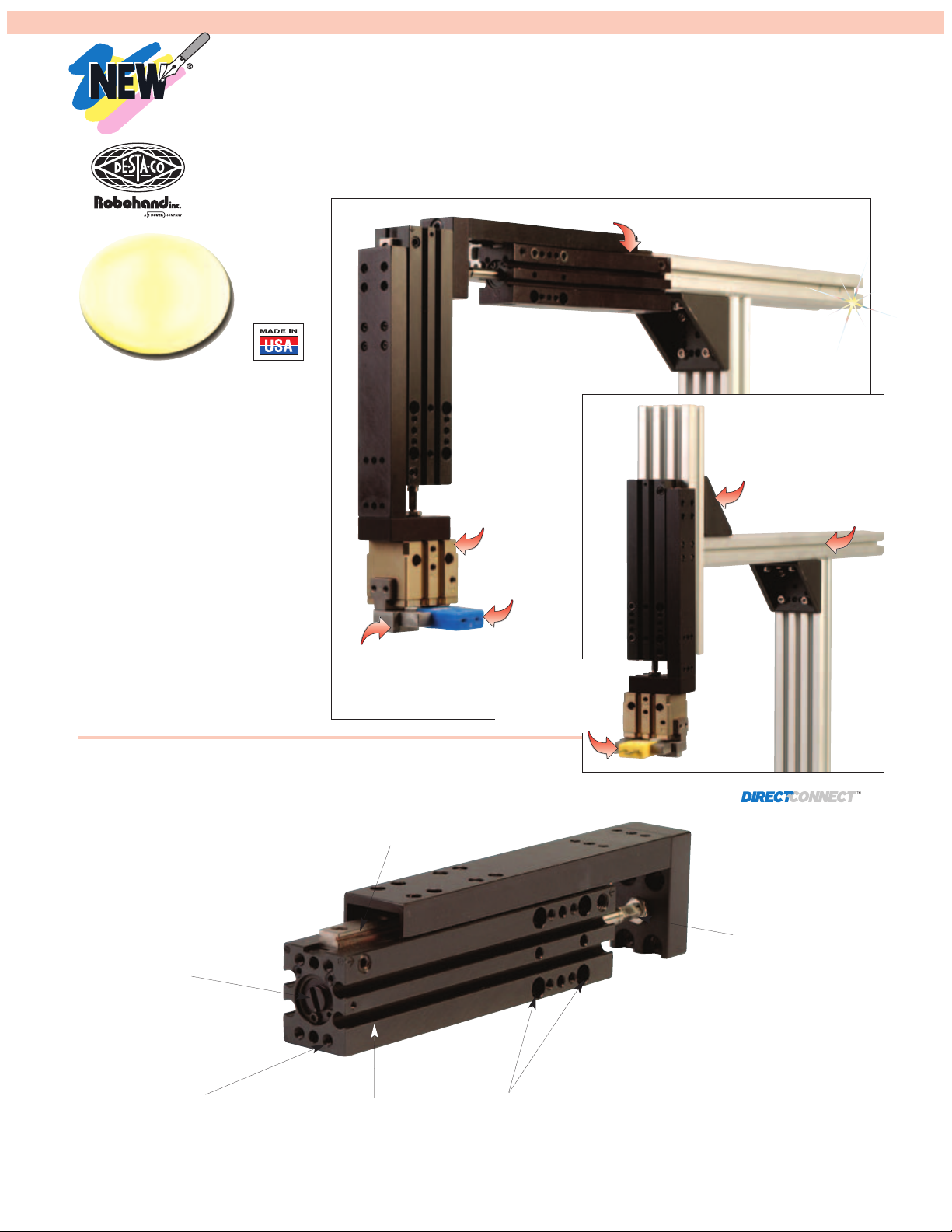

MINI DLM DIRECTCONNECT

TM

MODULAR SERIES

DLM Series

Starts at

$

221

l Highly Configurable Modular

Automation—Exclusive Direct

Connect™ Technology

l Precision Linear Motion—

12 to 100 mm of Travel with

0.005 mm (0.0002") Accuracy

l Repeatability 0.08 mm (0.003")

with Precision Stop Option

l Up to 5 Million Cycles in Typical

Application—Up to 10 Million

with Maintenance

l Temperature Operating Range

-35 to 80°C (-30 to 180°F)

l Double Acting Pneumatic

Cylinder Requiring 1.4 to 7 bar

(20 to 100 psi) Dry Filtered

(40 Micron or Better) Air

Supply Along with a 4-Way,

2 Position Valve

DLM-07M-12-12-P,

$221, shown close

to actual size.

Bearing Seals

Bearing blocks are equipped

with low friction seals

Double Bearing (-D Option)

Three longer stroke sizes available

with two bearings as an option for

greater moment capacity

Retract Stroke

Adjustment

5 mm adjustment

Dowel Holes Standard

Slip fit dowel holes in

body and tool plate

Multiple Air Port Locations

4 standard airport location

(bottom, back, and both sides)

Precision Stops (-P Option)

Delrin®internal stops are available

for increased repeatability

Magneto Resistive Sensing

Mounting slots and magnet are standard

for up to eight sensors (sensors sold separately)

Thru-Body Mounting

C’bored holes for socket head

cap screw on both sides

Manifold Air Ports

Bottom air ports are C’bored for

O-ring manifold seals

Mounting Patterns

Mounting on all six sides (standard)

Precision Tool Plate

Position Adjustment

5 mm adjustment

Recirculating Ball Bearings Rail Slide

Preloaded for accuracy,

built-in ball retention

PRODUCT FEATURES

Note: Gripper fingers and

custom tooling are shown

for reference purposes,

this tooling is customers

responsibility.

Shown smaller

than actual size.

DLM-07M-50-50-P mini linear slide, $261

DMDG-08 gusset kit

for DMEX-08

extrusion, $99, see

omegamation.com

DMEX-08-12 mounting

stanchions, $36, see

omegamation.com

SMPW-T-F

thermocouple

connector,

$2.25, see

omegamation.com

DPDS-056M-013-B-V,

$449, see

omegamation.com

SMPW-K-M

thermocouple

connector,

$1.75, see

omegamation.com

No Adaptor

Plates

Required!

Dual Axis

Motion

Control

Single Axis

Motion

Control

Page 2

C-4

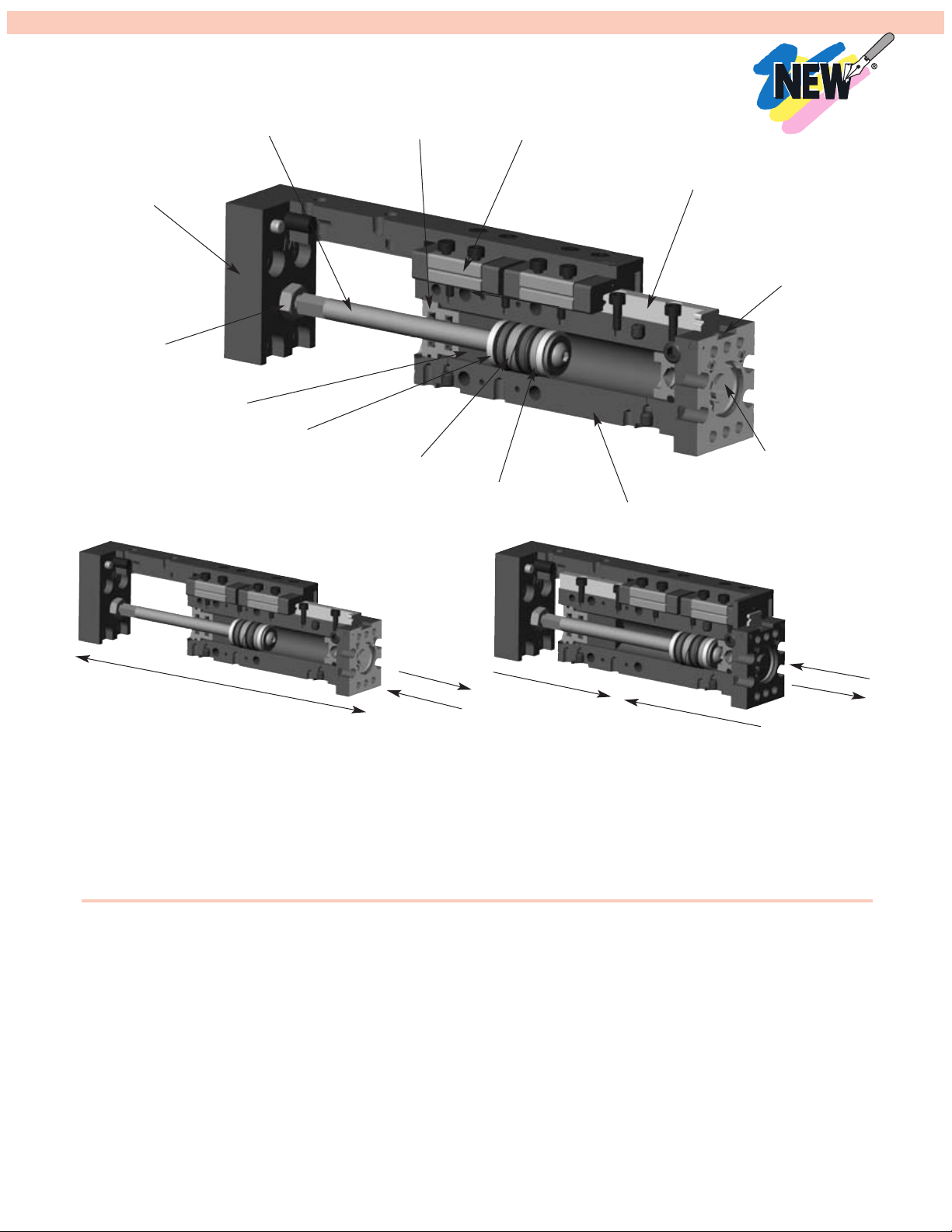

l A Double Acting Piston Slides Within the Body Bore

When Pressure is Applied

l The Piston is Coupled to the Tool Plate With

the Piston Rod

l The Tool Plate is Connected to the Ball Rail Slide

Block Which is Guided by the Precision Rail

l The Stops are Internal and Attached to the Piston

and Piston Rod

l Combination of Internal Spacers and User Retract

Adjustment Allow for Infinite Adjustment Within

Stroke Range

OPERATING PRINCIPLE

Piston Rod

Rod End Cap

Recirculating

Ball Bearing

Block (-D

Shown)

Precision Rail

Retract

Adjustment

Lock Screw

Retract

Adjustment

Body

Magnet

Piston

Pressure

Exhaust

Pressure

Exhaust

Slide Extends

Slide Retracts

Stop Pad (Standard)

(Precision Delrin

®

Available)

Stroke Spacer

Tool Plate

Position

Adjustment

Tool Plate

SPECIFICATIONS

PNEUMATIC SPECIFICATIONS

Pressure Operating Range: 20 to 100 psi (1.4 to 7 bar)

Cylinder Type: Double acting

Dynamic Seals: Internally lubricated buna-N

Valve Required to Operate: 4-way, 2-position

AIR QUALITY REQUIREMENTS

Air Filtration: 40 micron or better

Air Lubrication: Not necessary*

Air Humidity: Low moisture content (dry)

TEMPERATURE OPERATING RANGE

Buna-N Seals (Standard): -35 to 80°C (-30 to 180°F)

MAINTENANCE SPECIFICATIONS

Expected Life:

Normal Application: 5 million cycles

With Preventative Maintenance: 10+ million cycles*

Field Repairable: Yes

Seal Repair Kits Available: Yes

Application Restrictions:

Machine operations generating chips

Environments with loose particulate

* Addition of lubrication will greatly increase service life.

Page 3

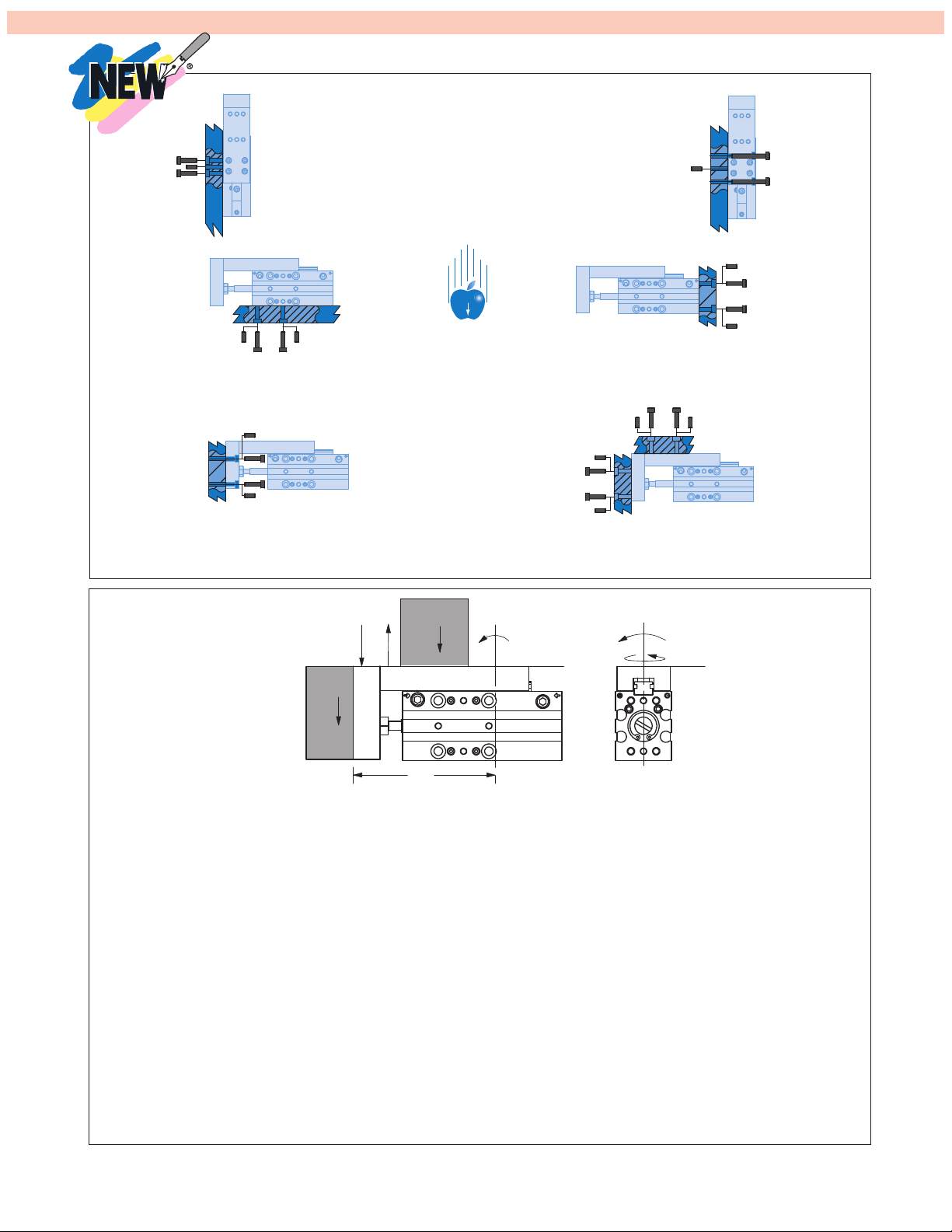

L

My

Z

T

X

C

Z

Y

Mx

Mz

W

W

Flow Controls are recommended for nearly all applications

Loading Capacity DLM-07M DLM-09M DLM-12M

Static Dynamic Static Dynamic Static Dynamic

Maximum Tensile T 490 N (110 lb) 301 N (67 lb) 735 M (165 lb) 413 M (92 lb) 1214 N (273 lb) 808 N (181 lb)

Maximum

Compressive C 490 N (110 lb) 301 N (67 lb) 735 M (165 lb) 413 M (92 lb) 1214 N (273 lb) 808 N (181 lb)

Maximum

Moment MX 5.1 Nm (45 in-lb) 3.1 NM (27in-lb) 9.6 Nm (84 in-lb) 5.4 Nm (47 in-lb) 20.6 NM (182 in-lb) 13.7 Nm (121 in-lb)

Maximum

Moment MY 3.2 Nm (28in-lb) 1.9 NM (16in-lb) 6.4 Nm (56 in-lb) 3.6 Nm (31 in-lb) 11.8 Nm (104 in-lb) 7.9 Nm (69 in-lb)

Maximum

Moment MZ 3.2 Nm (28in-lb) 1.9 NM (16in-lb) 6.4 Nm (56 in-lb) 3.6 Nm (31 in-lb) 11.8 Nm (104 in-lb) 7.9 Nm (69 in-lb)

Distance to Bearing

Centerline L -07M-12 53 mm (2.10") -09M-25 86 mm (3.40") -12M-25 88 mm (3.45")

Distance to Bearing

Centerline L -07M-25 61 mm (2.39") -09M-50 105 mm (4.13") -12M-50 104 mm (4.10")

Distance to Bearing

Centerline L -07M-38 74 mm (2.90") -09M-75 126 mm (4.95") -12M-75 132 mm (5.21")

Distance to Bearing

Centerline L -07M-50 50 mm (3.37") -09M-100 155 mm (6.10") -12M-100 154 mm (6.07")

Slides can be mounted in any orientation

Body can be mounted from either side

using the DIRECTCONNECT™ pattern

of tapped and dowel holes or thru bolts

mounting and dowel holes

Body can be mounted from the bottom

using the DIRECTCONNECT™ pattern of

tapped and dowel holes.

Payload attaches to tool plate

DIRECTCONNECT™ mounting pattern

with screws and locates using

slip fit dowel holes.

Body can be mounted from the back

using the DIRECTCONNECT™ pattern

of tapped and dowel holes.

Payload attaches to tool plate DIRECTCONNECT™

to the front or to the top of the slide with

tapped and dowel holes.

C-5

MOUNTING INFORMATION

G

Page 4

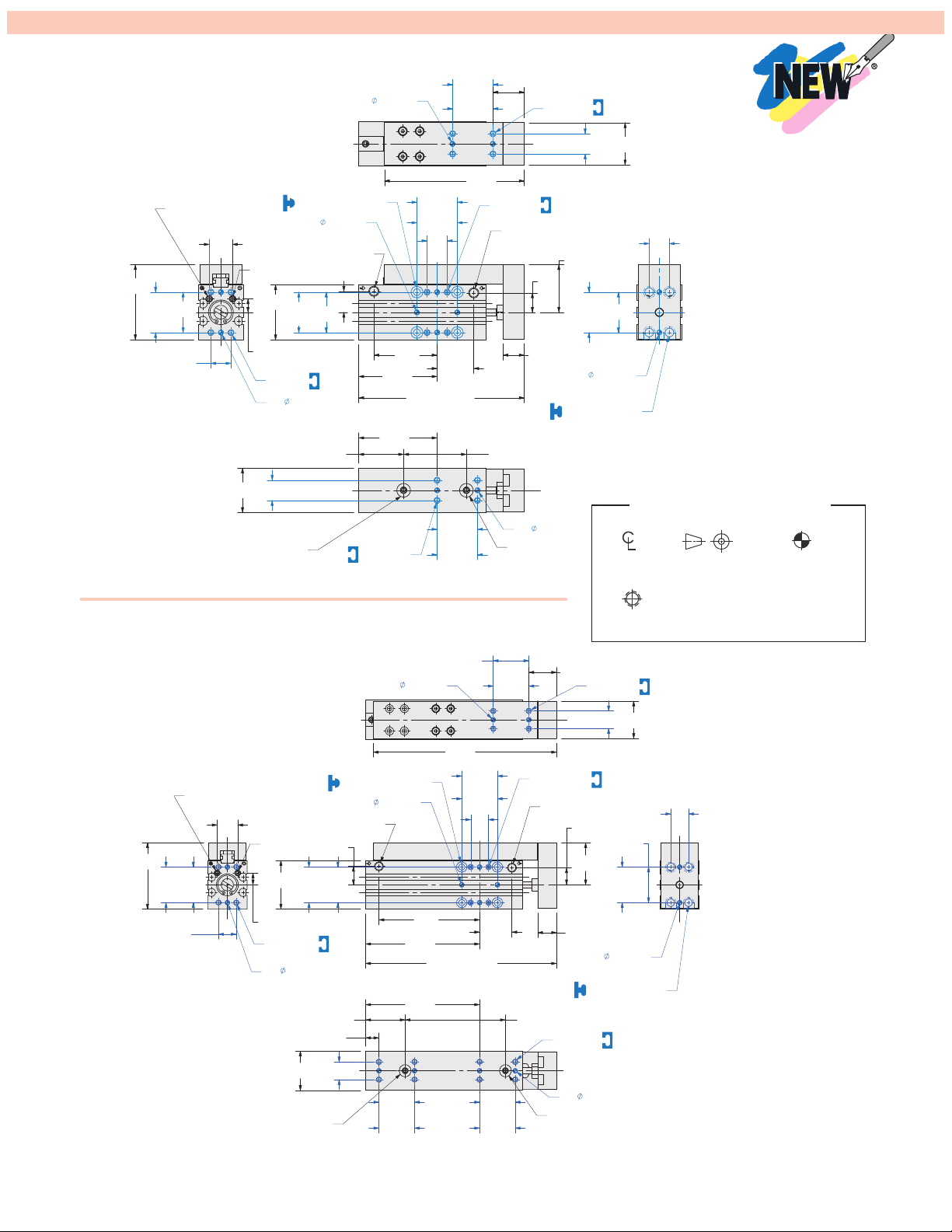

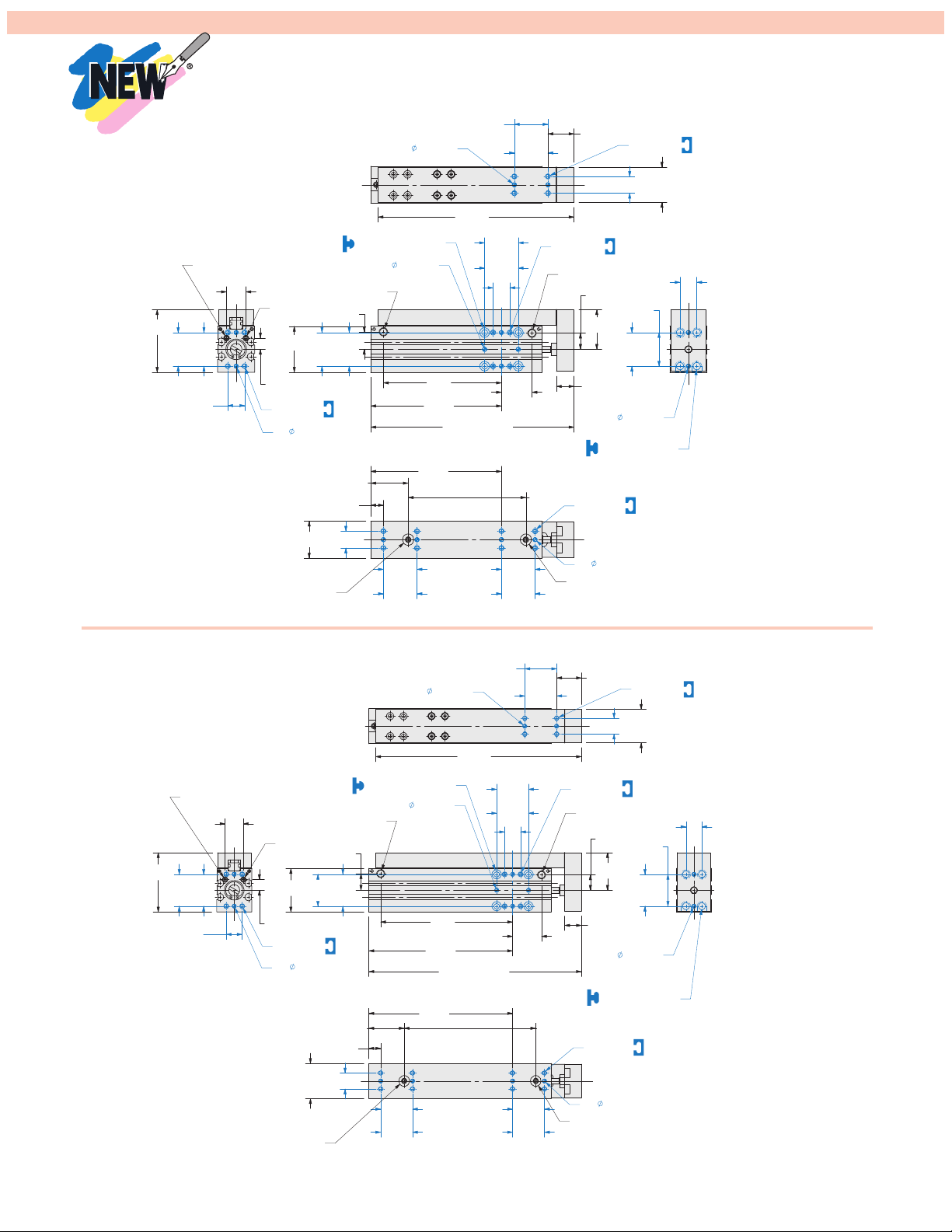

Dimensions: mm (in)

DIRECTCONNECT

TM

dimensions shown in blue

Dimensions: mm (in)

DIRECTCONNECT

TM

dimensions shown in blue

DLM-07M-12-12-P

MINI BALL

RAIL SLIDE

DLM-07M-25-25-P

MINI BALL

RAIL SLIDE

C

L

19.05

(

C

L

19.05

Third Angle

Projection

Dimensions are

symmetrical about

centerline

Imperial in Metric [mm]

0.00 = ±0 .01 [0.] = [±0 .25]

0.000 = ±0 .005 [0.0] = [±0.13]

0.0000 = ±0 .0005 [0.00] = [± 0 .013]

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±0.013 mm or (±.0005")

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

Metric Threads

Course Pitch

C-6

2X [M3 X 3 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

11

35.5

1.398)

19.05

(0.7500)

(DOWELS)

19.1

(0.750)

9.5

(0.375)

(0.43)

C

L

21.0

(0.827)

RETRACT

C

(0.25)

OPPOSITE SIDE PLUGGED

26.0

19.05

(1.024)

L

(0.7500)

(DOWELS)

6

[M3 X 2 DP]

[3 H7 X 2 DP]

2X

9.5

(0.375)

2X [ 3 H7 X 2 DP]

8X C'BORE & CLEARANCE

FOR [M3] SHCS

8X

[3 H7 X 2 DP]

2X [M5 X 4 DP]

(EXTEND PORT)

10

(0.39)

19.1

(0.750)

ALL DIMENSIONS THIS VIEW TYPICAL BOTH SIDES

21.2

(0.833)

37.0

(1.456)

37.0

(1.456)

(1.18)

30

19.05

(0.7500)

(DOWELS)

19.1

(0.750)

9.5

(0.375)

C

L

(0.68)

78 (3.08) RETRACT

(0.7500)

(DOWELS)

19.1

(0.750)

(2.599)

17

66.0

[M3 X 4 DP]

8X

OPPOSITE SIDE PLUGGED

29.6

(1.167)

14.8

(0.582)

[M3 X 4 DP]

4X

C

L

2X [M5 X 4 DP]

(RETRACT PORT)

9

(0.36)

C

L

10.0

(0.394)

C

L

9.5

20.0

(0.375)

(0.787)

22.5

(0.886)

19.05

19.1

(0.7500)

(0.750)

(DOWELS)

[3 H7 X 5 DP]

2X

4X [M4] THRU

C'BORE & CLEARANCE

FOR [M3]

(FROM FAR SIDE)

9.5

(0.375)

C

L

SUPPLIED PLUGGED

35.5

(1.398)

19.1

19.05

(0.750)

(0.7500)

(DOWELS)

9.5

(0.375)

2X MANIFOLD AIRPORTS:

[M3 X 3 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

2X [M3 X 3 DP]

(EXTEND PORT)

11

(0.43)

C

L

C

L

2X MANIFOLD AIRPORTS:

SUPPLIED PLUGGED

RETRACT

26.0

C

(1.024)

L

6

(0.25)

[M3 X 2 DP]

4X

[3 H7 X 2 DP]

2X

[M3 X 3 DP]

(EXTEND PORT)

8X C'BORE & CLEARANCE

2X [M5 X 4 DP]

OPPOSITE SIDE PLUGGED

(EXTEND PORT)

10

(0.39)

19.05

19.10

(0.7500)

(0.750)

(DOWELS)

21.2

(0.833)

7.1

(0.280)

21.0

9.5

(0.827)

(0.375)

19.1

(0.750)

54

(2.12)

61.0

(2.401)

102 (4.02) RETRACT

60.9

(2.401)

19.05

(0.7500)

(DOWELS)

(0.7500)

(DOWELS)

98.0

(3.859)

19.05

(0.7500)

(DOWELS)

19.1

(0.750)

9.5

(0.375)

C

L

(DOWELS)

(0.68)

(0.750)

19.05

(0.7500)

[M3 X 4 DP]

4X

[3 H7 X 2 DP]

2X

FOR [M3] SHCS

8X [ 3 H7 X 2 DP]

ALL DIMENSIONS THIS VIEW TYPICAL BOTH SIDES

19.1

(0.750)

19.05

(0.7500)

(DOWELS)

19.1

17

19.1

(0.750)

[3 H7 X 4 DP]

2X

RETRACT PORT

8X #4-40 X .17 DP

[M3 X 4 DP]

OPPOSITE SIDE PLUGGED

53.6

(2.112)

14.8

(0.582)

C

L

2X [M5 X 4 DP]

(RETRACT PORT)

9

(0.36)

22.5

(0.886)

10.0

(0.394)

C'BORE & CLEARANCE

8X

[M3 X 4 DP]

C

L

[3 H7 X 4 DP]

2X

RETRACT PORT

4X [M3 X 4 DP]

9.5

(0.375)

19.1

(0.750)

19.05

C

(0.7500)

L

(DOWELS)

[3 H7 X 5 DP]

2X

4X [M4] THRU

FOR [M3]

(FROM FAR SIDE)

20.0

(0.787)

9.5

(0.375)

C

L

Page 5

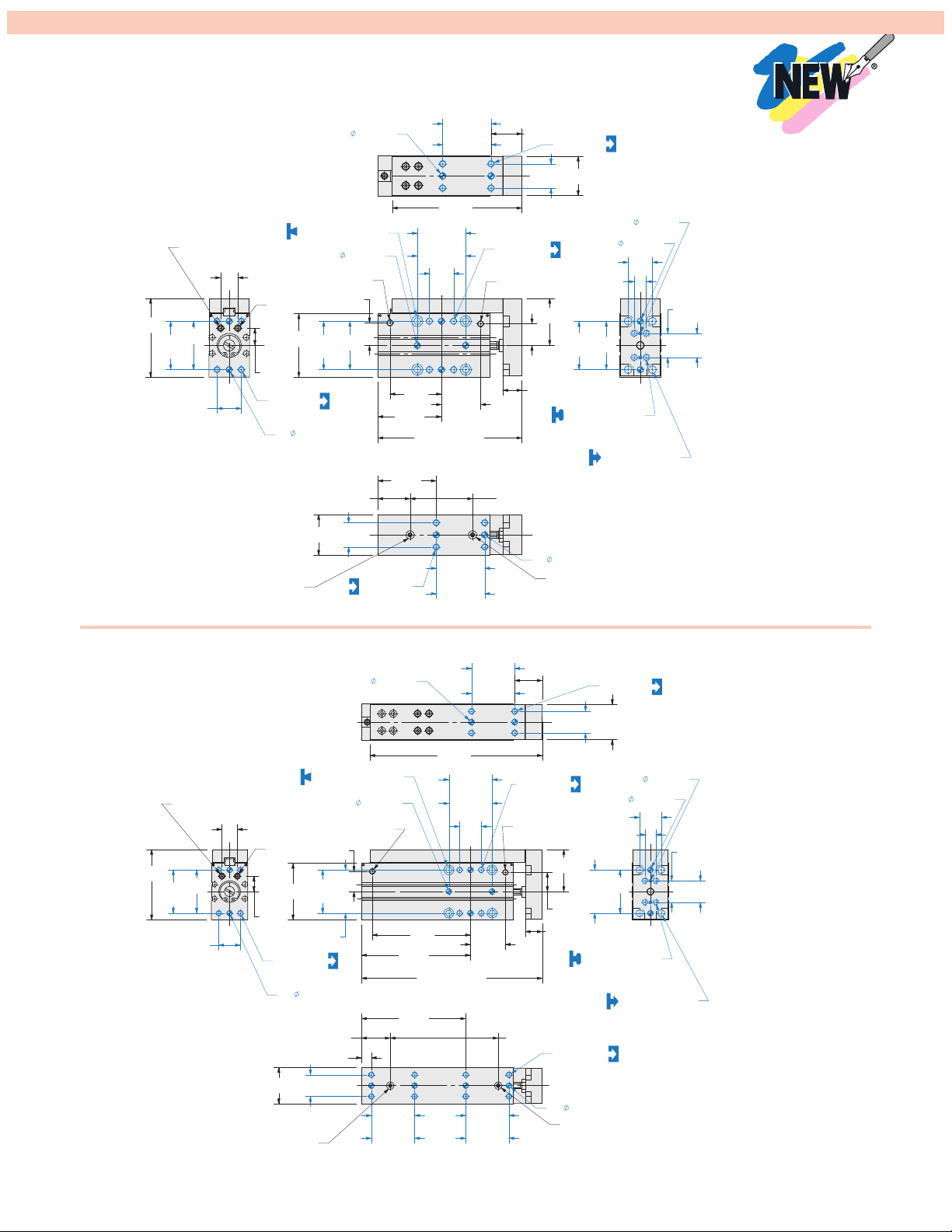

C-7

Dimensions: mm (in)

DIRECTCONNECT

TM

dimensions shown in blue

Dimensions: mm (in)

DIRECTCONNECT

TM

dimensions shown in blue

DLM-07M-38-38-P

MINI BALL

RAIL SLIDE

DLM-07M-50-50-P

MINI BALL

RAIL SLIDE

C

L

19.05

(

C

L

19.05

(

2X [M3 X 3 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

35.5

1.398)

19.05

(0.7500)

(DOWELS)

19.1

(0.750)

9.5

(0.375)

11

(0.43)

C

L

OPPOSITE SIDE PLUGGED

RETRACT

26.0

(1.024)

C

L

6

(0.25)

[M3 X 2 DP]

4X

[3 H7 X 2 DP]

2X

(0.827)

2X MANIFOLD AIRPORTS:

[M3 X 3 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

2X [M5 X 4 DP]

(EXTEND PORT)

19.05

(0.7500)

(DOWELS)

21.0

8X C'BORE & CLEARANCE

FOR [M3] SHCS

8X

10

(0.39)

19.1

(0.750)

21.2

(0.833)

7.1

(0.280)

9.5

(0.375)

(0.7500)

(DOWELS)

[3 H7 X 2 DP]

2X

111.0

(4.370)

[3 H7 X 2 DP]

67

(2.63)

74.0

(2.913)

115 (4.53) RETRACT

ALL DIMENSIONS THIS VIEW TYPICAL BOTH SIDES

74.0

(2.913)

19.1

(0.750)

19.05

(0.7500)

(DOWELS)

19.05

(0.7500)

(DOWELS)

19.1

(0.750)

9.5

(0.375)

C

L

(DOWELS)

17

(0.68)

19.1

(0.750)

19.05

(0.7500)

19.1

(0.750)

[M3 X 4 DP]

8X

OPPOSITE SIDE PLUGGED

66.6

(2.624)

14.8

(0.582)

C

L

2X [M5 X 4 DP]

(RETRACT PORT)

9

(0.36)

22.5

(0.886)

C

L

10.0

(0.394)

2X

C'BORE & CLEARANCE

[M3 X 4 DP]

8X

C

L

[3 H7 X 4 DP]

2X

RETRACT PORT

[M3 X 4 DP]

4X

9.5

(0.375)

19.1

(0.750)

19.05

(0.7500)

(DOWELS)

[3 H7 X 5 DP]

4X [M4] THRU

FOR [M3]

(FROM FAR SIDE)

20.0

(0.787)

9.5

(0.375)

C

L

[3 H7 X 2 DP]

2X

2X [M3 X 3 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

11

(0.43)

35.5

1.398)

19.05

(0.7500)

(DOWELS)

(0.375)

9.5

19.1

(0.750)

C

L

6

C

L

(0.25)

2X MANIFOLD AIRPORTS:

[M3 X 3 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

OPPOSITE SIDE PLUGGED

(EXTEND PORT)

RETRACT

19.05

26.0

(0.7500)

(1.024)

(DOWELS)

[M3 X 2 DP]

4X

[3 H7 X 2 DP]

2X

21.0

(0.827)

2X [M5 X 4 DP]

8X C'BORE & CLEARANCE

10

(0.39)

19.1

(0.750)

21.2

(0.833)

7.1

(0.280)

9.5

(0.375)

FOR [M3] SHCS

[3 H7 X 2 DP]

8X

(3.10)

86.0

(3.385)

ALL DIMENSIONS THIS VIEW TYPICAL BOTH SIDES

86.0

(3.385)

19.1

(0.750)

19.05

(0.7500)

(DOWELS)

(0.7500)

(DOWELS)

123.0

(4.843)

79

127 (5.00) RETRACT

19.05

(0.7500)

(DOWELS)

19.1

(0.750)

9.5

(0.375)

C

L

(DOWELS)

17

(0.68)

19.1

(0.750)

19.05

(0.7500)

19.1

(0.750)

78.6

(3.096)

8X

RETRACT PORT

14.8

(0.582)

C

L

[M3 X 4 DP]

OPPOSITE SIDE PLUGGED

(RETRACT PORT)

(0.36)

10.0

(0.394)

[M3 X 4 DP]

8X

C

L

[3 H7 X 4 DP]

2X

[M3 X 4 DP]

4X

9.5

20.0

(0.375)

(0.787)

2X [M5 X 4 DP]

9

19.1

(0.750)

22.5

(0.886)

19.05

C

(0.7500)

L

(DOWELS)

[3 H7 X 5 DP]

2X

4X [M4] THRU

C'BORE & CLEARANCE

FOR [M3]

(FROM FAR SIDE)

9.5

(0.375)

C

L

Page 6

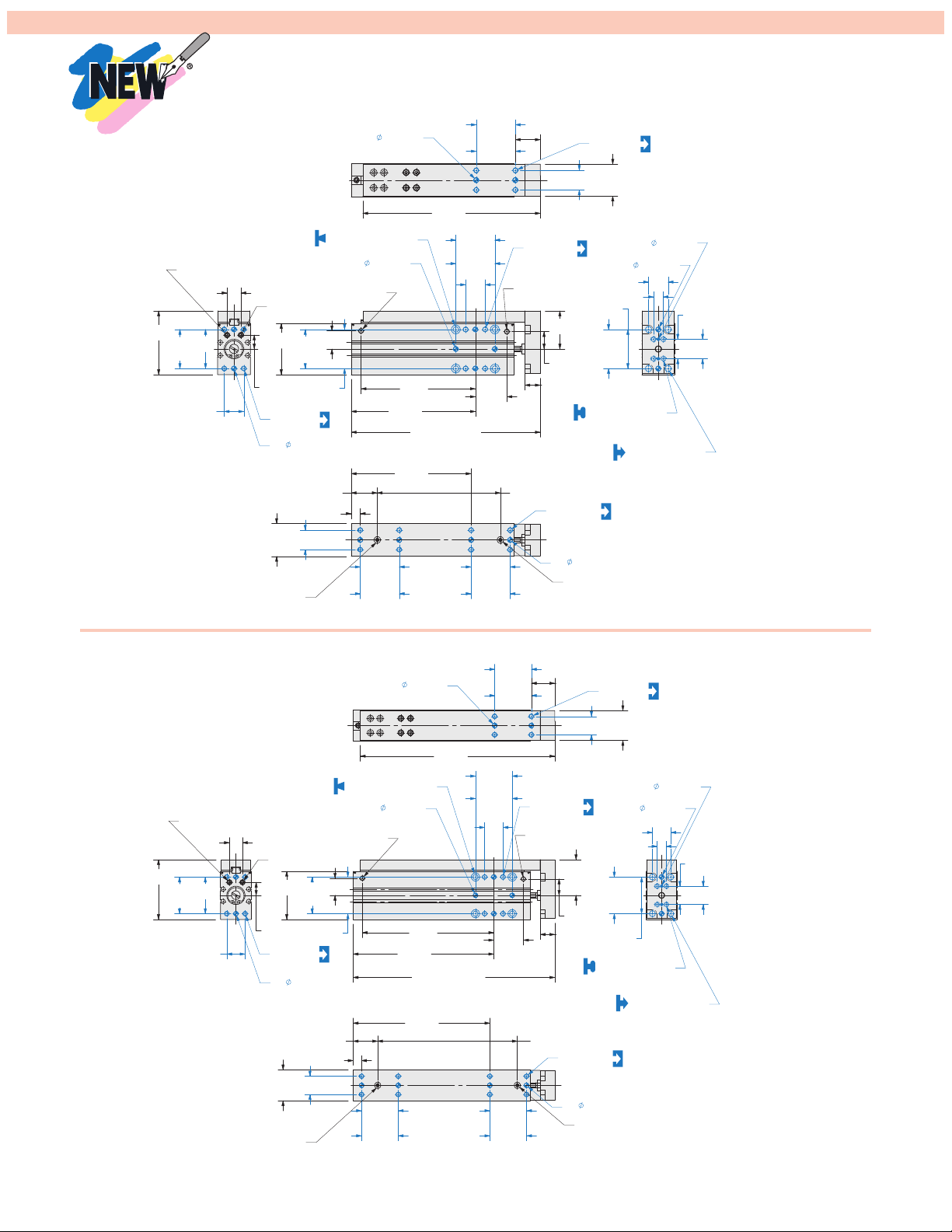

C-8

Dimensions: mm (in)

DIRECTCONNECT

TM

dimensions shown in blue

Dimensions: mm (in)

DIRECTCONNECT

TM

dimensions shown in blue

DLM-09M-25-25-P

MINI BALL

RAIL SLIDE

DLM-09M-50-50-P

MINI BALL

RAIL SLIDE

38.10

(

)

)

S)

38.10

(

)

)

S)

2X [M5 X 4 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

62.0

2.443)

38.10

(1.5000)

(DOWELS)

38.1

(1.500)

19.1

(0.750)

14

(0.53)

C

L

2X MANIFOLD AIRPORTS:

SUPPLIED PLUGGED

(EXTEND PORT)

C

(0.53)

[M5 X 3 DP]

OPPOSITE SIDE PLUGGED

RETRACT

50.0

(1.969)

L

13

[M5 X 5 DP]

4X

[5 H7 X 3 DP]

2X

[5 H7 X 3 DP]

2X

8X C'BORE & CLEARANCE

FOR [M5] SHCS

[5 H7 X 3 DP]

8X

2X [M5 X 4 DP]

(EXTEND PORT)

18

(0.70)

38.10

38.1

(1.5000)

(1.500)

(DOWELS)

ALL DIMENSIONS THIS VIEW TYPICAL BOTH SIDES

25.4

(1.000)

32.0

19.1

(1.260)

(0.750)

4X

(1.809)

[M5 X 10 DP]

38.10

(1.5000)

(DOWELS)

(1.500)

(0.750)

41

(1.60)

50.1

(1.973)

113 (4.46) RETRACT

45.9

38.1

19.1

C

(4.016)

L

(1.5000)

(DOWELS)

38.1

(1.500)

102.0

31

(1.21)

38.1

(1.500)

38.10

(1.5000)

(DOWELS)

25.3

(0.957)

4X

19.1

C

L

(0.750)

[M5 X 10 DP]

8X

2X [M5 X 4 DP]

OPPOSITE SIDE PLUGGED

(RETRACT PORT)

37.0

(1.458)

17

(0.67)

C

L

15.0

(0.591)

49.1

(1.934)

C

L

[5 H7 X 3 DP]

2X

RETRACT PORT

[M5 X 5 DP]

31.0

(1.220)

[5 H7 X 5 DP]

2X

9.5

(0.375)

38.10

38.1

(1.5000)

(1.500)

(DOWELS)

4X [M4] THRU

C'BORE & CLEARANCE

FOR [M3]

(FROM FAR SIDE)

4X [M6] THRU

C'BORE & CLEARANCE

(FROM FAR SIDE)

[3 H7 X 5 DP]

2X

19.1

(0.750)

19.05

(0.7500

(DOWEL

19.1

C

L

(0.750

C

L

FOR [M5]

152.0

(5.985)

38.10

(1.5000)

(DOWELS)

38.1

(1.500)

19.1

(0.750)

C

L

(DOWELS)

(1.5000)

(DOWELS)

38.1

(1.500)

31

(1.21)

38.1

(1.500)

38.10

(1.5000)

24.3

(0.957)

C

L

[M5 X 10 DP]

8X

2X [M5 X 4 DP]

OPPOSITE SIDE PLUGGED

(RETRACT PORT)

37.0

(1.458)

C

17

(0.67)

15.0

(0.591)

95.1

(3.745)

[M5 X 10 DP]

8X

C

L

[5 H7 X 3 DP]

4X

RETRACT PORT

4X

[M5 X 5 DP]

19.1

31.0

(0.750)

(1.220)

2X

(0.375)

38.1

38.10

(1.500)

L

(1.5000)

(DOWELS)

4X [M4] THRU

C'BORE & CLEARANCE

FOR [M3]

(FROM FAR SIDE)

[3 H7 X 5 DP]

2X

[5 H7 X 5 DP]

19.1

(0.750)

9.5

C

L

C

L

4X [M6] THRU

C'BORE & CLEARANCE

FOR [M5]

(FROM FAR SIDE)

19.05

(0.7500

(DOWEL

19.1

(0.750

[5 H7 X 3 DP]

2X

8X C'BORE & CLEARANCE

2X [M5 X 4 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

14

(0.53)

RETRACT

62.0

2.443)

38.1

38.10

(1.500)

(1.5000)

(DOWELS)

19.1

(0.750)

C

L

14

(0.53)

C

L

4X

2X

32.0

(1.260)

2X MANIFOLD AIRPORTS:

[M5 X 3 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

FOR [M5] SHCS

2X [M5 X 4 DP]

OPPOSITE SIDE PLUGGED

(EXTEND PORT)

(0.70)

38.10

50.0

(1.5000)

(1.969)

(DOWELS)

38.1

(1.500)

[M5 X 5 DP]

[5 H7 X 3 DP]

25.4

(1.000)

(0.344)

19.1

(0.750)

[5 H7 X 3 DP]

8X

18

87

(3.41)

96.1

(3.784)

159 (6.27) RETRACT

ALL DIMENSIONS THIS VIEW TYPICAL BOTH SIDES

91.9

(3.620)

8.7

38.1

(1.500)

38.10

(1.5000)

(DOWELS)

Page 7

C-9

Dimensions: mm (in)

DIRECTCONNECT

TM

dimensions shown in blue

Dimensions: mm (in)

DIRECTCONNECT

TM

dimensions shown in blue

DLM-09M-75-75-P

MINI BALL

RAIL SLIDE

DLM-09M-100-100-P

MINI BALL

RAIL SLIDE

38.10

(

)

S)

38.10

(

)

S)

2X [M5 X 4 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

62.0

2.443)

38.10

(1.5000)

(DOWELS)

14

(0.53)

38.1

(1.500)

C

19.1

(0.750)

2X MANIFOLD AIRPORTS:

SUPPLIED PLUGGED

L

[M5 X 3 DP]

(EXTEND PORT)

OPPOSITE SIDE PLUGGED

RETRACT

50.0

38.10

(1.969)

C

L

(1.5000)

(DOWELS)

14

(0.53)

[M5 X 5 DP]

4X

[5 H7 X 3 DP]

2X

19.1

32.0

(0.750)

(1.260)

8X C'BORE & CLEARANCE

FOR [M5] SHCS

8X

2X [M5 X 4 DP]

(EXTEND PORT)

18

(0.70)

38.1

(1.500)

25.4

(1.000)

8.7

(0.344)

(1.5000)

173.0

(6.811)

38.10

(1.5000)

(DOWELS)

38.1

(1.500)

19.1

(0.750)

C

L

(DOWELS)

(DOWELS)

38.1

(1.500)

(1.21)

38.1

(1.500)

38.10

(1.5000)

[5 H7 X 3 DP]

2X

[5 H7 X 3 DP]

112

(4.39) 31

121.1

(4.768)

184 (7.26) RETRACT

ALL DIMENSIONS THIS VIEW TYPICAL BOTH SIDES

116.9

(4.604)

38.1

(1.500)

38.10

(1.5000)

(DOWELS)

24.3

(0.957)

19.1

C

L

(0.750)

[M5 X 10 DP]

8X

2X [M5 X 4 DP]

OPPOSITE SIDE PLUGGED

(RETRACT PORT)

37.0

(1.458)

C

L

17

(0.67)

15.0

(0.591)

120.1

(4.729)

[M5 X 10 DP]

8X

C

L

[5 H7 X 3 DP]

4X

RETRACT PORT

[M5 X 5 DP]

4X

31.0

(1.220)

[3 H7 X 5 DP]

2X

[5 H7 X 5 DP]

2X

(0.750)

9.5

(0.375)

38.1

(1.500)

38.10

(1.5000)

(DOWELS)

4X [M4] THRU

C'BORE & CLEARANCE

FOR [M3]

(FROM FAR SIDE)

4X [M6] THRU

C'BORE & CLEARANCE

FOR [M5]

(FROM FAR SIDE)

19.1

19.05

(0.7500

(DOWEL

19.1

C

L

(0.750)

C

L

[5 H7 X 3 DP]

2X

8X C'BORE & CLEARANCE

(0.70)

38.1

(1.500)

25.4

(1.000)

(0.344)

FOR [M5] SHCS

[5 H7 X 3 DP]

8X

18

ALL DIMENSIONS THIS VIEW TYPICAL BOTH SIDES

8.7

38.1

(1.500)

38.10

(1.5000)

(DOWELS)

2X [M5 X 4 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

62.0

2.443)

38.10

(1.5000)

(DOWELS)

14

(0.53)

38.1

(1.500)

C

L

19.1

(0.750)

2X MANIFOLD AIRPORTS:

SUPPLIED PLUGGED

(EXTEND PORT)

C

[M5 X 3 DP]

OPPOSITE SIDE PLUGGED

RETRACT

50.0

38.10

(1.969)

(1.5000)

L

(DOWELS)

14

(0.53)

[M5 X 5 DP]

4X

[5 H7 X 3 DP]

2X

32.0

19.1

(1.260)

(0.750)

2X [M5 X 4 DP]

(EXTEND PORT)

137

(5.38)

146.1

(5.752)

209 (8.24) RETRACT

141.9

(5.588)

202.0

(7.953)

(DOWELS)

38.10

(1.5000)

(DOWELS)

38.1

(1.500)

19.1

(0.750)

C

L

(1.5000)

(DOWELS)

(1.5000)

38.1

(1.500)

8X

OPPOSITE SIDE PLUGGED

31

(1.21)

145.1

(5.713)

38.1

(1.500)

38.10

24.3

(0.957)

C

L

(0.750)

[M5 X 10 DP]

2X [M5 X 4 DP]

(RETRACT PORT)

37.0

(1.458)

17

(0.67)

15.0

(0.591)

[M5 X 10 DP]

8X

C

L

[5 H7 X 3 DP]

4X

RETRACT PORT

[M5 X 5 DP]

4X

19.1

31.0

(1.220)

2X

(0.375)

38.10

C

(1.5000)

L

(DOWELS)

38.1

(1.500)

4X [M4] THRU

C'BORE & CLEARANCE

FOR [M3]

(FROM FAR SIDE)

[3 H7 X 5 DP]

2X

[5 H7 X 5 DP]

19.1

(0.750)

9.5

4X [M6] THRU

C'BORE & CLEARANCE

(FROM FAR SIDE)

C

L

FOR [M5]

C

L

19.05

(0.7500

(DOWEL

19.1

(0.750)

Page 8

C-10

Dimensions: mm (in)

DIRECTCONNECT

TM

dimensions shown in blue

Dimensions: mm (in)

DIRECTCONNECT

TM

dimensions shown in blue

DLM-12M-25-25-P

MINI BALL

RAIL SLIDE

DLM-12M-50-50-P

MINI BALL

RAIL SLIDE

38.10

(

)

)

S)

38.10

(

)

S)

2X [M5 X 4 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

17

65.0

2.561)

38.10

(1.5000)

(DOWELS)

38.1

(1.500)

19.1

(0.750)

(0.69)

C

L

2X MANIFOLD AIRPORTS:

[M5 X 7 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

OPPOSITE SIDE PLUGGED

RETRACT

50.0

(1.969)

C

L

13

(0.53)

[M5 X 5 DP]

4X

[5 H7 X 3 DP]

2X

[5 H7 X 3 DP]

2X

8X C'BORE & CLEARANCE

FOR [M5] SHCS

[5 H7 X 3 DP]

8X

2X [M5 X 4 DP]

(EXTEND PORT)

18

(0.70)

38.1

38.10

(1.500)

(1.5000)

(DOWELS)

ALL DIMENSIONS THIS VIEW TYPICAL BOTH SIDES

29.6

(1.165)

32.0

19.1

(1.260)

(0.750)

4X

56.9

(2.242)

56.9

(2.242)

[M5 X 10 DP]

38.10

(1.5000)

(DOWELS)

38.1

(1.500)

19.1

(0.750)

C

L

41

(1.62)

126 (4.97) RETRACT

(1.5000)

(DOWELS) 26.8

38.1

(1.500)

105.0

(4.134)

[M5 X 10 DP]

8X

2X [M5 X 4 DP]

OPPOSITE SIDE PLUGGED

(RETRACT PORT)

35

(1.38)

53.5

(2.108)

38.1

(1.500)

38.10

(1.5000)

(DOWELS)

(1.054)

C

L

40.0

(1.576)

17

(0.67)

15.0

(0.591)

C

L

[5 H7 X 3 DP]

2X

RETRACT PORT

[M5 X 5 DP]

4X

19.1

31.0

(0.750)

(1.220)

(0.375)

38.10

38.1

C

(1.5000)

L

(1.500)

(DOWELS)

4X [M4] THRU

C'BORE & CLEARANCE

FOR [M3]

(FROM FAR SIDE)

[3 H7 X 5 DP]

2X

[5 H7 X 5 DP]

2X

19.1

(0.750)

9.5

C

L

4X [M6] THRU

C'BORE & CLEARANCE

FOR [M5]

(FROM FAR SIDE)

C

L

19.05

(0.7500

(DOWEL

19.1

(0.750

158.0

(6.221)

38.10

(1.5000)

(DOWELS)

38.1

(1.500)

19.1

(0.750)

(DOWELS)

C

L

(DOWELS)

(1.5000)

38.1

(1.500)

35

(1.38)

38.1

(1.500)

38.10

(1.5000)

26.8

(1.054)

C

L

(0.750)

[M5 X 10 DP]

8X

2X [M5 X 4 DP]

OPPOSITE SIDE PLUGGED

(RETRACT PORT)

40.0

(1.576)

C

(1.5000)

L

(DOWELS)

17

(0.67)

15.0

(0.591)

97.1

(3.824)

C

L

[5 H7 X 3 DP]

4X

RETRACT PORT

[M5 X 5 DP]

4X

19.1

31.0

(1.220)

[3 H7 X 5 DP]

2X

[5 H7 X 5 DP]

2X

(0.750)

9.5

(0.375)

38.10

38.1

(1.500)

4X [M4] THRU

C'BORE & CLEARANCE

FOR [M3]

(FROM FAR SIDE)

4X [M6] THRU

C'BORE & CLEARANCE

FOR [M5]

(FROM FAR SIDE)

19.1

19.05

(0.7500

(DOWEL

19.1

C

L

(0.750)

C

L

[5 H7 X 3 DP]

2X

8X C'BORE & CLEARANCE

FOR [M5] SHCS

2X [M5 X 4 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

17

(0.69)

65.0

2.561)

38.10

(1.5000)

(DOWELS)

19.1

(0.750)

38.1

(1.500)

2X MANIFOLD AIRPORTS:

RETRACT

C

L

(1.969)

13

(0.53)

C

L

[M5 X 5 DP]

4X

2X

[M5 X 7 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

50.0

[5 H7 X 3 DP]

8X

[5 H7 X 3 DP]

2X [M5 X 4 DP]

OPPOSITE SIDE PLUGGED

(EXTEND PORT)

18

(0.70)

38.1

38.10

(1.500)

(1.5000)

(DOWELS)

28.6

(1.125)

32.0

19.1

(1.260)

(0.750)

81

(3.19)

96.9

(3.816)

166 (6.55) RETRACT

ALL DIMENSIONS THIS VIEW TYPICAL BOTH SIDES

96.9

(3.816)

8.7

(0.344)

[M5 X 10 DP]

8X

Page 9

C-11

Dimensions: mm (in)

DIRECTCONNECT

TM

dimensions shown in blue

Dimensions: mm (in)

DIRECTCONNECT

TM

dimensions shown in blue

DLM-12M-75-75-P

MINI BALL

RAIL SLIDE

DLM-12M-100-100-P

MINI BALL

RAIL SLIDE

38.10

(

)

)

S)

38.10

(

)

S)

2X [M5 X 4 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

.69

[ 17 ]

RETRACT

65.0

2.561)

38.10

(1.5000)

(DOWELS)

38.1

(1.500)

19.1

(0.750)

2X MANIFOLD AIRPORTS:

SUPPLIED PLUGGED

C

L

[M5 X 7 DP]

(EXTEND PORT)

C

L

(0.53)

13

50.0

(1.969)

4X

2X

(DOWELS)

[M5 X 5 DP]

[5 H7 X 3 DP]

8X C'BORE & CLEARANCE

FOR [M5] SHCS

[5 H7 X 3 DP]

8X

2X [M5 X 4 DP]

OPPOSITE SIDE PLUGGED

(EXTEND PORT)

18

(0.70)

38.10

38.1

(1.5000)

(1.500)

28.6

(1.125)

32.0

19.1

(1.260)

(0.750)

(1.5000)

186.0

(7.323)

38.10

(1.5000)

(DOWELS)

38.1

(1.500)

19.1

(0.750)

C

L

(DOWELS)

38.1

(1.500)

35

(1.38)

38.1

(1.500)

38.10

(1.5000)

(DOWELS)

8X

OPPOSITE SIDE PLUGGED

[5 H7 X 3 DP]

2X

108

(4.25)

123.9

(4.879)

193 (7.61) RETRACT

ALL DIMENSIONS THIS VIEW TYPICAL BOTH SIDES

123.9

(4.879)

8.7

(0.344)

[M5 X 10 DP]

8X

26.8

(1.054)

C

L

[M5 X 10 DP]

2X [M5 X 4 DP]

(RETRACT PORT)

40.0

(1.576)

(0.67)

15.0

(0.591)

124.1

(4.887)

C

L

4X

31.0

19.1

(1.220)

(0.750)

38.10

C

(1.5000)

L

(DOWELS)

17

4X [M4] THRU

C'BORE & CLEARANCE

(FROM FAR SIDE)

[5 H7 X 3 DP]

RETRACT PORT

[M5 X 5 DP]

4X

[3 H7 X 5 DP]

2X

[5 H7 X 5 DP]

2X

19.1

(0.750)

9.5

(0.375)

38.1

(1.500)

C

L

FOR [M3]

4X [M6] THRU

C'BORE & CLEARANCE

FOR [M5]

(FROM FAR SIDE)

19.05

(0.7500

(DOWEL

19.1

C

L

(0.750

(1.5000)

208.0

38.10

(1.5000)

(DOWELS)

38.1

(1.500)

19.1

(0.750)

C

L

(DOWELS)

(DOWELS)

38.1

(1.500)

8X

OPPOSITE SIDE PLUGGED

35

(1.38)

38.1

(1.500)

38.10

(1.5000)

26.8

(1.054)

C

L

[M5 X 10 DP]

2X [M5 X 4 DP]

(RETRACT PORT)

40.0

(1.576)

17

(0.67)

15.0

(0.591)

149.1

(5.872)

C

L

4X

[M5 X 5 DP]

4X

19.1

31.0

(0.750)

(1.220)

2X

(0.375)

38.10

38.1

C

(1.5000)

L

(1.500)

(DOWELS)

4X [M4] THRU

C'BORE & CLEARANCE

FOR [M3]

(FROM FAR SIDE)

[5 H7 X 3 DP]

RETRACT PORT

[3 H7 X 5 DP]

2X

[5 H7 X 5 DP]

19.1

(0.750)

9.5

C

L

C

L

4X [M6] THRU

C'BORE & CLEARANCE

FOR [M5]

(FROM FAR SIDE)

19.05

(0.7500

(DOWEL

19.1

(0.750)

[ 5 H7 X 3 DP]

2X

8X C'BORE & CLEARANCE

2X [M5 X 4 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

17

(0.69)

RETRACT

65.0

2.561)

38.10

38.1

(1.5000)

(1.500)

(DOWELS)

19.1

(0.750)

50.0

C

L

(1.969)

(1.5000)

(DOWELS)

13

C

L

(0.53)

[M5 X 5 DP]

4X

[5 H7 X 3 DP]

2X

32.0

(1.260)

2X MANIFOLD AIRPORTS:

[M5 X 7 DP]

SUPPLIED PLUGGED

(EXTEND PORT)

FOR [M5] SHCS

8X

[5 H7 X 3 DP]

2X [M5 X 4 DP]

OPPOSITE SIDE PLUGGED

(EXTEND PORT)

18

(0.70)

38.1

38.10

(1.500)

28.6

(1.125)

19.1

(0.750)

148.9

(5.864)

ALL DIMENSIONS THIS VIEW TYPICAL BOTH SIDES

8.7

(0.344)

[M5 X 10 DP]

8X

(8.189)

133

(5.24)

218 (8.60) RETRACT

148.9

(5.864)

Page 10

28

(1.09)

19

(0.76)

Flow Controls

18

(0.72)

1

(0.02)

5

(0.19)

OHSP-011

OHSN-011

($63 each)

5

(0.19)

18

(0.73)

Position Sensors

Dimensions:

mm (in)

l Position Sensors Available—PNP and NPN Magneto

Resistive Style, 2 per Slide Recommended

l Sensors are Slot Mounted, No Mounting Kits Required

l Simple Adjustment with Slotted Screw Driver

l Built-In LED for Ease of Positioning and Troubleshooting

l Low Profile Sensor Version or 90° Wire Exit Sensor Version

l Sensor Extension Cables Available—5 m Long, Quick-

Disconnect Style (Model No. CABL-013, $26)

Pneumatic Controls

l Adjustable Flow Controls:

• Thumb Screw Adjust with Locking Nut for

Adjusting Actuation Time

• Pneumatic Tubing Available

l Manifold O-Ring Seals (Model No. SLKT-239 and SLKT-240)

l Additional Pneumatic Controls and Accessories Available,

Visit omega.com/pneumatic-valves or Consult Sales

To Order (Specify Model Number)

MOST POPULAR MODELS HIGHLIGHTED!

LENGTH LENGTH MAXIMUM MAXIMUM MAXIMUM

RETRACTED EXTENDED STROKE FORCE PAYLOAD

MODEL NO. PRICE mm (in) mm (in) mm (in) @ 6.2 bar (90 psi) kg (lb)

DLM-07M-12-12-P $221 78 (3.08) 90 (3.58) 12 (0.50) 66.7 (15) 0.45 (1.0)

DLM-07M-25-15-P 231 102 (4.02) 117 (4.60) 15 (0.59) 66.7 (15) 0.45 (1.0)

DLM-07M-25-25-P 231 102 (4.02) 127 (5.02) 25 (1.00) 66.7 (15) 0.45 (1.0)

DLM-07M-38-38-P 241 115 (4.53) 153 (6.03) 38 (1.50) 66.7 (15) 0.45 (1.0)

DLM-07M-50-50-P 261 127 (5.00) 177 (7.00) 50 (1.96) 66.7 (15) 0.45 (1.0)

DLM-09M-25-25-P 283 113 (4.46) 138 (5.56) 25 (1.00) 138 (31) 0.91 (2.0)

DLM-09M-50-50-P 303 160 (6.28) 210 (8.28) 50 (1.96) 138 (31) 0.91 (2.0)

DLM-09M-75-75-P 324 185 (7.26) 260 (10.26) 75 (3.00) 138 (31) 0.91 (2.0)

DLM-09M-100-100-P 344 209 (8.24) 309 (12.24) 100 (3.93) 138 (31) 0.91 (2.0)

DLM-12M-25-25-P 305 126 (4.97) 151 (5.97) 25 (1.00) 231 (52) 1.81 (4.0)

DLM-12M-50-50-P 336 166 (6.55) 216 (8.55) 50 (1.96) 231 (52) 1.81 (4.0)

DLM-12M-75-75-P 356 194 (7.61) 269 (10.61) 75 (3.00) 231 (52) 1.81 (4.0)

DLM-12M-100-100-P 377 220 (8.60) 320 (12.60) 100 (3.93) 231 (52) 1.81 (4.0)

Recommended accessories include 2 sensors and 2 flow control valves for each slide, along with a 4 way 2 position valve.

Ordering Examples: DLM-07M-12-12-P, mini pneumatic powered precision rail slide with a maximim stroke of 12 mm (0.50") $221.

DLM-09M-75-75-P and DLM-09M-100-100P, mini precision rail slides can be quickly assembled without adaptor plates to make a

pick-and-place with 75 mm (3") horizontal and 100 mm (4") vertical motion, $324 + 344 = $668.

ACCESSORIES

MODEL NO. PRICE DESCRIPTION

SENSOR ACCESSORIES

OHSP-011 $63.00 PNP magneto resistive sensor 90° barrell with quick disconnect fitting

OHSN-011 63.00 NPN magneto resistive sensor 90° barrell with quick disconnect fitting

OHSP-017 63.00 PNP magneto resistive sensor short barrell with quick disconnect fitting

OHSN-017 63.00 NPN magneto resistive sensor short barrell with quick disconnect fitting

CABL-010 23.00 2 m sensor extension cable with quick disconnect fitting

CABL-013 26.00 5 m sensor extension cable with quick disconnect fitting

PNEUMATIC ACCESSORIES

TYUTH95-532332-100 $15.00 Polyurethane 4 mm (

TYUTH95-14160-100 34.00 Polyurethane 6 mm (

OM-AIR-C0K510405 5.20 Push-to-connect flow control valve, M5 thread – 4 mm (

OM-AIR-C2VA00405 6.25 Push-to-connect flow control valve, M5 thread – 6 mm (

see omega.com/airline-tubing

OM-AIR-M02250403-5PK 11.00 Push-to-connect male adaptor, M3 thread – 4 mm (

5

") tubing 31 m (100'), assorted colors available,

⁄

32

1

") tubing 31 m (100')

⁄

4

5

") OD

⁄

32

1

") OD

⁄

4

5

") OD, package of 5

⁄

32

C-12

Page 11

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...