Page 1

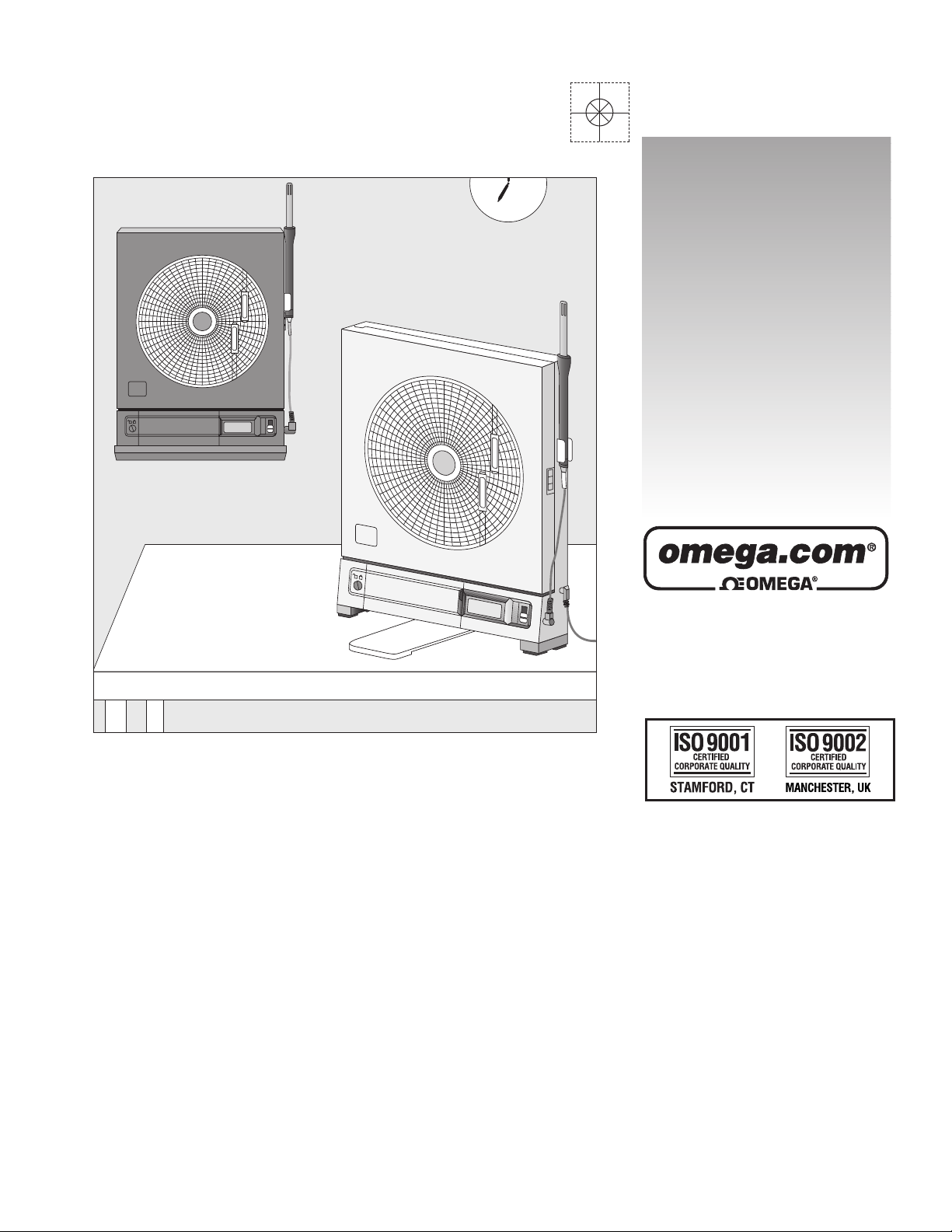

CT485B-110V-G-AL,

CT485B-220V-G-AL,

CT485B-110V-W-AL,

CT485B-220V-W-AL

High Performance

Microprocessor-Based Temperature

and Humidity Recorder

6

7

8

9

5

4

3

R

H

°

F

°

C

74

T

E

M

P

E

R

A

T

U

R

E

H

U

M

I

D

I

T

Y

H

O

T

O

RH

°F

°C

H

35 T2

T

E

M

P

E

R

A

T

U

R

E

H

U

M

I

D

I

T

Y

74

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

Shop online at

User’s Guide

Page 2

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

TEL: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Espan˜ol: (001) 203-359-7803

e-mail: espanol@omega.com

FAX: (001) 203-359-7807

info@omega.com.mx

Servicing Europe:

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

High Performance Microprocessor-Based

Temperature/Humidity Recorder with Remote Sensor

i

TABLE OF

CONTENTS

Page

Chapter 1 Introduction ....................................................................... 1-1

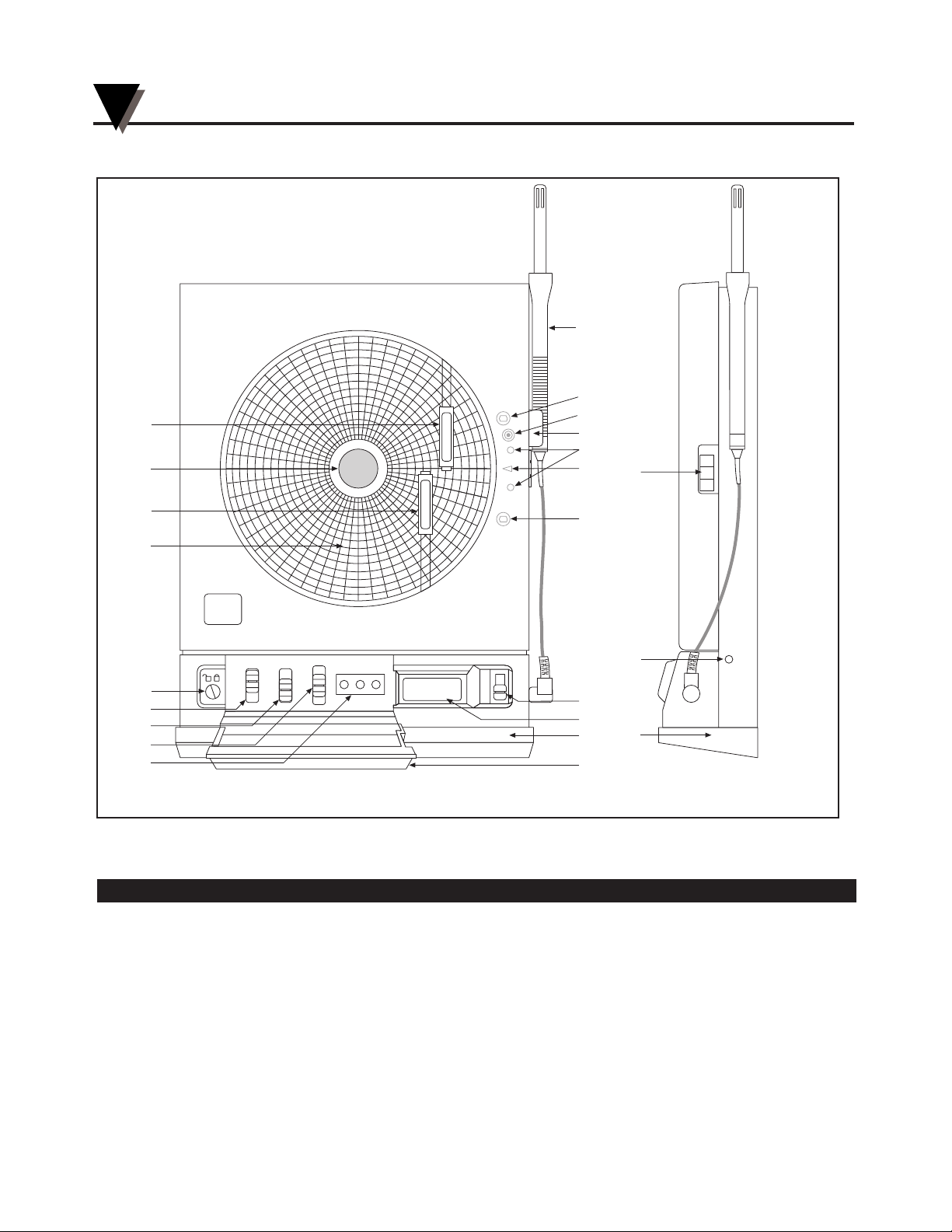

1.1 Parts of the Recorder - Front and Side Views .................................. 1-2

1.2 Parts of the Recorder - Rear View ...................................................... 1-4

Chapter 2 Setting Up the Recorder ..................................................... 2-1

2.1 Placing the Recorder on the Bench Top ............................................ 2-1

2.2 Mounting the Recorder on the Wall .................................................. 2-3

2.3 Using Batteries ...................................................................................... 2-4

2.3.1 Installing Batteries ................................................................... 2-4

2.3.2 Connecting ac power .............................................................. 2-5

2.4 Installing the Chart Paper ................................................................... 2-6

2.5 Installing and Removing Pens ........................................................... 2-8

2.5.1 Installing the Pens ................................................................... 2-8

2.5.2 Removing the Pens ................................................................ 2-10

2.6 Installing the Temperature/Humidity Sensor ............................... 2-11

2.6.1 Using the Short Cable ........................................................... 2-11

2.6.2 Using the Remote Sensor Cable .......................................... 2-12

2.6.3 Using the Sensor Clip ........................................................... 2-13

Chapter 3 Powering Up the Recorder ................................................. 3-1

3.1 Turning on the Recorder ..................................................................... 3-1

3.2 Recording the Code Numbers ............................................................ 3-1

3.3 Comparing Code Numbers ................................................................ 3-2

3.4 Final Display Mode .............................................................................. 3-3

Chapter 4 Alarm Operation ............................................................... 4-1

4.1 Alarm Description ............................................................................... 4-1

4.2 Checking Alarm Limits ....................................................................... 4-1

4.3 Unlocking/Locking the Control Panel Door ................................... 4-2

4.3.1 Unlocking the Control Panel Door ....................................... 4-2

4.3.2 Locking the Control Panel Door ........................................... 4-2

4.4 Setting/Changing Alarm Limits ........................................................ 4-3

4.5 Turning the Alarm Off ......................................................................... 4-4

4.6 Disabling the Alarm ............................................................................ 4-5

Chapter 5 Calibrating the Recorder .................................................... 5-1

5.1 Factory Calibration Information ........................................................ 5-1

5.2 Changing Calibration Codes .............................................................. 5-1

5.3 Calibrating Humidity Readings ......................................................... 5-4

5.3.1 Humidity Calibration at 33% Humidity .............................. 5-6

5.3.2 Humidity Calibration at 75% Humidity .............................. 5-7

5.4 Calibrating Temperature Readings .................................................... 5-8

Page 4

High Performance Microprocessor-Based

Temperature/Humidity Recorder with Remote Sensor

ii

TABLE OF

CONTENTS

Page

Chapter 6 Using the Cal-Lock Kit ........................................................ 6-1

Chapter 7 Using the Voltage Input Adapter (Optional) ........................ 7-1

Chapter 8 Maintaining the Recorder .................................................. 8-1

8.1 General Considerations ....................................................................... 8-1

8.2 Light Bulb, Display Backlighting and Push Button Information .... 8-2

8.3 Case Care................................................................................................ 8-3

8.4 Storage of Chart Paper ........................................................................ 8-3

8.5 Power Failure Mode (Chart Paper Indication) ................................ 8-3

Chapter 9 Troubleshooting the Recorder ............................................ 9-1

Chapter 10 Technical Details ............................................................ 10-1

10.1 Sensors and Measurement ................................................................ 10-1

10.2 Pen Arm Drive .................................................................................... 10-1

10.3 Chart Paper Drive Mechanism ......................................................... 10-2

10.4 Power Supply Supervision ............................................................... 10-2

Chapter 11 Specifications ................................................................ 11-1

Chapter 12 Sensor Design for CE Conformity .....................................12-1

Index ....................................................................................................... I

Page 5

Introduction

1-1

1

This Electronic Temperature and Humidity Chart Recorder with Remote Sensor

is an advanced micro computer controlled measuring and recording instrument.

The recorder affords precision rapid response, memory and display of peak

readings, remote sensing, recording flexibility and simplicity of operation. This

compact, portable instrument offers advanced features previously unavailable in

its price range.

Features include:

• Continuous Update of Ambient °C or °F Temperature and Relative

Humidity

• Rapid Response to Changes in Ambient Temperature and Humidity

• Remote Mount Sensor

• Digital Plots in 1° or 1% Increments

• Memory and Display of Peak Readings

• 1, 7 or 32 Day Charts

• Battery or ac Power Operation With Automatic Battery Power Backup

• Chart Indication for ac Power Failure/ac Power Return

• Audible Alarm with Relay Contact

• Low Battery Indicator

• Portable

• Wall Mount or Benchtop Mount

• Optional Analog Voltage Input Adapter to record an external 20 to 1200mV

dc signal using the temperature pen

• Chart Lighting and display backlighting with use of ac adaptor

• Control Panel Lock

• Decorative Foot Cover for wall mounting

These features provide precise documentation, flexibility in application and ease

of use, all made possible through the incorporation of advanced electronics.

Page 6

1.1 Parts of the Recorder - Front and Side Views

Figure 1-1. Front and Side Views of the Recorder

Item Description Function

1 Chart Paper Knob (magnetic) Holds chart paper in place.

2 Light Bulbs Lights up the paper in a dark room. Note that the bulbs function only

when the recorder is powered by the 9Vdc adapter.

3 Pen Cap Posts Holds the loose pen caps.

4 Time Set Arrow Helps align the time on the new chart paper with the actual time.

5 Chart Paper (double sided) Charts are available for 1, 7, and 32 day recording times in both °C

and °F. See the inside back cover for a detailed list of paper

available.

H

35 T2

RH

°F

°C

HIGH SET LOW

1

7

32

°F

°C

0

I

CHART TYPE

PWR

ALARM

1

6

15

5

15

T

E

M

P

E

R

A

T

U

R

E

H

U

M

I

D

I

T

Y

74

17

7

8

10

9

2

2

3

4

16

13

12

11

18

14

18

19

20

Introduction

1

1-2

FRONT VIEW SIDE VIEW

Page 7

Item Description Function

6 ac Power Jack Allows the unit to be powered from ac power using the ac adaptor

(110Vac stepped down to 9Vdc) supplied.

7 Power Switch Turns unit ON (|) or OFF (O).

8 °C/°F Mode Switch Selects °C or °F chart operation. Note the following :

When switching from °C to °F, ONLY the humidity pen will move. The

humidity zero point and scaling are different on C° and °F paper, causing the

humidity pen to move when switching from °C to °F. The temperature zero

point and scaling are the same on °C and °F paper (only the units change).

Therefore, the temperature pen will not move.

9 1/7/32 Day Mode Switch Selects chart type, 1, 7, or 32 day operation.

10 Alarm Display Buttons These buttons are accessible behind the control panel door.

(HIGH, SET, LOW) High and Low buttons:

1. Selects and changes calibration codes.

2. Chooses the high/low alarm limit (for either °F, °C or %RH).

3. Selects and changes the alarm limits.

4. Checks alarm limits in operating mode.

5. Low button only: when pressed during power up, disables the

alarm function.

Set button:

1. Activates calibration mode when pressed during power up.

2. Enters calibration codes in memory.

3. Activates alarm limits.

4. Enters alarm limits in memory.

5. Disables the sounding of the alarm (and activation of the relay)

for 10 seconds.

11 LCD Display Displays temperature and humidity values (depending on the setting of

Display Selection Switch.

12 Display Selection Switch Allows the user to select display of the current relative humidity, or

ambient temperature in either °C or °F. Refer also to item #10.

13 Temperature/Humidity Sensor Houses the electronic sensors which measure ambient temperature and

relative humidity.

14 Sensor Holder (clip) Holds the temperature/humidity sensor to the side of the recorder.

15 Pen Arm and Holder (2 each) Holds and moves the temperature and humidity pens.

16 Latch Button Releases and secures the recorder’s door.

17 Control Panel Door Lock Locks or unlocks the control panel door.

18 Decorative Foot Cover Stays in place for wall-mounting the recorder. The cover must be

removed for upright bench-top use (otherwise the recorder topples over)!

19 Control Panel Door Covers the alarm display buttons (High, Set, and Low), power switch,

1/7/32 day mode switch, and °F/°C mode switch.

20 Light Bulb/Display Backlighting Turns the light bulbs and LCD Backlighting on and off

Push Button

Introduction

1

1-3

Page 8

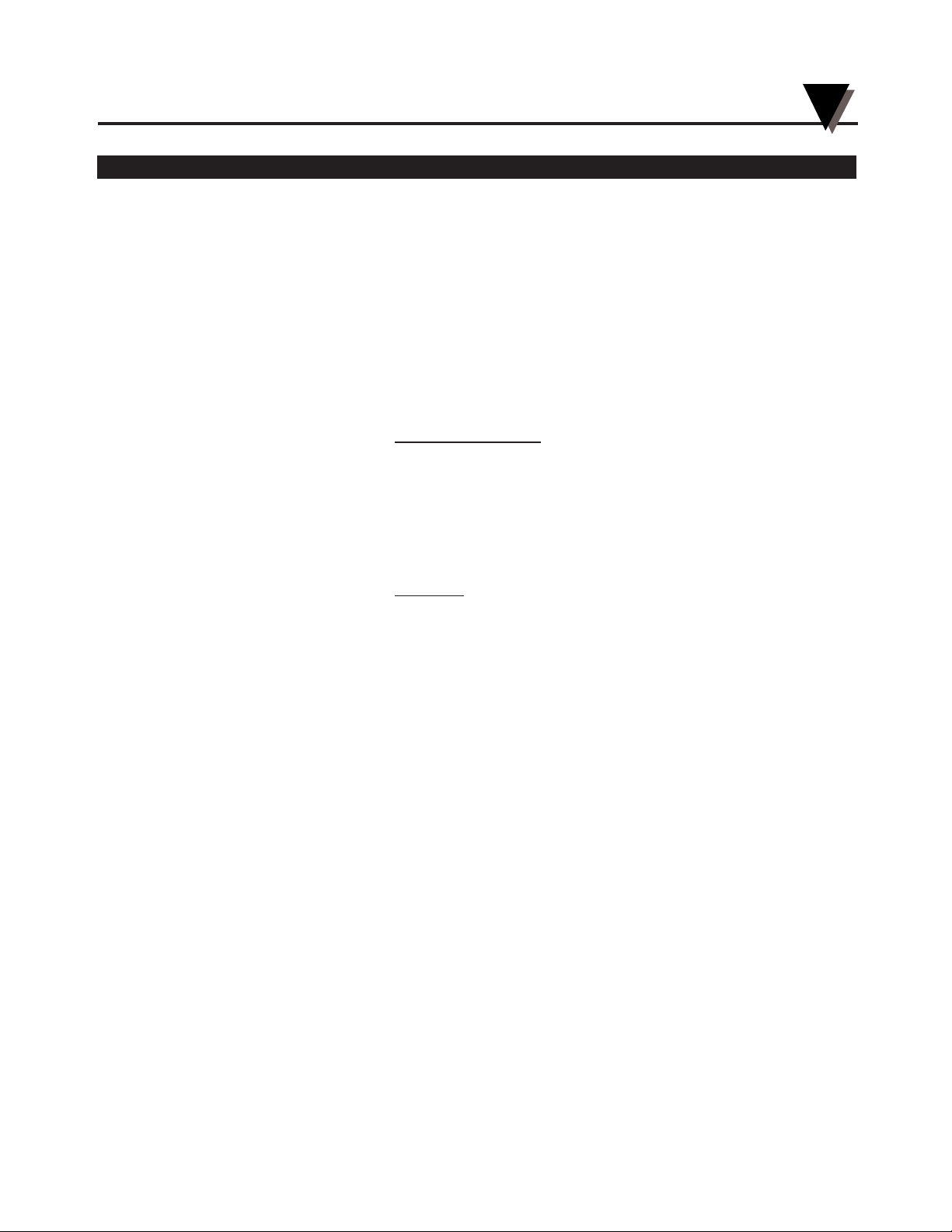

1.2 Parts of the Recorder - Rear View

Figure 1-2. Rear View

Item Description Function

21 “Keyhole” Slot Mounting Holes Allows the recorder to be mounted on the wall.

22 Carrying Slot Allows the user to carry the recorder conveniently.

23 Product Label Product information label.

24 Alarm/Relay Contacts Allows the user to hook up an external, dry contact alarm to the

recorder.

25 Battery Compartment Holds 4 “D” size batteries which provide power if the ac adaptor is

not used, or provide power backup in case of ac power failure.

25

21

22

24

23

H

35 T2

Foot Cover Removed

Introduction

1

1-4

Page 9

Setting Up the Recorder

2-1

2

Now that you have learned about the different parts of the recorder, you can set

it up.

Determine whether you want the recorder wall mounted or sitting on a bench

top.

2.1 Placing the Recorder on the Bench Top

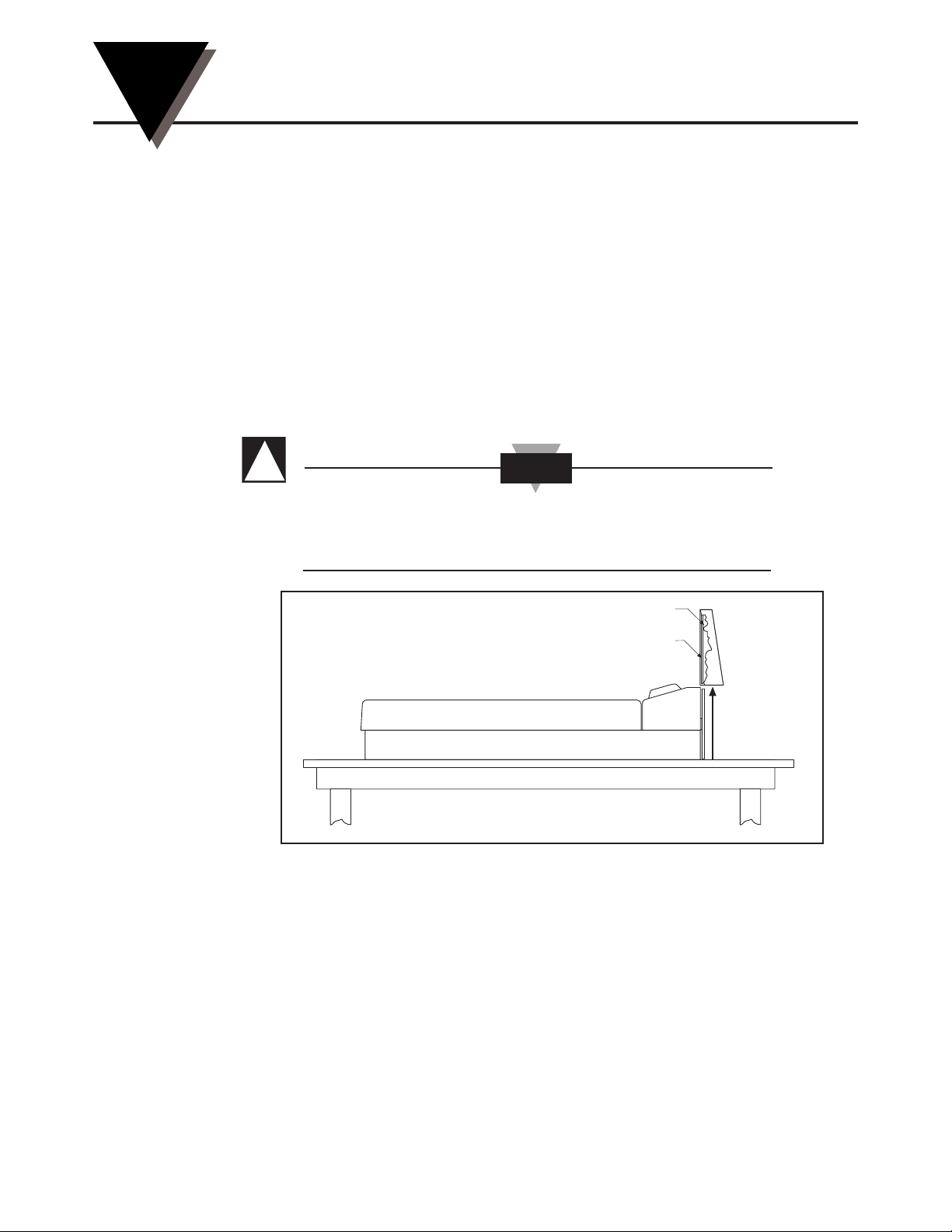

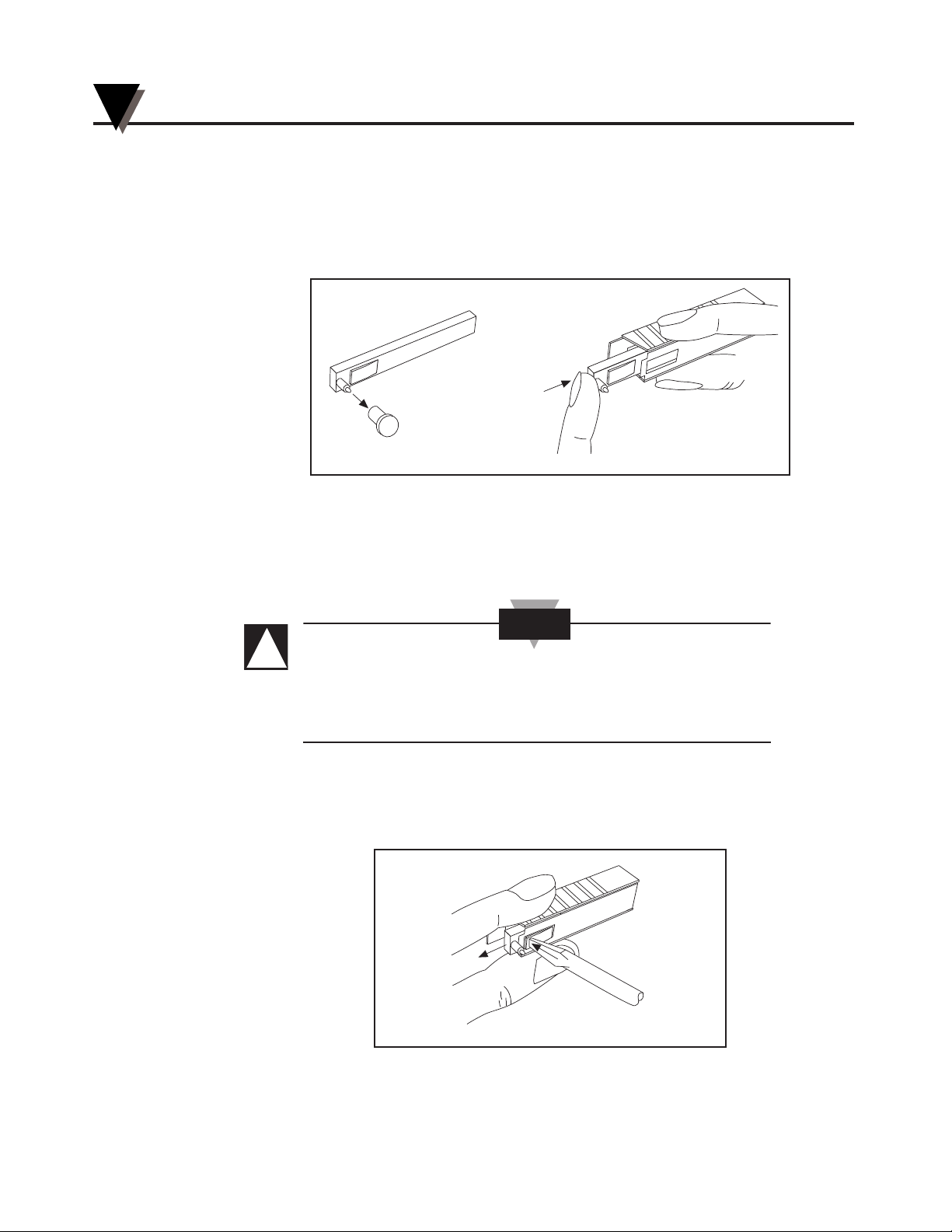

Figure 2-1 shows the removal of the decorative foot cover.

1. Place the recorder on its back (so it is face up).

2. Remove the clip-on foot cover by lifting up on the cover and releasing it from

the stabilizing arm at the bottom of the recorder. This exposes the rubber feet

and stabilizing arm. The rubber feet protect the bench top surface.

DO NOT ATTEMPT TO SET THE RECORDER UPRIGHT ON

THE BENCH WHEN THE CLIP-ON FOOT COVER IS IN

PLACE. THE RECORDER WILL TOPPLE OVER.

Figure 2-1. Foot Cover Removal

Clip

Cutaway View

CAUTION

!

Page 10

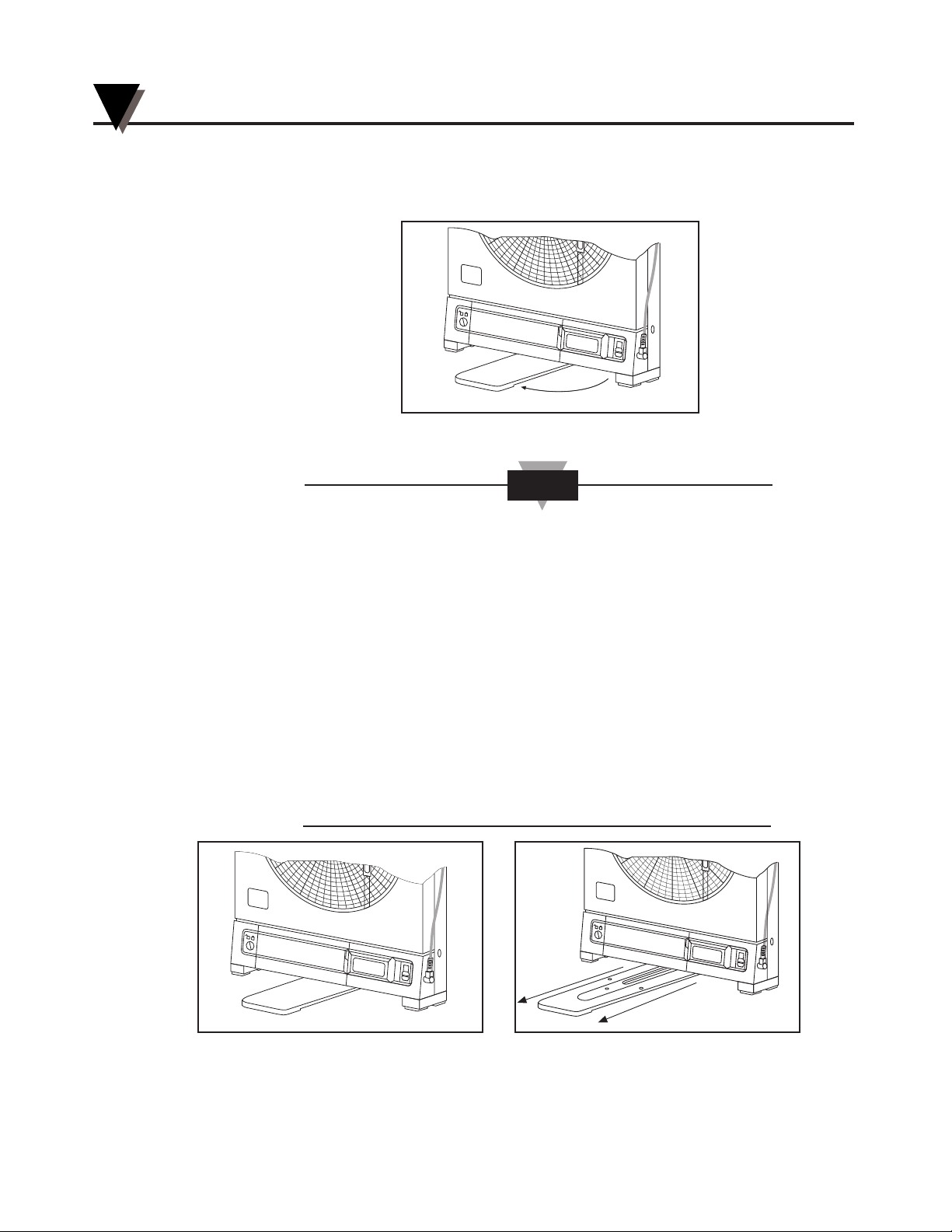

3. Swing out the stabilizing arm and extend it towards you. Figure 2-2 shows

how to swing out the stabilizing arm. Make sure the slot in the stabilizing arm

extends out the rear of the recorder.

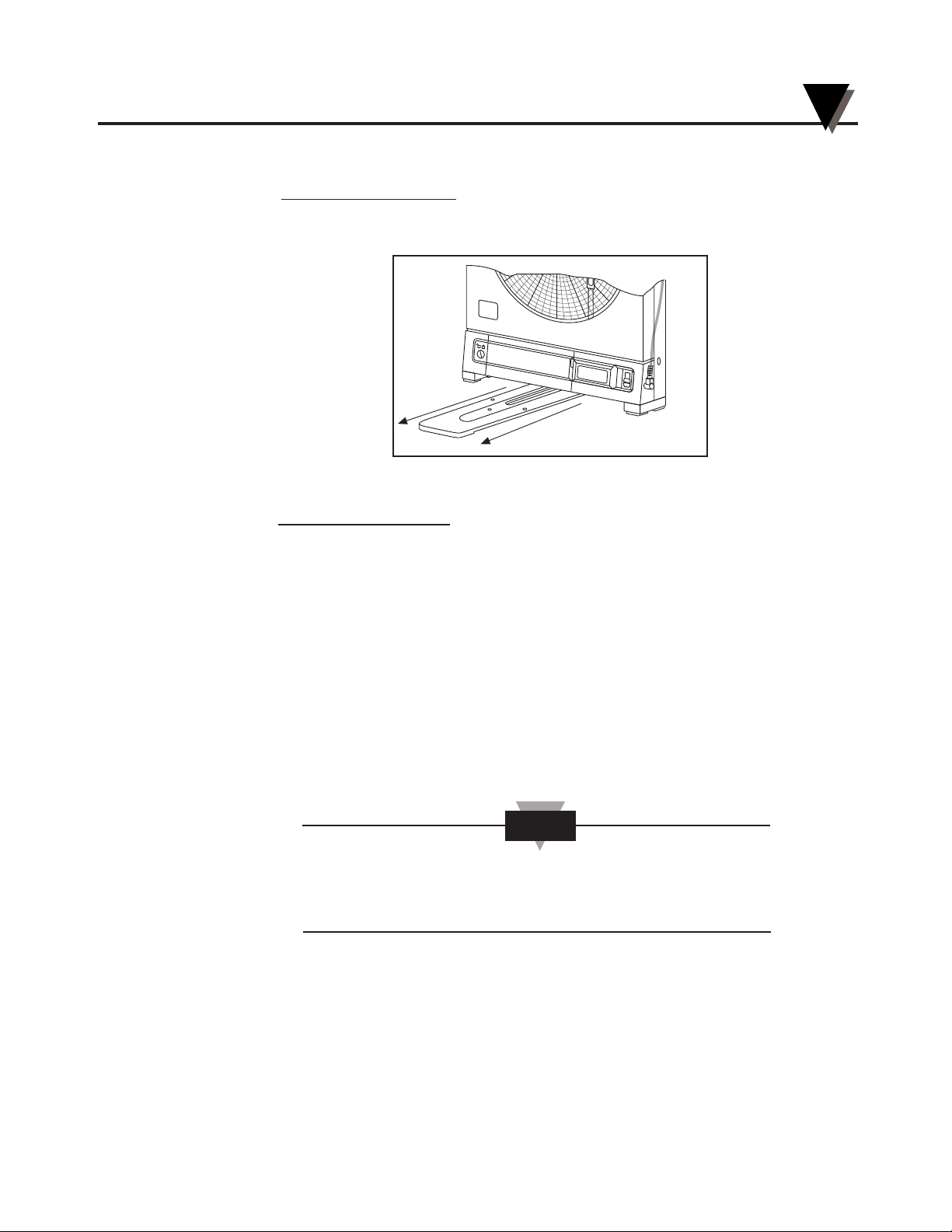

Figure 2-2. Swiveling Stabilizing Arm

When the recorder is in normal operating position (the door

is closed and the control panel door is closed), the stabilizing

arm should be pushed to middle position (the bumps on the

arm will click in place under the recorder). Refer to Figure

2-3a.

Before opening the chart door, pull the stabilizing arm out to

its full extension position to provide full stability. Refer to

Figure 2-3b. After closing the door, return the arm to its

middle position. Refer to Figure 2-3a.

Note that the arm extends towards the front or rear of the

case. If the unit is placed on a bench top snug against the

wall, extend the stabilizing arm fully to the front of the unit.

Refer to Figure 2-3b.

Figure 2-3a. Stabilizing Arm use Figure 2-3b. Stabilizing Arm in Extended

for Bench Top Use (normal position) Position (position when you open door)

H

U

M

I

D

I

T

Y

RH

°

F

°

C

H

U

M

I

D

I

T

Y

RH

°

F

°

C

NOTE

Swing

H

U

M

I

D

I

T

Y

RH

°

F

°

C

Setting Up the Recorder

2

2-2

Page 11

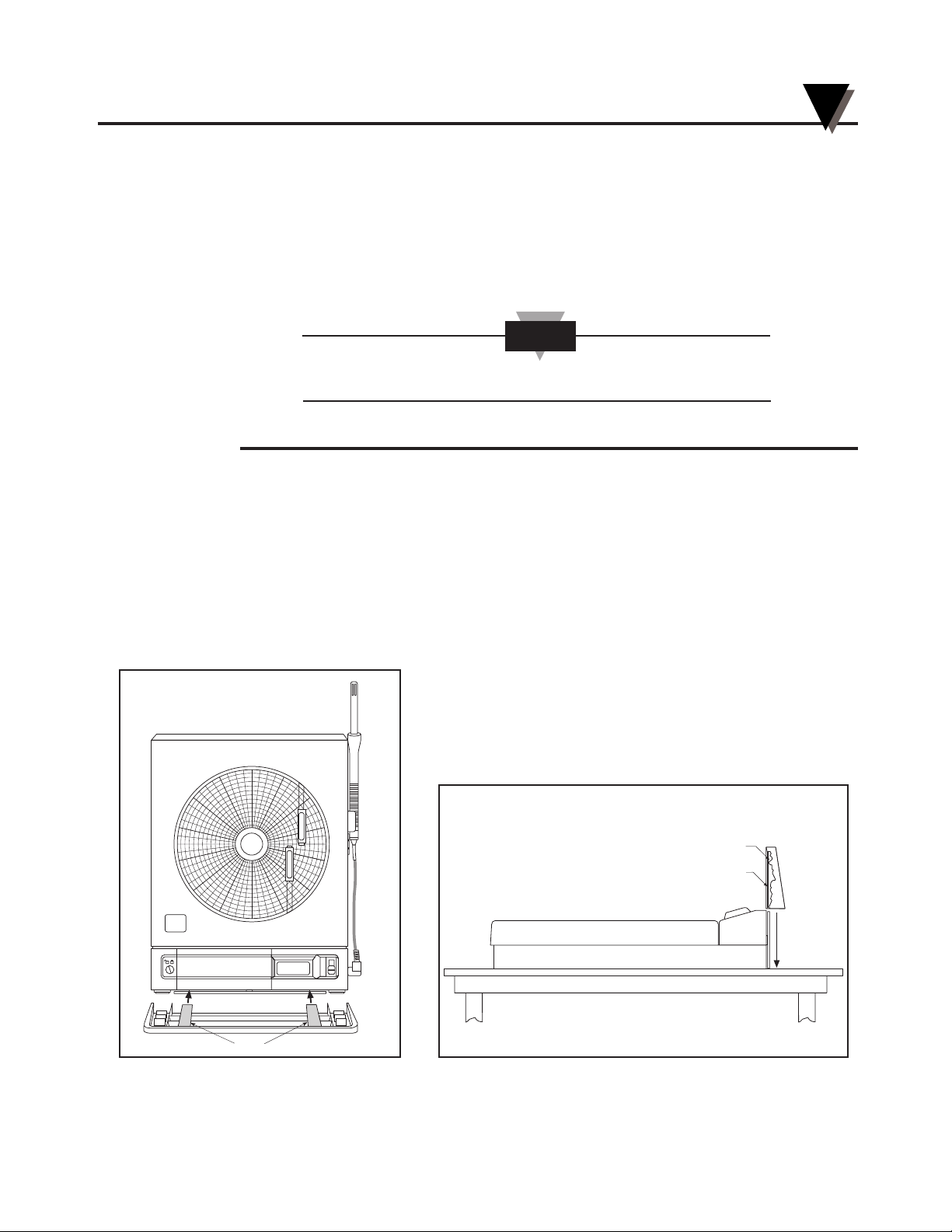

2.2 Mounting the Recorder on the Wall

To mount the recorder on the wall, first locate the wall mounting holes using the

template provided in the wall mounting kit. Leave the decorative foot cover

(Figure 1-1, item #18) in place*. After drilling the holes, insert the wall anchors

and put in the screws, leaving

1

⁄8 inch (3 mm) between the screw heads and the

wall. Hang the recorder by positioning the two (2) “keyholes” in the rear cover

over the screw heads.

The ac adaptor has a 6 foot (2 meter) cable.

* If the decorative foot cover is not in place, go through the following steps to

reinstall the cover (if desired):

1. Place the recorder on the table (so it is front face up).

2. Roughly position the foot cover so the clips are in line with the stabilizing

arm. Gently “stretch” the clips out and position over the arm as shown in

Figure 2-4a.

3. Once the clips are in place, gently slide down until the foot cover is even

with the front of the recorder as shown in Figure 2-4b.

Figure 2-4a. Installing the Foot Cover Figure 2-4b. Installing the Foot Cover (Side View)

(Top View)

Clip

Cutaway View

Clips

RH

°F

°C

H35 T

2

T

E

M

P

E

R

A

T

U

R

E

H

U

M

I

D

I

T

Y

NOTE

Setting Up the Recorder

2

2-3

Page 12

2.3 Using Batteries

The recorder operates on either four “D” size batteries or on ac power. 110Vac

and 220Vac adaptors are available.

In the event of ac power failure, the unit will switch over to

battery power automatically.

Keep a fresh set of batteries in the unit in case of power

outage, when it will be especially important to have a record

of ambient temperature and humidity.

2.3.1 Installing Batteries

You may power the recorder with four “D” size batteries. For adequate

performance and battery life, use alkaline batteries. The recorder operates full

time on battery power alone for up to one month when using fresh alkaline

batteries. When replacing batteries, we recommend that you use Duracell

MN1300 “D” size batteries for long life and for best performance at low

temperatures.

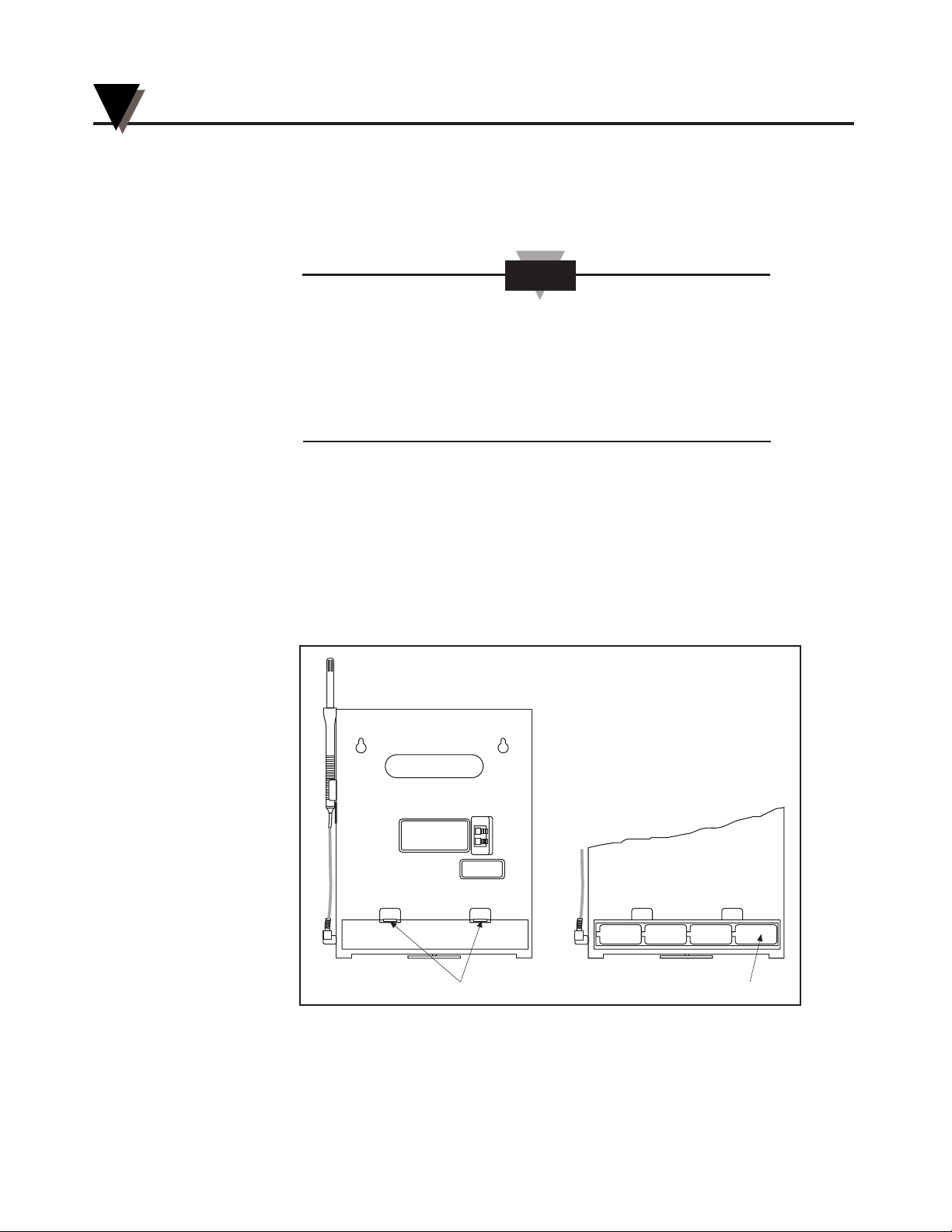

To install the batteries (refer to Figure 2-5):

Figure 2-5. Battery Compartment and Battery Orientation

To Open Battery Orientation

+–+–+–+–

Bench Top Set-Up

NOTE

Setting Up the Recorder

2

2-4

Page 13

1. Open the control panel door.

2. Turn the power switch to the OFF or “O” position.

3. Place the recorder on a soft surface front face down. Locate the battery

compartment at the bottom.

4. Open the battery compartment door by pressing down firmly on the tabs

located along the top edge.

5. Remove the battery door.

6. Install the batteries, oriented as shown in Figure 2-5, in the battery

compartment.

7. To replace the battery door, first place the bottom edge of the door into the

positioning slots in the compartment.

8. Push down on the door to snap the tabs in place.

The recorder continuously monitors the battery voltage. A “LO BAT”

indication in the upper left-hand corner of the main LCD (refer to Figure 2-6)

indicates that only one to two weeks of reliable battery operation remain, and

that the batteries need replacing within this time frame. Also, if the unit is

operating under battery power and the battery voltage is too low to permit

reliable operation, the system shuts down and displays “---” in the LCD. The

system may be restarted by changing the batteries or by the re-initiation of ac

power. If ac power fails, the circuitry will attempt to automatically switch to

battery backup. If viable battery power is available, the system will operate on

battery power until the batteries fail or ac power returns. When ac power

returns, the recorder will automatically reset itself (refer to Section 8.5).

Figure 2-6. Battery Warnings

2.3.2 Connecting ac Power

The recorder can be ac powered using the 9Vdc, 1Amp ac adaptor supplied. The

ac power jack is located on the right side of the unit (refer to Figure 1-1, item #6.).

Make sure the power switch on the control panel (refer to Figure 1-1, item #7) is

in the OFF or “O” position when plugging in the ac adaptor. The adaptor cable

is 6 feet (2 meters) long.

RH

°F

°C

LO BAT

System Shut-Down

Setting Up the Recorder

2

2-5

Page 14

2.4 Installing the Chart Paper

The recorder accepts six different types of chart paper. Charts are available for

1, 7 and 32 day recording times in both Fahrenheit or Celsius versions. Although

chart paper replacing is very simple, you must take care to set the appropriate

front panel switches for the paper being used. Set the chart type and °C/°F

switches (refer to Figure 2-7) to the following positions for these six (6) modes of

operation.

Chart Type Switch (Days) C/F Switch Paper Type

1 F 1-day, Fahrenheit paper

1 C 1-day, Celsius paper

7 F 7-day, Fahrenheit paper

7 C 7-day, Celsius paper

32 F 32-day, Fahrenheit paper

32 C 32-day, Celsius paper

Figure 2-7. Chart Switches

You may obtain specialized paper as well. Refer to the inside back cover for the

complete list.

RH

°F

°C

HIGH SET LOW

1

7

32

°F

°C

0

I

CHART TYPE

PWR

ALARM

Setting Up the Recorder

2

2-6

Page 15

To change the chart paper:

1a. T

able Mounted Recorder:

To balance the recorder, fully extend the stabilizing arm at the bottom of the

recorder. Refer to Figure 2-8. Continue to Step 2.

Figure 2-8. Stabilizing Arm Fully Extended

1b. W

all Mounted Recorder

:

You can also leave the recorder on the wall if it is easily accessible.

2. Open the door and hold it open with left hand.

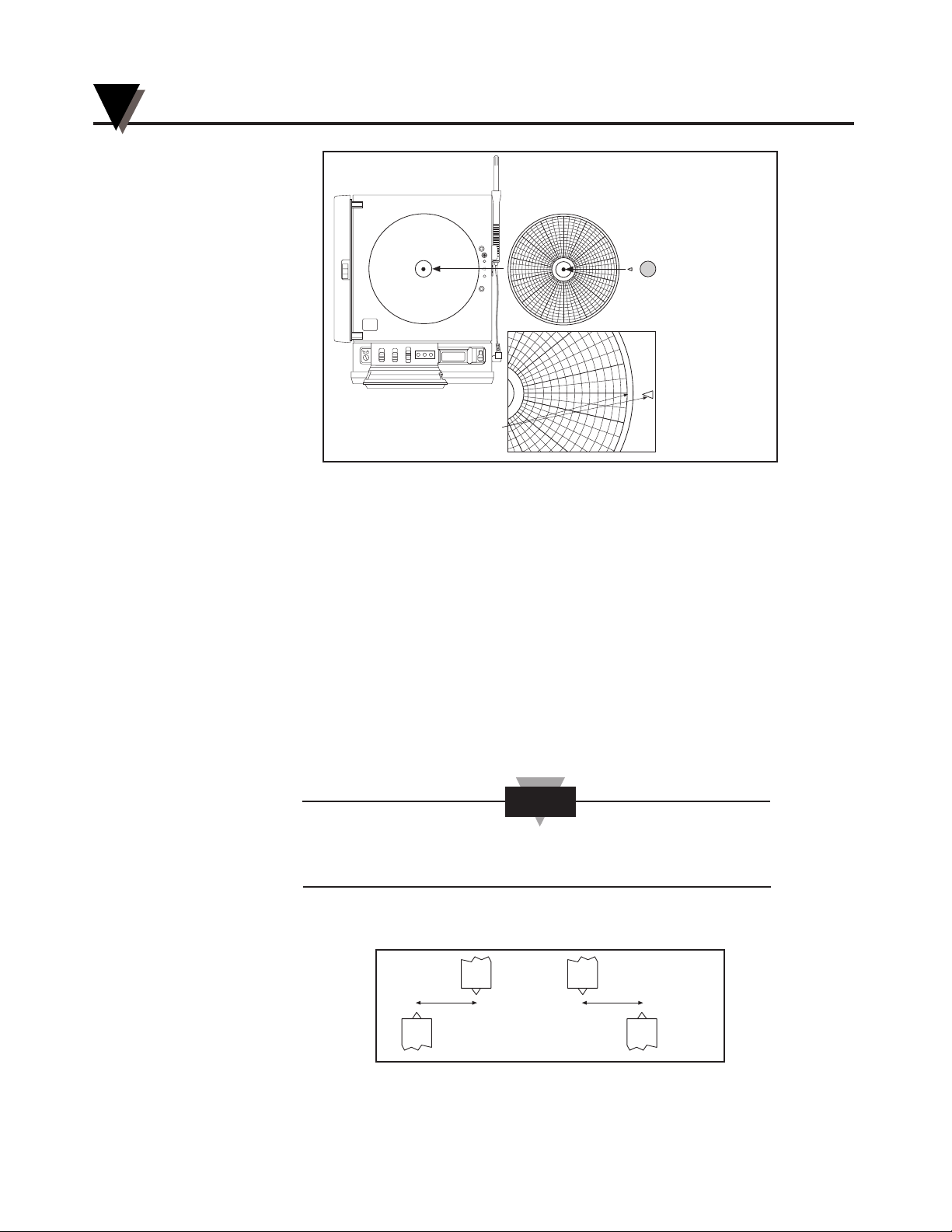

3. Remove the magnetic chart paper knob (Figure 2-9, item #2) and any used

chart paper.

4. Place the new chart paper (Figure 2-9, item #1) on the spindle and rotate it

until the current time on the chart paper is aligned with the time arrow on the

chart base of the recorder. See Figure 2-9 detail.

5. When the chart paper is correctly oriented, replace the magnetic knob

(Figure 2-9, item #2), being careful not to alter the position of the chart paper.

6. Make sure that the “Chart Type” switch, located behind the control panel door,

is in the correct position relative to the chart paper used.

If the switch is in the wrong position, the chart paper will not

rotate at the correct speed causing the chart time not to be

synchronized with the current time.

NOTE

H

U

M

I

D

I

T

Y

RH

°

F

°

C

Setting Up the Recorder

2

2-7

Page 16

Figure 2-9. Changing Chart Paper and Setting the Time

2.5 Installing and Removing Pens

2.5.1 Installing the Pens

The recorder uses two different colored pens to record information. The red

(upper) pen records temperature. The blue (lower) pen records relative

humidity. Pen life varies with use and climate. Under normal operating

conditions, pens last at least one month. We recommend that you install a fresh

set of pens after every month of use.

To install pens:

1. Make sure the power switch on the front panel is in the OFF or “O” position.

The front panel is located under the control panel door. The recorder door

should be closed too.

The control panel door opens easily by gently gripping the

recessed area at the right side and slowly pulling down.

2. Examine the location of the pen arms through the window in the recorder door.

a. If the pen arms are offset as shown in Figure 2-10, continue to Step 3:

Figure 2-10. Offset Alignment of Pens (for ease of pen installation)

OR

Temperature

Pen

Temperature

Pen

Humidity

Pen

Humidity

Pen

NOTE

RH

°F

°C

HIGH SET LOW

1

7

32

°F°C0

CHART TYPE

PWR

ALARM

1

7 PM

8 PM

9

PM

6 PM

5

P

NOTE: ROTATE CHART PAPER

UNTIL PRESENT TIME

LINES UP WITH ARROW.

H

35 T2

1

2

Setting Up the Recorder

2

2-8

7:00 PM

Page 17

b. If the pen arms are vertically aligned as shown in Figure 2-11, do the

following and then proceed to Step 3.

Figure 2-11. Vertical Alignment of Pens (pens can’t be inserted)

(The pen arms must be offset sufficiently to allow for clearance before insertion

or removal is attempted. The pens must be moved electrically.)

• Make sure the recorder door is closed and a piece of chart paper is

installed on the spindle on the chart base.

• Turn the unit back on by moving the power switch to “|” and wait for

the pens to be far enough apart to remove a used pen one at a time or

to insert a new pen one at a time.

DO NOT ATTEMPT TO OFFSET THE PENS

MANUALLY (BY HAND). THE DRIVE MECHANISM

COULD BE DAMAGED. DO NOT ATTEMPT TO

CHANGE THE PENS WHILE THEY ARE IN MOTION.

• Turn off the unit (PWR switch position in “O” position) to stop the pen

movement.

3. Open the recorder door by applying downward pressure on the latch button

(refer to Figure 1-1, item #16).

4. Remove the pens from the package and the cap from each pen.

We recommend that you put the pen caps on special posts located on the chart

base of the recorder near the light bulbs. Figure 2-12 shows the location of the

posts.

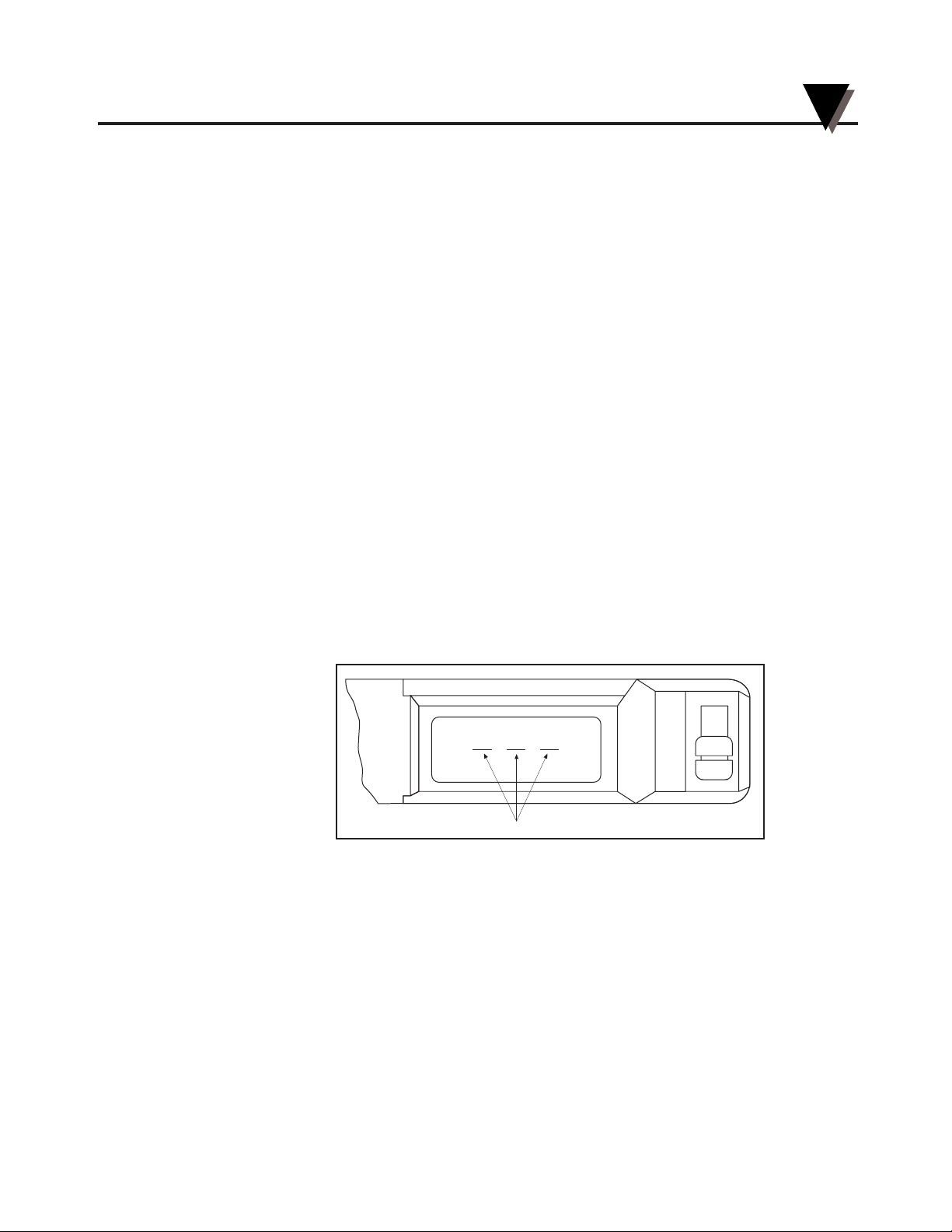

Figure 2-12. Post Location for Pen Caps

H

35 T2

T

E

M

P

E

R

A

T

U

R

E

H

U

M

I

D

I

T

Y

Pen Cap Posts

CAUTION

Temperature

Pen

Humidity

Pen

Setting Up the Recorder

2

2-9

!

Page 18

5. Insert the blue pen fully into the lower (humidity) holder and the red pen fully

into the upper (temperature) holder.

If you installed the pens correctly, you will hear a click as they position

themselves in the holders. Figure 2-13 shows how to insert the pens.

6. Close the recorder door.

Figure 2-13. Pen Installation

2.5.2 Removing the Pens

1. Check to see that the pens are offset as shown in Figure 2-10. Otherwise, you

can damage the arm and drive mechanism if you try to remove them.

DO NOT ATTEMPT TO OFFSET THE PENS MANUALLY (BY

HAND). THE DRIVE MECHANISM COULD BE DAMAGED.

DO NOT ATTEMPT TO CHANGE THE PENS WHILE THEY

ARE IN MOTION.

2. Perform Step 2b in Section 2.5.1 to offset the pens.

3. With a screwdriver in one hand, push on the rectangular area of the pen

shown in Figure 2-14. Using the other hand, release the pen from the spring

clip attached to the pen holder.

Figure 2-14. Pen Removal

CAUTION

Setting Up the Recorder

2

2-10

!

Page 19

4. At the same time, slide the pen out from the pen holder.

5. Install new pens following Section 2.5.1, Steps 3 through 6.

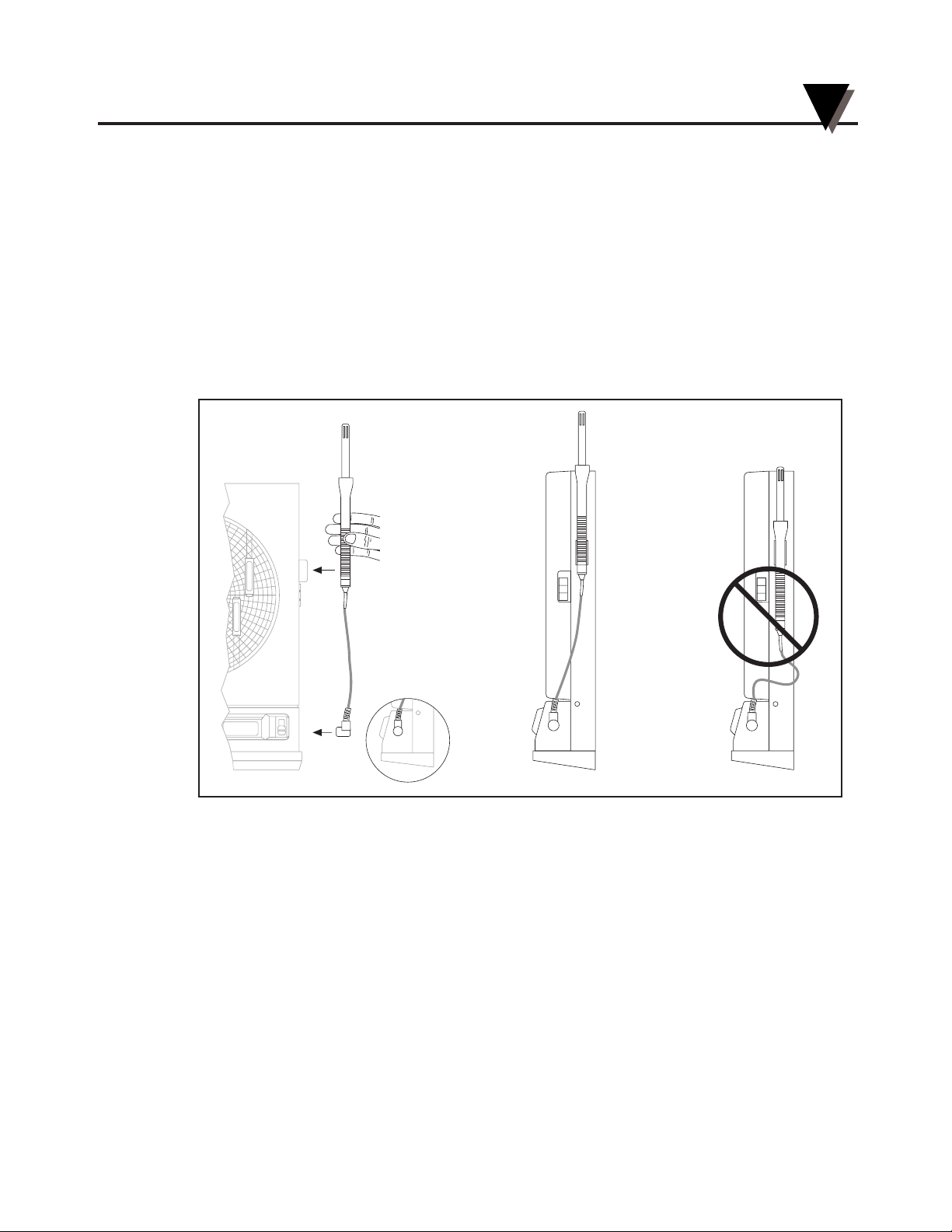

2.6 Installing the Temperature/Humidity Sensor

The temperature/humidity sensor can either be directly attached to the recorder

using its own attached short cable or be extended by using the 6 ft remote sensor

cable.

2.6.1 Using the Short Cable

1. Place the handle part of the sensor in to the sensor clip on the side of the

recorder as shown in Figure 2-15.

Figure 2-15. Attaching the Sensor (left picture), Correct Position (center),

Incorrect Position (right)

2. Install the connector into the socket at the side of the recorder. Make sure the

sensor cable is untwisted.

3. Slide the sensor up so that the sensor vents are well above the top of the case.

Refer to the center picture in Figure 2-15.

RH

°F

°C

T

E

M

P

E

R

A

T

U

R

E

H

U

M

I

D

I

T

Y

SIDE VIEW

H

35 T2

H

35 T2

H

35 T2

Setting Up the Recorder

2

2-11

Page 20

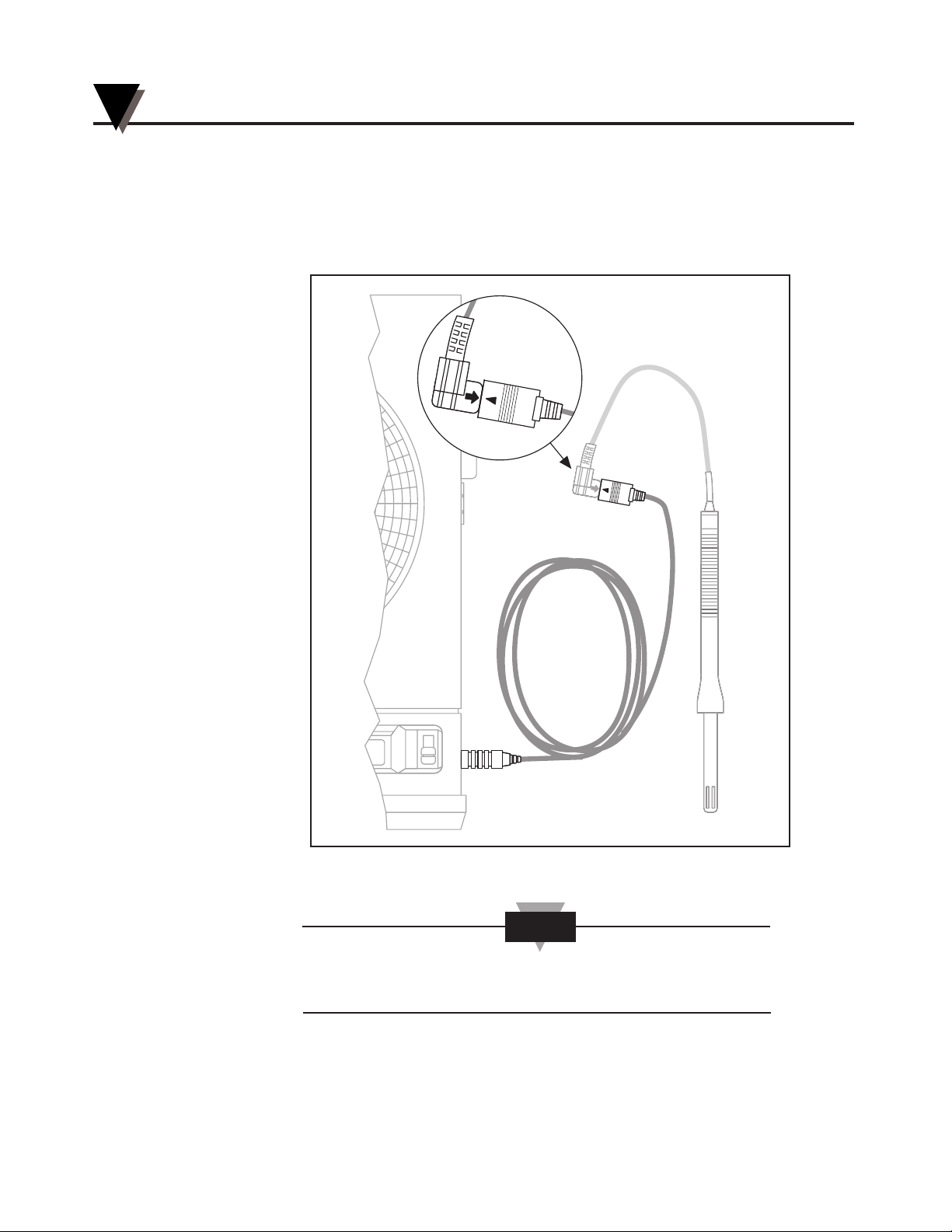

2.6.2 Using the Remote Sensor Cable

1. Connect the end of the cable with the arrow to the short cable on the sensor.

Line up the two arrows as shown in Figure 2-16 before mating the two cables.

2. Connect the other end of the remote sensor cable (without the arrow) to the

socket at the side of the recorder.

Figure 2-16. Using the Remote Sensor Cable

For accurate temperature and humidity readings, only one

length of remote sensor cable may be used.

NOTE

RH

°F

°C

T

E

M

P

E

R

A

T

U

R

E

H

35 T2H

35 T2

Setting Up the Recorder

2

2-12

Page 21

2.6.3 Using the Sensor Clip

An extra sensor clip is provided in the shipping box, so you can hang the sensor

in a remote location. Two self-tapping screws are provided for mounting to

wood, sheet rock or plastic surfaces. When mounting to wood or sheet rock

surfaces, drill two

1

⁄16" (1.5 mm) diameter holes. When mounting to plastic, drill

two

5

⁄64" (1.9 mm) diameter holes. Appropriate hardware must be selected when

mounting to metal surfaces. Refer to Figure 2-17.

Figure 2-17. Using the Sensor Clip for Mounting Sensor in a Remote Location

R

H

°

F

°

C

74

T

E

M

P

E

R

A

T

U

R

E

H

U

M

I

D

I

T

Y

6

7

8

9

5

4

3

2

1

12

10

11

Setting Up the Recorder

2

2-13

Page 22

Setting Up the Recorder

2

2-14

Notes

Page 23

Powering Up the Recorder

3-1

3

3.1 Turning on the Recorder

Open the control panel door by gently gripping the recessed area at the right

side of the door and slowly pulling down.

Turn the recorder on by moving the power switch located on the control panel to

the “|” position. Refer to Figure 3-1 for the location of the switch.

Figure 3-1. Power Switch

You then hear 1 beep and the LCD display shows the following:

Figure 3-2. First LCD Display

The displays in Section 3.2 come up quickly once you turn on the

recorder. Be prepared to write down the codes as you see them on the

recorder display. You can then compare the codes your recorder

displayed with the probe label as described below. After the two groups

of codes are displayed, the recorder continues with its sequence, and the

pens move. More details are provided in Sections 3.3 and 3.4.

3.2 Recording the Code Numbers

A two-character humidity code made up of numbers and/or letters 0, 1, 2,

3, ... , 8, 9, a, b, and c appears. An example is shown in Figure 3-3; the numbers

will vary:

Figure 3-3. Relative Humidity Code

Then, a single-character temperature code, a number or letter 0, 1, 2, 3, ... , 8, 9, a,

b, or c, appears. An example is shown in Figure 3-4; the numbers will vary:

Figure 3-4. Temperature Code

Write your code here

RH

°F

°C

2

Write your code here

RH

°F

°C

35

RH

°F

°C

LO BAT

RH

°F

°C

HIGH SET LOW

1

7

32

°F

°C

0

I

CHART TYPE

PWR

ALARM

Page 24

3.3 Comparing Code Numbers

The recorder will continue with its initialization process for about another 30

seconds. Locate the code numbers on the sensor calibration label. Refer to

Figures 3-5 and 3-6. The two-character Humidity Code you wrote down should

match the two-character code following the letter “H “on the label. If it does not,

refer to Section 5.1, Changing Calibration Codes.

The single character Temperature code should match the single-character code

following the letter “T” on the label. Refer to Figure 3-7. If it does not, refer to

Section 5.1, Changing Calibration Codes.

Figure 3-5. Location of Sensor Codes

Figure 3-6. Relative Humidity Code Location

Figure 3-7. Temperature Code Location

RH

°F

°C

2

H

35 T2

H

35 T2

RH

°F

°C

35

H

35 T2

H

35 T2

Powering Up the Recorder

3

3-2

Page 25

3.4 Final Display Mode

After the relative humidity and temperature codes appear, the LCD displays the

current relative humidity in %RH or temperature in °F or °C, depending on the

position of the display selection switch (refer to Figure 3-8).

Figure 3-8. Display Selector Switch

At the same time, the temperature pen and humidity pen, one at a time, move to

the right a short distance and then move to the left to the zero position. Then,

both pens, one at a time, move to the positions which correspond to the current

relative humidity and temperature.

At this point, the recorder is ready to use.

RH

°F

°C

HIGH SET LOW

1

7

32

°F

°C

0

I

CHART TYPE

PWR

ALARM

Powering Up the Recorder

3

3-3

Page 26

Powering Up the Recorder

3

3-4

Notes

Page 27

Alarm Operation

4-1

4

4.1 Alarm Description

The chart recorder is equipped with an alarm system which is activated when

the sensor conditions exceed user-set limits. The system consists of a built-in

audible piezo-electric beeper and a set of normally open dry relay contacts for

activating an external alarm. The contacts are rated for 2 amps at 110Vac or 2

amps at 30Vdc. The contact terminals are mounted on the rear of the recorder

(refer to Figure 4-1). In addition, the LCD display will flash upon alarm

activation.

Figure 4-1. Alarm/Relay Contacts Location

4.2 Checking Alarm Limits

WAIT UNTIL THE UNIT HAS STABILIZED AND THE PENS STOP MOVING

BEFORE PRESSING ANY KEYS ON THE KEYBOARD.

• Depending on the Display Selection Switch position, the display will

be in °F, °C, or %RH for the alarm limit viewing.

• The word ‘hi’ and the high limit value of the alarm may be seen on the

display after pressing the “HIGH” button on the front panel.

• The word ‘lo’ and the low limit value of the alarm may be seen on the

display after pressing the “LOW” button on the front panel.

The alarm limits are stored in permanent EEPROM memory

and will not be lost even if power is interrupted and battery

backup fails.

NOTE

H

35 T2

Alarm

dc or ac

Power

Supply

Rear

Battery

Compartment

(External Power

Supply And Alarm

Not Included)

Foot Cover Removed

Page 28

4.3 Unlocking/Locking the Control Panel Door

To access the Alarm Display Buttons (Figure 1-1, item #10) under the control

panel door, you may have to unlock the door. You’ll find the control panel door

lock to the left of the control panel. Refer to Figure 4-2.

Figure 4-2. Location of the Door Lock

4.3.1 Unlocking the Control Panel Door

Use a small screwdriver to turn the lock to the left as far as it will go. Figure 4-3

shows the unlocked position.

Figure 4-3. Door Unlock Position

4.3.2 Locking the Control Panel Door

Use a small screwdriver to turn the lock to the right as far as it will go. Figure

4-4 shows the locked position.

Figure 4-4. Door Lock Position

RH

°F

°C

HIGH SET LOW

1

7

32

°F

°C

0

I

CHART TYPE

PWR

ALARM

74

Alarm Operation

4

4-2

Page 29

4.4 Setting/Changing Alarm Limits

To set the alarm limits on the alarm recorder:

1. Set the display selection switch (Figure 1-1, item #12) to %RH, °C, or °F

depending on the parameter for which you would like to set the alarm limits.

Refer to Figure 3-8 for the location of the switch.

°C and °F alarm are really the same alarm , shown in

different measuring units.

2. Open the control panel door (unlock it, if necessary).

3. Press the “SET” button to activate the display to set either the high OR low

alarm limit. At this time, “SE” is displayed. Figure 4-5 shows the location of

the Alarm Display Buttons.

Figure 4-5. Alarm Display Buttons (HIGH/SET/LOW)

4. Release the “SET” button. The display will alternately flash “hi” and “lo”

repeatedly.

5a. To change the high alarm limit:

• Press and hold the “HIGH” button for 4 seconds, then release.

‘hi’ is displayed and then the current high alarm limit is displayed.

• Press the “HIGH” or “LOW” button to respectively increase or decrease the

value.

• Press the “SET” button to lock in the value(s); the display now shows “SA”.

• Continue to step 6.

OR

RH

°F

°C

HIGH SET LOW

1

7

32

°F

°C

0

I

CHART TYPE

PWR

ALARM

74

NOTE

Alarm Operation

4

4-3

Page 30

5b. To change the low alarm limit:

• Press and hold the “LOW” button for 4 seconds, then release.

‘lo’ is displayed and then the current low alarm limit is displayed.

• Press the “HIGH” or “LOW” button to respectively increase or decrease the

value.

• Press the “SET” button again to lock in the value(s); the display now shows

“SA”.

If, after about 15 seconds, you don’t press the “SET” button to

enter the desired value, the alarm recorder returns the display

to the normal operation.

You can double check, at any time, your limits by pressing the “HIGH” and

“LOW” buttons.

6. Go through steps 1-5 to check and/or change the limits for the other

parameters. For example, if you already checked or changed °F, you may

check or change °C or %RH if you choose.

7. After you are all done with the changes, close and lock the control panel door,

if necessary.

4.5 Turning the Alarm Off

If the high or low alarm limit for humidity or temperature is exceeded, you will

hear the alarm. In addition, if the unit is operating under battery power and the

batteries are about to fail, you will hear the alarm.

The alarm will stay on even after the condition which caused the alarm

disappears. Refer to the example below:

Temp High Limit Actual Temp. Alarm Sounding

75° 74° OFF

75° 75° ON (temp rises)

75° 74° ON (temp drops) ***

***The alarm stays on even though the temperature drops below the limit.

The alarm recorder will not reset automatically.

NOTE

Alarm Operation

4

4-4

Page 31

1. Unlock the control panel door if necessary.

2. After the alarm becomes activated, the “SET” button must be pressed to disable it.

The message “AO” appears in the display. The alarm is disabled for 10

seconds. After 10 seconds, the alarm may activate again, but only if an

alarm condition is present.

If the alarm is activated and you wish to change the alarm units:

a. Press the “SET” button for 5 seconds.

First “AO”, then “SE” message will appear in the display.

b. You can now proceed with the changing the alarm limits as described in Section

4.4.

c. After you are all done with the changes, lock the control panel door if

necessary.

4.6 Disabling the Alarm

1. Unlock the control panel door if necessary.

2. On power up, when you hold the “LOW” button down, an “AO” message

appears in the display and the beeper sounds. This will disable the alar

m

function.

(This action sets the high temperature limit to 121(°F) or 49(°C), the low

temperature limit to 01(°F) or –17(°C), the high humidity limit to 99, and the

low humidity limit to 01. Since these limits are outside the normal

measuring range of the alarm recorder, the alarm function is effectively

disabled.)

The alarm limits are set this way when you receive the unit. If the alarm is

disabled, you must re-initialize the instr

ument. After you are done with the

changes, lock the door, if necessary.

3. To verify the settings after re-initializing is completed, press the “LOW” button to

get the low value, and the “HIGH” button to get the high value.

Alarm Operation

4

4-5

Page 32

Alarm Operation

4

4-6

Notes

Page 33

Calibrating the Recorder

5-1

5

5.1 Factory Calibration Information

The recorder is factory calibrated during final assembly by calibrating the sensor

(shipped with the recorder) to known temperature and humidity standards in an

environmental chamber. This technique avoids tracking and positioning errors

due to temperature changes and mechanical shock. However, if the humidity

readings drift or appear out of calibration, follow Section 5.2 to recalibrate your

recorder.

5.2 Changing Calibration Codes

You may want to change the calibration codes for several reasons:

• The calibration codes on the sensor probe and the recorder do not match.

• A replacement probe is being used, and the calibration codes must be

changed to match.

• You want the recorder to more closely match the reading of another

instrument.

• You wish to perform your own recalibration. In this case, go through

Sections 5.3 and 5.4, Calibrating Humidity Readings and Calibrating

Temperature Readings.

To change the calibration codes:

1. Open the control panel door (unlock it, if necessary).

2. Turn the power switch to the off (“O”) position.

3. Press and hold down the “SET” button while turning on the power switch. This

button is one of three Alarm buttons shown in Figure 4-5.

After you hear an audible beep, you will see the following display:

Figure 5-1. First Display

Then “CH” appears on the display.

4. At this time, release the “SET” button.

RH

°F

°C

LO BAT

Page 34

A 2-character humidity calibration code should now appear in the display

with the first character blinking. Refer to Figure 5-2. Remember, this

calibration code must match the code on the sensor probe.

Figure 5-2. Humidity Code - First Character Blinking

5a. If the first character is correct,

press the “SET” button and go to step 6.

5b. If the first character is not cor

rect,

press the “HIGH” button to increase the value of the character or the

“LOW” button to decrease the value of the character. When this character

is correct, press the “SET” button.

6. The second character should now be blinking. Refer to Figure 5-3. If it is not,

press the “SET” button until it does.

Figure 5-3. Humidity Code - Second Character Blinking

7a. If the second character of the humidity calibration code is correct,

press the “SET” button and go to step 8.

7b. If the second character is not cor

rect,

press the “HIGH” button to increase the value of the character or the

“LOW” button to decrease the value of the character. When this character

is correct, press the “SET” button.

RH

°F

°C

57

RH

°F

°C

57

Calibrating the Recorder

5

5-2

Page 35

8. A single character temperature calibration code should be blinking in the

display. Refer to Figure 5-4. If it is not, press the “SET” button again.

Figure 5-4. Blinking Temperature Code

9a. If the temperature code is correct,

press the “SET” button and go to step 10.

9b. If the temperatur

e code is not correct,

press the “HIGH” button to increase the value of the character or the

“LOW” button to decrease the value of the character. When this character

is correct, press the “SET” button to lock in the values.

At this time, you see the humidity and temperature codes on the display as

you entered them. This way, you can verify that you entered them correctly.

10. The unit should now automatically go through the power up sequence as

described in Chapter 3. If it does not, hold down the “SET” button until it does.

While the unit goes through the power up sequence, observe the display to

see that the calibration values are what they should be and that they have

been entered correctly.

11. If either the temperatur

e or humidity code is incorrect,

repeat steps 1-10. After you are all done with the changes, lock the

control panel door, if necessary. Refer to Section 4.3 for details.

12. If you have altered the humidity or temperature codes in order to have the

recorder match the reading of another instrument, or you have performed your

own recalibration of the instrument, the code on the probe must be changed or

documented to reflect the changes made to the recorder. For recalibration,

refer to Sections 5.3 and 5.4.

RH

°F

°C

6

Calibrating the Recorder

5

5-3

Page 36

5.3 Calibrating Humidity Readings

If you have access to accurate temperature and humidity calibration equipment,

you may want to calibrate the instrument on your own as described in this

section. Figure 5-5 shows how to set up the calibration equipment. The

following flowchart shows the basic path that you should take to calibrate the

sensor.

Take 33%

Solution

Reading

(after waiting

one hour)

Take 75%

Solution

Reading

(after waiting

one hour)

Go to Temperature Calibration

(Section 5.4)

Too Low?

Too High?

Go to

Section

5.3.1

Case 2

Go to Section 5.2

to change Calibration Code

and probe label

Go to

Section

5.3.1

Case 1

Too Low?

Too High?

Go to

Section

5.3.2

Case 2

Go to

Section

5.3.2

Case 1

33% Reading

is Correct

75% Reading

is Correct

Go to Section 5.2

to change Calibration Code

and probe label

Calibrating the Recorder

5

5-4

Page 37

Figure 5-5. Calibration Setup

Section 5.3.1 discusses how to change the first half of the humidity code which

corrects the 33% humidity reading if your recorder does not show 33%. Section

5.3.2 discusses how to change the second half of the humidity code which

corrects the 75% humidity reading if your recorder does not show 75%.

Figure 5-6 shows the two parts of the humidity calibration code. This humidity

code consists of a two-digit alpha-numeric code. Digits may be any one of these

characters: 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, a, b, or c.

Figure 5-6. General Breakdown of the Humidity Code

RH

°F

°C

57

Corrects For

33% Humidity

Corrects For

75% Humidity

H

35 T2

RH

°F

°C

HIGH SET LOW

1

7

32

°F°C0

I

CHART TYPE

PWR

ALARM

T

E

M

P

E

R

A

T

U

R

E

H

U

M

I

D

I

T

Y

74

Sensor

O-Ring

For

Sealing

Remote

Sensor

Cable

Note: Do not immerse the tip of the sensor into the saturated solution.

Lid

Saturated

Solution

Calibrating the Recorder

5

5-5

Page 38

5.3.1 Humidity Calibration at 33% Humidity

1. Set up the recorder with the temperature/humidity sensor in a sealed jar (33% RH) using

saturated magnesium chloride as shown in Figure 5-5. If you are not experienced with

saturated salt solutions, you may not obtain good results. If you are experiencing difficulty,

contact our Engineering Department.

2. After the probe reading reaches equilibrium (after 1 hour), take a reading.

CASE 1: The 33% reading is too low by n counts, so DECREASE the humidity

code by n counts.

EXAMPLE 1:

you obtain a reading of 31%. The error is -2 since 31 is 2 counts lower than

33%. The initial humidity code of 87 (in this example) must be reduced to 67 (–2 counts).

READING INITIAL ERROR CHANGED (NEW) HUMIDITY

IN 33% HUMIDITY CODE CODE IN 33% “HUMID”

ENVIRONMENT CODE ENVIRONMENT

31 87

*

-2 67

*

* the first digit is flashing and changes in this case.

CASE 2: The 33% reading is too high by n counts, so INCREASE the humidity

code by n counts.

EXAMPLE 2

: you obtain a reading of 37%. The error is +4 since 37 is 4 counts higher

than 33%. The initial humidity code of 65 in this example must be increased to A5

(+4 counts; A comes after 9).

READING INITIAL ERROR CHANGED (NEW) HUMIDITY

IN 33% HUMIDITY CODE CODE IN 33% “HUMID”

ENVIRONMENT CODE ENVIRONMENT

37 65

*

+4 A5

*

* the first digit is flashing and changes in this case.

3. Change the first digit before proceeding to the next step, since a change in the first digit

affects readings throughout the range. Go through Section 5.1 to set the calibration codes in

the recorder. Then recheck to see that the reading is 33. If it is not, adjust the first digit of

the code again. After pressing the “SET” button, the second digit will start flashing.

4 Next, place the probe in a saturated salt environment of 75% RH using NaCl.

5. After the probe equalizes (after 1 hour), take a reading (the second digit displayed may have

changed).

6. Continue to Section 5.3.2.

Calibrating the Recorder

5

5-6

Page 39

5.3.2 Humidity Calibration at 75% Humidity

CASE 1 The 75% reading is too low by n counts, so DECREASE the humidity

code by n counts.

EXAMPLE 1

: you obtain a reading of 72%. The error is -3 since 72 is 3 counts lower than

75%. The initial humidity code of 67 (from Case 1: Example 1 in previous section) must

be reduced to 64 (–3 counts).

READING INITIAL ERROR CHANGED (NEW) HUMIDITY

IN 75% HUMIDITY CODE IN 75% “HUMID”

ENVIRONMENT CODE ENVIRONMENT

72 67

*

-3 64

*

* the second digit is flashing and changes in this case.

CASE 2 The 75% reading is too high by n counts, so INCREASE the humidity

code by n counts.

EXAMPLE 2

: you obtain a reading of 76%. The error is +1 since 76 is 1 count higher

than 75%. The initial humidity code of A5 (from Case 2: Example 2 in previous section)

must be increased to A6 (+1 counts).

READING INITIAL ERROR CHANGED (NEW) HUMIDITY

IN 75% HUMIDITY CODE IN 75% “HUMID”

ENVIRONMENT CODE ENVIRONMENT

76 A5*+1 A6

*

* the second digit is flashing and changes in this case.

Changing the second digit (following Section 5.2 ) does not affect readings at 33% and

lower. Check to see that the reading is 75. If it is not, adjust the second digit of the code

again.

You must continue to Section 5.4 to finish the calibration process.

Calibrating the Recorder

5

5-7

Page 40

5.4 Calibrating Temperature Readings

1. To calibrate temperature, set the instrument to °F (DO NOT USE °C) and place

the sensor probe in a known, stable environment between 60°F and 90°F.

Read the display after allowing the probe to reach equilibrium after a 15

minute warm-up period.

2. If the reading is TOO LOW by n counts, DECREASE the temperature code

(code following the letter “T”) by n counts. If the reading is TOO HIGH by n

counts, INCREASE the temperature code by n counts.

Changing the temperature code will not affect the humidity calibration.

Calibrating the Recorder

5

5-8

Page 41

Using the Cal-Lock Kit

6-1

6

The CT485B-CAL-LOCK kit that comes with the CT485B is used to preserve and

protect the settings that were entered into the CT485B during the calibration

process. The CT485B-CAL-LOCK cover shields the HIGH, SET and LOW

calibration buttons to prevent any additional button pressing. This method is

more “permanent” than using the control panel door lock. Here’s the procedure:

USE EXTREME CAUTION WHEN USING THE GLUE. READ

THE WARNING LABEL ON THE TUBE.

1. Calibrate the CT485B.

2. Apply a small amount of glue to the back of the cover. Refer to Figure 6-1.

Figure 6-1. Glue Application

DO NOT LET GLUE COME IN CONTACT WITH BUTTONS.

3. Place cover over calibration buttons.

4. Fill in the label information.

5. Apply label to cover as shown in Figure 6-2.

Figure 6-2. Label Application

An additional label is supplied for future calibrations. A

damaged label or removal of the label implies that the

calibration of the recorder may have been altered.

NOTE

CALIBRA

TED

BY:

DATE:

CAUTION

WARNING

!

Page 42

Using the Cal-Lock Kit

6

6-2

Notes

Page 43

Using the Voltage Input Adapter (Optional)

7-1

7

Use the optional voltage input adapter to record an external 20mV to 1200mV

signal with the temperature pen. When using the Fahrenheit scale chart paper,

values between 2° and 120°F correspond to adaptor inputs of 20mV dc to

1200mV dc. The same correspondence applies to the °F display (2°F = 20mV dc;

20°F = 200mV dc; 120°F = 1200mV dc). While the voltage adapter is in use, the

humidity pen is inoperative and the humidity display is invalid.

Typical applications include monitoring analog output of panel meters, process

signals, and lab equipment. For example, if the adapter is used with a

10mV/degree analog signal, the recorder will display and record 20mV to

1200mV over the range of 2° to 120°F. If the adapter is used with a 1mV/degree

analog signal, the recorder will still display and record 20mV to 1200mV over the

range of 2° to 120°F scale on the chart. However, this plotted range now

corresponds to a range of actual temperatures of 20° to 1200°F.

Polarity of the dc input signal should correspond to the + and – markings on the

adapter.

INPUT VOLTAGES GREATER THAN 20VDC OR 10VAC RMS

MAY DAMAGE THE RECORDER.

Figure 7-1 shows a typical setup using the voltage input adapter.

Figure 7-1. Voltage Input Adapter Setup

Voltage

Source

20 mV to 1200 mV

1200 mV

Max

Voltage Input

Adaptor

RH

°F

°C

HIGH SET LOW

1

7

32

°F°C0

I

CHART TYPE

PWR

ALARM

T

E

M

P

E

R

A

T

U

R

E

H

U

M

I

D

I

T

Y

74

CAUTION

!

Page 44

Using the Voltage Input Adapter (Optional)

7

7-2

Notes

Page 45

Maintaining the Recorder

8-1

8

8.1 General Considerations

73

Keep the recorder in a dry place. If it

gets wet, wipe the case as soon as

possible to get rid of any moisture.

Do not expose the recorder to temperatures

other than those stated in the specifications

(Chapter 11). The recorder can operate in

temperatures as high as 120°F (49°C) or as

low as 32°F (0°C).

121

31

73

Handle the recorder carefully

(DO NOT DROP IT).

Keep the recorder away from

excessive dirt and dust. Do not

use the recorder or the sensor

in a corrosive air environment.

Do not use strong cleaning solvents or

alcohol when cleaning the outer case. Refer

to Section 8.3 for more details.

Do not use old or weak batteries in

the recorder. It is important to

change the batteries monthly or

when you see the LO BAT indicator

(refer to Section 2.3.1).

SOLVENT

DUST

DUST

DUST

DUST

Page 46

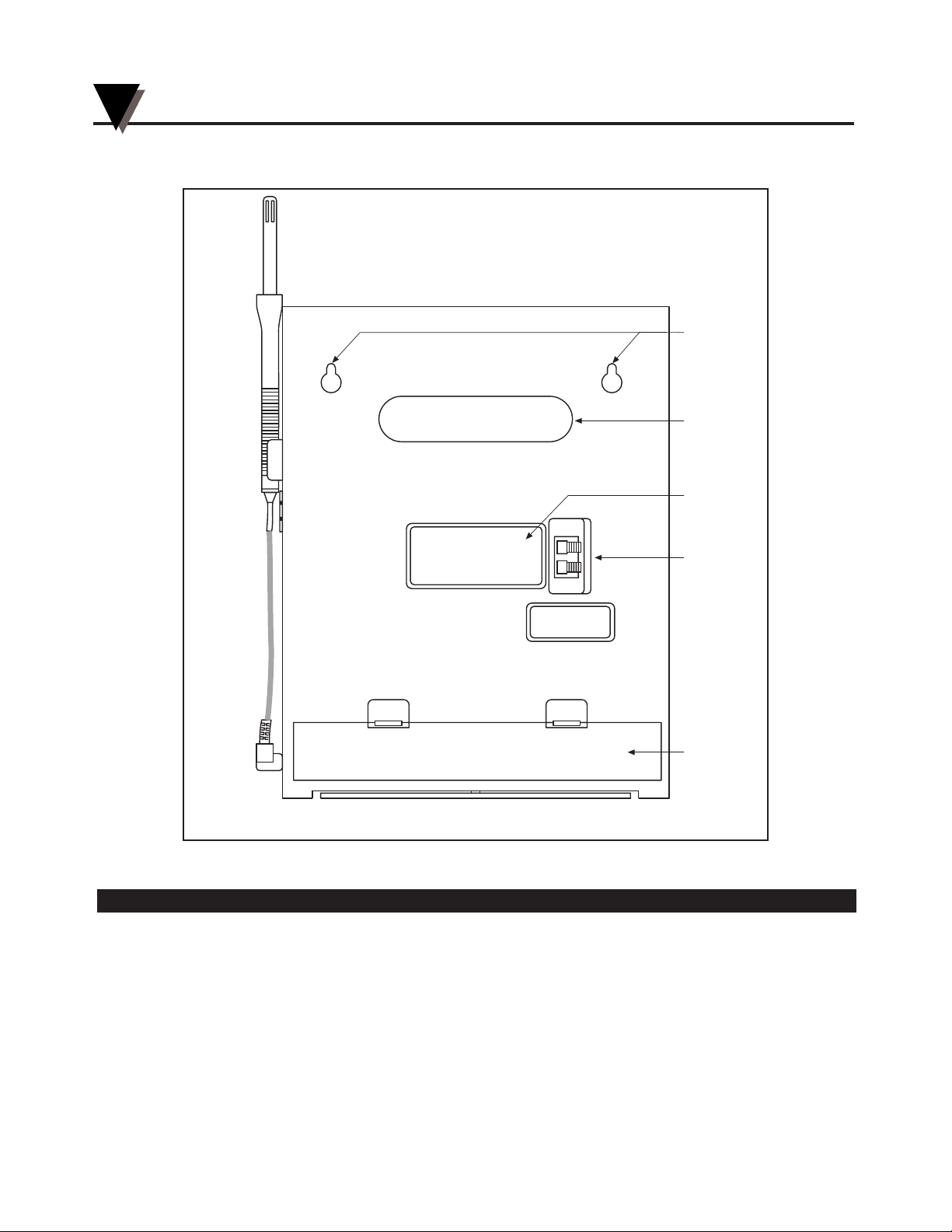

8.2 Light Bulb, Display Backlighting and Push Button Information

You may notice that the light bulbs flicker slightly while the pens are moving.

The flickering stops once the pens are stationary.

The light bulbs on the chart base of the recorder are long-life specialty bulbs.

Even though they last a very long time, they will burn out eventually. Always

replace both bulbs. The part number for ordering 10 bulb/holder assemblies is

listed on the inside back cover. One extra pair of bulb assemblies is supplied

with the recorder.

When removing the bulbs, grasp the bulb holder that contains the bulb and pull

it out. Do not pull on the bulb itself. When reinserting the new bulbs in the

sockets, orient the bulbs to fit as shown in Figure 8-1.

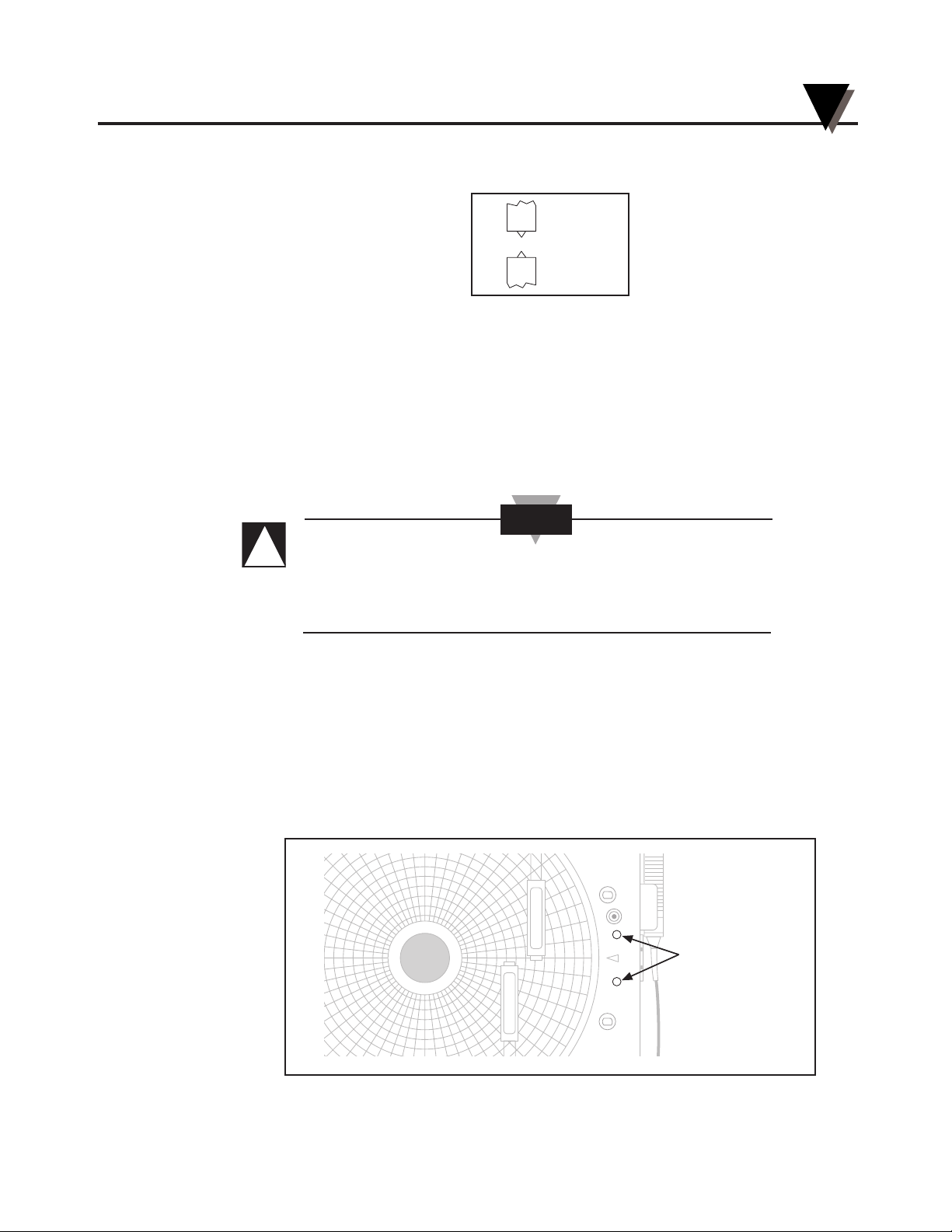

Figure 8-1. How to Hold the Bulb Assembly and Where the Bulbs are Located

In the event that the ac power to the recorder is cut off (e.g.,

blackout), the recorder will continue to operate with the 4 “D”

size backup batteries. The chart lights and the display

backlighting operate on ac power only.

The recorder is equipped with a push button located on the chart base. This

push button turns on and off the chart light bulbs as well as the display

backlighting. One press of the push button turns on the lights and a second

press turns them off. Figure 8-2 shows the location of the push button.

Figure 8-2. Push Button Location

H

U

M

I

D

I

T

Y

T

E

M

P

E

R

A

T

U

R

E

Light Bulb

Push Button

H

35 T2

NOTE

H

35 T2

T

E

M

P

E

R

A

T

U

R

E

H

U

M

I

D

I

T

Y

Maintaining the Recorder

8

8-2

Page 47

8.3 Case Care

The case, front window and pen arms of the recorder should be cleaned with a

mild soap solution. Under no circumstances should you use an alcohol or

solvent based cleaner anywhere on this recorder.

8.4 Storage of Chart Paper

For optimum performance, store the chart paper in the plastic bag provided.

Store the paper in rooms that have humidity levels lower

than 80% relative

humidity.

8.5 Power Failure Mode (Chart Paper Indication)

The chart paper indicates when the ac power failure occurred, the battery back

up period and when the ac power returns. It is important to have fresh “D” size

batteries in the recorder for battery backup so you have continuous recording.

Figure 8-3 shows an example of chart paper with the power failure lines.

Figure 8-3. ac Power Failure Indication on Chart Paper

8.6 Sensor Maintenance

Under normal operating conditions the sensor requires no maintenance.

However, the sensor should not be used in a corrosive air environment, even for

limited time frames. The sensor electronic components are very sensitive, and

will not perform to spec if chemically degraded.

ac Power

Return

Battery

Back Up

Period

ac Power Failure

Chart Start

Chart End

Maintaining the Recorder

8

8-3

Page 48

8-4

Notes

Maintaining the Recorder

8

Page 49

Troubleshooting the Recorder

9-1

9

Table 9-1 contains a brief troubleshooting guide.

Table 9-1. Troubleshooting Guide

If this occurs Perform these steps

If using fresh batteries, make sure they

are inserted correctly.

Make sure the ac adaptor is securely

plugged into the wall and into the power

jack on the recorder.

Make sure POWER switch is in the “|”

(ON) position.

Recorder appears not to

function at all.

?

Page 50

Make sure the door is completely closed

and the latch button is in the uppermost

position. It may be necessary to squeeze

the case slightly to close the latch completely.

The pens do not appear to

be leaving traces on the

paper.

?

Make sure the “CHART TYPE” °C/°F

switch (under the control panel door) is in

the correct position.

The humidity pen (blue)

appears to be in the wrong

position.

?

Make sure the “CHART TYPE” 1/7/32

switch is in the correct position.

Make sure the magnetic chart knob is in

place.

Chart paper appears not to

turn, or to turn at the wrong

speed.

?

If using old batteries, replace with a fresh

set of alkaline batteries.

Troubleshooting the Recorder

9

9-2

Page 51

Table 9-1. Troubleshooting Guide (Cont’d)

If this occurs Perform these steps

The chart recorder is operating off

batteries. Switch over to ac power if you

wish to light up the paper.

Bulbs are blown. Replace them with new

bulbs.

Bulbs don’t light.

?

Make sure pen caps are removed (and

secured on the cap posts as

recommended).

Check that the pens are locked firmly in

position in their holders.

Make sure the pens are fresh. Remove a

pen and test it on a piece of

chart p

aper.

Insert new pens if necessary.

The pens do not appear to

be leaving traces on the

paper.

?

Xxxx

9

9-3

Page 52

Technical Details

10-1

10

10.1 Sensors and Measurement

The recorder has an external plug-in temperature/humidity sensor. A six-foot

remote sensor cable is provided to allow remote sensing of both temperature and

humidity.

Unlike many circular hygrothermographs, this recorder utilizes electronic

sensors to measure both ambient temperature and relative humidity. The

temperature sensor is a low-power, semiconductor type, with a linear voltage

output proportional to temperature. The humidity sensor consists of a bulk

polymer material deposited on a ceramic substrate. The mobility of the ions in

the polymer changes with moisture content of the surrounding atmosphere. As

a result, the sensor presents an impedance which is a highly non-linear function

of the relative humidity. The sensor is driven by ac excitation and the wide

dynamic range of its output is compressed with a logarithmic amplifier.

All humidity sensors are susceptible to contamination from

outside sources that can affect accuracy and response time.

Take care to prevent excessive contamination by dirt, oil,

grease, solvents, or a corrosive air environment.

The electronically conditioned output of both sensors is fed to a microprocessor

via an analog to digital converter. The processor linearizes and temperature

compensates the output of the humidity circuit employing a “look-up table

approach”. The results of the processor calculations are then used to update the

front panel display and to position the pen arms on the chart paper.

10.2 Pen Arm Drive

This recorder utilizes a motor-driven lead screw pen arm drive located in the

door of the unit. This provides several advantages over conventional pivot arm

mechanisms. First, the recorder pens move along straight, radial lines as the

temperature and humidity change. Thus, the time scales on the chart paper are

straight lines and are much easier for the user to interpret than the swooping

arcs produced by a conventional recorder. Second, the placement of the recorder

pen arms directly opposite one another allows the pen tips to be placed very

close together. This minimizes time offset between information recorded by the

temperature and humidity pens, making the charts easier to interpret. Finally,

the location of the drive mechanism in the door provides an automatic pen lift

when changing the chart paper.

The position of the pen arms on the lead screw mechanism is controlled by

optical encoders. On power up or system reset, the pen arms move to the zero

position. This is detected by a photo interrupter, to provide absolute positional

information to the microprocessor.

NOTE

Page 53

From this point, a count wheel mounted on the lead screw provides positional

information relative to the zero position. There are 32 counts for each division

on the chart paper.

As with all positioning mechanisms, an error may appear in the tracking over a

period of time. To minimize this error, several steps have been taken. First, a

deadband for pen movement of

1

⁄2 chart division has been programmed in to

minimize pen motion without affecting usable chart resolution. Second,

whenever you change chart paper, a magnetic switch detects the opening of

the door and initiates a system reset, thus re-zeroing the pens and eliminating

any accumulated errors.

A further unique feature of the recorder is its ability to utilize charts with either

Fahrenheit or Celsius scales via switch selection on the front panel. The

microprocessor adjusts the range of travel for the temperature and humidity

pens so that convenient scales for both can be used.

10.3 Chart Paper Drive Mechanism

The recorder incorporates a stepper motor to impart rotational motion to the

chart paper. A novel feature of the unit is its ability to utilize 1, 7 or 32 day

chart paper simply through front panel switching. This capability is provided

by a special digital timing circuit which precisely controls the stepping rate of

the magnetic armature in the motor.

10.4 Power Supply Supervision

The recorder contains power supply monitoring and switching circuitry which

enables it to be used in a variety of circumstances. Under ordinary

circumstances, the unit will be powered by 110 or 220 Vac with the ac adaptor

provided. This is the preferred mode of operation. The recorder can also

operate via 4 “D” size batteries installed in the rear of the unit which will

power the unit up to 30 days.

The system may be restarted by changing the batteries or by the re-initiation of

ac power. If ac power fails, the circuitry will attempt to automatically switch to

battery backup. If viable battery power is available, the system will operate on

battery power until the batteries fail or ac power returns. When ac power

returns, the recorder will automatically reset itself (refer to Section 8.5).

Typically, the unit will operate with fresh alkaline batteries for about 1 month. It

should be noted that to conserve battery power, the system timing turns the

sensors on and updates the display and pen position only once every 0.5, 3.5 or

16 minutes while in the 1, 7 or 32 day modes respectively. However, the display

remains in continuous operation during battery operation. You should be aware,

then, that during battery operation it is possible for the display and pens to lag

behind actual ambient conditions by up to 0.5, 3.5, or 16 minutes to save power.

Only when using the ac adaptor do the display and pens constantly update for

changes in ambient conditions.

Technical Details

10

10-2

Page 54

Specifications

11-1

11

General

Measurement Input: Temperature and humidity, with plug-in external

sensor

Removable for remote location (up to six feet)

Temperature

Range: 2° to 120°F, –17° to 49°C

Accuracy: ±1°C

Sensor: Solid State

Response Time: 5 minutes for 63% step change

Display Resolution: 1°F/1°C

Humidity

Range: 2% to 98% RH

Accuracy: ±3% @ 25°C, between 20% and 90% of range;

±5% below 20%, above 90% @25°C

Sensor: Resistive polymer

Response Time: 5 minutes for a 30% to 80% step change

Display Resolution: 1% RH

Display

Types: 21⁄2 digit backlit LCD, 0.5” high; low battery and

parameter indication

Display Modes User-switchable between °F°,°C and %RH for

continuous display; max/min storage for both

temperature and humidity

Electronics

Type: Microprocessor-controlled and linearized HI &

LO Peak Hold for both temperature and humidity;

re-initializes position at every chart change (every

time door is opened)

Chart Paper

Type: 8 inch (200mm) circular, double-sided, with

linear radial divisions; 1, 7 and 32 day with both

°F and °C scales

Page 55

Chart Drive

Type: Stepper Motor

Ranges: 1, 7, 32 day; switchable

Accuracy: 1% of rotation

Chart Paper Hold Down: Magnetic hub lock

Recording Pens

Type: Disposable fiber-tip; red for temperature, blue for

humidity

Pen Drive

Type: Motorized linear screw drive

Deadband: 1°F, 1% RH

Zero: Automatic zero during chart change or power

interruption

Pen Arms: Clear plastic to allow full chart viewing

Pen Lift: Automatic upon door opening; pens are door

mounted and lift away from the chart whenever

the door opens.

Alarms

Alarms: User-selectable for high or low temperature and

humidity

Audible Alarm: Integral piezo-electric beeper

Alarm Relay Contacts: 2A 110Vac, 2A 30Vdc, Normally Open, Single

Pole, Single Throw (SPST)

Operating Conditions (Recorder)

Temperature: 32° to 120°F (0° to 49°C)

Humidity: 0% to 90% RH, non-condensing

Operating Conditions (Remote Sensor)

Temperature: 2° to 120°F (-17° to 49°C)

Humidity: 2% to 98% (should not be operated continuously

in condensing conditions)

Specifications

11

11-2

Page 56

Power (Recorder)

dc: Four (4) “D” size alkaline batteries; greater than

1 month continuous operation in 32 day mode;

bulbs will not light on battery power.

Recommended battery type: Duracell Type

MN1300 “D” size batteries for best performance

at low temperatures.

ac: 110Vac or 220Vac 50/60 Hz stepped down to

nominal 9Vdc using ac adaptor provided

Power 300 mA “normal” during pen movement for

Requirements: battery (dc power); 500 mA “normal” during pen

movement for ac power using ac adaptor.

(Note: The light bulbs draw 200 mA of current).

ac Power Jack 8.3 to 12.4 Vdc, (nominal 9Vdc) 1A max.

Voltage: An ac adaptor is supplied

Analog Voltage Input Adapter (Optional)

Input: 20 mV dc to 1200 mV dc records as 2° to 120°F

Input Protection: up to 20Vdc or 10Vac RMS

Input Impedance: 330k ohms minimum

Input Connections: Banana jacks, 0.75” spacing

Cable Length: 12" (30.5cm)

Mechanical

Dimensions: 133⁄16” x 1011⁄16” x 25⁄8”

(H x W x D) (33.5 x 27.1 x 6.7 cm)

Weight: Approx. 7 lbs, including alkaline batteries

Mounting: “Keyhole” slots for wall mounting; foot cover for

benchtop use

Case: Rugged ABS plastic, color: gray or white

Miscellaneous: Swing-out stabilizing arm for bench top use,

decorative foot cover for wall mounting, and 6 ft

remote sensor cable for remote sensing

(USE ONLY ONE 6 FT REMOTE SENSOR CABLE

PER RECORDER FOR ACCURATE READINGS)

The CT485B Chart Recorder may be susceptible to radio

frequency fields at selected frequencies. The reading error

can be up to 10% of reading (Both Temperature and

Humidity) when exposed to RF fields (Testing was performed

to,IEC1000-4-3, 80% AM Modulation).

Specifications

11

11-3

NOTE

Page 57

Specifications

11

11-4

NotesNotes

Page 58

12.1 Sensor Design for CE Conformity

For CE labelled recorders only, the sensor has been redesigned to meet

requirements as outlined in European Community EMC Directive EN50081-1/

EN50082-1. In particular the sensor cap is made from unplated plastic to pass

ESD (electro-static discharge) tests. In addition, a ferrite core has been attached to

the sensor cable to meet radiated immunity specifications. Refer to Figure 12-1.

Figure 12-1. Location of the Ferrite Core for CE Conformity

If you plan on using or are using the remote sensor cable, refer to the ferrite core

information below.

For best radiated immunity performance when using the remote sensor cable

(Section 2.6.2), you will need to move the ferrite core close to the input of the

recorder. To relocate the ferrite core, perform the following:

RH

°F

°C

T

E

M

P

E

R

A

T

U

R

E

H

U

M

I

D

I

T

Y

SIDE VIEW

H

35 T2

Plastic Cap

Ferrite Core

H

35 T2

RH

°F

°C

T

E

M

P

E

R

A

T

U

R

E

H

35 T2H

35 T2

Ferrite Core

Connector

Cable

1. Insert your fingernail in the place shown in

Figure 12-2 and unsnap the ferrite core

from the sensor cable.

2. Install the ferrite core on the remote sensor

cable next to the connector as shown in

Figure 12-3.

Figure 12-2. Ferrite Core

Figure 12-3. New Location of the Ferrite Core

(on the Remote Sensor Cable

)

12-1

CE Conformity

12

Page 59

CE Approval

12

Notes

12-2

Page 60

Index

I

I

A

Accessories ................. Inside Back Cover

ac Adapter ............................................. 2-5

ac Power Failure Indication ................ 8-3

ac Power Hookup ................................. 2-5

Alarm Display Buttons ................ 1-3, 4-3

HIGH ................................... 1-3, 4-3

LOW .................................... 1-3, 4-3

SET ....................................... 1-3, 4-3

Alarm Limits ......................................... 4-1

Disabling the alarm .................. 4-4

Setting the alarm ....................... 4-3

Turning off the alarm ............... 4-4

Operation of .............................. 4-1

Alarm/Relay Contacts ................. 1-4, 4-1

B

Batteries (“D” size) ............................... 2-3

Installing .................................... 2-4

Replacing ................................... 2-4

Battery Compartment .................. 1-4, 2-4

Battery Usage

Indication on Paper .................. 8-3

Bench Top Use ...................................... 2-1

Bulb Replacement ................................ 8-2

C

Calibrating ............................................ 5-4

Codes ................................... 3-1, 5-1