Page 1

Compact Benchtop Controllers

Optional Communications Bundled

with Free Software

U Rugged Metal Benchtop Enclosure

U 4-Digit Display, 1 or 0.1° Resolution

U Full Autotune PID Heat-Cool Control

CSC32 Series

U Single Ramp and Soak Capability

U High Accuracy (± 0.25% full scale ± 1.5°C)

U Models with Dedicated Thermocouple,

RTD, Process Voltage or Current Input

U Two 5 Amp 120 Vac SSR Outputs Standard

U Second Output May be Used for Control

or One of Five Types of Alarms

U Optional RS232 or RS485 MODBUS

Communications with Free CN9-SW

Communications Software and Cable

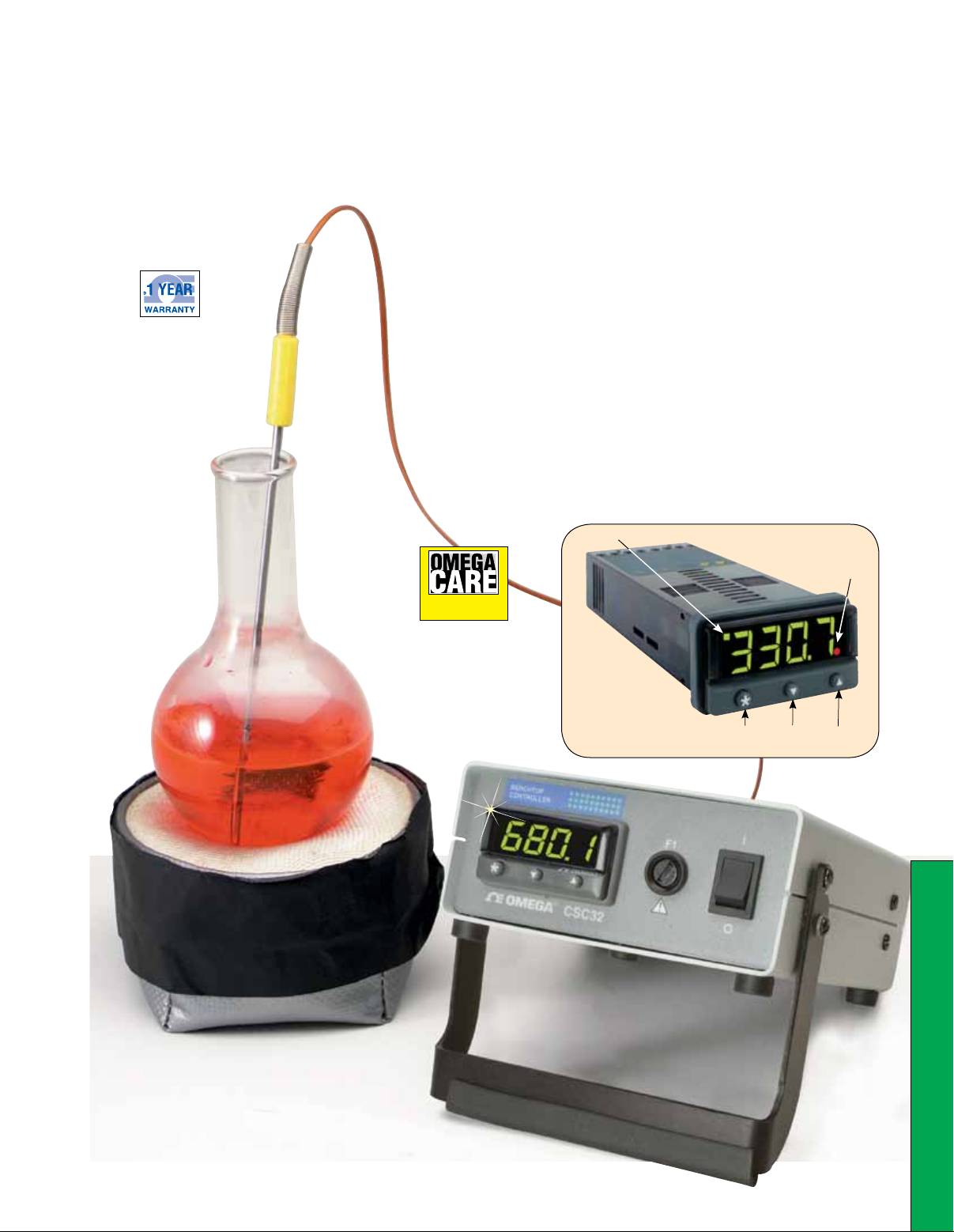

CN9500 Series Controllers are used

in the CSC32 series benchtop units.

Output 1 Indicator

SM

Output 2

Indicator

Extended Warranty

Program

OMEGACARESM extended

warranty program is available for

models shown on this page. Ask

your sales representative for full

details when placing an order.

OMEGACARESM covers parts,

labor and equivalent loaners.

1

⁄32 DIN

CN9500,

visit omega.com/

cn9500 for details

Function

Key

Down

Arrow

Up

Arrow

P

CSC32K Benchtop Controller shown with

LHM Series Heating Mantle, (Flask not included),

and KMTXL-125G-12 Thermocouple Probe,

visit omega.com/kmtxl_nmtxl for details.

P-80

Page 2

The CSC32 series compact

benchtop controllers are ideal for

laboratory use and applications

requiring portable temperature and

process control. Pre-wired input

and output receptacles in the rear

of the case enable quick and easy

connections to power, input, power

output and digital communications.

These benchtop controllers are

factory configured and calibrated

for a dedicated input type by

model number.

The 1⁄32 DIN CN9500 controller used

in this benchtop controller series

can be programmed for either On/

Off, or PID Autotune Control (with

autotune Feature) via the front panel

or through the use of a PC and

CN9-SW communications software.

CN9-SW software is designed to

interface with the CN9300, CN9400,

CN9500 and CSC32 Series

benchtop controllers with optional

communication hardware. Benefits:

• Time-saving benefit and

convenience of remotely

configuring and adjusting units.

• Saving and retrieving settings

to and from files.

• Highly flexible logging and “real

time” charting capability for

providing hard copy QA records for

ISO-9000 and other management

purposes.

• Software is capable of logging

readings from up to 128

instruments which it stores in

data files.

• The data can be exported into

text files in Comma Separated

Variable format.

• In addition, up to 12 controllers can

be displayed on a single chart, or

individual charts can be set up for

each instrument.

• A virtual full color chart recorder

can log process variables such as:

°C, °F, Bar, PSI, pH, rH, or user

defined engineering units

64

(2.5)

Dimensions:

mm (inch)

Fused Outputs

Depth

155 (6.1)

RJ12, RS232

Communications

Dual 5A @ 120 Vac SSR outputs

125 (4.9)

CSC32K-C2 Front View

or RS485

CSC32K-C2 Rear View

The Patented

UPJ-K-F Uni-Connector

Accepts Either a Miniature or

Standard Male Connector

AC power

Specifications

Power: 115 Vac, ±10%, 50/60 Hz

Display: 4-digit LED, 10 mm (0.4”),

high brightness green display

Display Range: -199 to 9999

counts (hi-res mode -199.9 to 999.9)

Range: Sensor limited 2000°C/3500°F;

-99.9 to 999.9° in 0.1° resolution

Graph Displaying Real Time Charting Using CN9-SW Software

P-81

Page 3

Display Indicators: Process

variable (PV), Setpoint (SP), LED

output indicators-flashing

Output 1 (SP1 square), green;

Output 2 (SP2 round), red; error

messages, Function/Option

mnemonics

Control Modes: PID Autotune, ON/

OFF, Direct/Reverse,

Alarm Modes: Deviation high,

deviation low, deviation band, full

Scale high, or full scale low

Thermocouple External

Resistance: 100 Ω max

Thermocouple: See Input and

Range Table

Standards: IPTS/68/DIN43710

RTD Input: Pt100 2-wire (.00385)

Linear Process Inputs: mV range:

0 to 50 mV (1 Ω shunt resistor

supplied for mA inputs)

Calibration Accuracy: ±0.25%

of Full Scale ±1.5°C (±2.7°F)

Sampling Frequency:

Input 10 Hz, CJC 2 sec

Common Mode Rejection:

Negligible effect up to 140 dB,

240V, 50 to 60 Hz

Temperature Coefficient:

150 ppm/°C sensor max

Input Connection:

Thermocouple: Accepts both

miniature and standard male

Thermocouple Connectors

Note: A miniature and standard size male

mating connector is included with each

benchtop controller

RTD, mA or mV: Accepts OMEGA®

T series model TA3F Keyed-3-pin

locking connector

Note: A mating connector is included with

each benchtop controller

Outputs: Two solid state relays

rated for 5 A @120 Vac (internally,

the controller provides two DC pulse

outputs to drive a built-in dual solid

state relay)

Operating Ambient Range:

0 to 50°C (32 to 130°F)

Benchtop Case Material:

Aluminum

Controller Case: Flame retardant

polycarbonate

Power Connection: Std. three

prong power cord (provided)

Output Connections: Two

standard 120 Vac outlets

Weight: 0.9 kg (2 lbs)

Software included

with “-C2” or

“-C4” options.

Computer screen depicting

the internal parameters setup

for tuning mode, ramp/soak

sequence and security lockouts

when using CN9-SW Software.

When a satisfactory instrument

configuration has been achieved,

these settings can be saved to a

file for later use or cloned to other

instruments on the network.

Input and Range Table

Linearized Range Linearity

Input

Input Type (Units are °C/°F Switchable) °C (°F)

Code

Iron-Constantan -0 to 800°C/32 to 1472°F 0.5 (0.9)

Copper-Constantan -200 to -250°C/-273 to 482°F 0.25 (4.5)

Pt-13%Rh/Pt -50 to 40°C/40 to 1768°F 2.0 (3.6)

Pt-10%Rh/Pt 0 to 1600°C/32 to 2912°F 2.0 (3.6)

CHROMEGA®-ALOMEGA

CHROMEGA®-Constantan 0 to 600°C/32 to 1112°F 0.5 (0.9)

OMEGA-P®-OMEGA-N

RTD 100ΩPt, 2-Wire -200 to 400°C/-273 to 752°F 0.25 (0.45)

MA LINEAR CURRENT 0 to 20 mA (-250 to 3000 Max. Scale) ±0.5% (±0.9%)

MV LINEAR VOLTAGE 0 to 20 mV (-250 to 3000 Max. Scale) ±0.5% (±0.9%)

®

-50 to -1200°C/-58 to 2192°F 0.25 (4.5)

®

-50 to 1200°C/-58 to 2912°F 0.25 (0.45)

To Order Visit omega.com/csc32series for Pricing and Details

Model Number Description

CSC32(*) Benchtop controller

Insert Input Code: J, K, T, E, R, S, N, RTD, MV or MA from Input and Range Table

*

Comes complete with operator’s manual, 120 Vac power cord and input connector.

Ordering Example: CSC32K-C2, benchtop controller, Type K input and RS232

communications option. OCW-3 OMEGACARESM extends standard 1-year warranty to a total

of 4 years.

Communications Options

(Pre-Wired 6’ Communications Cable Included)

Suffix Description

-C2 RS232 communications bundled with free CN9-SW

-C4 RS485 communications bundled with free CN9-SW

Protocol Manual for CN9-SW Software

Model Number Description

BD9-PROTOCOL* MODBUS® Protocol Manual (not required when

using the CN9-SW software)

Note: This protocol manual provides the address information necessary to communicate

*

with the CN9300/CN9400/CN9500 and CSC32 Series, with communications options installed,

when interacting with custom or other commercially available software.

P

P-82

Loading...

Loading...