Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

CS7500 / CS7600

M-4382/1006

Shop online at

Page 2

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

TABLE OF CONTENTS

SPECIFICATIONS 2

UNPACKING AND STARTUP 3

OPERATIONAL FEATURES 5

MENU ACCESS 7

OPTION CONFIGURATION 9

MENU NAVIGATION 14

7600 MENU ENTRY 14

7500 MENU ENTRY 15

CAL 40, FILTER & CALIBRATION 16

CFG 50 COUNTING FUNCTIONS 17

CFG 60 RS232 CONFIGURATION 17

CAL 70 TIME AND DATE 18

CAL 80 FORMATED PRINT SLOT 18

CONTINUOUS OUTPUT PRINT CODES 19

COMMAND FORMATS 21

RS232 PIN ASSIGNMENTS 23

AVERAGE PIECE WEIGHT STORAGE 24

WEIGHING WITH/WITHOUT TARE 25

COUNTING 26

DISPLAY MESSAGES 32

STATUS CHARACTERS 33

115 TO 220 VAC CONVERSION 34

1

Page 4

SPECIFICATIONS

LOAD CELL A/D CONVERTER

TYPE: 24 bit delta sigma

EXCITATION: 5 VDC, 120 mA max .

SIGNAL INPUT: 16 mv

SENSITIVITY: 0.1 uV/grad

UPDATE RATE: 30 update/second

DISPLAY: Six (6) Decades, 0.6 inch LED

INDICATORS: Gross, Tare, Net, Zero, Stable, Base, Units, Count .

POWER INPUT: 117/217 VAC, 50-60 HZ, 20 watts, fuse 0.25 A Slo-Blow.

SERIAL PORT: RS232C

COUNTING SCALE: Cast Aluminum, 14” (L) x 15.5” (W) x 5.25 (H); 15.25 lbs.

OPTIONS:

TIME & DATE: 12/24 hr, battery backed.

AC/DC: Battery backed (counting Scale).

REMOTE DISPLAY: Wall or post mount.

DUAL CHANNEL: Independent A/D converter.

2

Page 5

Unpacking and Startup

Counting Scales:

After opening the shipping carton, remove the molded foam top from the carton. (On

2 lb. and 5 lb. capacity scales the platform is packaged on top of this foam, remove it

first and lay it aside.)

Gently lift and remove the stainless steel platform cover only.

Remove any options which may be packed with the scale.

Carefully remove scale from the packaging by grasping both sides of the base.

DO NOT LIFT SCALE BY THE TOP SPIDER OR SUB-PLATFORM ASSEMBLY.

Place the scale on a stable, level surface for operation.

Adjust the corner leveling feet until the level bubble indicates the unit is level. Firmly

tighten hex jam nuts on the leveling feet. (Any time the scale is relocated, it should be

leveled.)

Remove the protective plastic wrap from the platform and place the platform on the

spider.

To activate the scale, plug the line cord into any grounded 50/60 hertz 120 volt outlet.

3

Page 6

Operational Features

Automatic Zero-Tracking (AZT) - Maintains the system zero and is normally set to +/-

1/4 of the display resolution.

Count/Weigh - Scale is capable of both counting and weighing functions. The count

may be turned off on the 7600 if not needed.

Four Selectable Sample Sizes - Four different sample sizes may be entered into the

scale memory during programming.

Counting Functions - A variety of different counting methods may be employed,

depending on type of counting selected during calibration.

Sample Update - Piece weight accuracy may be improved after the initial sample by

adding a quantity of parts between 10% and 100% of the original sample to the

platform. When this is done the scale will recalculate the piece weight, display the new

percent error/accuracy for 2 seconds and then return to the counting mode.

Second Base - An optional second base is available to expand the capacity of the

scale.

Peak/Hold – Captures the peak reading directly (based on filter settings) or after preset

number of “stable” readings.

Accumulation – Based on count or weight.

Counting Scale Connectors:

The following connectors may be accessed through the opening on the bottom of the

scale.

D-Subminiature Connector (9-pin) - Used with RS-232 Interface.

Remote Display Connector - Used to connect a remote display option to the scale.

REMOTE BASE CPC Style connector (8 pin) - Same as indicator wiring.

5

Page 7

Operational Features

Push-Button Functions

ZERO Button - Sets the scale to zero.

UNITS Button - Used to switch the scale between the primary weighing unit,

secondary weighing unit, and the count mode.

PRINT Button - Transmits formatted print to any device connected to the RS-232

port. Holding this push-button for four seconds will access the RS-232 configuration

mode.

SAMPLE SET Button - Places the scale in the sample set mode for counting

operations. Hold to access setpoint targets when enabled.

7600 18-Key: Full Numeric + Enhanced Operation

GROSS/NET Button - Switches the scale display between Gross weight and Net

weight.

PIECE WEIGHT Button - Will cause the scale to display the presently stored piece

weight, if any, and puts it into the piece weight entry mode.

TARE Button - Will tare off any weight setting on the platform and enter it into the tare

memory.

KEYPAD TARE Button - Will display whatever tare is presently stored in the tare

memory and puts the scale into the keypad tare entry mode.

BASE Button - Used to switch the scale between base 1 and base 2, when the

second base option is installed.

% Button - Used to display the percent of error, or percent of accuracy. (Only if these

features have been selected during programming.)

ID Button - Will display whatever ID number is presently stored in the ID memory

and puts the scale into the ID entry mode.

CHECK Button - Pressing this button will cause the scale to initiate the diagnostic

countdown. It may also be used as a continue key if the scale should freeze on any of

the diagnostic numbers during countdown.

CLEAR Button - Used when the scale is in one of the data entry modes. Pressing this

button once will put a decimal point onto the display and pressing it a second time will

clear the display.

ENT Button - Used when the scale is in one of the data entry modes. Button is used

to enter information into the system memory.

6

Page 8

Menu Access:

To access instrument configuration, calibration or to enable options, depress the “Zero”

key for five seconds.

The Audit Trail counters (“Pxxxx” and “Cxxxx”) are displayed first followed by access

code request (“AC?”). The initial factory setting is “0000” which is entered “AC0000” and

“Print”. If no entry is made, instrument returns to operate mode. Stepping the “Zero” key

when “AC?” is on, will display software version, display check and keypad test.

Configuration and Calibration

Key Functions

The 7500 4-Key access functions (------)

ZERO

(DP/Clear)

DP/Clear: Enters a decimal point or double push clears the display.

Increment: Scrolls selection of sub parameters or increments value for numeric entry.

Advance: Multiplies a numeric entry by “10”.

Enter: Stores entry and steps to the next parameter or exit.

The 7600 (18-Key) uses direct key entry.

The access code can be changed to any four digit combination when exiting setup and

display is “AC ?”, either input change and enter or use enter alone to exit.

SAMPLE

(Increment)

UNITS

(Advance)

PRINT

(Enter)

Front panel access is inhibited if conventional “sealing” is applied by

setting jumper J1-1 in the B position. The internal “CAL” button is

then used for access.

subsequent stepping of the button will select 7300, 7400, 7500, 7600, etc. Leave on

current model and allow time out to incorporate.

Holding the “CAL”, will display the current “7X00” and

7

Page 9

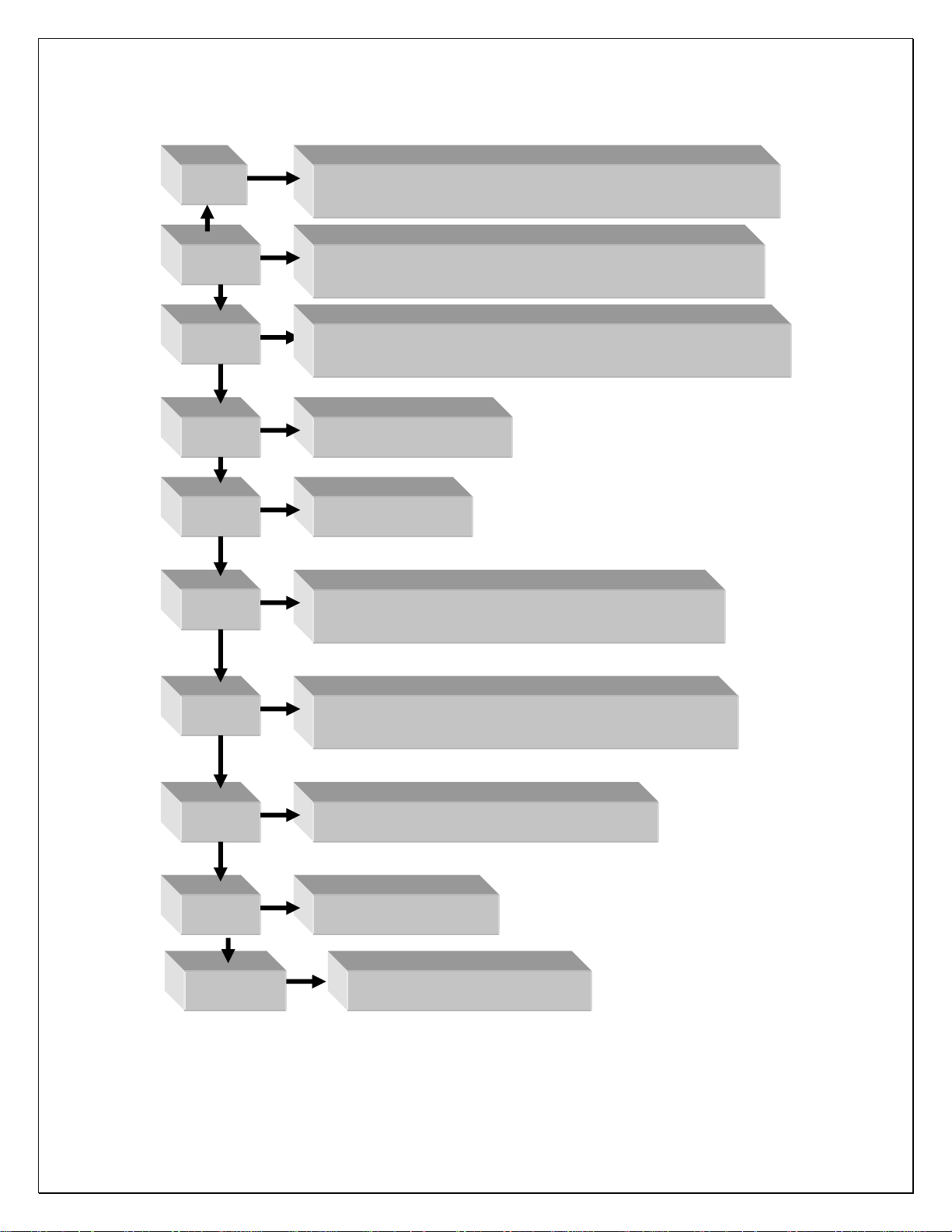

Menu Layout:

CAL1

Options: Dual / Triple Range, Peak Hold, Remote Inputs,

Setpoints, UPS Worldship, Accumulate, Analog Output

CAL 10

Capacity, Auto Configuration, Initial Zero, Enable Count,

Enhance Mode

CAL 20

Capacity, Resolution, Zero Range, Units, Print, Overrange,

Zero Tracking

CAL 30

Secondary Resolution

CAL 40

Filter, Zero, Span

CFG50

Counting Functions, Sample Size, Switch Mode,

Percent Error, Auto Sample/Bulk, Negative Sample

CFG60

RS232 Configuration: Baud Rate, Word, Stop, Parity,

Echo, Address

CAL 70

Time & Date: 12/24 hr, AC/DC Sleep Set

CAL 80

Formatted Print Slot

CAL 200 Remote Display AC/DC only

8

Page 10

Option Configuration (Cal 1):

Step Parameter Definition

bat 1 OFF, On

dtr 2 0……15

dtr High Res. Medium Res.

0 ---- --- ---- ---1 50% X2 ---- ---2 50% X5 ---- ---3 25% X2 ---- ---4 25% X5 ---- ---5 20% X2 ---- ---6 20% X5 ---- ---7 20% X10 ---- ---8 10% X2 ---- ----

9 10% X5 ---- ---10 10% X10 ---- ---11 25% X5 50% X2

12 10% X5 50% X2

13 25% X10 50% X2

14 10% X10 50% X2

15 1% X100 10% X10

Charger enabled/disabled

(AC/DC board only)

Dual/Triple Range (0 = off)

Step Parameter Definition

Peak/Hold function, zero key clears current

PHd 3 OFF, Peak-H, Hold

peak, tare function is disabled, print code 22

and 32 are modified to value and value with

labels (xx.xxx / Peak xx.xxx lb)

HdS 3.1 0……240

Hold after “samples”: Weight must be stable

for 0 – 240 samples to “hold”.

Remote inputs,(with DIO option) Input 1:

Rln 4 no, yes

Gross/net, Input 2: Tare, Input 3: Zero,

Input 4: Print

UPS WorldShip, Parameters 25, 60-69, 80 +

UPS 5 no, yes

are hidden, format:9600/odd/7/2,“39” outputs

the UPS format.

9

Page 11

ACC 6 OFF, A-Cnt, Cnt, A-Prl, Prl

AOS 7 Gross, Net, Display

Zr 7.1 0.00

FS 7.2 Full-scale

Zr.A 7.3 Zero Cal Adjust

SP.A 7.4 Span Cal Adjust

INSTRUMENT CAL UP CAL DOWN

A-Cnt: Auto count accumulator

Cnt: Manual count accumulator

A-Pri: Auto primary units accumulator

Pri: Manual primary units accumulator

Sets the weight that the output represents:

Gross, Net, or Display.

Sets the value of weight that is equal to

4mA/0V.

Sets the value of weight that is equal to

20mA/10V.

Use the cal up/down keys (table II) to set the

output to as close to 4mA/0V that is

acceptable to one’s requirements.

Use the cal up/down keys (table II) to set the

output to as close to 20mA/10V that is

acceptable to one’s requirements.

7500 SAMPLE UNITS

7600 UNITS/4 PRINT/7

SPt 8

OFF, Tr, Prtr, drtr, drtk,

C tr, C Prtr, C drtr, C drtk

Out 8.1 CHG, dIO

dIO Relays as per SPt 8

CHG

tr : Target weight relay K1

Prtr : tr + Preact weight

Drtr : tr + Dribble weight relay K2

Drtk : tr + dr + Trickle weight relay K3

C tr : Target count relay K1

C Prtr : tr + Preact count

C drtr : tr + Dribble count relay K2

C drtk : tr + dr + Trickle count relay K3

CHG : Uses battery ckt to drive LED

dIO : Uses relay board, K1-3.

tr : LED on < tr, off > tr

Prtr : on < Pr, flashes <tr, off > tr

Drtr : on < dr, flashes <tr, off > tr

Drtk : on < dr, flashes fast < tk, slow < tr

10

Page 12

r

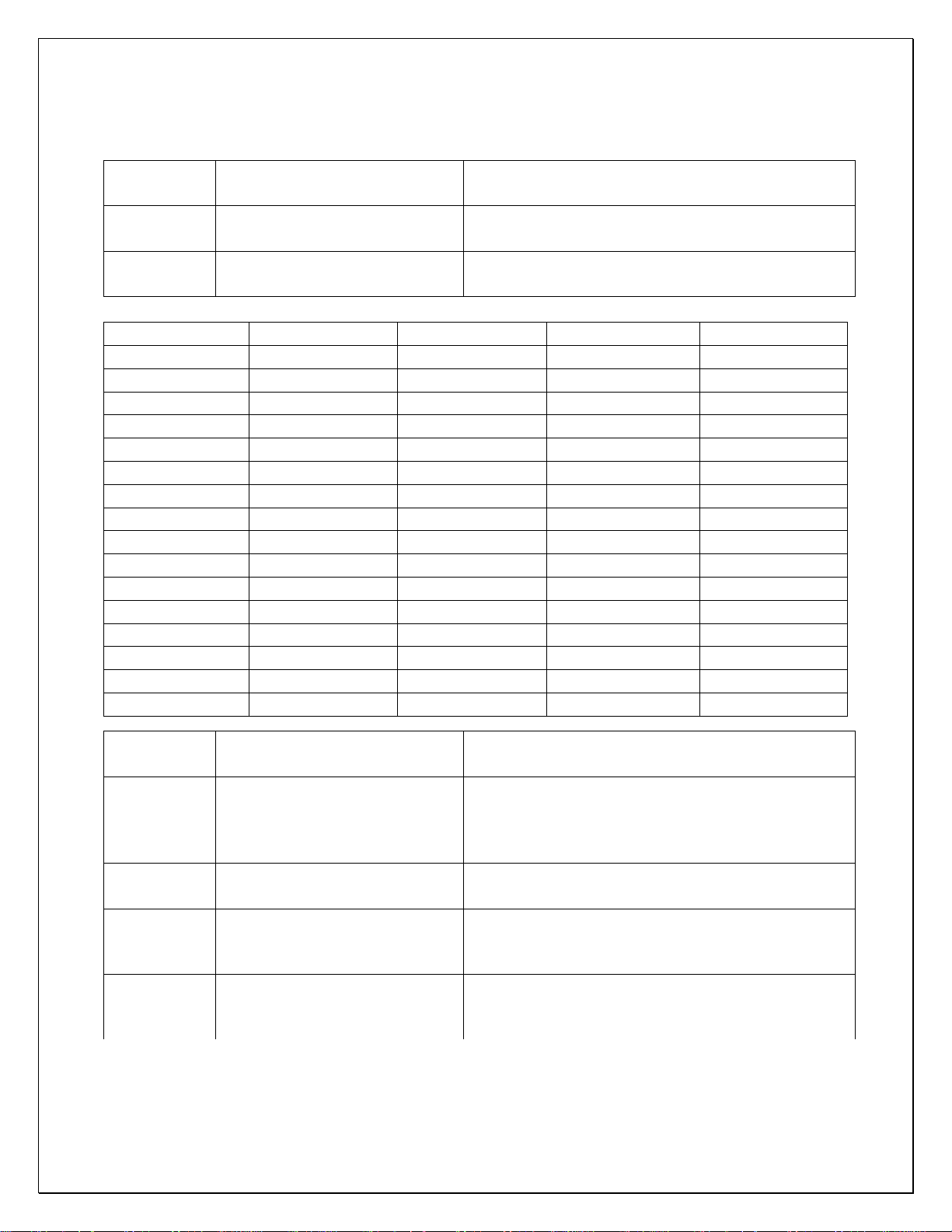

Option Configuration Dual Channel:

P20

Sense Jumpers

Plus….. 1-2

Minus… 3-4

1 2

A

J1

B

EW-1000 Rev…..

Excitation +

Excitation –

P5

P20

Sense +

Sense -

Transformer

1 2

3 4

6 5 4 3 2 1 TB-20

EW -1000-CH2

A/D Converter

F1

Line

Filte

0.25A

SB

CAL/SEL

Signal +

Signal -

11

Page 13

Option Configuration DIO:

AC Inputs; D1, D2 are not installed, J1 = short (underside), J2 = open, R1 – R4 = 18k

(3w, 5%, flame proof).

DC Inputs; D1, D2 are installed, J1 = open (cut trace), J2 = short, R1 – R4 = 1.5k (1/2w,

5%, carbon film).

Gross/Net IN 1

COM

COM

Tare IN 2

Zero IN 3

Print IN 4

K1

K2

K3

TB 30

1

2

3

4

5

6

D1

D2

1

2

3

4

5

6

7

8

TB 31

J1

J2

EW-1000-DIO

P4

EW-1000 Rev…

12

Page 14

r

Option Configuration Analog Output:

Transformer

P5

A

J1

B

1 2

J1

V

I

8 7 6 5 P11

EW-1000 Rev…..

6 5 4 3 2 1 TB-1

F1

Line

Filte

EW-1000-AOUT

TB 20

1 2

- +

- +

0 – 10 Vdc or 4 – 20 ma

Position J1 & J2 for V/I

0.25A

SB

J2

V

I

13

Page 15

Menu Navigation

Configuration Blocks: 50, 60, 70 and 80 may be accessed form the front panel of the

scale by pressing and holding the PRINT button for 2 seconds. The scale will then

display CFG 60. At this point, you can press ENT to select this category or key in the

number of any of the other accessible categories.

Configuration/Calibration Main Blocks: 10, 20, 30, etc can be stepped to directly

by incrementing “CAL 10” to “20” and “enter” (Options are CAL 1). The sub

parameters need to step through to the next “main” before a direct change.

From any “main” point, exit by changing to “CAL 0” and “enter”. A “store” “no”

will need to be changed to “yes” to save any changes. Changing to “CAL 0” from

within “CAL 40” allows exit prior to adjusting span.

NOTE: During the setup procedure each step will be printed to any device interfaced to

the RS-232 port. If options are not present, steps will not appear.

7600 Menu entry point:

Step Parameter Definition

bAS ? 1, 2

CAL 10

CAP 11

Full Capacity Key in the capacity of the base.

ACL 12 Yes, No

A-0 13 Yes, No

Cnt 14 Yes, No

EnH 15 Yes, No

Str 16 OFF, A

Select 1(main) or 2(remote base) and ENT.

Only when dual channel installed.

Capacity, auto-config, Initial zero, count

(Press ENT or inc/ENT to step).

Auto configuration. Use the UNITS button to

select YES or NO. If YES the scale will jump

to Cnt 14, EnH, Prt 25 and CAL 40 storing

defaults "*". If NO is selected the scale will

proceed to the next step.

Select if scale is to auto zero when first

turned on. Use the UNITS button to select

YES or NO*.

Turn count mode on or off. Use the UNITS

button to select YES* or NO.

Turn on for count “enhance” mode. (skipped

if count is off)

Enables average piece weight storage.

14

Page 16

Step Parameter Definition

CAL 20

CAP 21 Full capacity

rES 22 1, 2, 5

-0- 23 1.9, 10, 30

UnS 24 1, 2, 3, 4, …..14

Prt 25 Stable, First, Unstbl, ntEP

Cnd 26 Yes, No

0-t 27 0.00

Capacity, resolution, zero, units, print, zero

track .

By-passed when entered in CAL 10.

Resolution - Input Scale Resolution. Default

(*) entry is the capacity of the scale divided

by 5000 and rounded to the nearest 1, 2, 5.

Zero Range - Input the Zero Range in % of

full scale. The amount of weight the scale is

allowed to Zero.

Select the primary weighing unit by keying in

a number :1 = lb*, 2 = kg, 3 = g, 4 = oz t, 5 =

lb t, 6 = g, 7 = dwt, 8 = oz, 9 = c, 10 = oz f,

12 = l, 11 = ml, 13 = tons, 14 = lb - oz

Print: Select whether the scale will respond

to a print request when stable, first (positive)

stable, any time (unstable), or NTEP.

Overrange: Select YES (9d) or NO (105%)*.

Zero tracking value entered as a percent of

display resolution. Entering a 0.25* equals

25% of one display graduation. “0” disables

the zero tracking feature.

SbL 28 OFF, 1, 3, 5, 10

CAL 30

2Un 31 1, 2, 3, 4, …..14..15(user)

2rE 32 1, 2, 5, (plus user)

CnU 33 0.000001 to 999999

EPn 34 n = -4 to 4, (10^n)

PUd 39

PrI, SEC, SEC On, COUnt,

SELECt

Select motion in grads/sec.

Secondary units, resolution.

Select secondary weighing unit by keying in a

number: 1 = lb*, 2 = kg, 3 = g, 4 = oz t, 5 = lbt,

6 = g, 7 = dwt, 8 = oz, 9 = c, 10 = oz f, 12 = l,

11 = ml, 13 = tons, 14 = lb – oz, 15 = user

Secondary weighing resolution. Key in the

resolution for the secondary weighing unit.

Conversion Factor ( 31 must be set on 15)

Multiplier exponent (0.0001 to 10000)

Power up: Primary units, Secondary units,

Secondary units and Count, Count, With RTC

Gross/Net restored.

15

Page 17

Step Parameter Definition

CAL 40

FIL 41 0, 1, 2, 3, ….9, 11…15

nol 42 0.00

HLF43 XXX.XX

FUL44 XXX.XX

nol 45

Filter, zero/span calibration.

Response time: 0-9 selects conversions to

average directly. 11-15 correspond to 25,

30, 35, 40, & 50 conversions for extended

filtering.

No Load - With the platform in place but no

weight on the scale, press ENT. Display will

indicate “------“ and step if reading is

acceptable.

Entering a “0” during this sub-menu will

jump to the beginning “CAL 40” to allow

bypassing span changes. A second “0”

will exit setup and question “SAVE” to

effect changes or abort.

Half Capacity - Apply a half capacity weight

to the platform and press ENT.1/2-capacity

weight is unavailable, place a substitute

weight on the platform and key in the amount

of weight being used and press ENT. Display

will indicate “------“ and step if reading is

acceptable.

Full Capacity - Apply a full capacity weight to

the platform and press ENT. If a full-capacity

weight is unavailable, place a substitute

weight on the platform, key in the amount of

weight being used and press ENT.

No Load - Remove all weight from the

platform and enter.

16

Page 18

Step Parameter Definition

CFG 50 (7500, 7600 only) Counting functions. (Cnt 14-yes)

SS1 51 10

SS2 52 20

SS3 53 50

SS4 54 100

PCt 55 Yes, No (7600 only)

Enh 55 Yes, No (7500 only)

2S 56 Yes, No (7600 only)

Pr 57

ASb 58 Yes, No (7600 only)

nEG 59 Yes, No

CFG 60

bAU 61

P Err, P Acc, disable

(7600 only)

300,600,1200,2400,

4800, 9600*, 19200, 38400

Key in first sample size. (Normal entry is 10).

Set to “0” to turn off count mode.

Key in sample size two. (normal entry is 20)

Key in sample size three (normal entry is 50)

Key in sample size four (normal entry is 100)

Select if piece weight is to be displayed as

weight per 1000.

Turn on for count “enhance” mode. (skipped

if count is off)

Enable Two Switch counting method.

Percent of error, percent accuracy, disable

the percent error feature.

Select automatic sample-to-bulk. (dual

channel required)

Select if negative sampling will be allowed

during two switch, top end counting.

RS-232 Configuration (This step can also be

reached from the front panel by pressing and

holding the PRINT button for 2 sec.)

BAUD RATE: Select a baud rate using the

UNITS button.

LEn 62 7, 8

SPb 63 1, 2

PAr 64 None, Odd, Even

Ech 65 No Ech, Ech

Cdr 66 0…255

WORD LENGTH: Select: 7 bits*, 8 bits.

STOP BITS: Select: 1 stop bit*, 2 stop bits.

PARITY: Select: None, Even, Odd*.

Select: No Echo*, Echo.

ADDRESS: Key in a number from 0* to 255,

0 disables this feature.

17

Page 19

Step Parameter Definition

CAL 70 7600 std, 7500 option

StF 71 0, 1, 2, 3

td1 72 HH MM SS

td2 73 MM DD YY

SLP 74 0…12

Setting of time and date.

Select type of clock: 0 = Time and date OK,

skip to SLP 74, 1 = 24 hour clock, 2 = 12

hour clock, currently AM, 3 = 12 hour clock,

currently PM.

Enter the current time as HHMMSS. Based

on the type of clock selected in step 71.

Clock will begin with the pressing of the ENT

button.

Enter the current date as MMDDYY.

For AC/DC versions of the scale, enter the

amount of time the display is to remain on

before going into the battery saver sleep

mode. The time is entered in number of

minutes, from .5 to 12. Entering a zero will

disable the sleep mode for AC only scales.

CAL 80 Formatted print slot programing

BUILDING A FORMATTED PRINT

The user defined formatted print is the string of information sent from the RS-232 port

when the PRINT button is pressed, or the scale receives an SRP command from a

computer or terminal. The user selects the format of this string by entering two digit print

codes into the 20 available print slots, PSL 81 through PSL 101. When you are finished

entering data to construct the formatted print, "99" is entered to mark the end of print

formatting.

EXAMPLE OF BUILDING A FORMATTED PRINT

To build a simple formatted print that could be sent to a ticket printer the following print

codes could be entered:

PSL 81 - 30 (gross w/ prefix & suffix.) The result:

PSL 82 - 65 (CR/LF)

PSL 83 - 32 (net w/ prefix & suffix.)

PSL 84 - 65 (CR/LF)

PSL 85 - 31 (tare w/ prefix & suffix.)

PSL 86 - 65 (CR/LF)

PSL 87 - 99 (End)

GROSS 1.205 lb

NET 0.205 lb

TARE 1.000 lb

18

Page 20

FORMATTED PRINT CODES

02 Time 12 "Base" prefix 22

03 Date 13 "ID" prefix 23 Count 33 Count pre.data & suffix

net weight

(or Peak)

Net weight prefix, data,

32

suffix, (or Peak)

04 unit suffix label 14 FR”F1” 24 Piece Weight 34

"GROSS"

05

prefix

06 "TARE" prefix 16 P1 26

07 "NET" prefix 17 27 Base in use 37

"COUNT"

08

prefix

"PIECE

09

WEIGHT"

prefix

"SAMPLE

10

SIZE" prefix

"err" or "acc"

11

prefix (%=error

/ accuracy)

Note: In lb-oz mode, 20-22 will print oz only, 30-32 will print lb-oz.

15 25 Sample Size 35

% Error or

Accuracy

18 28 ID Number 38 ID Number prefix, data

19 "Pcs" suffix 29 39 UPS format

Gross weight

20 gross weight 30

21 tare weight 31

prefix, data

and suffix

Tare pre.data

& suffix

Continuous Output Print Codes

Continuous output (Formatted print will be sent continuously as long as scale is

50

turned on.)

Toggled continuous output (The formatted print will be sent continuously after the

51

PRINT button is pressed or an SRP command is received by the scale. Pressing

the PRINT or sending SRP a second time will turn off the continuous output.)

Status Character (May be used by a computer to determine the condition of the

52

scale at any given moment.

ABO Checksum (May be used in building a continuous output compatible with other

53

Pennsylvania Scales.)

Piece Weight prefix, data,

suffix

Sample Size prefix data &

suffix

Percent Error/Accuracy

36

prefix, data, and suffix

Base in Use prefix & data

40-

Print strings 1 – 9

49

54 Select Leading Zeros

19

Page 21

Print Special ASCII Characters Formatted Print Codes

60 ASCII space (SP)

61 ASCII horizontal tab (HT)

62 ASCII line-feed (LF)

63 ASCII start of header (SOH)

64 ASCII carriage return (CR)

65 ASCII carriage return and line feed (CR LF)

66 ASCII form-feed (FF)

67 Turn on large print (PA Scale printer)(SO, HEX 0EH)

68 Turn off large print (PA Scale printer)(SI, HEX 0FH)

69 ASCII null (NUL)

78 Invert print (PA Scale printer)(DC3, HEX 13H)

79 End inverted print (PA Scale printer)(DC4, HEX 14H)

80 Print accumulator name, value and units

81 Print “Accum. Total”

82 Print accumulator value

83 Print Force a clear accumulator and transaction counter

84 Print Prompt clear accumulator and transaction counter

85 Print transaction name and counter

86 Print “Transaction”

87 Print transaction counter

98 “98” is a second print string triggered by the Accumulator.

99 Marks the end of the formatted print

CAL 0 Press ENT to exit calibration.

20

Page 22

COMMAND FORMATS

The Model 7600 can be controlled from an external device (such as a computer or

terminal) by various commands, each three letters long, which represent related English

phrases or words. For example, to tell the scale to zero, type ZRO followed by a carriage return.

The basic command formats are:

[<add>]<cmd><cr>

<cmd> [<xx.xx>]<cr>

Where <cmd> is a three-letter command, <add> is a scale address number (0-255),

<cr> represents a carriage return, and <xx.xx> is a mixed number, the brackets [ ] are

used to indicate an optional part of the command.

Examples:

SRP<cr> Send a formatted print

ITW 13.43<cr> Instructs scale to set tare weight

to 13.43 in the current unit

5 SGW<cr> Instructs the scale with address #5 to

send the Gross weight.

General Commands

ATW Acquire Tare Weight

CHK Initiate self-diagnostics CHecK

LCK LoCK out keypad

RES RESet, clears tare weight and count information

SCM Select Count Mode

SSS Select Sample Size

SWM Select Weight Mode

UCK UnloCK keypad

UNP UNit Primary

UNS UNit Secondary

ZRO ZeRO scale

21

Page 23

Commands Which Enter Information into the Unit

IBA [ FLOATING POINT NUMBER ] Input BAse number (with option)

IPW [ FLOATING POINT NUMBER ] Input Piece Weight

ITW [ FLOATING POINT NUMBER ] Input Tare Weight

IID [Up to 15 characters, 0 - 9 & hyphen] Input ID

IUS [Print string, 40 – 49] Input Print string

Commands Which Request Information

SBA Send BAse in use (with second base option)

SCO Send COunt

SDT Send DaTe

SGW Send Gross Weight

SID Send Part ID

SMI Send Metrological Information

SNW Send Net Weight

SPC Send Print Codes

SPR Send PeRcent error or accuracy

SPW Send Piece Weight

SRP Send Requested Print

SSZ Send Sample siZe

STM Send TiMe

STW Send Tare Weight

SVN Send Software Version Number

NOTES: All commands and parameters must be separated by spaces. The entire

command string must be terminated with a carriage return.

22

Page 24

Custom serial string command: IUS

IUS x y, where x selects the string 1 – 10 and y is the string comprised of up to 22

characters. The strings are printed with using the format codes 40 – 49

where string 1 is 40, 2 is 41, etc.

IUS <enter>: List all strings

IUS 1<enter>: Clears string one

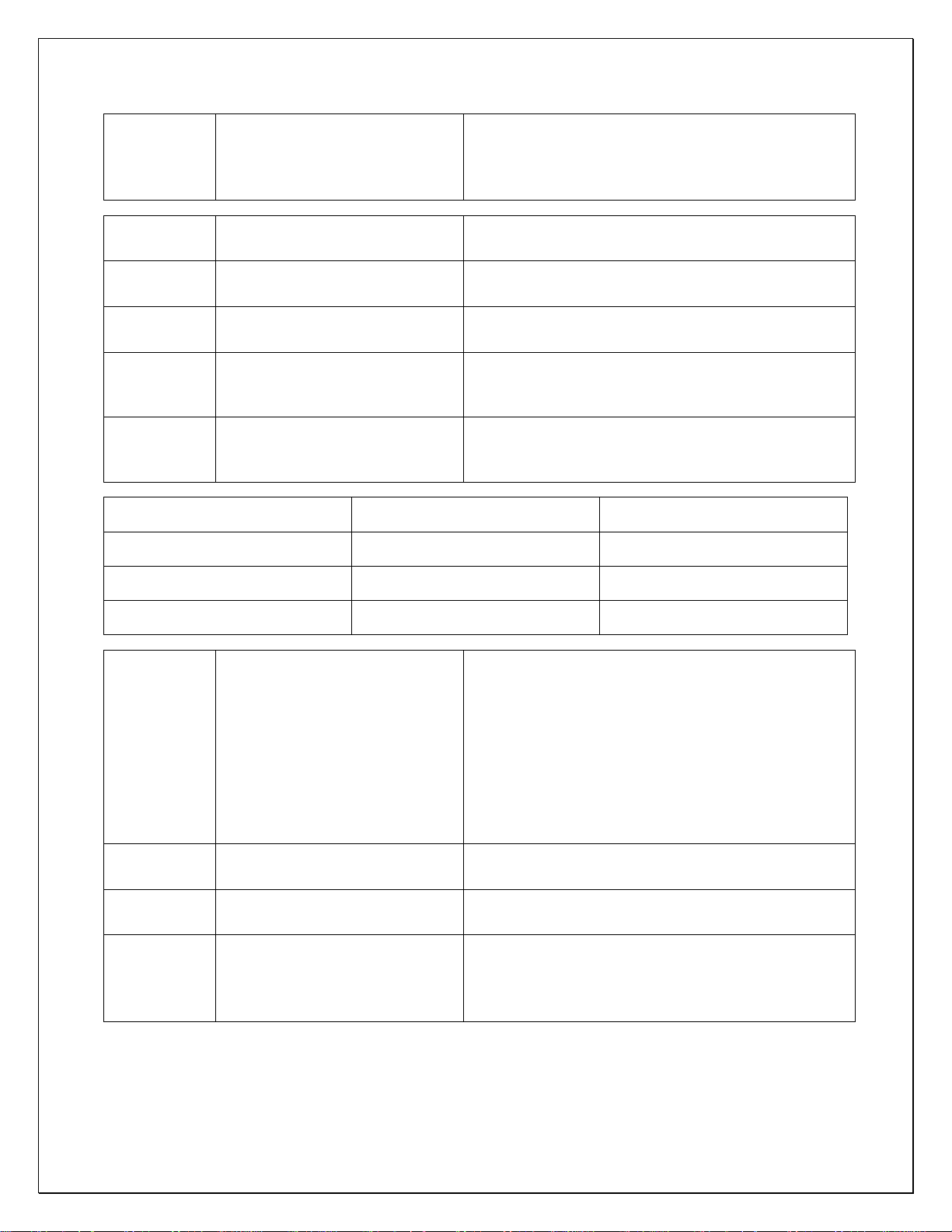

RS-232 PIN ASSIGNMENTS AND IMPLEMENTED FUNCTIONS

Connection to the Serial Port is made via a DB-9 female connector found in the access

area on the bottom of the scale. Instrument connection is on TB-2.

PIN EIA CODE FUNCTION DIRECTION

2 BB Transmit Data Output

3 BA Receive Data Input

5 AB Signal Ground -

GND

Tx1, RS232

Rx1, RS232

TB-2

1

2

3

DB-9

EW-1000 Rev…

23

Page 25

Average Piece Weight Storage

APW ID memory in 7600 counting scale mode (This function is not available for

other instrument selections).

Parameter 16, “STr 16” selects OFF or A.

The “A” selection is expanded storage of APW’s. Key in an ID or, using the TARE

(NEXT) or KEYPAD TARE (LAST) keys, selects a currently stored ID. If the ID exists

and has APW>0, the stored APW is loaded into the PIECE WEIGHT memory and

the count display is selected. If the ID is new or has an APW= 0 (initial value when

the ID is first entered), the “Add xx” prompt is displayed so an APW can be

established and stored to ID memory.

Key functions during ID selection/entry:

KEY FUNCTION

ZERO Clear ID

Print all IDs w/ their stored APWs and

GROSS/NET

integrity status (OK or ERR). See the text

box to the right.

TARE Select next ID

TARE

Select last ID

RECALL

Press and release to clear the currently

CLEAR

selected ID, or press and hold to access

the “clear all” prompt.

ENTER

Enter if keyed in or select the displayed

ID.

COUNTING SCALE ID MEMORY

0 1200 0.00500 OK

1 2000 0.00338 OK

2 8080 0.00484 OK

3 6800 0.00415 OK

4 6811 0.00472 OK

5 8085 0.00326 OK

6 6812 0.00470 OK

7 100000 0.00163 OK

8 80188 0.02129 OK

9 6808 0.0003 OK

10 1000 0.00334 OK

11 8051 0.00831 OK

12 80186 0.00166 OK

13 6502 0.00117 OK

14 74244 0.00014 OK

15 74573 0.00799 OK

16 100 0.00824 OK

Key in a new or existing ID and then

press the enter key to accept.

0-9

Note: While one is keying in an ID, one can press the blue zero key to abort the

entry and view the last keyed or selected ID.

Specifications:

Storage locations: 250

ID size: six-digit (0-9)

Data stored: ID, APW, and CRC verification number.

24

Page 26

WEIGHING WITHOUT TARE

1. If the second base option has been installed, press the BASE button to select

base 1 or base 2. When base 2 is selected the base 2 LED will be lit. When base

one is selected the base 2 LED will be out. If base 2 has been locked out during

calibration, the word "Error" will momentarily show on the display.

2. Press the UNITS button to select either the Primary weighing unit or the

secondary weighing unit. (Associated indicator will be lit.)

3. Verify that the "GROSS" indicator is lit. If not, press the GROSS/NET button to

light this indicator and put the scale into the gross weight mode.

4. Establish a base zero by pressing ZERO with nothing on the scale platform to

clear any existing weight readings.

5. Place the item(s) to be weighed on the platform and read the weight on the

display.

NOTE: If very light items (less then 1/4 of the display resolution) are placed

on the platform individually, the weight may be zeroed off by the AZT

feature. Add light items to the platform simultaneously.

WEIGHING WITH TARE

1. If the second base option has been installed, press the BASE button to select

base 1 or base 2. When base 2 is selected the "base 2" LED will be lit. When

base one is selected the base 2 LED will be out. If base two has been locked out

during calibration, the word "Error" will momentarily show on the display.

2. Press the UNITS button to select either the Primary or the Secondary weighing

unit. (Associated indicator will be lit.)

3. Press the ZERO button with nothing on the platform to establish a base zero.

4. A tare weight may be acquired using one of the following methods:

a. Place the container or object to be tared off on the platform and press

TARE; or

b. Press the KEYPAD TARE button and then key in the weight of the

container or object, and press ENT.

5. The net weight value will be displayed on the weight display and the NET

indicator will be lit.

6. Pressing the GROSS/NET button will toggle between gross weight and net

weight.

7. When a tare value is stored in the system, the TARE indicator will be illuminated.

8. Place the objects to be weighed in the container and read the net weight on the

display. To clear a tare value, remove all weight from the scale and press TARE,

or press KEYPAD TARE, key in 0 and press ENT.

NOTE: IF the tare has been acquired using the TARE button, the tare value may

be viewed by pressing KEYPAD TARE. Pres ENT to return to the weight display

without altering the tare weight.

25

Page 27

COUNTING

An electronic counting scale counts parts by knowing the weight of a single piece,

dividing that into the total weight on the scale and displaying the result. With the 7600,

this piece weight may

be entered into the scale by one of two methods:

FIRST: Counting out a "sample" quantity of the parts and placing them onto the

scale. The scale will take the weight of the sample, divide it by the known

quantity and derive a piece weight used to count the rest (or "bulk") of the

parts.

SECOND: If the individual piece weight of the parts is already known, this weight

value may be entered into the scale via the keypad.

SAMPLE SIZE:

If the "sample" method of piece weight entry is used, the total weight of the sample must

be at least 0.04% of platform capacity or the scale will not recognize the sample. When

sampling, it is always advantageous to use the largest sample possible. Not only does

the larger quantity tend to average variations in the weight of individual pieces, but the

heavier sample weight improves the counting accuracy of the scale itself.

NORMAL COUNTING PROCEDURE

ONE SWITCH COUNTING - The 7600 is normally shipped from the factory set

up to follow this counting procedure. Unless your 7600 has been programmed for one of

the

alternate counting choices, this procedure is the only one necessary to learn.

NORMAL COUNTING - Using Sample

1. If a container will be used to hold items being counted, place it on the platform.

2. Press the SAMPLE SET button. The scale zeroes. "AddXXX" appears on the display

(where "XXX" is one of the four pre-programmed sample sizes.). Repeated pressing

of the switch successively displays the four sample sizes entered during calibration.

3. If a different sample size is required, key in the desired sample size (do not press

ENT).

4. Place the entire sample on the platform at one time. (If the scale has been

programmed to show the percent of error; this value will be displayed momentarily at

this time.) The scale will now automatically switch to the count mode, displaying the

number of parts in the sample.

5. All of the remaining parts may now be added to the scale and counted. ZERO,

TARE and KEYPAD TARE buttons may now be used without affecting the piece

weight.

6. To count a different part, return to step one.

26

Page 28

NORMAL COUNTING - Keypad Piece Weight Entry

If the individual weight of the parts being counted is known in advance the piece weight

may be entered through the keypad. This eliminates the need for the sample set

operation. (If the percent of error feature has been selected in programming, the scale

will not calculate the percent of error when keypad entry of piece weight is used.)

1. Select the appropriate weighing unit (primary or secondary) for the piece weight

being entered by pressing the UNITS/4 switch.

2. Press the PIECE WEIGHT switch. The display will alternately show "PC" and any

previously stored piece weight.

3. Key in the weight of one piece and press ENT.

4. The scale will go into the count mode.

5. If a container will be used to hold the parts, place it onto the scale and use the

ZERO and/or TARE buttons to zero the scale. Add the parts to the scale at this time.

NOTE: The parts in a full container may also be counted by placing the full container

onto the scale and using KEYPAD TARE to key in the tare weight of the container.

ALTERNATE COUNTING METHODS

The 7600 may be programmed to perform a wide variety of different counting methods.

the following section describes these counting methods, refer to the "Calibration and

Programming Manual" for information on setting your scale to perform one of these.

Two Switch Counting

The 7600 can be programmed so that when the scale is in the sample set mode, the

sample will not be accepted until the ENT button is pressed. This allows parts to be

added to the platform one at a time, where as with the one switch method all of the

sample must be added at once.

Top-End Counting

The total number of items in an unsealed container can be determined without removing

the items from the container (except a sample). The container with parts is placed on

the platform and the piece weight is calculated when a sample quantity is either added

to (one switch) or removed from (two-switch operation) the container. Based on the

piece weight, the total number of items in the container is displayed.

Automatic Sample-to-Bulk Counting

This method requires that the scale be configured with two bases, a "sample" and a

"bulk" base. The lighter capacity "sample" base is used to calculate the piece weight,

and the parts are counted on a heavier capacity "bulk" base. In most cases, higher

counting accuracy is achieved with this method because the calculated piece is more

precise when the sample is weighed on the light-capacity sample base. In normal

operation, when the sample is placed on the sample base, the scale automatically

switches to the bulk base and items to be counted are placed on the bulk base.

27

Page 29

Counting by First Determining Error of Count (One-Switch Method using

Automatic Sample Update)

The percent error/accuracy of count can be updated by adding more items to the

sample after the initial sample size is placed on the platform and the percent

error/accuracy has been displayed. In normal operation , the sample is placed on the

platform and a percent error/accuracy is momentarily displayed, followed by the count.

More pieces are then placed on the platform in the range of 10% to 100% of the original

sample. A new piece weight is calculated based on the larger sample size, and the new

percent of error/accuracy will be momentarily displayed. This may continue until a

satisfactory percent of error/accuracy is achieved.

Counting by First Determining Error of Count (Two-Switch Method)

The percent error of count can be determined before the piece weight is established.

Sample pieces are added to the platform until the percent of error/accuracy is

acceptable. The sample size (number of pieces) is then keyed-in and entered, and the

scale is ready to be used for counting.

Piece Weight Displayed as Weight Per 1000 Pieces

If selected in calibration, the piece weight can be displayed as weight per 1000 pieces.

This option is useful when the items being counted are very light and the piece weight

for one item would be an extremely small number. When entering the piece weight

through the keypad (for normal counting), enter the weight for 1000 items if the piece

weight is to be displayed as weight per 1000 pieces.

Negative Counting

This method is used to count the number of items removed from a container without first

knowing the piece weight. The number of items removed from the container is shown on

the display as a negative number.

Normal Operation with Two Switch Counting

1. If a container will be used to hold items being counted, place it on the platform.

2. Press the SAMPLE SET button. The scale zeroes. "AddXXX" appears on the display

(Where "XXX" is one of the four pre-programmed sample sizes.). Repeated pressing

of the switch successively displays the four sample sizes entered during calibration.

3. If desired, a different sample size may be keyed into the scale. As this number is

entered, the word "Add" will disappear and only the count indicator will be lit to

indicate that the scale is in the sample entry mode.

4. The sample may now be placed onto the scale, all at once or one at a time. (If the

percent of error feature has been selected in programming, the percent of error will

be displayed as the parts are placed onto the platform. The more parts that are

added, the lower the percent of error will be.)

5. Press the ENT button. The scale will switch to the count mode and display the

sample count.

6. The remaining parts to be counted may now be placed onto the scale.

28

Page 30

Normal Operation with Automatic Sample to Bulk Feature

The second base option needs to be installed and calibrated for automatic

sample to bulk to operate. Base one is always the sample base and base two is

always the bulk base.

1. Press the BASE/1 switch to select the bulk base. (Base two indicator should

be lit)

2. Press the ZERO switch to zero the bulk base.

3. If an empty container will be used to hold items on the bulk base place it on

the platform and press either the ZERO or TARE switch.

4. If a full container will be counted on the bulk base. Place the container on the

platform, press the KEYPAD TARE switch and key in the weight of the

container, press ENT.

5. If a container will be used to hold the sample on base 1, place the container

on the scale at this time.

6. Press the SAMPLE SET button. The scale will switch to the sample base

(base 1). "AddXXX" will appear on the display (where "XXX" is one of the four

pre-programmed sample sizes). Select the desired sample size by repeatedly

pressing the SAMPLE SET switch, or key in an alternative sample size.

7. If the scale is programmed for a one-switch operation place the entire sample

on the sample base all at one time. The scale will momentarily display the

percent error/accuracy (If selected in calibration.), switch to the bulk base and

enter the counting mode. The bulk base is now ready to count the parts.

8. If the scale is programmed for a two switch operation, place the sample parts

onto the platform all at once or one at a time. The display will show the

percent of error/accuracy (If selected in calibration.). When all of the sample

parts are on the scale press ENT. The scale will switch to the bulk base and

enter the count mode. The bulk base is now ready to count the parts.

9. At this point ZERO and TARE switches may be used without affecting the

piece weight.

Top-End Counting (One-Switch Method; Sample Added)

1. Press ZERO to zero the scale.

2. Place container with parts on the platform.

3. Press KEYPAD TARE, key in the tare weight of the container, then press

ENT.

4. Remove the sample from the container.

5. Press the SAMPLE SET switch. "AddXXX" will appear on the display (where

"XXX" is one of the four pre-programmed sample sizes). Select the desired

sample size by repeatedly pressing the SAMPLE SET switch, or key in an

alternative sample size. IMPORTANT:The displayed sample size must

equal the number of sample items removed.

6. Place the sample pieces that were removed back into the container. The

scale will momentarily display the percent error/accuracy (If selected in

calibration.) and enter the count mode.

7. The display will show the total count for the items in the container.

29

Page 31

Top-End Counting (Two-Switch method; Sample Removed)

1. Press ZERO to zero the scale.

2. Press KEYPAD TARE, key in the tare weight of the container, then press

ENT.

3. Place the container with contents on the platform and press the SAMPLE

SET switch. "AddXXX" will appear on the display (where "XXX" is one of the

four pre-programmed sample sizes). Select the desired sample size by

repeatedly pressing the SAMPLE SET switch, or key in an alternative sample

size.

4. Remove the displayed sample quantity from the container. The display will show the

percent error/accuracy (If selected in calibration.). Press ENT.

5. The scale will enter the count mode and display the number of parts in the container.

6. Return the sample pieces to the container.

Counting by First Determining Error of Count using Automatic Sample

Update (Normal Operation; One-Switch Method)

1. If a container will be used to hold items being counted, place it on the

platform.

2. Press the SAMPLE SET switch. "AddXXX" appears on the display (where

"XXX" is one of the pre-programmed sample sizes). Select the desired

sample size by repeatedly pressing the SAMPLE SET switch, or key in an

alternative sample size.

3. Place the sample pieces on the platform simultaneously. The Percent

error/accuracy will be momentarily displayed and the scale will enter the

counting mode.

4. To either decrease the percent of error or increase the percent of accuracy,

place more items on the platform in the range of 10% to 100% of the original

sample quantity. A new piece weight is calculated based on the larger sample

size, the new percent of error/accuracy is momentarily displayed and the

scale returns to the count mode. This may continue until the desire percent

error/accuracy is achieved.

5. Removing the original sample or adding a quantity of parts greater than the

original sample will disable the automatic update feature.

30

Page 32

Counting by First Determining Error of Count (Two-Switch Method)

1. If a container will be used to hold the items being counted, place it on the

platform.

2. Press the SAMPLE SET switch for two seconds. "AddXXX" will appear on the

display (where "XXX" is one of the pre-programmed sample sizes). Select the

desired sample size by repeatedly pressing the SAMPLE SET button or key

in a new sample size.

3. Place the sample onto the platform all at one time (this should be done if the

parts are extremely small) or count them onto the platform one at a time.

4. The display will show the percent error/accuracy. Continue to count parts onto

the platform, as the sample increases the percent error will decrease and

accuracy will increase. When the percent error/accuracy is acceptable key in

the quantity of parts on the platform and press ENT.

Counting by First Determining Error of Count with Automatic Sample-ToBulk Feature (Two-Switch-Method)

1. Press the BASE/1 switch to select the bulk base. (BASE 2 light should be lit)

2. Press the ZERO to zero the bulk base.

3. If a container will be used to hold items on the bulk base, place the container

on the platform and press ZERO or TARE.

4. If a container will be used to hold the sample parts, place it onto the sample

base at this time.

5. Press the SAMPLE SET switch for two seconds. "AddXXX" will appear on the

display (where "XXX" is one of the pre-programmed sample sizes). Select the

desired sample size by repeatedly pressing the SAMPLE SET switch or key

in a new sample size.

6. Place the sample onto the platform all at once (this should be done if the

parts are extremely small) or count them onto the platform one at a time.

7. The display will show the percent error/accuracy. If the percent error/accuracy

is not acceptable, continue to count parts onto the platform, as the sample

increases the percent error will decrease and the percent accuracy will

increase. When the percent error/accuracy is acceptable, key in the quantity

of parts on the platform and press ENT.

8. The scale will switch to the bulk base. Items may now be counted on the bulk

base.

Negative Counting, Sample Removed (Two Switch Method)

1. With nothing on the scale platform, press the TARE to set tare to zero.

2. Place the container with contents on the platform.

3. Press the SAMPLE SET switch. “AddXXX” will appear on the display (where

“XXX” is one of the four pre-programmed sample sizes). Select the desired

sample size by repeatedly pressing the SAMPLE SET switch, or key in an

alternative sample size.

4. Remove the displayed sample quantity from the container. The display will

show the percent error/accuracy (If selected in calibration). Press ENT.

5. The scale will enter the count mode and display the number of parts removed

from the container as a negative number. Removing pieces increases the

negative count.

31

Page 33

MESSAGE DESCRIPTION

DAC D/A card detected - Displayed under the check function.

IIC.ERR IIC short - Power-up hardware failure indication.

RST EEPROM is reset by EER command - Power-up message

ON

AUTO EEPROM is reset - Power-up message

ERR6.x Key-pad key is stuck.

-232- Serial calibration/setup is active.

UPDATE Enhancement calculation in progress.

LO.BATT Low battery

D BATT Dead battery

ULULUL Under-load (-400 graduations under dead-zero)

OLOLOL

------ A/D acquisition is in progress.

7x00 Instrument mode selection.

Err 10 Number > 999999

Err 13 Number < -99999

ADC.Err A/D hardware failure (channel one only).

CHECK Check mode accessed.

rC.xxxx Lower four-digits of the ROM check-sum.

Err.80 Serial command data error.

Err.81 Unknown serial command.

-CAL- Remote calibration

Err.OFF Hardware failure of the D.C. power on/off circuitry.

RTC.RST The clock is reset to 01:01:04 12:00:00am.

RST ID

AC OK Access code entered has been accepted.

E-1234 EEPROM set 1,2,3, and/or 4 have been fixed.

Err 40

Err 31 Bad tare entry

Err 30 Push to Zero out of range

PC Err Piece Weight Entry is out of range

Displayed on power-up when the DC power push-button is

pressed.

Over-load (+9 graduations or 105% from dead-zero

reference)

The ID EEPROM has been reset since it was detected as

corrupt.

Positive or negative signal overload (check sense

connections).

32

Page 34

STATUS CHARACTERS:

@ Gr, pri, sta, non-zero U Net, sec, sta, zero

A Gr, pri, sta, zero V

B Gr, pri, unsta, non-zero W Net, sec, unsta, zero

C Gr, pri, unsta, zero X OL/UL, Net, pri, sta

D Gr, sec, sta, non-zero Z OL/UL, Net, pri, unsta

E Gr, sec, sta, zero \ OL/UL, Net, sec, sta

F Gr, sec, unsta, non-zero ^ OL/UL, Net, sec, unsta

G Gr, sec, unsta, zero ‘ Cnt, pri, sta, non-zero

H OL/UL, Gr, pri, sta a Cnt, pri, sta, zero

J OL/UL, Gr, pri, unsta b Cnt, pri, unsta, non-zero

L OL/UL, Gr, sec, sta c Cnt, pri, unsta, zero

N OL/UL, Gr, sec, unsta d Cnt, sec, sta, non-zero

Net, sec, unsta, nonzero

P Net, pri, sta, non-zero e Cnt, sec, sta, zero

Q Net, pri, sta, zero f

R Net, pri, unsta, non-zero g

S Net, pri, unsta, zero h OL/UL, Cnt, pri, sta

T Net, sec, sta, non-zero j

l OL/UL, Cnt, sec, sta n OL/UL, Cnt, sec, unsta

p

r

t

v

x OL/UL, Net, Cnt, pri, sta z

Net, Cnt, pri, sta, nonzero

Net, Cnt, pri, unsta, nonzero

Net, Cnt, sec, sta, nonzero

Net, Cnt, sec, unsta,

non-zero

Cnt, sec, unsta, nonzero

Cnt, sec, unsta, zero

OL/UL, Cnt, pri, unsta

q Net, Cnt, pri, sta, zero

s Net, Cnt, pri, unsta, zero

u Net, Cnt, sec, sta, zero

Net, Cnt, sec, unsta,

w

zero

OL/UL, Net, Cnt, pri,

unsta

33

Page 35

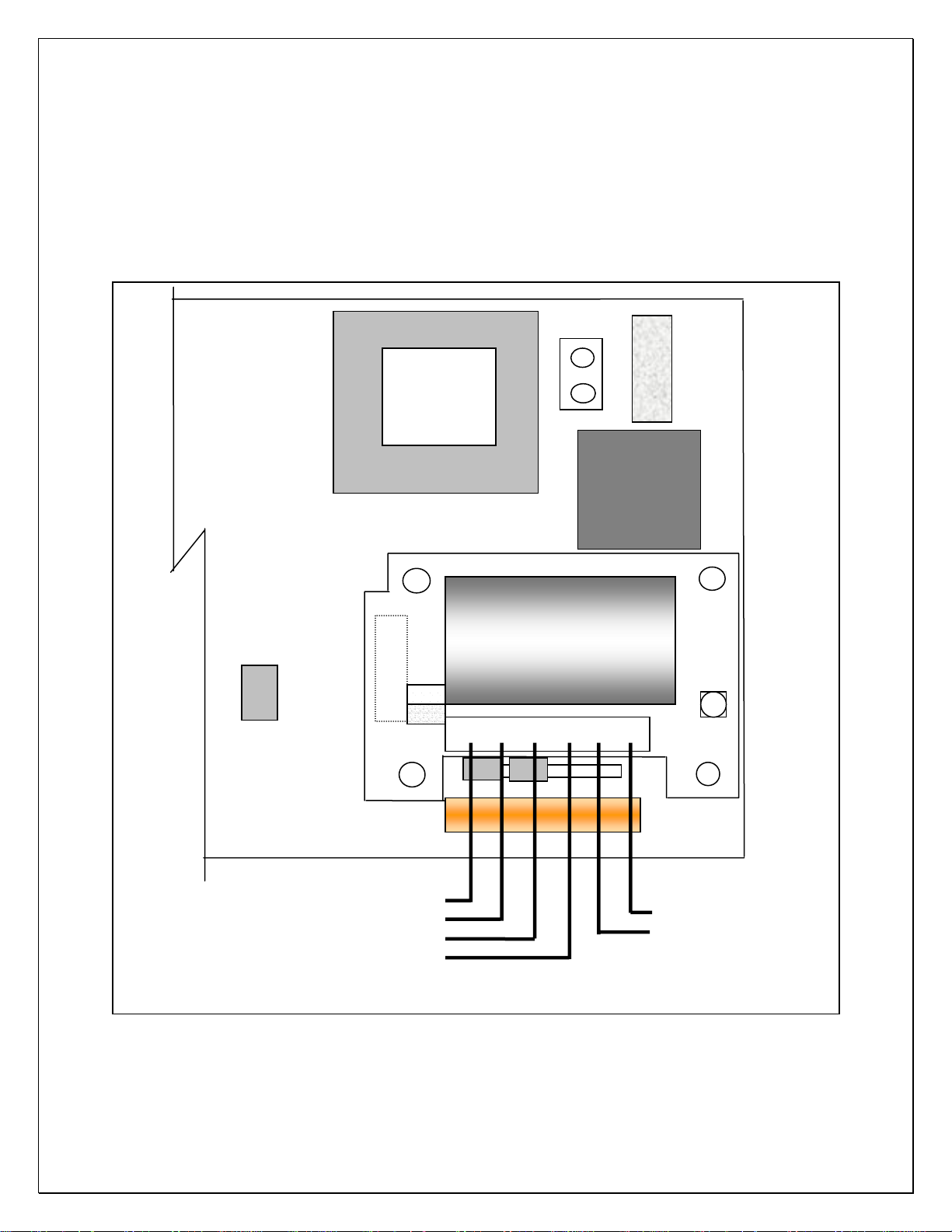

115 to 220 VAC Conversion : EW1000 Bottom Side

CUT CLAD

2-Places

ADD Jumper

34

Page 36

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

ARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

Page 37

M-4382/1006

Where Do I Find Everything I Need for

Process Measurement and Contr ol?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERA TURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DA TA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEA TERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENT AL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...