Omega Products CN1501 Installation Manual

http://www.omega.com

e-mail: info@omega.com

CN1501

Series

Panel-Mount PID & ON/OFF

CONTROLLER

SPECIFICATIONS.......................................................................................................................................................... 4

DESCRIPTION................................................................................................................................................................ 5

THERMOCOUPLE OR RTD SELECTION................................................................................................................. 5

HOW TO RESET AND PROGRAM THERMOCOUPLE TYPE (OR RTD).................................................................................. 5

FIGURE 1. THERMOCOUPLE/RTD SELECTION KEYS ..................................................................................................... 6

DISPLAY MODES........................................................................................................................................................... 6

RETAINING USER SETTINGS ON POWER DOWN................................................................................................ 6

FLOW CHART ................................................................................................................................................................ 7

'RAMP & SOAK PROFILE' SELECTION .................................................................................................................. 8

SETUP MODE................................................................................................................................................................. 8

ENTERING AND EXITING SETUP MODE:.......................................................................................................................... 8

HOW TO INCREASE/DECREASE PROGRAMMABLE VALUES IN SETUP .............................................................................. 8

PASSCODE ENTRY:..........................................................................................................................................................8

'PROGRAM CONTROLLER' MODE.......................................................................................................................... 9

SELECTING ON/OFF OR PID CONTROL .......................................................................................................................... 9

ENTERING ON/OFF VARIABLE ....................................................................................................................................... 9

On/Off Hysteresis (Dead-Band) ................................................................................................................................. 9

ENTERING PID VARIABLES ............................................................................................................................................. 9

Proportional band...................................................................................................................................................... 9

Reset ......................................................................................................................................................................... 10

Rate........................................................................................................................................................................... 10

ENGINEERING UNITS (C/F)........................................................................................................................................... 10

DISPLAY TIME............................................................................................................................................................... 10

DISPLAY OPTION:.......................................................................................................................................................... 10

HEAT/COOL SETUP: ................................................................................................................................................... 11

RATE TIME-BASE:......................................................................................................................................................... 11

COLD JUNCTION ADJUSTMENT: ..................................................................................................................................... 11

THERMOCOUPLE CALIBRATION:.................................................................................................................................... 11

THERMOCOUPLE TYPE SELECTION: ............................................................................................................................... 12

‘PROGRAM LIMITS’ MODE:.................................................................................................................................... 12

PROCESS LIMITS (1 THRU 4):......................................................................................................................................... 12

SELECTION OF LIMIT 3 AS PROCESS OR RATE LIMIT:..................................................................................................... 13

PROGRAMMING LIMIT 3: ............................................................................................................................................... 13

As Process Limit:...................................................................................................................................................... 13

As Rate Limit:........................................................................................................................................................... 13

SELECTION OF LIMIT 4 AS PROCESS OR DEVIATION LIMIT: ........................................................................................... 13

PROGRAMMING LIMIT 4: ............................................................................................................................................... 13

As Process Limit:...................................................................................................................................................... 13

As Deviation Limit:................................................................................................................................................... 13

CONFIGURE TIMING MODE............................................................................................................................................ 13

TIMERS 1 AND 2: ........................................................................................................................................................... 14

RELAY DEADBAND: ...................................................................................................................................................... 14

CONFIGURING LIMITS NORMALLY OPEN/NORMALLY CLOSED:.................................................................................... 14

RELAY LATCHING/NON LATCHING:............................................................................................................................... 14

AUDIO ALARM ON/OFF:................................................................................................................................................ 15

'VERIFY' MODE:.......................................................................................................................................................... 15

PROFILE MODE (ENTERING RAMP & SOAK):................................................................................................... 15

RAMP/SOAK PROFILE EXAMPLE.......................................................................................................................... 16

2

Page

EXTERNAL CONTROL RELAY INSTALLATION FOR RAMP/SOAK OPERATION..................................... 17

Figure 3. Solid State relay hookup for controller output......................................................................................... 17

VARIOUS CONTROLLER MODES........................................................................................................................... 17

CONTROLLER RUN MODE............................................................................................................................................. 17

CONTROLLER HOLD MODE .......................................................................................................................................... 17

CONTROLLER STOP MODE............................................................................................................................................ 17

CONTROLLER MANUAL MODE .................................................................................................................................... 18

RATE............................................................................................................................................................................... 18

RATE ALARM:............................................................................................................................................................... 18

RESETTING RATE ALARM: ............................................................................................................................................ 18

SETPOINT DEVIATION: ............................................................................................................................................ 18

DEVIATION ALARM:...................................................................................................................................................... 19

RESETTING DEVIATION ALARM:...................................................................................................................................19

PROCESS ALARMS.....................................................................................................................................................19

DISPLAYING:................................................................................................................................................................. 19

RESETTING:................................................................................................................................................................... 19

ELECTRO-MECHANICAL RELAY OPTION ....................................................................................................................... 19

Figure 4. Electro-mechanical Relays Hookup Example........................................................................................... 20

OPEN COLLECTOR OPTION............................................................................................................................................ 20

Figure 5. Open Collector Hookup Example............................................................................................................ 20

TIMERS.......................................................................................................................................................................... 20

RESETTING TIMERS:...................................................................................................................................................... 20

TIMER MODES............................................................................................................................................................. 21

TIMER MODE #0............................................................................................................................................................ 21

TIMER MODE #1............................................................................................................................................................ 21

TIMER MODE #2............................................................................................................................................................ 21

ELAPSED TIME........................................................................................................................................................... 21

HOW TO RESET ELAPSED TIME...................................................................................................................................... 21

HIGH AND LOW PEAKS ............................................................................................................................................ 21

HOW TO RESET HIGH & LOW PEAK READINGS.............................................................................................................. 21

OUTPUT STATUS:........................................................................................................................................................ 22

POWER........................................................................................................................................................................... 22

SIGNAL CONNECTION.............................................................................................................................................. 23

OUTPUT CONNECTOR PIN ASSIGNMENT.......................................................................................................... 23

TABLE 1. OUTPUT CONNECTOR PIN ASSIGNMENT...................................................................................................... 23

MOUNTING................................................................................................................................................................... 24

DIRECT INTERFACE TO UNIVERSAL RELAY MODULE................................................................................. 25

3

Page

SPECIFICATIONS

Typical @ 25 C and rated supply voltage unless otherwise specified.

INPUTS:

• Input types: J,K,T,E,R,S,B t/c, RTD, Voltage, Millivolt, Current & thermistor

• Cold junction compensation error: +/- 0.5C max (10C to 40C)

• Open thermocouple indication: ‘OPEN TC’ displayed

OPTIONS:

• 240Vac @ 50 Hz Power Supply

• 15Vdc @ 1000ma. Power Supply

• Open Collector output: 6 open collector transistors @ 50ma. sink each

• Relay output: 4 SPST 1 Amp. @ 28Vdc, 0.5 Amp. @ 120Vac (resistive load)

(for 220 Vac units only 0.25Amp.@ 240Vac (resistive load))

2 open collector transistors @ 50ma. sink each

ACCURACY:

• Temperature resolution: 1 C/1 F, 0.1C for Thermistor

• 0.1% of Full Scale (Base metal T/C), 0.5% others

ANALOG TO DIGITAL CONVERSION:

• 4 1/2 Digit (20000 count) A/D conversion.

• Dual slope integrating converter.

• Conversion Rate: 7 /sec. typical

POWER REQUIREMENTS:

• 120Vac, 0.2 Amp. @ 60 Hz

DIMENSIONS:

• Case: 7.55"W x 6.29"H x 4.05"D

•

IP65 rated plastic enclosure

• Weight: 2.63 lb. (1.19kg.)

• Enclosure: All Plastic enclosure—IP65 Ingress Protection

DISPLAY:

• Red 7-segment LED display, 0.39 inch (10mm) digit height

• Negative polarity indication

• Out of range indication: HELP

• Display Test: Briefly displays 8.8.8.8.8.8.8. on power up

RELIABILITY:

• Calibration: NIST traceable

• Recalibration: Recommended at 12 months interval

4

Page

DESCRIPTION

The CN1501 series is a highly versatile temperature controller which offers the ease of an ON/OFF

controller combined with the precision of a PID controller. Selectable heat/cool mode allows the unit to be

used for either heating (direct acting) or cooling (reverse acting).

The unit has the capability of accepting five different ramp and soak programs, each one with up to ten

segments. Separate pass-codes are required for selecting or entering a program. This keeps the operators

from making any inadvertent changes. Manual hold feature allows for an indefinite hold any where along the

ramp/soak profile. Also offered is a manual set-point entry mode for a quick 'ramp to set-point' function. This

eliminates entering a complete ramp/soak program.

Maximum and minimum temperature readings are constantly tracked and can be helpful in quality control or

monitoring unattended processes (e.g. overnight).

Various process parameters monitored by the system may be displayed by pushing the appropriate keys on

the front panel, e.g. (Rate, Peak etc.). The respective parameter will be displayed as long as the key is kept

pressed. Alternately, if the key is pressed and then released, the unit will display a particular parameter

briefly and then go back to temperature display mode.

The CN1501 Series supports six outputs: 4 relay outputs for process limits and 2 solid state outputs for

timers. Process limit relays may be operated in two different modes:

1. Non-latching mode, in which the relays reset automatically as soon as the temperature

falls below the limit (minus the relay dead-band).

2. Latching mode, in which the relays stay energized even after the temperature falls below

the programmed limit. In this mode the relays will stay on until manually reset.

THERMOCOUPLE OR RTD SELECTION

CN1501 instruments ordered for Thermocouples or RTD’s can be programmed through the front panel keys

to work with one of these specific inputs (Input type or options depends on Model number ordered).

When CN1501 is first turned on, a ‘display segment test’ is done by briefly displaying 8.8.8.8.8.8.8.,

followed by the software revision number (rEn X.XX) and input signal type.

J (R,S,B, rtd 385, Thermistor, J tC (r, S, B, rtd 385, tHrStor,

Millivolt, Voltage, Current) Lo VoLt, HI VoLt, CurrEnt)

K (rtd 392) Cr.AL tC (rtd 392)

T t tC

E E tC

Factory default thermocouple/RTD selection can be obtained as explained below:

How to Reset and Program Thermocouple Type (or RTD)

A CN1501-TC that is calibrated for a J, K, T, or E type thermocouple or an RTD model may be

programmed for a specific thermocouple, or RTD (385/392) type, by going into SETUP mode (Look under

‘SETUP’). Alternately, a thermocouple/RTD may be selected by turning

in the appropriate key (see Figure 1). This procedure also clears the memory and programs factory default

values for limits, rate time-base etc. Therefore, after performing Power-up reset, various parameters such as

limits, ramp and soak profiles, rate time base etc., must be re-programmed. However, if done in SETUP

Input type Display shows:

On power to the unit while holding

5

Page

mode, no programmed parameters such as limits, ramp & soak profiles etc. are erased from the memory. It is mode, no programmed parameters such as limits, ramp & soak profiles etc. are erased from the memory. It is

recommended that thermocouple (RTD) selection be done in SETUP. Power-up reset should be performed if

it is suspected that program memory may have been corrupted due to power surge, noise on electrical lines

etc.

FIGURE 1. Thermocouple/RTD Selection Keys

Memory Clear only

E t/c

K t/c, RTD392,

T t/c

J (R, S or B) t/c,

RTD385 , Thermistor

KEY Input Type Selected

DATA J (R, S or B , RTD 385)

Thermistor

STOP K (RTD 392)

RUN T

TIMER E

RESET Memory cleared – no

factory default values

. programmed.

NOTE: All keys, except RESET, clear

memory and program necessary factory

default values. RESET key clears memory

only and programs no default values.

However, previous thermocouple type is

retained.

DISPLAY MODES

The CN1501 can be programmed to display in one of the following three modes:

Mode Display Description

PROCESS PrOCESS

SETPOINT SE

PROCESS - SETPOINT P

Setpoint value.

SEE SETUP ON HOW TO SELECT ONE OF THE DISPLAY MODES.

tPt Displays only the setpoint value.

r-StPt Alternately displays Process as well as

Displays only the process value.

RETAINING USER SETTINGS ON POWER DOWN

CN1501 saves all the programmed parameters in an EEPROM (electrically erasable programmable read only

memory). An EEPROM stores the programmed parameters even when the power is removed from the unit.

However, it is important to note that if the parameters are being changed during setup, they must be saved in

the EEPROM by

SETUP. If parameters are

will be lost ( the unit will, however, maintain the old values).

pressing and holding the ‘RESET’ key (till SAVING is displayed) as described under

NOT saved and the power is removed from the unit, any newly changed values

6

Page

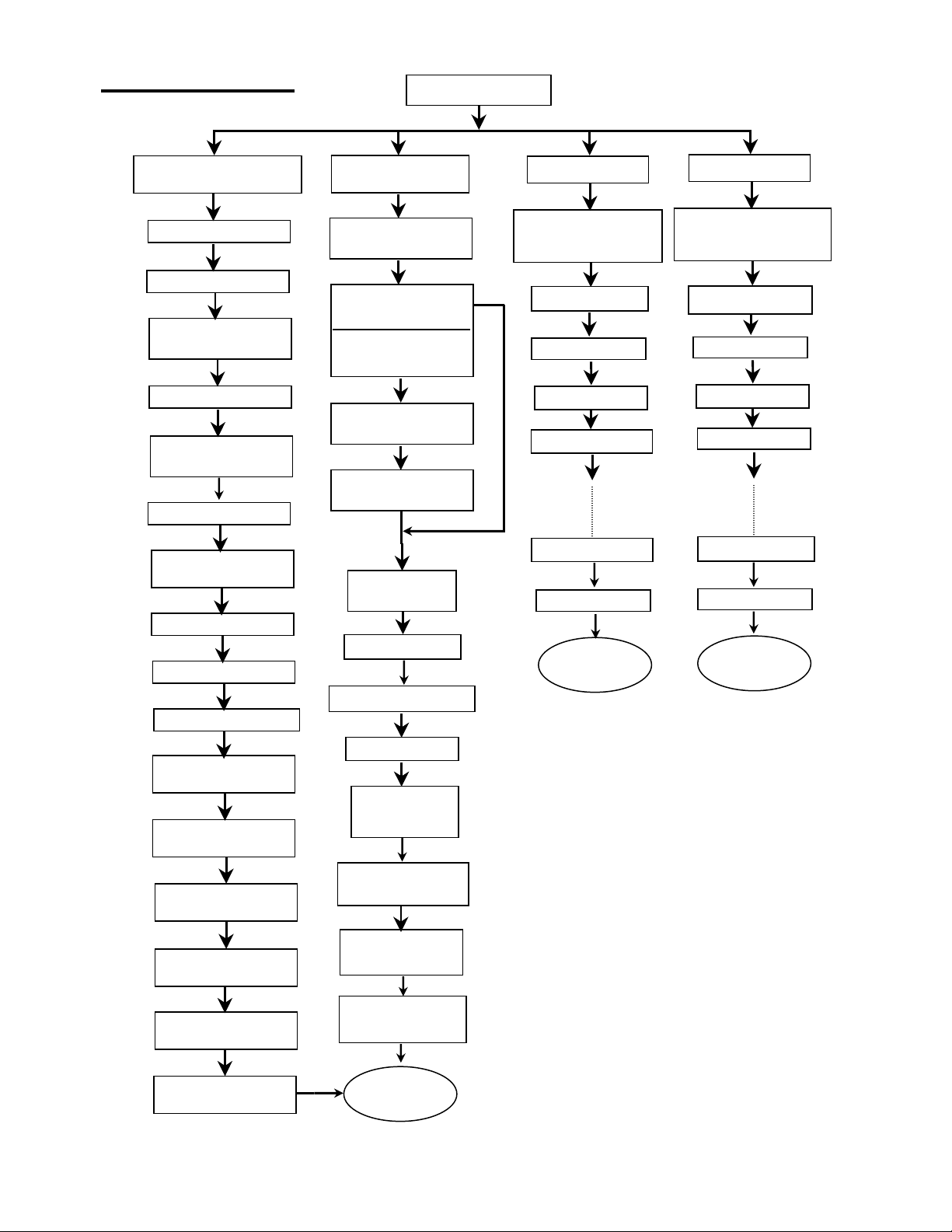

FLOW CHART

PROGRAM LIMITS

PROGRAM LIMIT1

PROGRAM LIMIT2

Configure Limit3 as

Process or Rate

PROGRAM LIMIT3

Configure Limit4 as

Process or Deviation

PROGRAM LIMIT4

SETUP

PROGRAM

CONTROLLER

Type of Control ---

PID or ON/OFF

If ON/OFF, Enter

Controller Deadband

If PID Mode, Enter

Proportional Band

If PID Mode, Enter

RESET

If PID Mode,

Enter RATE

VERIFY

SELECT PROG NO.

PROG1, PROG2, ETC.

START SETPT

ENTER SETPT1

ENTER TIME

ENTER SETPT2

Verify

segment 2

thru 9

PROFILE

SELECT PROG NO.

PROG 1, PROG2, ETC

START SETPT

ENTER SETPT1

ENTER TIME

ENTER SETPT2

Program

segment 2

thru 9

Select Timer Modes

0,1 or 2

PROGRAM TIMER1

PROGRAM TIMER2

RELAY DEADBAND

Limit1 Normally open

or closed

Limit2 Normally open

or closed

Limit3 Normally open

or closed

Limit4 Normally open

or closed

DEGREE ‘C’

OR ‘F’

DISPLAY TIME

DISPLAY OPTION

HEAT/COOL

RATE

TIMEBASE

COLD JUNCTION

CALIBRATION

INPUT

CALIBRATION

ENTER SETPT10

ENTER TIME

Back to

SETUP

ENTER SETPT10

ENTER TIME

Back to

SETUP

Limits Latching or

Non-Latching

Audio Alarm ON or

OFF

INPUT

SIGNAL TYPE

Back to

SETUP

Page

7

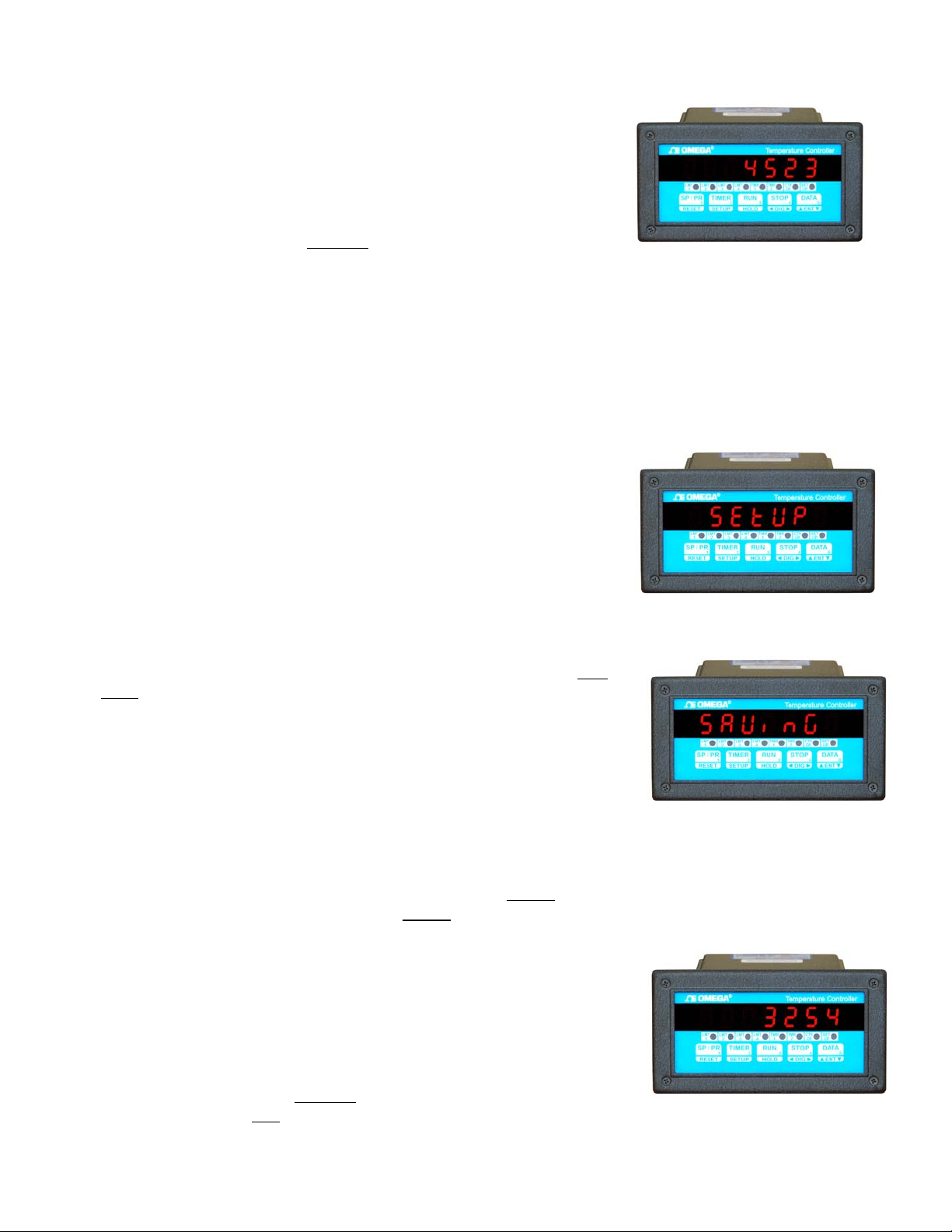

'RAMP & SOAK PROFILE' SELECTION

CN1501 has the capability of five different ramp and soak profiles. Each

of these programs can have up to ten segments. The desired profile can be

selected by going into SETUP mode and entering the correct pass-code.

To enter setup, push and hold SETUP key till the display starts scrolling

the message 'EnTER PASCOdE'. At this point two different pass-code

options are available. One is to get into ramp/soak or system

programming and the other is

& soak profile. To get into selection mode, enter pass-code '4523' (also

look under SETUP). On accepting the pass-code, the unit will scroll the message 'SELECt PROG nO.'

followed by the indication of active program number. The display format for program number is 'ProG x'

(where x = the program number, which can be from 1 to 5). To select an alternate program, push ‘^ENTv’

key. After making the selection, push RESET key to indicate so. Doing so will also exit program selection

mode.

selection of an already programmed ramp

SETUP MODE

Setup is used for configuring various parameters of CN1501 unit. These

parameters include entering ramp/soak profiles, verifying temperature

profiles, entering limits, timers, dead-bands etc.

Entering and Exiting Setup Mode:

To get into setup mode, press and hold SETUP key. The display will

show ELPSd t and then the value of elapsed time. Keep holding-in ‘SETUP’ key till the display shows

‘SETUP’ and scrolls the message 'EntEr PASSCOdE'.

To return from SETUP to normal display/run mode, simply push and

down the ‘RESET’ key. On exiting, the display will briefly show

'SAVING' to indicate that the new data is being saved in nonvolatile

memory (key should be held in until the word ‘SAVING’ shows up on the

display). Setup mode is also exited automatically if no key action is

detected for about 5 minutes.

How To Increase/Decrease Programmable Values in Setup

Once a parameter is displayed (e.g. 01234), the ‘^Ent v’ key can then be used for increasing or decreasing

the value of the flashing digit. For incrementing, push and

‘^Ent v’ key and immediately push it (and

till the desired digit starts flashing. Again, use ‘^Ent v’ key to change its value.

hold in) again. To move on to the next digit, push ‘<DIG>’ key

hold in ‘^Ent v’ key. To decrement, release

Passcode Entry:

Passcode entry is a four digit number which keeps unauthorized personnel

from changing the unit’s parameters. Front panel keys are each marked

with a small digit in the lower right corner. For the five keys there are five

digits --- 1,2,3,4,5. Pass-code is a combination of these digits and for

CN1501 units, passcode for

pass-code to program

entering the correct pass-code are allowed. Anytime a wrong digit is entered, the display will read HELP. If

correct pass-code is not entered within three attempts, the system will exit SETUP and return to normal

selection of ramp/soak programs is 4523. The

new ramp/soak profiles, limits , controller parameters , etc. is 3254. Three attempts at

hold

8

Page

display mode. To make another attempt, you have to get into setup again by

holding in ‘SETUP’ key.

As soon as correct four digit pass-code is entered, the unit is ready for setup.

At this point the unit will display ‘PrG Ctr’ (for 'Program Controller'). All

the options available for programming at this point are:

1. PrG Ctr (for 'Program Controller’) 2. PrOG Lt (for 'Program Limits')

3. VErIFy (for 'Program Verification') 4. PrOFILE (for 'Ramp/Soak Profile')

The unit starts with 'Program Controller’ as the active mode (displaying PrG Ctr). To select any other

mode, push ‘^Ent v’ key. Once the desired mode is displayed, push ‘SETUP’ key to select it.

‘PROGRAM

’

'PROGRAM CONTROLLER' MODE

Selecting ON/OFF or PID Control

On entering Program Controller mode, the very first step lets you program the type of control i.e. simple

ON/OFF or PID. The display will read ‘Pid Ctr’ (for PID control) or ‘On-OFF’ (for ON/OFF control).

Push ^ENTv key to make alternate selection. Push SETUP key to go to the next step.

NOTE: The next step depends on whether PID or ON/OFF control was selected. If PID mode is selected,

then the next three steps programmed are Proportional band, Reset and Rate. For ON/OFF mode, controller

deadband is programmed.

Entering ON/OFF Variable

On/Off Hysteresis (Dead-Band)

Controller dead-band (hyteresis) determines how tight a control around

setpoint is achieved. A smaller number results in a tighter control. This

function is indicated by the message ‘CntL db’ followed by the value of

previously programmed dead-band. The flashing digit is the active digit.

Pushing ^ENTv key and keeping it pushed, will increment the digit. Releasing ^ENTv key and then

pushing it again will decrement the value (^ENTv key works as a toggle -- alternating between increment

and decrement). To change the next digit, first push the <DIG> key. This will advance the flashing to the

following digit. Use ^ENTv key to change the value. After the desired setting is displayed, push SETUP

key. This will take you to the next step.

NOTE: This step comes up for programming only if the unit is programmed to work as ON/OFF

controller. If not, Rate, Reset and Proportional Band are programmed.

Entering PID Variables

Proportional band

If PID mode is selected, then next parameter to be programmed is the proportional band. Proportional band,

also referred to as gain, determines the output in proportion to the error between setpoint and actual process

temperature. It is based on percent error of 1000 degrees if the display units are Centigrade and 2000 degrees

if units are Fahrenheit (or scaled for voltage/current inputs). For example, if the proportional band is set to

5.0 and the units are Centigrade, then a process error of 50 degrees between setpoint and temperature will

result in an output that will be fully on.To enter a new value for proportional band, use ^ENTv and <DIG>

keys . Once the value has been entered, push SETUP key.

9

Page

Loading...

Loading...