Omega Products CN1500 Installation Manual

TM

TM

TMTM

O

Omega.com

mega.com

OO

mega.commega.com

http://www.omega.com

e-mail: info@omega.com

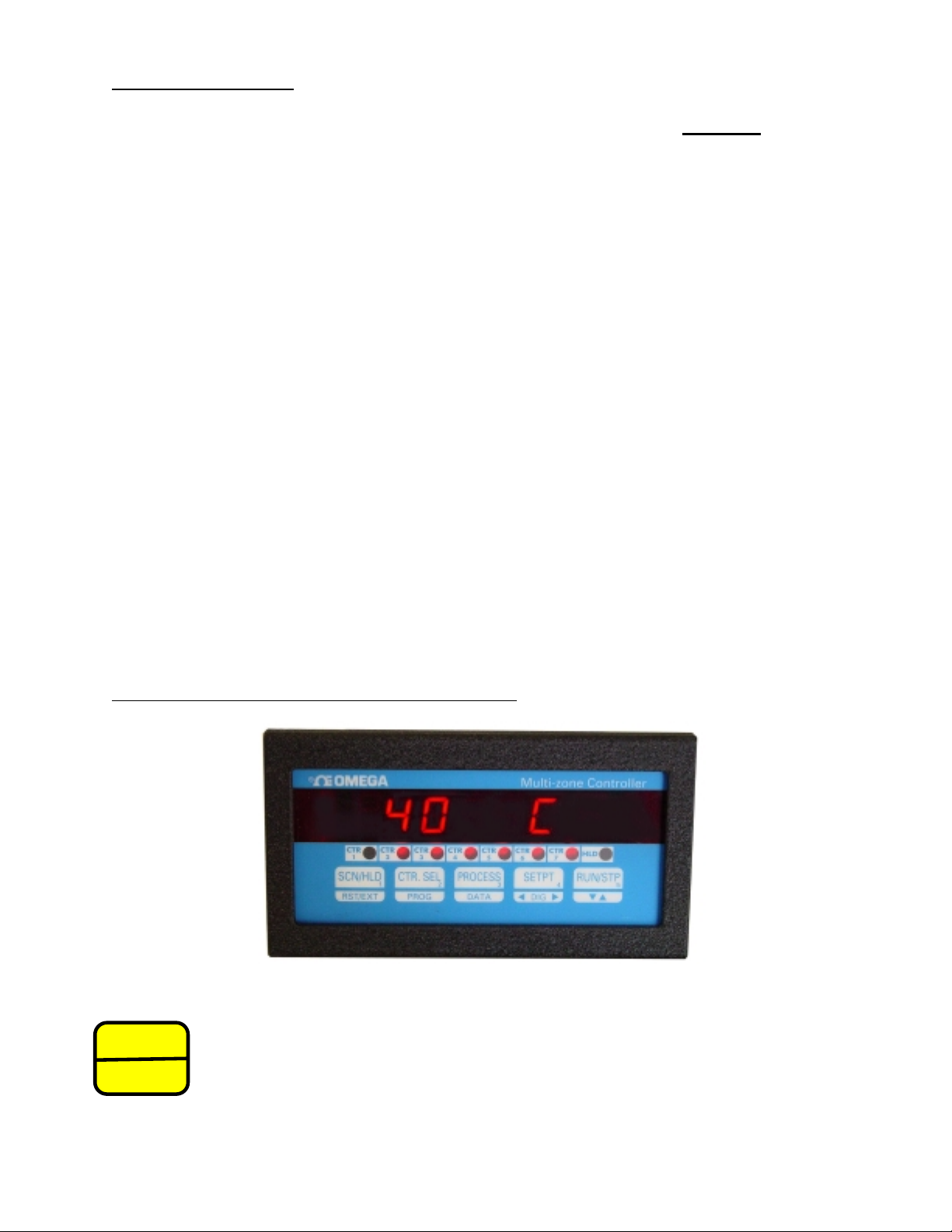

CN1500 SERIES

Multi-Zone Ramp & Soak

Controller

SPECIFICATIONS......................................................................................................................................................................3

DESCRIPTION............................................................................................................................................................................4

CN1500 KEYS AND FUNCTION............................................................................................................................................4

DISPLAY MODES......................................................................................................................................................................5

Process Mode...........................................................................................................................................................................5

Setpoint Mode..........................................................................................................................................................................6

Process-Setpoint Mode ............................................................................................................................................................6

PROGRAMMING MODES .......................................................................................................................................................6

Tuning Mode:...........................................................................................................................................................................6

On/Off Hysteresis (Dead-Band)...........................................................................................................................................7

Entering PID Variables............................................................................................................................................................7

Proportional band.................................................................................................................................................................7

Reset.....................................................................................................................................................................................7

Rate......................................................................................................................................................................................7

Verify Mode:............................................................................................................................................................................7

Profile Mode (Entering Ramp/Soak): ......................................................................................................................................8

How to Enter a Typical Process Profile...............................................................................................................................8

Ramp/Soak Profile Example................................................................................................................................................9

‘Program Controller’ mode:.....................................................................................................................................................9

Programming ‘Voltage or Current’ Input: .............................................................................................................................10

Controller Selection ...........................................................................................................................................................10

Controller Type (On/Off or PID):......................................................................................................................................10

‘Input Signal’ Type............................................................................................................................................................10

Controller ON/OFF............................................................................................................................................................10

Decimal Point Position.......................................................................................................................................................11

High Scale..........................................................................................................................................................................11

Low Scale...........................................................................................................................................................................11

Offset .................................................................................................................................................................................11

Tare....................................................................................................................................................................................12

Heat/Cool...........................................................................................................................................................................12

Engineering Units ..............................................................................................................................................................12

Programming ‘Thermocouple/ Thermistor/ RTD’ Inputs:.....................................................................................................13

Controller Selection ...........................................................................................................................................................13

Controller type (On/Off or PID):.......................................................................................................................................14

‘Input SIGNAL’ Type........................................................................................................................................................14

Turning Controller ON/OFF..............................................................................................................................................14

Temperature Units..............................................................................................................................................................14

Heat/Cool...........................................................................................................................................................................14

Engineering Units ..............................................................................................................................................................15

‘PROGRAM SYSTEM’ MODE................................................................................................................................................15

Display Options .....................................................................................................................................................................15

Dispaly Time..........................................................................................................................................................................15

Profile starting point: .............................................................................................................................................................16

Rate Time-Base:.....................................................................................................................................................................16

Cold Junction Setting.............................................................................................................................................................16

Calibration Mode...................................................................................................................................................................16

Input Range ( Current and Voltage)......................................................................................................................................16

Voltage Range (0-10vdc)..................................................................................................................................................16

Voltage Range ( Millivolt inputs).....................................................................................................................................17

Current Range....................................................................................................................................................................17

Correct Range Settings.......................................................................................................................................................17

Thermocouple Calibration Procedure....................................................................................................................................17

FLOW CHART:.........................................................................................................................................................................18

SAVING PARAMETER ...........................................................................................................................................................19

OPERATING CONTROLLER.................................................................................................................................................19

Run Mode...............................................................................................................................................................................19

Stop Mode..............................................................................................................................................................................19

Hold Mode.............................................................................................................................................................................20

MANUAL SETPOINT OPERATION.......................................................................................................................................20

QUICK STOP............................................................................................................................................................................20

DISPLAY SCAN/HOLD MODE..............................................................................................................................................20

Display Scan ..........................................................................................................................................................................21

1

Display Hold..........................................................................................................................................................................21

DISPLAYING PROCESS .........................................................................................................................................................21

DISPLAYING SETPOINT........................................................................................................................................................21

DISPLAYING DATA................................................................................................................................................................22

Data Description ....................................................................................................................................................................22

External Control Relay Installation............................................................................................................................................23

Figure 3. Solid State relay hookup to a controller output......................................................................................................23

ERROR MESSAGES AND SOLUTIONS................................................................................................................................23

POWER .....................................................................................................................................................................................23

Figure 5. REAR VIEW OF CN1500 INSTRUMENT...........................................................................................................24

Input/OUTPUT CONNECTORs PIN ASSIGNMENTS ...........................................................................................................24

MOUNTING..............................................................................................................................................................................25

WARRANTY ............................................................................................................................................................................25

2

SPECIFICATIONS

Typical @ 25 C and rated supply voltage unless otherwise specified.

INPUT TYPE:

i) J,K,T,E,R,S,B, thermistor, RTD

ii) 4-20milliamp loop current

iii) 0-10 vdc

iv) 0-100 millivolt

Cold junction error: +/- 0.5 C (10C to 45C)

Open thermocouple indication: ‘HELP’ displayed

ACCURACY:

Temperature resolution: 1C/1F, 0.1% of Full Scale

Voltage = 0.05% FS

Current = 0.05% FS

ANALOG TO DIGITAL CONVERSION

20,000 count A/D converter

Dual slope inte grating converter.

Conversion rate: Seven conversions/sec (typical)

DISPLAY

Red 7-segment LED display, 0.39 inch (10mm) height

Negative polarity indication

Over-range indication: HELP

Display test: Briefly indicates 8.8.8.8.8.8.8. on power up

SCAN RATE

Two channels per second

Channel display time: programmable from 1 - 999 seconds

POWER OPTION

120VAC -- 60 Hz (Standard)

220VAC -- 50 HZ (Optional)

15VDC @ 900ma (optional)

SCALE/OFFSET

Scale programmable from 1 - 30000

Offset : 0 - 20.00 (current), 0 - 10.000 (voltage input), 0 - 100.00 (millivolt)

Decimal Point: Programmable No decimal pt, 10th, 100th & 1000th pos.

RATE:

0 - 500 Seconds

PROPORTIONAL BAND: RESET:

0 - 100% of span 0.00 TO 50.00 repeats per minute

3

DESCRIPTION

The CN1500 series is a compact unit that offers the features of up to seven full blown PID controllers

in a single 1/8th DIN (cutout) enclosure. Careful design, high functionality and its compactness allows it

to offer unmatched cost/performance ratio of any controller in its class.

CN1500 series offers PID control for optimum process stability. Additionally, processes that do not

require tight control through complex tuning of PID parameters can be run under simple ON/OFF

control.

Programmable from the front keys, the unit will accept signals from many different types of transducers.

These include thermocouples, thermistors, RTD’s, 4-20ma loop current, 0-10vdc and 0-100mv etc.

(Check Model number for specific input types). Input signal for each zone is selected independently.

Scaling and offset allows current and voltage signals to be converted to engineering units. Additionally,

each zone has its own ramp/soak profile which can be tailored to its specific requirements. ON/OFF as

well as PID parameters (Rate, Reset and Proportional band) for each zone are also independent of each

other.

Each zone can be programmed for either heating or cooling. Setpoint deviation, positive as well as

negative, can be viewed by the push of a key.

The maximum and minimum readings for each zone are also captured. This feature can be helpful in

quality control or as a tool in fine tuning the PID parameters.

Any zone can be put on an indefinite hold anywhere along the process profile. Also, a manual mode for

setpoint entry is available. Using this feature, a setpoint can be entered without going into the program

mode and entering the entire ramp/soak profile for a given zone.

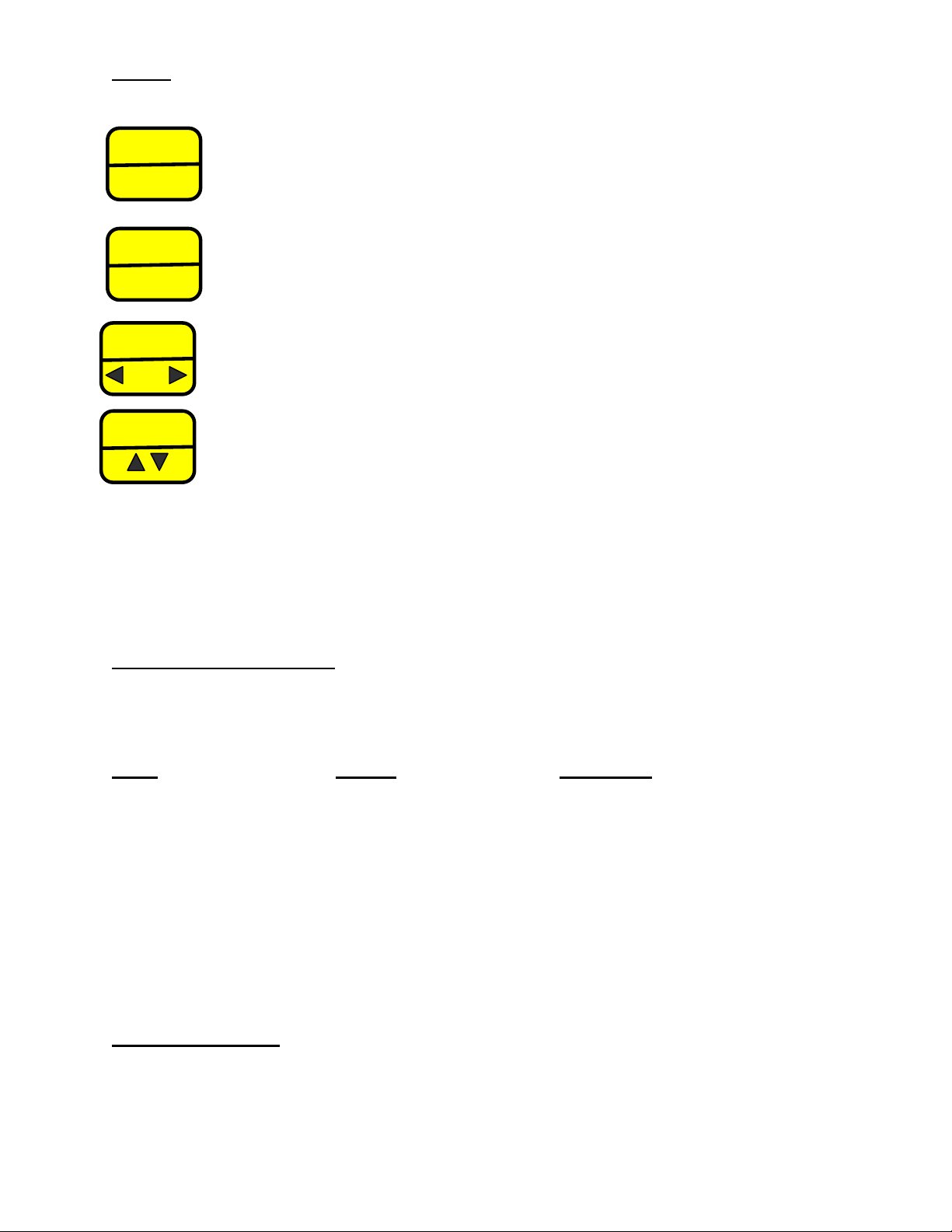

CN1500 KEYS AND FUNCTION

The five CN1500 keys have several functions packed into each key. These Functions are listed below.

* Pushing this key, while scanning, will place the display in a hold mode. The

SCN/HLD

Display will hold on the current display function until the key is pushed again.

RST/EXT

* If the unit is in a display hold mode, push this key to continue scanning

between controllers.

* This key is also used to exit Programming Mode, indicated by the word ‘SAVInG'

being displayed.

4

NOTE: HOLD mode places only the display on hold. Internally, all the enabled channels keep on

scanning and controlling. The HLD led comes on when the unit is placed in a hold mode.

* To select a controller, toggle this key until the unit displays the desired controller

CTR./SEL

* To enter programming mode, push and hold this key, on the desired

PROG

controller to be programmed, until the unit displays 'EntEr PASSCOdE'.

* Toggling this key will sequentially display process value for each controller. DATA

PROCESS

* If a controller is selected (by pushing CTR SEL key) before pushing this key , it will

DATA

SETPT

* This key's function is similar to the above (Process/Data) key except that it

displays setpoint instead of process for each controller.

DIG

* In Programming Mode this key is used to select a digit to be increment or decremented.

RUN/STP

* This key functions only after a controller has been selected by pushing CTR. SEL

key. It is used for displaying and changing the current status of selected

controller (RUNNING, HOLDING. STOPPED & ENTER SP).

* In Programming Mode this key is used to increment or decrement a selected

digit or to toggle between selections.

The LEDS on the front indicate the controller status. They are turned on when each controller is in auto

run (automatic ramping) or in manual setpoint entry mode. The HLD led indicates that the display is

being held on any one parameter (e.g. controller number 1's process value).

number.

cause the unit to display the following data for that controller: process value, soak time,

deviation, Min/Max readings and rate of process change.

DISPLAY MODES

The CN1500 can be programmed to display in one of the following modes:

Mode Display Description

PROCESS PrOCESS

SETPOINT SEtPt Displays only the setpoint value for each

controller.

(Only those controllers that are in run/hold mode)

PROCESS - SETPOINT Pr-StPt Displays Process as well as Setpoint Values for

each controller that is running a program.

SEE PROGRAMMING ON HOW TO SELECT ONE OF THE DISPLAY MODES.

PROCESS MODE

Process Display Mode sequentially displays the process value of each controller. Process value is

displayed, regardless of whether the controller is running or not. All the controllers that are enabled will

be displayed. The display time is as setup during programming.

Display only the process value for the controllers.

5

SETPOINT MODE

This mode displays ONLY the setpoint value for those controllers that are running. If NO controller is

running, the unit will scroll the message 'nO CntrL rUnnInG' on the display. Setpoints are displayed

for the programmed amount of display time.

PROCESS-SETPOINT MODE

This mode displays Process as well as Setpoint value for each controller that is in run/hold mode. If no

controller is running a profile, the unit will display only the process reading of the controllers that are

enabled. If any controllers are being run, then their process value is displayed followed by their

setpoint. The display period is as programmed during setup, for example, if display time is 10 seconds,

the process will be displayed for ten seconds, followed by setpoint for ten seconds.

PROGRAMMING MODES

Programming mode is used for configuring various parameters of the unit. This is accomplished by first

selecting the controller that needs to be programmed (by pushing the CTR SEL key), and then holding

in the CTR.SEL (Controller Select) key until the units displays 'EntEr PASSCOdE'. At this point,

pass code for the system can be entered. The entry code is a four digit number which keeps unauthorized

personnel from changing the system parameters. The front panel keys are each marked with a small

digit in the lower right corner. For the five keys there are five digits --- 1,2,3,4,5. The pass-code is a

combination of these digits and for CN1500 systems it is 3254.

If, at any time during programming, it is desired to exit, just push the RESET key twice (and hold it in

till the display reads ‘SAVInG’). First push takes you to the very beginning of the program mode

(display shows 'PrG CTr '), and the second push will exit. Display briefly reads 'SAVING' to indicate

that the data is being saved in nonvolatile memory.

As soon as the correct four digit pass-code is entered, the system is ready for programming. Once in

programming mode, one of the following selections can be made:

Display Description

tuninG Enter PID parameters or hysteresis for ON/OFF control

VErIFY Verify a previously entered Ramp/Soak profile .

PrOFILE Program a Ramp/Soak profile for a controller.

PrG CTr

PrG SYS Program System parameters

TUNING MODE:

Tuning mode is used for entering relay hysteresis (if controller is programmed for ON/OFF mode) or

Rate, Reset and Proportional Band (if the unit is set as a PID controller). This mode is selected in

SETUP mode by pushing PROG key while the unit is displaying 'tUnIng'. After this selection, the

unit will display any one of the following: 'Cntr 1', 'Cntr 2', 'Cntr 3', 'Cntr 4', 'Cntr 5', 'Cntr 6', or

'Cntr 7'. At this time any controller can be selected by pushing key. LED for selected controller

will flash (this provides an easy way to track the controller being programmed). After selecting a

controller, use PROG key to step through programming. To exit, push EXT key.

Program Controller parameters.

6

NOTE: ‘TUNING’ mode can also be entered by pushing and holding ‘DATA’ key till the display

reads ‘TuninG’. Once in this mode, any controller can be selected by pushing key. (This procedure

can only be done from normal display mode and not frome SETUP). To exit, push & hold RESET key.

ON/OFF HYSTERESIS (DEAD-BAND)

This step is used for setting up controller deadband or hysteresis and is indicated by the message

‘Cntr db’ followed by the display of current deadband value. The flashing digit is the active digit.

Pushing key and keeping it pushed, will increment the digit. Releasing key and then pushing it

again will decrement the value ( key works as a toggle -- alternating between increment and

decrement). To change the next digit, first push the <DIG> key. This will advance the flashing to the

following digit. Use key to change the value. After the desired setting is displayed, push PROG

key. This will take you to the beginning of setup mode (or Tunning Mode)

NOTE: This step comes up for programming only if the unit is programmed to work as ON/OFF

controller. If not, Rate, Reset and Proportional Band are programmed.

ENTERING PID VARIABLES

PROPORTIONAL BAND

If PID mode is selected, then next parameter to be programmed is the proportional band. Proportional

band, also referred to as gain, determines the output in proportion to the error between setpoint and

actual process temperature. It is based on percent error of 1000 degrees if the display units are

Centigrade and 2000 degrees if units are Fahrenheit (or scaled for voltage/current inputs). For example,

if the proportional band is set to 5.0 and the units are Centigrade, then a process error of 50 degrees

between setpoint and temperature will result in an output that will be fully on.To enter a new value for

proportional band, use and <DIG> keys . Once the value has been entered, push PROG key.

RESET

Parameter programmed after proportional band is Reset. As with other functions, this is indicated by the

display first showing the message followed by current reset value. The message in this case is 'RESET'.

Again, use key in conjunction with <DIG> key to change the value.

Reset is used with proportional band to fine tune the controller. Proportional band alone will bring down

the error between setpoint and process up to a certain point only. To reset the differential left by

proportional band, the error is integrated slowly over time until setpoint and process coincide. This is

done by introducing the reset factor. After programming reset, push PROG key to program RATE.

RATE

Rate is the third factor in the PID control. This factor provides the anticipation for the control as to how

fast or slow process change is being realized. This factor is usually handy at start ups when, generally,

process tends to lag setpoint and a higher output is required. On entering rate mode, the display first

reads 'RAtE' followed by rate value. This value can be change by using and DIG keys.

VERIFY MODE:

The Verify function is used for checking a previously programmed ramp/soak profile. This mode is

selected by pushing PROG key while the unit is displaying 'VE

7

rIFY'. After this selection, the unit

will display one of the following: 'Cntr 1', 'Cntr 2', 'Cntr 3', 'Cntr 4', 'Cntr 5', 'Cntr 6', or 'Cntr 7'.

At this time any one of the controllers can be selected by pushing the key. After selecting a

controller, use PROG key to step through the profile. To exit Verify mode at any time, push EXT key.

Unlike exiting 'ProFILE' mode, exiting VERIFY at any point does not mark the end of a profile.

NOTE: Verify mode should only be used to check or change a previously programmed

parameter. DO NOT USE THIS MODE TO ENTER A NEW PROFILE. TO ENTER A

NEW RAMP/SOAK PROFILE, USE 'PrOFILE' MODE.

NOTE: Before verifying a profile, all Controllers must be in Stopped Mode. If not, the unit will

scroll the message 'StOP rUnnInG'

PROFILE MODE (ENTERING RAMP/SOAK):

This programming mode is used for entering process profile for a selected controller. Once in

programming mode (after entering pass-code), use key until the unit displays PrOFILE (for

ramp/soak ‘Profile’ ). Next, push the PROG key. The unit will display one of the following with each

push on key: CntrL 1, CntrL 2, CntrL 3, CntrL4, CntrL 5, CntrL 6 or CntrL 7). After

selecting the desired controller, push PROG key to select it. A profile can now be programmed in the

following manner:

NOTE: Before programming or checking a programmed profile the Controller Must Be in the

Stopped Mode. If not, the unit will scroll the message "STOP RUNNING'.

HOW TO ENTER A TYPICAL PROCESS PROFILE

Upon entering the process profile mode, the display will briefly read Strt SP (for ‘Start Setpoint’), and

then the current value of Starting setpoint. Use and <DIG > keys to enter a desired value. The

key increments and decrements the FLASHING digit, where as the <DIG> key selects the digit to

increment or decrement. Next, press SETUP key to go on to the next function.

At this point the display will briefly read SetPt 1 and then the current value of Setpoint #1. Use

and <DIG > keys to enter a desired value. Next, press ‘PROG’ key to go to the following function.

The display will now read EntEr t (for ‘Enter time’), and then show the current time value. Time

entered is the time that it takes to ramp to the set point (or soak time, if the previous and current setpoints are same). The value shown for time is in minutes. Use and <DIG > keys to enter the

desired value, and then press PROG key to go on to the next function.

Repeat the above steps to program setpoints #2 thru #7. Once all 7 segments have been programmed,

the display will revert back to beginning of Programming mode selection. If all the seven segments are

not desired, the program can be aborted at any segment by simply pushing the EXT key. The segment in

which the EXT key is pushed is the one that is considered to be the end of the program. During Verify

Program mode, that segment and all the following segments are labeled as ‘PrG End’.

NOTE: DO NOT PUSH 'EXT' KEY IN THE LAST SEGMENT OF YOUR RAMP/SOAK

PROFILE. AFTER ENTERING TIME FOR THE LAST SEGMENT GO TO THE NEXT

SEGMENT

AND THEN HIT THE EXIT KEY. THE UNIT MARKS THE SEGMENT BEING

DISPLAYED AT THE TIME OF PUSHING 'EXT' KEY AS THE END OF PROGRAM.

THEREFORE, MAKE SURE THAT THE UNIT IS IN THE SEGMENT THAT YOU WISH TO

BE CONSIDERED AS THE END OF PROGRAM BEFORE PUSHING 'EXT' KEY.

8

Loading...

Loading...