Omega Products CN1166 Installation Manual

1

-DIN

16

RAMP/SOAK PROFILE

CONTROLLER

Product Manual

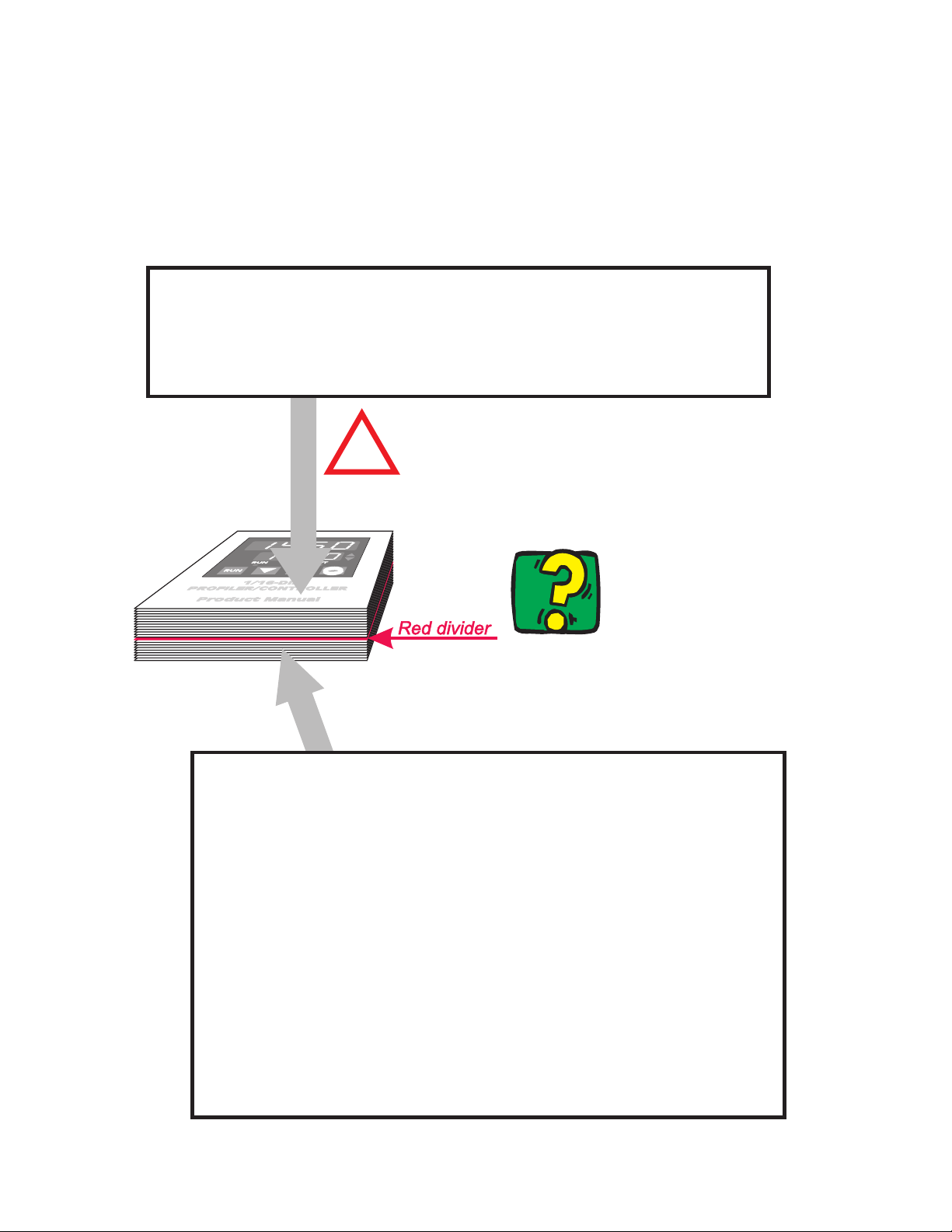

HOW TO USE THIS MANUAL

This manual comprises two volumes:

VOLUME I

INST ALLA T ION & CONF IGURA T ION INST RUC T IONS

SECTION 1 Panel-mounting and wiring-up the Profile Controller

SECTION 2 Selecting the required input/output type(s)

SECTION 3 Matching software to hardware fitted

Selecting input range, control action, alarm type(s)

and Program Mode

!

The functions described in Volum e Imust

be perform ed only by personnel who are

trained, equipped and authorised to do so.

To find a specific

topic, refer to the index

at the rear of this manual

VOLUME II

OPERATINGINSTRUCTIONS

SECTION 1 Monitoring the process and adjusting the setpoint

Starting/holding/releasing/aborting a program

Monitoring a running/held program

Manual Control

SECTION 2 Setting up the controller parameters

SECTION 3 Creating/editing a program

Using Guaranteed Soak Band

Segment Event Status

SECTION 4 Setting up and using the communications

link between the Profile Controller and your

computer

APPENDIX A Product specification

APPENDIX B Summary of front panel displays

1

-DIN RAMP/SOAK PROFILE CONTROLLER

16

PRODUCT MANUAL

VOLUME I

INSTALLATION & CONFIGURATION

INSTRUCTIONS

The procedures described in this Volume must be undertaken only by

technically-competent servicing personnel.

CONTENTS

1 INSTALLATION 1-1

1.1 UNPACKING PROCEDURE 1-1

1.2 PANEL-MOUNTING THE CONTROLLER 1-1

1.3 CONNECTIONS AND WIRING 1-2

2 INTERNAL LINKS AND SWITCHES 2-1

2.1 REMOVING THE PROFILE CONTROLLER FROM ITS HOUSING 2-1

2.2 REMOVING/REPLACING THE OUTPUT 2/OUTPUT 3 OPTION PCBs 2-3

2.3 REMOVING/REPLACING THE RS485 COMMUNICATIONS

OPTION PCB OR REMOTE RUN/HOLD OPTION PCB 2-3

2.4 REPLACING THE INSTRUMENT IN ITS HOUSING 2-3

2.5 SELECTION OF INPUT TYPE AND OUTPUT 1 TYPE 2-4

2.6 OUTPUT 2 TYPE/OUTPUT 3 TYPE 2-6

3 CONFIGURATION MODE 3-1

3.1 ENTRY INTO CONFIGURATION MODE 3-1

3.2 HARDWARE DEFINITION CODE 3-1

3.3 OPTION SELECTION 3-3

3.4 CONFIGURATION MODE PARAMETERS 3-4

3.5 EXIT FROM CONFIGURATION MODE 3-9

PM077-V1 Volume I (i)

1 INSTALLATION

1.1

1.2

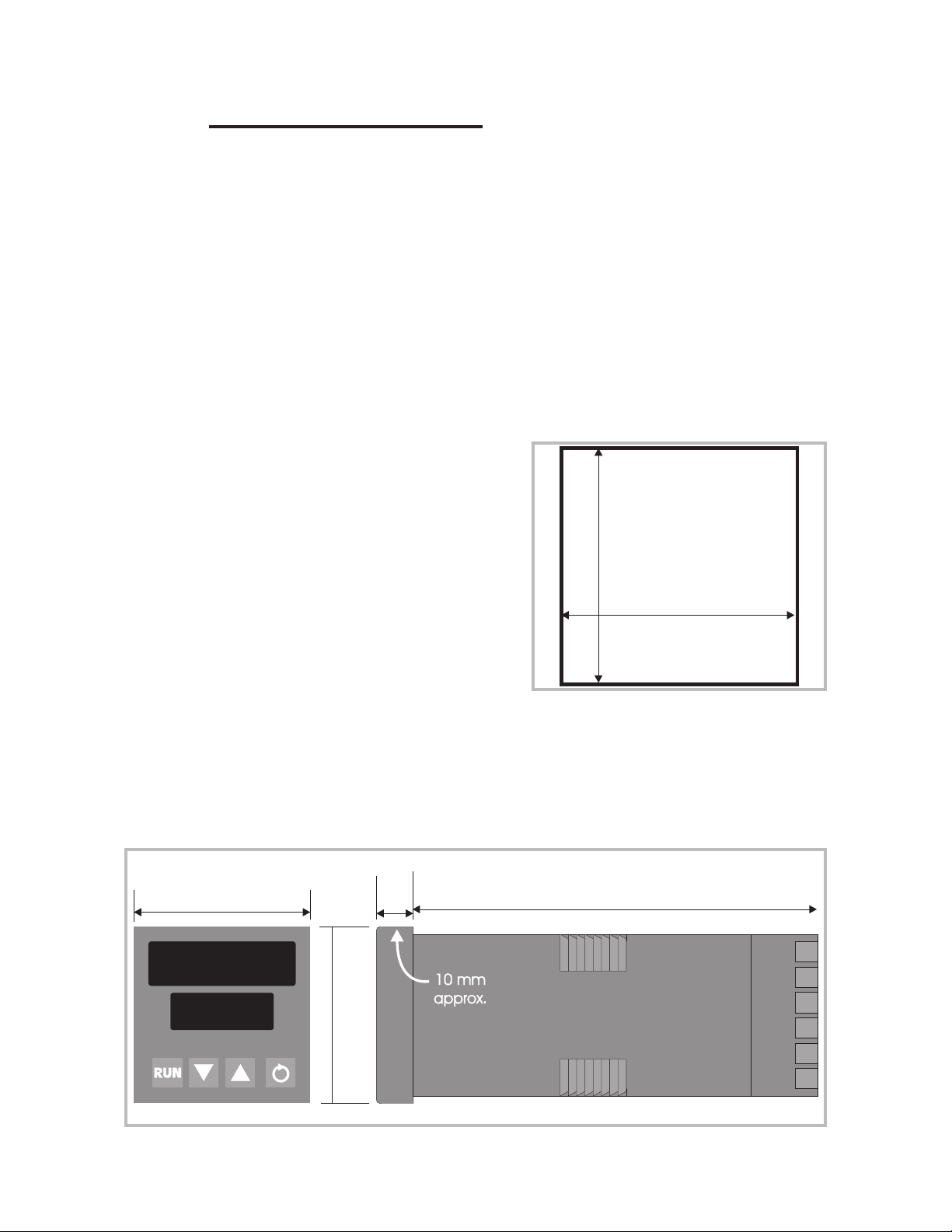

The panel on which the Profile Controller is to

be mounted must be rigid and may be up to

6.0mm (0.25 inches) thick. The cut-out required

for a single Profile Controller is as shown in

Figure 1-1.

Several instruments may be installed in a single

cut-out, side-by-side. For n Profile Controllers

mounted side-by-side, the width of the cut-out

would be:

UNPACKING PROCEDURE

1. Remove the Profile Controller from its packing. The Controller is

supplied with a panel gasket and push-fit fixing strap. Retain the

packing for future use, should it be necessary to transport the Profile

Controller to a different site or to return it to the supplier for

repair/testing.

2. Examine the delivered items for damage or deficiencies. If any is

found, notify the carrier immediately.

PANEL-MOUNTING THE CONTROLLER

45m m +0.5 -0.0

45m m +0.5 -0.0

(48n - 4) millimetres or (3.78n - 0.16) inches.

The Profile Controller is 110mm deep (measured from the rear face of the front

panel). The front panel is 48mm high and 48mm wide. When panel-mounted, the

front panel projects 10mm from the mounting panel. The main dimensions of the

Profile Controller are shown in Figure 1-2.

48m m

48m m

Figure 1-2 Main Dimensions

Figure 1-1

110m m

S077-1 Volume I 1-1

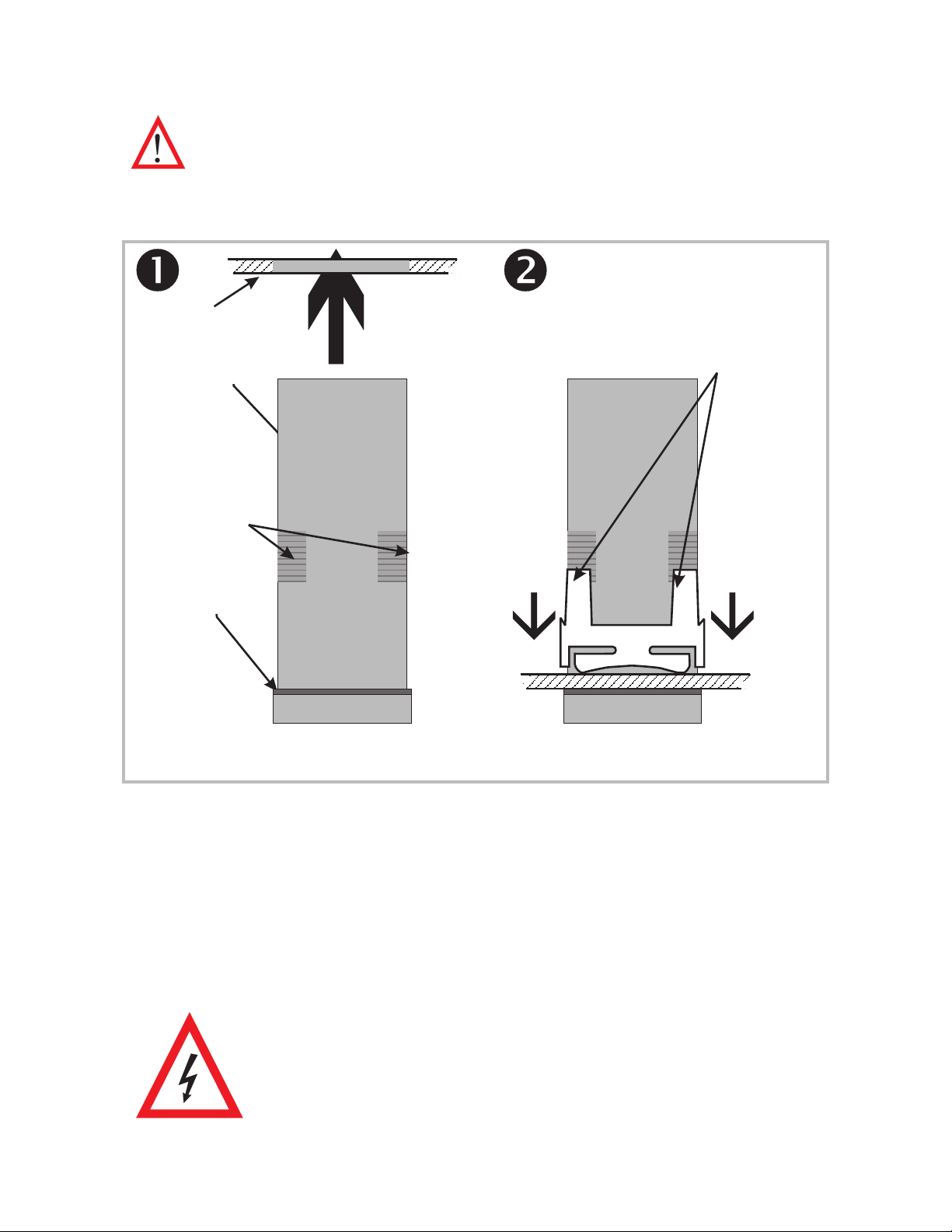

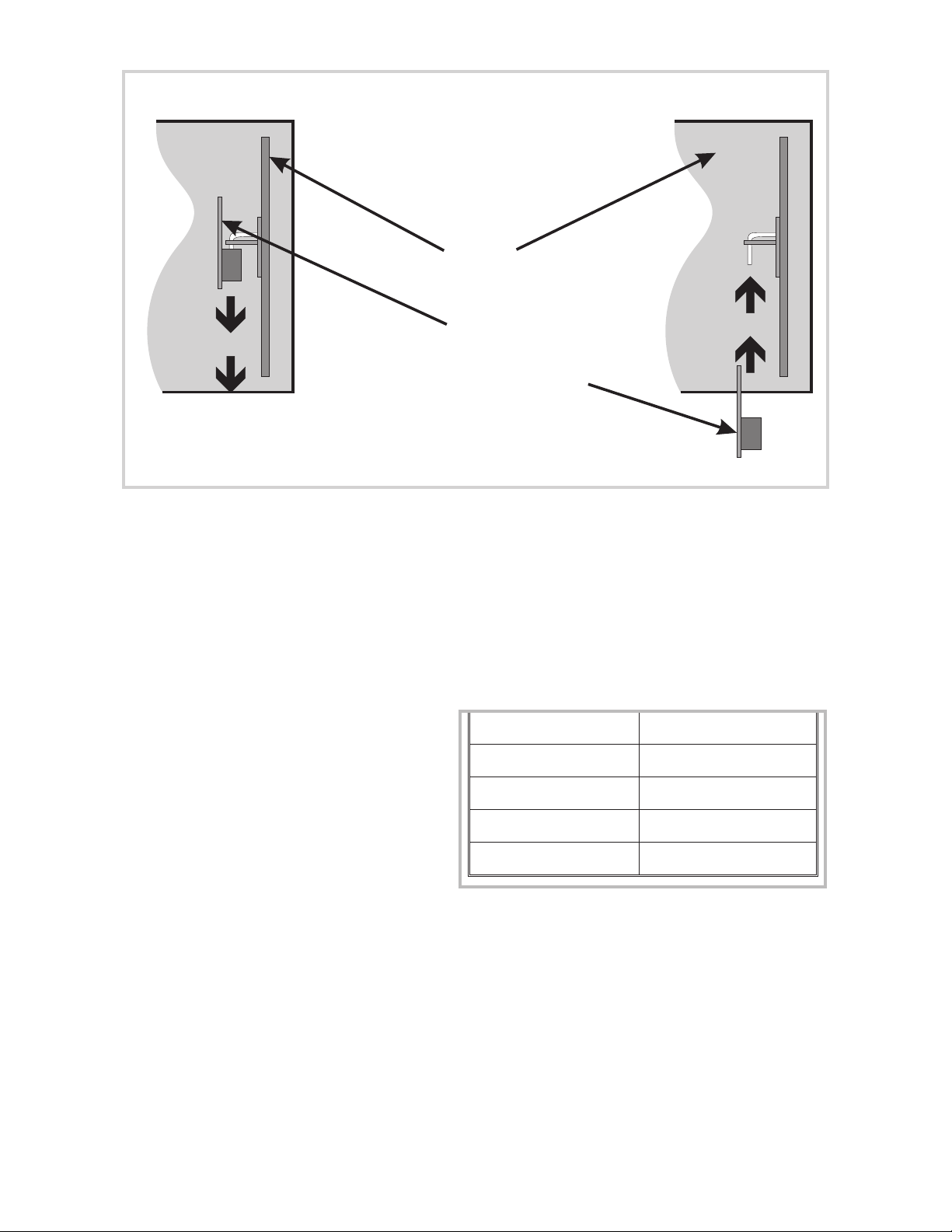

The procedure to panel-mount the Profile Controller is shown in Figure 1-3.

r

CAUTION: Do not remove the panel gasket, as this may result in

inadequate clamping of the instrument in the panel.

NOTE: When installing several instruments side-by-side in one

cut-out, use the ratchets on the top/bottom faces.

Slid e m o u n ting c lam p ove

Profile Controlle r housing towa rd s

rear face of mounting panel

Mounting panel

Profile

until tongues engage in ratchets

a n d Profile Co ntrolle r is c lam pe d

firm ly in p o sition.

Controlle r

Ho u sin g

Ratc hets

Gasket

Hold Profile Controlle r firm ly in p osition

(apply pressure to bezelonly)

Figure 1-3 Panel-Mounting the Profile Controller

Once the Profile Controller is installed in its mounting panel, it may be

subsequently removed from its housing, if necessary, as described in Subsection

2.1.

1.3

CONNECTIONS AND WIRING

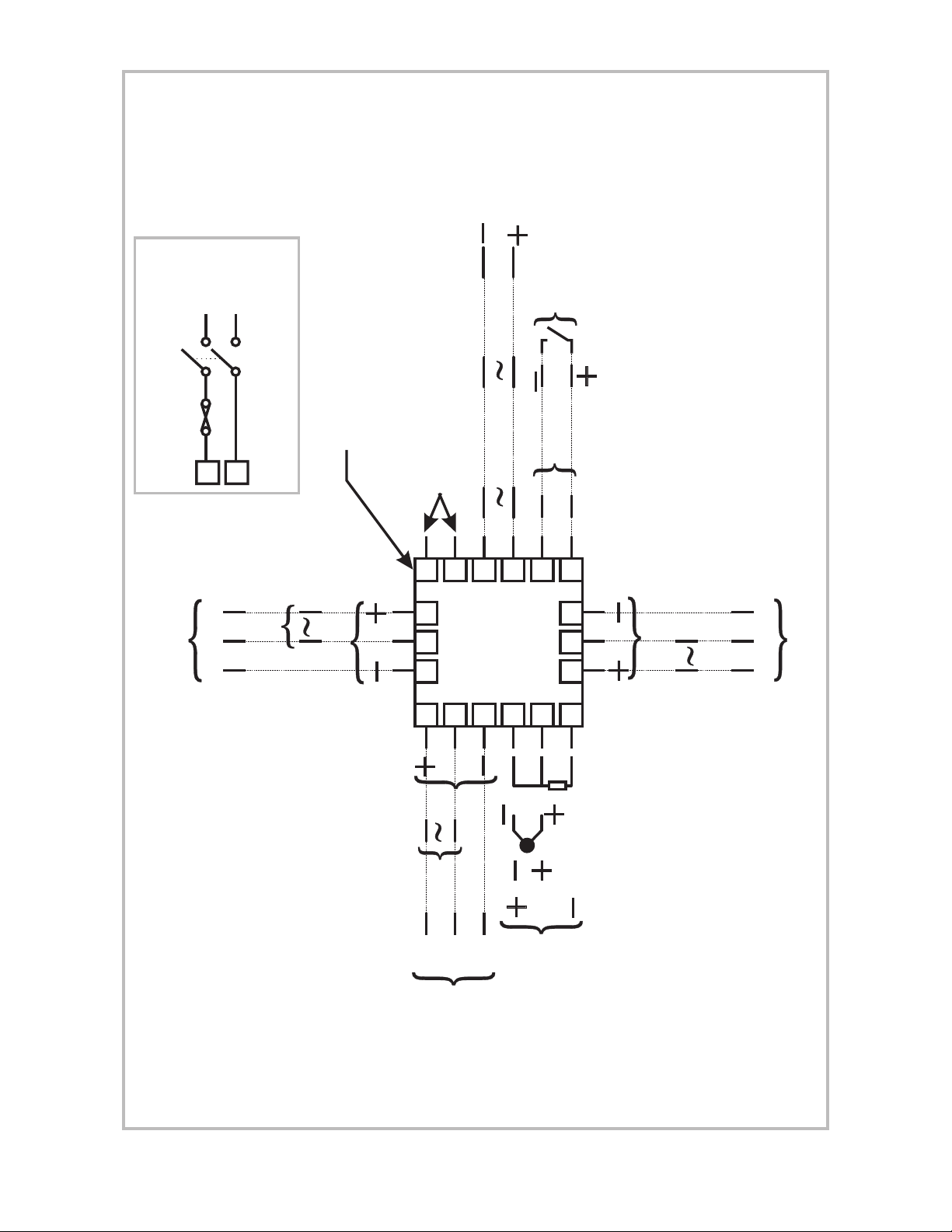

The rear terminal connections are illustrated in Figure 1-4.

This instrument is designed for installation in an enclosure

which provides adequate protection against electric shock.

All pertinent local regulations should be rigidly observed.

Consideration should be given to prevention of access to the

rear terminals by unauthorised personnel.

1-2 Volume I S077-1

POWER

OU

U

INPUT

24VDC *

REMOTE

Lor -

Nor +

*Option

RUN/HOLD

24V

50/60Hz *

POWER C ONNECTION

RECOMMENDED MODE OF

9

10

N/O

C

Re la y

OUT PUT 3

N/C

appropr iate) for fuse ratings.

See Subsection 1.3.1 or 1.3.2 (as

Solid State

Top of Controller

No external connections

to be made to these

terminals.

7

8

DC/SSR Dr iv e

16 17 18

1

2

96 - 264V

L

9

3

SERIAL

COMMS.

50/60Hz

N

A

10

11

4

5

B

12

13 14 15

6

Output 1 is always the primary control

(HEAT) o u tp u t - re la y, SSR d riv e , solid

state or DC.

Re la y

T2

TP

N/C

C

DC/SSR Dr iv e

Solid State

N/O

RS485

RTD

DC/SSR Dr iv e

Th e rm o c o u p l e

Solid State

UNIVERSAL

C

N/O

Output3isusedeitherasalarm output

(relay, SSR drive or solid state) or

Output2isusedasSecondary

Con tro l (C OOL) outp u t (re la y, SSR

d riv e , solid st a te o r DC), a la rm out p ut,

EventoutputorProgram Activeoutput

(relay, SSR drive or solid state)

recorder output (DC only for SP orPV)

Re la y

OUT PUT 1

N/C

INPUT

Linear (V/m V)

Linear (m A)

Figure 1-4 Rear Terminal Connections

S077-1 Volume I 1-3

1.3.1 Mains (Line) Input

The Profile Controller will operate on 96 - 264V AC 50/60Hz mains (line) supply.

The power consumption is approximately 4 VA. Power should be connected via a

two-pole isolating switch (preferably situated near the equipment) and a 1A fuse.

If the Profile Controller has relay outputs in which the contacts are to carry mains

(line) voltage, it is recommended that the relay contact mains (line) supply should

be switched and fused in a similar manner but should be separate from the Profile

Controller mains (line) supply.

1.3.2 24V (Nominal) AC/DC Supply

The supply connections for the 24V AC/DC option of the Profile Controller are as

shown in Figure 1-4. Power should be connected via a two-pole isolating switch

and a 315mA slow-blow (anti-surge Type T) fuse.

With the 24V AC/DC supply option fitted, these terminals will accept the following

supply voltage ranges:

24V (nominal) AC 50/60Hz - 20 - 50V

24V (nominal) DC - 22 - 65V

1.3.3 Thermocouple Input

The correct type of thermocouple extension leadwire or compensating cable must

be used for the entire distance between the Profile Controller and the

thermocouple, ensuring that the correct polarity is observed throughout. Joints in

the cable should be avoided, if possible. The CJC facility must be enabled (normal

conditions) for this input (see Subsection 3.4).

NOTE: Do not run thermocouple cables adjacent to power-carrying

conductors. If the wiring is run in a conduit, use a separate conduit for the

thermocouple wiring. If the thermocouple is grounded, this must be done

at one point only. If the thermocouple extension lead is shielded, the shield

must be grounded at one point only.

1.3.4 RTD Inputs

The compensating lead should be connected to Terminal 4. For two-wire RTD

inputs, Terminals 4 and 5 should be linked. The extension leads should be of

copper and the resistance of the wires connecting the resistance element should

not exceed 5 ohms per lead (the leads should be of equal resistance).

1-4 Volume I S077-1

1.3.5 Linear Inputs

For linear mA input ranges, connection is made to Terminals 4 and 6 in the

polarity shown in Figure 1-4. For linear mV and V ranges, connection is made to

Terminals 4 and 5 in the polarity shown in Figure 1-4. For details of the linear

input ranges available, refer to Appendix A.

1.3.6 Remote Run/Hold Input

With this option fitted, Terminals 11 and 12 are used for external Run/Hold

control of the currently-selected program; this has an effect identical to that of the

front panel RUN key. These terminals may be connected to (a) the voltage-free

contacts of a switch or relay, or (b) a TTL-compatible voltage. This is an

edge-sensitive input for which the following convention has been adopted:

For TTL input, OFF = logic 1 and ON = logic 0

For a voltage-free input, OFF = open and ON = closed

Program control is as follows:

OFF-ON transition: The currently-selected program will run (or

will resume running if it is currently held).

ON-OFF transition: The currently-running program will be

held.

NOTE: When this input is used, the front panel RUN key can be

used only to abort a program. Powering-up the Profile Controller

whilst this input is ON will not cause a program to run. The RS485

Serial Communications option and the Remote Run/Hold option are

mutually exclusive.

1.3.7 Relay Outputs

The contacts are rated at 2A resistive at 120/240V AC.

1.3.8 SSR Drive Outputs

These outputs produce a time-proportioned non-isolated DC signal (0 - 4.2V

nominal into 1k

W minimum).

1.3.9 Solid State Outputs

These outputs provide up to 1A AC drive with a longer lifetime than an

electromechanical relay. For further details, refer to Appendix A.

S077-1 Volume I 1-5

1.3.10 DC Outputs

See Appendix A.

1.3.11 RS485 Serial Communications Link

The cable used should be suitable for data transfer at the selected rate (1200,

2400, 4800 or 9600 Baud) over the required distance. Transmitters/receivers

conform to the recommendations in the EIA Standard RS485.

The “A” terminal (Terminal 11) on the Profile Controller should be connected to

the “A” terminal on the master device; the “B” terminal (Terminal 12) on the

Profile Controller should be connected to the “B” terminal on the master device.

Where several Profile Controllers are connected to one master port, the master

port transceiver in the active state should be capable of driving a load of 12k

Profile Controller; the master port transceiver in the passive state must have

pull-up/pull-down resistors of sufficiently low impedance to ensure that it remains

in the quiescent state whilst supplying up to ±100

mA each to the Profile Controller

transceivers in the high impedance state.

NOTE: The RS485 Serial Communications option and the Remote

Run/Hold option are mutually exclusive.

W per

1-6 Volume I S077-1

2 INTERNAL LINKS AND SWITCHES

C

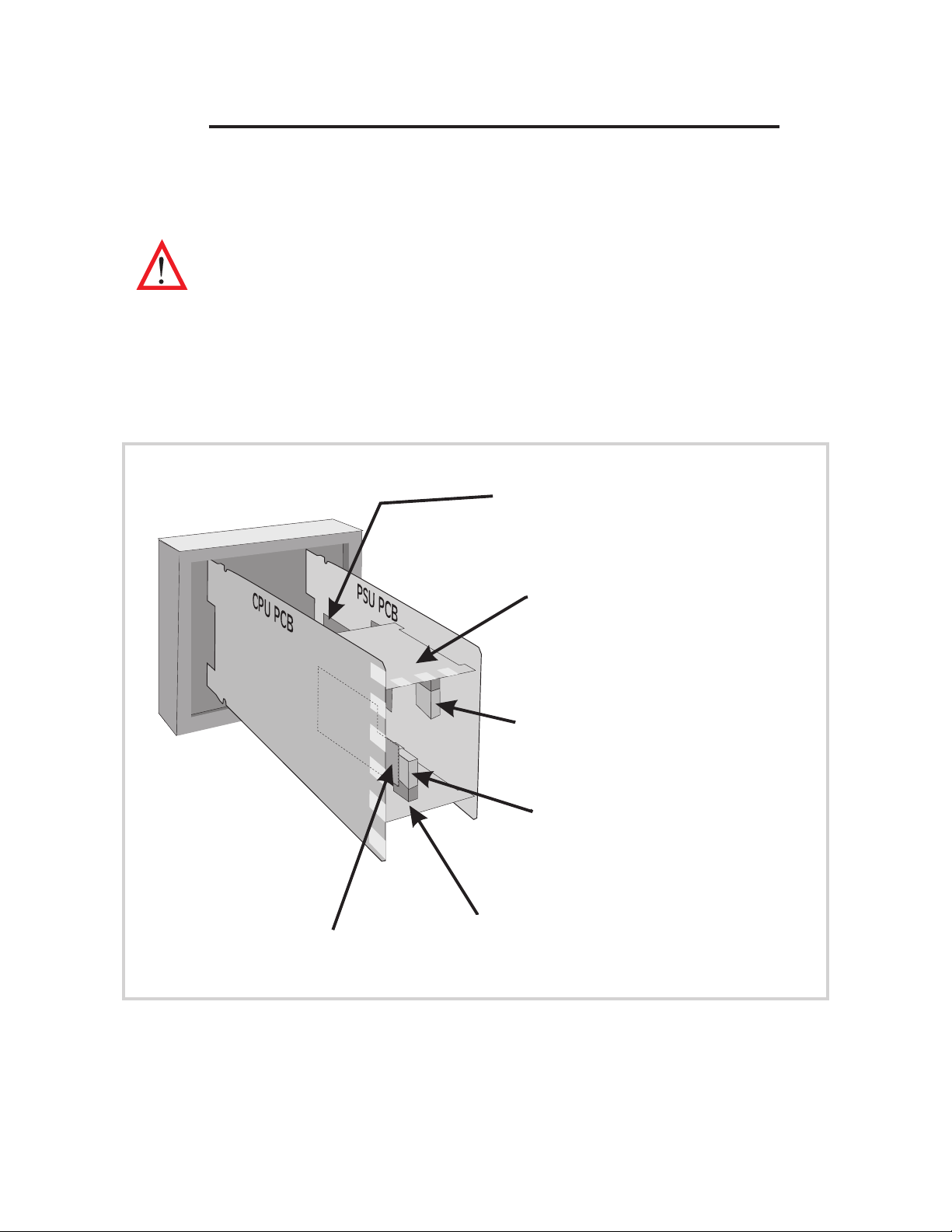

2.1 REMOVING THE PROFILE CONTROLLER FROM ITS

HOUSING

CAUTION: Before removing the instrument from its housing, ensure

that all power has been removed from the rear terminals.

To withdraw the instrument from its housing, simply grip the side edges of the

front panel (there is a finger grip on each edge) and pull the instrument forwards.

This will release the instrument from its rear connectors in the housing and will

give access to the instrument PCBs. Take note of the orientation of the instrument

for subsequent replacement into the housing.The positions of the PCBs in the

instrument are shown in Figure 2-1.

RS485CommunicationsOption P

or

Front Panel (top edge)

Remote Run/Hold Option PCB

DC Output 1 PCB (if fitted)

Figure 2-1 PCB Positions

Out p ut 3 Op t io n PCB

(Relay, SSR Drive,

Solid State or DC Output)

Output 3 Link Jumpers

(DC Output onl y)

Output 2 Link Jumpers

(DC Output onl y)

Out p ut 2 Op t io n PCB

(Relay, SSR Drive,

Solid State or DC Output)

S077-2 Volume I 2-1

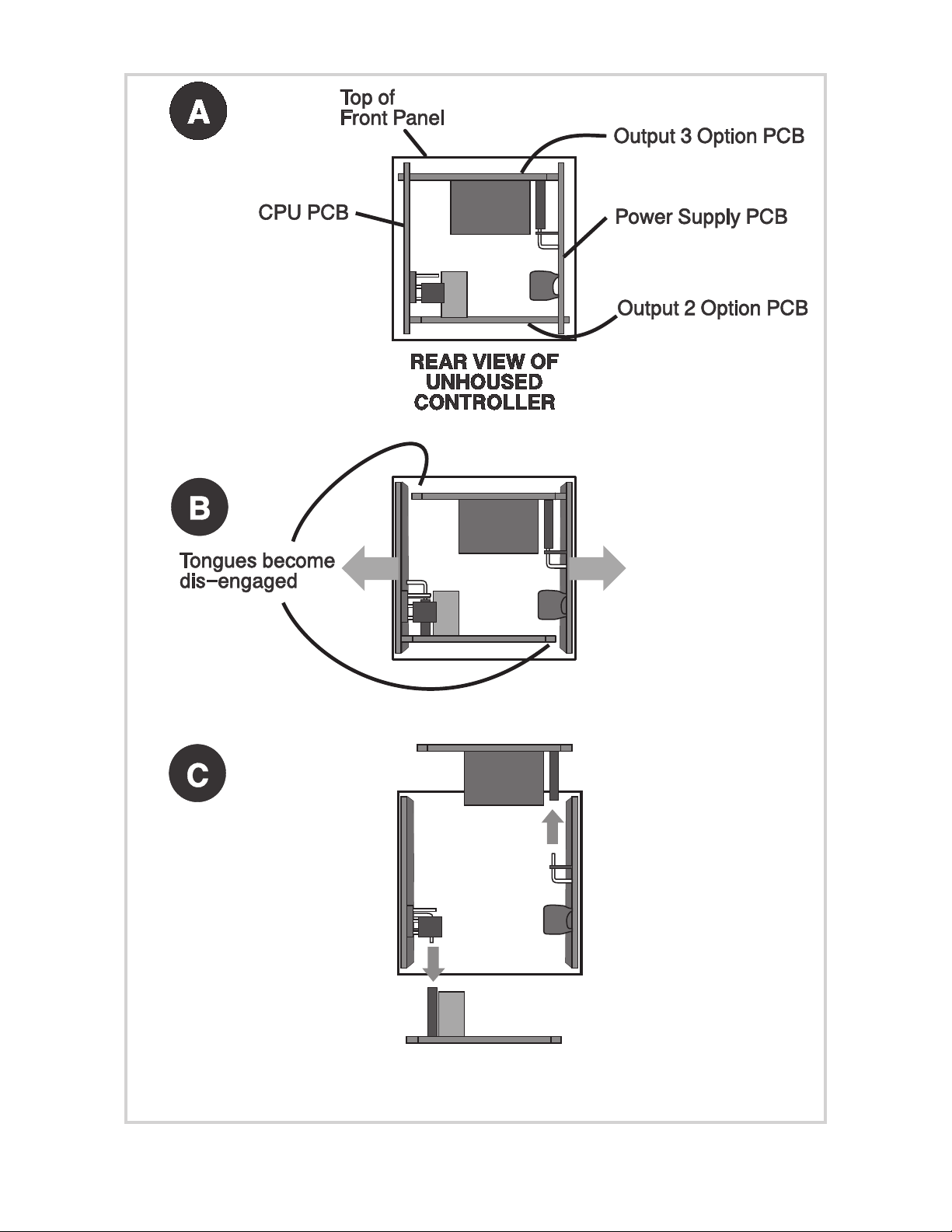

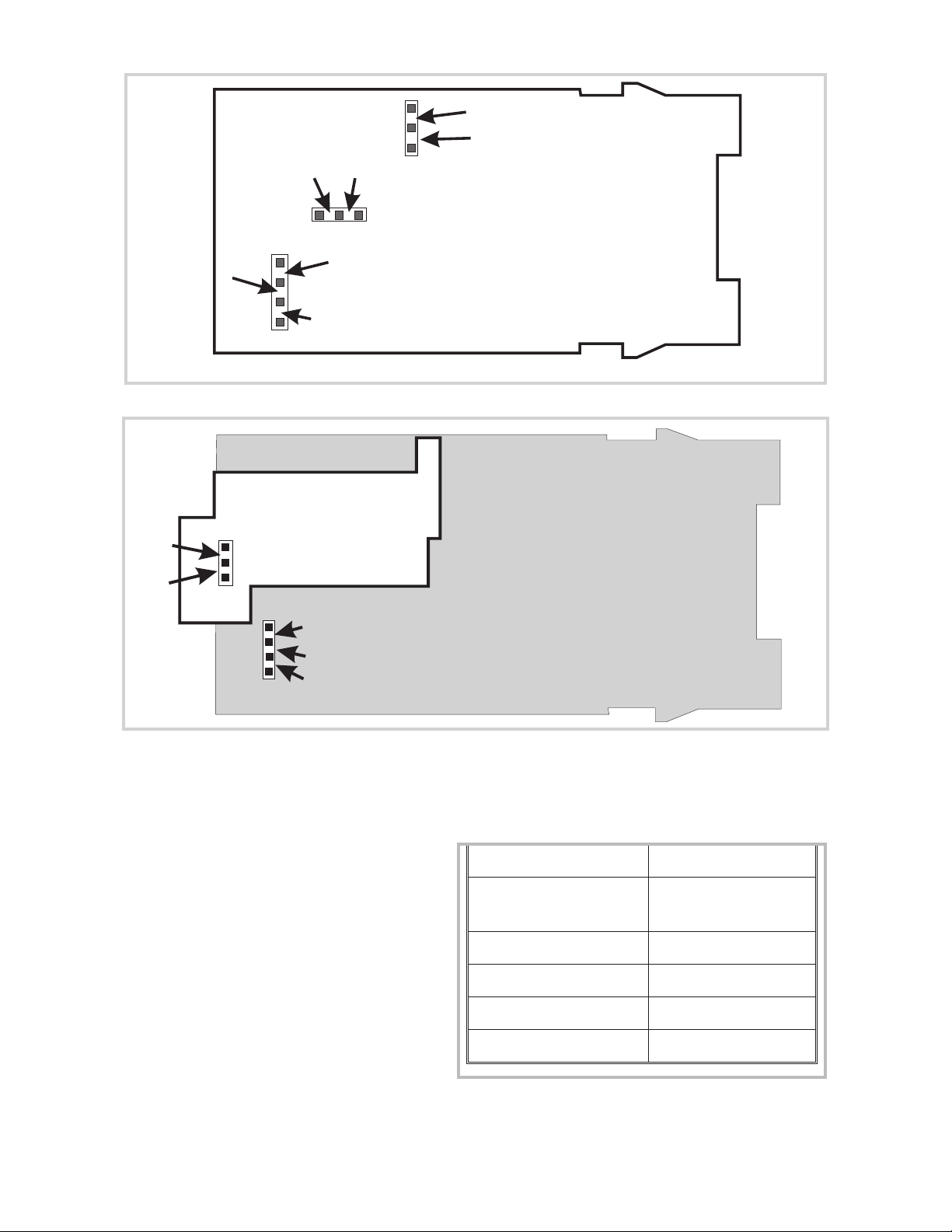

Figure 2-2 Removing the Output 2/Output 3 Option PCBs

2-2 Volume I S077-2

2.2 REMOVING/REPLACING THE OUTPUT 2/OUTPUT 3 OPTION

PCBs

With the instrument removed from its housing:

1. Gently push the rear ends of the CPU PCB and Power Supply PCB apart

slightly, until the two tongues on each of the Output 2/Output 3 Option

PCBs become disengaged - see Figure 2-2B; The Output 2 Option PCB

tongues engage in holes in the Power Supply PCB and the Output 3 Option

PCB tongues engage in holes on the CPU PCB.

2. Carefully pull the required Option PCB (Output 2 or Output 3) from its

connector (Output 2 Option PCB is connected to the CPU PCB and Output

3 Option PCB is connected to the Power Supply PCB) - see Figure 2-2C.

Note the orientation of the PCB in preparation for its replacement.

Adjustments may now be made to the link jumpers on the CPU PCB, the Output

2/Output 3 Option PCBs (if DC output) and (if fitted) the DC Output 1 PCB. The

replacement procedure is a simple reversal of the removal procedure.

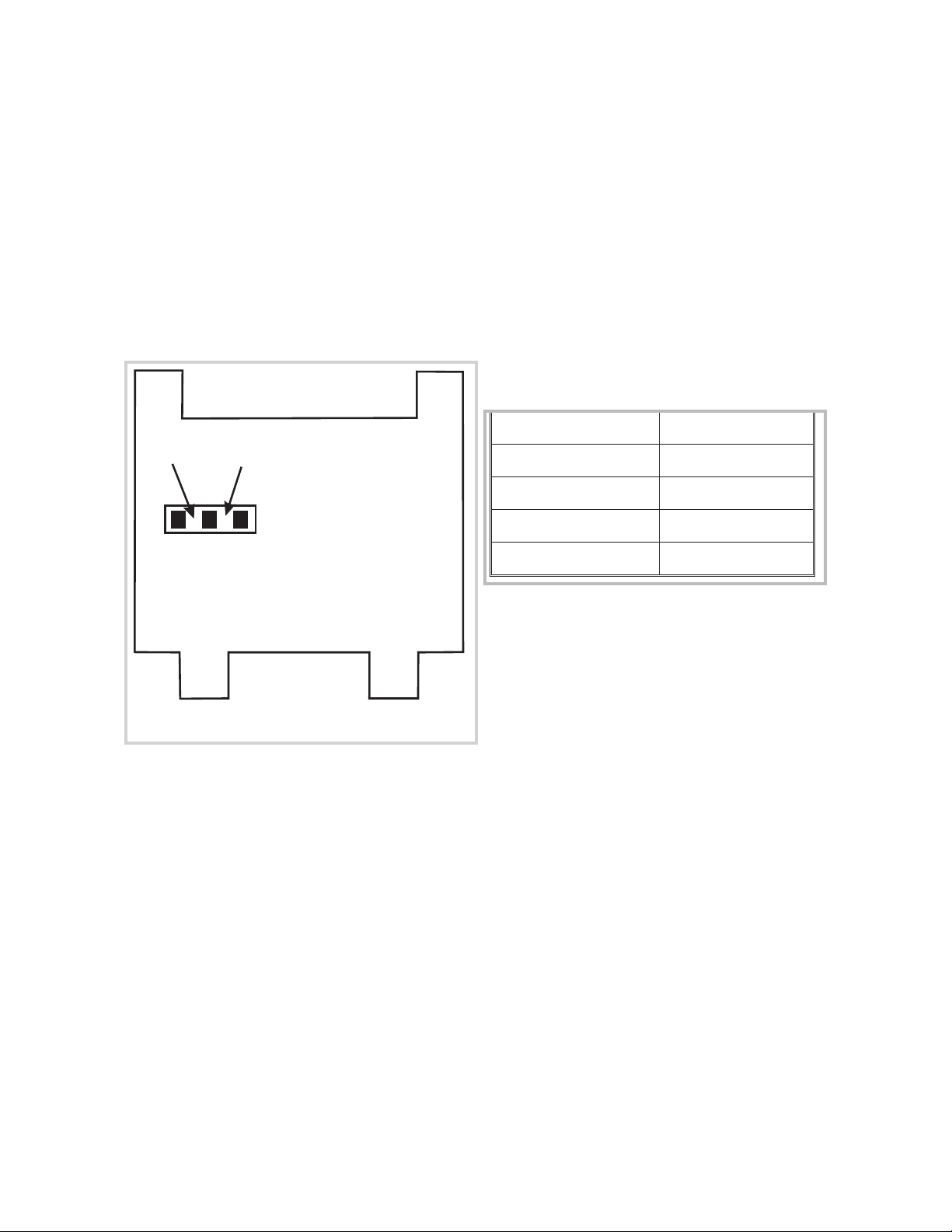

2.3 REMOVING/REPLACING THE RS485 COMMUNICATIONS

OPTION PCB OR REMOTE RUN/HOLD OPTION PCB

The RS485 Communications Option PCB or Remote Run/Hold Option PCB is

mounted on the inner surface of the Power Supply PCB and can be removed when

the instrument is removed from its housing (see Subsection 2.1) Figure 2-3

illustrates the removal/replacement procedure. It is not necessary to remove the

Output 2/Output 3 Option PCBs to perform this procedure.

2.4 REPLACING THE INSTRUMENT IN ITS HOUSING

To replace the instrument, simply align the CPU PCB and Power Supply PCB with

their guides and connectors in the housing and slowly but firmly push the

instrument into position.

CAUTION: Ensure that the instrument is correctly orientated. A stop

will operate if an attempt is made to insert the instrument in the

wrong orientation (e.g. upside-down). This stop must not be

overridden.

S077-2 Volume I 2-3

REMOVAL REPLACEMENT

View of Controller from the rear.

For clarity, the Output 2 and Output 3

Option PCBs are not shown.

PSUPCB

RS485 Serial Comms. Option PCB

or

Remote Run/Hold Option PCB

Figure 2-3 Removing the RS485 Communications Option PCB

or the Remote Run/Hold Option PCB

2.5 SELECTION OF INPUT TYPE AND OUTPUT 1 TYPE

The selection of input type and Output 1 type is accomplished on link jumpers on

the CPU PCB. The CPU PCB may be either of two forms: (a) for a relay, solid state

or SSR drive Output 1 (see Figure 2-4) or for a DC Output 1 (see Figure 2-5).

2.5.1 Input Type

The required input type is selected on

link jumpers LJ1/LJ2/LJ3 on the CPU

PCB (see Figure 2-4 or 2-5, as

appropriate, and Table 2-1).

Table 2-1 Selection of Input Type

Input Type Link Jumpers Fitted

RTD or DC (mV) None (Parked)

Thermocouple LJ3

DC (mA) LJ2

DC (V) LJ1

2-4 Volume I S077-2

LJ6

LJ4

LJ5

LJ7

LJ8

LJ9

LJ2

LJ1

LJ3

Figure 2-4 CPU PCB (Relay/SSR Drive/Solid State Output 1)

LJ1

LJ2

LJ3

Figure 2-5 CPU PCB (DC Output 1)

2.5.2 Primary Output (Output 1) Type

The required type of Output 1 is

selected by Link Jumpers LJ4, LJ5,

LJ6 and LJ7 on the Relay/SSR

Drive/Solid State Output 1 CPU PCB

(see Figure 2-4 and Table 2-2) or, on

the DC Output 1 CPU PCB, Link

Jumpers LJ8 and LJ9 (see Figure 2-5

and Table 2-2).

Table 2-2 Selection of Output 1 Type

Relay or Solid

DC (0 - 10V) LJ8

DC (0 - 20mA) LJ9

Output 1 Type Link Jumpers Fitted

LJ5 & LJ6

State

SSR Drive LJ4 & LJ7

DC (0 - 5V) LJ8

S077-2 Volume I 2-5

2.6 OUTPUT 2 TYPE/OUTPUT 3 TYPE

The type of output for Output 2 and Output 3 is determined by the Option PCB

fitted in the appropriate position (see Figure 2-1) and, in the case of the DC

Output Option PCB being fitted, the setting of Link Jumpers LJ8 and LJ9 on that

Option PCB (see Figure 2-6 and Table 2-3). There are three types of option PCB

which may be used for Output 2 and Output 3:

1. Relay Output Option PCB (no link jumpers)

2. Solid State Output Option PCB (no link jumpers)

3. SSR Drive Output Option PCB (no link jumpers)

3. DC Output Option PCB (link jumpers as shown in Figure 2-6)

Table 2-3 Selection of Output 2 &

Output 3 Type

DC Output Range Link Jumpers Fitted

LJ9 LJ8

DC (0 - 10V) LJ8

DC (0 - 20mA) LJ9

DC (0 - 5V) LJ8

Figure 2-6 DC Output Option PCB

(Output 2/Output 3)

DC (4 - 20mA) LJ9

2-6 Volume I S077-2

3 CONFIGURATION MODE

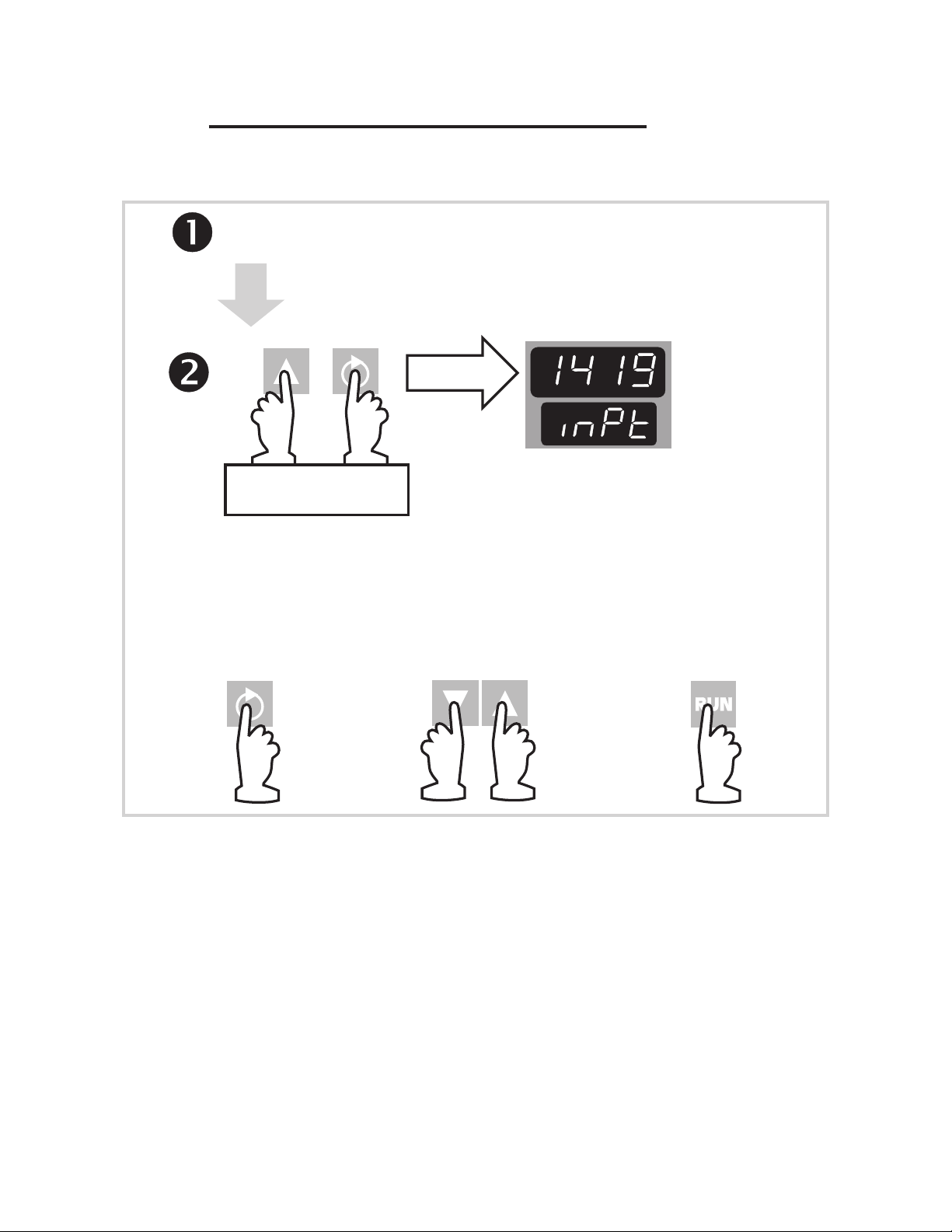

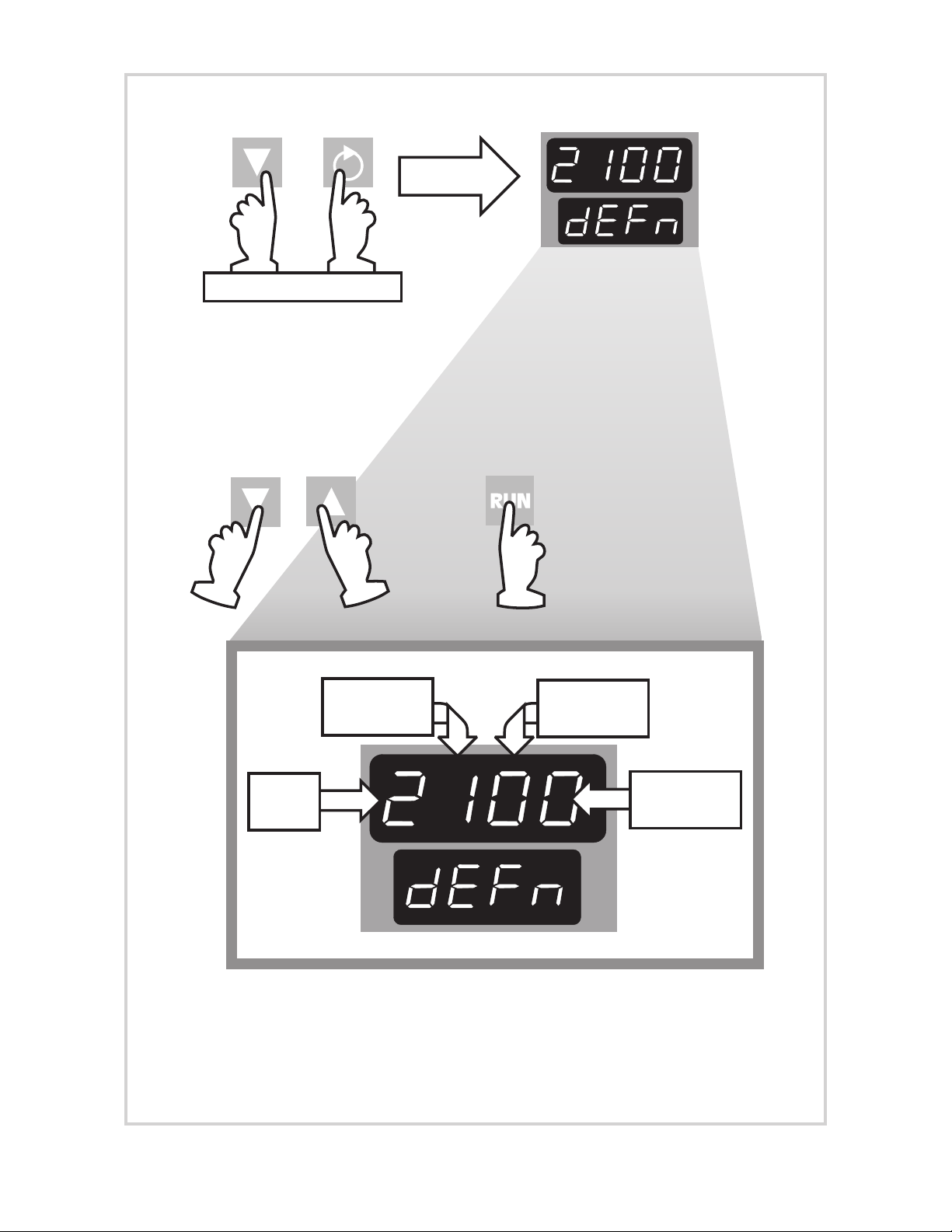

3.1 ENTRY INTO CONFIGURATION MODE

Pow e r-up the Profile C o ntrolle r.

Within 30 secs. as 1st

key action after power-up.

To di spl ay

HOLD DO WN

SIM U LTA N EO U S LY

For five seconds

In Configurat ion Mode:

To s el ec t

parameter

To c hange val ue

(upper display flashes)

Va l u e

Identifier

Profile Controller is in

Configuration Mode and

displays current input code

To c on fi r m new

value (upper

display is static)

Figure 3-1 Entry into Configuration Mode

NOTE: Changes to the value/setting of certain Configuration Mode

parameters (e.g. input range, output use and type) will cause the Set

Up Mode parameters to be automatically set to their default values

the next time Set Up Mode is entered (see also Volume II, beginning

of Section 2).

3.2 HARDWARE DEFINITION CODE

This parameter is a special facility in Configuration Mode, which is used to

represent the hardware fitted (input type, Output 1 type, Output 2 type and

Output 3 type); this must be compatible with the hardware actually fitted. For

access to, and adjustment of, the Hardware Definition Code, see Figure 3-2 and

Table 3-1.

S077-3 Volume I 3-1

C

urrentHardwar e

In Conf igurat ion Mode:

Defini tion Code

To di spl ay

SIM U LTA N EO U S LY

Use these keys also to return

to Configuration Mode.

With Hardware Definition Code displayed:

To conf ir m new

To change val ue

(upper display flashes)

value (upper

display is static)

OR

Input

Type

Output 1

Type

See also Table 3-1

Output 2

Type

Output 3

Type

Figure 3-2 Hardware Definition Code - Access and Adjustment

3-2 Volume I S077-3

Table 3-1 Hardware Definition Code - Input/Output Type Selection

Value 0 1 2 3 4 5 7 8

Input RTD/

Linear

DC mV

Output

1

Output

2/3

Not

fitted

Relay SSR

Relay SSR

Thermocouple

Drive

Drive

Linear

DC mA

DC

0 - 10VDC0 - 20mADC0-5VDC4 - 20mA

DC

0 - 10VDC0 - 20mADC0-5VDC4 - 20mA

Linear

DC V

* Output 2 only

NOTES:

1. If Output 2 is a relay/SSR drive/solid state output, it may be a control

output (COOL), an event output or an alarm output; if it is set to be a DC

output, it can only be a control output (COOL).

2. If Output 3 is a relay/SSR drive output (it cannot be a solid state output),

it can only be an event output or an alarm output; if it is set to be a DC

output, it can only be a recorder (i.e. retransmitted process variable or

setpoint) output.

Solid

State

Solid

State*

The maximum setting available for this code is 4887. For example, the code for a

thermocouple input, DC 4 - 20mA primary output (Output 1) and relay Output 3

would be 2701.

NOTE: It is essential that this code is changed promptly

whenever there is a change to the instrument’s hardware

configuration (change of input/output type, alarm/recorder

output added/removed etc.). The instrument software depends

upon this code to ensure that the instrument operates

correctly.

This code may be viewed as a Read Only display in Base Mode (see Volume II,

Subsection 1.11).

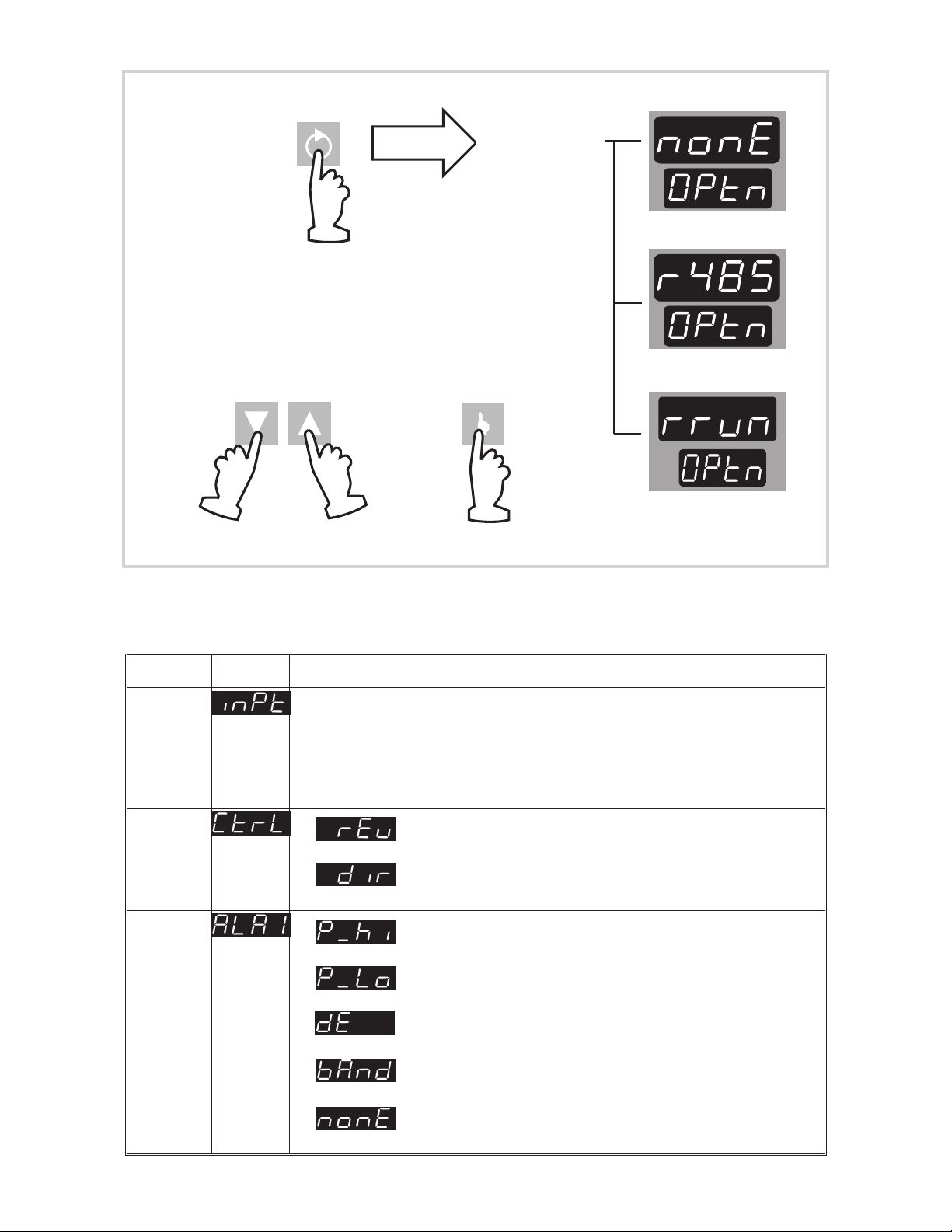

3.3 OPTION SELECTION

This indicates the option fitted (Communications Option, Remote Run/Hold option

or no option at all). It is accessed whilst the Hardware Definition Code is

displayed (see Figure 3-3).

S077-3 Volume I 3-3

With Hardw are Definition Code displayed:

To di spl ay

Use this key also to return to

the Hardware Definition Code

To confi r m new

To change selection

(upper display flashes)

selection (upper

display is static)

OR

Figure 3-3 Option Selection

One of three

No option

RS485

Rem ote

Run/Hold

3.4 CONFIGURATION MODE PARAMETERS

Parameter Identifier Description

Input

Range

Output

1

Action

Alarm 1

Type

A four-digit code (see Appendix A). Default settings:

Thermocouple - 1419 (Type J, 0 - 761°C)

RTD/Linear mV - 7220 (RTD Pt100 0 - 800°C)

Linear mA - 3414 (4 - 20mA)

Linear V - 4446 (0 - 10V)

Reverse-acting

Direct-acting

Process High Alarm

Process Low Alarm

Deviation Alarm

Band Alarm

No alarm

3-4 Volume I S077-3

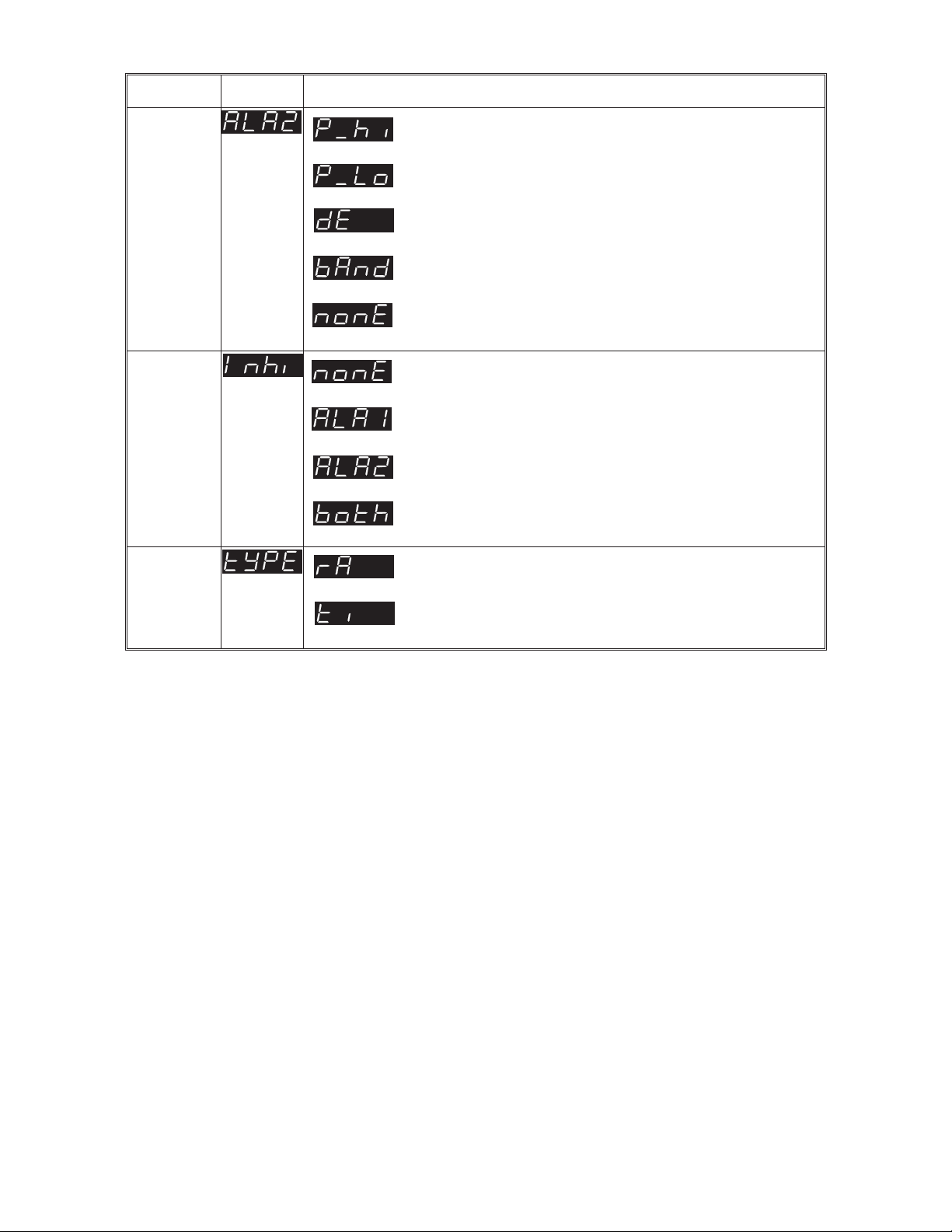

Parameter Identifier Description

Alarm 2

Type

Alarm

Inhibit

Program

Mode

Process High Alarm

Process Low Alarm (default)

Deviation Alarm

Band Alarm

No alarm

No alarms inhibited

Alarm 1 inhibited

Alarm 2 inhibited

Both Alarm 1 & Alarm 2 inhibited

Rate

Time

S077-3 Volume I 3-5

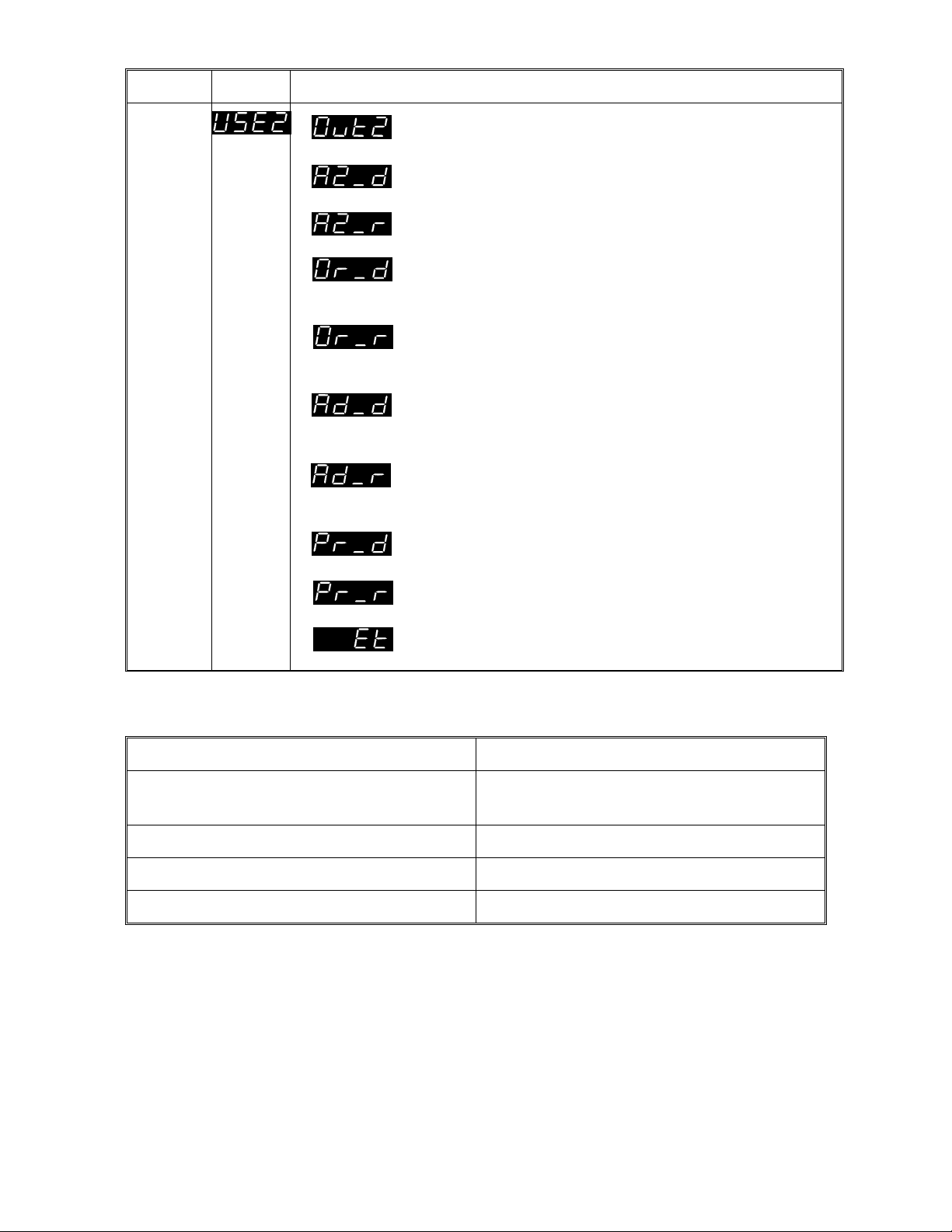

Parameter Identifier Description

Output

2

Usage

Output 2 secondary control (COOL) output

Alarm 2 hardware output, direct-acting. Available only if relay/SSR drive/solid state output.

Alarm 2 hardware output, reverse-acting. Available only if relay, SSR drive or solid state output.

Direct-acting output for Logical OR of Alarm 1

and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Reverse-acting output for Logical OR of Alarm 1

and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Direct-acting output for Logical AND of Alarm 1

and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Reverse-acting output for Logical AND of Alarm

1 and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Profile Active output, direct-acting. Available

only if relay, SSR drive or solid state output.

Profile Active output, reverse-acting. Available

only if relay, SSR drive or solid state output.

Event output, direct-acting. Available only if

relay, SSR drive or solid state output.

Example of Logical Combination of Alarms - Logical OR of Alarm 1 & Alarm 2.

Direct-acting Reverse-acting

AL1 OFF, AL2 OFF: Relay

de-energised

AL1 OFF, AL2 OFF: Relay

energised

AL1 ON, AL2 OFF: Relay energised AL1 ON, AL2 OFF: Relay de-energised

AL1 OFF, AL2 ON: Relay energised AL1 OFF, AL2 ON: Relay de-energised

AL1 ON, AL2 ON: Relay energised AL1 ON, AL2 ON: Relay de-energised

3-6 Volume I S077-3

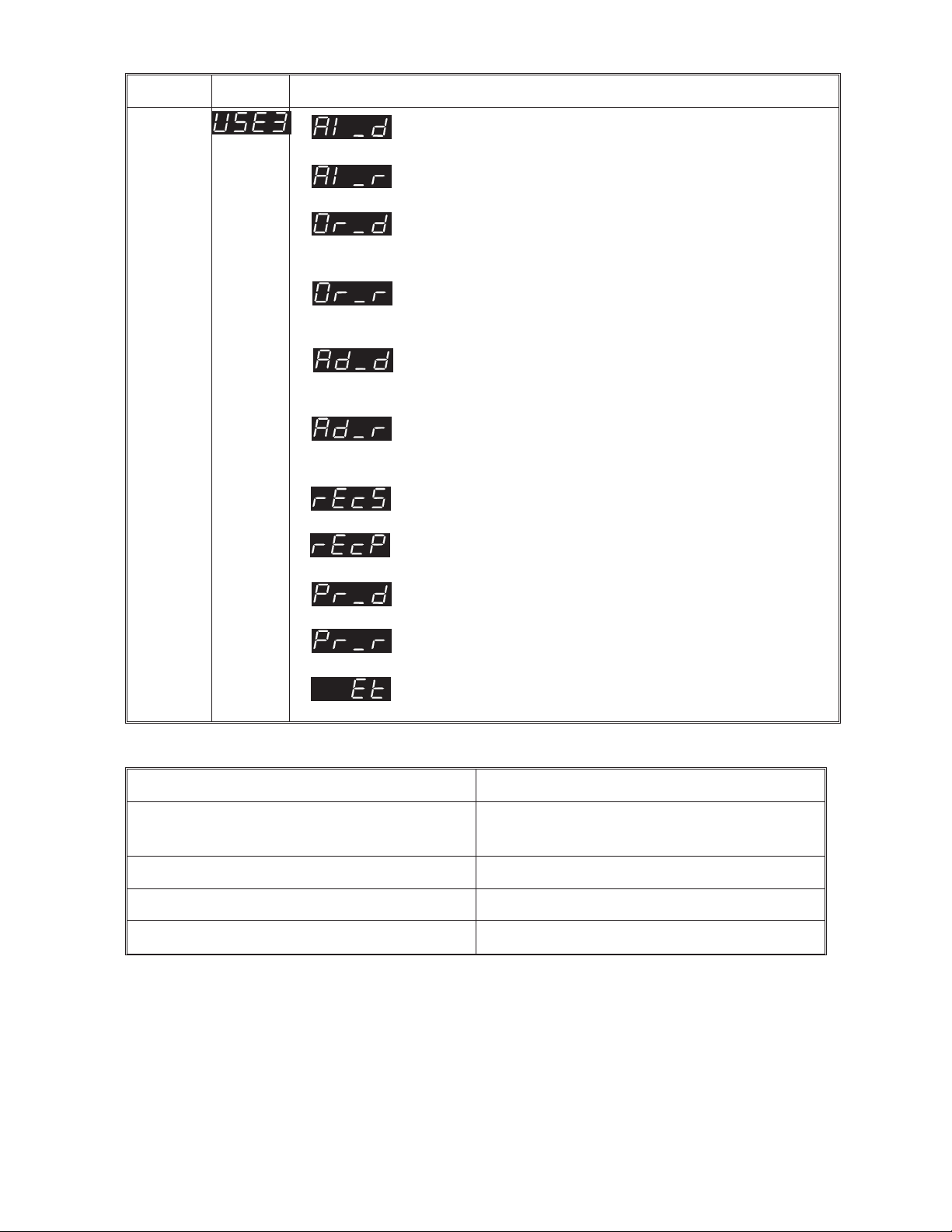

Parameter Identifier Description

Output

3

Usage

Alarm 1 hardware output, direct-acting. Available only if relay/SSR drive/solid state output.

Alarm 1 hardware output, reverse-acting. Available only if relay, SSR drive or solid state output.

Direct-acting output for Logical OR of Alarm 1

and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Reverse-acting output for Logical OR of Alarm 1

and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Direct-acting output for Logical AND of Alarm 1

and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Reverse-acting output for Logical AND of Alarm

1 and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Recorder Output - Setpoint (DC output only)

Recorder Output - Process Variable

(DC Output only)

Profile Active output, direct-acting. Available

only if relay or SSR drive output.

Profile Active output, reverse-acting. Available

only if relay or SSR drive output.

Event output, direct-acting. Available only if

relay or SSR drive output.

Example of Logical Combination of Alarms - Logical AND of Alarm 1 & Alarm 2

Direct-acting Reverse-acting

AL1 OFF, AL2 OFF: Relay

de-energised

AL1 OFF, AL2 OFF: Relay

energised

AL1 ON, AL2 OFF: Relay de-energised AL1 ON, AL2 OFF: Relay energised

AL1 OFF, AL2 ON: Relay de-energised AL1 OFF, AL2 ON: Relay energised

AL1 ON, AL2 ON: Relay energised AL1 ON, AL2 ON: Relay de-energised

S077-3 Volume I 3-7

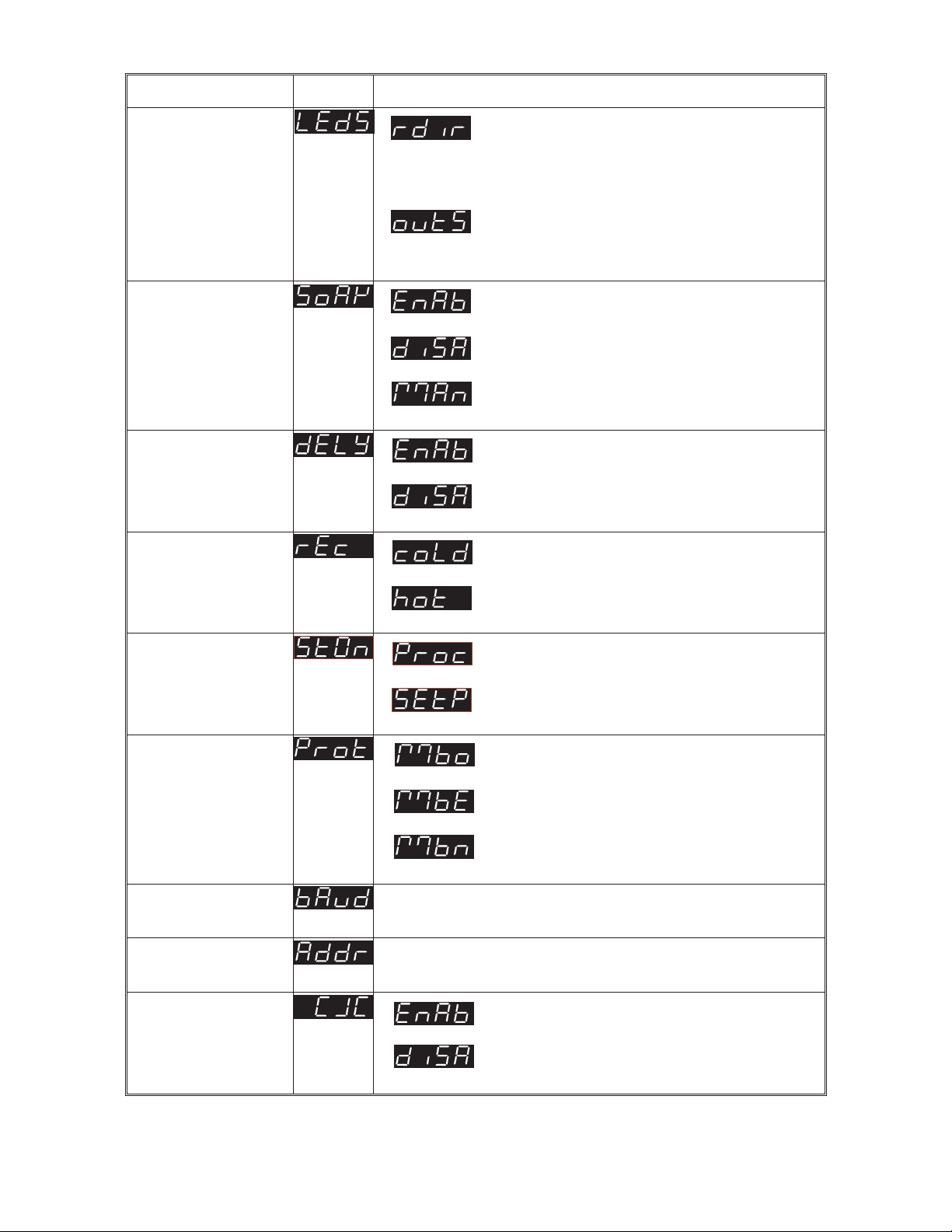

Parameter Identifier Description

D & Ñ LEDs

Usage

(on Front Panel)

Guaranteed Soak

Enable/Disable

(see Volume II,

Subsection 3.2.5)

Delayed Start

Enable/Disable

Power Loss

Recovery

Ramp direction:

D = positive ramp

Ñ = negative ramp

both = soak

Output state:

D = Output 1 ON

Ñ = Output 2 ON

Enabled

Disabled

Manual

Enabled

Disabled

Cold Start (program re-started from

beginning)

Warm Start (program resumed from

point at which power failed)

Start On Start program with setpoint at

current process variable value

Start program with setpoint at

Controller Setpoint value

Communications

MODBUS with odd parity

Protocol

MODBUS with even parity

MODBUS with no parity

Communications

Selectable: 1200, 2400, 4800, 9600 Baud

Baud Rate

Communications

Address

Cold Junction

Unique address assigned to the Profile Controller;

in the range 1 - 255.

Enabled (default)

Compensation

Enable/Disable*

Disabled

* Appears only if a thermocouple input is selected (see Hardware Definition Code).

3-8 Volume I S077-3

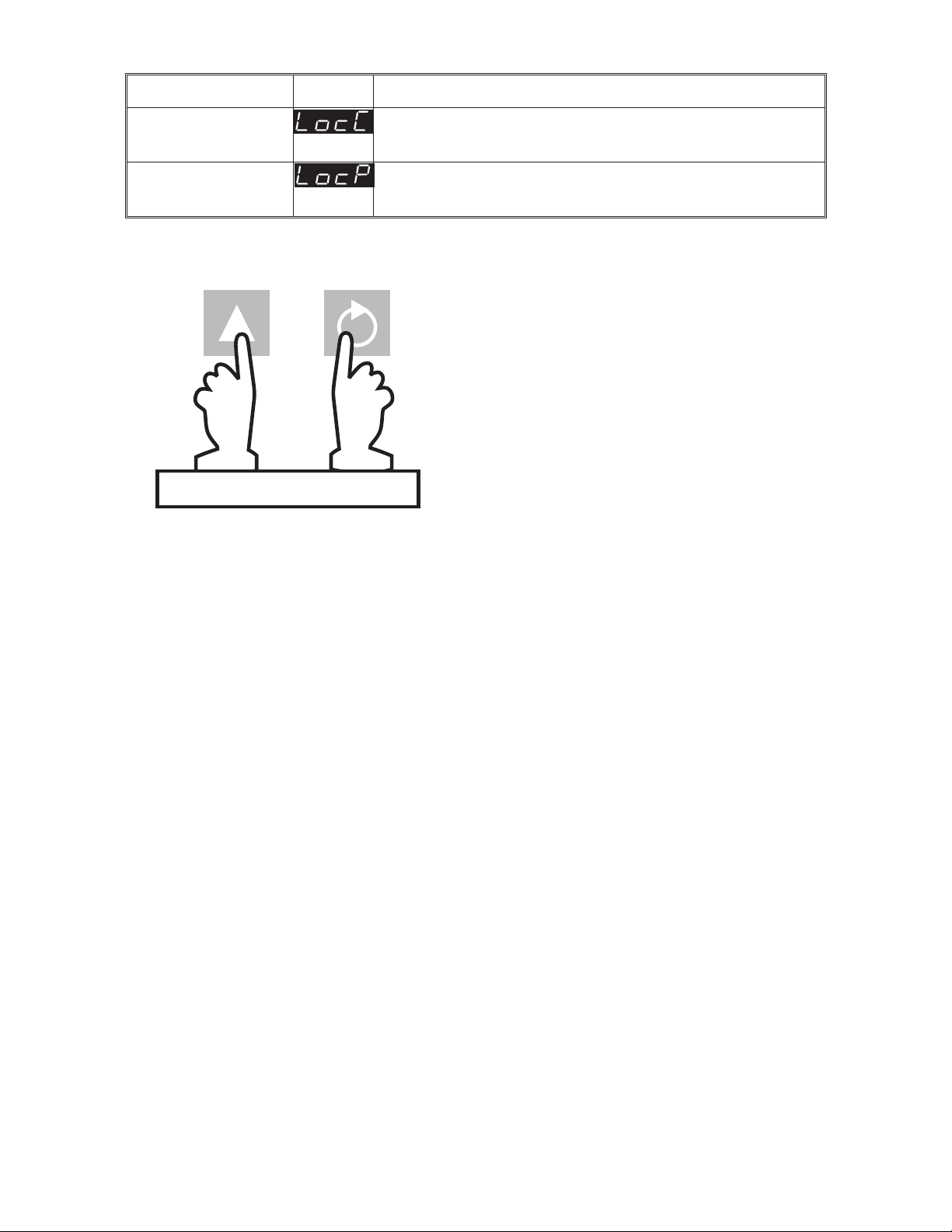

Parameter Identifier Description

Controller Set-Up

Mode Lock Code

Program Define

Mode Lock Code

Read Only display of current four-digit Set Up

Mode Lock Code.

Read Only display of current four-digit Program

Define Mode Lock Code.

3.5 EXIT FROM CONFIGURATION MODE

NOTE: An automatic exit to Operator

Mode will be made if, in Configuration

Mode, there is no front panel key

activity for two minutes.

The exit is made via the power-up self-test

routines which include a lamp test.

SIMU LTA N EO U SLY

S077-3 Volume I 3-9

1

-DIN RAMP/SOAK PROFILE CONTROLLER

16

PRODUCT MANUAL

VOLUME II

OPERATING INSTRUCTIONS

In normal operation, the operator must not remove the Ramp/Soak

Profile Controller from its housing or have unrestricted access to the

rear terminals, as this would provide potential contact with hazardous

live parts.

Installation and configuration must be undertaken only by

technically-competent servicing personnel. This is covered in Volume I

of this manual.

CONTENTS

1 BASE MODE 1-1

1.1 DISPLAY SEQUENCE - NO PROGRAM RUNNING 1-1

1.2 STARTING A PROGRAM 1-2

1.3 PUTTING A PROGRAM IN HOLD 1-2

1.4 RELEASING A PROGRAM FROM HOLD 1-2

1.5 ABORTING A PROGRAM 1-2

1.6 DISPLAY SEQUENCE - PROGRAM RUNNING 1-3

1.7 RaPID CONTROL FEATURE 1-4

1.8 PRE-TUNE FEATURE 1-4

1.9 ENGAGING BOTH PRE-TUNE AND RaPID FEATURES 1-5

1.10 INDICATION OF PRE-TUNE AND RaPID STATUS 1-5

1.11 VIEWING THE HARDWARE DEFINITION CODE 1-6

1.12 MANUAL CONTROL 1-7

PM077-V2 Volume II (i)