Page 1

Page 2

omega.com

omega.com

®

®

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

USA:

ISO 9001 Certified Stamford CT 06907-0047

One Omega Drive, Box 4047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

Servicing North America:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

®

®

®

Servicing Europe:

Benelux:

Czech Republic: Rude´ arma´dy 1868, 733 01 Karvina´ 8

France: 9, rue Denis Papin, 78190 Trappes

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Tel: +420 (0)69 6311899 FAX: +420 (0)69 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

Tel: +33 (0)130 621 400

Toll Free in France: 0800-4-06342

e-mail: sales@omega.fr

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.dl

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

FAX: +33 (0)130 699 120

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

TABLE OF CONTENTS

CNIOO SERIES TEMPERATURE MONITORS

SECTION PAGE

SECTION 1 INTRODUCTION 1

1.1 General Description 1

1.2 Available Models 1

SECTION 2 INSTALLATION 3

2.1 Unpacking 3

2.2 Controller Location 3

2.3 Mounting 3

2.4 Wiring Power Circuit 4

2.5 Sensor Placement 4

2.8 Setup Procedure 5

SECTION 3 OPERATION 6

3.1 Operation 6

3.1.1 Controls and Indicators 6

3.1.2 Relay Output 7

3.2 Adjusting Setpoints 7

3.3 Adjusting Scan Time 7

SECTION 4 SERVICE INFORMATION 7

4.1 Maintenance

4.2 Test Procedure 7

4.2.1 Visual Inspection 7

4.2.2 Functional Observation 7

4.2.3 Calibration Temperature 9

4.2.4 Calibration Alarm 10

4.2.5 Zone Crosstalk 10

4.3 Troubleshooting 11

SECTION 5 SPECIFICATIONS 12

5.1 Thermocouple 12

5.2 RTD 13

5.3 Parts List 14

5.4 Calibration Charts 17

5.4.1 Calibration Table 0-2000

5.4.2 Calibration Table 0-500

5.4.3 Calibration Table 0-250

0

F-Type K 18

0

F-Type K 19

0

C-RTD 20

5.5 Component Layouts 21

5.8 Schematic 23

7

Page 4

SECTION 1 INTRODUCTION

1.1 GENERAL DESCRIPTION

The OMEGA® CN100 Series temperature monitor is a temperature indicator with either high or low alarms. The six input

channels accept independent thermocouple inputs, and there is

an individual setpoint for each channel. In operation, the CN100

will scan each channel for 4 to 12 seconds (via side adjustment),

and the display will indicate the temperature measured by the

individual thermocouples. A red LED indicates an alarm condition; in the event of an alarm, scanning is halted and the relay deenergizes, until the manual reset button is depressed. The

CN101 models are high temperature alarms, while the CN102

units will alarm on low temperatures.

The CN102 models also feature a built-in cold start alarm

suppression. When the “START UP” LED is lit, the alarm action

is suspended until the temperatures of each input reach their

respective setpoints. Power failures for less than 30 minutes do

not affect the start-up operation.

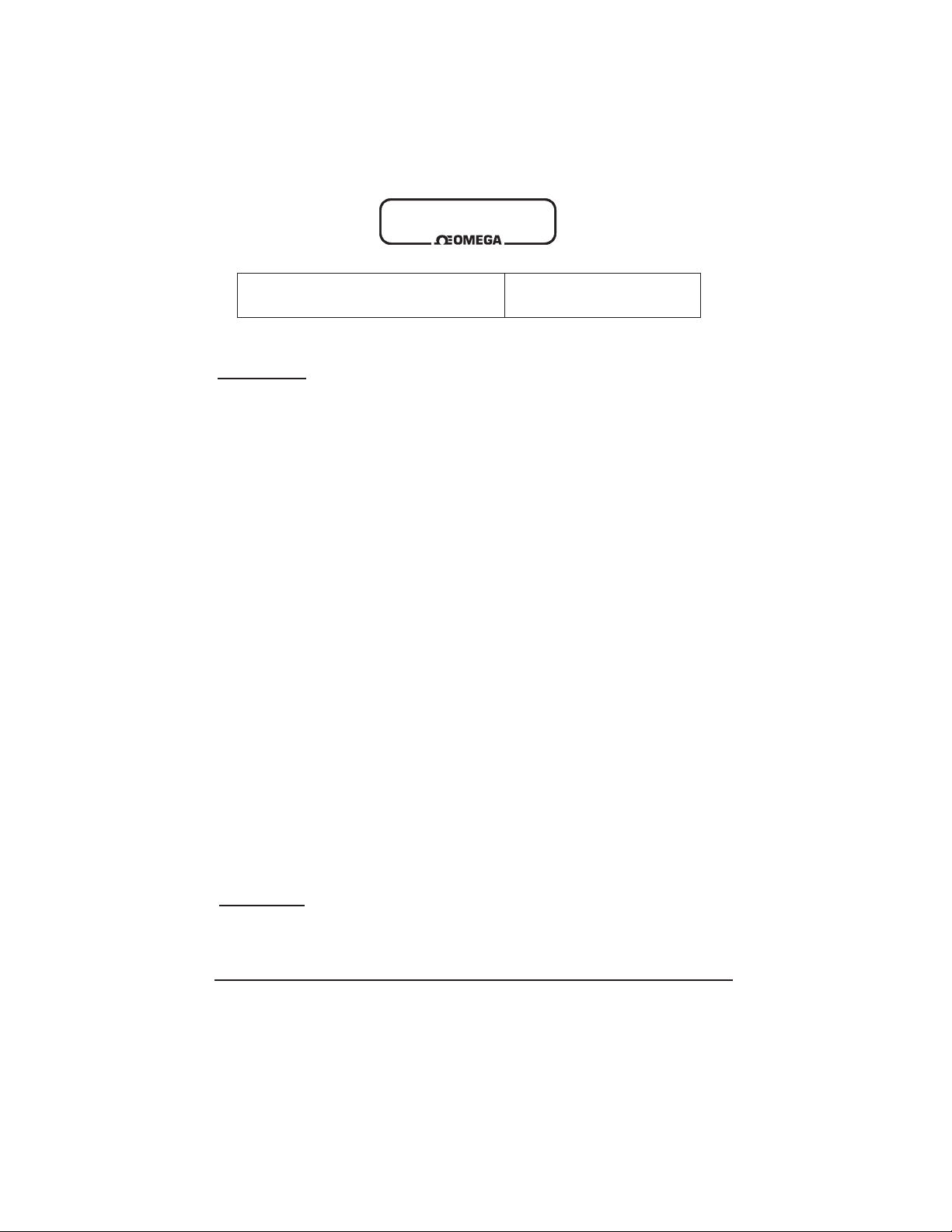

1.2 AVAILABLE MODELS

CN101(*)-(**) HIGH ALARM

1

Page 5

CN102(*)-(**) LOW ALARM

RTD#

2

Page 6

SECTION 2 INSTALLATION

2.1 UNPACKING

Remove the packing list and verify that all equipment has been

received. If there are any questions about the shipment, please

call OMEGA Customer Service Department.

Upon receipt of shipment, Inspect the container and equipment for any signs of damage. Take particular note of any

evidence of rough handling in transit. Immediately report any

damage to the shipping agent.

NOTE

The carrier will not honor any claims unless all

shipping materiel is saved for their examination.

After examining and removing contents, save

packing material and carton in the event reshipment is necessary.

2.2 CONTROLLER LOCATION

Select a location for the controller that is free from excessive

shock, vibration, dirt, moisture, and oil. The ambient temperature should be between 30° and 130°F(-1° and 54°C).

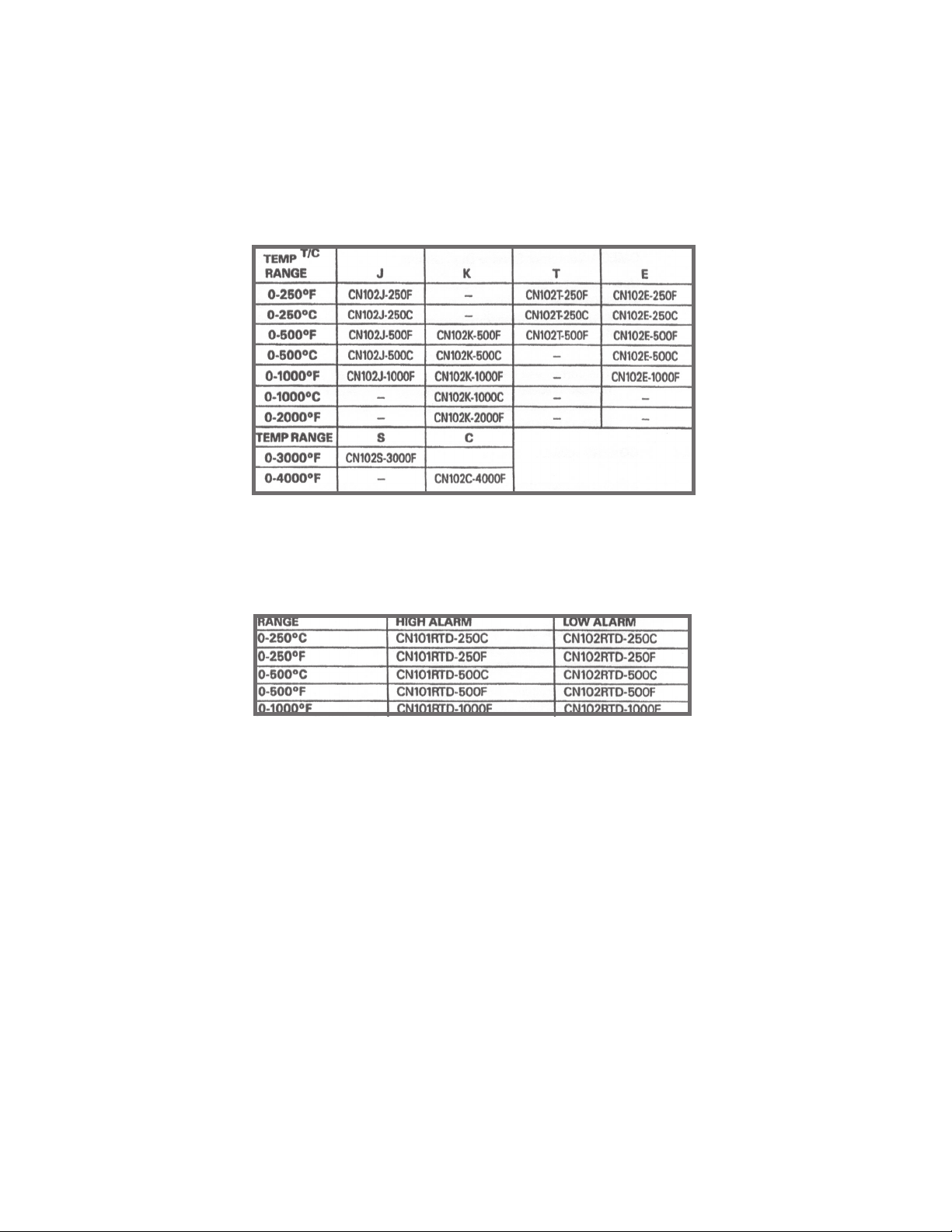

2.3 MOUNTING

Mount the controller into a 3 5/8” (92mm) square cutout. Refer

to Figure 2-1 for the cutout and case dimensions. The plugin controller does not have to be removed from its housing for

mounting.

Remove the two screws that hold the mounting slides; then

remove the slides. Insert the case into the cutout from the

front side of the panel and reinstall the two slides and two

screws. The length of the slides must be reduced if the controller is to be mounted in an extra thick panel. If the controller has been unplugged from its housing, the top of the housing can be determined by the serial tag.

.

3

Page 7

Figure 2-1. Outline Dimensions

2.4 WIRING POWER CIRCUIT

The controller operates on either 120 or 240 VAC, 50 to

60Hz line voltage when connected to the proper terminals.

Incoming power lines should be properly fused. Refer to

Figure 2-2.

NOTE

Fuse incoming high side of line with fast blow fuse

of appropriate rating. Shorted heater or wiring will

destroy the relay or output Triac.

2.5 SENSOR PLACEMENT

Proper sensor placement is essential. It can eliminate

many problems in the total system. The probe should be

placed so that it can detect any temperature change with

little thermal lag. In a process that requires fairly constant

heat output, the probe should be placed close to the heater.

In processes where the heat demand is variable, the probe

should be close to the work area. Experimenting with probe

location can often provide optimum results.

In an ice bath process, the addition of a stirrer will help to

eliminate lags. Some RTD’s are shock sensitive and

require care in handling and installation.

4

Page 8

2.2 SET UP PROCEDURE

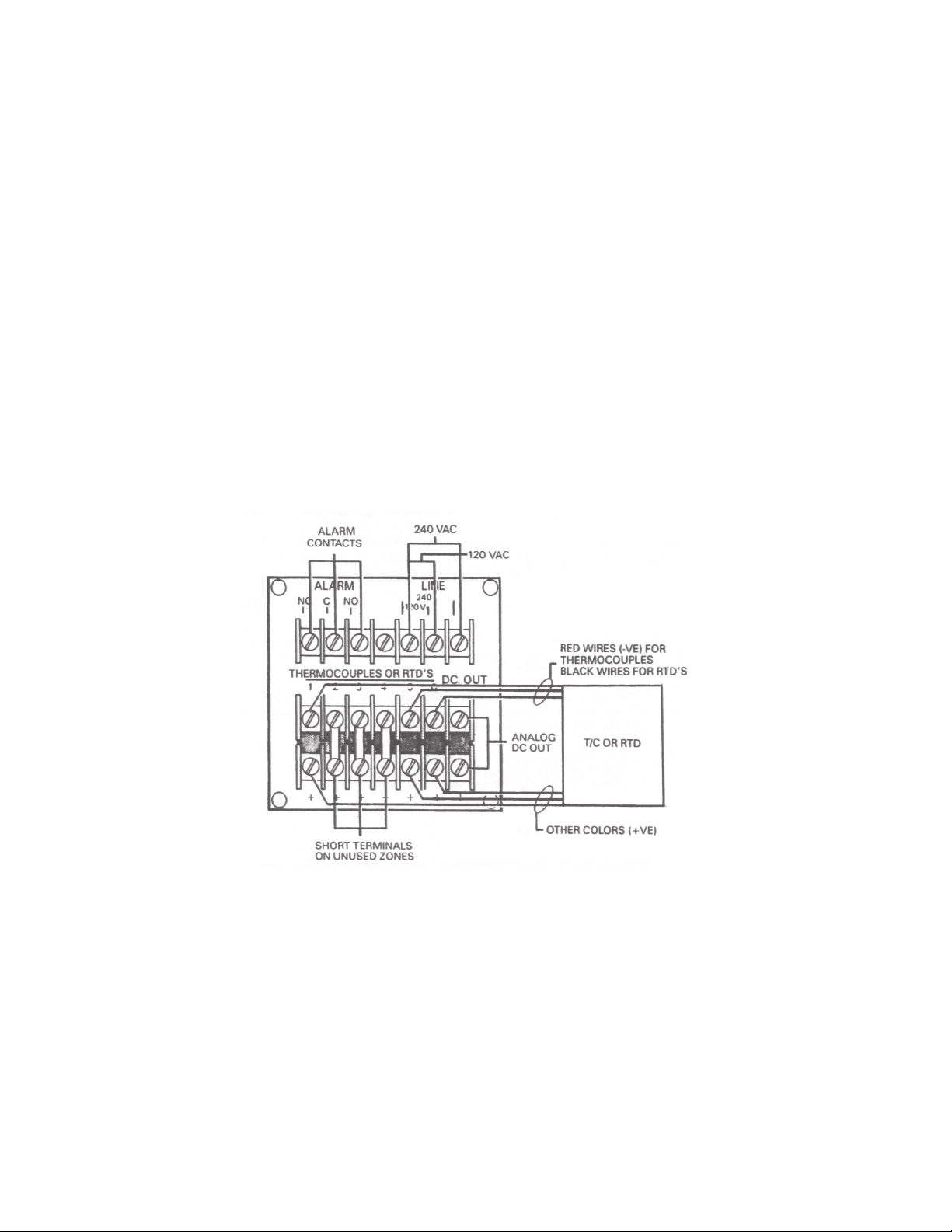

Wire the instrument as shown in Figure 2-2. Observe polarity

(on the thermocouples red is always negative, on RTDs black

is negative) and short all the unused zone inputs (do not short

the analog output). Turn all the setpoints fully CW on CN101

models and CCW on the CN102 models. Power up the

instrument. If any zone alarms, check for open thermocouples or setpoints turned the opposite way. Correct the

problem and push the RESET button. Observe the scanning

rate and readjust if needed at the side of the instrument. Push

the SET button and release. The green light should appear for

about 10 seconds and the display indicates the setpoint Adjust

the setpoint of the indicated zone to the desired alarm temperature. If more time Is needed, push the SET button to get

an additional 10 seconds. Wait for the green light to disappear

and repeat the procedure for all used zones. For unused

zones, leave the setpoints fully CW for CN101 models and

fully CCW for CN102 models.

Figure 2-2. Wiring Diagram

5

Page 9

SECTION 3 OPERATION

3.1 OPERATION

The typical control system contains the sensor, controller and

the process. The thermocouple sensor produces a small

voltage change proportional to the measured temperature of

the process. An RTD produces a change in resistance

proportional to the measured temperature of the process.

This is linearized in a unique active circuit, and amplified by the

controller, where it is compared with setpoint temperature. If

the temperature of the sensor is above setpoint, the output

circuitry will be actuated. This is indicated by means of an LED

light. The digital meter displays the sensor’s process temperature, and when switched, displays the alarm setpoints.

Six zones share common amplifier and display.

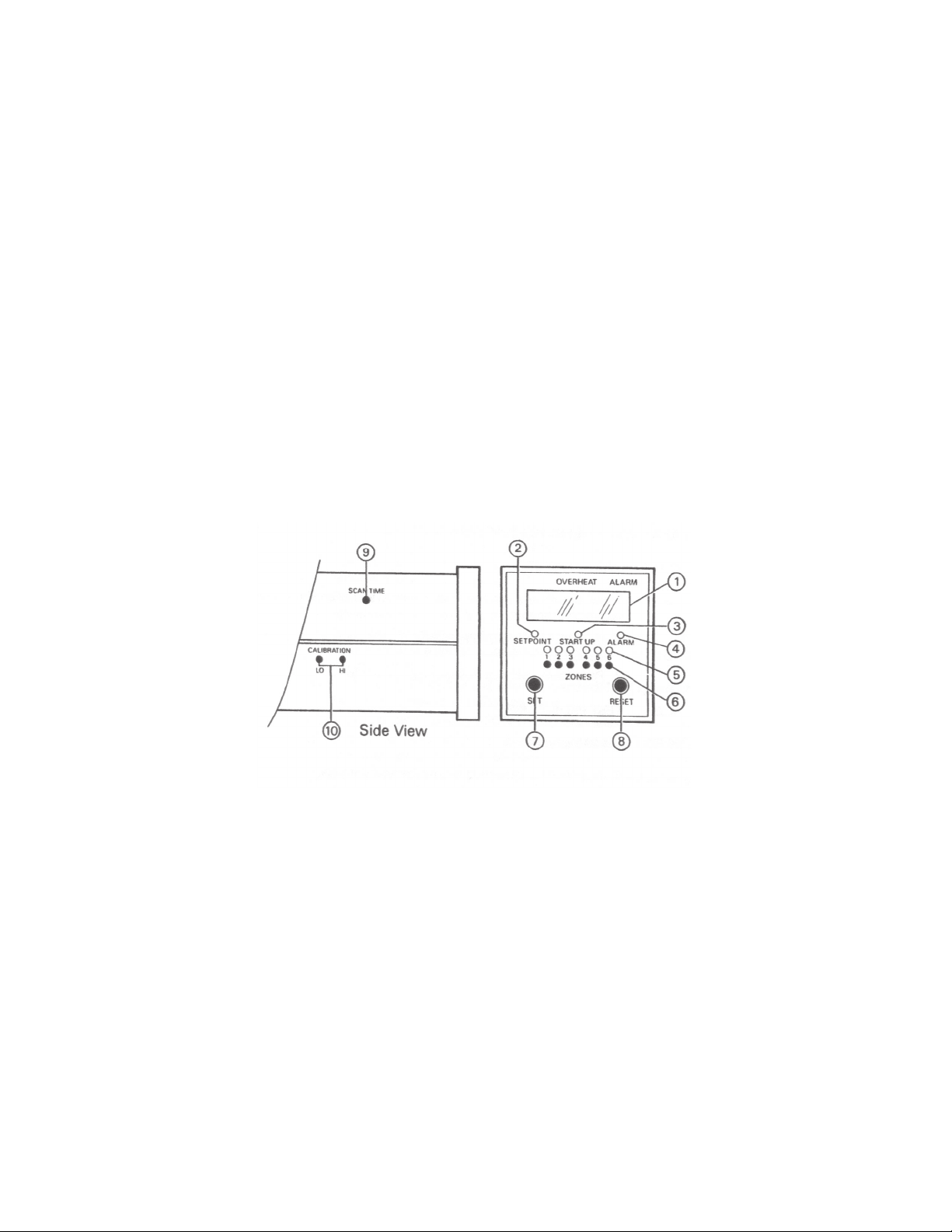

3.1.1 Controls and Indicators (Refer to Figure 3-1)

1. LED Display (temperature or setpoint)

2. Setpoint (displayed by green LED)

3. Start Up button—cold start (CN102 only)

4. Alarm Light (red LED)

5. Zone Light (yellow LED)

6. Setpoint Control

7. Setpoint Enable

8. Manual Alarm Reset

9. Scan Time Adjust

10. Calibration LO and HI potentiometers

6

Page 10

3.1.2 RELAY OUTPUT

The output relay has SPDT contacts rated 5 amps at 120V

and 3 amps at 240 VAC. These contacts can be wired to

provide power to the alarm. This is a latching relay.

3.2 ADJUSTING SETPOINTS

Six setpoint adjustments are located on the faceplate. These

are 15-turn potentiometers with slotted shafts. A small screwdriver is required.

3.3 ADJUSTING SCAN TIME

This adjustment is located on the side of the instrument. It is a

15-tum potentiometer with slotted shaft CW rotation increases the scan time.

SECTION 4 SERVICE INFORMATION

4.1 MAINTENANCE

Some simple preventative maintenance will keep the

controller operating properly:

1. Keep the controller clean and protected from dirt, oil and

corrosion.

2. Periodically recheck all electrical connections.

4.2 TEST PROCEDURE

4.2.1 Visual Inspection

1. Inspect the instrument for mechanical damage.

2. Make sure that all screws are tight.

3. Make sure all switches and lights are properly installed.

4. Make sure all labels are properly and correctly attached.

4.2.2 Functional Observation

1. Short the thermocouple or RTD inputs to each zone.

2. Attach cord and plug to 120 VAC line terminals.

3. Attach ohmmeter to C and NO relay terminals.

4. Insert the power cord to 120 VAC line outlet.

5. Observe that ohmmeter reads near zero ohms.

6. Observe that digital display is “on” and all the digits are

working properly.

7

Page 11

7. Observe that only one scan light is on.

8. Observe that digital display reading is more than zero and

less than 100

9. Adjust LO calibration potentiometer on the side of the

instrument until the display reads 75 ±5

0

F (or 0C).

0

F (25 ±50C). Refer

to Figure 4.1.

10. Turn all setpoint controls 10 turns clockwise.

11. If the alarm light (red) is on, push the RESET button and

remove the alarm.

12. Observe that zone light scans sequentially from zone to

zone without skipping any zones.

13. Turn the scan time control fully CW (about 20 turns) and

observe that the scan rate is more than 12 seconds.

14. Turn the scan time control fully CCW and observe that the

scan rate is between 2-5 seconds.

15. Set the scan time at 5 seconds ±1 second.

16. When the scan light comes to zone 1, push the set switch

and observe that the green setpoint light comes on. Observe that the light stays on for 7-15 seconds and the zone

scan light stays on zone 1 as long as green light is on.

17. Push the SET button and turn the setpoint control fully

CCW; observe that indication goes to 0000 -0 +2.

18. Observe that the alarm light comes on and ohmmeter

resistance measures HI (open).

19. Push the SET button and turn the setpoint control fully CW.

Observe that the display rises gradually from 0 to full range

of the instrument.

20. Push the RESET button and observe that the RESET light

is off and the instrument resumes scanning.

21. Repeat steps 17 through 20 for other channels.

22. Switch the power on and off several times and observe that

the unit does not go to alarm condition.

23. Disconnect the thermocouple short from zone 1 and

observe that when the scan light comes to zone 1, the

instrument indicates alarm, the meter reeds full scale, and

the scanning has stopped.

8

Page 12

4.2.3 Calibration Temperature

1. After the instrument has been warmed up for 15

minutes,

attach proper thermocouple or RTD wire to zone 1.

2. Connect the other end of the wire to the thermocouple

signal generator. Select proper cold junction compensation. Refer to Figure 4-2. For RTD version use precision

decade resistance box.

3. Bring the instrument to alarm condition by setting the

millivolt or resistance signal higher than the range of the

instrument. This will stop the scanning and keep the

instrument latched to the zone being calibrated.

4. Set the millivolt source or decade resistance box to low

calibration point as indicated on the calibration tables.

5. Adjust the LO calibration potentiometer on the side of

the instrument to read the proper typical value ±1

0

C.

±1

6. Set the millivolt source or decade resistance box to high

calibration point as indicated on the calibration tables.

7. Adjust the Hi calibration potentiometer on the side of the

instrument to read the proper typical value ±1

0

C.

±1

8. If large adjustments are made on HI calibration potentiometer, repeat steps 4 through 7 until all errors are

eliminated.

9. Check all calibration points on the table to be within

±.25% of the typical calibration.

10.Measure that the DC voltage output corresponds to the

calibration table. For RTD version, check resistance

output.

0

F or

0

F or

9

Page 13

Figure 4-2. Thermocouple Calibration

4.2.4 Calibration Alarm

1. Push the SET button and adjust zone 1 setpoint to

mid-range.

2. Set the temperature input to .25% of range below the

setpoint.

3. Push the RESET button and allow the scan light to go to

zone2.

4. Set the input to zone 1 to .25% of range above the

setpoint.

5. Observe that when the zone light comes to zone 1, the

unit goes into alarm condition within 4 seconds.

4.2.5 Zone Crosstalk

1. Set zone 1 setpoint to full range.

2. Set zone 1 temperature to 90% of its range.

3. Set zone 2 setpoint to .25% of range above its shorted

thermocouple temperature.

4. Reset alarm if necessary and allow the unit to scan.

5. Observe that zone 2 does not alarm.

10

Page 14

SYMPTOM

PROBABLE CAUSE

CORRECTIVE ACTION

1. instrument is

inactive

2. Display reads full

range unit in

alarm no scanning

3. No output, unit in

alarm

4. Reading is zero

5. Reads ambient

6. Alarm does not

reset

7. Does not read

setpoints

8. Erratic indication

9. Cannot reach

range

10.Cannot adjust

scan rate

No line voltage

Blown fuse

Dirty screw terminal

Open transformer

primary

Open thermocouple

probe or RTD probe

Burned input l.C.

Relay contacts or

relay coil

Reversed thermocouple leads

Shorted thermocouple

Broken or jammed

reset switch

Broken or loose

switch

Loose ribbon cable.

Power supply faulty

5V Reference

Broken potentiometer

Check line voltage

Replace fuse

Clean terminal

Replace power transformer.

Check probe

Replace

Check relay.

Clean or replace

Check and correct.

Check and correct.

Check and replace.

Tighten or replace.

Check cable.

Check ±12V regulators.

Check 5.03V ±.02;

adjust if necessary.

Replace potentiometer

11

Page 15

SECTION 5 SPECIFICATIONS

5.1 THERMOCOUPLE

ALARM TYPE

ACCURACY:

INPUTS:

NO. OF SETPOINTS:

SCANNING RATE:

RELAY:

ANALOG OUTPUT:

ALARM OPERATION:

RESET:

MAX. VOLTAGE BETWEEN INPUTS:

POWER:

POWER LOSS:

DISPLAY:

AMBIENT OPERATING RANGE:

DIMENSIONS:

PANEL CUTOUT:

DEPTH BEHIND PANEL:

TERMINALS:

CN1O1 models-high alarm; CN1O2

models-low alarm

±1% of range

6, thermocouple

6, independent for each input

4 to 12 seconds per channel, side

adjustment

SPDT Mechanical, rated 5A at

120 VAC, 3A at 240 VAC latching

0 to 5 VDC, scans sequentially from

zone to zone (non-isolated)

Relay de-energized. ALARM ON LED

indicator on, scan hold until reset

Manual, front pushbutton

10 VDC or 6 VRMS

120/240 VAC, 50/60 Hz

Unit returns to ready state

4-digit LED, 0.6”

32 to 1350F

3.56”H x 3.56”W x 6.25”D

1/4 DIN, 3.622” x 3.622”

6.25”

Type 6-32 screws

12

Page 16

5.2 RTD

ACCURACY:

INPUTS:

NO. OF SETPOINTS:

OPEN SENSOR INDICATION:

SCANNING RATE:

RELAY:

ANALOG OUTPUT:

ALARM OPERATION:

RESET:

MAX. VOLTAGE BETWEEN INPUTS:

POWER:

POWER LOSS:

RESOLUTION:

DISPLAY:

AMBIENT OPERATING RANGE:

DIMENSIONS:

PANEL CUTOUT:

DEPTH BEHIND PANEL:

TERMINALS:

Greater than 0.5% range ±1

RTD 100 ohm Platinum (European)

—2 wire “Top” input connector—

common to all 6 channels (negative

wire). “Bottom” input connector—

single inputs to each channel (positive

wire)

6, independent for each input

Treated as alarm

4 to 12s per channel, side adjustment

Mechanical, rate 5A @ 120 Vac

(24 Vdc), 3A @ 240 Vac (48 Vdc);

SPDT type

0 to 5 Vdc, non-isolated

Relay de-energized, ALARM ON LED

indicator on, scan hold until reset

Manual, front pushbutton

10 Vdc or 6Vrms

120/240 Vac, 50/60 Hz

Unit returns to ready state after power

resumption

10

4-digit LED, 0.6”

32 to 135

0

F

3.56” H x 3.56”W x 7” D

¼ DIN, 3.622” x 3.622”

6.25”

Type 6-32 screws

13

Page 17

5.3 PARTS LIST

P.C. Board-A

RESISTORS 1/4 WATT

1 - 220 ohm (R26)

2

- 1K (R6, R22)

4 - 1.5K (R9, R10, R11, R12)

1 - 2.2K (R17)

1 - 2.7K (R16)

6 - 4.7K (R4, R7, R8, R24, R29, R30)

7 - 10K (R2, R3, R5, R13.2, R14. R15, R23)

1 - 8.2K (R27)

1 - 18K (R28)

1 - 33K(R1)

1 - 66K (R19)

1 - lOOK (R20)

1 - 470K (R25)

PRECISION RESISTORS:

1 ‘ 400K(R18)

POTS:

1 - 2K (P3) (89PR)

2 - 1OOK (P1, P2) (89PR)

CAPACITORS:

1 - 68pF (C3)

1 - 220pF (C2)

1 - 4700 pF(C4)

3 - 0.01uF (Mylar) (C5, C8, near Q14)

1 - 2.2/50V (C7)

1

2

1

2

1

- 10/25V(C6)

- 10/50V (C9. C10)

- 100/25V (C1)

- 100/50V (C13. C141

- 1000/16V (C12)

DiODES:

9 - 1N4148 (D1, D2, D3, D4, D5, D6, D7, D8, D9)

4 - 1N4004 (D0, D11, D1Z, D13, D14)

TRANSISTORS:

7- 2N4424(Q2,Q3, Q4, Q5, Q7, Q23, Q24)

CRYSTAL:

1 ‘ 3.5795

14

Page 18

INTEGRATED CIRCUITS:

1 - 741 (Q19)

1 - 311 (Q18)

3 - 4518(Q 8,Q12, Q13)

2 - 4028 (Q1, Q16)

2 - 4040(Q11, Qi4)

2 - 4052(Q9, Q10)

1 - 4066(Q17)

1 - 4011 (Q6)

VOLTAGE REGULATORS:

1 . 317LZ (Q22)

1 - 7812(Q20)

1 - 7819(Q21)

RELAYS:

1 - 5 AMP Relay MS64-932

TRANSFORMER:

1 - 830957

HEADERS:

1 - 4161-14-03-P1 (Straight)

1 - 4162-22-06-P1

SOCKETS:

2 - 16 Pin MEGA 16MP

CONNECTOR:

1 - 4002-14-00-P5

P.C. Board-B

PRECISION RESISTOR 1%:

1 1K (R52)

1 - 250K (R53)

1 - 174K(NearP10)

POTS:

1 - 200 ohm (P10) 89PR

7 - 10K (P4, P5, P6, P7, P8, P9, P11) 89PR

15

Page 19

CAPACITORS:

1 - 2.2/50 (C25)

1 - 4.7/50V (C22)

4 - 22/50 (C15, C16, C19, C23)

RESISTORS 1/4 WATT

6 - 100 ohm (R76, R77, R78, R79, R80, R81)

7 - 1K (R29, R49, R56, R57, R58, R62, R63)

1 - 1.5K (R72)

1 - 2.2K (R64)

2 - 4.7 (R74, R83)

5 - 10K (R27, R51, R59, R67, R69)

17 - 33K (R32, R33, R34, R37, R38, R39, R40, R45, R47,

R48, R50, R54, R55, R60, R61, R68, R70)

3 - 100K (R28, R46, R91)

1 - 220K(R35)

- 330K (R30)

2 - 1 Meg. (R36, R41)

1 - 1.5 Meg. (R42)

2 - 10 Meg. (R65, R66)

DIODES:

6 - 1N4148 (D15, D16, D18, D19, D20, D23)

6 - 1N751, 1N753 or 1N754 (Z2, Z3, Z4, Z5, Z6, Z7)

TRANSISTORS:

1 - 2N4424 (Q29)

INTEGRATED CIRCUITS:

3 - 4051(Q24,Q30,Q31)

2 - uA339 (Q25,Q26)

1 - 4066(Q27)

I - 0P20 (Q28)

HEADERS:

1 - 14 PIn #4161-14-03-Pi (Straight)

SWITCHES:

2 - C&K8168(S1,S2)

2 - BIackCaps8025

2 - Metal Guards G-12A

2 - Washers

BARRIER CONNECTOR:

1 - A204207NLR50

1 - A20720NLR53

16

Page 20

CONNECTOR:

1-

4002-14-00-P5

1 - Cable #455-240-14

PC Board-C

RESISTOR 1/4 W:

7 - 47ohm

LED’s:

1 - Red (MV5754)

1 - Green (MV5454)

6 - Yellow(MV5354)

DISPLAY MODULE:

2- MAN6740

HARDWARE:

1 - Case

1-Backplate

1 - Bezel

1 - Face Plate (Metal)

1 - Face Plate (Plastic)

1 - SprIng

4 - 3/8” x 5/32” F/HD Screws

4 - 3/8” x 5/32” R/MD Screws

2 - 5/32 Nuts

1 - Red Lens

5.4 CALIBRATION CHARTS

The following charts are sample calibration charts for the

ranges 0-5000FJ, and 0-20000FK. For models other than these

ranges,it is advisable to calibrate the units at 10% and 90% FS.

17

Page 21

5.4.1 CALIBRATION TABLE 0-2000°F-TYPE-K

CN101(*)-(**)

RANGE COMPONENTS

R13.4 - 10K

R18 - 400K 1%

R62 - 1.5K

R63 - 2.2K

R64 - 1.3K

R73 - 43K

R84 - 13.3K

R85 - 27K

R86 - 110K 1%

18

Page 22

5.4.3 CALIBRATION TABLE 0-500°F-TYPE J

RANGE COMPONENTS

R13.2 - 10K

R18 - 400K 1%

R62 - 1K

R63 - 1K

R64 - 2.2K

R73 - 33K

R84 - OUT

R85 - 10K

R86 - 350K 1%

19

Page 23

5.4.3 CALIBRATION TABLE 0-250°C-RTD

NOTES

Actual temperature rounded off to whole digit (no decimal

point). Accuracy better than 0.5% of 25

0

C-2250C range.

Recommended lead wire distances to obtain stated accuracy

with proper calibration. Use copper wire. Based on ambient

temperature.

AWG Distance

14 150ft

20 50ft

24 25ft

20

Page 24

5.5 COMPONENT LAYOUT-P.C. Board A

1. Select nearest standard range resistor

(e.g. 800° = R13.3).

2. Set setpoint pot full CW (maximum).

3. Adjust P2 for required range readout.

4. Reduce R18 If range cannot be reached.

27

Page 25

5.5 COMPONENT LAYOUT-P.C. Board B

Page 26

5.6 SCHEMATIC

Page 27

Page 28

M0666/0702

Loading...

Loading...