Omega Products CN1001-RTD Installation Manual

CN1001-RTD

RTD Temperature Controller

omega.com

e-mail: info@omega.com

For latest product manuals

omegamanual.info

MADE IN

User’s Guide

Shop on line at

USA

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to alter

specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

This device is marked with the international caution symbol. It is important to read the Setup Guide before installing or commissioning this device as the guide contains important

information relating to safety and EMC.

This device is marked with the international caution symbol. It is important to read the Setup Guide before installing or commissioning this device as the guide contains

important information relating to safety and EMC.

!

®

®

OMEGAnet® On-Line Service

www.omega.com

Internet e-mail

info@omega.com

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

Mexico and TEL: (001)800-TC-OMEGA® FAX: (001) 203-359-7807

Latin America: En Español: (001) 203-359-7803

e-mail: espanol@omega.com

®

®

®

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 20 3472121 FAX: +31 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná

TEL: +420 59 6311899 FAX: +420 59 6311114

e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt

TEL: +33 1 61 37 29 00 FAX: +33 1 30 57 54 27

Toll Free in France: 0800 466 342

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 7056 9398-0 FAX: +49 7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive

ISO 9002 Certified River Bend Technology Centre

Northbank, Irlam Manchester M44 5BD United Kingdom

TEL: +44 161 777 6611 FAX: +44 161 777 6622

Toll Free in England: 0800 488 488

e-mail: sales@omega.co.uk

e-mail: sales@omega.fr

i

Table of Contents

Section Page

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. AVAILABLE ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

3. UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4. SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

5. PARTS OF THE METER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

5.1 FRONT OF THE METER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

5.2 REAR OF THE METER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

6. SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

6.1 CONDITIONS REQUIRING DISASSEMBLY . . . . . . . . . . . . . . . .10

6.2 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

6.3 RATING/PRODUCT LABEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

6.4 MAIN BOARD POWER JUMPERS . . . . . . . . . . . . . . . . . . . . . . .10

6.5 PANEL MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

7. SENSOR INPUT AND MAIN POWER CONNECTIONS . . . . . . . . . . . . . .14

7.1 SENSOR INPUT CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . .14

7.2 MAIN POWER CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . .15

7.3 ANALOG AND RELAY OUTPUT CONNECTIONS . . . . . . . . . . .17

8. INPUT TYPE (INPT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

9. DECIMAL POINT POSITION (DEC.P) . . . . . . . . . . . . . . . . . . . . . . . . . . .20

10. READING CONFIGURATION ("RD.CF") . . . . . . . . . . . . . . . . . . . . . . . .21

11. SETPOINT 1 CONFIGURATION (S1.CF) . . . . . . . . . . . . . . . . . . . . . . .22

12. SETPOINT 2 CONFIGURATION (S2.CF) . . . . . . . . . . . . . . . . . . . . . . .24

13A. SETPOINT 1 DEADBAND (S1.DB) . . . . . . . . . . . . . . . . . . . . . . . . . . .25

13B. CYCLE TIME (TIME) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

14. SETPOINT 2 DEADBAND (S2.DB) . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

ii

15. OUTPUT CONFIGURATION (OT.CF) . . . . . . . . . . . . . . . . . . . . . . . . . . .28

15.1 To Enable or Disable The Analog Output . . . . . . . . . . . . .28

15.2 To Select Analog Output as Current or Voltage . . . . . . . .29

15.3 To Select Analog Output or Proportional Control . . . . . . .29

16. PROPORTIONAL BAND (P.BND) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

17. MANUAL RESET (M.RST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

18. OUTPUT SCALE AND OFFSET (OT.S.O) . . . . . . . . . . . . . . . . . . . . . . .34

19. TUNING PROPORTIONAL CONTROLLER . . . . . . . . . . . . . . . . . . . . . .37

20. LOCK OUT CONFIGURATION (LK.CF) . . . . . . . . . . . . . . . . . . . . . . . . .38

21. DISPLAY MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

22. MENU CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

23. FRONT PANEL DISPLAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

24. SETPOINT CONFIGURATION DISPLAYS . . . . . . . . . . . . . . . . . . . . . .46

25. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

26. FACTORY PRESET VALUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

CE APPROVALS INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

iii

List of Figures

Figure Page

Figure 5-1. Front-Panel Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Figure 5-2. Connector Label (AC-Powered and DC-Powered Detail) . . . . . . .8

Figure 6-1. Main Board Power Jumpers (W1, W2, W3) . . . . . . . . . . . . . . . .11

Figure 6-2. Main Board Jumper Positions (6 S2 Pins) . . . . . . . . . . . . . . . . .11

Figure 6-3. Upper Option Board Installation . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 6-4. Meter - Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figure 6-5. Panel Cut-Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

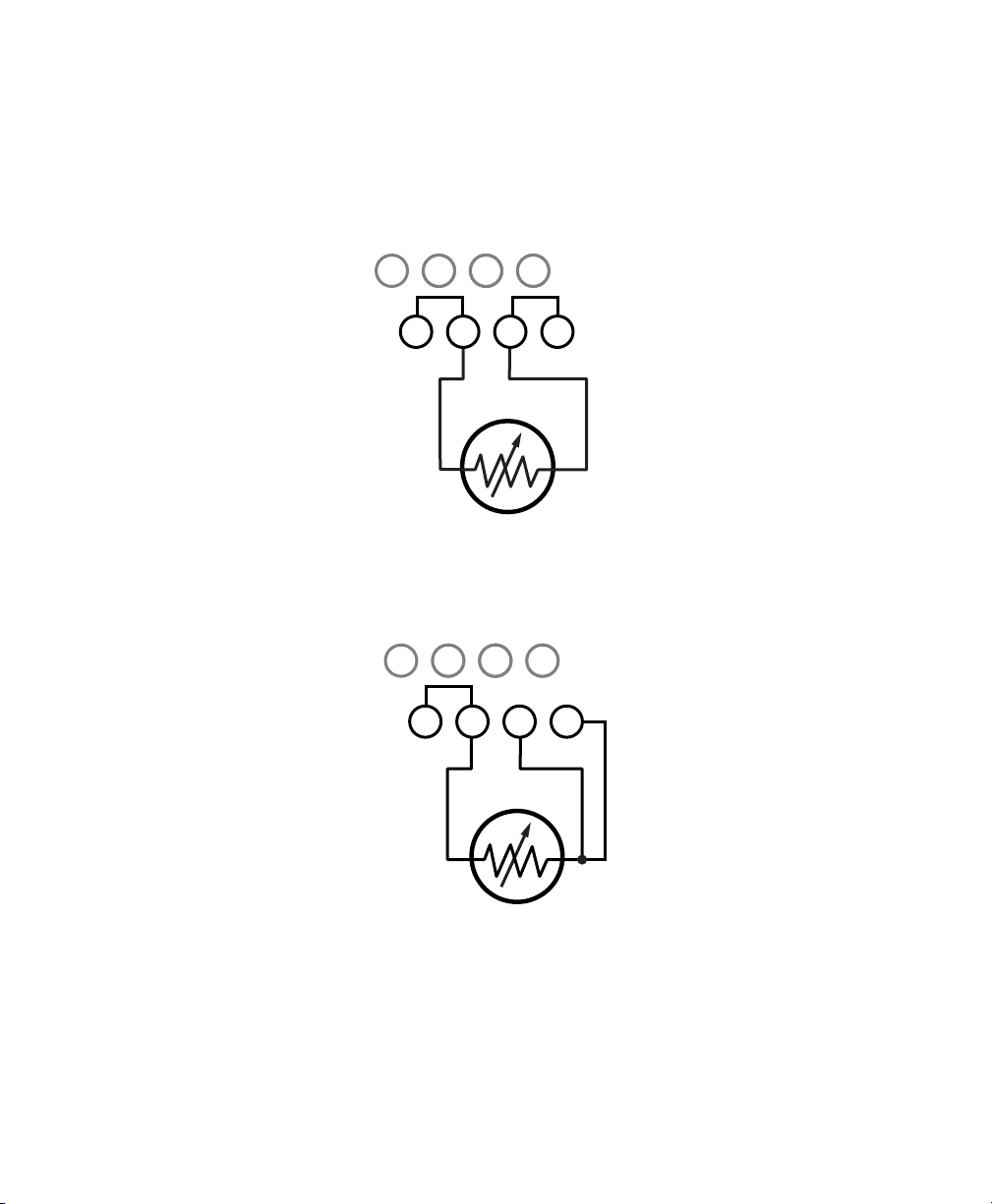

Figure 7-1. 2-Wire RTD Input Connection . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 7-2. 3-Wire RTD Input Connection . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 7-3. 4-Wire RTD Input connection . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 7-4. Main Power Connections - AC Powered Unit . . . . . . . . . . . . . . .15

Figure 7-5. Main Power Connections - DC Powered Unit . . . . . . . . . . . . . . .16

Figure 7-6. Analog Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 7-7. Relay Output Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 7-8. Transistor Output Connections. . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 7-9. Isolated Analog Output Connections. . . . . . . . . . . . . . . . . . . . . .18

Figure 16-1. Proportional Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Figure 25-1. Meter Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

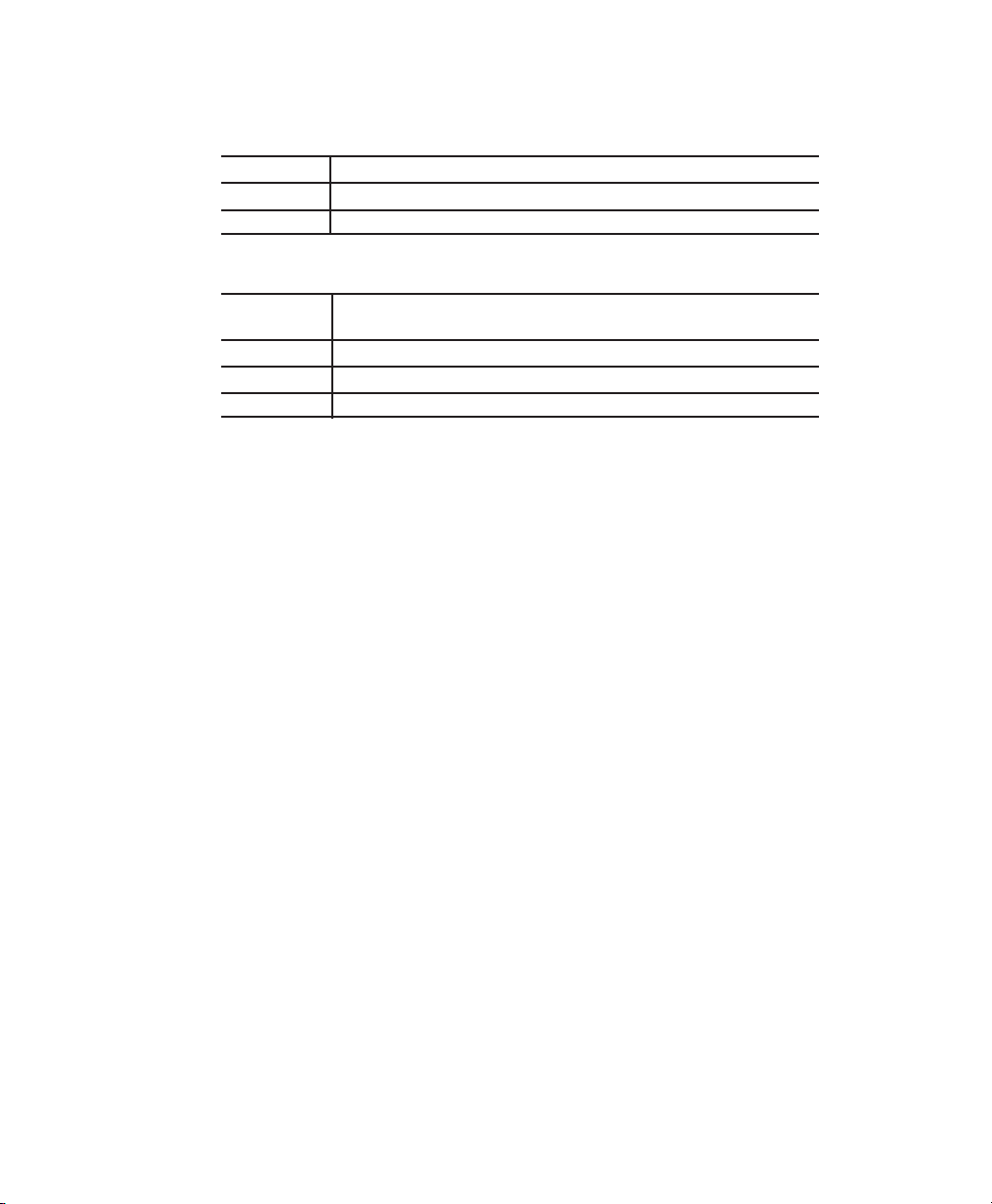

List of Tables

Table Page

Table 2-1. Accessories and Add-Ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Table 5-1. Front Panle Part Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Table 5-2. Rear Connector Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Table 6-1. S3 Jumper Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Table 7-1. Main Power Connections - AC Powered Unit . . . . . . . . . . . . . . .16

Table 21-1. Display Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Table 22-1. Menu Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Table 23-1. Front Panel Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Table 23-2. Run Mode Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Table 24-1. Setpoint Configuration Displays . . . . . . . . . . . . . . . . . . . . . . . .46

Table 26-1. Factory Preset Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

iv

SECTION 1. INTRODUCTION

1.1 DESCRIPTION

The Resistance Temperature Dector meter with Time Proportional is a

value packed indicator/ controller. Four full digits allow for an accurate

display of your temperature. Select from 2, 3, or 4 wire input

configuration. A fully scalable analog output is standard. You may

configure this output as a proportional controller, or to follow your display.

Dual 5 amp, form C relays outputs are also included with all units for

alarm or control of critical processes. Front panel peak detection and

memory is also standard. A mechanical lockout has been included to

guard against unauthorized changes.

1.2 STANDARD FEATURES

The following is a list of features:

* 4-digit, red, 14 segment LED Display

* NEMA 4 / Type 4 Front Bezel

* ±0.5 °C accuracy

* Peak Detection and Memory

* Dual 5 amp, form C relay outputs

* Scalable Analog output

* Analog out proportional or time proportional control

* Front panel controller tuning

* Non-volatile memory-no battery backup

* Easy setup for proportional control

* 115 or 230 Vac 50/60 Hz power supply or

10-32 Vdc or 26-56 Vdc

1

2

SECTION 2. AVAILABLE ACCESSORIES

Add-On Options

FS Special Calibration/Configuration

SPC4 NEMA-4 Splash Proof Cover

SPC18 NEMA-4 Splash Proof Cover, NEW

Accessories

TP1A Trimplate panel adaptor.

Adapts DIN1A/DIN2A cases to larger panel cutouts

RP18 19-In. Rack Panel for one (1) 1/8 DIN instrument

RP28 19-In. Rack Panel for two (2) 1/8 DIN instrument

RP38 19-In. Rack Panel for three (3) 1/8 DIN instrument

3

SECTION 3. UNPACKING

Remove the Packing List and verify that all equipment has been received. If

there are any questions about the shipment, use the phone numbers listed on

the back cover to contact the Customer Service Department nearest you.

Upon receipt of shipment, inspect the container and equipment for any signs of

damage. Take particular note of any evidence of rough handling in transit.

Immediately report any damage to the shipping agent.

The carrier will not honor any claims unless all shipping material is

saved for their examination. After examining and removing

contents, save packing material and carton in the event reshipment

is necessary.

Verify that you receive the following items in the shipping box:

QTY DESCRIPTION

1 Indicator/controller with all applicable connectors attached.

1 Owner's Manual

1 Set Mounting brackets

1 QuickStart Manual

If you ordered any of the available options (except the "BL" Blank

Lens option), they will be shipped in a separate container to avoid

any damage to your indicator/controller.

SECTION 4. SAFETY CONSIDERATIONS

1.2 SAFETY CONSIDERATIONS

This device is marked with the international caution symbol. It is important to

read this manual before installing or commissioning this device as it contains

important information relating to Safety and EMC (Electromagnetic Compatibility).

This instrument is a panel mount device protected in accordance with EN 610101:2001, electrical safety requirements for electrical equipment for measurement, control

and laboratory. Installation of this instrument should be done by qualified personnel. In

order to ensure safe operation, the following instructions should be followed.

This instrument has no power-on switch. An external switch or circuit-breaker shall

be included in the building installation as a disconnecting device. It shall be marked to

indicate this function, and it shall be in close proximity to the equipment within easy

reach of the operator. The switch or circuit-breaker shall not interrupt the Protective

Conductor (Earth wire), and it shall meet the relevant requirements of IEC 947–1 and

IEC 947-3 (International Electrotechnical Commission). The switch shall not be

incorporated in the main supply cord.

Furthermore, to provide protection against excessive energy being drawn from the main

supply in case of a fault in the equipment, an overcurrent protection device shall be

installed.

• Do not exceed voltage rating on the label located on the top of the instrument

housing.

• Always disconnect power before changing signal and power connections.

• Do not use this instrument on a work bench without its case for safety reasons.

• Do not operate this instrument in flammable or explosive atmospheres.

• Do not expose this instrument to rain or moisture.

• Unit mounting should allow for adequate ventilation to ensure instrument does not

exceed operating temperature rating.

• Use electrical wires with adequate size to handle mechanical strain and power

requirements. Install without exposing bare wire outside the connector to minimize

electrical shock hazards.

EMC Considerations

• Whenever EMC is an issue, always use shielded cables.

• Never run signal and power wires in the same conduit.

• Use signal wire connections with twisted-pair cables.

• Install Ferrite Bead(s) on signal wires close to the instrument if EMC problems

persist.

Failure to follow all instructions and warnings may result in injury!

4

SECTION 5. PARTS OF THE METER

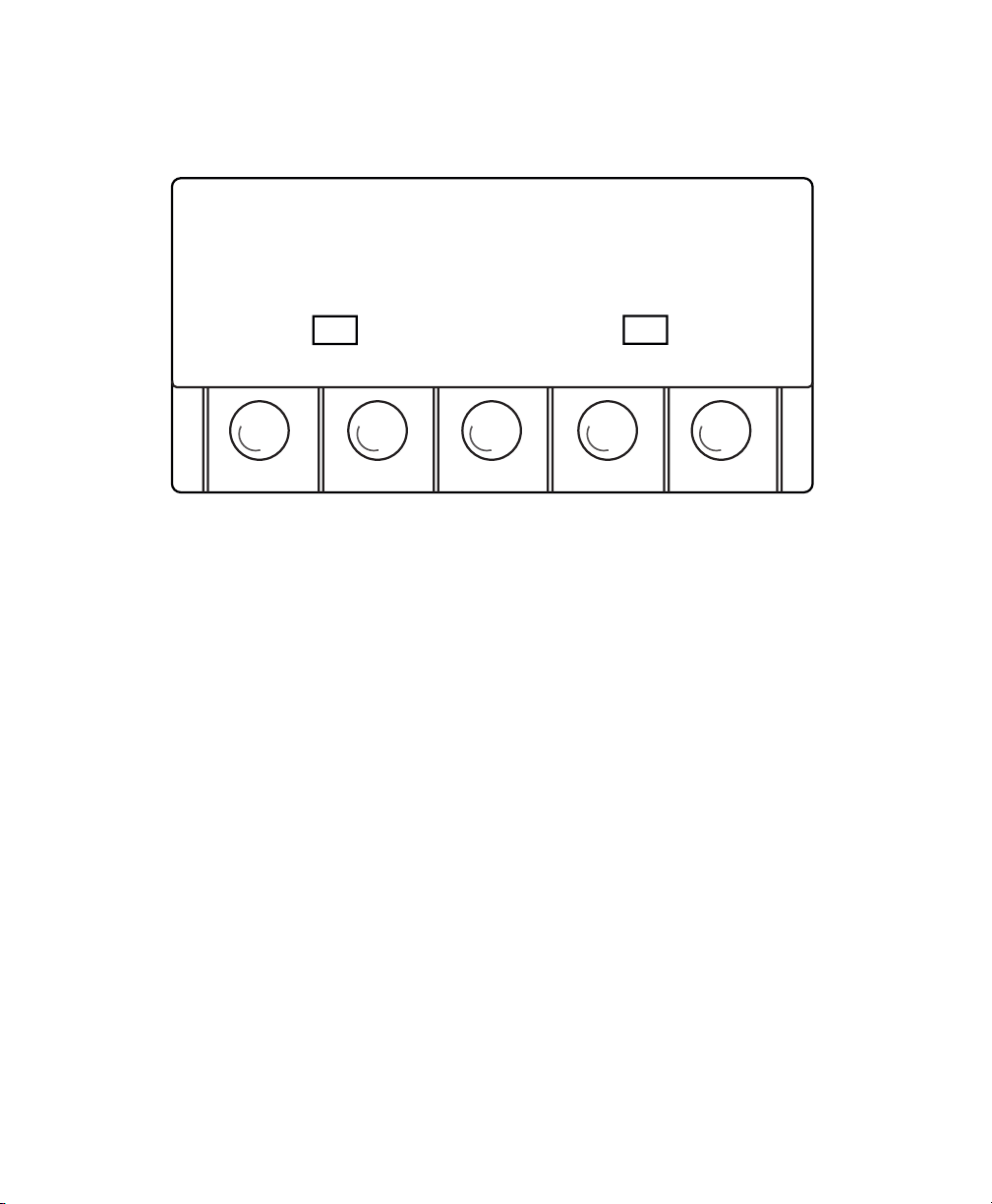

Figure 5-1 shows each part of the front of the meter. Table 5-1 gives a

brief description of each part.

Figure 5-1 Front Panel Illustration

1- Setpoint 1 status

2 - Setpoint 2 status

5

//

••••

12

RESETMENU

DEVMAXSETPTS

Table 5-1 Front PanelPart Description

ITEM Description

1 -1.9.9.9. or 9.9.9.9.

4-digit 14 segment, 0.54” high LED display with programmable

decimal point.

2 SETPOINT LED

These LEDs labled 1 and 2 display the status of setpoints 1 and 2.

3 SETPTS Button

This button functions only in the run mode. When the meter is in the run

mode, press this button to sequentially recall the previous setpoint

settings. After using the

/MAX and /DEV buttons to alter these

settings as desired, press the SETPTS button to store these new values.

Unless you press the SETPTS button within 20 seconds to store your

input, the meter will scroll to setpoint 2 and retain the last value stored.

If the “L.3=1” on the “LK.CF” menu, pressing the SETPTS button will

display the meter's firmware version.

4

/MAX Button

During the run mode, press the

/MAX button to recall the PEAK reading

since the last press of the RESET button. To return to the current

readings without resetting the PEAK reading, press the

/MAX button.

To reset the PEAK reading, press the RESET button.

During the configuration mode, use the

/MAX button to change the

values of the flashing digit shown on the display and/or toggle between

menu choices, such as "R.1=F" or "R.1=C". When configuring your

setpoint values, press the

/MAX button to increment the flashing digit

from 0 to 9 by 1's.

6

5

/DEV Button

During the run mode press the

/DEV button to display the deviation

from setpoint 1.

When configuring your setpoint values, press the

/DEV button to scroll

to the next digit.

6 MENU Button

In the run mode, press the MENU button to terminate the current

measuring process and enter you into the configuration mode.

In the configuration mode, press the MENU button to store changes in

the non-volatile memory and then advance you to the next menu item.

7 RESET Button

In the run mode, press the RESET button to reset the setpoints and

display "SP.RS". If display shows peak value, press the RESET button

to reset peak value. Display shows "PK.RS".

In the configuration mode, press the RESET button once to review the

previous menu.

Pressing the RESET button twice results in a hard reset and returns you

to the run mode.

7

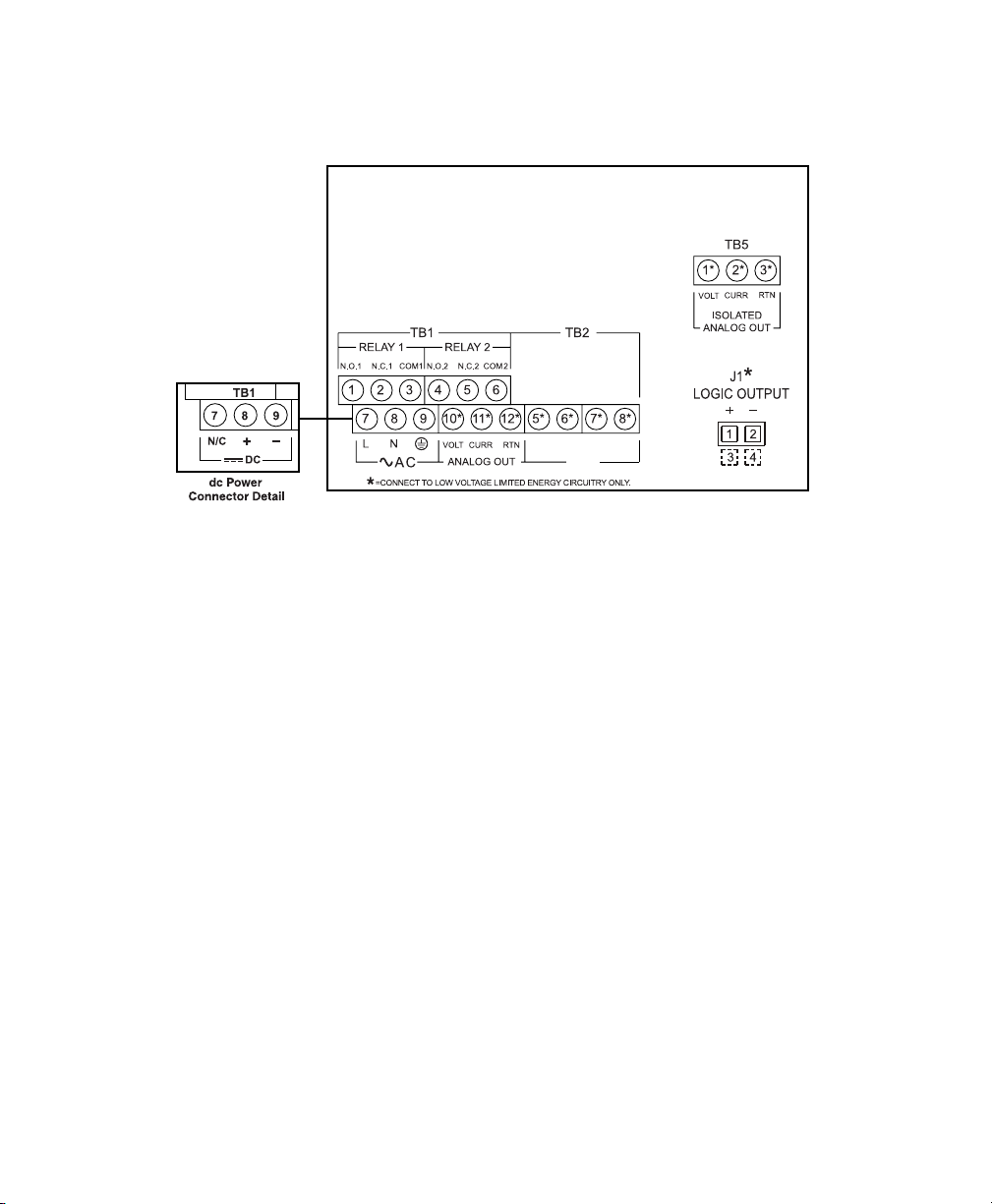

5.2 REAR OF THE METER

Figure 5-2 shows the connector label mounted at the top of the meter

housing. Table 5-2 gives a brief description of each connector at the back

of the meter.

Figure 5-2 Connector Label (ac power with dc detail)

8

POWER & INPUT CONNECTIONS

(RTD PROPORTIONAL)

+E1 +S1 -S1 -E1

RTD

5.2 REAR OF THE METER (Continued)

Table 5-2 Rear Connector Description

Connector Description

TB1-1 Setpoint 1: Normally open (N.O.1) connection

TB1-2 Setpoint 1: Normally closed (N.C.1) connection

TB1-3 Setpoint 1: Common (COM1) connection

TB1-4 Setpoint 2: Normally open (N.O.2) connection

TB1-5 Setpoint 2: Normally closed (N.C.2) connection

TB1-6 Setpoint 2: Common (COM2) connection

TB1-7 ac line connection (no connections on dc-powered units)

TB1-8 ac neutral connection (+ Input on dc-powered units)

TB1-9 ac Earth ground (-dc-power return on dc-powered units)

TB1-10 Analog 1 voltage output

TB1-11 Analog 2 current output

TB1-12 Analog 3 return

TB2-1 not used

TB2-2 not used

TB2-3 not used

TB2-4 not used

TB2-5 +E1: Positive excitation (current source)

TB2-6 +S1: Positive signal input

TB2-7 -S1: Negative signal input

TB2-8 -E1: Negative excitation

TB5-1 Isolated Analog Voltage Output

TB5-2 Isolated Analog Current Output

TB5-3 Isolated Analog Output Return

J1-1 Transistor Logic Output (positive)

J1-2 Transistor Logic Output (negative)

9

10

SECTION 6. SETUP

6.1 CONDITIONS REQUIRING DISASSEMBLY

You may need to open up the meter for one of the following reasons:

• To check or change the 115 or 230 Vac power jumpers.

• To install or remove jumpers on the main board.

6.2 CONDITIONS REQUIRING DISASSEMBLY

Disconnect the power supply before proceeding.

To remove and access the main board, follow these steps:

• Disconnect the main power from the meter.

• Remove the back case cover.

• Lift the back of the main board upwards and let it slide out of the

case.

Caution: The meter has no power-on switch, so it will be in

operation as soon you apply power.

6.3 RATING/PRODUCT LABEL

This label is located on top of the meter housing (Refer to Figure 6-4).

6.4 MAIN BOARD POWER JUMPERS

Important: If you want to change the Factory preset jumpers, do the

following steps; otherwise go to section 6.5.

Warning: Disconnect the power from the unit before proceeding.

This device must only be reconfigured by a specially trained

electrician with corresponding qualifications. Failure to follow all

instructions and warnings may result in injury!

To check voltage jumpers, or to change from 115 V to 230 V ac:

1. Remove the main board from the case. Refer to Section 6.2.

2. Locate the solder jumpers W1, W2, and W3 (located near the edge of

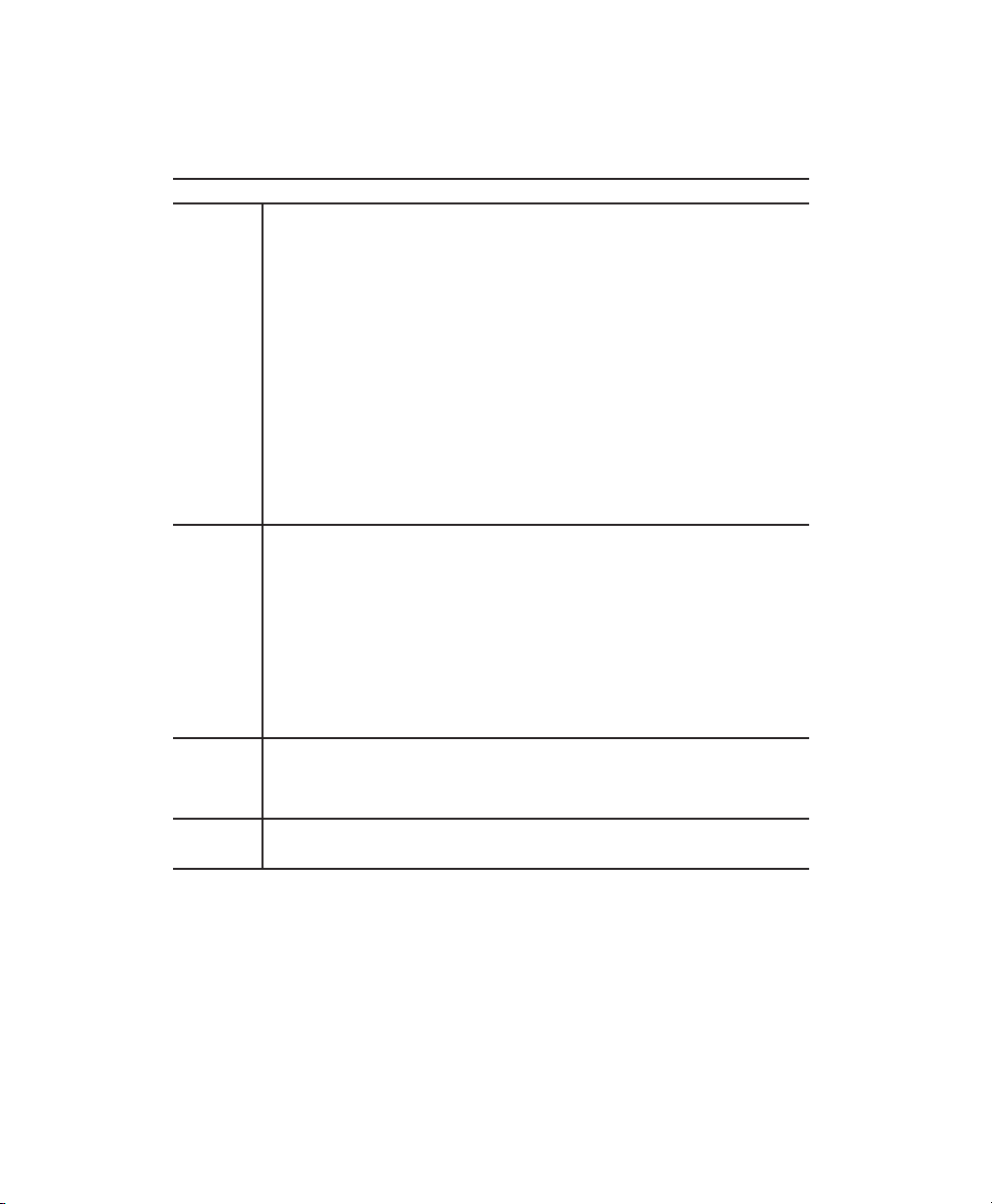

the main board alongside the transformer - refer to Figure 6-1).

3. If your power requirement is 115 V ac, solder jumpers W1 and W3

should be wired, but jumper W2 should not. If your power

requirement is 230 V ac, solder jumper W2 should be wired, but

jumpers W1 and W3 should not.

6.4 MAIN BOARD POWER JUMPERS (continued)

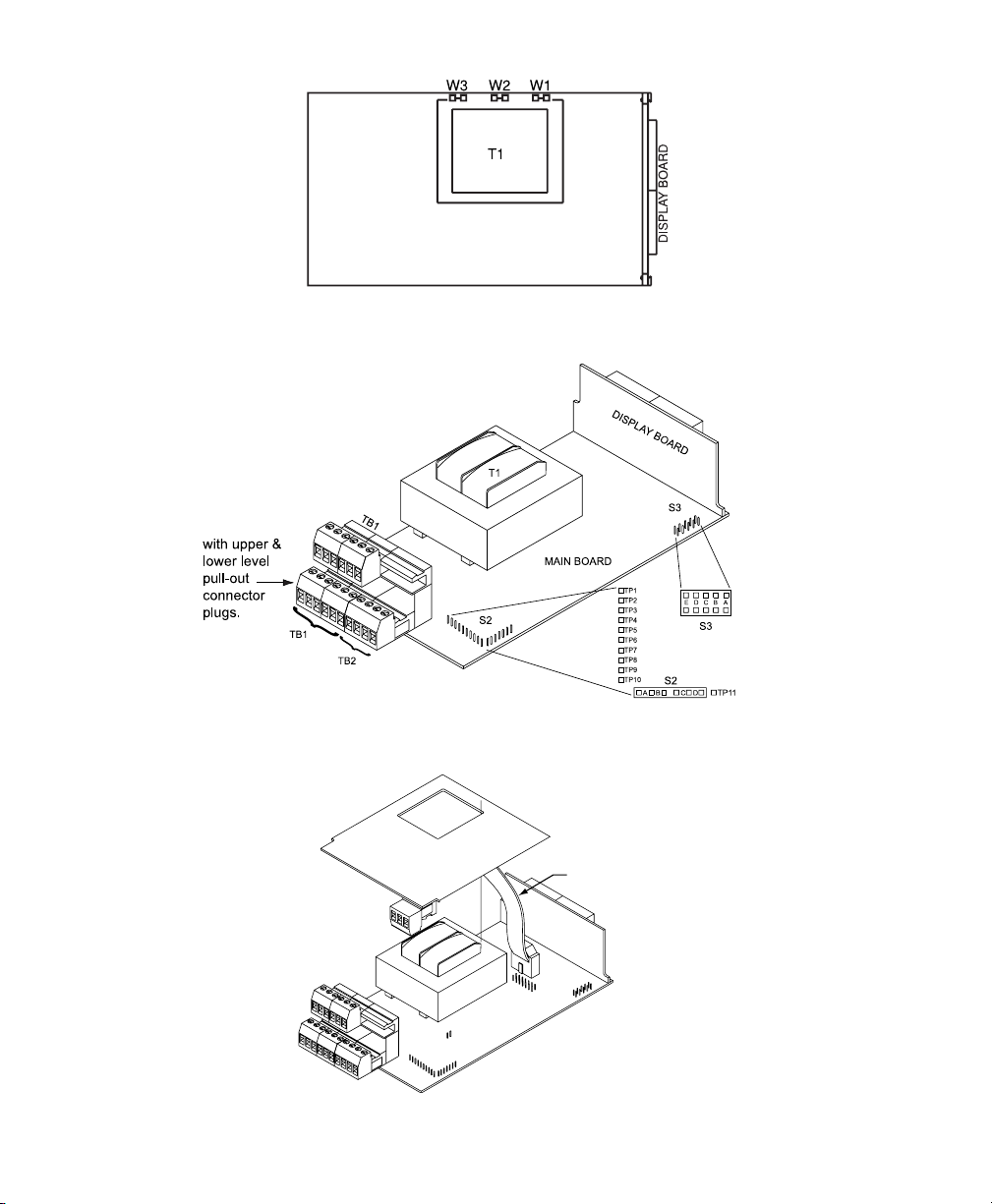

Figure 6-1 Main Board Power Jumpers (W1, W2, W3)

Figure 6-2 Main Board Jumper Positions

Figure 6-3 Upper Isolated Analog Outlook Option Board Installation

11

Attach cable

to P1.

TB5

P1

6.4 MAIN BOARD POWER JUMPERS (Continued)

Refer to Figure 6-2.

S2 jumpers are for sensor break indications:

* S2A jumper is not used

* S2B jumper is for positive sensor break (i.e. heating)

* S2C & S2D are not used

S3 jumpers are used for the following (refer to Table 6-1):

* To enable or disable the front panel push-buttons

* To allow for an extremely low resistance load for analog output

* To disable the MENU button

Test pins TP1 - TP11 are for testing purposes. Do not use as reading errors

may result.

Table 6-1 Jumper Functions

Jumper Description

S3-A Install to enable front panel push-buttons.

Remove to disable all front panel push-buttons

S3-B Removed. Install for factory calibration only.

S3-C Normally removed. Install for analog voltage output

when load is less than 1 KW impedance. Care should be

taken when installing this jumper.

S3-D Removed. Not used.

S3-E If installed without S3-B, the MENU button locks out.

If you press the MENU button, the meter shows "LOCK".

12

6.5 PANEL MOUNTING

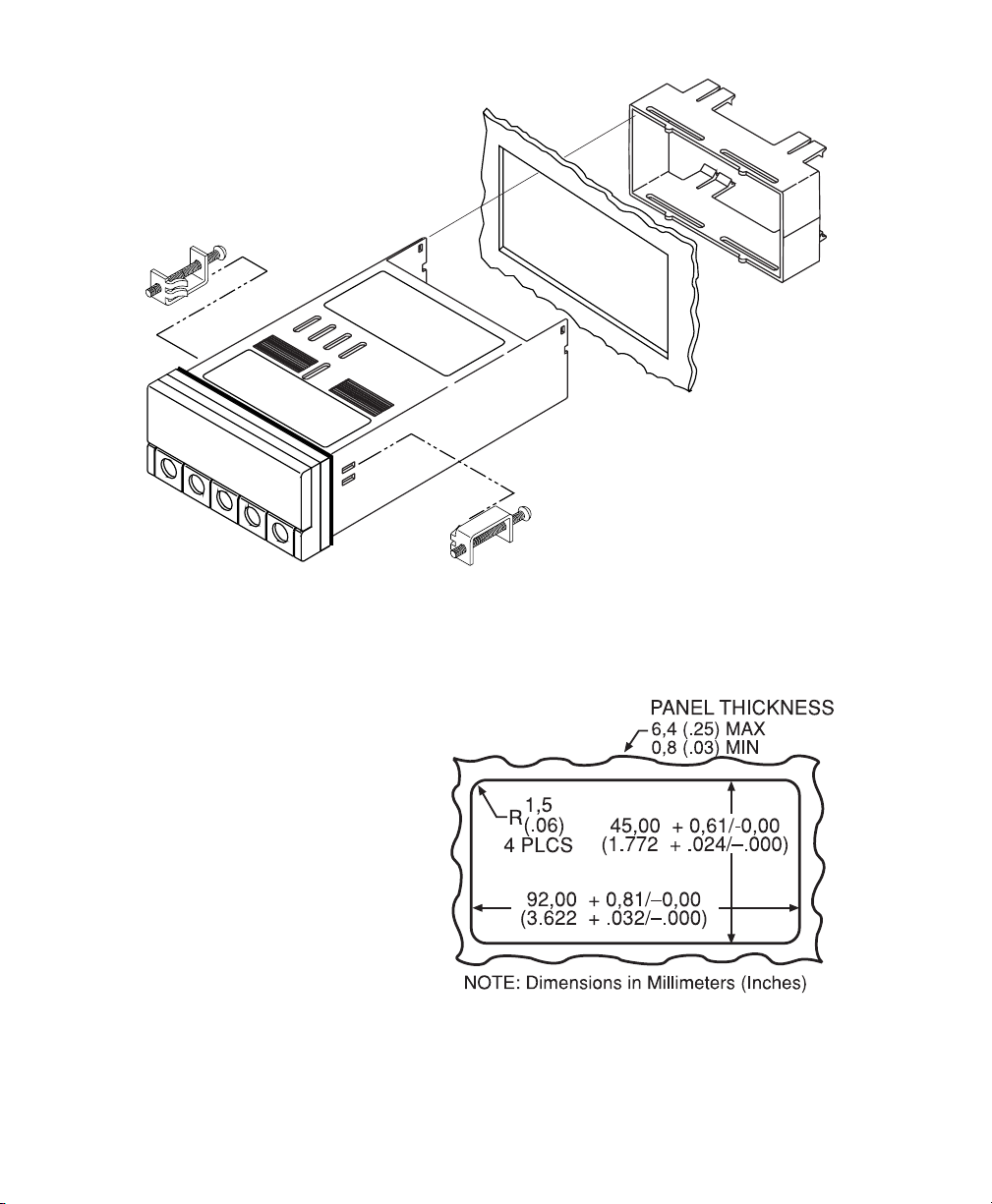

Figure 6-4 Meter - Exploded VIew

1. Cut a hole in your

panel, as shown in

Figure 6-4. For

specific dimensions

refer to Figure 6-5.

2. Insert the meter into

the hole.

Be sure the front

bezel gasket is flush

to the panel.

3. Slide on mounting

bracket to secure.

4. Proceed to Section 7

to connect your

sensor input and

main power.

13

Figure 6-5 Panel Cut-Out

CONNECTOR

LABEL

REAR COVER

(REMOVED)

PANEL

CUT-OUT

"NEW" STYLE

MOUNTING

BRACKET

PRODUCT

LABEL

GASKET

FRONT BEZEL

CASE

"OLDER" STYLE

MOUNTING

BRACKET 2 PCS

SECTION 7. SENSOR INPUT/

MAIN POWER CONNECTIONS

7.1 SENSOR INPUT CONNECTIONS

Figures 7-1 through 7-3 describe how to connect your sensors.

Figure 7-1 2-Wire RTD Input Connection

Figure 7-2 3-Wire RTD Input Connection

RTD

TB2

1234

5678

+E1 +S1 -S1

-E1

14

RTD

TB2

1234

5678

+E1 +S1 -S1 -E1

Loading...

Loading...