Page 1

http://www.omega.com

e-mail: info@omega.com

CL550 - SOFT

Software Packages

Page 2

OMEGAnetSM On-Line Service

Internet e-mail

http://www.omega.com

Servicing North America:

USA:

ISO 9001 Certified

Canada:

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

e-mail: info@omega.com

976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

e-mail: info@omega.ca

For immediate technical or application assistance:

Usa and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America:

Tel: (95) 800-826-6342

En Español: (95) 203-359-7803

e-mail: espanol@omega.com

Servicing Europe:

info@omega.com

FAX: (203) 359-7700

FAX: (514) 856-6886

SM

SM

SM

FAX: (95) 203-359-7807

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice, Czech Republic

Tel: 420 (69) 6311899

Toll free: 0800-1-66342

e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom:

ISO 9002 Certified

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly

pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every

appropriate device upon certification.

The information contained in this document is believed to be corrected but OMEGA Engineering Inc. accepts no liability for any errors it

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

One Omega Drive , River Bend Technology Centre

Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611

Toll Free in United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

contains, and reserves the right to alter specifications without notice.

FAX: (31) 20 6434643

FAX: 420 (69) 6311114

FAX: (33) 130-699-120

FAX: 49 (07056) 8540

FAX: 44 (161) 777-6622

2

Page 3

TABLE OF CONTENTS

1 GENERAL....................................................................................................................................... 4

1.1 Setup .......................................................................................................................................................................5

1.2 Manual or Automatic calibration.............................................................................................................................5

2 PROGRAM ARCHITECTURE......................................................................................................... 6

2.1 Calibration Procedures...........................................................................................................................................6

2.2 Tags.........................................................................................................................................................................9

2.3 Test........................................................................................................................................................................10

2.4 Calendar................................................................................................................................................................12

2.5 Standards..............................................................................................................................................................12

2.6 Options..................................................................................................................................................................12

2.7 Exit.........................................................................................................................................................................13

3 APPLICATIONS............................................................................................................................14

3.1 Rtd certification.....................................................................................................................................................14

3.1.1 Standards programming..................................................................................................................................15

3.1.2 Procedure programming..................................................................................................................................15

3.1.3 Run the procedure ...........................................................................................................................................17

3.1.4 Print the test results .........................................................................................................................................17

3

Page 4

1 GENERAL

Standard Agencies and Quality Auditors require the collection, organization and analysis of traceability documents.

CalpMan 2000 (Calibration Procedure Manager) is the software package able to manage all the calibration activities as

required by the regulations. Using the Windows 95/98/NTTM software, it is easy to set both simple and complex testing

procedure using different instruments. It is possible, using the standard instrument drivers, to use all of OMEGA

temperature, pressure, and signal calibrators to test instruments in your laboratory and process.

You can set the complete calibration procedure on PC, save and recall it every time you want; and run the procedure in

laboratory synchronizing the instruments using RS232, save data in the Hard-disk and print the documentation to show

the results in compliance with ISO 9000 requirements.

The main features of CalpMan 2000 are:

• Complete Tag identification and historical documenting of test results;

• Many testing procedures for each defined Tag;

• Many Test points;

• Reference and Tags error limits programming;

• Up to two RS232 connections for multiple instruments control;

• Standards database;

• Calendar for calibration due date.

Benefits to be gained from this system are:

• Optimisation of the maintenance period. By keeping a record of the time required among necessary adjustments,

the optimum maintenance period can be determined.

• Print of the Certificate; a test report can be printed for each TAG.

• Aid in maintenance planning. Data can be used to analyse the time and cost required for instrument calibrations

and can help in planning manpower, specifying supplier, etc.

Test and calibration data are memory stored in a Microsoft Access database in PC Hard-disk to document the calibration

activity. This allows operator to build the Quality control chart/data bank from a single calibration sheet to a detailed

historical report.

Each instrument, called “Tag”, to be calibrated/inspected is identified by name, model, manufacturer and serial number.

In you calibration procedure you can use external reference instruments (non OMEGA units, or Tc, or Rtd). The software

allows you to define these standard and to include their descriptions on the calibration report.

Calibration procedure can be performed either in automatic mode (Reference and instrument are connected using

RS232) or in manual mode (values entered using keyboard).

4

Page 5

1.1 Setup

CalpMan 2000 (CL550-SOFT) runs on IBM PC under WINDOWS 95®. Minimum requirements are a Pentium CPU with

16Mb RAM and 10 Megabyte free on hard disk, Colour monitor and Microsoft mouse or compatible one.

In order to install the package, proceed as follow.

• Place the Calpman 2000 CD-ROM inside the drive on your PC;

Follows the below procedure to install the program:

• From the Windows “Start” Menu, select <RUN>;

• Enter the filename D:\Disk1\SETUP.EXE (substitute the letter D for the disk drive that contains Calpman 2000

CD-ROM);

• Follow on screen instructions making sure to provide the correct path to your Calpman 2000 directory when

prompted.

Once installed, the Calpman 2000 icon will appear on your Windows “Start” button and it will be possible to boot it by

clicking on the icon as usual.

1.2 Manual or Automatic calibration

CalpMan 2000 (CL550-SOFT) is designed to work as a sand alone calibration procedure manager. You can program

your calibration procedures for any instruments you have.

Two different calibration mode are available to match all your needs: Manual or Automatic mode.

§ In manual mode, you can input by keyboard the reference and/or the Tag measured value. This mode can be used

when you have analogic instruments or digital non compatible with OMEGA serial protocol.

§ If you have an OMEGA calibrator (all Unical and MicroCal units are compatible), you can use RS232 serial interface

to program its output or read its input. CalpMan 2000 will communicate directly with the instrument and make your

calibration certificate free from manual input errors.

5

Page 6

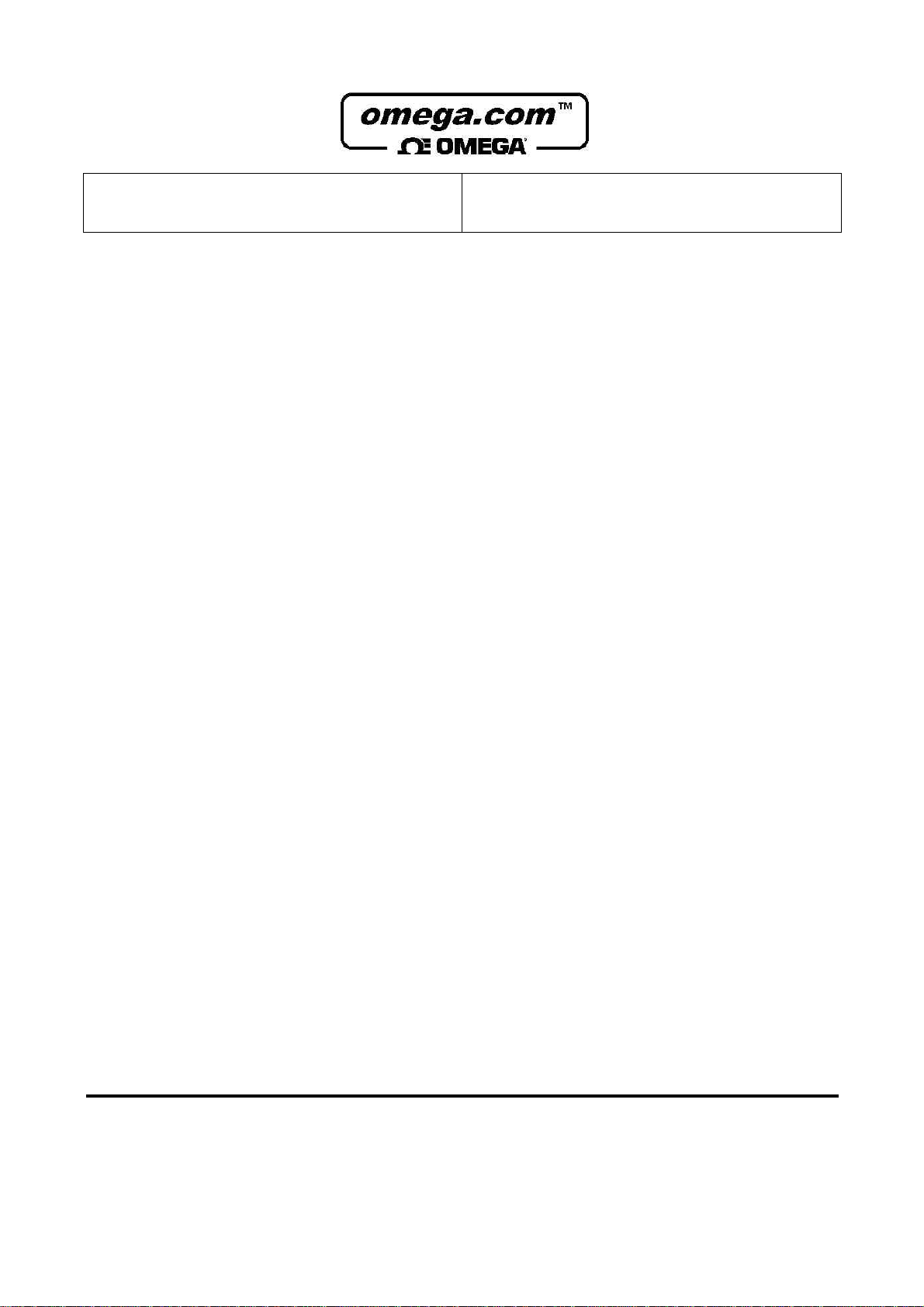

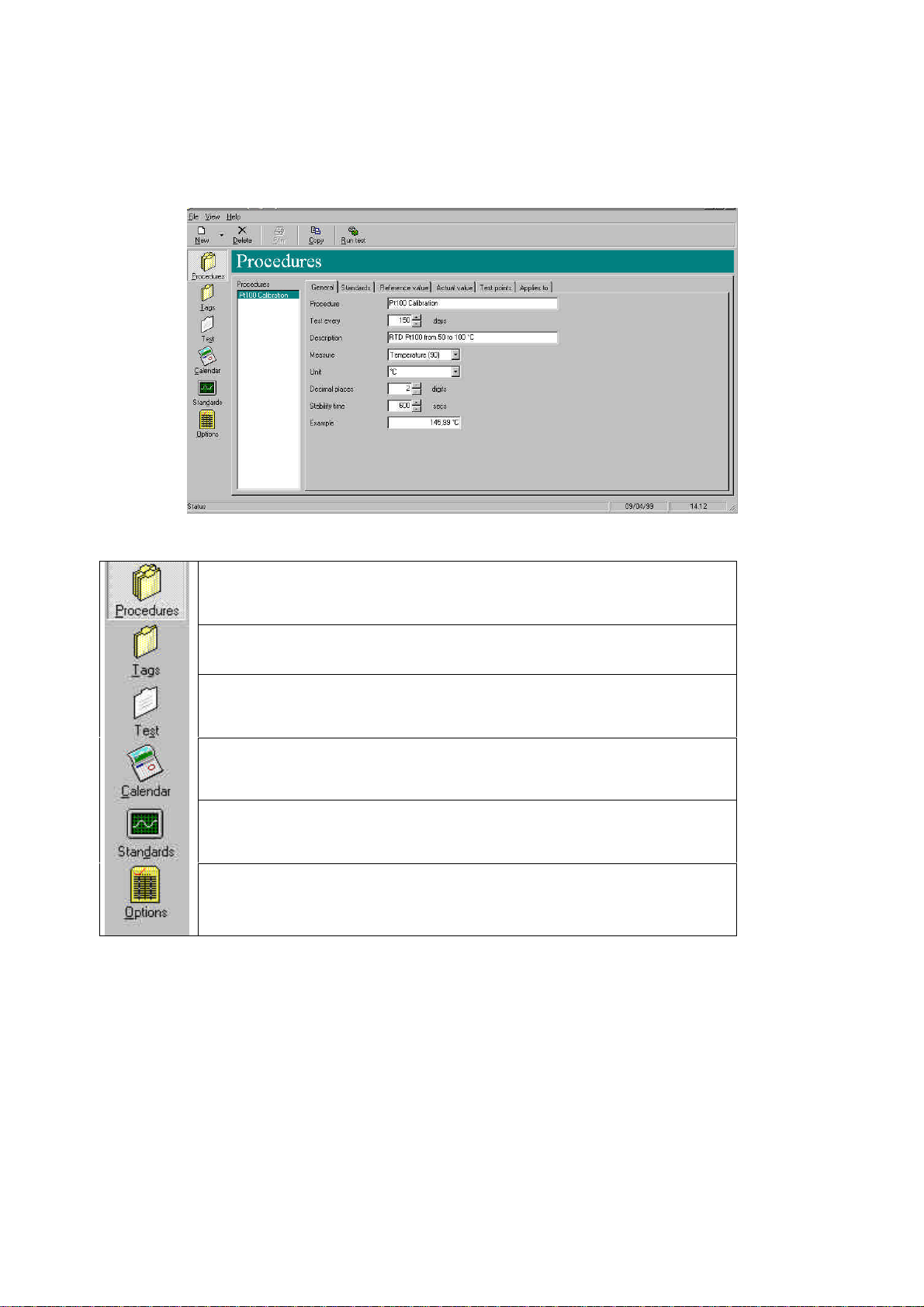

2 Program architecture

CalpMan 2000 (CL550-SOFT) has a typical Windows structure with a series of menu and options that can be recalled by

clicking on the name, or on the icon which represents the action the user wants to carry out.

All program options are available using the main menu bar. The button functions are the following:

This option allows you to program the calibration procedure. You can input all general

information, instruments used as standards, calibrators used as simulator and as

reader, test points and error limits, Tags.

This option allows you to add, delete, modify all Tag’s information: name,

Manufacturer, model, S/N, and applied calibration procedure.

This option allows you to review and print calibration procedure results database.

This option shows the calibration due date for all Tags. When you calibrate the

instrument, the date will be changed by the software for the new expiration date.

This option allows you to set all information about instruments used as reference in

calibration activities.

This option allows you to edit al header and footer for your calibration reports

2.1 Calibration Procedures

This is the core of CalpMan 2000 (CL550-SOFT). Using this option, you can program all data for a new calibration

procedure.

6

Page 7

Create a new procedure is easy by pressing the button and selecting the “Procedure” option.

The procedure windows will be displayed. All fields assumes the pre-set values. You can modify procedure data for

compliance with your testing procedure.

Edit a procedure is possible by selecting the procedure name and changing the values directly on the windows. All

changes will be stored automatically in the PC hard-disk.

Deleting a procedure is possible by selecting the procedure name and pressing the button.

The procedures data are divided into 6 forms: General, Standards, Reference value, Actual value, Test points, and

Applies to.

GENERAL: The procedure main information should be inserted in this form: Procedure name and

description, calibration validity period (this value will be used by CalpMan to update the

calibration due date for the Tag), type of measurements (Pressure, Frequency,

Temperature, current, etc.), engineering unit, number of decimals, stability time (the

procedure will wait for this time before make the measurement from Tag).

STANDARDS: Up to 4 external standards units can be assigned to each procedure. This units will be

printed on your calibration reports. You can select between the available in “Standards”

option (see paragraph 2.5).

7

Page 8

REFERENCE VALUE: This form allows you to define how the reference values can be input by program:

Manual or automatic (by calibrator) mode.

In manual input mode, the reference values are input by typing the values using the

keyboard. This operative mode can be used when the calibrator used is not an OMEGA

unit.

In calibrator input mode, the reference values are read by an OMEGA calibrator using the

RS232 serial interface. Select the used unit and the communication parameters. The

“calibrator function” mode can be selected program the unit as generator or as meter.

ACTUAL VALUE: This form allows you to define how the actual values (measured from the tag) can be

input by program: Manual or automatic (by calibrator) mode.

In manual input mode, the actual values are input by typing the values using the

keyboard. This operative mode can be used when the Tag used is not an OMEGA unit.

In calibrator input mode, the actual values are read by an OMEGA unit using the RS232

serial interface. Select the used unit and the communication parameters. The “calibrator

function” mode can be selected program the unit as generator or as meter. If meter

mode is selected, you can choose to read the data directly or linearized (e.g. 4-20mA to

0-100mbar).

TEST POINTS: This form allows you to program all procedure test points and limits of errors. Input all

test points values, then choose for full scale error or for of reading error input. Two kind

of error can be input: Reference error and Actual error.

Reference error is the maximum error band for the generated values. The Procedure will

not accepted the generated value if it is outside the band.

Actual error is the maximum error band for the measured values. The Procedure will

mark the value as fault if it is outside the band.

8

Page 9

Press “Generate Error Data” button to calculate the error limits.

APPLIES TO: This form allows you to input the Tags to be assigned to the calibration procedure. You

can input the following information: Name, Manufacturer, Model and S/N. When you

insert a new Tag to the procedure, the calibration due date will be automatically set to

the currency day.

You can also add a new Tag using the “New Tag” function in “Tag” option.

2.2 Tags

This option allows to edit all entered Tag information. You can read all units information and the procedure assigned.

If no test procedure was performed for the Tag, you can modify all parameters. If a Test procedure was done, you cannot

change the assigned calibration procedure.

9

Page 10

To delete a Tag, you have to select it using the mouse and then pressing the button.

2.3 Test

This option allows you to browse the previous testing data and to run a new test procedure. The column on the left of the

window shows the Tags list. Choosing one Tag from list, it will be shown (if existing) the performed tests ordered by date.

To perform a new test procedure, you have to select the Tag and then to press the button. The following

window will be displayed:

Make all electrical connections and connect, if programmed, the RS232 connection cables. Press the “OK” button to run

the procedure.

If RS232 serial communication is programmed for Tag and Reference units, you have only to wait for procedure ends.

The following monitor windows will be displayed:

10

Page 11

If manual values input is programmed the program will ask for the reference and the actual values.

When all data are entered (or the automatic procedure terminate), the program will show you for the calibration results.

A red line will highlight you for procedure error.

A Yellow line will inform you for a wrong result.

A white line will inform you for a good result.

You can preview the testing report by selecting the “File – Print preview” option. And print it by pressing the button.

Another features is the possibility to insert a bitmap file (e.g. with your logo) on the report. If you save your image file

using the name “header.bmp” in CalpMan 2000 main directory, this image will be printed below the Report Header.

11

Page 12

2.4 Calendar

This option views the certification due date for each entered Tag ordered by date. If a Tag certification is expired, its

description line is highlighted using red characters.

You can select the desired Tag and run the testing procedure by pressing the button.

2.5 Standards

This option allows you to manage the Standard units database. You can add, delete, or modify the data for the reference

instruments used for the procedure. You can enter many important information: Model, S/N, internal reference, notes,

OMEGA model, Manufacturer, and next calibration date. Next calibration date field, is very important because allows you

to manage the calibration due date for your standards: the red characters will inform you that a new calibration should be

performed.

2.6 Options

This option allows you to edit Report and Page Headers and Footers for documentation printing. Each certification of

calibration can be personalized with your name, address or with a document introduction.

12

Page 13

2.7 Exit

By selecting this option on the File menu, you can quit CalPMan 2000 software.

13

Page 14

3 APPLICATIONS

RS232 COM2

connection

Typical procedures to check and certificate the most common instruments are shown in the following paragraphs.

IMPORTANT: THE FOLLOWING PARAGRAPH IS ONLY TO SHOW HOW THE PROGRAM WORKS. THE DATA ARE INDICATIVE FOR THE

DESCRIBED EXAMPLE.

3.1 Rtd certification

The application consists to certificate a resistance thermometer (Pt01) using the system described below. CalpMan 2000

(CL550-SOFT) package is designed to work with all OMEGA calibration instruments. As example we have choose to use

CL526 multifunction calibrator for Rtd temperature reading and CL551 dry block temperature calibrator for temperature

generation.

We need the following components:

§ A Personal Computer with two RS232 board (we recommend a Pentium or equivalent processor)

§ CalpMan 2000 (CL550-SOFT) software.

§ OMEGA CL551 or other OMEGA temperature calibrator completed of a multiple hole insert block.

§ OMEGA CL526 signal calibrator with RS232 communication cable.

§ The Rtd to be certified.

Connect all system components and the Rtd to be certified as follows:

RS232 COM1

Rtd

CL551

CL526

• Connect the RS232 serial communication cables among the PC and the instruments.

• Insert the resistance thermometer in CL551 dry block.

• Connect the Rtd to the CL526.

• Switch the instruments and the Personal Computer on.

Rtd specifications are:

• Model: Pt100 3w produced by UKB S.r.l.

• Tag name: Pt-01-123

• Resistance thermometer type Pt100 3-wires

• Measuring range: 30…120°C

• S/N: 97I13/04

• Certification temperature test point:

50°C max error ±1.0°C

100°C max error ±1.0°C

3 wire Pt100

Run the CalPMan 2000 calibration package.

14

Page 15

3.1.1 Standards programming

Before starting procedure programming, you have to input the data of the instruments used as Standards in calibration

procedure.

Press “Standards” menu button on the vertical menu bar.

Add the following two records for CL526 and CL551 calibrators in database table.

3.1.2 Procedure programming

Press “Procedures” menu button on the vertical menu bar.

Create a new procedure is easy by pressing the button and selecting the “Procedure” option.

The procedure windows will be displayed. All fields assumes the pre-set values. You can modify procedure data for

compliance with your testing procedure.

GENERAL

The procedure main information should be inserted in this form.

Program the form as following:

Procedure: Pt100 Calibration

Test every: 150 days

Description: RTD certification Pt100 3w from 50 to 100°C

Measure: Temperature (90)

Unit: °C

Decimal places: 2 digits

Stability time: 600 secs

STANDARDS

15

Page 16

This form allows you to define up to 4 external standards to be assigned to the procedure. We don’t have any external

standards: all field have to be set to “none”.

REFERENCE VALUE

This form allows you to define how the reference values can be input by program: Manual or automatic (by calibrator)

mode.

Program the form as following:

Manual/Calibrator: Calibrator

Standard: TCAL012 (CL550 /551)

Version: 1

COM Port: COM1

Baud Rate: 9600

Temperature: Furnace (RJ int.)

Calibration function: Generate

ACTUAL VALUE

This form allows you to define how the actual values (measured from the tag) can be input by program: Manual or

automatic (by calibrator) mode.

Program the form as following:

Manual/Calibrator: Calibrator

Standard: UCAL 023 (CL526)

Version: 4

COM Port: COM2

Baud Rate: 9600

Temperature: RTD 3 wires

RTD Type: Pt100 (.385)

Calibration function: Measure

Input type: Direct

TEST POINTS

This form allows you to program all procedure test points and error limits. Enter data as following:

APPLIES TO

This form allows you to input the Tags to be assigned to the calibration procedure.

16

Page 17

3.1.3 Run the procedure

To perform a new test procedure, you have to select the Tag and press the button. The following window will be

displayed:

Check all electrical connections. Press the “OK” button to run the procedure. The following window will be displayed:

When all test point will be performed, it will be shown the calibration result.

A red line will highlight you for procedure error.

A Yellow line will inform you for a wrong result.

A white line will inform you for a good result.

3.1.4 Print the test results

Press “Test” menu button on the vertical menu bar.

17

Page 18

Select the Tag by the list; select the procedure you have to view and/or print.

You can preview the certificate by selecting the “File – Print preview” option.

You can print the certificate by pressing the button.

18

Page 19

WARRANTY/DISCLAIMER

FOR WARRANTY RETURNS, please has the

FOR NON-WARRANTY REPAIRS, consult OMEGA for

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13

months from date of purchase. OMEGA Warranty adds an additional one (1) month grace period to the normal one (1)

year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive maximum

coverage on each product.

If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department

will issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA,

if the unit is found to be defective it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to

defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing,

operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit

shows evidence of having been tampered with or shows evidence of being damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions

outside of OMEGA’s control. Components which wear are not warranted, including but not limited to contact points,

fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products However, OMEGA neither assumes

responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its

products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only

that the parts manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSEO OR IMPUED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTlES INCLUDING ANY WARRANTY OF MERCHANTABIUTY AND RTNESS

FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of

purchaser set forth herein ate exclusive and the total liability of OMEGA with respect to this order, whether

based on contract, warranty, negligence. Indemnification, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a ”Basic Component”

under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on

humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on

humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER

language, and additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage

whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING

ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM

OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR

number should then be marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in

transit.

following information available BEFORE contacting

OMEGA:

1. P.O. number under which the product was

PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

current repair charges. Have the following information

available BEFORE contacting OMEGA:

1. P.O. number to cover the COST of the repair,

2. Model and serial number of product, and

3. Repair instructions and/or specific problems relative to

the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the

latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

(C) Copyright 1999 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced,

translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without prior written consent of OMEGA

ENGINEERING, INC.

19

Page 20

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

RR Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

RR Wire: Thermocouple, RTD & Thermistor

RR Calibrators & Ice Point References

RR Recorders, Controllers & Process Monitors

RR Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

RR Transducers & Strain Gauges

RR Load Cells & Pressure Gauges

RR Displacement Transducers

RR Instrumentation & Accessories

FLOW/LEVEL

RR Rotameters, Gas Mass Flowmeters & Flow Computers

RR Air Velocity Indicators

RR Turbine/Paddlewheel Systems

RR Totalizers & Batch Controllers

pH/CONDUCTIVITY

RR pH Electrodes, Testers & Accessories

RR Benchtop/Laboratory Meters

RR Controllers, Calibrators, Simulators & Pumps

RR Industrial pH & Conductivity Equipment

DATA ACQUISITION

RR Data Acquisition & Engineering Software

RR Communications-Based Acquisition Systems

RR Plug-in Cards for Apple, IBM & Compatibles

RR Datalogging Systems

RR Recorders, Printers & Plotters

HEATERS

RR Heating Cable

RR Cartridge & Strip Heaters

RR Immersion & Band Heaters

RR Flexible Heaters

RR Laboratory Heaters

ENVIRONMENTAL MONITORING AND CONTROL

RR Metering & Control Instrumentation

RR Refractometers

RR Pumps & Tubing

RR Air, Soil & Water Monitors

RR Industrial Water & Wastewater Treatment

RR pH, Conductivity & Dissolved Oxygen Instruments

20

Loading...

Loading...