Page 1

http://www.omega.com

y

e-mail: info@omega.com

CL524 & CL525

2 channel High Accurac

Multifunction Calibrators

Page 2

OMEGAnetSM On-Line Service

Internet e-mail

http://www.omega.com

info@omega.com

Servicing North America:

USA:

ISO 9001 Certified

Canada:

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

e-mail: info@omega.com

976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

e-mail: info@omega.ca

FAX: (203) 359-7700

FAX: (514) 856-6886

For immediate technical or application assistance:

Usa and Canada:

Mexico and

Latin America:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Tel: (95) 800-826-6342

En Español: (95) 203-359-7803

e-mail: espanol@omega.com

SM

SM

SM

FAX: (95) 203-359-7807

Servicing Europe:

Benelux:

Czech Republic:

France:

Germany/Austria:

United Kingdom:

ISO 9002 Certified

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly

pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every

appropriate device upon certification.

The information contained in this document is believed to be corrected but OMEGA Engineering Inc. accepts no liability for any errors it

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

ul. Rude armady 1868, 733 01 Karvina-Hranice, Czech Republic

Tel: 420 (69) 6311899

Toll free: 0800-1-66342

e-mail: czech@omega.com

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

One Omega Drive , River Bend Technology Centre

Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611

Toll Free in United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

contains, and reserves the right to alter specifications without notice.

FAX: (31) 20 6434643

FAX: 420 (69) 6311114

FAX: (33) 130-699-120

FAX: 49 (07056) 8540

FAX: 44 (161) 777-6622

2

Page 3

INTRODUCTORY NOTE

This manual has been with all the information you need to install, operate and maintain the 2 channels

multifunction calibrator CL520 series and its accessories.

OMEGA has used the best care and efforts in preparing this book and believes the information in this

publication are accurate. The OMEGA products are subjected to continuous improvement, in order to pursue

the technological leadership; these improvements could require changes to the information of this book.

OMEGA reserves the right to change such information without notice.

No part of this document may be stored in a retrieval system, or transmitted in any form, electronic or

mechanical, without prior written permission of OMEGA Engineering, inc..

CL520 series multifunction calibrator uses sophisticated analogic and digital technologies. Any maintenance

operation must be carried out by qualified personnel

ONLY. OMEGA supplies instructions and operative

procedures for any operation on the instrument. We recommend to contact our technicians for any support

requirements.

CL520 series is fully tested in conformity with the directive n°89/336/CEE Electromagnetic Compatibility.

OMEGA shall not be liable in any event, technical and publishing error or omissions, for any incidental and

consequential damages, in connection with, or arising out of the use of this book.

3

Page 4

TABLE OF CONTENTS

1 PERFORMANCE.................................................................................................................................. 6

1.2 Specifications ................................................................................................................................................... 7

1.3 Table of ranges and accuracy .......................................................................................................................... 8

2 GENERAL FEATURES........................................................................................................................ 9

2.1 Innovative design ............................................................................................................................................. 9

2.2 Flexibility .......................................................................................................................................................... 9

2.3 Keyboard - Display........................................................................................................................................... 9

2.4 Digital interface ................................................................................................................................................9

2.5 Firmware .......................................................................................................................................................... 9

2.6 Scale factor - Square root ................................................................................................................................9

2.7 Cold Junction compensation ..........................................................................................................................10

2.8 Calculated readings .......................................................................................................................................10

2.9 Transmitter simulation and calibration............................................................................................................ 10

2.10 Frequency - Counts........................................................................................................................................ 10

2.11 Programmable signal converter .....................................................................................................................10

2.12 Resistance thermometer ................................................................................................................................10

2.13 Remote temperature probe ............................................................................................................................ 10

2.14 Graphic mode................................................................................................................................................. 10

2.15 Simulation programs ...................................................................................................................................... 10

2.16 Power supply.................................................................................................................................................. 11

2.17 Report of Calibration ...................................................................................................................................... 11

2.18 CL520-CPS Software - Documents calibration data ...................................................................................... 11

2.19 CL520-LGM Software for data acquisition ..................................................................................................... 11

2.20 CL520-SLS Software for special linearizations .............................................................................................. 11

3 PHYSICAL DESCRIPTION................................................................................................................ 12

4 FUNCTIONAL DESCRIPTION........................................................................................................... 13

4.1 Power supply.................................................................................................................................................. 13

4.2 Keyboard........................................................................................................................................................ 14

4.3 Input circuit..................................................................................................................................................... 14

4.4 Microcontroller................................................................................................................................................ 15

4.5 Firmware ........................................................................................................................................................ 15

4.6 Display ........................................................................................................................................................... 15

4.7 Digital to analog converter ............................................................................................................................. 16

4.8 External battery charger or mains line operation............................................................................................ 16

4.9 Digital interface ..............................................................................................................................................17

4.10 Resistance and RTD measurements ............................................................................................................. 17

4.11 Resistance and RTD simulation ..................................................................................................................... 17

4.12 Thermocouples input/output circuit ................................................................................................................ 17

5 PRE-OPERATIONAL CHECK ........................................................................................................... 19

5.1 Unpacking ......................................................................................................................................................19

5.2 Case............................................................................................................................................................... 19

5.2.1 Portable cases........................................................................................................................................... 19

5.2.2 Panel mounting .........................................................................................................................................19

5.2.3 Table top use............................................................................................................................................. 19

6 POWER SUPPLY............................................................................................................................... 20

6.1 Power supply.................................................................................................................................................. 20

6.1.1 Rechargeable battery ................................................................................................................................ 20

6.1.2 Charging the battery.................................................................................................................................. 20

6.1.3 How to maximize the life span of the battery............................................................................................. 20

7 ELECTRICAL CONNECTIONS ......................................................................................................... 21

7.1 Wiring practice ...............................................................................................................................................21

7.2 Thermocouple wires....................................................................................................................................... 22

7.3 Remote connections ...................................................................................................................................... 22

7.3.1 External contact......................................................................................................................................... 22

7.3.2 Remote Rj ................................................................................................................................................. 23

8 OPERATION & APPLICATIONS....................................................................................................... 24

8.1 Power ON ...................................................................................................................................................... 24

8.2 Configuration Reset ....................................................................................................................................... 25

8.3 Next Calibration date...................................................................................................................................... 25

8.4 Display adjustments ....................................................................................................................................... 25

8.4.1 Display backlight .......................................................................................................................................25

8.4.2 Autolamp mode ......................................................................................................................................... 26

4

Page 5

8.5 "Help" key....................................................................................................................................................... 26

8.6 Configuration review (Status)......................................................................................................................... 26

8.7 General configuration set-up.......................................................................................................................... 29

8.8 Slot display swapping..................................................................................................................................... 30

8.9 Channels scrolling.......................................................................................................................................... 31

8.10 Decimal point position .................................................................................................................................... 31

8.11 Average mode................................................................................................................................................ 31

8.12 Autorange ...................................................................................................................................................... 31

8.13 Alarm function ................................................................................................................................................ 31

8.14 Parameter or sensor selection .......................................................................................................................32

8.15 Scale factor mode set-up ............................................................................................................................... 33

8.16 Temperature parameters selection ................................................................................................................ 34

8.17 Rj fast mode selection.................................................................................................................................... 35

8.18 Resistance thermometer selection ................................................................................................................. 35

8.19 IN-OUT data memories .................................................................................................................................. 36

8.20 Autoscan program mode................................................................................................................................ 36

8.21 Ramp program mode ..................................................................................................................................... 36

8.22 Bargraph function........................................................................................................................................... 37

8.23 Switch test routine.......................................................................................................................................... 38

8.24 Offset mode set-up......................................................................................................................................... 40

8.25 Frequency IN - OUT...................................................................................................................................... 40

8.25.1 Frequency OUT........................................................................................................................................ 40

8.25.2 Frequency IN............................................................................................................................................ 40

8.26 Transmitter simulation.................................................................................................................................... 41

8.27 Graphic operative mode................................................................................................................................. 42

8.28 Pulse IN-OUT................................................................................................................................................. 42

8.28.1 Pulse generation ....................................................................................................................................... 42

8.28.2 Pulse frequency measurement and counter mode.................................................................................... 43

8.29 Percentage and error displays .......................................................................................................................45

9 OPTIONS & ACCESSORIES............................................................................................................ 47

9.1 External printer............................................................................................................................................... 47

9.1.1 General recommendation .......................................................................................................................... 47

9.1.2 Printer operations: General .......................................................................................................................47

9.1.3 Printer operation: Normal In-Out mode ..................................................................................................... 48

9.2 Data Logging function .................................................................................................................................... 48

9.2.1 Printout of memory stored date .................................................................................................................51

9.3 RAM card ....................................................................................................................................................... 52

10 DIGITAL INTERFACE........................................................................................................................ 53

10.1 Digital output wiring practice...................................................................................................................... 53

10.2 Communication protocol ................................................................................................................................ 54

10.2.1 Computer data request from CL520 series................................................................................................54

10.2.2 Computer data setting from PC ................................................................................................................. 60

11 MAINTENANCE ................................................................................................................................. 64

11.1 Faulty operating conditions ........................................................................................................................... 64

11.2 Protection fuses replacement......................................................................................................................... 64

11.3 Safety recommendations ............................................................................................................................... 65

11.4 Accessories & Spare parts............................................................................................................................. 65

11.5 Storage .......................................................................................................................................................... 65

5

Page 6

1 PERFORMANCE

A fundamental tool to monitor quality assurance test equipment as required by ISO 9000 and to mantain the traceability

in accordance with National Standards.

The indicator-simulator CL524 and CL525 are high accuracy multifunction instruments, with 2 isolated and independent

channels, designed to meet the needs of instrumentation engineers, both in laboratory and in field work.

Accurate, compact, rugged, easy to use; the ideal solution to measure and simulate:

Both Channel 1 (In) and Channel 2 (Out) have the following operative mode capability:

• millivolts

• volts

• milliamperes (active and passive loop)

• ohms

• temperature with thermocouples

• temperature with resistance thermometers

• frequency

• pulse and counter

Remote auxiliary inputs are available for :

• Relative humidity and temperature

(the temperature sensor uses the same input of the remote cold junction sensor. The above inputs are non isolated

from the "Out" channel)

CL520 series calibrators have been developed using the most advanced A/D conversion and a fast and powerful 32 bit

microcontroller to provide high accuracy on extended ranges and a powerful operative flexibility. The firmware is stored

in a flash memory to allow future upgrade directly from serial interface using a floppy disk in a Personal Computer

• All normalized IEC, DIN, JIS thermocouples

• Pt, Ni, Cu resistance thermometers, temperature measurement and active simulation with a proprietary circuit

(patent n. 206327).

• mA, mV, V,

• IPTS 68 and ITS 90 selection directly through keyboard

• Current INput/OUTput mode directly on active or passive loops

• Rechargeable Ni-Cd battery and line operations

• Bidirectional digital interface

• Portable, table top and panel mounting

• Report of Calibration

The CL525 has an improved performance and accuracy, is equipped with a PCMCIA Memory Card and with a

communication bus for an extension with pressure or optional modules.

Ω, frequency, pulse

6

Page 7

1.2 Specifications

• IN/OUT parameters:

Signal type

thermocouples type

resistance thermometers

• Reference junction compensation:

internal automatic

external adjustable

remote with external Pt100

• Rj compensation drift: ±0.015°C/°C (from -10 °C to +55 °C)

• Common mode rejection: >140 dB at ac operation

• Normal mode rejection: >60 dB at 50 or 60 Hz

• Temperature stability:

full scale

zero

• Output impedance (emf output): less than 0.5 ohm with a maximum current of 0.5 mA

• Input impedance (mV, V and Tc ranges): >10 M Ω

• Input impedance (mA ranges): <130 Ω at 1 mA

• Source resistance effects: ±1 µV error for 1000 ohms source resistance

• RTD and Ω simulation excitation current: from 0.1 to 2 mA

• RTD and Ω measurement excitation current: 0.4 mA

• RTD terminals: 2, 3 or 4 wires

• RTD cable compensation: up to 100 Ω (for each wire)

• RTD cable compensation error (Pt100): ±0.005°C/ Ω of total wire

• Maximum load resistance: 1000 Ω at 20 mA

• Display: graphic LCD 240 x 64 dots display with backlight device

• Measurement sampling time: 250 ms

• Output noise (at 300 Hz): <2 µVpp for ranges up to 200 mV f.s., <10 µVpp for ranges up to 2000 mV f.s. and

<80 µVpp for ranges up to 20 V f.s.

• Digital interface: full bi-directional TTL (a RS232 adapter normal or insulated, is available as an option)

• Channel 1-Channel 2 insulation: 250 Vdc

• Calculation functions: hold, max, min, offset, average

• Simulation mode: in-line single digit setting, numerical entry, memory loaded value, autostep, autoramp,

autoscan, autocycle

• Selection °C/°F/K: through the configuration procedure

• Convert function: displays the electrical equivalent of the engineering unit

• Scale factor: 5 setting with zero and span programmable within -399999 and +999999

• Square root: in combination with scale factor

• Calibration: self learning technique with automatic procedure

• Logging mode: >1500 input data items (optional memory card for memory extension)

• In/Out data memory: 20 data with manual or automatic recall

• Power supply: external charger and rechargeable Ni-Cd battery

• Self contained operation:

6 h on Tc and mV input/output (backlight Off)

3.5 h with 20 mA simulation (backlight Off)

• Recharging time: 5 h at 90% and 6 h at 99% with instrument switched off. The battery recharge is active only

with the instrument switched off.

• Battery charge indication: bar graph on the LCD display

• Line operation: 100V - 115 V - 230V Vac through the external battery charger

• Line transformer insulation: 2500 Vac

• Firmware release identification: release code on the display

• Operating environment temperature range: from -10 °C to +55 °C

• Storage temperature range: from -30 °C to +60 °C

• Case: Injection molded ABS

• Dimensions: 264 x 96 x 172 mm (DIN size)

• Weights: net 4 Kg gross 5.5 Kg

mV, V, mA, Ω, K Ω, frequency, pulses

J, K, T, R, S, B, N, C, E, U, L, F, G, D

Pt100 IEC, OIML, USLAB, US, SAMA, JIS Pt200, 500, 1000, 1000 OIML, Ni100,

Ni120, Cu10, Cu100

from -10 °C to +55 °C

from -50 °C to +100 °C

from -10°C to +100 °C

: ± 8 ppm/°C

: ± 0.2 µV /°C

7

Page 8

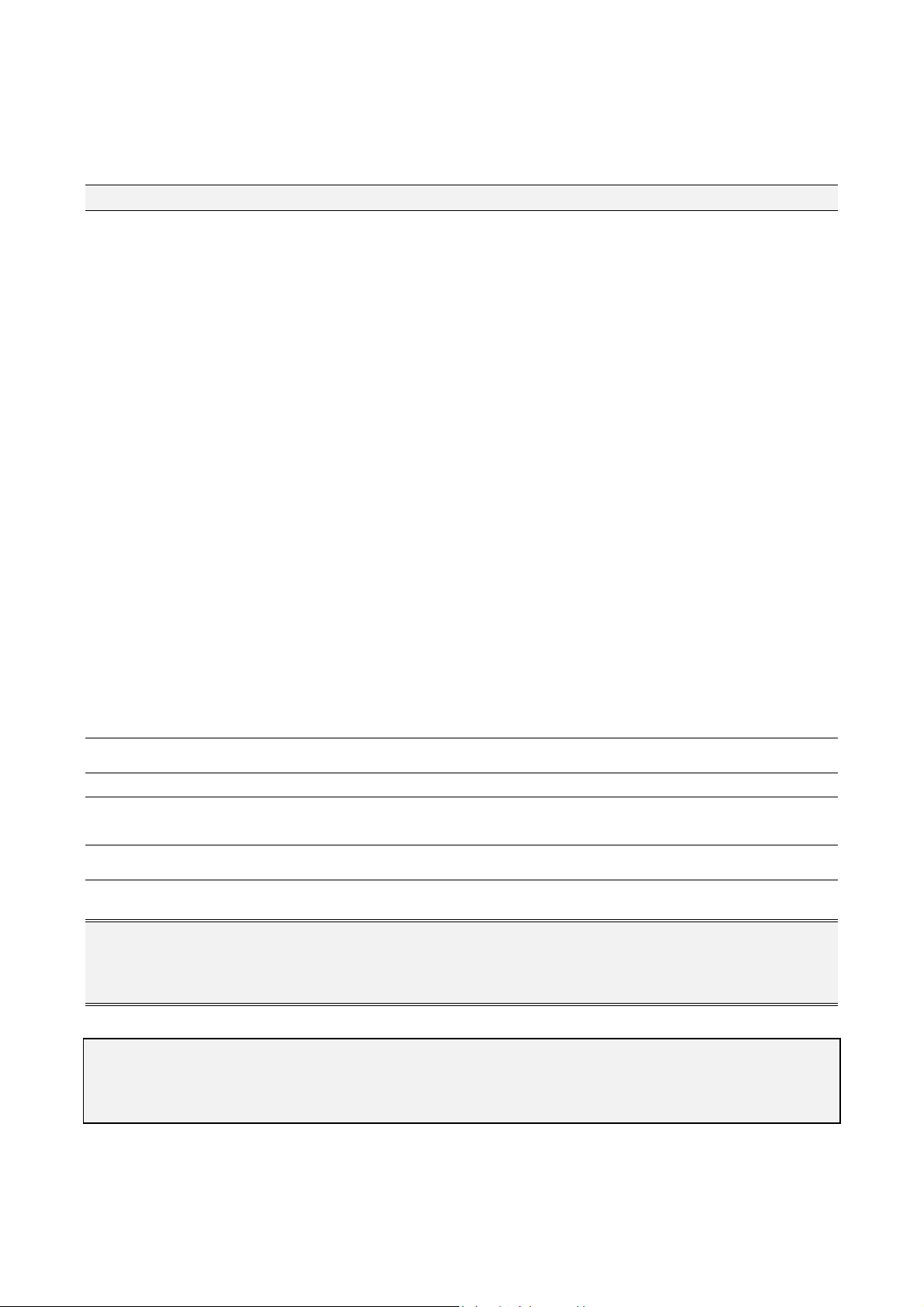

1.3 Table of ranges and accuracy

IN-OUT RANGES

CL525 CL524

Sensor or Total range Accuracy range Resolution Accuracy Accuracy

parameter (% of reading) (% of reading)

Tc type J -210 to 1200°C -190 to 1200°C 0.1°C ±(0.01% +0.1°C) ± (0.02% +0.1 °C)

-350 to 2200°F -310 to 2192°F 0.1°F ±(0.01% +0.18F) ± (0.02% +0.18 °F)

Tc type K -270 to 1370°C -160 to 1260°C 0.1°C ±(0.01% +0.1°C) ± (0.02% +0.1 °C)

454 to 2500°F -256 to 2300°F 0.1°F ±(0.01% +0.18°F) ± (0.02% +0.18 °F)

Tc type T -270 to 400°C -130 to 400°C 0.01°C ±(0.01% +0.1°C) ± (0.02% +0.1 °C)

-454 to 760°F -238 to 752°F 0.1°F ±(0.01% +0.18°F) ± (0.02% +0.18 °F)

Tc type R -50 to 1760°C 150 to 1760°C 0.1°C ±(0.01% +0.2°C) ± (0.02% +0.2 °C)

-60 to 3200°F 302 to 3200°F 0.1°F ±(0.01% +0.36°F) ± (0.02% +0.36 °F)

Tc type S -50 to 1760°C 170 to 1760°C 0.1°C ±(0.01% +0.2°C) ± (0.02% +0.2 °C)

-60 to 3200°F 338 to 3200°F 0.1°F ±(0.01% +0.36°F) ± (0.02% +0.36 °F)

Tc type B 50 to 1820°C 920 to 1820°C 0.1°C ±(0.01% +0.3°C) ± (0.02% +0.3 °C)

140 to 3310°F 1688 to 3308°F 0.1°F ±(0.01% +0.54°F) ± (0.02% +0.54 °F)

Tc type C 0 to 2300°C 0 to 2000°C 0.1°C ±(0.01% +0.2°C) ± (0.02% +0.2 °C)

32 to 4180°F 32 to 3632°F 0.1°F ±(0.01% +0.36°F) ± (0.02% +0.36 °F)

Tc type G 0 to 2300°C 190 to 2300°C 0.1°C ±(0.01% +0.3°C) ± (0.02% +0.3 °C)

32 to 4180°F 374 to 4172°F 0.1°F ±(0.01% +0.54°F) ± (0.02% +0.54 °F)

Tc type D 0 to 2300°C 0 to 2130°C 0.1°C ±(0.01% +0.3°C) ± (0.02% +0.3 °C)

32 to 4180°F 32 to 3866°F 0.1°F ±(0.01% +0.54°F) ± (0.02% +0.54 °F)

Tc type U -200 to 400°C -160 to 400°C 0.1°C ±(0.01% +0.1°C) ± (0.02% +0.1 °C)

-330 to 760°F -256 to 752°F 0.1°F ±(0.01% +0.18°F) ± (0.02% +0.18 °F)

Tc type L -200 to 760°C -200 to 760°C 0.1°C ±(0.01% +0.1°C) ± (0.02% + 0.1 °C)

-330 to 1400°F -328 to 1400°F 0.1°F ±(0.01% +0.18°F) ± (0.02% +0.18 °F)

Tc type N -270 to 1300°C 0 to 1300°C 0.1°C ±(0.01% +0.1°C) ± (0.02% +0.1 °C)

-450 to 2380°F 32 to 2372°F 0.1°F ±(0.01% +0.18°F) ± (0.02% +0.18 °F)

Tc type E -270 to 1000°C -200 to 1000°C 0.1°C ±(0.01% +0.1°C) ± (0.02% +0.1 °C)

-454 to 1840°F -328 to 1832°F 0.1°F ±(0.01% +0.18°F) ± (0.02% +0.18 °F)

Tc type F 0 to 1400°C 0 to 1400°C 0.1°C ±(0.01% +0.1°C) ± (0.02% +0.1 °C)

32 to 2560°F 32 to 2552°F 0.1°F ±(0.01% +0.18°F) ± (0.02% +0.18 °F)

Pt100 IEC -200 to 850°C -200 to 850°C 0.01°C ±(0.01% +0.05°C) ± (0.02% +0.05 °C)

OIML, a 3926 -330 to 1570°F -328 to 1562 °F 0.1°F ±(0.01% +0.09°F) ± (0.02% +0.09 °F)

Pt100 -200 to 650°C -200 to 650°C 0.01°C ±(0.01% +0.05°C) ± (0.02% +0.05 °C)

a 3902 -330 to 1210°F -328 to 1210°F 0.1°F ±(0.01% +0.09°F) ± (0.02% +0.09 °F)

Pt100 JIS -200 to 600°C -200 to 600°C 0.01°C ±(0.01% +0.05°C) ± (0.02% +0.05 °C)

SAMA -330 to 1120°F -328 to 1112°F 0.1°F ±(0.01% +0.09°F) ± (0.02% +0.09 °F)

Pt 200 -200 to 850°C -200 to 850°C 0.1°C ±(0.01% +0.15°C) ± (0.02% +0.15 °C)

-330 to 1570°F -328 to 1562°F 0.1°F ±(0.01% +0.27°F) ± (0.02% +0.27 °F)

Pt 500 -200 to 850°C -200 to 530°C 0.1°C ±(0.01% +0.1°C) ± (0.02% +0.1 °C)

-330 to 1570°F -328 to 986°F 0.1°F ±(0.01% +0.18°F) ± (0.02% +0.18 °F)

Pt1000 IEC -200 to 850°C -200 to 850°C 0.01°C ±(0.01% +0.1°C) ± (0.02% +0.1 °C)

OIML -330 to 1570°F -328 to 1562°F 0.1°F ±(0.01% +0.18°F) ± (0.02 % +0.18 °F)

CU10 -70 to 150°C -70 to 150°C 0.1°C ±(0.01% +0.4°C) ± (0.02% +0.4 °C)

-100 to 310°F -94 to 302°F 0.1°F ±(0.01% +0.72°F) ± (0.02% +0.72 °F)

CU100 -180 to 150°C -180 to 150°C 0.1°C ±(0.01% +0.05°C) ± (0.02% +0.05 °C)

-300 to 310°F -292 to 302°F 0.1°F ±(0.01% +0.09°F) ± (0.02% +0.09 °F)

Ni100 -60 to 180°C -60 to 180°C 0.1°C ±(0.01% +0.05°C) ± (0.02% +0.05 °C)

-80 to 360°F -76 to 356°F 0.1°F ±(0.01% +0.09°F) ± (0.02% +0.09 °F)

Ni120 0 to 150°C 0 to 150°C 0.1°C ±(0.01% +0.05°C) ± (0.02% +0.05 °C)

32 to 310°F 32 to 302°F 0.1°F ±(0.01% +0.09°F) ± (0.02% +0.09 °F)

mV -20 to +200mV 1µV ±(0.01% +2µV) ± (0.02% +2 µV)

mV -0.2 to +2 V 10 µV ±(0.01% +10 µV ± (0.02% +10 µV)

V -2 to +20 V 0.1mV ±(0.01% +0.08mV) ± (0.02% +0.08 mV)

mA (In) -5 to +50mA 0.1µA ±(0.01% +0.4µA) ± (0.02% +0.4 µA)

mA (Out) 0 to +50mA 0.1µA ±(0.01% +0.4µA) ± (0.02% +0.4 µA)

Ω IN 0 to 500Ω 1mΩ ±(0.01% +12mΩ) ± 0.02% +12 mΩ)

0 to 5000 Ω 0.01Ω ±(0.01% +120mΩ) ± (0.02% +120 mΩ)

Ω OUT 0 to 500 Ω 1 mΩ ±(0.01% +20mΩ) ± (0.02% +20 mΩ)

0 to 5000 Ω 0.01Ω ±(0.01% +200mΩ) ± (0.02% +200 mΩ)

Frequency 1 to 200 Hz 0.001 Hz ±(0.005% +0.001 Hz)

1 to 2000 Hz 0.01 ±(0.005% +0.001 Hz)

1 to 20000 Hz 0.1 Hz ±(0.005% +0.001 Hz)

Pulse counter 0 to 106 counts 1 count infinite

Pulse (Out) 0 to 6000 pulse/min 1 pulse/min 1 pulse / min

0 to 36000 pulse/h 1 pulse/h 1 pulse / min

Note:

• The relative accuracy shown above are stated for 360 days and the operative conditions are from +18°C to +28°C

• Typical 90 day relative accuracy can be estimated by dividing the "% of reading" specifications by 1.6.

• Typical 2 year relative accuracy can be estimated by multiplying the "% of reading" specifications by 1.4.

• All input ranges: additional error ±1 digit.

• OMEGA traceability chart and uncertainty can be supplied on request.

IMPORTANT NOTES

REMEMBER THAT TO OBTAIN THE MAXIMUM PERFORMANCE IN TERM OF ACCURACY THE BACKLIGHT SHOULD BE SWITCHED OFF. IN

FACT THE BACKLIGHT DEVICE IS A SOURCE OF INTERNAL HEATING THAT CAN CONTRIBUTE TO THE OVERALL ERROR OF THE

INSTRUMENT. THE STATED RELATIVE ACCURACY IS DECLARED WITH THE BACKLIGHT DEVICE SWITCHED OFF.

8

Page 9

2 GENERAL FEATURES

2.1 Innovative design

CL520 series calibrators use innovative electronics based an a powerful 32 bit microcontroller and sophisticated high

stability, low level signal, thermal e.m.f. free analog circuit.

A Flash memory allows firmware updating through serial interface and modem.

CL525 Incorporates a real time clock, PCMCIA Memory Card and improved performances.

2.2 Flexibility

The operative set-up mode is simplified by a sequence of menu pages that only require <Select> and <Enter>

instructions. A full set of operators notes are memory stored allowing a direct operator's assistance and instructions. Any

relevant instruction may be recalled through the <Help> key. Separate terminals for Channel 1 and Channel 2 are

installed on the front panel. The instrument accepts 2,3,4 wire resistance thermometers.

2.3 Keyboard - Display

A thermoformed metal-click polycarbonate membrane keyboard, with a working life of one million operations per key,

seals the internal electronics from the surrounding environment.

Contact closure of the membrane keys is acknowledged as a coded signal directly by the microprocessor.

The setting of the simulation signal value uses the typical OMEGA in-line single digit setting mode or a direct numerical

entry mode.

The high contrast LCD graphic display, equipped with a backlight device, allows easy reading even in poor light

conditions.

The graphic display allows a simultaneous indication of the measured and simulated value (large digit), together with a

comprehensive number of messages related to engineering units, type of sensor or signal, temperature scale, cold

junction selection and battery level of charge.

A backlight auto power OFF mode is installed to save battery life.

A swap feature is also installed to change the position on the display of the IN and OUT parameters.

2.4 Digital interface

It is a full bi-directional TTL level digital interface for communication with computerized systems.

A RS232 adapter with galvanic insulation is available on request.

2.5 Firmware

The real time clock, Flash Memory and RAM handle logic functions, mathematical computation and data storage.

A removable Memory Card (PCMCIA) is installed on CL525 only.

The firmware includes the following capabilities:

• multiple measurements and generation mode

• signal processing: filter, average, peak, alarms

• downloadable test procedure (CL520-CPS)

• data acquisition (CL520-LGM)

• switch test routine

• ramping and stepping for dynamic testing

• user definable linearization (CL520-SLS)

• user entry of probe specific calibration coefficients (CL520-SLS)

2.6 Scale factor - Square root

All non temperature ranges are fully programmable to read both measured and output values in term of engineering unit.

Four characters, adjustable in an alphanumeric way, are available on the display to show the symbol of the parameter

(i.e. mbar, % RH, % CO, etc.) mA reading and output can be e.g. related to flow when using a ∆P transmitter across a

calibrated flange.

9

Page 10

2.7 Cold Junction compensation

Accurate and fast response automatic internal Rj compensation through a special low thermal capacity design of binding

posts incorporating a thin film high accuracy Pt100.

The cold junction temperature is measured, acknowledged by the microprocessor, directly displayed for automatic Rj

compensation.

In addiction to the automatic internal Rj compensation two alternative compensation modes can be selected: “external”

with a programmable temperature value or “remote” automatic with an external resistance thermometer.

2.8 Calculated readings

To allow measurements of unstable input signals by a programmable averaging of a programmable number of

conversions and min and max value identification.

A “hold” function is also present on the keyboard or external contact instructions.

2.9 Transmitter simulation and calibration

The instrument can be connected to system inputs to simulate a 4-20 mA transmitter.

It has an adequate power to drive 20 mA into a load of 1000

The operator can set and change temperature values while obtaining the equivalent mA output.

The mA mode may be connected directly either on passive or on active loops.

Ω in the source mode (50 mA su 350 Ω).

2.10 Frequency - Counts

The "Out" mode is designed to generate zero based pulses, with an adjustable amplitude, at a frequency up to 20 KHz.

A preset number of pulses may be programmed and transmitted to test or calibrate totalizers and counters.

The instrument can be configured to measure frequency and count pulse (totalizer mode).

Technical units in Hz, pulse/h and pulse/min.

The input threshold is adjustable from 0 to 20 V with 0.01 V resolution.

2.11 Programmable signal converter

The instrument can be used as a temporary signal convert replacement.

Any input signal (including the remote auxiliary inputs) can be converted into any of the available output signals while

maintaining full galvanic isolation.

2.12 Resistance thermometer

Although resistance and temperature with resistance thermometer may be measured on a 2, 3 wire connection, the

instrument is also designed for 4-wire measurements with a resolution as low as 0.01°C.

2.13 Remote temperature probe

A high accuracy probe is available on request for general purpose temperature measurement and/or remote cold junction

compensation.

2.14 Graphic mode

To obtain a real time graph of the measured parameter.

The input data are memory stored and the actual values, relevant to the required time, can be digital displayed using the

cursor key.

2.15 Simulation programs

Menu-driven set up to generate:

• a continuous or step ramp output where the total time, the starting point, the final point and the size of the steps are

requested by the set-up procedure to run the program;

• a repetitive programmable cycle rises, soaks, falls;

• a manual requested increment through keyboard;

10

Page 11

• an automatic sequence of up to 20 stored values (2 groups of 10 memories).

2.16 Power supply

External charger circuit and internal rechargeable battery.

The instrument can operate from mains line continuously without removing the battery.

When in normal operation from mains supply the battery is not recharged.

To recharge the battery the instrument must be switched off.

2.17 Report of Calibration

Each instrument is factory calibrated against Standards, that are periodically certified by an International recognized

Laboratory to ensure traceability, and shipped with a Report of Calibration stating the nominal and actual values and the

deviation errors. A special calibration report can be supplied on request.

2.18 CL520-CPS Software - Documents calibration data

Standard Agencies and Quality Auditors require the collections, organization and analysis of traceability documents.

A supporting software for DOS/Windows (CL520-CPS Calibration Procedure Manager) is available to transfer a selection

of calibration routines from a PC to the internal memory of the instrument in order to simplify field calibrations selecting

the appropriate tag number. Test and calibration data can be memory stored and downloaded to a PC to document the

calibration activity. ( “before" and “after” data).

2.19 CL520-LGM Software for data acquisition

Supporting software for DOS/Windows to download logged data from an internal memory to a PC. Data can be saved on

disks, loaded from disks, viewed in a numeric or graphic mode and also printed in a numeric or graphic mode.

2.20 CL520-SLS Software for special linearizations

Supporting software for DOS/Windows to configure the instrument with, Tcx, RTDx special linearization. The program

allows a highly accurate temperature measurement with a calibrated Pt100 loading the coefficients of the Calibration

Report.

11

Page 12

3 PHYSICAL DESCRIPTION

The CL520 series calibrator consists of a rugged and compact case, a mother board with all base and IN/OUT circuits, a

tactile polycarbonate membrane keyboard, a LCD display and a group of four Ni-Cd rechargeable batteries.

The internal surface of the case is metal coated through a special process to improve the characteristics of electrical

noise shielding and thermal equalization of all internal circuits.

On the CL520 series the battery container is located on the upper part of the case, and it is accessible through a cover

with two fasteners.

The two sections of the case are joined together and fastened by five metal screws located on the bottom part of the

case.

The optional leather case, with shoulder strap, assures better protection of the instrument against mechanical knocks or

scratches.

12

Page 13

4 FUNCTIONAL DESCRIPTION

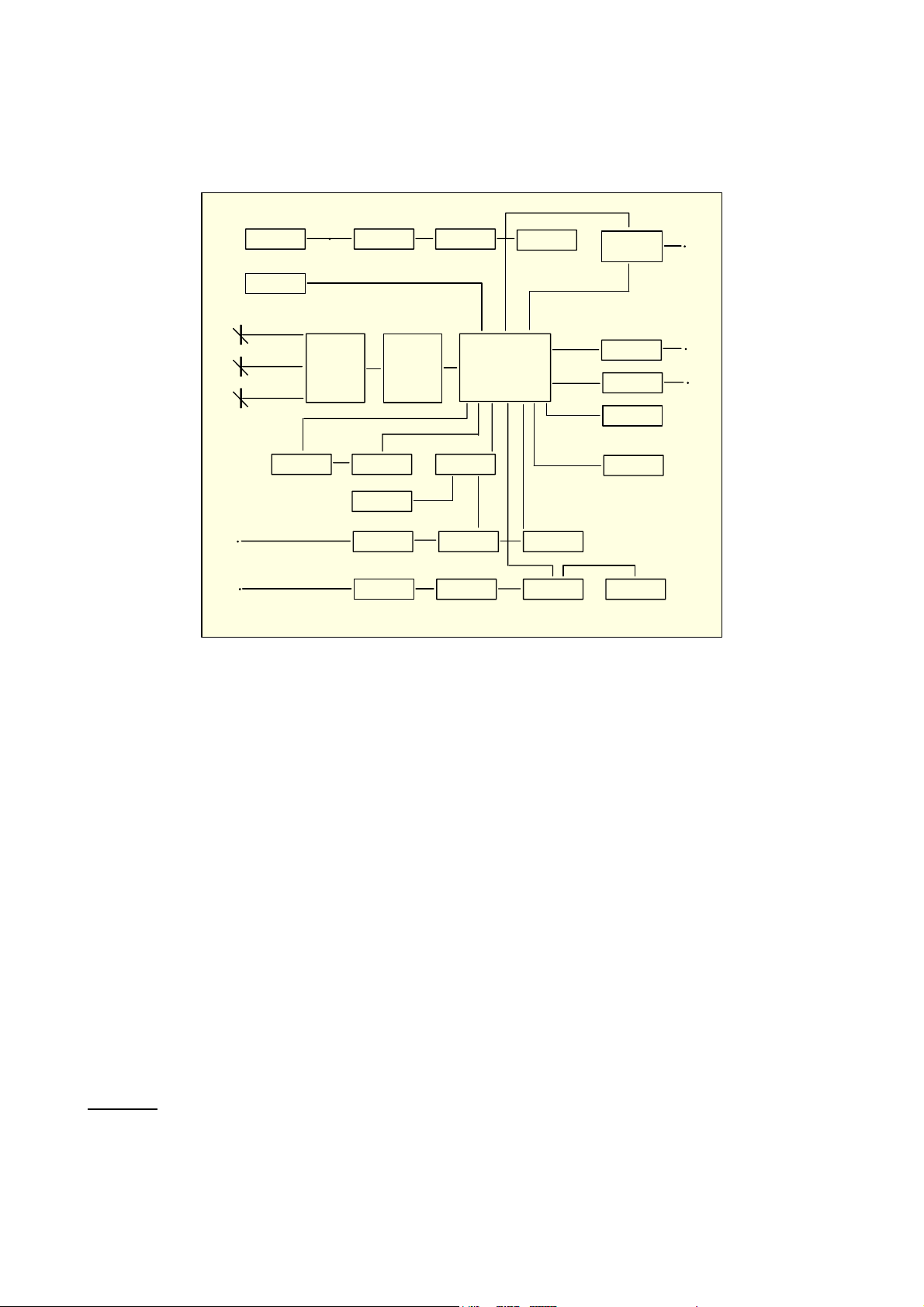

The calibrator functional block diagram is shown below.

External

Power Supply

RAM card

Internal Rj In

Internal Rj Out

Remote Rj

Contrast &

Backlight adj.

IN

OUT

Switch

and

Amplifier

Battery

A/D Converter

Display KeyboardA/D converter

Ref.

IN Switch sel.

V-mA-ž-Hz

OUT

Amplifier

• external power supply module

• microprocessor (central unit + program)

• input circuit

• reference junction compensation (Rj)

• LCD display

• operative keyboard

• analog to digital converter

• digital to analog converter

• auxiliary power supply at 24Vdc

• RAM + Clock (optional on CL524, standard on CL525)

On - Off

Microprocessor

+ Program

Input ampl.

OUT Switch sel.

V-mA-ž-Hz

Switching

Frequency IN

Comparator

D/A converter

In/Out auxiliary

PS & excitation

current for Rtd

Digital Out

Serial interface

& printer Out

RAM + Clock

Ref.

In/Out

P.S.

• PCMCIA Memory Card (on CL525 only)

4.1 Power supply

The instrument is powered by a group of four internal rechargeable Ni-Cd batteries. The battery is charged through an

external power supply module.

When required the instrument can be powered directly from the mains line without removing the batteries.

Pressing the <ON> key you will provide the dc voltage levels for the circuitry of the instrument:

IN Circuits

+ 24 V analog circuit

+ 5 V digital/analog circuit

-10 V analog circuit

..... auxiliary power supply In

13

Page 14

OUT Circuits

+ 24 V analog circuit

+ 5 V digital/analog circuit

- 5 V analog circuit

- 10 V analog circuit

..... auxiliary power supply Out

Two separate groups of voltage levels respectively for Channel 1 and Channel 2 circuits.

A galvanic insulation of 250 Vac is present between the two group of voltage levels.

4.2 Keyboard

The front panel is a thermoformed metal-click tactile polycarbonate keyboard, and has a working life of one million

operations per key.

The contact closure of the membrane keyboard is acknowledged as a coded signal by the microprocessor that

recognizes the operators' instructions .

The ergonomics are simplified with a reduced number of instruction keys referring to the display for additional set-up

instructions.

1 IN terminals

2 OUT terminals

ON Power ON switch

OFF Power OFF switch

STO Memory load

RCL Memory data recall

ÍÎ Parameter scanning during selection or decimal point position setting

0......9 Single digit setting, numerical entry, parameter scanning during selection, IN/OUT

memories

SELECT Operative menu-driven set-up

± Polarity simulation setting or parameter scanning during selection

, Decimal point simulation setting

IN/OUT Enable IN/OUT configuration set-up

MENU Scrolling between the auxiliary operative modes

ENTER Memory load - Operator's message acknowledgement

SHIFT Key secondary function

STATUS To view the pages of the actual installed operative mode and of memory stored data

HELP Operator's instruction menu pages

NUM Direct numerical setting of the simulated value

LAMP To switch the display backlight

RAMP To start the simulation program

IN and OUT displaying position swapping

ENTER + <4> or <9> Display contrast adjustment

ENTER + <±> or <,> Display backlight intensity adjustment

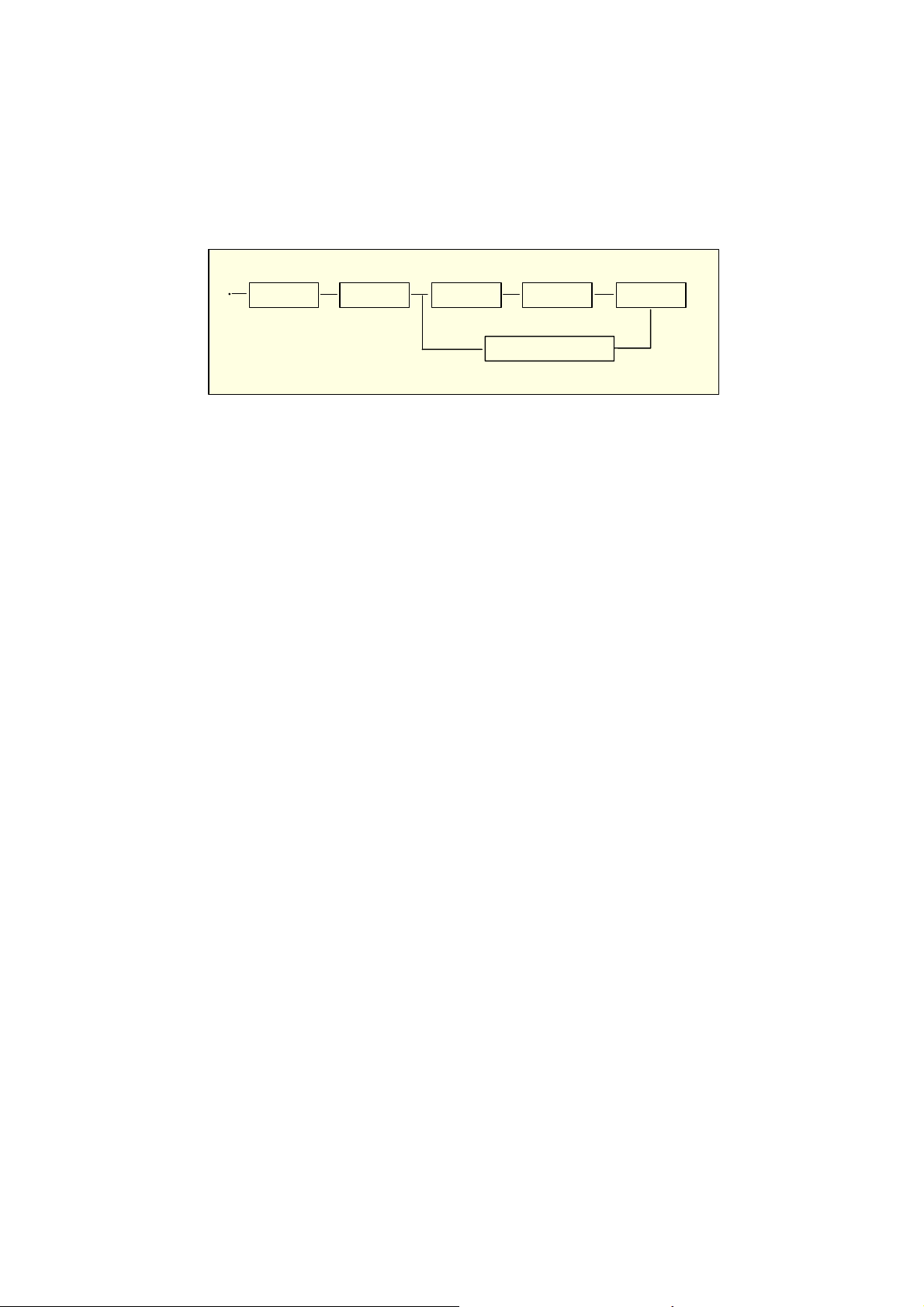

4.3 Input circuit

The A/D converter is a monolithic 20 bit ADC which uses a sigma delta conversion technique.

The analog input is continuously sampled by an analog modulator whose mean output duty cycle is proportional to the

input signal.

The modulator output is processed by an on-chip digital filter with a six-pole Gaussian response, which updates the

output data register with 20-bit binary words at word rates up to 4 kHz. The sampling rate, filter corner frequency and

output word rate are set by a master clock input supplied externally from a dedicated quartz with frequency multiple of

50/60 Hz to improve noise rejection.

14

Page 15

The inherent linearity of the ADC is excellent (0.003%), and the endpoint accuracy is ensured by a self-calibration of

zero and a full scale which is started every 5 minutes.

The self-calibration scheme can also be extended to null system offset in the input channel.

Output data are accessed through a serial port by the microprocessor in a synchronous mode.

CMOS/HCCMOS construction ensures a low power dissipation and high speed.

Analog switches provide for the gain and input parameter selection.

The front end amplifier is a high performance amplifier with very low noise and zero-drift with a combination of low-frontend noise and dc precision and it is followed by an autozero circuit.

The internal clock is set at 5 KHz for an optimum low frequency noise and offset drift.

IN

Input ampl. Microprocessor

Autozero circuitParameter select

A/D converter

Comparator (for frequency In only)

4.4 Microcontroller

The microprocontroller handles all the logic functions of the instrument, performs the linearization for non linear

transducers, compensates for the reference junction temperature, drives the digital display and acknowledges all the

operator's instructions.

The core of the circuit is the MC68332; a 32 bit integrated microcontroller, combining high performance data

manipulation capabilities with powerful peripheral subsystems and featuring a fully static, high speed complementary

metal oxide semiconductor (HCMOS) technology.

The MC68332 contains intelligent peripheral modules such as the time processor unit (TPU), which provides 16

macrocode channels to perform time related activities from a single input capture or output compared to sophisticated

pulse width modulation (PWM).

High speed serial communications are provided by the queued serial module (QSM) with available synchronous and

asynchronous protocols.

Two kilobytes of fully static standby RAM allow a fast two cycle access for system and data stacks and for variable

storage with provision for battery back-up.

Twelve chip selections enhance system integration for fast external memory or peripheral access.

These modules are connected on-chip via intermodule bus (IMB)

4.5 Firmware

The operating firmware system (256 Kbyte memory) is divided in to two sections:

• one section contains the boot-loader that is a routine to enable the base firmware loading through the serial port

• the second section contains the base firmware that handles all logic instructions for internal peripheral circuits and

performs the computation of the linearization equations. Moreover it contains the "Help" key operator's instructions

and gives instructions to the secondary graphic controller for the character generation.

The application system firmware (e.g. calibration data) is resident on a non-volatile ”Flash” EPROM.

It is used to store the installation parameters (calibration data, simulation program data, etc.)

4.6 Display

The Liquid Crystal Display module is a graphic display with high contrast and a wide viewing angle. It is equipped with a

LED backlight device to allow easy readings also in poor light conditions.

The character generation is made through the main microprocessor that gives pertinent instructions to a secondary

microprocessor driving the display in a graphic mode.

15

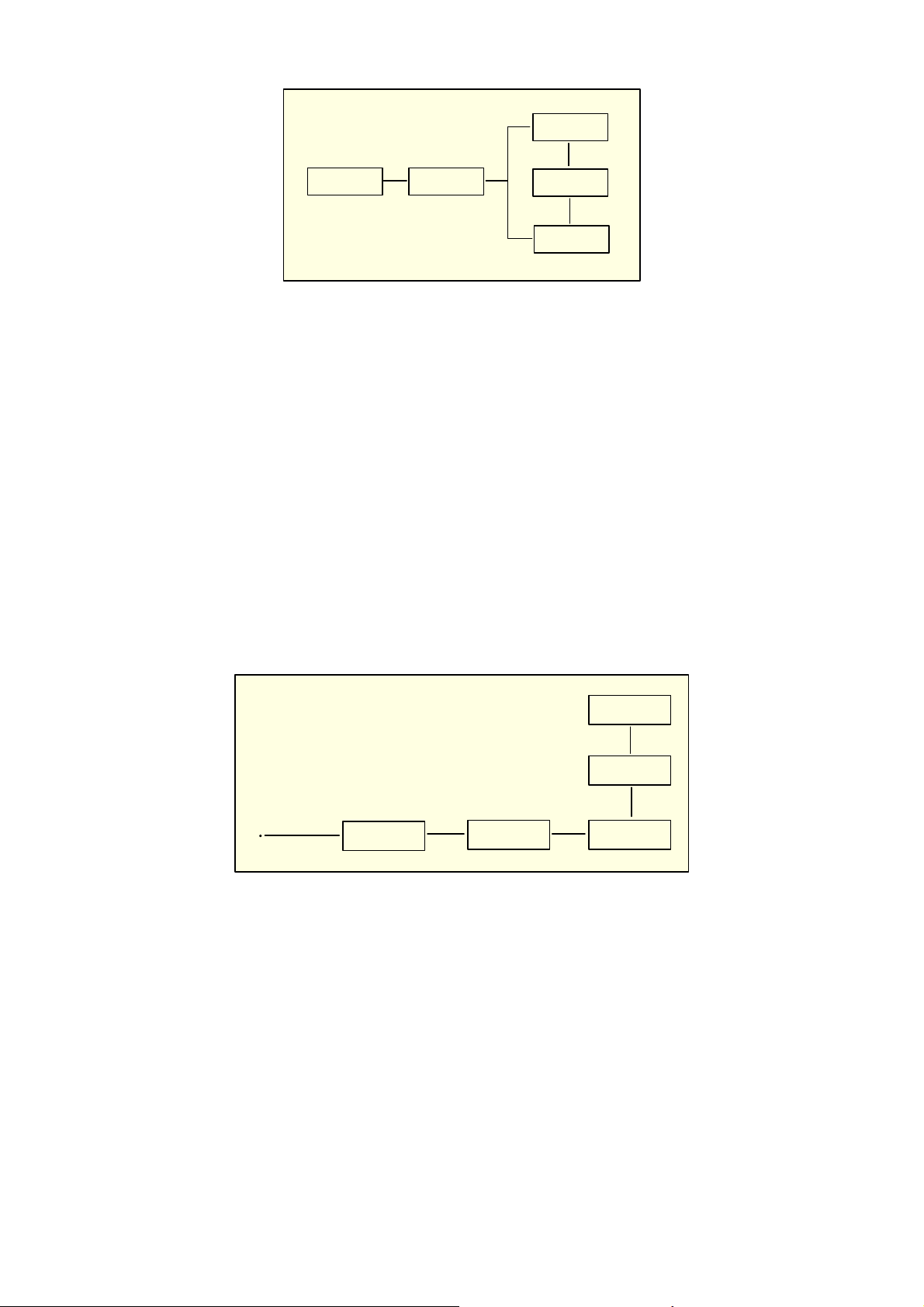

Page 16

Pixel driver

Main microP Aux. microP

Liquid Crystal

Segm. driver

4.7 Digital to analog converter

The D/A converter is based on a joint configuration, with a partial overlapping, of a 10-bit and 12-bit converter to obtain a

±21 bit resolution .

The two analog to digital converters are designed using the two PWM (pulse with modulation) processes available in the

micrprocessor chip.

These two PWM outputs drive the relevant switches to generate a voltage output proportional to Ton or Toff with an

accuracy theoretically absolute.

The resultant ±21 bit D/A device, driven directly by the microprocessor, converts the digital value of the selected

parameter into an analog voltage output function of the time modulation of the PWM and of the internal high stability,

high accuracy reference.

Analog switches are used to select one of the following six available output values as a function of the selected range:

-20 to +200 mV

-2 to +20 V

-200 to +2000 mV

0 to 500 Ω

0 to 5 K Ω

0 to 50 mA

The above signal, through an output buffer, is sent to an integrated circuit that will generate the voltage or current

requested by the operator's keyboard settings.

Keyboard

Microprocessor

OUT

Output amplif.

Parameter select

D/A converter

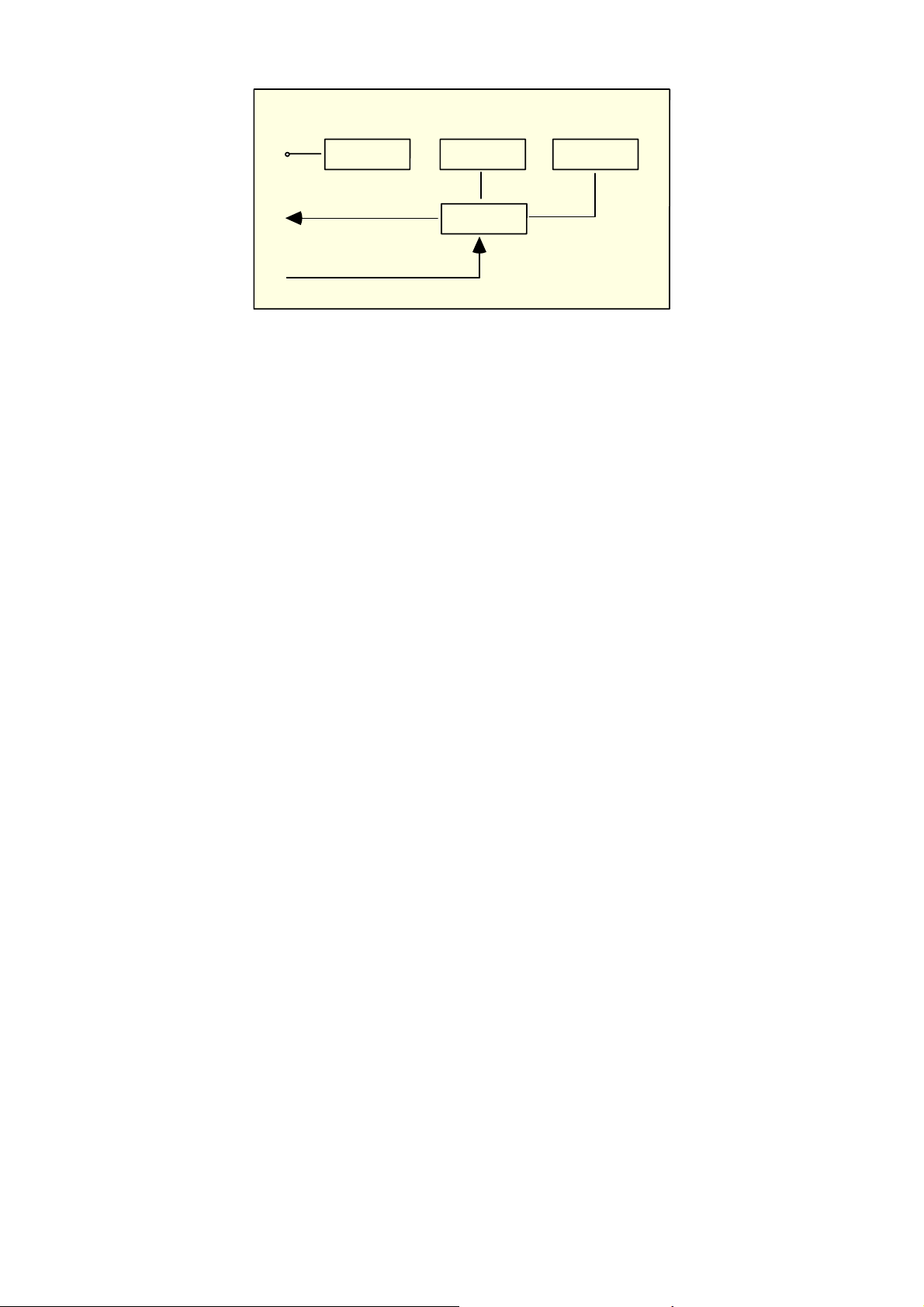

4.8 External battery charger or mains line operation

The instrument is equipped with an external power supply module for line operation 100, 115, 230 Vac 50/60 Hz.

The external power supply module uses a step down transformer, a rectifier, a filter, a serial current controller, protection

sections for over current and a battery charge circuit equipped with a timer for three different ways of charge driven by

the battery status.

The charging circuit uses two different references for:

• voltage control to 5.5 Vdc during instrument operations (5 V dc internal lines)

• battery charge current controller with a maximum of 1 Adc (when the instrument is switched Off) and a maximum of

1.8 A , limited to 5.5 V with the instrument switched On.

16

Page 17

Mains

Line ac

Transformer

dc supply to the instrument

feedback from the instrument

Rectifier-filter Timer

Current controller

4.9 Digital interface

The serial digital interface circuit is essentially based on the serial communication interface subsystem (SCI) on the chip

of the microprocessor (0 to +5V level).

An external adapter is available on request to convert TTL to RS 232 voltage levels .

4.10 Resistance and RTD measurements

The instrument can measure temperature with 2, 3 or 4 wire resistance thermometers.

For the 2 and 4 wire resistance thermometers the method used is a special configuration of a potentiometric circuit where

a constant current is injected from terminals "I+" and "I-" and the voltage drop across the thermometer is measured and

converted in engineering unit.

With 3 wire thermometers a current equivalent to that generated on terminal "I+" is injected on terminal "V-" to

compensate for connecting cable unbalance.

O---- I +

O---- V +

O---- V O---- I -

4.11 Resistance and RTD simulation

This line of calibrators is equipped with a proprietary electronic circuit for the active simulations of platinum resistance

thermometers, nickel resistance thermometers, copper resistance thermometers and resistance.

It is based on the assumption that the instrument to be calibrated will supply the excitation current to the sensor; this

current must be between 0.1 and 2 mA for up to 100 Ω nominal value RTD and between 0.01 mA and 0.5 mA for

Pt1000 and KΩ ranges.

A lower value will cause a lower accuracy level and a higher current will not allow the simulation of high resistance

values (the maximum voltage drop on the simulated resistance is 2.5 V ).

The excitation current must be applied to the pertinent terminals as indicated in par. 7.1 (simulation).

The measured current is converted to voltage through an inverting amplifier and used as a reference for the digital to

analog converter.

The output amplifier will simulate the variation of the output resistance as a function of the value set by the operator

through the keyboard.

4.12 Thermocouples input/output circuit

A thermocouple is a temperature sensor that in its most common form, consists of two wires of different composition,

joined together at one end ("measuring" junction).

The two free ends of the thermocouple must be kept at the same known temperature. These joints are , by definition, the

“reference” junction (Rj).

The reference junction is also often, but less preferably, called the “cold” junction.

17

Page 18

Tc wires

Reference Junction

emf

output

Measuring junction

Copper wires

The temperature of the reference junction can be held constant or its variation can be electrically compensated in the

associated measuring instrumentation.

A thermocouple is useful for temperature sensing because it generates a measurable electrical signal.

The signal is proportional to the difference in temperature between the measurement and the reference junctions and

it is defined, by means of tables, based on the International Temperature Scale.

The CL520 series has the reference junction located in the negative (black) terminal post. To improve overall accuracy

the terminals are designed with a very low thermal capacity.

Inside the body of the negative terminal it is placed a thin film Pt100 resistance thermometer that dynamically

measures, with high accuracy and 0.01°C resolution , the temperature of the reference junction.

The microprocessor uses the above signal (Pt100) to adjust the input signal to compensate for the Rj temperature.

Reference junction compensation can be internal, external or remote, depending upon the application requirements.

18

Page 19

5 PRE-OPERATIONAL CHECK

5.1 Unpacking

Remove the instrument from its packing case and remove any shipping ties, clamps, or packing materials.

Carefully follow any instructions given on any attached tags.

Inspect the instrument from scratches, dents, damages to case corners etc. which may have occurred during shipment.

If any mechanical damage is noted, report the damage to the shipping carrier and then notify OMEGA directly or its

nearest agent, and retain the damaged packaging for inspection.

A label, on the back of the instrument case, indicates the serial number of the instrument. The serial number is also

shown in the display.

Refer to this number for any inquiry for service, spare parts supply or application and technical support requirements.

OMEGA will keep a data base with all information regarding your instrument.

5.2 Case

The instrument case, made in shock-resistant injection molded ABS has an internal metal coating for electric interference

protection. It allows the use of the instrument in three different ways:

• portable with leather case for an easy transport

• table top with tilting feet

• panel mounted (DIN cutout)

A leather protection case is supplied as an option only on request.

5.2.1 Portable cases

Two different leather cases, with cover and shoulder strap, are available on request for the instrument alone or

instrument, printer and accessories. These are extremely useful for a practical use since they allow to leave one hand

free for instruments under test tuning.

CL520-CASE is used with the instrument alone while CL520-COMBO has a zoom for the instrument, printer and

accessories.

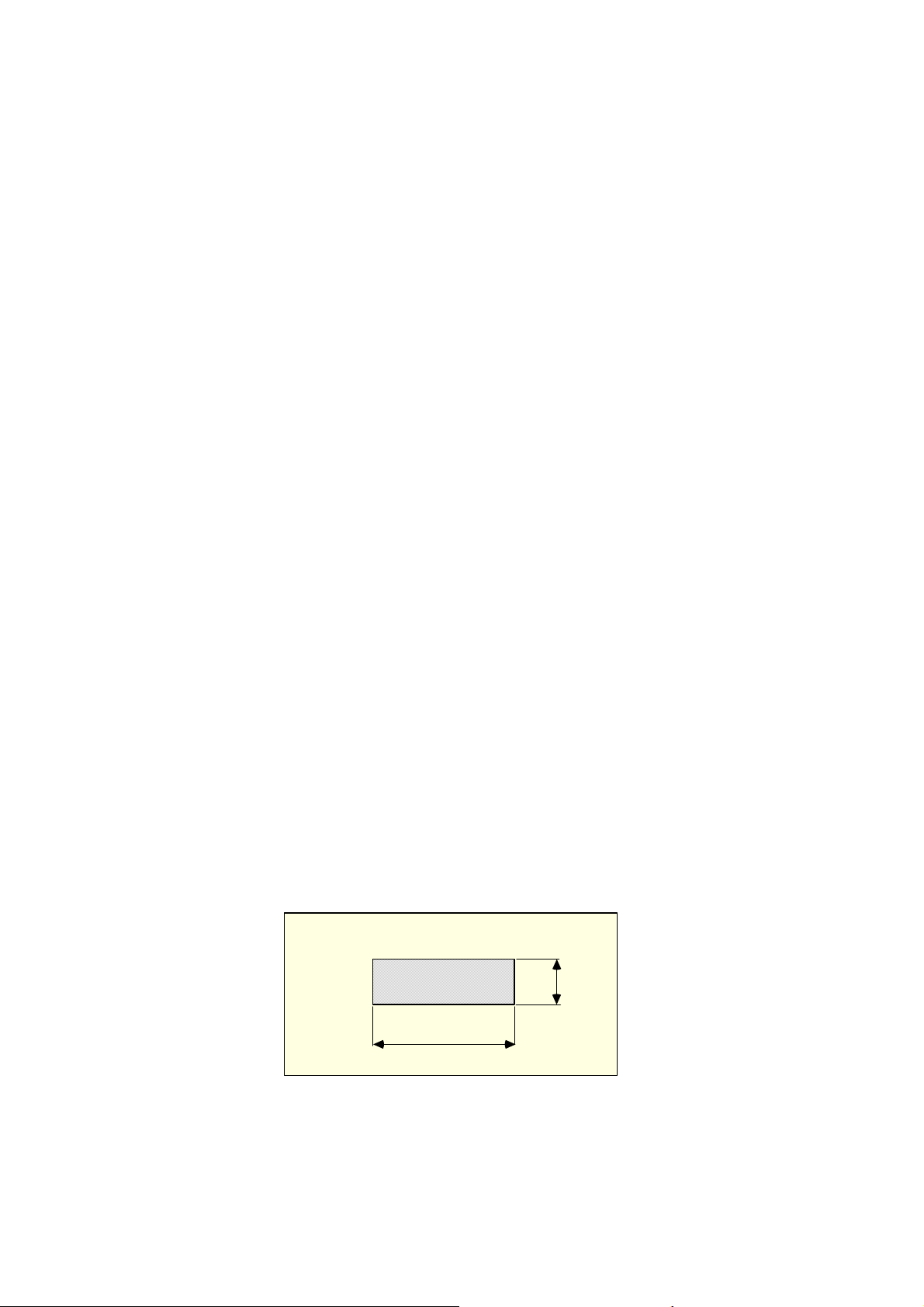

5.2.2 Panel mounting

For panel mounting each instrument is supplied with two mounting brackets to be installed on the two sides of the case.

The instrument bezel flange butts against the front of the mounting plate; the mounting brackets fit over the instrument

rear panel.

The bracket screws force it against the rear of the mounting panel, locking the instrument in place. Panel cutout

dimensions are 242 x 88 mm (max. panel thickness 6 mm). Rack mounting adapters (112 x 433 mm) are available with

openings for two instruments.

Front bezel 96 x 212 mm

88 mm

242 mm

5.2.3 Table top use

The case is equipped with 2 pivot feet to change the vertical viewing angle when using the instrument on the top of the

table.

19

Page 20

6 POWER SUPPLY

C

6.1 Power supply

6.1.1 Rechargeable battery

The CL520 series calibrator is powered by four built-in rechargeable batteries. The instrument is shipped with an

average level of charge.

After unpacking, a full charge of the batteries is recommended; connect the instrument to the charger module (“Off”

condition) for a period of 8 hours minimum.

Energize the display backlight device only in poor light conditions to limit battery discharge.

The Ni-Cd rechargeable batteries do not suffer when used in cyclic operations. The cyclic operation is understood as a

method of operation by which the battery is continually charged and discharged.

Avoid leaving the instrument, with batteries totally or partially discharged, for a long time without recharging.

In case of "low battery" (voltage lower than 4.6 V) the display will show the warning message indicated below and an

acoustic signal (internal buzzer) will inform the operator that he has only few additional minutes of operation and then the

battery should be recharged.

At "low battery" condition the display shows the following message.

!WARNING!

Battery low

Battery voltage is critical

onnect the line power to recharge

battery

6.1.2 Charging the battery

Battery is only partially charged at the time of purchase. Therefore charge it before using your calibrator. A total

discharge of the battery before recharging it, will allow the battery to be charged to its highest capacity.

When not in use, the battery slowly discharges. When not in use for a long period, the battery may be completely

discharged. The battery self-discharge time is minimum 2, maximum 6 months it depends, upon battery efficiency and

environment conditions. A full battery charge is obtained in 4 hours at 90% with the instrument switched "Off". Using the

instrument with line power supply the battery charge level is limited to 50% maximum.

IN

I

OUT

O

1088.4

TcT

°C

68

Rji

mVL

A "plug" symbol on the upper-left side of the display indicates that the battery charging process is active.

A -red- LED, inside the battery charger module, indicates that the charging process is active.

A -green- LED, inside the battery charger module, indicates that the power supply is connected.

0.4880

mV

6.1.3 How to maximize the life span of the battery

Disconnect the external module from ac mains supply when the battery is charged. Use the battery until it is completely

discharged. Note that the operating time decreases at low temperatures.

A Ni-Cd battery can be recharged about 500 times when used following the recommended instructions.

When replacing the Ni-Cd batteries with a new set always replace simultaneously the four pieces.

For long period of storage it is also recommended to keep the instrument at temperatures below 40°C; higher

temperatures accelerate the battery self discharging process and derate battery performances.

20

Page 21

7 ELECTRICAL CONNECTIONS

A

Appropriate extension wires should be used between the thermocouple (or instrument under calibration) and the CL520

series unless the thermocouple leads permit direct connection. Make sure that both thermocouple and compensating

cable are connected with the correct polarity. If in doubt, the polarity of the compensating leads can be checked by

connecting a length of lead to the indicator, shortening the free ends of the wires together and noting that the indicator

reading increases when the wire connection is heated. Color codes of compensating cables change in different

countries. Check the appropriate table. For RTD connection use a cable of adequate gauge to lower the overall input

resistance. The use of a cable with a good resistance balance between conductors is also necessary.

7.1 Wiring practice

Although the CL520 series calibrator is designed to be insensitive to transients or noise, the following recommendations

should be followed to reduce ac pick up in the signal leads and to ensure a good performance.

The input leads should not be run near ac line wiring, transformers and heating elements.

Input/output leads should, if possible, be twisted and shielded with the shield grounded at the end of the cable. When

shielded wires are used the shield must be connected to the negative terminal.

For a better understanding of the appropriate connection when using the instrument to simulate current into industrial 2

wire loop please, note the meaning of the terminal used.

Passive loop

This type of connection is to be used when the external loop is not equipped with the loop power supplied.

The calibrator can be, as an example, connected directly to a recorder, controller, etc. with input circuits configured for

current measurements.

Active loop

This type of connection must be used when the external loop is equipped with its loop power supplied.

The power supply is not required to be disconnected.

The loop circuit must be opened and the CL520 series connections are placed in series on the loop.

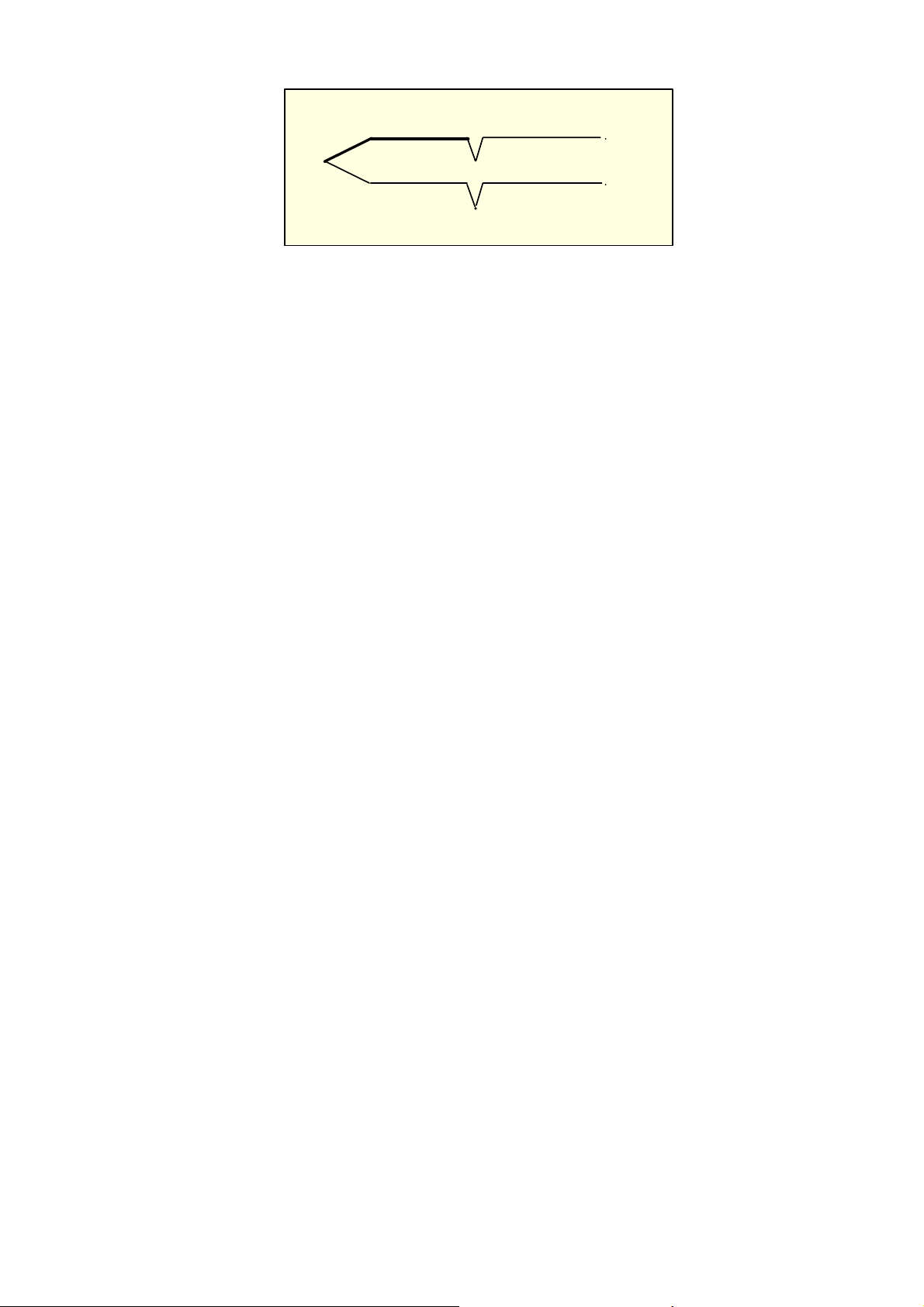

The following figure shows some examples of input/output wiring of the instrument:

SIMULATION MEASURE

Trx mA

passive

loop

+

-

Use the

compensatin g

cable for conn ections

with a Tc recorder

Recorder

for Tc

and dc

signals

CL520 series

+

--

+

-

Thermocoupl e

dc signals

CL520 series

CL520 seriesCL520 series

Trx mA

acti ve

loop

+

-

P.S.

Trx mA

acti ve

loop

P.S.

+

-

+

-

Counter

Frequency

Meter

Recorder

for Rtd

(3 wires)

Recorder

for Rtd

(2 wires)

Recorder

for Rtd

(4 wires)

B

C

A

B

C

D

A

B

C

D

Trx (4 wires)

+

--

Ext.P.S.

Rtd (2 wires)

Frequency

generator

+

OUT

--

Trx (2 wires)

+

--

Rtd (3 wires)

Rtd (4 wires)

21

Page 22

7.2 Thermocouple wires

When making measurements where additional wires have to be connected to the thermocouple leads, care must be

exercised in selecting these wire types, not only when they are claimed to be of the same composition as the

thermocouples involved, but, also, of their same "quality".

Performance results, where high precision is required and in circumstances where some types of thermocouple wire

leads are added to the original installation, should be reviewed carefully for the impact of the choice of the additional wire

leads.

The quality of the thermocouple wire is established by the limit of error to be expected with its use.

There are three recognized levels of quality:

- Special limits of error

- Standard Tc grade

- Extension wire grade

The error limits determining the grade quality differ from thermocouple type to thermocouple type, reflecting the degree of

difficulty in maintaining the precise levels of purity of the metal used.

The table below summarizes the error limits for Premium and Standard grades, while the Extension Grade wire is

characterized by limits of error exceeding those in the table.

Errors up to ±2.5 °C may be experienced when using Extension grade thermocouple wire for J and K thermocouples.

Limit of Error of thermocouple

The tolerance and the e.m.f. versus temperature reference table are defined by the IEC 584-2(Cenelec HD 446,2) and

listed as it follows:

Tolerance is meant as the maximum deviation, in °C, from the above indicated reference table with reference Junction at

0°C and the measuring junction at an appropriate temperature.

The range indicated is the temperature limit for the indicated relative errors.

Reference junction at 0 °C.

Tc Class 1 Class 2 Class 3

type T ± 0.5°C (-40 to +125°C) ± 1°C (-40 to 133°C) ± 1°C (-67 to 40°C)

± 0.004 . T (T >125°C) ± 0.0075 . T (T >133 °C) ± 0.015. T (T <-67°C)

T range -40 to +350°C -40 to +350°C -200 to 40°C

type E ± 1.5°C (-40 to 375°C) ± 2.5°C (-40 to 333 °C) ± 2.5°C (-167 to +40°C)

± 0.004.T (T >375°C) ± 0.0075.T (T >333°C) ± 0.015.T (T <-167°C)

T range -40 to 800°C -40 to 900°C -200°C to 40°C

type J ± 1.5°C (-40 to 375°C) ± 2.5°C (-40 to 333 °C)

± 0.004.T (T >375°C) ± 0.0075.T (T >333°C)

T range -40 to 750°C -40 to 750°C

type K & N ± 1.5°C (-40 to 375°C) ± 2.5°C (-40 to 333 °C) ± 2.5°C (-167 to +40°C)

± 0.004.T (T >375°C) ± 0.0075.T (T >333°C) ± 0.015.T (T <-167°C)

T range -40 to 1000°C -40 to 1200°C -200°C to 40°C

type R & S ± 1°C (0 to 1100°C) ± 1.5°C (-40 to 600 °C)

± 1 + 0.003 (T-100) ± 0.0075.T (T >600°C)

(T >1100°C)

T range 0 to 1600°C 0 to 1600°C

type B ± 4°C (600 to +800°C)

± 0.0025.T (T >600°C) ± 0.005.T (T>800°C)

T range 600 to 1700°C 800 to 1700°C

Special selected premium grade wires are available on request.

7.3 Remote connections

7.3.1 External contact

The instrument is equipped with a contact switch programmable for several functions

The type and mode of the event can be programmed (see par. 8.6) for operations:

Cnct Fnct = none / hold In / hold InP / ons IN / ons OUT /swtc In / swtc InP / swtc OUT

When the "Contact" function is selected the type of contact should be programmed as it follows:

Cnct STATE = n. open (normally open)

Cnct STATE = n. closed (normally closed)

The remote contact must be wired to the pin 11 (Contact +) and 24 (Contact -) of the back panel connector.

22

Page 23

13

11

24

NO/NC Switch

14

1

7.3.2 Remote Rj

The instrument can also operate with a remote cold junction (Rj) compensation. This operative mode require an external

Pt100 to be wired to pin 9 (Rj rem B) and 22 (Rj rem C) and pin 10 (Rj rem A) of the back panel connector as indicated in

the figure/table below.

13

10

RTD

22

9

14

1

23

Page 24

8 OPERATION & APPLICATIONS

A

r

The CL520 series calibrator has been factory calibrated before shipment.

During the start-up the operator should only select and load the required application parameters as described below.

If the instrument has been manufactured with a special thermocouple linearization, and/or with a special hardware, see

also notes in the Appendix.

The instrument should be used in environments where the temperature does not exceed the specified limits (from -10 °C

to +55 °C) and where the relative humidity is lower than 95%

N

OTE: ALL NUMERIC VALUES SHOWIN IN THE FIGURES OF THIS MANUAL ARE LISTED AS AN EXAMPLE.

During the set-up and memory loading remember that the instructions of the manual related to key operation have the

following meaning:

• <A> + <B> Press the <A> key and keeping the pressure on it, press then the <B> key.

• <A> , <B> Press in sequence first the <A> key and then the <B> key.

If an operative message (eg. “Instrument config”, ”Set”, ”Esc”, etc.) is present under the <NUM> or <LAMP> or <RAMP>

key this instruction can be entered pressing the corresponding key.

8.1 Power ON

To power on the instrument press the <ON> key; the following indication will appear for few seconds.

CL524

Version 4.001

S/N 0019220

The instrument will run an autodiagnostic routine for the self-checking of critical circuits and components.

The serial number, the version number of the firmware installed on the instrument and the next calibration date are

important peace of information for servicing activities.

To achieve a better performance in terms of accuracy wait at least for 5 minutes for the instrument to warm up.

When possible avoid using the display backlight in order to save the charge of the battery and to limit the heating inside

the instrument, so that you can obtain the most accurate results.

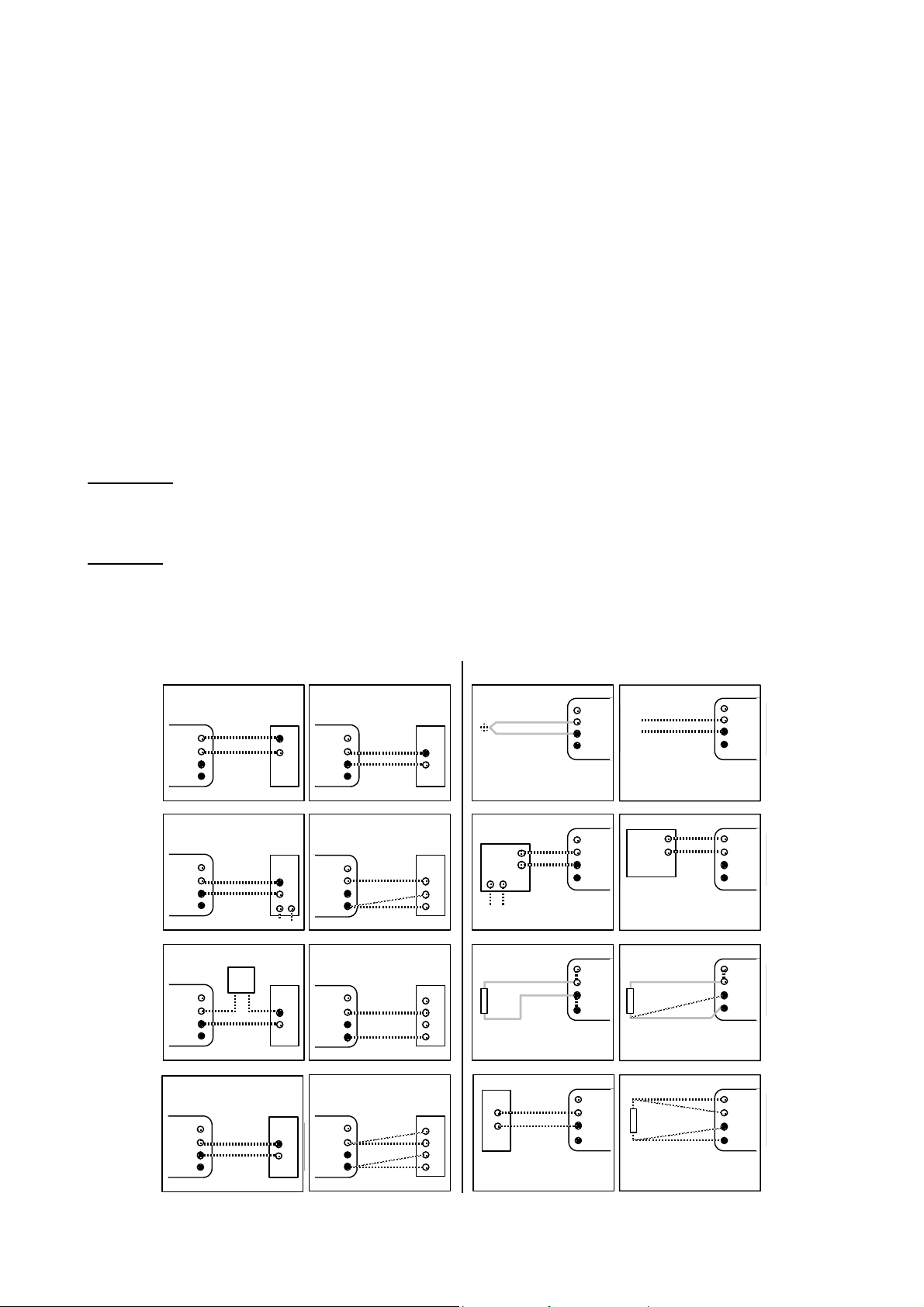

The instrument is ready for measurement with the previously selected operating mode with, for example, the following

indication:

AL OL

IN

O

OUT

I

0.478

AL OL

1088.4

mVL

mV

Tc K

°C

68

Rji

Annunciators area

ctive Slot indicato

Menù and option area

Lower slot display

Upper slot display

The CL520 series is able to visualize simultaneously on the display, two of the three I/O channels : pressure input (InP),

signal Input (IN) or signal output (OUT). Make reference to par. 8.8 and 8.9 for scrolling and swapping operations among

the channels.

All the keyboard operations are performed on the active slot display. To activate the desired slot display, press the <In-

Out> key in order to visualize the two arrow indicator on the slot.

Some graphical symbols could be displayed on the 'enunciators area' or in the 'option area' of the display. They have

special meanings.

These symbols are :

RAM card (PCMCIA) inserted

Low battery indication

Pump vacuum mode selected

Pressure module connected

Switch input status

24

Page 25

The external battery charger unit is connected to the mains line

8.2 Configuration Reset

It is possible to reset CL520 series to the OMEGA standard configuration pressing <RCL>+<Help> keys. The

instrument will ask to confirm the operation before to reset the instrument. All operator’s setting and data will be lose.

8.3 Next Calibration date

The instrument is equipped with a function to warn the operator when a new calibration of the instrument is

recommended .

By default the next calibration date is factory set at 01/01/80: this date set-up must be used when the warning message

is not required.

The “next calibration date” warning is enabled when the relevant date is programmed in the calibration set-up procedure.

When the instrument is powered, during the diagnostic routine, the following page is displayed with the indication of the

next programmed calibration date in the bottom line.

CL525

Version 4.001

S/N 0019220

When the programmed next calibration date has expired the instrument, at the start-up, will warn the operator with an

acoustic signal and the following message:

Next cal 30/06/97

! WARNING !

Calibration data expired

Press any key to acknowledge the warning message and to enter the operative mode. The operator should inform the

pertinent service of the organization charged for the instrument recalibration.

Press any key to acknowledge

8.4 Display adjustments

The digital display is a graphic LCD module with High contrast and a wide viewing angle. It is equipped with a LED

backlight device to allow easy reading also in poor light conditions.

Different character sizes are used to differentiate the measured and simulated value from the operative mode and from

messages to the operator as indicated below.

OUT

O

The display contrast can be adjusted using the <ENTER> + <4> or <9> keys.

The backlight intensity can be adjusted using <ENTER> + <±> or < , > keys.

Important notes :

• Remember that a high backlight intensity reduces the battery operative live

• Remember that to obtain the maximum performance in term of accuracy the backlight must be switched off. In fact

the backlight device is a source of internal heating that can contribute to the overall error of the instrument. The

stated relative accuracy is declared with the backlight device switched off.

IN

I

0.478

1088.4

mVL

mV

Tc K

°C

68

Rji

8.4.1 Display backlight

The backlight of the display can be switched “On “ and “Off “ using the <LAMP> key. If an operative message is

present under the <LAMP> key the above operation can be obtained using the <ENTER> + <LAMP> key.

25

Page 26

8.4.2 Autolamp mode

<

<

To save the energy of the battery and to extend the operative life a programmable routine is used to automatically switch

the backlight off 5 minutes after the operator's last keyboard instruction.

• To enable (or to disable) the -Autolamp- mode press the <MENU> key to obtain the <Instrument Config> message.

• Press one of the <Instrument Config> keys to obtain the following indication.

• Press the <Pag> key to visualize the next page menu

• Press the <> or <> key to reach the -Autolamp- message

• Press the <Set> key to enable the parameter change

• Press the <> or <> key to select the required “enabled” or “disabled” mode

• Press <Enter> to acknowledge the selection.

• Press the <Esc> key to return to the main operative page.

Set

Pag

Pag

Esc

Esc

Date : 28/02/93

Time : 18:12:26

Date fmt.: dmy

Cnt fnct.: none

Cnt state: n.open

Set

Probe error: 0.00°C

Avg weight S: 1

Avg weight P: 1

STO/RCL mode: single

O key funct.: swap

Autolamp off: disable

Instrument config.

ID name: 1

Baud : 9600

Printer: disable

Instrument config.

8.5 "Help" key

All the operations on the keyboard are simple and easy; any key action displays both a comprehensive instruction or

incorrect operation messages.

To make the operator's task easier during operating modes, the firmware includes a comprehensive instruction manual

with a full set of "Help" pages with an immediate indication of pertinent actions required.

Three typical pages obtained when pressing the <HELP> key are:

OUT

O

1088.4°C

IN

I

0.4880

Pg Esc Set IN Type

Lin mVL mVH V mA k Hz pulse Ω

X X1 X2 X3 X4 X5

Tc J K T F R S B U L N E

Pt100 IEC OIML USLAB US SAMA JIS

Pt 200 500 1000 1000OIML

Ω

Set Esc

E.U. : °C

Rj : internal

Rj ext : 0.00°C

ITS : 1968

Set Tc

TcT

mVL

mV

<Select> Select technical unit or

68

Rji

<NUM> Entry numeric value

<RAMP> Start programmed ramp

STATUS> View active configuration

MENU> Scroll menu functions

<STO>+<ENTER>+<n> Memory store

<RCL>+<ENTER>+<n> Memory recall

Set Select ITS Rj °C-°F-K

Pg Page selection

Esc Return to main page

<> Select tech.unit or sensor

<ENTER> Store new selection

Set Enter selection procedure

Esc Return to previous page or

keep previous setting

<> Move function pointer or

move through choices

(ENTER) Store new selection

sensor

8.6 Configuration review (Status)