Omega Lift 40500 User Manual

Operating Instructions Manual

Hydraulic Clutch Jack

Model: 40500 Capacity: 500 lb.

SFA Companies

http://www.omegalift.com

Read this manual and follow all the Safety Rules and Operating Instructions before using this product.

Printed in China

40500-M0 05/07

Save these instructions. For your safety, read, understand, and follow the information provided with and on

this jack. The owner and operator of this equipment shall have an understanding of this jack and safe operating

procedures before attempting to use. The owner and operator shall be aware that use and repair of this product

may require special skills and knowledge. Instructions and safety information shall be conveyed in the operator's

native language before use of this jack is authorized. If any doubt exists as to the safe and proper use of this jack,

remove from service immediately. Inspect before each use. Do not use if broken, bent, cracked, or damaged parts

(including labels) are noted. Any jack that appears damaged in any way, operates abnormally or is missing parts,

shall be removed from service immediately. If the jack has been or suspected to have been subjected to a shock

load (a load dropped suddenly, unexpectedly upon it), immediately discontinue use until jack has been checked by

an Omega authorized service center. It is recommended that an annual inspection be done by qualified personnel.

Labels and Operator's Manuals are available from manufacturer.

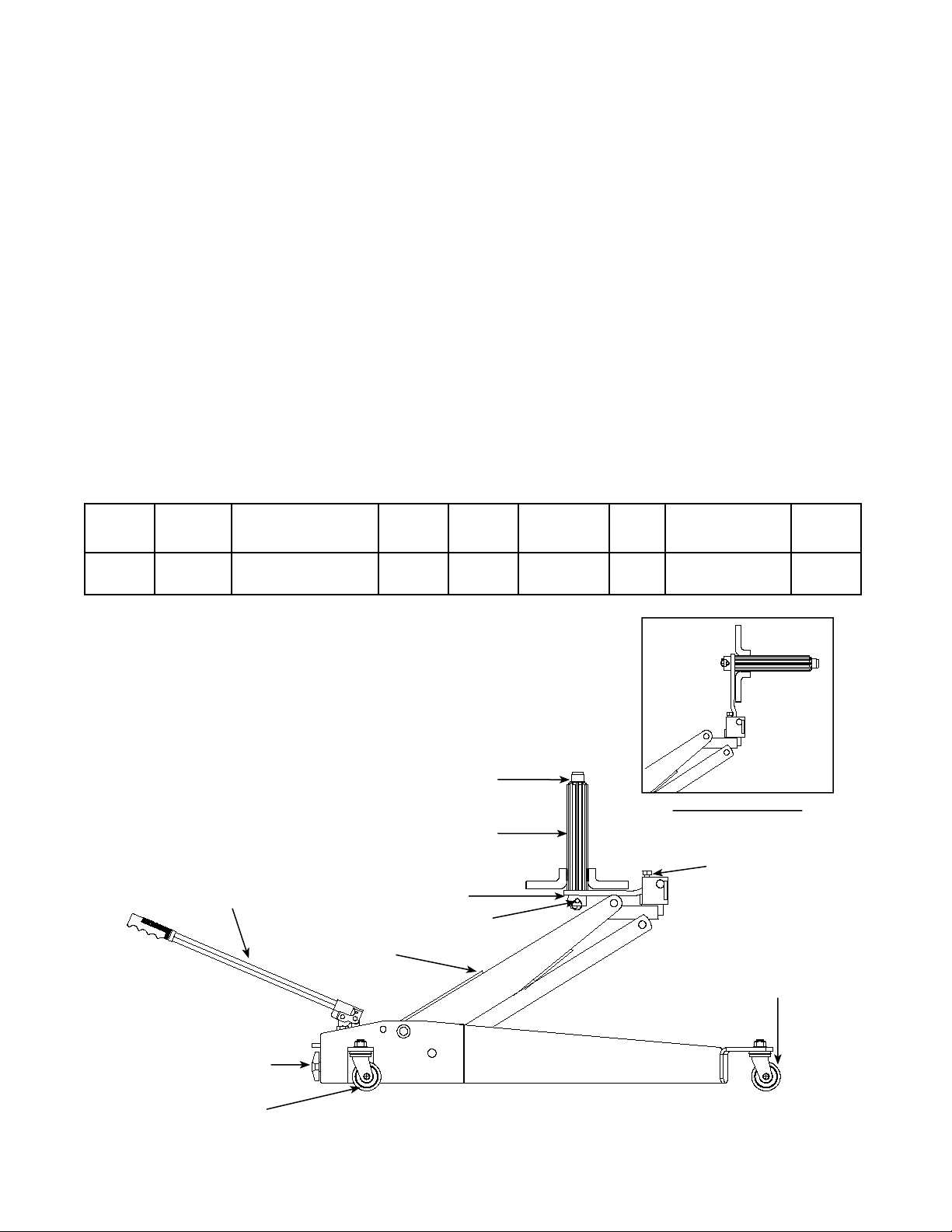

PRODUCT DESCRIPTION

The Omega Hydraulic Clutch Jack is designed for clutch/ flywheel removal and installation. Intended use: to remove,

install and transport (in lowest position) both 14" and 15-1/2" clutches and flywheels. The two most common spline

sizes, 1-3/4" and 2" diameter, are included with this product. The head plate enables clutch to be positioned in either

horizontal position for clearing underneath vehicle or vertical position for installation and removal. The spline sleeve

rotates 360 degrees, turns side to side and vertically tilts for precise clutch alignment.

DO NOT USE FOR ANY PURPOSE OTHER THAN THOSE USES OUTLINED ABOVE !

SPECIFICATIONS

Model Capacity Jack Size (L x W )

40500 500 lb. 44 1/2" x 22 1/2" 16 1/2" 42" 1-3/4" & 2" 1" 6.6 OZ/ 195

Pump Handle

Lifting Arm

Min.

Height

Adapter Shaft

Spline Sleeve

Head Plate

Release Pin

Max.

Height

Spline

Dia.

Shaft

Dia.

Volume of

Hyd. Oil

Horizonta

l Position

Tilt Adjustment Bolt

mL

Net

Weight

145 lb.

Release Valve Knob

Rear Caster

Front Caster

Figure 1 - Model 40500 Components

2

BEFORE USE

1. Verify that the product and the application are

compatible, if in doubt call Omega Technical Service

(888) 332-6419.

2. Before using this product, read the operator's manual

completely and familiarize yourself thoroughly with

the product, its components and recognize the

potential hazards associated with its use.

3. Open the release valve by turning the release valve

knob counter-clockwise (no more than 1/2 full turn).

4. With lifting arm fully lowered, locate and remove the

oil filler plug. Pump handle 6 to 8 full strokes. Ensure

the oil level is within ~3/16" from the inner cylinder

as viewed from the oil filler hole. Reinstall the oil filler

plug. Close release valve by turning it clockwise until

firm resistance is felt.

5. Check to ensure that jack rolls freely, that the pump

and release valve operate smoothly. Raise and lower

the unloaded jack throughout the advertised lift range

before putting into service.

6. Replace worn or damaged parts and assemblies

with Factory Authorized Replacement Parts only.

Lubricate as instructed in Maintenance Section.

OPERATION

Removing a Clutch

1. Select the correct size spline sleeve. Place the spline

on the adapter shaft, then attach to the head plate

with the release pin & retaining pin provided.

2. Close the release valve by tightening the release

valve knob. Pump the handle to raise the lifting arm

and align the spline sleeve with the clutch.

3. Tilt the head plate with the tilt adjustment bolt to align

it with the clutch bore. Slide the spline sleeve into

the clutch.

4. Remove the clutch mounting bolts and back the jack

and clutch away from the flywheel.

! WARNING

Be sure all tools and personnel are clear before

lowering load.

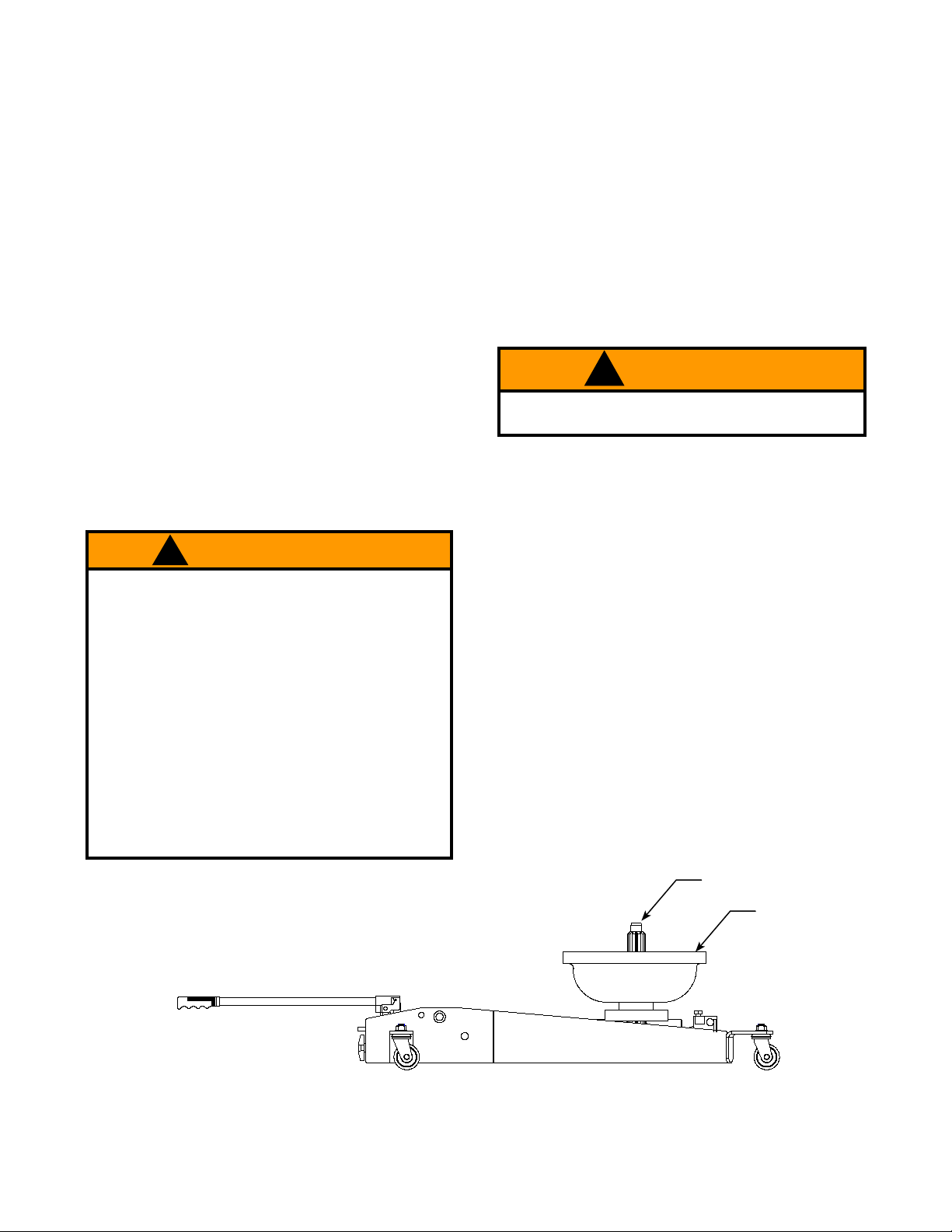

Transporting the Clutch while on Jack

Be sure the adapter shaft is in the vertical position and

the jack is fully lowered before transporting, as shown

in Figure 2.

! WARNING

• Study, understand, and follow all printed materials

provided with/on this device before use.

•

Do not exceed rated capacity.

•

Use only on hard, level, seamless surface.

•

Do not allow any part of your body under the lift

arm or load while the jack is supporting a load.

•

Use only the factory supplied adapters as a

means of contacting the load. Never use any

other part of the jack as a lifting surface.

•

Use of this jack is limited to the removal,

installation and transportation of clutch/flywheel.

•

Adequately support the vehicle before starting

repairs.

•

Failure to heed these markings may result in

personal injury and/or property damage.

Loading and Unloading a Clutch from the Jack

1. To load or unload a clutch from the jack, be sure the

adapter shaft is in the vertical position, as shown in

Figure 2.

2. Add or remove one piece of the clutch at a time.

Installing a Clutch

1. Raise the clutch into the horizontal position for

installation and tilt the clutch using the tilt adjustment

bolt to align with the flywheel.

2. Put the jack and clutch into position so that the spline

shaft engages the pilot bearing in the flywheel. Install

and tighten the clutch mounting bolts.

Adapter Shaft

Clutch

Figure 2 - Illustration of Lowest Position with Clutch

3

Loading...

Loading...